service CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 283 of 364

Symptom:

* CHECKING THE ENGINE MECHANICAL SYSTEMS

POSSIBLE CAUSES

ENGINE COMPRESSION OUT OF SPECIFICATION

VALVE TIMING OUT OF SPECIFICATION

POWERTRAIN CONTROL MODULE DEFECTIVE

CLEAN SPARK PLUGS

SPARK PLUG CABLES POSITIONED INCORRECTLY

TEST ACTION APPLICABILITY

1 Turn Ignition off.

Inspect Spark Plug Cables for correct placement.

Are all Spark Plug Cables positioned correctly?All

Ye s®Go To 2

No®Reinstall Spark Plug Cables as necessary.

2 Turn Ignition off.

Remove all Spark Plugs and inspect the tips for wet fuel.

Are the Spark Plug tips wet?All

Ye s®Clean the spark plugs.

No®Go To 3

3 Turn Ignition off.

Using service information procedures, check Engine compression.

Is Engine compression within specifications?All

Ye s®Go To 4

No®Repair the Engine as necessary.

Perform Verification Test VER-1A.

4 Turn Ignition off.

Using service information procedures, check Engine Valve timing.

Is Valve timing within specifications?All

Ye s®Go To 5

No®Repair Valve timing as necessary.

Perform Verification Test VER-1A.

5 If there are no potential causes or DTCs remaining, the Powertrain Control Module

is assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-1A.

277

STARTING

ProCarManuals.com

Page 304 of 364

TEST ACTION APPLICABILITY

8 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-1A.

9 Ignition Off.

Ensure the Transmission is in Park.

With the DRB, read the Park/Neutral Position Switch.

Does the Switch show Park?All

Ye s®Go To 10

No®Repair Park/Neutral Switch.

Perform Powertrain Verification Test VER-1A.

10 Ignition Off

Disconnect the Starter Relay Connector.

Note: Check connectors - Clean/repair as necessary.

Warning: The Engine may be cranked in the next step. Keep away from

moving parts.

Warning: The engine may be cranked in the next step. Keep away from

moving parts.

Briefly connect a jumper wire between Starter Relay Output and Fused B(+)

Circuits.

Did the Starter Solenoid click when the jumper wire was connected?All

Ye s®Go To 11

No®Go To 15

11 Ignition Off

Check the Battery Cables for high resistance. (Use Service Manual procedure.)

Did either Battery Circuit have a voltage drop greater than 0.2 volt?All

Ye s®Repair the Battery Circuit for high resistance.

Perform Powertrain Verification Test VER-1A.

No®Go To 12

12 Ignition Off

Attempt to manually rotate the Crankshaft 360 degrees.

Is the Crankshaft able to rotate 360 degrees?All

Ye s®Go To 13

No®Repair the Engine mechanical problem as necessary.

Perform Powertrain Verification Test VER-1A.

13 Ignition Off.

Disconnect the Starter Relay Connector.

Note: Check connectors - Clean/repair as necessary.

With a Voltmeter, measure the Fused B(+) Circuit.

Is the voltage above 11.6 volts?All

Ye s®Go To 14

No®Repair open Fused B(+) Circuit. (check Ignition Switch Fuse in

PDC).

Perform Powertrain Verification Test VER-1A.

298

STARTING

* NO CRANK CONDITION ÐContinued

ProCarManuals.com

Page 305 of 364

TEST ACTION APPLICABILITY

14 Ignition Off.

Disconnect Starter Relay Output Wire from the Starter Solenoid.

Disconnect the Starter Relay Connector.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure Starter Relay Output Circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 19

No®Repair open Starter Relay Output Circuit.

Perform Powertrain Verification Test VER-1A.

15 Ignition Off

Check the Battery Cables for high resistance. (Use Service Manual procedure.)

Did either Battery Circuit have a voltage drop greater than 0.2 volt?All

Ye s®Repair the Battery Circuit for high resistance.

Perform Powertrain Verification Test VER-1A.

No®Go To 16

16 Ignition Off

Attempt to manually rotate the Crankshaft 360 degrees.

Is the Crankshaft able to rotate 360 degrees?All

Ye s®Go To 17

No®Repair the Engine mechanical problem as necessary.

