wheel torque CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3574 of 4284

(5) Install fuel filler housing to outer quarter

panel.

(6) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(7) Engage fuel filler lockout link into clip on fuel

fill blocker latch arm.

(8) Install water shield patch covering access hole

in C-pillar.

(9) Install left quarter trim panel.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.

(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove hood cable.

(6) Remove hood prop rod.

(7) Remove screw attaching coolant recovery bottle

to crossmember.

(8) Remove bolts attaching radiator isolators to

crossmember.

(9) Remove bolts attaching ends of crossmember to

radiator closure panel (Fig. 14) .

(10) Lift crossmember upward and away from

radiator closure panel.

(11) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

(3) Align with paint breaks around bolt heads.

(4) Install bolts attaching ends of crossmember to

radiator closure panel (Fig. 14) . Tighten bolts to 19

N´m (14 ft. lbs.) torque.

(5) Install bolts attaching radiator isolators to

crossmember.

(6) Install screw attaching coolant recovery bottle

to crossmember.

(7) Install bolt attaching air cleaner housing to

crossmember.

(8) Install engine air inlet resonator.

(9) Install radiator sight shield.

(10) Install hood prop rod.

(11) Align hood latch by placing latch over net

pierce tabs. If alignment is required, flatten tabs.

(12) Install bolts attaching hood latch to cross-

member. Tighten bolts to 13.5 N´m (10 ft. lbs.)

torque.

(13) Verify hood latch operation and hood align-

ment.

FRONT WHEELHOUSE

SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(2) Remove front wheel. Refer to section 22, Tires/

Wheels, for recommended procedures.

(3) Remove push-in fasteners holding splash shield

to frame rail forward of suspension.

(4) Remove push-in fasteners holding splash shield

to frame rail rearward of suspension.

(5) Remove screws holding wheelhouse splash

shield to front fender.

(6) Remove splash shield from vehicle (Fig. 15).

Fig. 14 Radiator Closure Panel Crossmember

1 - RADIATOR CLOSURE PANEL CROSSMEMBER

2 - FRONT FASCIA

23 - 194 EXTERIORRS

FUEL FILL DOOR BLOCKER LOCKOUT LINK (Continued)

Page 3576 of 4284

INSTALLATION

NOTE: The crossbar assemblies are designed to be

installed in only one way. Check top and bottom

surfaces of the crossbar for the word FRONT and

directional arrows. The directional arrows must

point toward the front of the vehicle.

(1) Place crossbar in position on vehicle.

(2) Work from side to side sliding the crossbar

assembly back a little at a time to ensure it remains

perpendicular to the side rails.

(3) Position first crossbar assembly crossbar at the

second most rearward locator holes. Press the top of

the stanchion lever to lock it into position.

(4) Position the second crossbar assembly in the

second hole from the front. Lock into place.

(5) Place luggage rack riser into position.

(6) Install two fasteners into riser. Tighten fasten-

ers to 4 mm (35 in. lbs.) torque.

REAR QUARTER PANEL/

FENDER AIR EXHAUSTER

DESCRIPTION

Air exhausters, designed to conform to the body

structure, allow air entering at the front of the vehi-

cle to flow out the back. By reducing air pressure

within the vehicle, the exhausters also reduce blower

noise at any given air flow level compared to operat-

ing without them and help reduce door closing effort.

They are located in the lower rear comers of the

body.

