wheel torque CHRYSLER VOYAGER 2001 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2671 of 4284

²Step 3: Final torque collar to transaxle bolts to

101 N´m (75 ft. lbs.)

²Step 4: Final torque collar to oil pan bolts to 54

N´m (40 ft. lbs.).

(2) Install engine front mount bracket and insula-

tor. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - INSTALLATION)

(3) Lower vehicle.

ENGINE MOUNTING

DESCRIPTION

The engine mounting system consist of four

mounts; right and a left side support the powertrain,

and a front and a rear mount control powertrain

torque. The right side mount is a hydro-type (Fig.

79), all others are of molded rubber material.

FRONT MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the front engine mount through bolt

from the insulator (Fig. 80).

(3) Remove the engine front mount bolts and

remove the insulator assembly (Fig. 80).(4) Remove the front mounting bracket from

engine, if necessary (Fig. 80).

INSTALLATION

(1) Install the front mount bracket to engine, if

removed (Fig. 80).

(2) Install the insulator mount assembly (Fig. 80).

(3) Install the front engine mount through bolt to

the insulator (Fig. 80).

(4) Lower the vehicle.

LEFT MOUNT

REMOVAL

(1) Raise the vehicle on hoist.

(2) Remove the left front wheel.

(3) Remove the left mount through bolt access

cover.

(4) Support the transaxle with a suitable jack.

(5) Remove the engine front mount through bolt to

allow left mount removal clearance (Fig. 90).

(6) Remove the left mount through frame rail bolt

(Fig. 81).

(7) Lower transaxle for access to horizontal bolts.

Fig. 79 Engine Hydro-type Mount - Right Side

1 - BOLT

2 - BOLT

3 - FRAME RAIL

4 - RIGHT MOUNT - 2.4L ENGINE

5 - RIGHT MOUNT - 3.3/3.8L ENGINE

Fig. 80 Front Mount and Bracket

1 - BRACKET - FRONT MOUNT

2 - NUT - 68 N´m (50 ft. lbs.)

3 - BOLT - 54 N´m (40 ft. lbs.)

4 - MOUNT - FRONT INSULATOR

5 - BOLT - 68 N´m (50 ft. lbs.)

6 - BOLT - 68 N´m (50 ft. lbs.)

7 - FRONT CROSSMEMBER

RSENGINE 2.4L9-47

STRUCTURAL COLLAR (Continued)

Page 2700 of 4284

DIAGNOSIS AND TESTING - ENGINE MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in crankcase. 1. Check and correct engine oil level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating temperature.

(c) Change engine oil and filter again.

4. Low oil pressure. 4. Check and correct engine oil level.

5. Dirt in tappets/lash adjusters. 5. Replace rocker arm/hydraulic lash

adjuster assembly.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn tappets/lash adjusters. 7. Install new rocker arm/hydraulic lash

adjuster assembly.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats on valve

faces.9. Grind valve seats and valves.

10. Missing adjuster pivot. 10. Replace rocker arm/hydraulic lash

adjuster assembly.

CONNECTING

ROD NOISE1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil pump

relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating temperature.

(c) Change engine oil and filter again.

5. Excessive bearing clearance. 5. Measure bearings for correct clearance.

Repair as necessary.

6. Connecting rod journal out-of-round. 6. Replace crankshaft or grind surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

MAIN BEARING

NOISE1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil pump

relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating temperature.

(c) Change engine oil and filter again.

5. Excessive bearing clearance. 5. Measure bearings for correct clearance.

Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on flanges.

7. Crankshaft journal out-of-round or worn. 7. Replace crankshaft or grind journals.

8. Loose flywheel or torque converter. 8. Tighten to correct torque.

9 - 76 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 2789 of 4284

(7) Attach front engine mount bracket to lower

radiator support. Torque to 54N´m (40 ft. lbs.)

(8) Connect cabin heater coolant hose.

