engine CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3799 of 4284

Once the auto shutdown and fuel pump relays

have been energized, the PCM determines the fuel

injector pulse width based on the following:

± engine coolant temperature

± manifold absolute pressure

± intake air temperature

± engine revolutions

± throttle position

The PCM determines the spark advance based on

the following:

± engine coolant temperature

± crankshaft position

± intake air temperature

± manifold absolute pressure

± throttle position

Engine Warm-Up Modeþ This is an open loop

mode. The PCM adjusts injector pulse width and

controls injector synchronization by controlling the

fuel injectors' ground paths. The PCM adjusts igni-

tion timing and engine idle speed. The PCM adjusts

the idle speed by controlling the idle air control

motor.

Cruise or Idle Modeþ When the engine is at

normal operating temperature, this is a closed loop

mode.

Acceleration Modeþ This is a closed loop mode.

The PCM recognizes an increase in throttle position

and a decrease in Manifold Vacuum as engine load

increases. In response, the PCM increases the in-

jector pulse width to meet the increased load. The

A/C compressor may be de-energized for a short

period of time.

Decelerationþ This is a closed loop mode. The

PCM recognizes a decrease in throttle position and

an increase in Manifold Vacuum as engine load

decreases. In response, the PCM decreases the

injector pulse width to meet the decreased load.

Full injector shut off may be obtained during high

speed deceleration.

Wide Open Throttle Modeþ This is an open

loop mode. The throttle position sensor notifies the

PCM of a wide open throttle condition. Once a wide

open throttle is sensed, the PCM de-energizes the

A/C compressor clutch relay for 20 seconds.

3.2.5 NON-MONITORED CIRCUITS

The PCM does not monitor the following circuits,

systems, and conditions even though they could

have malfunctions that result in driveability prob-

lems. A diagnostic code may not be displayed for the

following conditions. However, problems with these

systems may cause a diagnostic code to be displayed

for other systems. For example, a fuel pressure

problem will not register a diagnostic code directly,

but could cause a rich or lean condition. This couldcause an oxygen sensor, fuel system, or misfire

monitor trouble code to be stored in the PCM.

Engine Timingþ The PCM cannot detect an

incorrectly indexed timing chain, camshaft

sprocket, or crankshaft sprocket. The PCM also

cannot detect an incorrectly indexed distributor.(*)

Fuel Pressureþ Fuel pressure is controlled by

the fuel pressure regulator. The PCM cannot detect

a clogged fuel pump inlet filter, clogged in-line filter,

or a pinched fuel supply.(*)

Fuel Injectorsþ The PCM cannot detect if a fuel

injector is clogged, the pintle is sticking, or the

wrong injectors are installed.(*)

Fuel Requirementsþ Poor quality gasoline can

cause problems such as hard starting, stalling, and

stumble. Use of methanol-gasoline blends may re-

sult in starting and driveability problems. See indi-

vidual symptoms and their definitions in Section

6.0 (Glossary of Terms).

PCM Groundsþ The PCM cannot detect a poor

system ground. However, a diagnostic trouble code

may be stored in the PCM as a result of this

condition.

Throttle Body Air Flowþ The PCM cannot

detect a clogged or restricted air cleaner inlet or

filter element.(*)

Exhaust Systemþ The PCM cannot detect a

plugged, restricted, or leaking exhaust system.(*)

Cylinder Compressionþ The PCM cannot de-

tect uneven, low, or high engine cylinder compres-

sion.(*)

Excessive Oil Consumptionþ Although the

PCM monitors the exhaust stream oxygen content

through the oxygen sensor when the system is in a

closed loop, it cannot determine excessive oil con-

sumption.

NOTE: ANY OF THESE CONDITIONS

COULD RESULT IN A RICH OR LEAN

CONDITION CAUSING AN OXYGEN SENSOR

TROUBLE CODE TO BE STORED IN THE

PCM, OR THE VEHICLE MAY EXHIBIT ONE

OR MORE OF THE DRIVEABILITY

SYMPTOMS LISTED IN THE TABLE OF

CONTENTS.

3.2.6 SKIS OVERVIEW

The Sentry Key Immobilizer System (SKIS) is

designed to prevent unauthorized vehicle opera-

tion. The system consists of a Sentry Key Immobi-

lizer Module (SKIM), ignition key(s) equipped with

a transponder chip and PCM. When the ignition

switch is turned on, the SKIM interrogates the

ignition key. If the ignition key is Valid or Invalid,

the SKIM sends a PCI Bus message to the PCM

indicating ignition key status. Upon receiving this

5

GENERAL INFORMATION

Page 3800 of 4284

message the PCM will terminate engine operation,

or allow the engine to continue to operate.