REMOVAL

SHORT WHEELBASE

(1) Remove the rear fascia from the body. (Refer to

13 - FRAMES & BUMPERS/BUMPERS/REAR FAS-

CIA - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

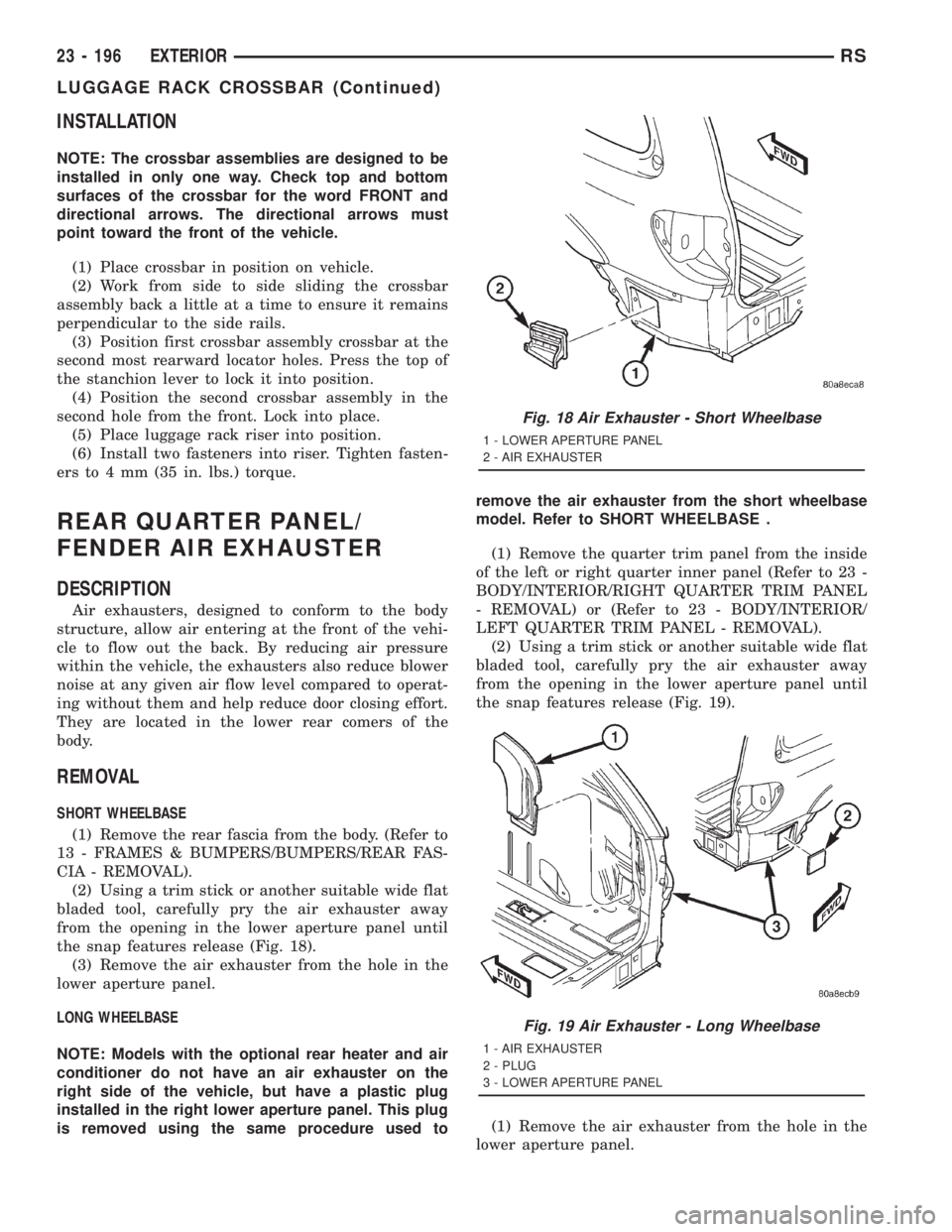

the snap features release (Fig. 18).

(3) Remove the air exhauster from the hole in the

lower aperture panel.

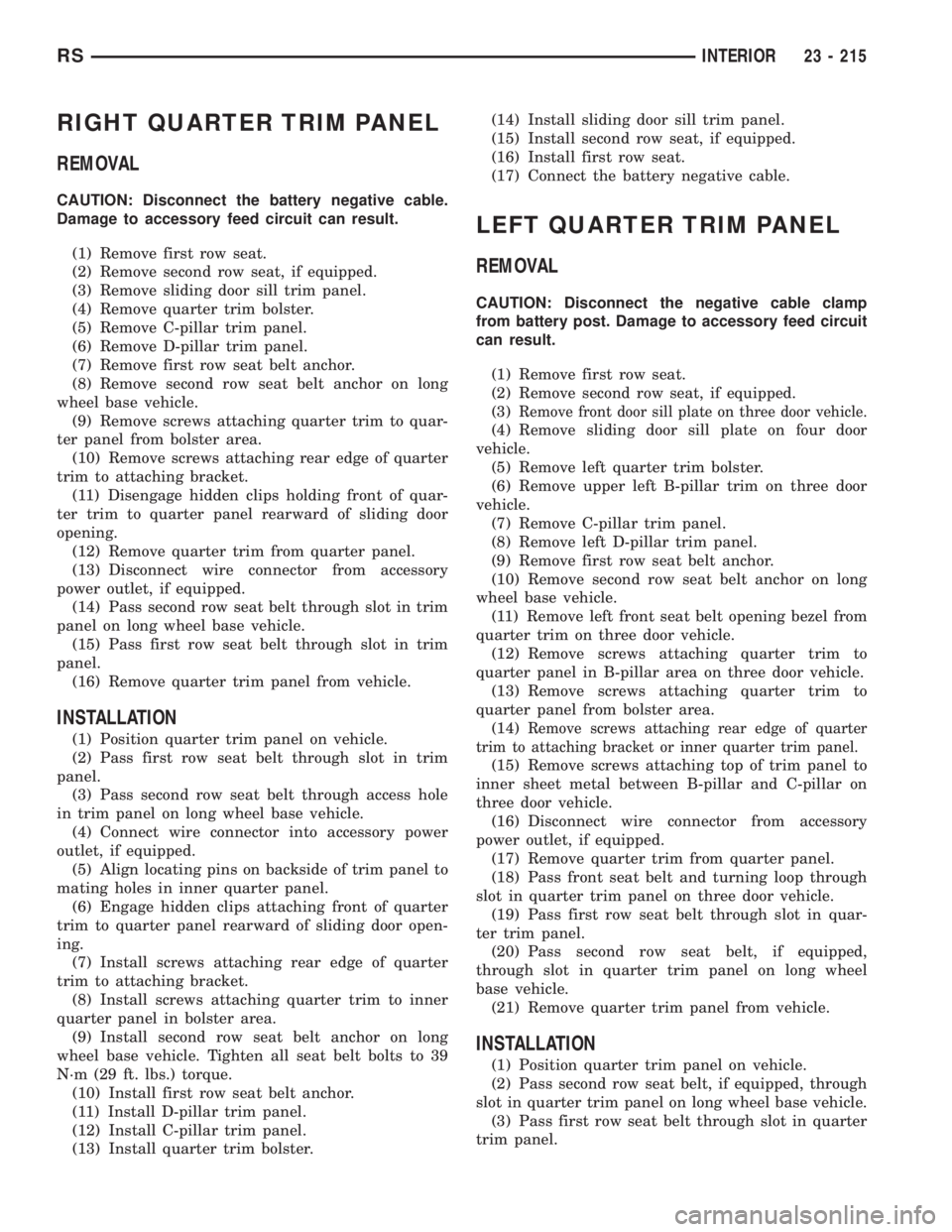

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is removed using the same procedure used toremove the air exhauster from the short wheelbase

model. Refer to SHORT WHEELBASE .

(1) Remove the quarter trim panel from the inside

of the left or right quarter inner panel (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- REMOVAL) or (Refer to 23 - BODY/INTERIOR/

LEFT QUARTER TRIM PANEL - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 19).

(1) Remove the air exhauster from the hole in the

lower aperture panel.