(9) Connect exhaust pipe to the turbocharger

downpipe flange. Torque to 28 N´m (250 in. lbs.)

(10) Connect reverse lamp electrical connector at

transmission.

(11) Connect both shifter cables (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/GEAR

SHIFT CABLE - INSTALLATION).

(12) Connect the clutch slave cylinder quick dis-

connect connector (RHD only)(Refer to 6 - CLUTCH/

SLAVE CYLINDER - INSTALLATION).

(13) Install engine harness into bracket on trans-

mission.

(14) Lower vehicle.

(15) Connect fuel supply and return lines.

(16) Connect A/C lines to A/C compressor. Torque

to 23N´m (17 ft. lbs.)

(17) Route engine wiring harnes to proper location.

(18) Connect engine harness ground cables to

engine block

(19) Connect starter solenoid electrical connector

and battery feed wire to starter. Torque to 10N´m (90

in. lbs.)

(20) Connect A/C compressor, injection pump, glow

plugs, and coolant temperature sensor electrical con-

nectors.

(21) Connect generator electrical connector. Torque

to 9N´m (75 in. lbs.)

(22) Connect the fuel injector, fuel pressure sensor,

boost pressure/intake air temp sensor, cam sensor,

and egr solenoid electrical connectors (Fig. 9).

(23) Connect egr solenoid vacuum supply line to

brake boost vacuum supply line.

(24) Connect brake booster vacuum supply line.

(25) Connect heater core return hose to coolant

pipe.

(26) Connect lower radiator hose to engine (Fig. 8).

(27) Install charger air cooler inlet hose (Fig. 7).

(28) Install charge air cooler outlet hose (Fig. 7).

(29) Connect upper radiator hose to engine (Fig.

8).

(30) Install battery shield.

(31) Install coolant reserve pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(32) Install power steering reservoir and bracket

(Fig. 5).

(33) Raise vehicle

(34) Connect oil pressure sensor, oil temperature

sensor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 10).(35) Install suspension cradle in vehicle (Refer to

13 - FRAME & BUMPERS/FRAME/ENGINE CRA-

DLE CROSSMEMBER - INSTALLATION).

(36) Install both axle shaft assemblies (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(37) Connect the power steering supply, pressure,

and return lines to power steering pump (Fig. 5).

(38) Install the power steering line brackets on oil

pan (Fig. 5).

(39) Install lower splash shield and side panels.

(40) Install both front wheel and tire assemblies.

(41) Lower vehicle.

(42) Install air cleaner housing, MAF sensor, and

air intake tube assembly (Fig. 4).

(43) Refill transmission to proper level (Refer to 21

- TRANSMISSION/TRANSAXLE/MANUAL/FLUID -

STANDARD PROCEDURE).

(44) Refill engine coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(45) Recharge A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT - STANDARD PROCEDURE) .

(46) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION) (Fig. 3).

(47) Connect negative battery cable.

INSTALLATION - ENGINE COVER

(1) Install engine cover on engine.

(2) Install the engine cover mounting bolts (Fig.

11).

SPECIFICATIONS

SPECIFICATIONS - 2.5L COMMON RAIL

DIESEL ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type R2516C

Number of Cylinders 4

Bore 92 mm

Stroke 94 mm

Displacement 2499.5cc

Injection Order 1-3-4-2

Compression Ratio 17.5:1 ( 0.5)

Maximum Power 103kW (140 HP) @ 4000

RPM

Peak Torque 340Nm (34.6 kgm) @

1800 RPM

RGENGINE 2.5L TURBO DIESEL9a-7

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2792 of 4284

SPECIFICATIONS - TORQUE

2.5L DIESEL TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Oil Pump Bolts 10.8 8 96