3.2.7 SKIM ON-BOARD DIAGNOSTICS

The SKIM has been programmed to transmit and

monitor many different coded messages as well as

PCI Bus messages. This monitoring is called On

Board Diagnosis.

Certain criteria must be met for a diagnostic

trouble code to be entered into the SKIM memory.

The criteria may be a range of; Input voltage, PCI

Bus message, or coded messages to the SKIM. If all

of the criteria for monitoring a circuit or function

are met and a fault is sensed, a diagnostic trouble

code will be stored in the SKIM memory.

3.2.8 SKIS OPERATION

When ignition power is supplied to the SKIM, the

SKIM performs an internal self-test. After the self-

test is completed, the SKIM energizes the antenna

(this activates the transponder chip) and sends a

challenge to the transponder chip. The transponder

chip responds to the challenge by generating an

encrypted response message using the following:

Secret Key -This is an electronically stored

value (identification number) that is unique to each

SKIS. The secret key is stored in the SKIM, PCM

and all ignition key transponders.

Challenge- This is a random number that is

generated by the SKIM at each ignition key cycle.

The secret key and challenge are the two vari-

ables used in the algorithm that produces the

encrypted response message. The transponder uses

the crypto algorithm to receive, decode and respond

to the message sent by the SKIM. After responding

to the coded message, the transponder sends a

transponder I.D. message to the SKIM. The SKIM

compares the transponder I.D. to the available valid

key codes in the SKIM memory (8 key maximum at

any one time). After validating the key ignition the

SKIM sends a PCI Bus message called a Seed

Request to the engine controller then waits for a

PCM response. If the PCM does not respond, the

SKIM will send the seed request again. After three

failed attempts the SKIM will stop sending the seed

request and store a trouble code. If the PCM sends

a seed response, the SKIM sends a valid/invalid key

message to the PCM. This is an encrypted message

that is generated using the following:

VIN -Vehicle Identification Number

Seed -This is a random number that is generated

by the PCM at each ignition key cycle.

The VIN and seed are the two variables used in

the rolling code algorithm that encrypts the valid/

invalid key message. The PCM uses the rolling code

algorithm to receive, decode and respond to the

valid/invalid key message sent by the SKIM. Aftersending the valid/invalid key message the SKIM

waits 3.5 seconds for a PCM status message from

the PCM. If the PCM does not respond with a valid

key message to the SKIM, a fault is detected and a

trouble code is stored.

The SKIS incorporates a VTSS LED located on

the instrument panel upper cover. The LED re-

ceives switched ignition voltage and is hardwired to

the body control module. The LED is actuated when

the SKIM sends a PCI Bus message to the body

controller requesting the LED on. The body control-

ler then provides the ground for the LED. The

SKIM will request VTSS LED operation for the

following:

± bulb checks at ignition on

± to alert the vehicle operator to a SKIS mal-

function

± customer key programming mode

For all faults except transponder faults and VTSS

LED remains on steady. In the event of a transpon-

der fault the LED flashes at a rate of 1 Hz (once per

second). If a fault is present the LED will remain on

or flashing for the complete ignition cycle. If a fault

is stored in SKIM memory which prevents the

system from operating properly, the PCM will allow

the engine to start and run (for 2 seconds) up to six

times. After the sixth attempt, the PCM disables

the starter relay until the fault is corrected.

3.2.9 PROGRAMMING THE POWERTRAIN

CONTROL MODULE

Important Note:Before replacing the PCM for a

failed driver, control circuit or ground circuit, be

sure to check the related component/circuit integ-

rity for failures not detected due to a double fault in

the circuit. Most PCM driver/control circuit failures

are caused by internal failure to components (i.e.

12-volt pull-ups, drivers and ground sensors). These

failures are difficult to detect when a double fault

has occurred and only one DTC has set.

NOTE: IF THE PCM AND THE SKIM ARE

REPLACED AT THE SAME TIME, PROGRAM

THE VIN INTO THE PCM FIRST. ALL VEHICLE

KEYS WILL THEN NEED TO BE REPLACED

AND PROGRAMMED TO THE NEW SKIM.