Fig. 18 Air Exhauster - Short Wheelbase

1 - LOWER APERTURE PANEL

2 - AIR EXHAUSTER

Fig. 19 Air Exhauster - Long Wheelbase

1 - AIR EXHAUSTER

2 - PLUG

3 - LOWER APERTURE PANEL

23 - 196 EXTERIORRS

LUGGAGE RACK CROSSBAR (Continued)

Page 3595 of 4284

RIGHT QUARTER TRIM PANEL

REMOVAL

CAUTION: Disconnect the battery negative cable.

Damage to accessory feed circuit can result.

(1) Remove first row seat.

(2) Remove second row seat, if equipped.

(3) Remove sliding door sill trim panel.

(4) Remove quarter trim bolster.

(5) Remove C-pillar trim panel.

(6) Remove D-pillar trim panel.

(7) Remove first row seat belt anchor.

(8) Remove second row seat belt anchor on long

wheel base vehicle.

(9) Remove screws attaching quarter trim to quar-

ter panel from bolster area.

(10) Remove screws attaching rear edge of quarter

trim to attaching bracket.

(11) Disengage hidden clips holding front of quar-

ter trim to quarter panel rearward of sliding door

opening.

(12) Remove quarter trim from quarter panel.

(13) Disconnect wire connector from accessory

power outlet, if equipped.

(14) Pass second row seat belt through slot in trim

panel on long wheel base vehicle.

(15) Pass first row seat belt through slot in trim

panel.

(16) Remove quarter trim panel from vehicle.

INSTALLATION

(1) Position quarter trim panel on vehicle.

(2) Pass first row seat belt through slot in trim

panel.

(3) Pass second row seat belt through access hole

in trim panel on long wheel base vehicle.

(4) Connect wire connector into accessory power

outlet, if equipped.

(5) Align locating pins on backside of trim panel to

mating holes in inner quarter panel.

(6) Engage hidden clips attaching front of quarter

trim to quarter panel rearward of sliding door open-

ing.

(7) Install screws attaching rear edge of quarter

trim to attaching bracket.

(8) Install screws attaching quarter trim to inner

quarter panel in bolster area.

(9) Install second row seat belt anchor on long

wheel base vehicle. Tighten all seat belt bolts to 39

N´m (29 ft. lbs.) torque.

(10) Install first row seat belt anchor.

(11) Install D-pillar trim panel.

(12) Install C-pillar trim panel.

(13) Install quarter trim bolster.(14) Install sliding door sill trim panel.

(15) Install second row seat, if equipped.

(16) Install first row seat.

(17) Connect the battery negative cable.

LEFT QUARTER TRIM PANEL

REMOVAL

CAUTION: Disconnect the negative cable clamp

from battery post. Damage to accessory feed circuit

can result.

(1) Remove first row seat.

(2) Remove second row seat, if equipped.

(3)

Remove front door sill plate on three door vehicle.

(4) Remove sliding door sill plate on four door

vehicle.

(5) Remove left quarter trim bolster.

(6) Remove upper left B-pillar trim on three door

vehicle.

(7) Remove C-pillar trim panel.

(8) Remove left D-pillar trim panel.

(9) Remove first row seat belt anchor.

(10) Remove second row seat belt anchor on long

wheel base vehicle.

(11) Remove left front seat belt opening bezel from

quarter trim on three door vehicle.

(12) Remove screws attaching quarter trim to

quarter panel in B-pillar area on three door vehicle.

(13) Remove screws attaching quarter trim to

quarter panel from bolster area.

(14)

Remove screws attaching rear edge of quarter

trim to attaching bracket or inner quarter trim panel.

(15) Remove screws attaching top of trim panel to

inner sheet metal between B-pillar and C-pillar on

three door vehicle.

(16) Disconnect wire connector from accessory

power outlet, if equipped.

(17) Remove quarter trim from quarter panel.

(18) Pass front seat belt and turning loop through

slot in quarter trim panel on three door vehicle.

(19) Pass first row seat belt through slot in quar-

ter trim panel.

(20) Pass second row seat belt, if equipped,

through slot in quarter trim panel on long wheel

base vehicle.

(21) Remove quarter trim panel from vehicle.

INSTALLATION

(1) Position quarter trim panel on vehicle.

(2) Pass second row seat belt, if equipped, through

slot in quarter trim panel on long wheel base vehicle.

(3) Pass first row seat belt through slot in quarter

trim panel.

RSINTERIOR23 - 215

Page 3596 of 4284

(4) Pass front seat belt through slot in quarter

trim panel on three door vehicle.

(5) Connect wire connector into accessory power

outlet, if equipped.

(6) Align locating pins on backside of trim panel to

mating holes in inner panels.

(7) Position quarter trim panel on inner quarter

panel.

(8) Install screws attaching top of trim panel to

inner sheet metal between B-pillar and C-pillar on

three door vehicle.

(9) Install screws attaching rear edge of quarter

trim to attaching bracket or inner quarter panel.

(10) Install screws attaching quarter trim to inner

quarter panel in bolster area.

(11) Install screws attaching quarter trim to inner

quarter panel in B-pillar area on three door vehicle.

(12) Install left front seat belt opening bezel into

quarter trim on three door vehicle.

(13) Install second row seat belts anchor on long

wheel base vehicle. Tighten all seat belt bolts to 39

N´m (28 in. lbs.) torque.

(14) Install first row seat belt anchor.

(15) Install left D-pillar trim panel.

(16) Install C-pillar trim panel.

(17) Install upper left B-pillar trim on three door

vehicle.

(18) Install left quarter trim bolster.

(19)

Install front door sill plate on three door vehicle.

(20) Install sliding door sill plate on four door

vehicle.

(21) Install second row seat, if equipped.