Vacuum Pump Bolts 10.8 8 96

Crankshaft Gear Bolts 10.8 8 96

Crankshaft Position

Sensor Bolts10.8 8 96

Flywheel Bolts - Refer to the Service Procedure

Cylinder Head Bolts - Refer to the Service Procedure

Reluctor Wheel Bolts 14.6 11 130

Rear Main Bearing

Support Bolts27.5 21 240

Oil Cooler to Engine Block

Bolt47.1 35 Ð

Oil Cooler Mounting Stud 50 37 Ð

Water Pump Housing Nuts 24.4 18 212

Connecting Rod Bolts - Refer to the Service Procedure

Balance Shaft Bolts 32.4 24 Ð

Oil Jet Bolts 10.8 8 96

Oil Pan Bolts 11.8 8 96

Crankshaft Hub Bolt 304 225 Ð

Front Engine Cover Bolts 11.8 8 96

Transmission to Engine

Bolts83.4 62 Ð

Cylinder Head Cover /

Intake Manifold Bolts27.5 20 Ð

Camshaft Access Plugs 80 59 Ð

Oil Separator Bolts 10.8 8 96

Camshaft Position Sensor

Bolt10.8 8 96

Boost Pressure / Intake

Air Temp. Sensor Bolts5.4 Ð 48

Accessory Drive Bracket

Bolts47.1 35 Ð

Vacuum Line Fitting Bolt 56.9 42 Ð

Fuel Pump Nuts 27.5 21 Ð

Fuel Line Fittings at Pump 27.5 21 Ð

Inner Timing Belt Cover Bolts

8mm 10.8 8 96

10mm 47.1 35 Ð

Outer Timing Belt Cover Bolts

3mm 6 Ð 54

8mm 10.8 8 96

9a - 10 ENGINE 2.5L TURBO DIESELRG

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2816 of 4284

(5) Install front engine cover (Refer to 9 -

ENGINE/ENGINE BLOCK/ENGINE COVER -

INSTALLATION).

(6) Install rear main bearing support in engine

block.Be sure to align oil hole in rear main

bearing support with hole in block.

(7) Install adapter plate and retaining bolts (Fig.

37). Torque bolts to 27.5N´m.

(8) Install flywheel.

(9) Install piston and connecting rod assemblies

(Refer to 9 - ENGINE/ENGINE BLOCK/PISTON &

CONNECTING ROD - INSTALLATION).

(10) Install oil jets (Refer to 9 - ENGINE/LUBRI-

CATION/OIL JET - INSTALLATION).

(11) Install balance shaft assembly (Refer to 9 -

ENGINE/VALVE TIMING/BALANCE SHAFT -

INSTALLATION).

(12) Install oil pump pickup tube (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP - INSTALLA-

TION).

(13) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(14) Install cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(15) Install cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - INSTALLATION).

(16) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(17) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .(18) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(19) Install engine in vehicle.

(20) Fill engine oil with proper oil to correct level.

CYLINDER LINERS

DESCRIPTION

The cylinder wall liner used on this engine is of

the wet design. O-rings are used to seal the liner to

the engine block.

REMOVAL

(1) Remove engine from vehicle.

(2) With engine completely disassembled, use spe-

cial tool VM.1001 to remove liner assembly (Fig. 41).

(3) Tighten bolt on VM.1001 to remove liner from

block (Fig. 42).

(4) Remove shims from cylinder liner or cylinder

block recess. Keep shims with each cylinder liner.

INSPECTION

The cylinder walls should be checked for out-of-

round and taper with a dial bore gauge. The cylinder

bore out-of-round is 0.100 mm (.0039 in.) maximum

Fig. 40 CRANKSHAFT SUPPORT RETAINERS

1 - CRANKSHAFT SUPPORT RETAINERS

2 - ENGINE BLOCK

Fig. 41 CYLINDER LINER REMOVER

9a - 34 ENGINE 2.5L TURBO DIESELRG

CRANKSHAFT (Continued)

Page 2828 of 4284

INSTALLATION

CRANKSHAFT MAIN BEARINGS

(1) Install bearing halves in crankshaft supports.

(2) Lubricate crankshaft and main bearings with

clean engine oil.

