ignition CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 274 of 364

TEST ACTION APPLICABILITY

9 Ignition Off

Disconnect the Vacuum Supply to the Speed Control Servo.

Attach a Vacuum Gauge to the disconnected hose.

Start engine.

Does the Vacuum Gauge read Manifold Vacuum?All

Ye s®Go To 10

No®Repair the Vacuum Supply for a leak or restriction.

Perform Powertrain Verification Test VER-4A.

10 Ignition Off

Disconnect the Speed Control Servo Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter measure the Ground Circuit from Servo Connector to gnd.

Is the resistance below 5.0 ohms?All

Ye s®Go To 11

No®Repair the open Ground Circuit.

Perform Powertrain Verification Test VER-4A.

11 Ignition Off

Disconnect the Speed Control Servo Connector.

Note: Check connectors - Clean/repair as necessary.

Is any Terminal damaged, pushed out or miswired?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-4A.

No®Go To 12

12 Disconnect the vacuum supply from the Speed Control Servo.

Attach a vacuum gauge to the vacuum hose.

Start the Engine, allow to idle for 1 minute.

Turn engine off.

Observe Vacuum Gauge for 10 seconds.

Does the Vacuum hold for at least 10 seconds?All

Ye s®Go To 13

No®Replace the Vacuum Reservoir.

Perform Powertrain Verification Test VER-4A.

13 If there are no potential causes remaining, the S/C Servo is assumed to be defective.

View repair options.All

Repair

Replace the Speed Control Servo.

Perform Powertrain Verification Test VER-4A.

14 Ignition Off

Disconnect the Speed Control Servo Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter measure the Ground Circuit from Servo Connector to gnd.

Is the resistance below 5.0 ohms?All

Ye s®Go To 15

No®Repair the open Ground Circuit.

Perform Powertrain Verification Test VER-4A.