(22) Install first row seat.

(23) Connect the battery negative cable.

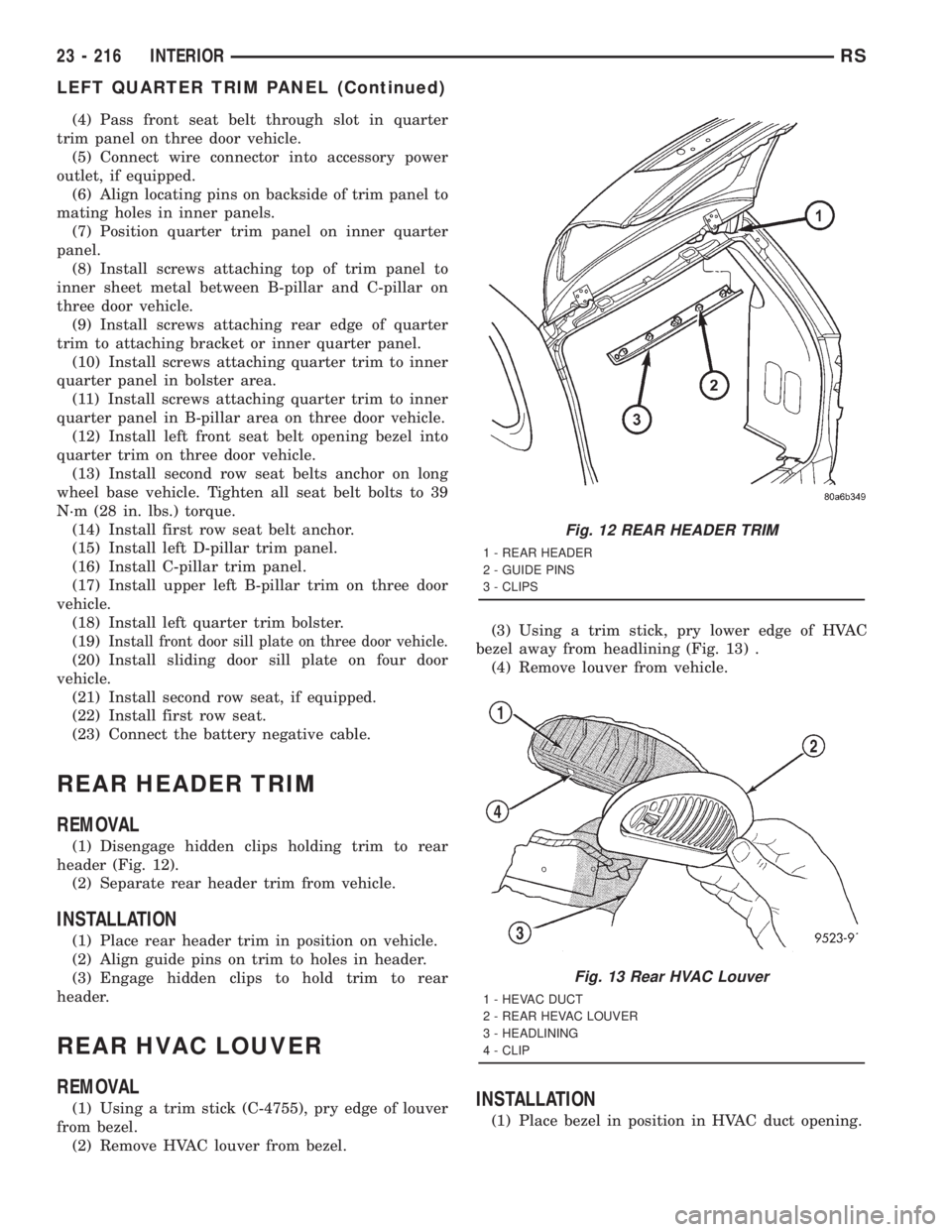

REAR HEADER TRIM

REMOVAL

(1) Disengage hidden clips holding trim to rear

header (Fig. 12).

(2) Separate rear header trim from vehicle.

INSTALLATION

(1) Place rear header trim in position on vehicle.

(2) Align guide pins on trim to holes in header.

(3) Engage hidden clips to hold trim to rear

header.