(3) Install crankshaft supports on crankshaft (Fig.

65). Torque bolts to 44.1N´m.

FRONT CRANKSHAFT MAIN BEARING

(1) Using special tool VM.1073, push front crank-

shaft main bearing in engine block (Fig. 66).

(2) Be sure oil hole in bearing lines up with oil gal-

lery in engine block (Fig. 67).

(3) Reassemble engine and install in vehicle.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

This must be done with either the engine or trans-

mission removed from vehicle.

(1) Remove flywheel assembly.

(2) Pry out old crankshaft oil seal.

INSTALLATION

(1) Using special tool VM.1050, install rear crank-

shaft oil seal in rear main bearing support (Fig. 68).

(2) Install engine or tranmission in vehicle.

OIL PAN

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle on hoist.

(3) Drain engine oil from engine.

(4) Remove all oil pan retaining bolts and oil pan

(Fig. 69).

Fig. 64 FRONT MAIN BEARING REMOVAL

1 - VM.1073

2 - FRONT CRANKSHAFT MAIN BEARING

3 - ENGINE BLOCK

Fig. 65 CRANKSHAFT ASSEMBLY

1 - CRANKSHAFT SUPPORT HALVE

2 - MAIN BEARING HALVE

3 - CRANKSHAFT

4 - MAIN BEARING HALVE

5 - CRANKSHAFT SUPPORT HALVE

6 - MAIN BEARING SUPPORT BOLTS

7 - WASHERS

9a - 46 ENGINE 2.5L TURBO DIESELRG

CRANKSHAFT MAIN BEARINGS (Continued)

Page 2839 of 4284

INSTALLATION

(1) Before installation of the balance shaft assem-

bly, the # 1 cylinder must be brought to TDC. Using

special tool VM.1051, roll engine over by hand until

tool can be inserted into engine block locking fly-

wheel from turning (Fig. 88). Once the # 1 cylinder is

brought to TDC, the balance shaft assembly can be

installed.

(2) With balance shaft assembly on work bench.

Insert special tool VM.1056 into balance shaft assem-

bly (Fig. 89). This will ensure proper balance shaft

and crankshaft timing after assembly.

(3) Install balance shaft assembly and retaining

bolts (Fig. 87). Torque bolts to 32.4N´m.

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Refill engine oil to proper level.

(6) Connect negative battery cable.

TIMING BELT / CHAIN

COVER(S)

REMOVAL - TIMING BELT OUTER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover retaining bolts

and remove cover (Fig. 90).

REMOVAL - TIMING BELT INNER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 88 TDC AND 90 DEGREES AFTER TDC

ALIGNMENT PIN LOCATION

1 - ENGINE BLOCK

2 - VM.1051 TDC PIN OR VM.1068 90 DEGREES ATDC PIN

3 - FLYWHEEL

Fig. 89 BALANCE SHAFT ALIGNMENT PIN VM.1056

1 - VM.1056

2 - BALANCE SHAFT ASSEMBLY

RGENGINE 2.5L TURBO DIESEL9a-57

BALANCE SHAFT (Continued)