The SKIS Secret Key is an I.D. code that is

unique to each SKIS. This code is programmed and

stored in the SKIM, engine controller and transpon-

der chip (ignition key). When replacing the PCM it

is necessary to program the secret key into the

PCM.

1. Turn the ignition on (transmission in park/

neutral).

2. Use the DRB and select THEFT ALARM, SKIM

then MISCELLANEOUS.

6

GENERAL INFORMATION

Page 3804 of 4284

SYMPTOM DIAGNOSTIC TEST

POOR FUEL ECONOMY CHECKING PCM POWER AND GND CKT

CHECKING THE FUEL PRESSURE

CHECKING ECT SENSOR

CHECKING THROTTLE POSITION SENSOR

CHECKING MAP SENSOR

CHECKING IDLE AIR CONTROL MOTOR OPERATION

CHECKING IAT SENSOR

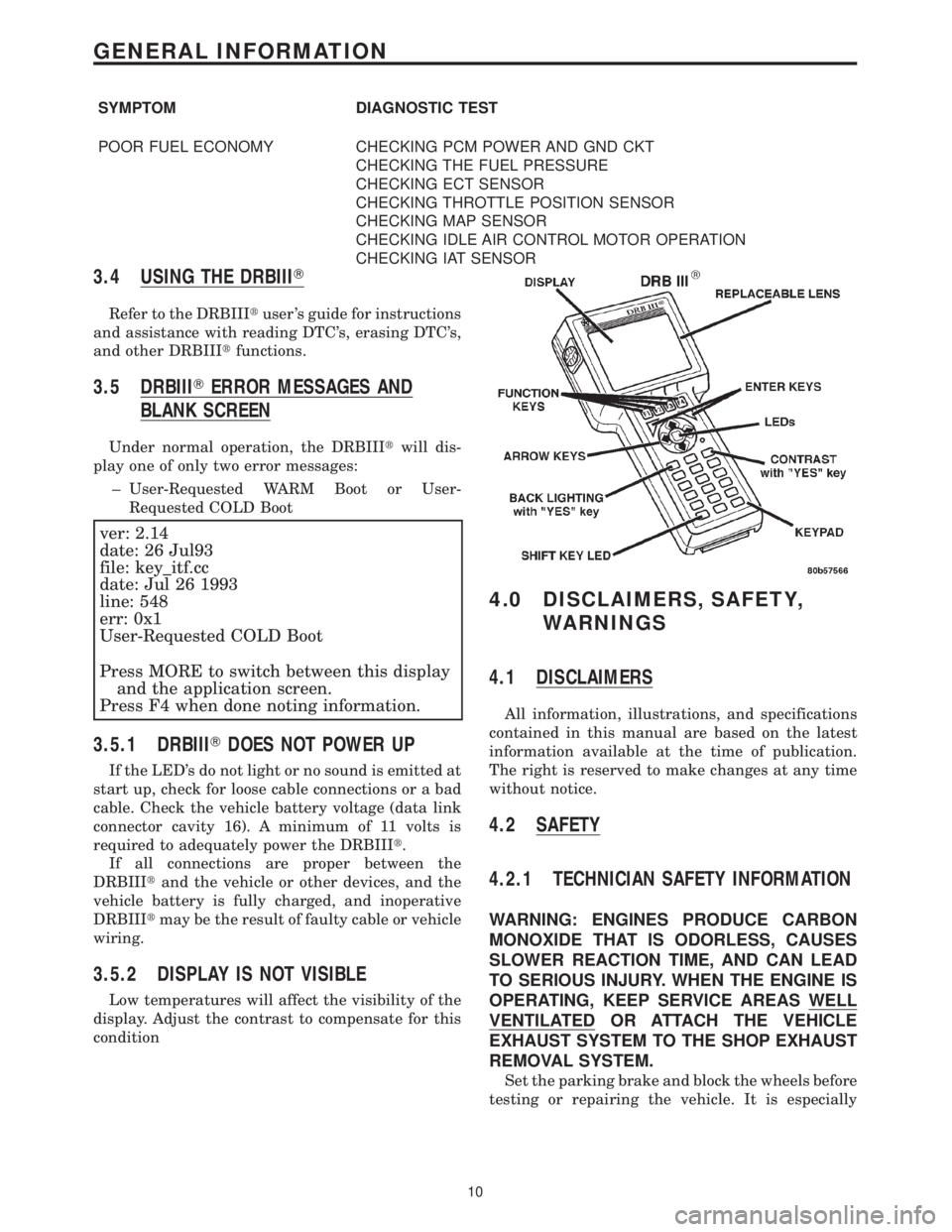

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading DTC's, erasing DTC's,

and other DRBIIItfunctions.

