check engine CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 3 of 364

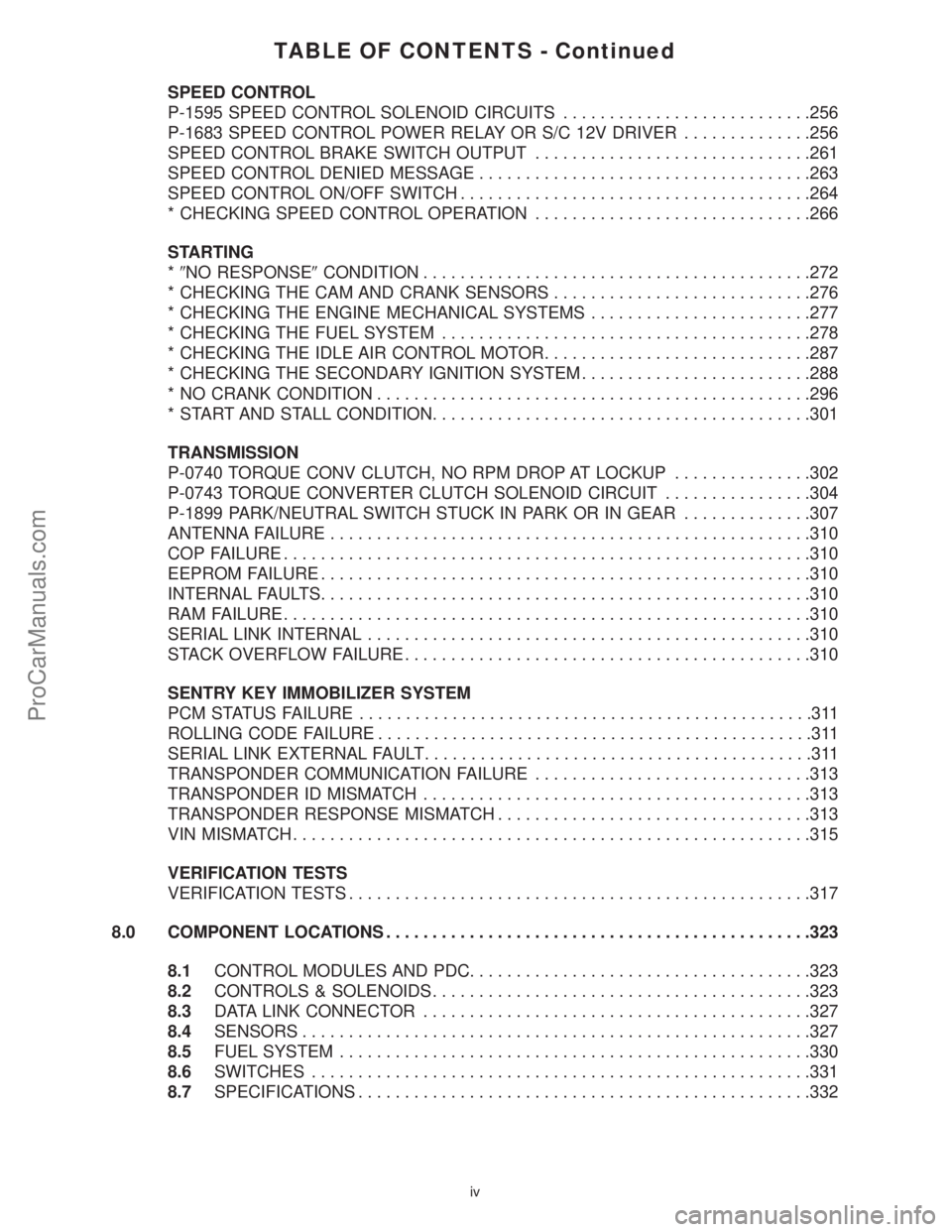

TABLE OF CONTENTS - Continued

P-0443 EVAP PURGE SOLENOID CIRCUIT................................143

P-0460 FUEL LEVEL UNIT NO CHANGE OVER MILES.......................148

P-0462 FUEL LEVEL SENDING UNIT VOLTS TOO LOW......................149

P-0463 FUEL LEVEL SENDING UNIT VOLTS TOO HIGH......................151

P-0500 NO VEHICLE SPEED SENSOR SIGNAL.............................153

P-0505 IDLE AIR CONTROL MOTOR CIRCUITS.............................159

P-0505B IDLE AIR CONTROL MOTOR CIRCUIT.............................164

P-0505C IDLE AIR CONTROL MOTOR CIRCUIT.............................165

P-0505D IDLE AIR CONTROL MOTOR CIRCUIT.............................166

P-0505E IDLE AIR CONTROL MOTOR CIRCUIT.............................167

P-0600 PCM FAILURE SPI COMMUNICATIONS.............................168

P-0601 INTERNAL CONTROLLER FAILURE................................169

P-0645 A/C CLUTCH RELAY CIRCUIT.....................................170

P-0703 BRAKE SWITCH STUCK PRESSED OR RELEASED..................172

P-1195 SLOW 1/1 O2S DURING CATALYST MONITOR.......................175

P-1281 ENGINE IS COLD TOO LONG.....................................177

P1282 FUEL PUMP RELAY CONTROL CIRCUIT.............................178

P-1294 TARGET IDLE NOT REACHED....................................180

P-1297 NO CHANGE IN MAP FROM START TO RUN........................183

P-1388 AUTO SHUTDOWN RELAY CONTROL CIRCUIT......................186

P-1389 NO ASD RELAY OUTPUT VOLTAGE AT PCM........................188

P-1391 INTERMITTENT LOSS OF CMP OR CKP............................191