268

SPEED CONTROL

* CHECKING SPEED CONTROL OPERATION ÐContinued

ProCarManuals.com

Page 275 of 364

TEST ACTION APPLICABILITY

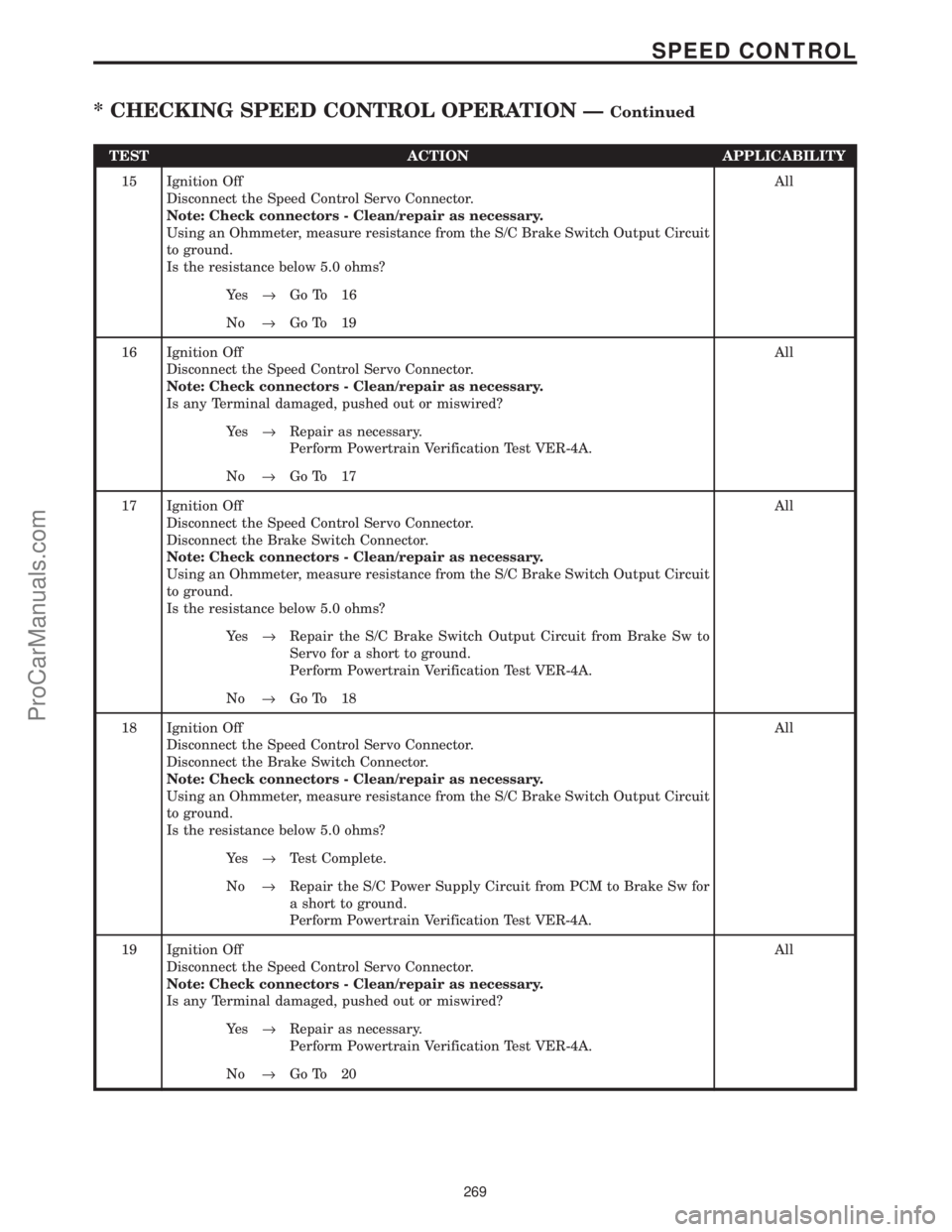

15 Ignition Off

Disconnect the Speed Control Servo Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure resistance from the S/C Brake Switch Output Circuit

to ground.

Is the resistance below 5.0 ohms?All

Ye s®Go To 16

No®Go To 19

16 Ignition Off

Disconnect the Speed Control Servo Connector.

Note: Check connectors - Clean/repair as necessary.

Is any Terminal damaged, pushed out or miswired?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-4A.

No®Go To 17

17 Ignition Off

Disconnect the Speed Control Servo Connector.

Disconnect the Brake Switch Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure resistance from the S/C Brake Switch Output Circuit

to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the S/C Brake Switch Output Circuit from Brake Sw to

Servo for a short to ground.

Perform Powertrain Verification Test VER-4A.

No®Go To 18

18 Ignition Off

Disconnect the Speed Control Servo Connector.

Disconnect the Brake Switch Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure resistance from the S/C Brake Switch Output Circuit

to ground.

Is the resistance below 5.0 ohms?All

Ye s®Test Complete.

No®Repair the S/C Power Supply Circuit from PCM to Brake Sw for

a short to ground.

Perform Powertrain Verification Test VER-4A.

19 Ignition Off

Disconnect the Speed Control Servo Connector.

Note: Check connectors - Clean/repair as necessary.

Is any Terminal damaged, pushed out or miswired?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-4A.