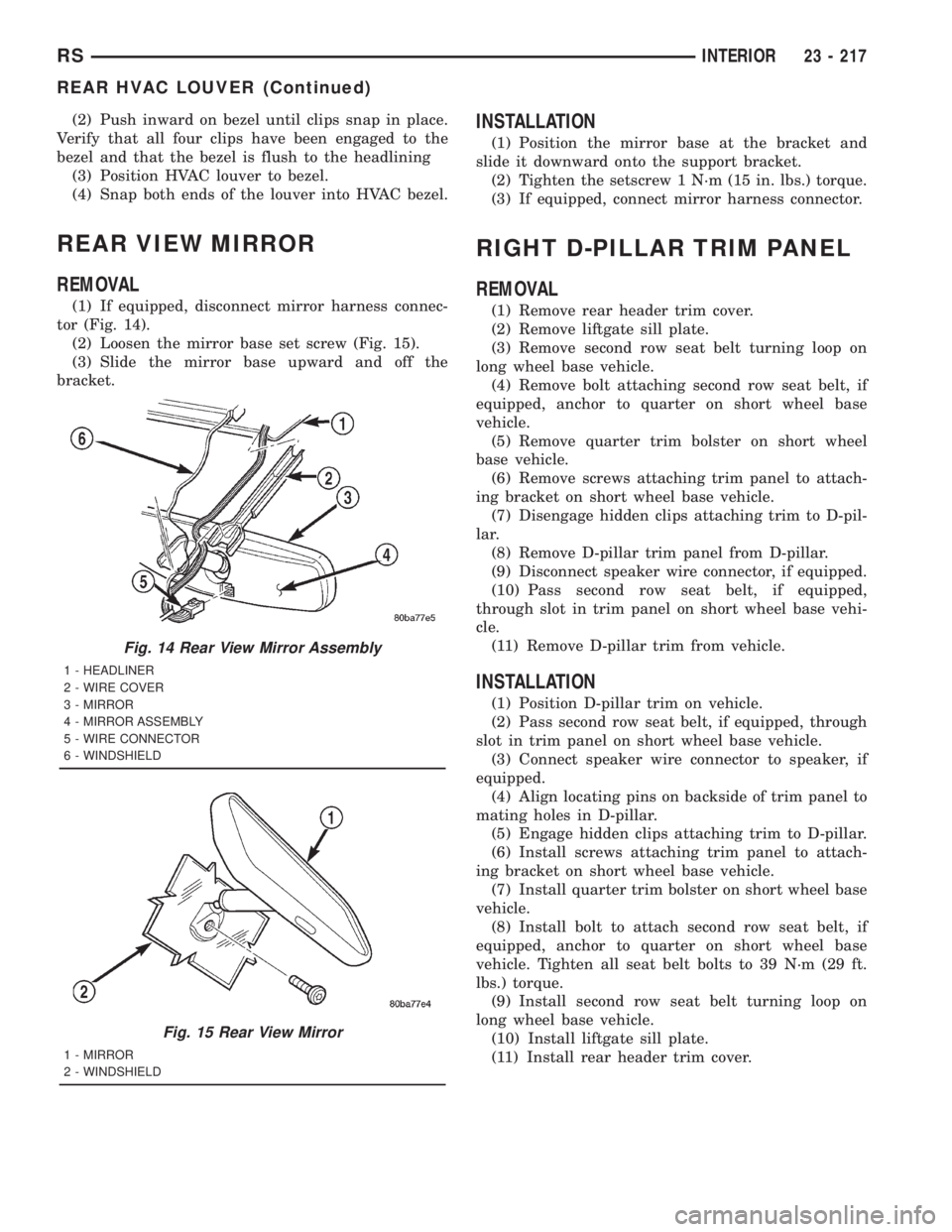

REAR HVAC LOUVER

REMOVAL

(1) Using a trim stick (C-4755), pry edge of louver

from bezel.

(2) Remove HVAC louver from bezel.(3) Using a trim stick, pry lower edge of HVAC

bezel away from headlining (Fig. 13) .

(4) Remove louver from vehicle.INSTALLATION

(1) Place bezel in position in HVAC duct opening.

Fig. 12 REAR HEADER TRIM

1 - REAR HEADER

2 - GUIDE PINS

3 - CLIPS

Fig. 13 Rear HVAC Louver

1 - HEVAC DUCT

2 - REAR HEVAC LOUVER

3 - HEADLINING

4 - CLIP

23 - 216 INTERIORRS

LEFT QUARTER TRIM PANEL (Continued)

Page 3597 of 4284

(2) Push inward on bezel until clips snap in place.

Verify that all four clips have been engaged to the

bezel and that the bezel is flush to the headlining

(3) Position HVAC louver to bezel.

(4) Snap both ends of the louver into HVAC bezel.

REAR VIEW MIRROR

REMOVAL

(1) If equipped, disconnect mirror harness connec-

tor (Fig. 14).

(2) Loosen the mirror base set screw (Fig. 15).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket.

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness connector.

RIGHT D-PILLAR TRIM PANEL

REMOVAL

(1) Remove rear header trim cover.

(2) Remove liftgate sill plate.

(3) Remove second row seat belt turning loop on

long wheel base vehicle.

(4) Remove bolt attaching second row seat belt, if

equipped, anchor to quarter on short wheel base

vehicle.

(5) Remove quarter trim bolster on short wheel

base vehicle.

(6) Remove screws attaching trim panel to attach-

ing bracket on short wheel base vehicle.

(7) Disengage hidden clips attaching trim to D-pil-

lar.

(8) Remove D-pillar trim panel from D-pillar.

(9) Disconnect speaker wire connector, if equipped.

(10) Pass second row seat belt, if equipped,

through slot in trim panel on short wheel base vehi-

cle.

(11) Remove D-pillar trim from vehicle.

INSTALLATION

(1) Position D-pillar trim on vehicle.

(2) Pass second row seat belt, if equipped, through

slot in trim panel on short wheel base vehicle.

(3) Connect speaker wire connector to speaker, if

equipped.

(4) Align locating pins on backside of trim panel to

mating holes in D-pillar.

(5) Engage hidden clips attaching trim to D-pillar.

(6) Install screws attaching trim panel to attach-

ing bracket on short wheel base vehicle.

(7) Install quarter trim bolster on short wheel base

vehicle.

(8) Install bolt to attach second row seat belt, if

equipped, anchor to quarter on short wheel base

vehicle. Tighten all seat belt bolts to 39 N´m (29 ft.

lbs.) torque.

(9) Install second row seat belt turning loop on

long wheel base vehicle.

(10) Install liftgate sill plate.

(11) Install rear header trim cover.

Fig. 14 Rear View Mirror Assembly

1 - HEADLINER

2 - WIRE COVER

3 - MIRROR

4 - MIRROR ASSEMBLY

5 - WIRE CONNECTOR

6 - WINDSHIELD

Fig. 15 Rear View Mirror

1 - MIRROR

2 - WINDSHIELD

RSINTERIOR23 - 217

REAR HVAC LOUVER (Continued)

Page 3767 of 4284

PCV VALVE

DESCRIPTION

The PCV valve contains a spring loaded plunger.

The plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

OPERATION

When the engine is not operating or during an

engine backfire, the spring forces the plunger back

against the seat. This prevents vapors from flowing

through the valve (Fig. 8).