P-1398 MISFIRE ADAPTIVE NUMERATOR AT LIMIT.........................198

P-1486 EVAP LEAK MONITOR PINCHED HOSE FOUND.....................200

P-1491 RADIATOR FAN CONTROL RELAY CIRCUIT.........................203

P-1494 LEAK DETECTION PUMP PRESSURE SWITCH......................206

P-1495 LEAK DETECTION PUMP SOLENOID CIRCUIT.......................209

P-1496 5 VOLT SUPPLY OUTPUT TOO LOW...............................212

P-1598 A/C PRESSURE SENSOR VOLTS TOO HIGH........................214

P-1599 A/C PRESSURE SENSOR VOLTS TOO LOW.........................217

P-1695 NO CCD MESSAGE FROM BODY CONTROLLER....................220

P-1696 PCM FAILURE EEPROM WRITE DENIED...........................222

P-1697 PCM FAILURE SRI MILE NOT STORED.............................222

P-1698 NO CCD MESSAGES FROM TCM..................................224

CHECKING 5 VOLT SUPPLY CIRCUIT.....................................226

* CHECKING EGR SYSTEM.............................................228

* CHECKING ENGINE VACUUM..........................................231

* CHECKING EVAPORATIVE EMISSION SYSTEM...........................232

* CHECKING FOR OXYGEN SENSOR SWITCHING..........................234

* CHECKING FUEL DELIVERY...........................................237

* CHECKING IDLE AIR CONTROL MOTOR.................................242

* CHECKING INTAKE AIR TEMPERATURE SENSOR.........................244

* CHECKING MAP SENSOR CALIBRATION................................245

* CHECKING MINIMUM IDLE AIR FLOW...................................246

* CHECKING OXYGEN SENSOR HEATER.................................247

* CHECKING PARK/NEUTRAL POSITION SWITCH..........................249