No®Go To 20

269

SPEED CONTROL

* CHECKING SPEED CONTROL OPERATION ÐContinued

ProCarManuals.com

Page 276 of 364

TEST ACTION APPLICABILITY

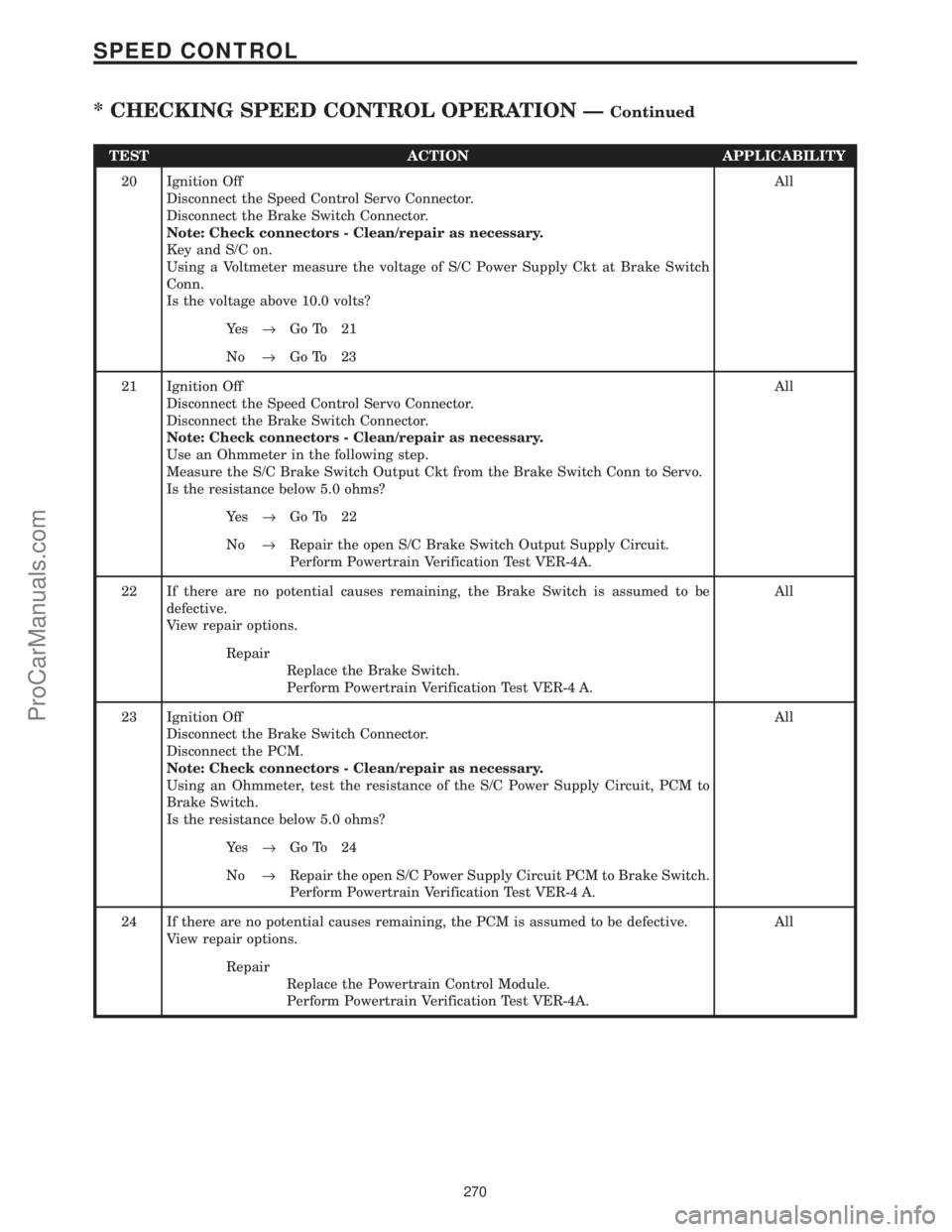

20 Ignition Off

Disconnect the Speed Control Servo Connector.

Disconnect the Brake Switch Connector.

Note: Check connectors - Clean/repair as necessary.

Key and S/C on.

Using a Voltmeter measure the voltage of S/C Power Supply Ckt at Brake Switch

Conn.

Is the voltage above 10.0 volts?All

Ye s®Go To 21

No®Go To 23

21 Ignition Off

Disconnect the Speed Control Servo Connector.

Disconnect the Brake Switch Connector.

Note: Check connectors - Clean/repair as necessary.