When the engine is at idle or cruising, high mani-

fold vacuum is present. At these times manifold vac-

uum is able to completely compress the spring and

pull the plunger to the top of the valve (Fig. 9). In

this position there is minimal vapor flow through the

valve.During periods of moderate intake manifold vac-

uum the plunger is only pulled part way back from

the inlet. This results in maximum vapor flow

through the valve (Fig. 10).

DIAGNOSIS AND TESTING - PCV SYSTEM

INSPECTION

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING ANY TEST

OR ADJUSTMENT WITH THE ENGINE OPERATING.

(1) With engine idling, remove the hose from the

PCV valve. If the valve is not plugged, a hissing

noise will be heard as air passes through the valve. A

strong vacuum should also be felt when a finger is

placed over the valve inlet.

(2) Install hose on PCV valve. Remove the

make-up air hose from the air plenum at the rear of

the engine. Hold a piece of stiff paper (parts tag)

loosely over the end of the make-up air hose.

(3)

After allowing approximately one minute for

crankcase pressure to reduce, the paper should draw up

against the hose with noticeable force. If the engine

does not draw the paper against the grommet after

installing a new valve, replace the PCV valve hose.

(4)Turn the engine off. Remove the PCV valve from

intake manifold. The valve should rattle when shaken.

(5) Replace the PCV valve and retest the system if

it does not operate as described in the preceding

tests.Do not attempt to clean the old PCV valve.

If the valve rattles, apply a light coating of Loctitet

Pipe Sealant With Teflon to the threads. Thread the

PCV valve into the manifold plenum and tighten to 7

N´m (60 in. lbs.) torque.

Fig. 7 PCV VALVE 2.4L

1 - PCV Valve

Fig. 8 Engine Off or Engine Backfire No Vapor Flow

Fig. 9 High Intake Manifold Vacuum Minimal Vapor

Flow

Fig. 10 Moderate Intake Manifold Vacuum Maximum

Vapor Flow

RSEVAPORATIVE EMISSIONS25-17

Page 3959 of 4284

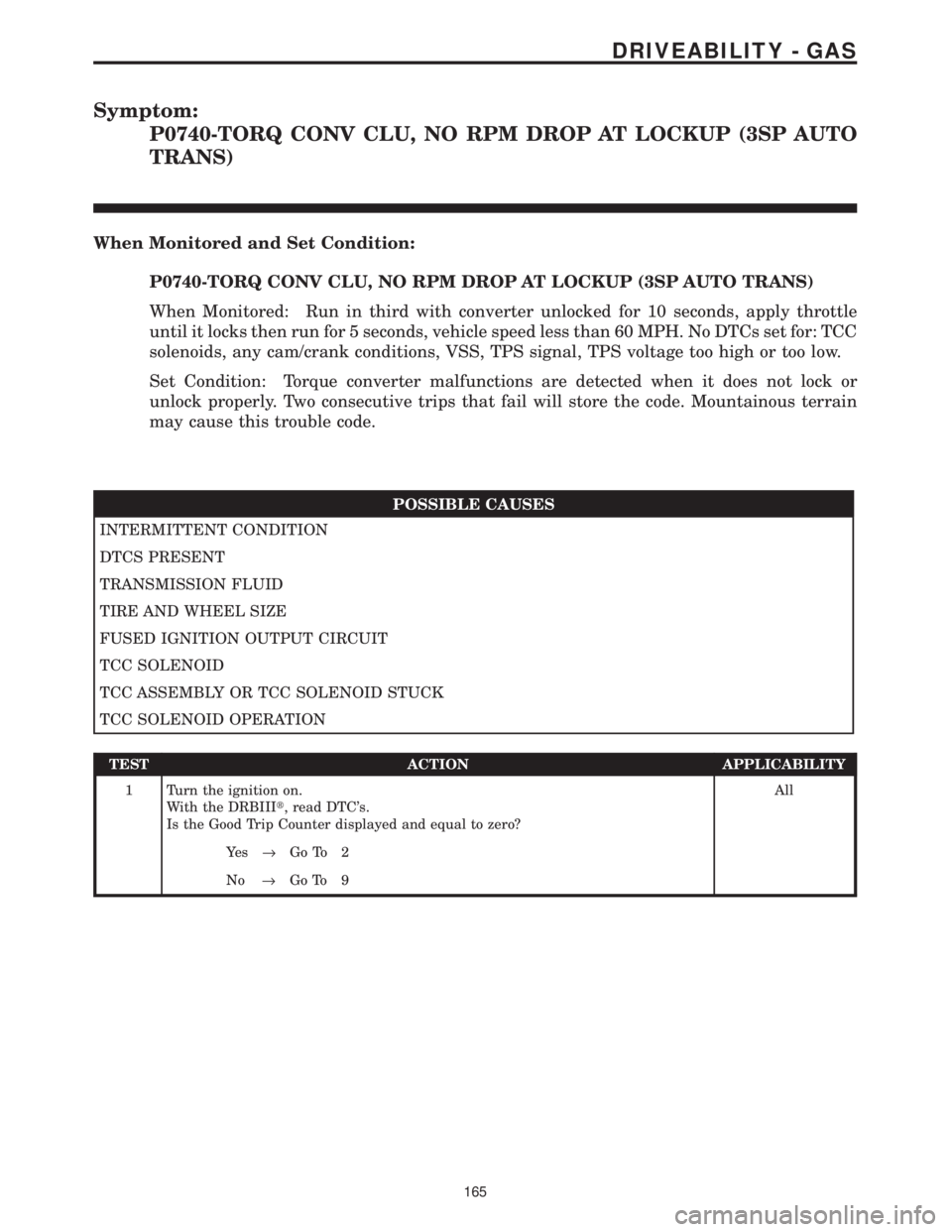

Symptom:

P0740-TORQ CONV CLU, NO RPM DROP AT LOCKUP (3SP AUTO

TRANS)

When Monitored and Set Condition:

P0740-TORQ CONV CLU, NO RPM DROP AT LOCKUP (3SP AUTO TRANS)

When Monitored: Run in third with converter unlocked for 10 seconds, apply throttle

until it locks then run for 5 seconds, vehicle speed less than 60 MPH. No DTCs set for: TCC

solenoids, any cam/crank conditions, VSS, TPS signal, TPS voltage too high or too low.