Perform Powertrain Verification Test VER-1A.

17 Ignition Off.

Disconnect Starter Relay Output Wire from the Starter Solenoid.

Disconnect the Starter Relay Connector.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure Starter Relay Output Circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 18

No®Repair open Starter Relay Output Circuit.

Perform Powertrain Verification Test VER-1A.

18 Ignition Off.

Disconnect the Starter Relay Connector.

Note: Check connectors - Clean/repair as necessary.

With a Voltmeter, measure the Fused B(+) Circuit.

Is the voltage above 11.6 volts?All

Ye s®Go To 19

No®Repair open Fused B(+) Circuit. (check Ignition Switch Fuse in

PDC).

Perform Powertrain Verification Test VER-1A.

299

STARTING

* NO CRANK CONDITION ÐContinued

ProCarManuals.com

Page 307 of 364

Symptom:

* START AND STALL CONDITION

TEST ACTION APPLICABILITY

1Note: Ensure the SKIM has proper communication and that there are no

SKIM DTC's present before continuing.

At this point in the diagnostic test procedure, it is assumed that all of the engine

electrical systems are operating as designed and are not the cause of a start and stall,

or a no start problem.

The following additional items should be checked as possible mechanical problems.

Any one of these items can produce a start and stall, or no start condition; none can

be overlooked as a possible cause.

1. ENGINE VALVE TIMING - must be within specifications

2. ENGINE COMPRESSION - must be within specifications

3. ENGINE EXHAUST SYSTEM - must be free of any restrictions

4. ENGINE PCV SYSTEM - must flow freely

5. FUEL - must be free of contamination

6. ENGINE SECONDARY IGNITION CHECK - must exhibit a normal scope pattern

7. THROTTLE BODY - must be free of any coking conditions.

8. IDLE AIR CONTROL MOTOR - passages must be free of any debris or carbon.

Always look for any Technical Service Bulletins that may relate to this condition.All

Test Complete.

301

STARTING

ProCarManuals.com

Page 308 of 364

Symptom:

P-0740 TORQUE CONV CLUTCH, NO RPM DROP AT LOCKUP

When Monitored and Set Condition:

P-0740 TORQUE CONV CLUTCH, NO RPM DROP AT LOCKUP

When Monitored: Continuously when no matured or maturing Trouble Code and throttle

position >10% and constant for 4.4 seconds before TCC engagement requested: No TCC

solenoid circuit, any cam/crank-related code, VSS, any TPS-related code and Battery

voltage >11.0

Set Condition: Torque Converter malfunctions that are detected are the FTC not locking

up properly when desired, and the torque converter not unlocking properly when desired.

3 consecutive test failures over one trip will store the code. 2 bad trips will set the code.

POSSIBLE CAUSES

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

DIFF, SHAFT, OR GEARS DEFECTIVE

TCC SOL DEFECTIVE

TORQUE CONVERTER ASSEMBLY DEF OR TCC SOL STUCK

TRANSMISSION FLUID DIRTY OR LEVEL LOW

VEHICLE CONFIGURATION NON-STANDARD

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, read codes.

Is the Global Good Trip displayed and equal to 0?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Go To 2

No®Test Complete.

2 Ignition Off

At the9Cooler In9port puta0to300PSIgauge using a9T9. Ensure line is long

enough to reach in driver's side of vehicle so gauge can be monitored while driving.

Road test vehicle. Gear select in drive. While monitoring DRB, achieve 50 MPH.

While doing this, notice the gauge will read around 15 PSI until lockup is achieved

in 3rd gear. If the TCC Solenoid is operating properly, the gauge pressure will

fluctuate when lockup is achieved.

Did gauge fluctuate?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Go To 3

No®Refer to service instructions for proper service procedure on

Torque Converter Assembly or stuck TCC Solenoid and repair as

necessary.

Perform Powertrain Verification Test VER-5A.

302

TRANSMISSION

ProCarManuals.com

Page 309 of 364

TEST ACTION APPLICABILITY

3 Ignition Off

Check Transmission Fluid level and ensure it is clear of any debris.

Is the Transmission Fluid okay?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Go To 4

No®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

4 Ignition Off

Disconnect the TCC Solenoid connector.