* CHECKING PCM POWER AND GROUND CIRCUITS.......................251

* CHECKING SECONDARY IGNITION.....................................252

* CHECKING THE ENGINE MECHANICAL SYSTEMS........................253

* CHECKING THROTTLE POSITION SENSOR CALIBRATION.................254

* CHECKING THE A/C PRESSURE SENSOR SIGNAL........................255

iii

ProCarManuals.com

Page 4 of 364

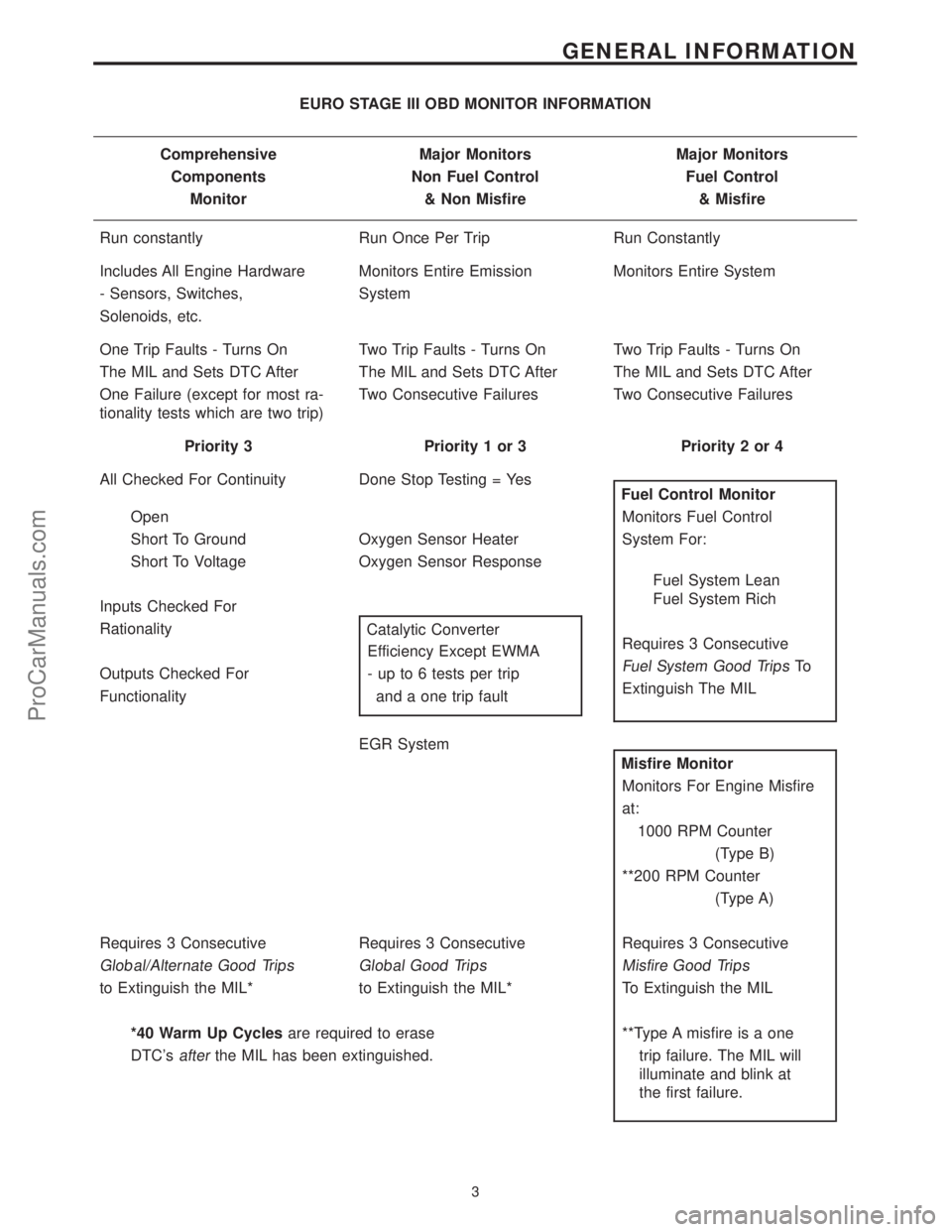

TABLE OF CONTENTS - Continued

SPEED CONTROL

P-1595 SPEED CONTROL SOLENOID CIRCUITS...........................256

P-1683 SPEED CONTROL POWER RELAY OR S/C 12V DRIVER..............256

SPEED CONTROL BRAKE SWITCH OUTPUT..............................261

SPEED CONTROL DENIED MESSAGE....................................263

SPEED CONTROL ON/OFF SWITCH......................................264

* CHECKING SPEED CONTROL OPERATION..............................266

STARTING

*9NO RESPONSE9CONDITION..........................................272

* CHECKING THE CAM AND CRANK SENSORS............................276

* CHECKING THE ENGINE MECHANICAL SYSTEMS........................277

* CHECKING THE FUEL SYSTEM........................................278

* CHECKING THE IDLE AIR CONTROL MOTOR.............................287

* CHECKING THE SECONDARY IGNITION SYSTEM.........................288

* NO CRANK CONDITION...............................................296

* START AND STALL CONDITION.........................................301

TRANSMISSION

P-0740 TORQUE CONV CLUTCH, NO RPM DROP AT LOCKUP...............302

P-0743 TORQUE CONVERTER CLUTCH SOLENOID CIRCUIT................304

P-1899 PARK/NEUTRAL SWITCH STUCK IN PARK OR IN GEAR..............307