Page 2922 of 4284

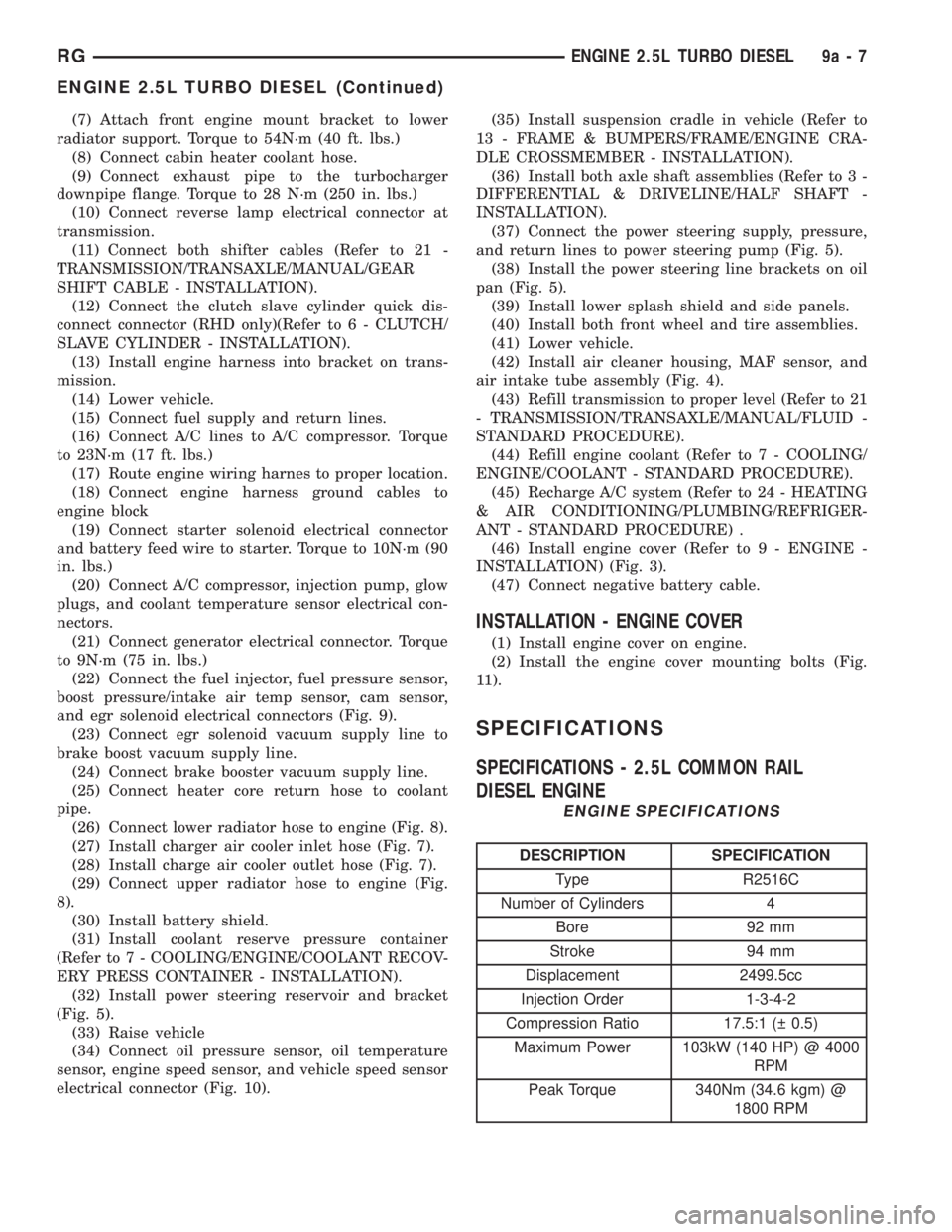

(3) Disconnect intake air temperature electrical

connector.

(4) Remove intake air temperature sensor retain-

ing screws and sensor (Fig. 6).

INSTALLATION

(1) Install intake air temperature sensor and

retaining bolts (Fig. 6). Torque to 5.4 N´m.

(2) Connect intake air temperature sensor.

(3) Install engine cover and retaining bolts (Refer

to 9 - ENGINE COVER - INSTALLATION).