3.5 DRBIIITERROR MESSAGES AND

BLANK SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRBIIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, and inoperative

DRBIIItmay be the result of faulty cable or vehicle

wiring.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

10

GENERAL INFORMATION

Page 3806 of 4284

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second DTC could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

Evaporative System Diagnostic Kit #6917

fuel filler adapter #8382

fuel pressure adapter (C-6631) or #6539

fuel pressure kit (C-4799-B) or #5069

fuel release hose (C-4799-1)

Min Air flow fitting #6714

jumper wires

ohmmeter

oscilloscope

vacuum gauge

voltmeter

12 volt test light minimum 25 ohms resistance

with probe #6801

CAUTION: A 12 VOLT TEST LIGHT SHOULD

NOT BE USED FOR THE FOLLOWING

CIRCUITS, DAMAGE TO THE POWERTRAIN

CONTROLLER WILL OCCUR.

²5 Volt Supply

²8 Volt Supply

²J1850 PCI Bus

²CCD Bus

²CKP Sensor Signal

²CMP Sensor Signal

²Vehicle Speed Sensor Signal

²O2 Sensor Signal

6.0 GLOSSARY OF TERMS

ABSanti-lock brake system

backfire,

popbackfuel ignites in either the intake or

the exhaust system

CKPcrank position sensor

CMPcamshaft position sensorcuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector (previously

called engine diagnostic connector)

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECTengine coolant temperature sensor

EGRexhaust gas recirculation valve

genera-

torpreviously called alternator

hard

startThe engine takes longer than usual

to start, even though it is able to

crank normally.

hesita-

tion, sag,

stumbleThere is a momentary lack of re-

sponse when the throttle is opened.

This can occur at all vehicle speeds.

If it is severe enough, the engine

may stall.

IATintake air temperature sensor

IACidle air control motor

JTECCombined engine and transmission

control module

lack of

power,

sluggishThe engine has less than expected

power, with little or no increase in

vehicle speed when the throttle is

opened.

LDPleak detection pump

MAPmanifold absolute pressure sensor

MILmalfunction indicator lamp

MTVmanifold tuning valve

O2Soxygen sensor

PCIprogrammable communication inter-

face

PCMpowertrain control module

PCVpositive crankcase ventilation

PEPperipheral expansion port

poor fuel

economyThere is significantly less fuel mile-

age than other vehicles of the same

design ad configuration

12

GENERAL INFORMATION

Page 3807 of 4284

rough,

unstable,

or er-

ratic idle

stallingThe engine runs unevenly at idle

and causes the engine to shake if it

is severe enough. The engine idle

rpm may vary (called hunting). This

condition may cause stalling if it is

severe enough.

SBECsingle board engine controller

SKIMsentry key immobilizer module

SKISsentry key immobilizer systemstart &

stallThe engine starts but immediately

dies.

surgeengine rpm fluctuation without cor-

responding change in throttle posi-

tion sensor

TPSthrottle position sensor

TRStransmission range sensor

VSSvehicle speed sensor/signal

13

GENERAL INFORMATION

Page 3810 of 4284

Symptom:

P0622-GENERATOR FIELD NOT SWITCHING PROPERLY

When Monitored and Set Condition:

P0622-GENERATOR FIELD NOT SWITCHING PROPERLY

When Monitored: With the ignition on. Engine running.

Set Condition: When the PCM tries to regulate the generator field with no result during

monitoring.

POSSIBLE CAUSES

WIRING HARNESS INTERMITTENT

INSPECT WIRING HARNESS

ASD RELAY OUTPUT CIRCUIT OPEN

GENERATOR FIELD DRIVER CIRCUIT SHORTED TO GROUND

GENERATOR FIELD DRIVER CIRCUIT OPEN

GENERATOR

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, actuate the Generator Field Driver circuit.

Using a 12-volt test light connected to ground, backprobe the Generator Field Driver

circuit in the back of the Generator.

Does the test light illuminate brightly and flash?All

Ye s®Go To 2

No®Go To 4

2 Turn the ignition on.

With the DRBIIItactuate the Generator Field Driver circuit.

Wiggle the wiring harness from the Generator to PCM.

With the DRBIIIt, read DTC's.

Did the DTC reset?All

Ye s®Repair as necessary .