ANTENNA FAILURE....................................................310

COP FAILURE.........................................................310

EEPROM FAILURE.....................................................310

INTERNAL FAULTS.....................................................310

RAM FAILURE.........................................................310

SERIAL LINK INTERNAL................................................310

STACK OVERFLOW FAILURE............................................310

SENTRY KEY IMMOBILIZER SYSTEM

PCM STATUS FAILURE.................................................311

ROLLING CODE FAILURE...............................................311

SERIAL LINK EXTERNAL FAULT..........................................311

TRANSPONDER COMMUNICATION FAILURE..............................313

TRANSPONDER ID MISMATCH..........................................313

TRANSPONDER RESPONSE MISMATCH..................................313

VIN MISMATCH........................................................315

VERIFICATION TESTS

VERIFICATION TESTS..................................................317

8.0 COMPONENT LOCATIONS..............................................323

8.1CONTROL MODULES AND PDC.....................................323

8.2CONTROLS & SOLENOIDS.........................................323

8.3DATA LINK CONNECTOR..........................................327

8.4SENSORS.......................................................327

8.5FUEL SYSTEM...................................................330

8.6SWITCHES......................................................331

8.7SPECIFICATIONS.................................................332

iv

ProCarManuals.com

Page 9 of 364

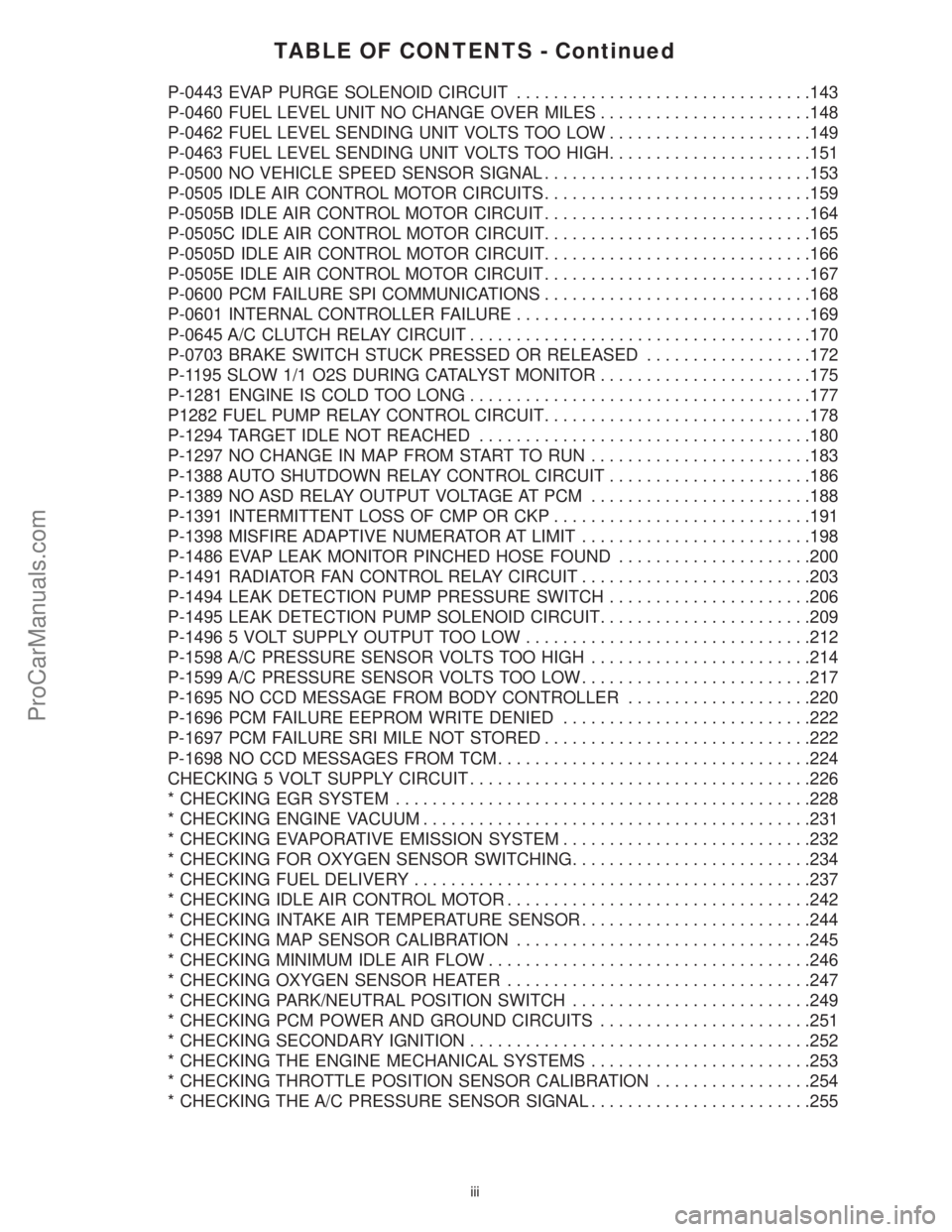

EURO STAGE III OBD MONITOR INFORMATION

Comprehensive Major Monitors Major Monitors

Components Non Fuel Control Fuel Control

Monitor & Non Misfire & Misfire

Run constantly Run Once Per Trip Run Constantly

Includes All Engine Hardware Monitors Entire Emission Monitors Entire System

- Sensors, Switches, System

Solenoids, etc.

One Trip Faults - Turns On Two Trip Faults - Turns On Two Trip Faults - Turns On

The MIL and Sets DTC After The MIL and Sets DTC After The MIL and Sets DTC After

One Failure (except for most ra-

tionality tests which are two trip)Two Consecutive Failures Two Consecutive Failures

Priority 3 Priority 1 or 3 Priority 2 or 4

All Checked For Continuity Done Stop Testing = Yes

Fuel Control Monitor

Open Monitors Fuel Control

Short To Ground Oxygen Sensor Heater System For:

Short To Voltage Oxygen Sensor Response

Fuel System Lean

Fuel System Rich

Inputs Checked For

Requires 3 Consecutive Rationality

Catalytic Converter

Fuel System Good TripsTo Efficiency Except EWMA

Extinguish The MIL Outputs Checked For - up to 6 tests per trip

Functionality and a one trip fault

EGR System

Misfire Monitor

Monitors For Engine Misfire

at:

1000 RPM Counter

(Type B)

**200 RPM Counter

(Type A)

Requires 3 Consecutive Requires 3 Consecutive Requires 3 Consecutive

Global/Alternate Good Trips Global Good Trips Misfire Good Trips

to Extinguish the MIL* to Extinguish the MIL* To Extinguish the MIL

*40 Warm Up Cyclesare required to erase **Type A misfire is a one

DTC's

afterthe MIL has been extinguished. trip failure. The MIL will

illuminate and blink at

the first failure.