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

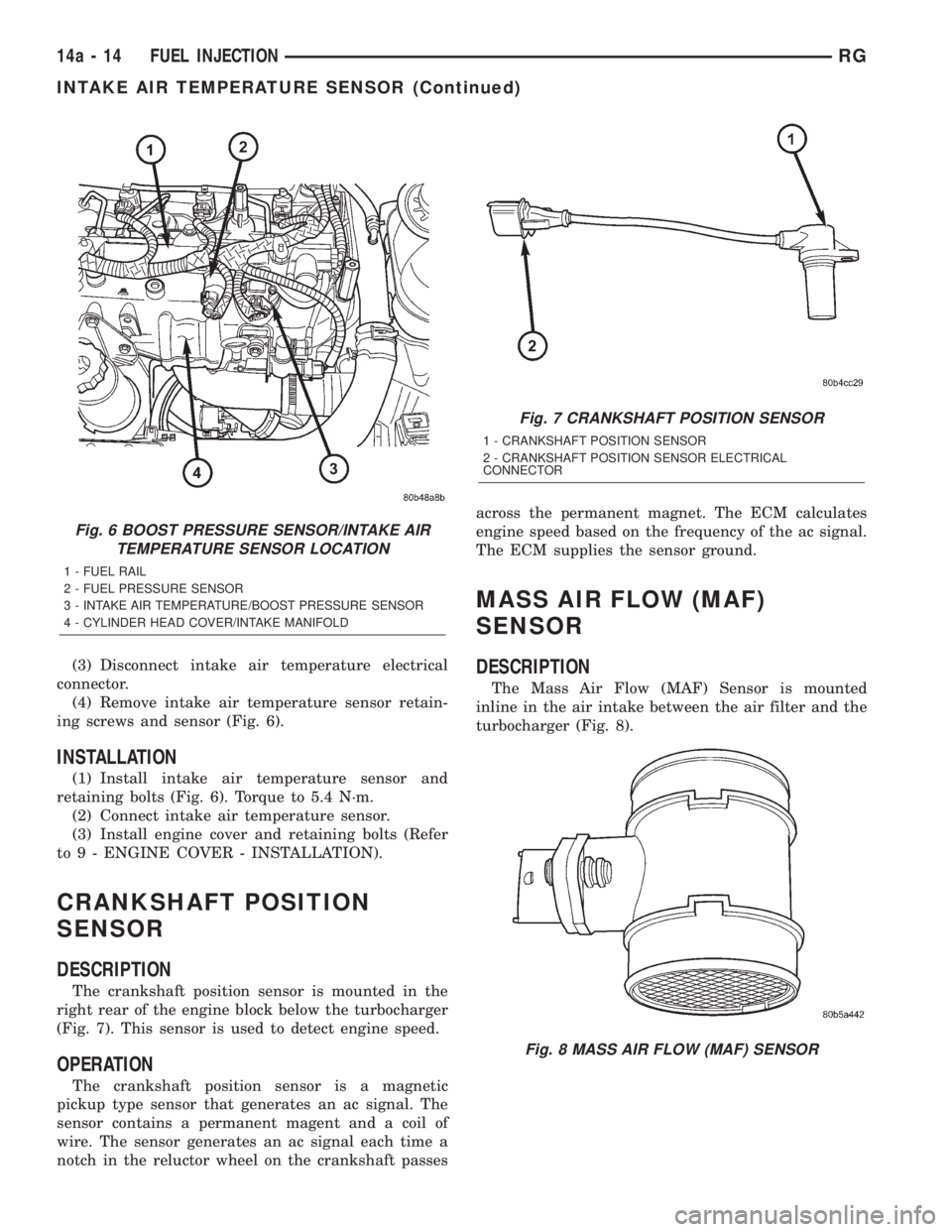

The crankshaft position sensor is mounted in the

right rear of the engine block below the turbocharger

(Fig. 7). This sensor is used to detect engine speed.

OPERATION

The crankshaft position sensor is a magnetic

pickup type sensor that generates an ac signal. The

sensor contains a permanent magent and a coil of

wire. The sensor generates an ac signal each time a

notch in the reluctor wheel on the crankshaft passesacross the permanent magnet. The ECM calculates

engine speed based on the frequency of the ac signal.

The ECM supplies the sensor ground.

MASS AIR FLOW (MAF)

SENSOR

DESCRIPTION

The Mass Air Flow (MAF) Sensor is mounted

inline in the air intake between the air filter and the

turbocharger (Fig. 8).