Use an Ohmmeter in the following step.

Measure the S/C Brake Switch Output Ckt from the Brake Switch Conn to Servo.

Is the resistance below 5.0 ohms?All

Ye s®Go To 22

No®Repair the open S/C Brake Switch Output Supply Circuit.

Perform Powertrain Verification Test VER-4A.

22 If there are no potential causes remaining, the Brake Switch is assumed to be

defective.

View repair options.All

Repair

Replace the Brake Switch.

Perform Powertrain Verification Test VER-4 A.

23 Ignition Off

Disconnect the Brake Switch Connector.

Disconnect the PCM.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, test the resistance of the S/C Power Supply Circuit, PCM to

Brake Switch.

Is the resistance below 5.0 ohms?All

Ye s®Go To 24

No®Repair the open S/C Power Supply Circuit PCM to Brake Switch.

Perform Powertrain Verification Test VER-4 A.

24 If there are no potential causes remaining, the PCM is assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-4A.

270

SPEED CONTROL

* CHECKING SPEED CONTROL OPERATION ÐContinued

ProCarManuals.com

Page 277 of 364

TEST ACTION APPLICABILITY

25 Ignition On.

With the DRB Select ªInputs/Outputsº, monitor the S/C Switch.

Press and hold each switch to see change in the parameter.

Does the parameter change for each switch?All

Ye s®Go To 26

No®Replace the S/C Switch.

Perform Powertrain Verification Test VER-4A.

26 Ignition On, Engine Not Running

With the DRB, monitor the Speed Control Switch inputs.

While observing display, press the Set Switch several times.

Does the DRB show the Set Switch pressed and released?All

Ye s®Go To 27

No®Replace the Speed Control On/Off/Set Switch.

Perform Powertrain Verification Test VER-4A.

27 If there are no potential causes remaining, the Clock Spring is assumed to be

defective.

View repair options.All

Repair

Replace Clock Spring.

Perform Powertrain Verification Test VER-4A.

271

SPEED CONTROL

* CHECKING SPEED CONTROL OPERATION ÐContinued

ProCarManuals.com

Page 278 of 364

Symptom:

*(NO RESPONSE(CONDITION

POSSIBLE CAUSES

IGNITION NOT ON

DIAGNOSTIC READ-OUT BOX ADAPTER CABLE DEFECTIVE

FUEL PUMP DEFECTIVE

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

PCM GROUNDS OPEN

FUEL PUMP RELAY OUT CKT INTERMITTENT SHORT TO GRND

FUEL PUMP RELAY OUTPUT CIRCUIT SHORT TO GROUND

SCI RECEIVE CIRCUIT OPEN

SCI RECEIVE CIRCUIT SHORT TO GROUND

SCI TRANSMIT CIRCUIT OPEN

SCI TRANSMIT CIRCUIT SHORTED TO GROUND

FUSED B(+) CIRCUIT OPEN BETWEEN FUSE AND BATTERY

DIAGNOSTIC READ-OUT BOX DEFECTIVE

PCM DEFECTIVE (NO RESPONSE)

FUSED B(+) CIRCUIT OPEN BETWEEN FUSE AND PCM

FUSED B(+) CIRCUIT SHORT TO GROUND

TEST ACTION APPLICABILITY

1 Attempt to start vehicle.

Does the vehicle start?All

Ye s®Go To 2

No®Go To 12

2 Was the Ignition on when the ªNo Responseº message was displayed? All

Ye s®Go To 3

No®Turn the ignition on to get a response.

3 Ignition off.

Using an Ohmmeter, measure the DLC ground circuit (terminals 4 and 5) to ground.

Is the resistance below 5.0 ohms for each measurement?All

Ye s®Go To 4

No®Repair the open ground circuit(s).

Perform Powertrain Verification Test VER-1A.