3

GENERAL INFORMATION

ProCarManuals.com

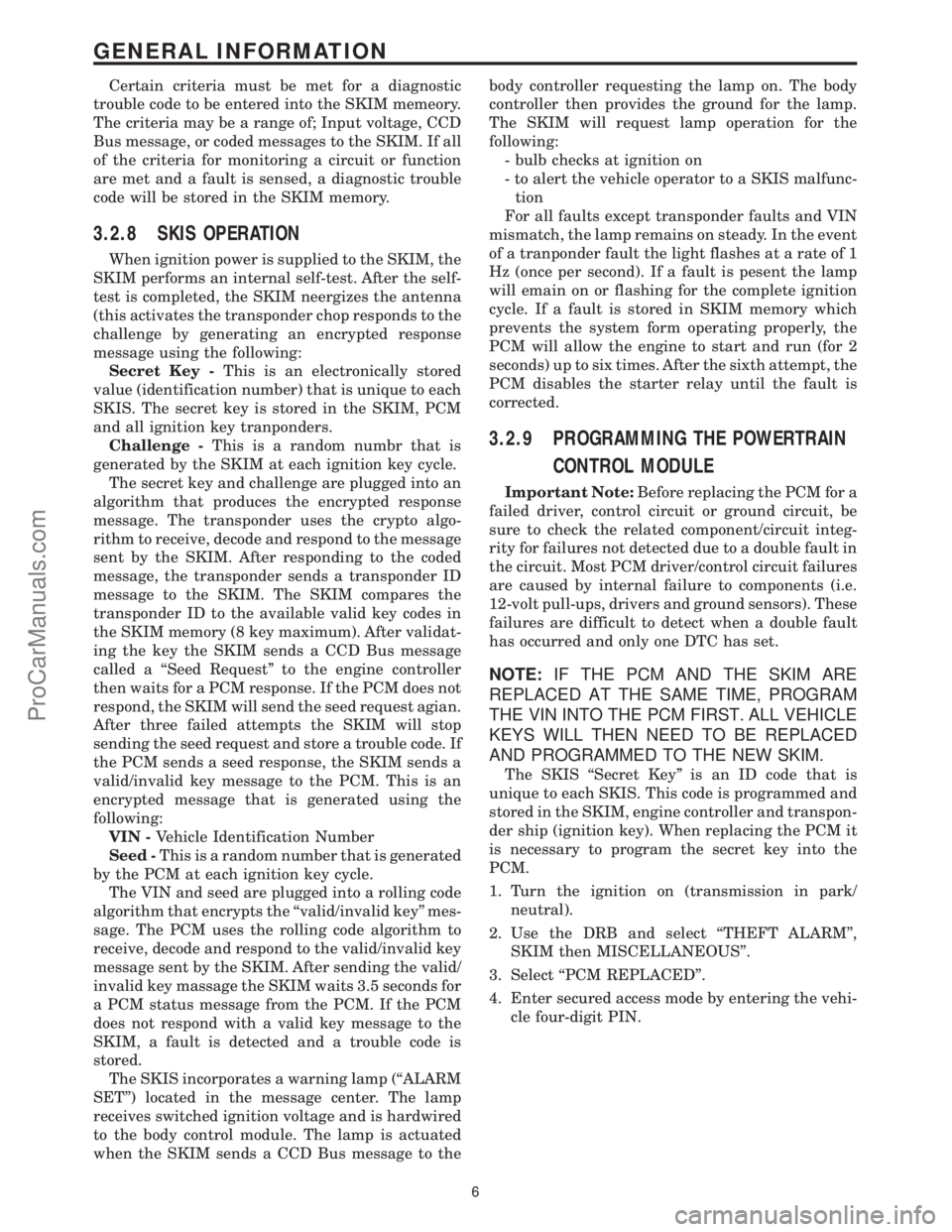

Page 12 of 364

Certain criteria must be met for a diagnostic

trouble code to be entered into the SKIM memeory.

The criteria may be a range of; Input voltage, CCD

Bus message, or coded messages to the SKIM. If all

of the criteria for monitoring a circuit or function

are met and a fault is sensed, a diagnostic trouble

code will be stored in the SKIM memory.

3.2.8 SKIS OPERATION

When ignition power is supplied to the SKIM, the

SKIM performs an internal self-test. After the self-

test is completed, the SKIM neergizes the antenna

(this activates the transponder chop responds to the

challenge by generating an encrypted response

message using the following:

Secret Key -This is an electronically stored

value (identification number) that is unique to each

SKIS. The secret key is stored in the SKIM, PCM

and all ignition key tranponders.

Challenge -This is a random numbr that is

generated by the SKIM at each ignition key cycle.

The secret key and challenge are plugged into an

algorithm that produces the encrypted response

message. The transponder uses the crypto algo-

rithm to receive, decode and respond to the message

sent by the SKIM. After responding to the coded

message, the transponder sends a transponder ID

message to the SKIM. The SKIM compares the

transponder ID to the available valid key codes in

the SKIM memory (8 key maximum). After validat-

ing the key the SKIM sends a CCD Bus message

called a ``Seed Request'' to the engine controller

then waits for a PCM response. If the PCM does not

respond, the SKIM will send the seed request agian.

After three failed attempts the SKIM will stop

sending the seed request and store a trouble code. If

the PCM sends a seed response, the SKIM sends a

valid/invalid key message to the PCM. This is an

encrypted message that is generated using the

following:

VIN -Vehicle Identification Number

Seed -This is a random number that is generated

by the PCM at each ignition key cycle.

The VIN and seed are plugged into a rolling code

algorithm that encrypts the ``valid/invalid key'' mes-

sage. The PCM uses the rolling code algorithm to

receive, decode and respond to the valid/invalid key

message sent by the SKIM. After sending the valid/

invalid key massage the SKIM waits 3.5 seconds for

a PCM status message from the PCM. If the PCM

does not respond with a valid key message to the

SKIM, a fault is detected and a trouble code is

stored.

The SKIS incorporates a warning lamp (``ALARM

SET'') located in the message center. The lamp

receives switched ignition voltage and is hardwired

to the body control module. The lamp is actuated

when the SKIM sends a CCD Bus message to thebody controller requesting the lamp on. The body

controller then provides the ground for the lamp.