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Go To 3

3 Turn the ignition off.

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Test Complete.

16

CHARGING

Page 3812 of 4284

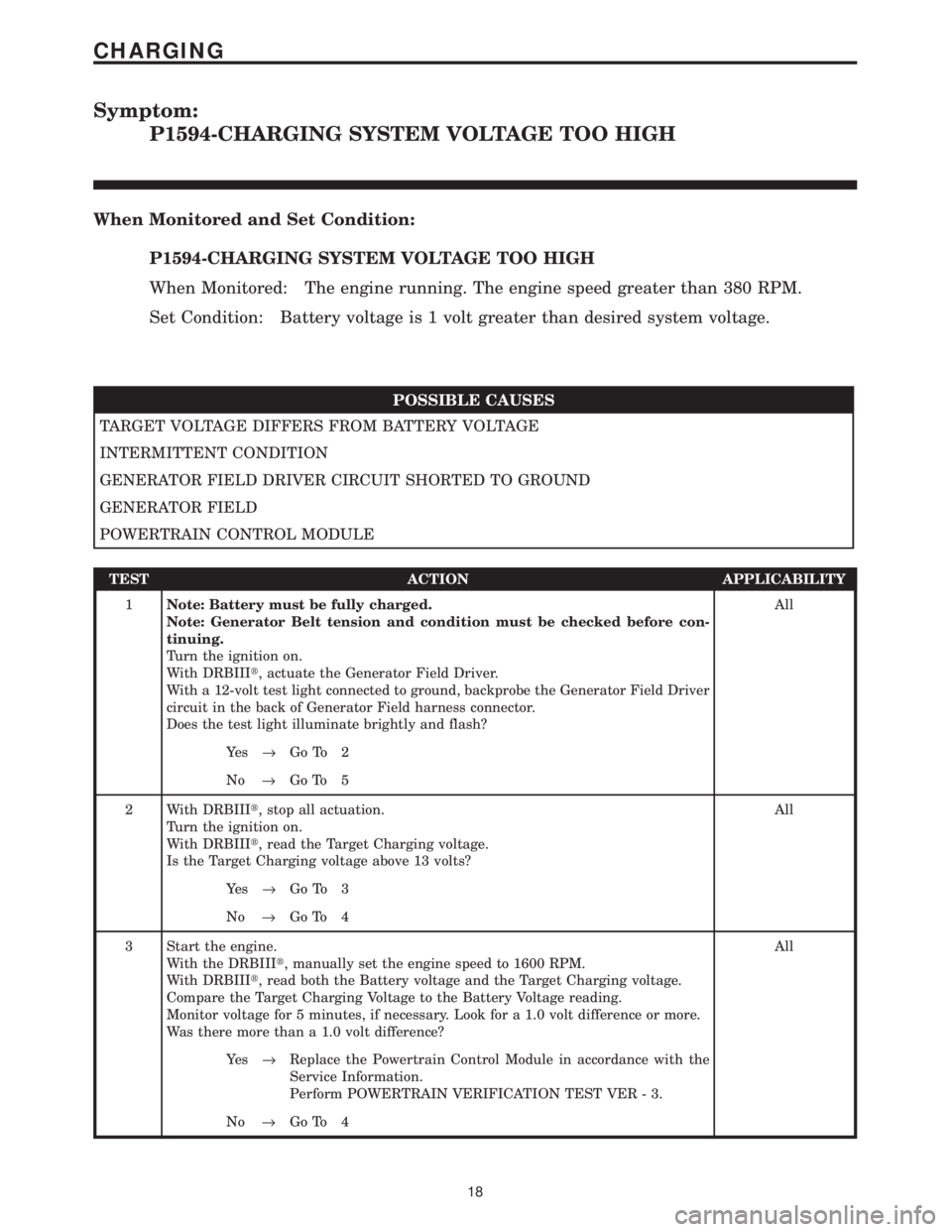

Symptom:

P1594-CHARGING SYSTEM VOLTAGE TOO HIGH

When Monitored and Set Condition:

P1594-CHARGING SYSTEM VOLTAGE TOO HIGH

When Monitored: The engine running. The engine speed greater than 380 RPM.

Set Condition: Battery voltage is 1 volt greater than desired system voltage.

POSSIBLE CAUSES

TARGET VOLTAGE DIFFERS FROM BATTERY VOLTAGE

INTERMITTENT CONDITION

GENERATOR FIELD DRIVER CIRCUIT SHORTED TO GROUND

GENERATOR FIELD

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1Note: Battery must be fully charged.