Note: Check connectors - Clean/repair as necessary.

Turn key on.

Use a Voltmeter in the following step.

Using a Voltmeter, measure the Fused Ignition Switch Output Circuit at Solenoid

Connector.

Is the voltage above 10.0 volts?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Go To 5

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Powertrain Verification Test VER-5A.

5 Ignition Off

Disconnect the TCC Solenoid connector.

Note: Check connectors - Clean/repair as necessary.

With an Ohmmeter, measure across the Solenoid for resistance.

Was resistance between 30.0 and 50.0 ohms?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Go To 6

No®Replace TCC Solenoid.

Perform Powertrain Verification Test VER-5A.

6 Drive Vehicle

Maintain 50 MPH per DRB. Wait 10 seconds in lockup. Record Engine RPM.

Was engine RPM 2200 +/- 50 RPM?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Go To 7

No®Inspect Differential, Output Shaft, or Gear Box. Refer to service

instructions for proper diagnosis.

Perform Powertrain Verification Test VER-5A.

7 Ignition Off

Remove VSS.

Note: Check connectors - Clean/repair as necessary.

Inspect sensor and gear for damage, also improper wheel size.

Were any problems found?TRANSMISSION -

AUTOMATIC

3-SPD, 31TH

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

303

TRANSMISSION

P-0740 TORQUE CONV CLUTCH, NO RPM DROP AT LOCKUP ÐContinued

ProCarManuals.com

Page 318 of 364

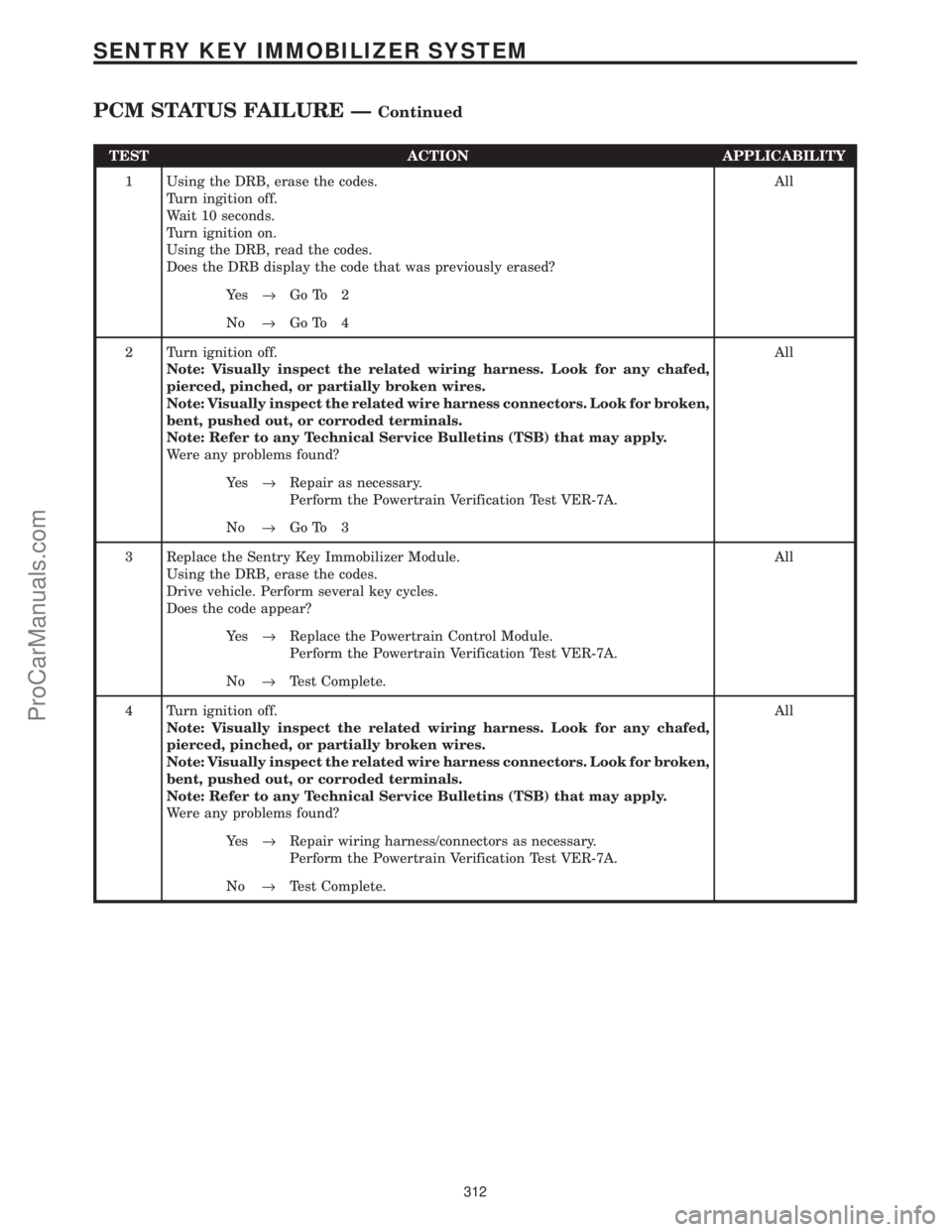

TEST ACTION APPLICABILITY

1 Using the DRB, erase the codes.

Turn ingition off.

Wait 10 seconds.

Turn ignition on.

Using the DRB, read the codes.

Does the DRB display the code that was previously erased?All

Ye s®Go To 2

No®Go To 4

2 Turn ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform the Powertrain Verification Test VER-7A.

No®Go To 3

3 Replace the Sentry Key Immobilizer Module.

Using the DRB, erase the codes.

Drive vehicle. Perform several key cycles.

Does the code appear?All

Ye s®Replace the Powertrain Control Module.

Perform the Powertrain Verification Test VER-7A.

No®Test Complete.

4 Turn ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform the Powertrain Verification Test VER-7A.

No®Test Complete.