The SKIM will request lamp operation for the

following:

- bulb checks at ignition on

- to alert the vehicle operator to a SKIS malfunc-

tion

For all faults except transponder faults and VIN

mismatch, the lamp remains on steady. In the event

of a tranponder fault the light flashes at a rate of 1

Hz (once per second). If a fault is pesent the lamp

will emain on or flashing for the complete ignition

cycle. If a fault is stored in SKIM memory which

prevents the system form operating properly, the

PCM will allow the engine to start and run (for 2

seconds) up to six times. After the sixth attempt, the

PCM disables the starter relay until the fault is

corrected.

3.2.9 PROGRAMMING THE POWERTRAIN

CONTROL MODULE

Important Note:Before replacing the PCM for a

failed driver, control circuit or ground circuit, be

sure to check the related component/circuit integ-

rity for failures not detected due to a double fault in

the circuit. Most PCM driver/control circuit failures

are caused by internal failure to components (i.e.

12-volt pull-ups, drivers and ground sensors). These

failures are difficult to detect when a double fault

has occurred and only one DTC has set.

NOTE:IF THE PCM AND THE SKIM ARE

REPLACED AT THE SAME TIME, PROGRAM

THE VIN INTO THE PCM FIRST. ALL VEHICLE

KEYS WILL THEN NEED TO BE REPLACED

AND PROGRAMMED TO THE NEW SKIM.

The SKIS ``Secret Key'' is an ID code that is

unique to each SKIS. This code is programmed and

stored in the SKIM, engine controller and transpon-

der ship (ignition key). When replacing the PCM it

is necessary to program the secret key into the

PCM.

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select ``THEFT ALARM'',

SKIM then MISCELLANEOUS''.

3. Select ``PCM REPLACED''.

4. Enter secured access mode by entering the vehi-

cle four-digit PIN.

6

GENERAL INFORMATION

ProCarManuals.com

Page 14 of 364

to non-emission codes, they will seem like an intermit-

tent. These codes require a set of parameters to be

performed (The DRBIIItpre-test screens will help

with this for MONITOR codes), this is called a ªTRIPº.

All EURO STAGE III OBD DTCs will be set after one

or in some cases two trip failures, and the MIL will be

turned on. These codes require three successful (no

failures) TRIPS to extinguish the MIL, followed by 40

warm-up cycles to erase the code.

3.3.2 INTERMITTENT CODE

A diagnostic trouble code that is not there every

time the PCM checks the circuit is an ªintermittentº

code. Most intermittent codes are caused by wiring

or connector problems. Defects that come and go

like this are the most difficult to diagnose; they

must be looked for under specific conditions that

cause them. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect related wire harness connectors.

Look for broken, bent, pushed out, or corroded

terminals.

²Visually inspect the related harnesses. Look for

chafed, pierced, or partially broken wire.

²Refer to any Hotline Newsletters or technical

service bulletins that may apply.

²Use the DRBIIItdata recorder or co-pilot.

²Use the DRBIIItPEP module lab scope.

3.3.3 RESET COUNTER

The reset counter counts the number of times the

vehicle has been started since codes were last set,

erased, or the battery was disconnected. The reset

counter will count up to 255 start counts.

The number of starts helps determine when the

trouble code actually happened. This is recorded by

the PCM and can be viewed on the DRBIIItas

STARTS since set.

When there are no trouble codes stored in mem-

ory, the DRBIIItwill display ªNO DTC'S Detectedº

and the reset counter will show ªSTARTS since

clear = XXX.º

3.3.4 HANDLING NO TROUBLE CODE

PROBLEMS

Symptom checks cannot be used properly unless

the driveability problem characteristic actually

happens while the vehicle is being tested.

Select the symptom that most accurately de-

scribes the vehicle's driveability problem and then

perform the test routine that pertains to this symp-

tom. Perform each routine test in sequence until the

problem is found. For definitions, see Section 6.0

Glossary of Terms.SYMPTOM DIAGNOSTIC TEST

HARD START CHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING ENGINE VAC-

UUM

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

START AND

STALLCHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

8

GENERAL INFORMATION

ProCarManuals.com

Page 15 of 364

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

HESITATION/

SAG/

STUMBLECHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING ENGINE VAC-

UUM

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING O2S HEATER

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

CHECKING PNP SWITCH

SURGE CHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATIONCHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING EVAP EMISSION