272

STARTING

ProCarManuals.com

Page 279 of 364

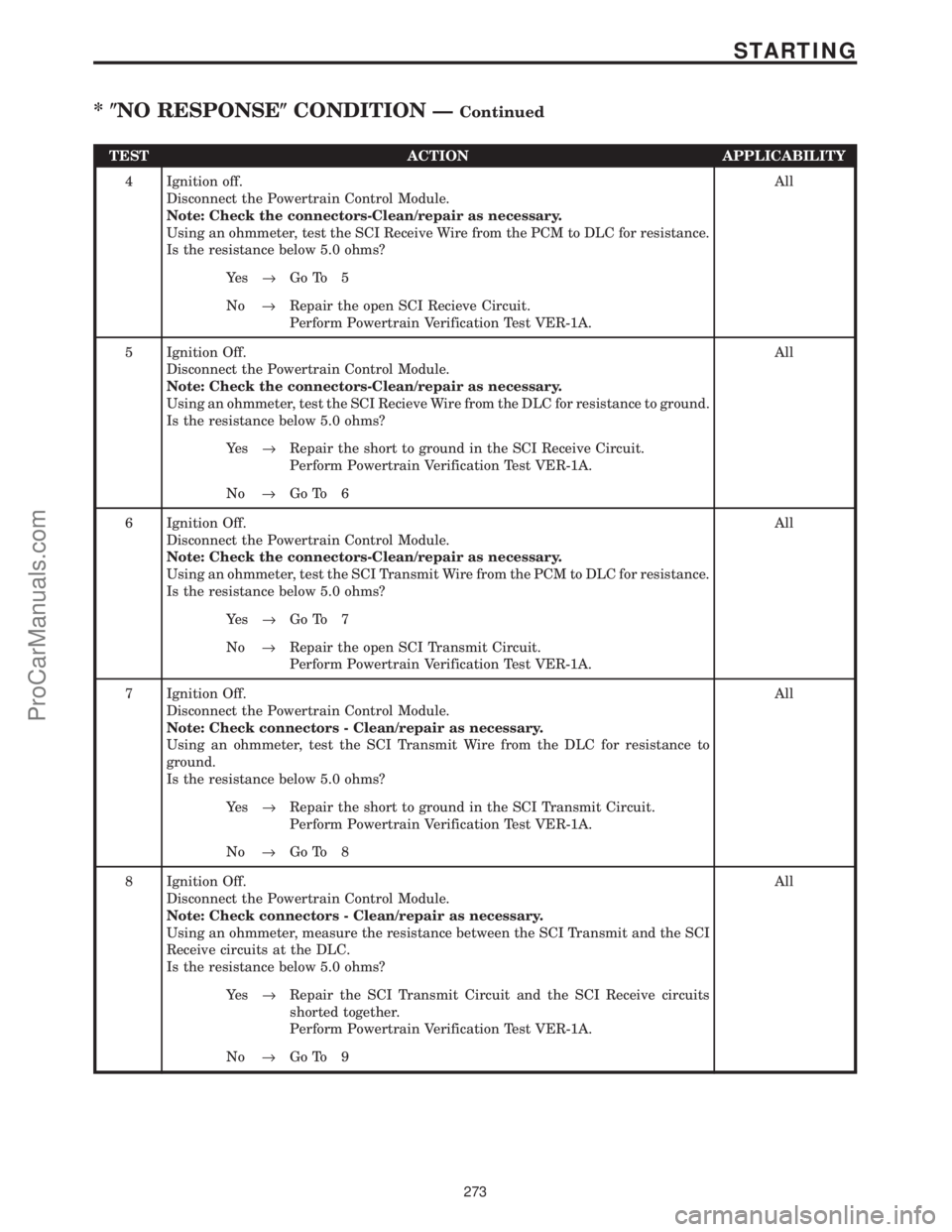

TEST ACTION APPLICABILITY

4 Ignition off.

Disconnect the Powertrain Control Module.

Note: Check the connectors-Clean/repair as necessary.