Set Condition: Torque converter malfunctions are detected when it does not lock or

unlock properly. Two consecutive trips that fail will store the code. Mountainous terrain

may cause this trouble code.

POSSIBLE CAUSES

INTERMITTENT CONDITION

DTCS PRESENT

TRANSMISSION FLUID

TIRE AND WHEEL SIZE

FUSED IGNITION OUTPUT CIRCUIT

TCC SOLENOID

TCC ASSEMBLY OR TCC SOLENOID STUCK

TCC SOLENOID OPERATION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip Counter displayed and equal to zero?All

Ye s®Go To 2

No®Go To 9

165

DRIVEABILITY - GAS

Page 3960 of 4284

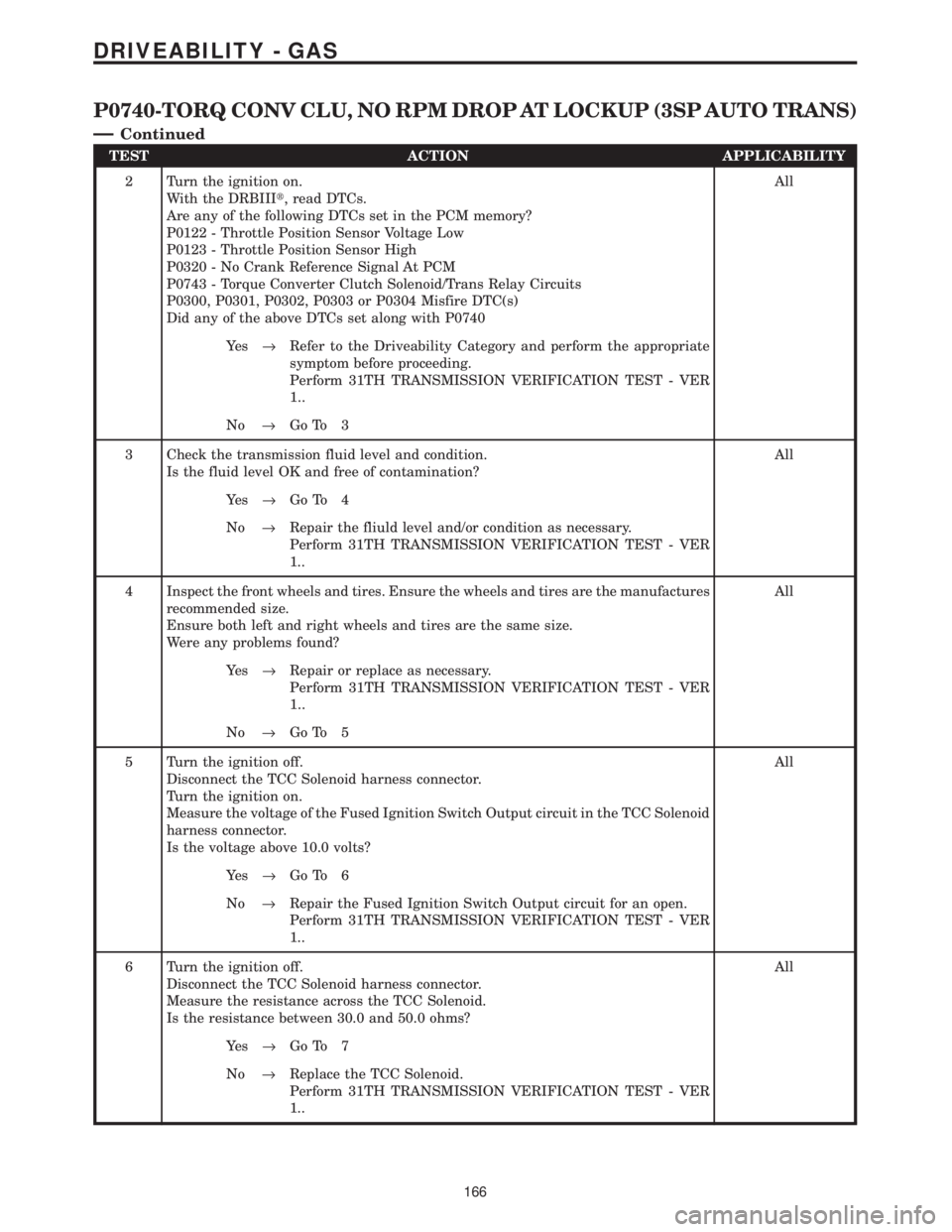

TEST ACTION APPLICABILITY

2 Turn the ignition on.

With the DRBIIIt, read DTCs.

Are any of the following DTCs set in the PCM memory?

P0122 - Throttle Position Sensor Voltage Low

P0123 - Throttle Position Sensor High

P0320 - No Crank Reference Signal At PCM

P0743 - Torque Converter Clutch Solenoid/Trans Relay Circuits

P0300, P0301, P0302, P0303 or P0304 Misfire DTC(s)

Did any of the above DTCs set along with P0740All

Ye s®Refer to the Driveability Category and perform the appropriate

symptom before proceeding.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

No®Go To 3

3 Check the transmission fluid level and condition.

Is the fluid level OK and free of contamination?All

Ye s®Go To 4

No®Repair the fliuld level and/or condition as necessary.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

4 Inspect the front wheels and tires. Ensure the wheels and tires are the manufactures

recommended size.