SYSTEM

LACK OF

POWER/

SLUGGISHCHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING EGR SYSTEM

SPARK

KNOCK/

DETONATIONCHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

9

GENERAL INFORMATION

ProCarManuals.com

Page 16 of 364

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING EVAP EMISSION

SYSTEM

CUTS OUT/

MISSESCHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING EGR SYSTEM

BACKFIRE/

POPBACKCHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING EGR SYSTEM

RUNS

ROUGH/

UNSTABLE/

ERRATIC

IDLECHECKING SECONDARY

IGNITION SYSTEMCHECKING PCM POWER

AND GND CKT

CHECKING ENGINE VAC-

UUM

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING O2S HEATER

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

CHECKING PNP SWITCH

POOR FUEL

ECONOMYCHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING ENGING VAC-

UUM

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

10

GENERAL INFORMATION

ProCarManuals.com

Page 17 of 364

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING O2S HEATER

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

CHECKING PNP SWITCH

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading trouble codes, erasing

trouble codes, and other DRBIIItfunctions.

3.5 DRB ERROR MESSAGES AND BLANK

SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot.

This is a sample of such an error message display:

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRB IIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of a faulty cable or

vehicle wiring. For a blank screen, refer to the

appropriate body diagnostics manual.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially impor-

tant to block the wheels on front-wheel drive vehicles;

the parking brake does not hold the drive wheels.

When servicing a vehicle, always wear eye pro-

tection, and remove any metal jewelry such as

watchbands or bracelets that might make an inad-

vertent electrical contact.

When diagnosing a powertrain system problem,

it is important to follow approved procedures where

11

GENERAL INFORMATION

ProCarManuals.com

Page 25 of 364

Symptom:

P-1594 CHARGING SYSTEM VOLTAGE TOO HIGH

POSSIBLE CAUSES

GENERATOR FIELD DRIVER CIRCUIT SHORT TO GROUND

GENERATOR SHORTED

PCM DEFECTIVE (CHARGING SYSTEM)

PCM BATT TEMP NOT W/I þ12 DEGREES C (10 DEGREES F) UNDER HOOD TEMP

PCM VOLT & TARGET CHARGING VOLT DIFFER BY > 1.0 V

TEST ACTION APPLICABILITY

1 Ignition on, engine not running.

Note: Battery must be fully charged.

Note: Generator Belt tension and condition must be checked before con-

tinuing.

With the DRB, actuate the Generator Field Driver.

Using a voltmeter, backprobe the Generator Field Driver Circuit voltage in back of

Generator.

Does the DRB show voltage shift low to high?All

Ye s®Go To 2

No®Go To 6

2 Ignition On, Engine Not Running

With the DRB, stop the Generator Field Driver actuation.

Read the target charging voltage.

Is the target charging voltage between 13.0 to 14.9 volts?All

Ye s®Test Complete.

No®Go To 3

3 Engine running.

Manually set the engine speed to 1600 RPM.

With the DRB, read both the voltage and the target charging voltage.

Compare the9target9to the9volt9reading.

Watch for up to 5 minutes, if necessary, for a 1.0 volt difference or more.

Was there more than a 1.0 volt difference?All

Ye s®Replace PCM.

Perform Powertrain Verification Test VER-3A.

No®Go To 4

4 Ignition On, Engine Not Running

Using the DRB Temperature Probe, measure the under hood temperature near PCM.

With the DRB, read the BTS temperature.

Is the Battery Temperature within þ12 degrees C (10 degrees F) of the under hood

temperature?All

Ye s®Go To 5

No®Replace PCM.

Perform Powertrain Verification Test VER-3A.

19

CHARGING

ProCarManuals.com

Page 26 of 364

TEST ACTION APPLICABILITY

5 Turn ignition on, engine not running.

Erase trouble codes.All

Refer to symptom * CHARGING SYSTEM NO CODE TEST in the

CHARGING category.

6 Ignition Off

Disconnect the Field Harness Connector at back of Generator.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure resistance of one of the Generator Field Terminals at

the Generator to Ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair or replace the shorted Generator as necessary.

Perform Powertrain Verification Test VER-3A.

No®Go To 7

7 Ignition Off

Disconnect the PCM Connector.

Disconnect the Field Harness Connector at back of Generator.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure the Generator Field Driver Circuit from PCM Connec-

tor to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Generator Field Driver Circuit short to ground.

Perform Powertrain Verification Test VER-3A.

No®Go To 8

8 Ignition off.

If there are no potential causes remaining, the PCM is assumed to be defective.

View repair optionsAll

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-3A.

20

CHARGING

P-1594 CHARGING SYSTEM VOLTAGE TOO HIGH ÐContinued

ProCarManuals.com