Using an ohmmeter, test the SCI Receive Wire from the PCM to DLC for resistance.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the open SCI Recieve Circuit.

Perform Powertrain Verification Test VER-1A.

5 Ignition Off.

Disconnect the Powertrain Control Module.

Note: Check the connectors-Clean/repair as necessary.

Using an ohmmeter, test the SCI Recieve Wire from the DLC for resistance to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the short to ground in the SCI Receive Circuit.

Perform Powertrain Verification Test VER-1A.

No®Go To 6

6 Ignition Off.

Disconnect the Powertrain Control Module.

Note: Check the connectors-Clean/repair as necessary.

Using an ohmmeter, test the SCI Transmit Wire from the PCM to DLC for resistance.

Is the resistance below 5.0 ohms?All

Ye s®Go To 7

No®Repair the open SCI Transmit Circuit.

Perform Powertrain Verification Test VER-1A.

7 Ignition Off.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, test the SCI Transmit Wire from the DLC for resistance to

ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the short to ground in the SCI Transmit Circuit.

Perform Powertrain Verification Test VER-1A.

No®Go To 8

8 Ignition Off.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure the resistance between the SCI Transmit and the SCI

Receive circuits at the DLC.

Is the resistance below 5.0 ohms?All

Ye s®Repair the SCI Transmit Circuit and the SCI Receive circuits

shorted together.

Perform Powertrain Verification Test VER-1A.

No®Go To 9

273

STARTING

*(NO RESPONSE(CONDITION ÐContinued

ProCarManuals.com

Page 280 of 364

TEST ACTION APPLICABILITY

9 Ignition Off.

Connect the DRB to a functional Data Link Connector on another vehicle.

Turn the ignition on.

With the DRB, attempt to read trouble codes.

Did the DRB display ªNo Responseº?All

Ye s®Go To 10

No®Replace the initial vehicle's Powertrain Control Module.

Perform Powertrain Verification Test VER-1A.

10 Ignition Off.

Substitute another DRB Adapter Cable.

Ignition on, Engine not running.

With the DRB, attempt to read trouble codes.

Did the DRB display ªNo Responseº?All

Ye s®Go To 11

No®Replace the DRB Adapter Cable.

Perform Powertrain Verification Test VER-1A.

11 If there are no potential causes remaining, the Diagnostic Readout Box is assumed to

be defective.

View repair options.All

Repair

Have the DRB repaired or replaced.

Perform Powertrain Verification Test VER-1A.

12 Ignition Off.

Disconnect the TP Sensor Connector.

Note: Check connector-Clean/repair as necessary.

Turn the ignition on.

With a voltage, measure the Throttle Position Sensor 5±volt Supply circuit.

Is the voltage above 6.0 volts?All

Ye s®Repair the open grounds at the Powertrain Control Module

Cavities 10 and 50.

Perform the Powertrain Verification Test VER-1A

No®Go To 13

13 Ignition Off.

Disconnect the Powertrain Control Module.

Note: Check connector-Clean/repair as necessary.

Turn the ignition on.

With a voltmeter, measure Fused Ignition Switch Output Circuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 14

No®Repair the open Fused Ignition Switch Output Circuit (check

Ignition Switch Fuse in PDC).

Perform Powertrain Verification Test VER-1A.

274

STARTING

*(NO RESPONSE(CONDITION ÐContinued

ProCarManuals.com

Page 281 of 364

TEST ACTION APPLICABILITY

14 Ignition Off.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Turn the ignition on.

With a voltmeter, mesure the Fused B(+) Curcuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 15

No®Go To 16

15 If there are no potential causes remaining, replace the Powertrain Control Module.

View repair options.All

Replace the Powertrain Control Module.

Perform the Powertrain Verification Test VER-1A.

16 Remove Fuel Pump Fuse from the Power Distribution Center.

Inspect the Fuse.