Ensure both left and right wheels and tires are the same size.

Were any problems found?All

Ye s®Repair or replace as necessary.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

No®Go To 5

5 Turn the ignition off.

Disconnect the TCC Solenoid harness connector.

Turn the ignition on.

Measure the voltage of the Fused Ignition Switch Output circuit in the TCC Solenoid

harness connector.

Is the voltage above 10.0 volts?All

Ye s®Go To 6

No®Repair the Fused Ignition Switch Output circuit for an open.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

6 Turn the ignition off.

Disconnect the TCC Solenoid harness connector.

Measure the resistance across the TCC Solenoid.

Is the resistance between 30.0 and 50.0 ohms?All

Ye s®Go To 7

No®Replace the TCC Solenoid.

Perform 31TH TRANSMISSION VERIFICATION TEST - VER

1..

166

DRIVEABILITY - GAS

P0740-TORQ CONV CLU, NO RPM DROP AT LOCKUP (3SP AUTO TRANS)

Ð

Continued

Page 4119 of 4284

then notice harsh bumps when the A/C clutch is

being cycled, but vehicle shudder will be elimi-

nated. After 35 OBDII (EURO STAGE III OBD)

warm-up starts or if the code is cleared, PEMCC

will be reactivated to see if shudder is still present.

If one shudder event occurs, the code will be reset.

Clearing the code and running battery disconnect

with the DRBIIItis the only way to reset the

shudder counter from 20 back to zero.

Transmission Effects:This code does not cause

the transmission to go into limp-in mode. However,

once the code is set, FEMCC to PEMCC operation

before the A/C clutch engagement will be disabled

for 35 OBDII (EURO STAGE III OBD) warm up

starts.

Possible causes:

> Degraded transmission fluid

> Wheels severely out of alignment

> Internal torque converter problem

Name of Code:P1799(74) - Calculated Oil Temper-

ature in Use

When Monitored:When ever the Engine is run-

ning.

Set condition:The code is set if any of the follow-

ing conditions exist for three consecutive key starts:

> The Temperature Sensor voltage is out of range

(below 0.07 volts or greater than 4.94 volts)

> If continuous erratic Temperature Sensor voltage

is sensed.

> The Temperature Sensor temperature stays be-

low 27C (80ÉF) for an extended period of time.

Theory of Operation:The TCM uses a Tempera-

ture Sensor to monitor the transmission sump tem-

perature. This temperature is used to determine

which shift schedule the TCM is to use. (See Trans-

mission Operation and Shift Scheduling at Various

Sump Temperatures in this diagnostic manual) If

the Temperature Sensor circuit fails to operate

properly the TCM will use the calculated oil tem-

perature routine found in prior model year TCM. If

this occurs for three consecutive key starts, the code

will be set. The TCM will then test the Temperature

Sensor circuit after every 35 OBDII (EURO STAGE

III OBD) warm-up starts. If the Temperature Sen-

sor circuit is OK, the Temperature Sensor data is

used in place of the Calculated Oil Temperature

data.

Transmission Effects:If the Temperature Sensor

indicates a temperature below -18C (0É F) or above

115C (240É F) at start up, The TCM compares the

calculated oil temperature to the indicated Temper-

ature Sensor oil temperature. If the calculated oil

temperature differs significantly from the Temper-

ature Sensor value, the calculated oil temperature

will be used for that key start.Possible Causes:

> Wiring or Connector problems in the transmis-

sion temperature sensor signal circuit.

> TRS

> TCM

Name of Code:P1738(75) - High Temperature

Operation Activated.

When Monitored:Whenever the engine is running.

Set Condition:Immediately once the Overheat

Shift Schedule is activated.

Theory of Operation:If the transmission oil tem-

perature rises above 115C (240ÉF), the overheat

shift schedule is activated refer to Transmission

Operation as a function of Transmission Oil Tem-

perature and the code is set. The DTC is an infor-

mation code only and is being set to aid the techni-

cian in determining root cause of a customer

driveability issue. The code is also intended to alert

the technician to determine if a cooling system

malfunction has occurred or if an additional trans-

mission air to oil cooler should be added to the

vehicle if the customer regularly drives in a manner

that overheats the transmission. Extended opera-

tion above 115C (240ÉF) will reduce the durability of

the transmission and should be avoided. Correcting

the cooling system malfunction or installing an

additional transmission oil cooler will improve

transmission durability especially for customers

who operate in city/construction stop and go traffic,

tow trailers regularly, drive aggressively in low gear

or drive regularly in mountainous areas.

Transmission Effects:Information only code. -

Overheat shift schedule was activated, no limp-in

condition occurs. 2nd gear partial EMCC above 40

Km/h (25 MPH), 3rd gear EMCC from 45-69 Km/h

(28-43 MPH), delayed 3-4 upshift at 69 Km/h (43

MPH), early 4-3 coastdown at 66 Km/h (41 MPH),

EMCC operation under all conditions above 40

Km/h (25 MPH) except at closed throttle or 1st gear.

Possible Causes:

± Transmission Overfilled with Oil

± Engine cooling fan failure

± Engine thermostat stuck closed

± Radiator corroded or packed with dirt

± Transmission Oil Cooler Plugged

± Customer driving pattern requires additional

transmission cooling

Name Of Code:P1739(76) - Power-Up at Speed

When Monitored:When TCM (transmission con-

trol module) initially powers-up.

Set Condition:If the TCM powers up while in the

9Drive9position and the vehicle is going above 32

Km/h (20 MPH), the code is set.

Theory of Operation:If a vehicle loses power to

the TCM, the vehicle will go to the 2nd gear mode

15

GENERAL INFORMATION