Note: Generator Belt tension and condition must be checked before con-

tinuing.

Turn the ignition on.

With DRBIIIt, actuate the Generator Field Driver.

With a 12-volt test light connected to ground, backprobe the Generator Field Driver

circuit in the back of Generator Field harness connector.

Does the test light illuminate brightly and flash?All

Ye s®Go To 2

No®Go To 5

2 With DRBIIIt, stop all actuation.

Turn the ignition on.

With DRBIIIt, read the Target Charging voltage.

Is the Target Charging voltage above 13 volts?All

Ye s®Go To 3

No®Go To 4

3 Start the engine.

With the DRBIIIt, manually set the engine speed to 1600 RPM.

With DRBIIIt, read both the Battery voltage and the Target Charging voltage.

Compare the Target Charging Voltage to the Battery Voltage reading.

Monitor voltage for 5 minutes, if necessary. Look for a 1.0 volt difference or more.

Was there more than a 1.0 volt difference?All

Ye s®Replace the Powertrain Control Module in accordance with the

Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Go To 4

18

CHARGING

Page 3813 of 4284

TEST ACTION APPLICABILITY

4WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Test Complete.

5 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Generator Field harness connector.

Measure the resistance of the Generator Field Driver circuit from the PCM harness

connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Generator Field Driver circuit shorted to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Go To 6

6 Turn the ignition off.

Disconnect the Generator Field harness connector.

Measure resistance of the Generator Field Driver terminal to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair or replace the shorted Generator as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Go To 7

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

19

CHARGING

P1594-CHARGING SYSTEM VOLTAGE TOO HIGH ÐContinued

Page 3814 of 4284

Symptom:

P1682-CHARGING SYSTEM VOLTAGE TOO LOW

When Monitored and Set Condition:

P1682-CHARGING SYSTEM VOLTAGE TOO LOW

When Monitored: With the ignition on. Engine RPM greater than 1152 RPM. With no

other charging system codes set.

Set Condition: The battery sensed voltage is 1 volt below the charging goal for 13.47

seconds. The PCM senses the battery voltage turns off the field driver and senses the

battery voltage again. If the voltages are the same, the code is set.

POSSIBLE CAUSES

BATTERY TEMPERATURE

B+ CIRCUIT HIGH RESISTANCE

GENERATOR GROUND HIGH RESISTANCE

INTERMITTENT CONDITION

GENERATOR FIELD DRIVER CIRCUIT OPEN

ASD RELAY OUTPUT CIRCUIT OPEN

GENERATOR

TEST ACTION APPLICABILITY

1NOTE: Inspect the vehicle for aftermarket accessories that may exceed the

Generator System output.

Turn the ignition off.

NOTE: The battery must be fully charged.

NOTE: The Generator belt tension and condition must be checked before

continuing.

Start the engine.

Allow the idle to stabilize.

With the DRBIIIt, read the Target Charging Voltage.

Is the Target Charging Voltage above 15.1 volts?All

Ye s®Go To 2

No®Go To 3

20

CHARGING

Page 3815 of 4284

TEST ACTION APPLICABILITY

2WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Turn the ignition on.

NOTE: Ensure all wires are clear of the engine's moving parts.

Measure the voltage between the Generator B+ Terminal and the Battery+ Post.

Start the engine.

Is the voltage above 0.4 volt?All

Ye s®Repair the B+ circuit for high resistance between the Generator

and Battery.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Go To 3

3WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Start the engine.

Warm the engine to operating temperature.

NOTE: Ensure all wires are clear of the engine's moving parts.

Measure the voltage between the Generator case and Battery ground post.

Is the voltage above 0.1 volt?All

Ye s®Repair Generator Ground for high resistance, Generator Case to

Battery ground side.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

No®Go To 4

4 Start the engine.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Turn on all accessories, manually set engine speed to 1600 RPM.

With DRBIIIt, read Target Charging and Charging voltage.

Compare the two readings.

Is there more than a 1.0 volt difference?All

Ye s®Go To 5

No®Go To 8

5 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Generator Field harness connector.

Measure the resistance of the Generator Field Driver circuit from the PCM harness

connector to Generator harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Generator Field Driver circuit an open.

Perform POWERTRAIN VERIFICATION TEST VER - 3.

21

CHARGING

P1682-CHARGING SYSTEM VOLTAGE TOO LOW ÐContinued