Is the fuse OK?All

Ye s®Go To 17

No®Go To 18

17 Ignition On.

Remove the Fuel Pump Fuse from the PCM.

With a voltmeter, measure the B(+) side of the Fuse Socket.

Is the voltage above 10.0 volts?All

Ye s®Repair the opem B(+) circuit between the Fuse and the PCM.

Perform Powertrain Verification Test VER-1A.

No®Repair the opem B(+) circuit between the Fuse and the battery.

Perform Powertrain Verification Test VER-1A.

18 Ignition Off

Disconnect the Fuel Pump Relay.

Disconnect the Fuel Pump Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

With an Ohmmeter, measure the Fuel Pump Relay Output Circuit to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Fuel Pump Relay Output Circuit for a short to ground.

Perform Powertrain Verification Test VER-1A.

No®Go To 19

19 If there are no potential causes remaining, the Fuel Pump is assumed to be defective.

View repair options.All

Repair

Replace the Fuel Pump. Replace Fuel Pump Fuse.

Perform Powertrain Verification Test VER-1A.

275

STARTING

*(NO RESPONSE(CONDITION ÐContinued

ProCarManuals.com

Page 282 of 364

Symptom:

* CHECKING THE CAM AND CRANK SENSORS

POSSIBLE CAUSES

SECONDARY INDICATORS PRESENT

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

Note: Address all trouble codes before continuing.

Note: Ensure PCM Connectors are secure.

With the DRB, read the secondary indicators while cranking the engine.

Were there any secondary indicators present while cranking the engine?All

Ye s®Refer to Symptom list for further diagnostic test.

No®Go To 2

2 Ignition On, Engine Not Running

With the DRB in Input/Output display, monitor the current CMP and CKP states.

Crank the engine for at least 15 seconds.

Does the DRB show current CKP state9present9while cranking?All

Ye s®Go To 3

No®Refer to symptom P-0340 NO CRANK REFERENCE SIGNAL AT

PCM in the DRIVEABILITY category.

3 Ignition On, Engine Not Running

With the DRB in Input/Output display, monitor the current CMP and CKP states.

Crank the engine for at least 15 seconds.

Does the DRB show current CMP state9present9while cranking?All

Ye s®Refer to symptom * CHECKING THE SECONDARY IGNITION

SYSTEM in the STARTING category.

No®Refer to symptom P-0340 NO CAM SIGNAL AT PCM in the

DRIVEABILITY category.

276

STARTING

ProCarManuals.com

Page 283 of 364

Symptom:

* CHECKING THE ENGINE MECHANICAL SYSTEMS

POSSIBLE CAUSES

ENGINE COMPRESSION OUT OF SPECIFICATION

VALVE TIMING OUT OF SPECIFICATION

POWERTRAIN CONTROL MODULE DEFECTIVE

CLEAN SPARK PLUGS

SPARK PLUG CABLES POSITIONED INCORRECTLY

TEST ACTION APPLICABILITY

1 Turn Ignition off.

Inspect Spark Plug Cables for correct placement.

Are all Spark Plug Cables positioned correctly?All

Ye s®Go To 2

No®Reinstall Spark Plug Cables as necessary.

2 Turn Ignition off.

Remove all Spark Plugs and inspect the tips for wet fuel.

Are the Spark Plug tips wet?All

Ye s®Clean the spark plugs.

No®Go To 3

3 Turn Ignition off.

Using service information procedures, check Engine compression.

Is Engine compression within specifications?All

Ye s®Go To 4

No®Repair the Engine as necessary.

Perform Verification Test VER-1A.

4 Turn Ignition off.

Using service information procedures, check Engine Valve timing.

Is Valve timing within specifications?All

Ye s®Go To 5

No®Repair Valve timing as necessary.

Perform Verification Test VER-1A.

5 If there are no potential causes or DTCs remaining, the Powertrain Control Module

is assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-1A.

277

STARTING

ProCarManuals.com