312

SENTRY KEY IMMOBILIZER SYSTEM

PCM STATUS FAILURE ÐContinued

ProCarManuals.com

Page 320 of 364

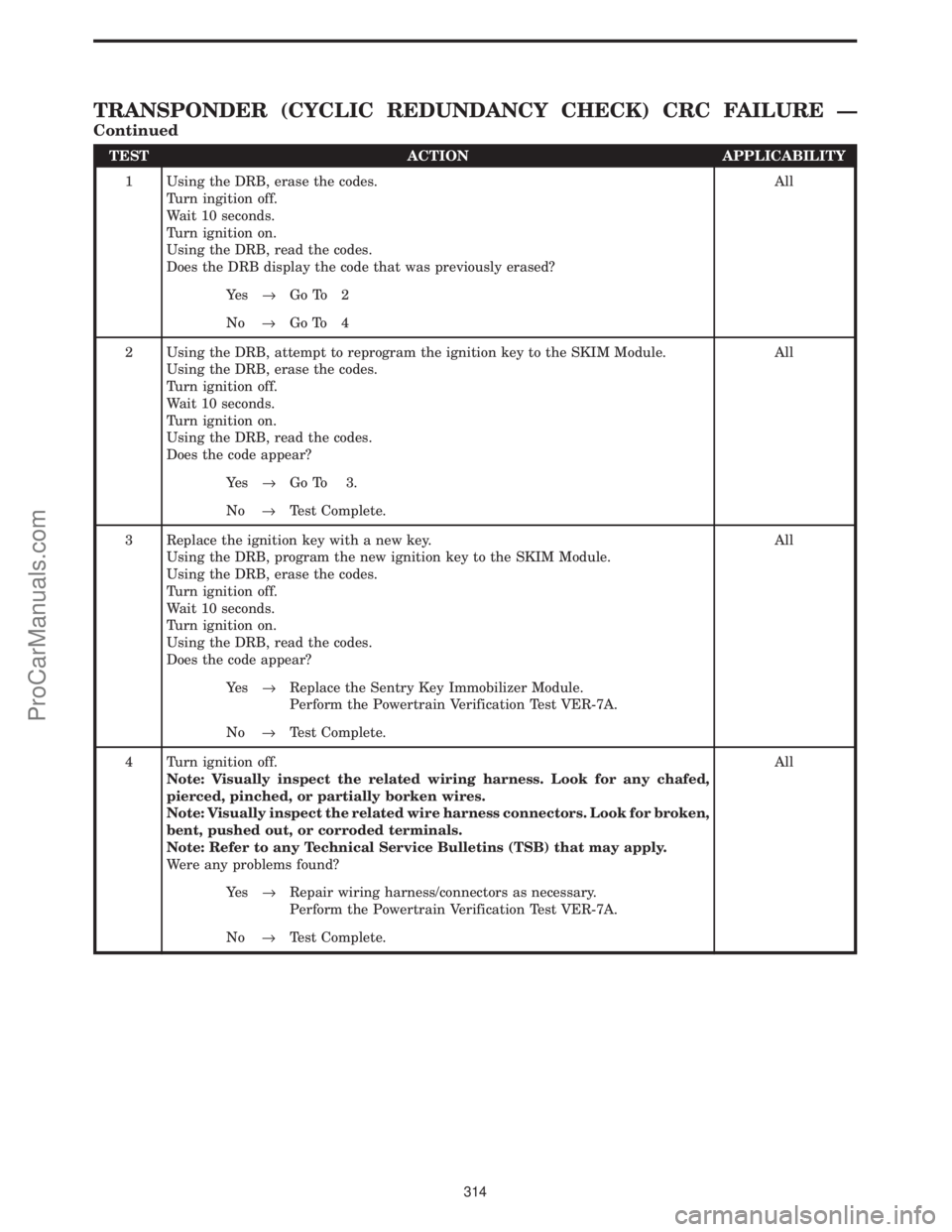

TEST ACTION APPLICABILITY

1 Using the DRB, erase the codes.

Turn ingition off.

Wait 10 seconds.

Turn ignition on.

Using the DRB, read the codes.

Does the DRB display the code that was previously erased?All

Ye s®Go To 2

No®Go To 4

2 Using the DRB, attempt to reprogram the ignition key to the SKIM Module.

Using the DRB, erase the codes.

Turn ignition off.

Wait 10 seconds.

Turn ignition on.

Using the DRB, read the codes.

Does the code appear?All

Ye s®Go To 3.

No®Test Complete.

3 Replace the ignition key with a new key.

Using the DRB, program the new ignition key to the SKIM Module.

Using the DRB, erase the codes.

Turn ignition off.

Wait 10 seconds.

Turn ignition on.

Using the DRB, read the codes.

Does the code appear?All

Ye s®Replace the Sentry Key Immobilizer Module.

Perform the Powertrain Verification Test VER-7A.

No®Test Complete.

4 Turn ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially borken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform the Powertrain Verification Test VER-7A.

No®Test Complete.