Fig. 6 BOOST PRESSURE SENSOR/INTAKE AIR

TEMPERATURE SENSOR LOCATION

1 - FUEL RAIL

2 - FUEL PRESSURE SENSOR

3 - INTAKE AIR TEMPERATURE/BOOST PRESSURE SENSOR

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD

Fig. 7 CRANKSHAFT POSITION SENSOR

1 - CRANKSHAFT POSITION SENSOR

2 - CRANKSHAFT POSITION SENSOR ELECTRICAL

CONNECTOR

Fig. 8 MASS AIR FLOW (MAF) SENSOR

14a - 14 FUEL INJECTIONRG

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 2927 of 4284

NOTE: Power steering pump maximum relief pres-

sure is 9,653 to 10,342 kPa (1,400 to 1,500 psi.).

(9) Close analyzer valve fully three times and

record highest pressure indicated each time. All three

readings must be above specifications and within 345

kPa (50 psi) of each other.

²If power steering pump pressures are above

specifications, but not within 345 kPa (50 psi) of each

other, replace pump.

²If power steering pump pressures are within 345

kPa (50 psi) of each other, but are below specifica-

tions, replace pump.

CAUTION: Do not force the pump to operate against

the stops for more than 2 to 4 seconds at a time

because, pump damage will result.

(10) Completely open the valve on the Power

Steering Analyzer. Turn the steering wheel to theextreme left until the stop in the steering gear is

met, then turn the steering wheel to the right until

the right stop is met. Record the highest indicated

pressure at each position. Compare the recorded

readings to the specifications. If the highest output

pressures are not the same against either stop, the

steering gear is leaking internally and must be

replaced.