314

TRANSPONDER (CYCLIC REDUNDANCY CHECK) CRC FAILURE Ð

Continued

ProCarManuals.com

Page 322 of 364

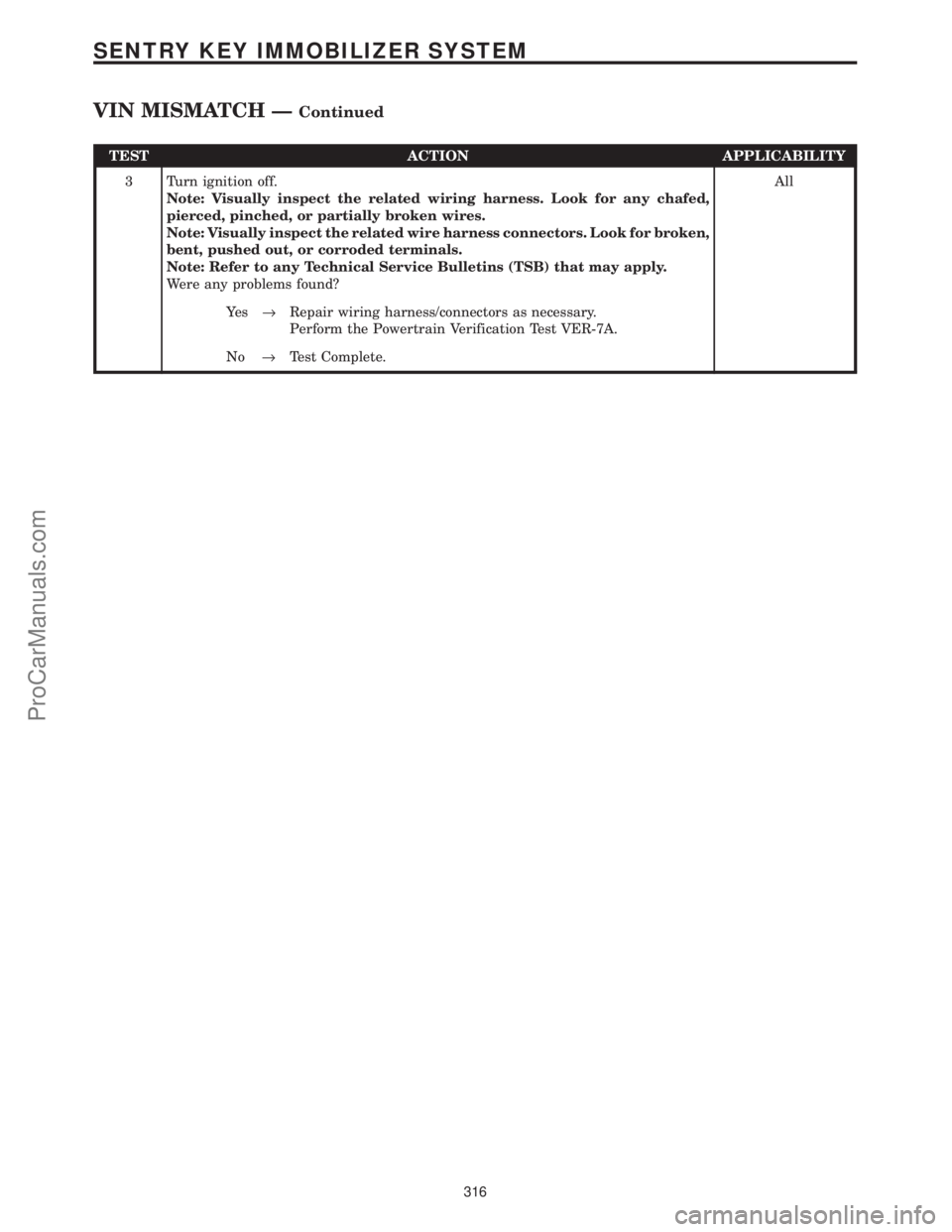

TEST ACTION APPLICABILITY

3 Turn ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform the Powertrain Verification Test VER-7A.

No®Test Complete.

316

SENTRY KEY IMMOBILIZER SYSTEM

VIN MISMATCH ÐContinued

ProCarManuals.com

Page 323 of 364

Verification Tests

VERIFICATION TEST VER-1A APPLICABILITY

No Start Verification

Use this test to verify that a No Start condition has been repaired and that the vehicle can be

returned to the customer.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. Inspect the engine oil for fuel contamination. Replace the oil and filter as necessary

3. Attempt to start the engine.

4. If the No Start condition is still present, refer to the symptom list and perform diagnostic

testing as necessary. Refer to any Technical Service Bulletins that may apply.

5. Run the engine for one warm-up cycle to verify proper operation. With the DRBIIIt, confirm

that no DTC's are present and that all components are functioning properly.

6. If DTC's are present, refer to the symptom list and perform diagnostic testing as necessary.ALL

VERIFICATION TEST VER-2A APPLICABILITY

Non-OBDII Verification

Use this test to verify that a non-OBDII symptom has been repaired and that the vehicle can

be returned to the customer. A non-OBDII symptom is a comprehensive component related

symptom that is not the result of a failed OBDII major monitor.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. With the DRBIIIt, Clear DTC's and Reset Memory (all engine values).

3. Run the engine for one warm-up cycle to verify proper operation.

4. Road test the vehicle. Use all accessories that may be related to this repair.

With the DRBIIIt, confirm that no DTC's are present and that all components are functioning

properly.

6. If this test is being performed after a No Trouble Code test, verify that the symptom is no

longer present. If the symptom is still present, or any other symptom or DTC is present, refer

to the symptom list for further diagnostic testing procedures. Check for any Technical Service

Bulletins that may apply.

7. If there are no DTC's present and all components are functioning properly, repair is

complete.ALL

317

VERIFICATION TESTS

ProCarManuals.com