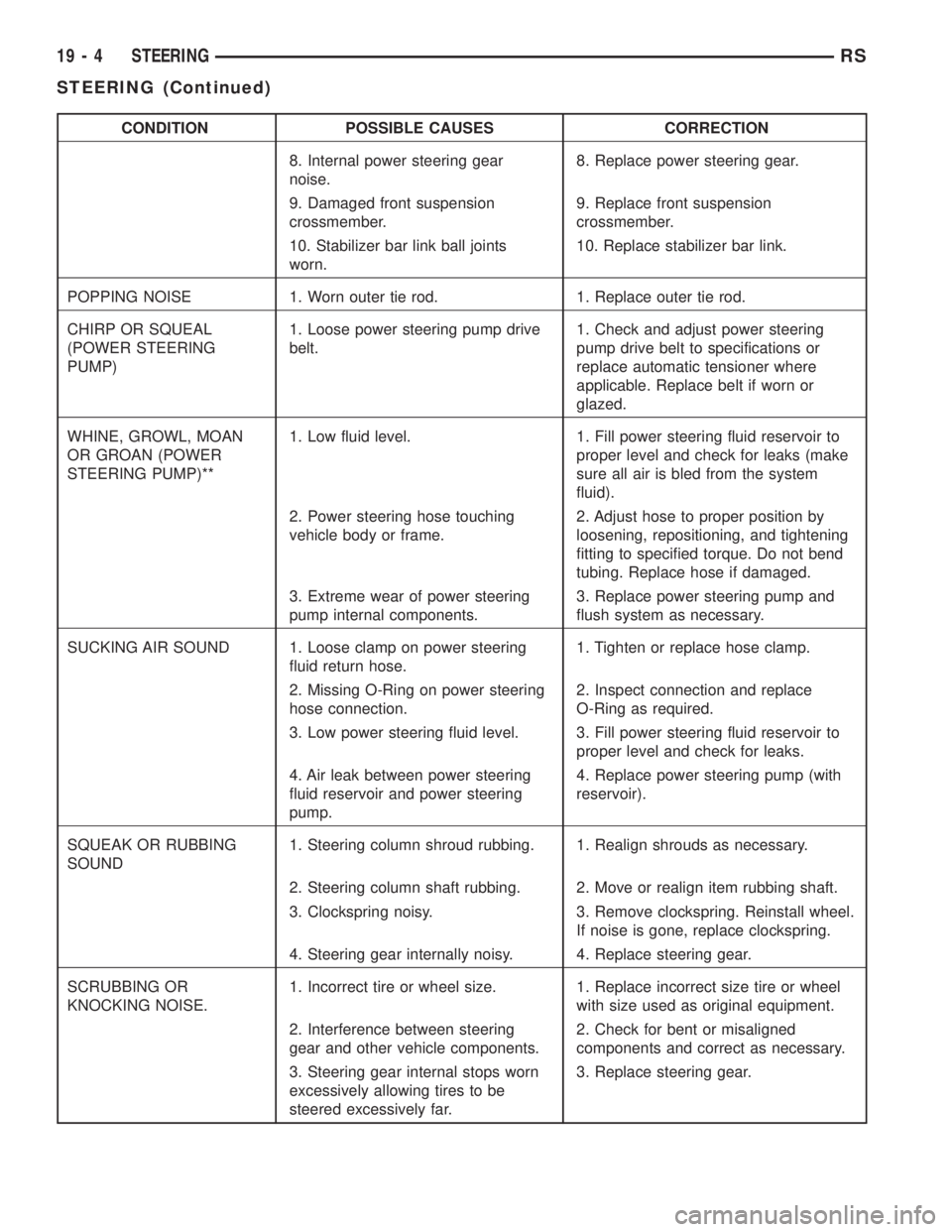

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS

NOTE: There are three diagnosis charts following

that cover POWER STEERING NOISE, STEERING

WHEEL FEEL, and POWER STEERING FLUID.

POWER STEERING NOISE

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONABLE HISS

OR WHISTLE*1. Damaged or mispositioned

steering column shaft/coupling dash

panel seal.1. Reposition or replace steering

column shaft/coupling dash panel seal.

2. Noisy valve in power steering

gear.2. Replace power steering gear.

3. Mis-routed power steering hose. 3. Check routing of power steering

hoses. Ensure hoses do not come in

unwanted contact with other

components and objects.

RATTLE OR CLUNK 1. Power steering gear loose on front

suspension crossmember.1. Inspect power steering gear

mounting bolts. Replace as necessary.

Tighten to the specified torque.

2. Front suspension crossmember

mounting fasteners loose at frame.2. Tighten the front suspension

crossmember mounting fasteners to the

specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for wear.

Replace worn/loose parts as required.

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting bolts to

the specified torques.

5. Lower control arm pivot bushing

worn.5. Replace lower control arm pivot

bushing.

6. Loose strut assembly mounting

fasteners at tower.6. Tighten strut assembly fasteners to

the specified torque.

7. Power steering fluid pressure

hose touching the body of the

vehicle.7. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing.

RSSTEERING19-3

STEERING (Continued)

Page 2928 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

8. Internal power steering gear

noise.8. Replace power steering gear.

9. Damaged front suspension

crossmember.9. Replace front suspension

crossmember.

10. Stabilizer bar link ball joints

worn.10. Replace stabilizer bar link.

POPPING NOISE 1. Worn outer tie rod. 1. Replace outer tie rod.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)**1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system

fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extreme wear of power steering

pump internal components.3. Replace power steering pump and

flush system as necessary.

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Air leak between power steering

fluid reservoir and power steering

pump.4. Replace power steering pump (with

reservoir).

SQUEAK OR RUBBING

SOUND1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing shaft.

3. Clockspring noisy. 3. Remove clockspring. Reinstall wheel.

If noise is gone, replace clockspring.

4. Steering gear internally noisy. 4. Replace steering gear.

SCRUBBING OR

KNOCKING NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or wheel

with size used as original equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as necessary.

3. Steering gear internal stops worn

excessively allowing tires to be

steered excessively far.3. Replace steering gear.

19 - 4 STEERINGRS

STEERING (Continued)