engine coolant CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2803 of 4284

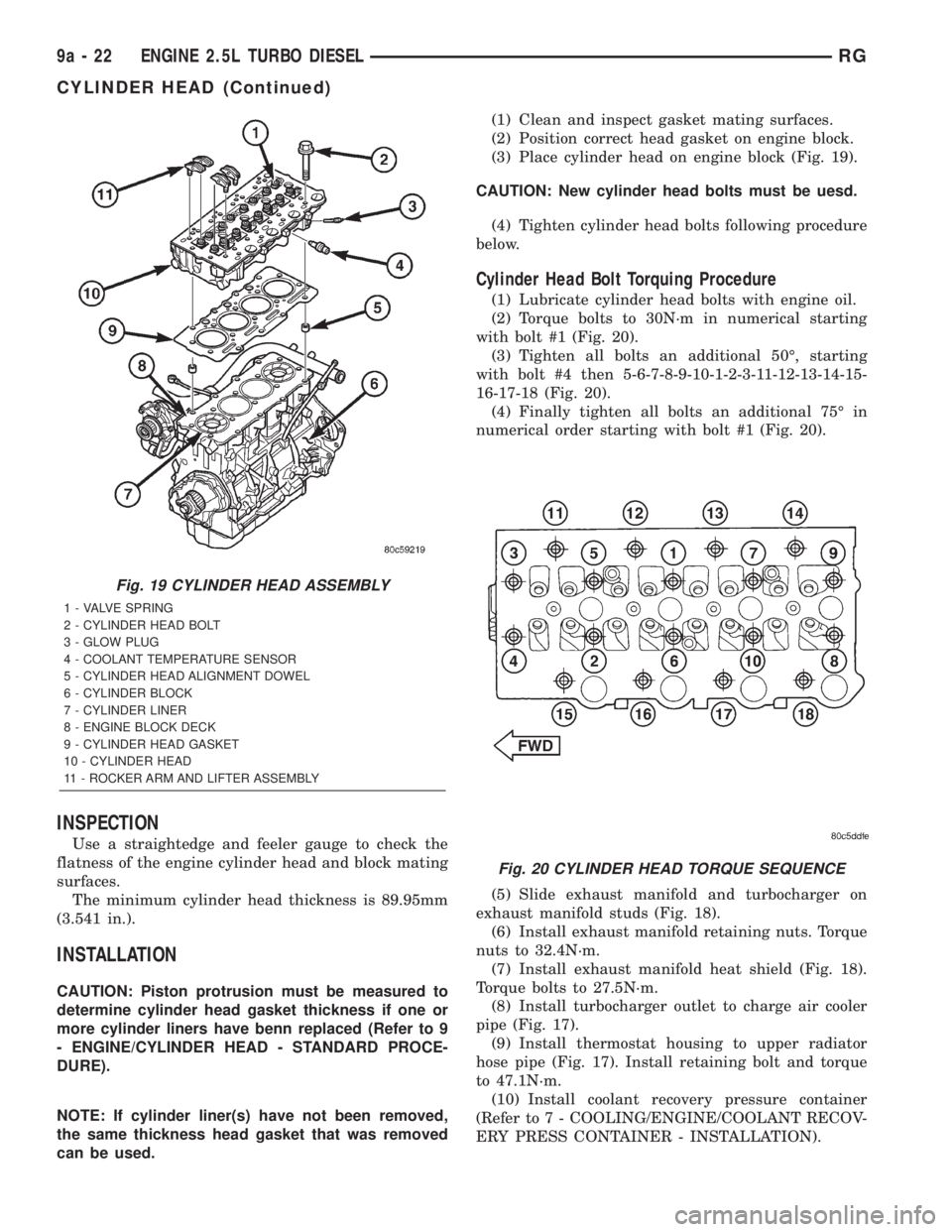

(19) Remove exhaust manifold heat shield (Fig.

18).

(20) Remove exhaust manifold retaining nuts (Fig.

18).

(21) Slide exhaust manifold and turbocharger off of

exhaust manifold studs (Fig. 18).

(22) Remove cylinder head bolts.

(23) Remove cylinder head assembly from engine

block (Fig. 19).CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

exhaust manifold and engine cylinder head mating

surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

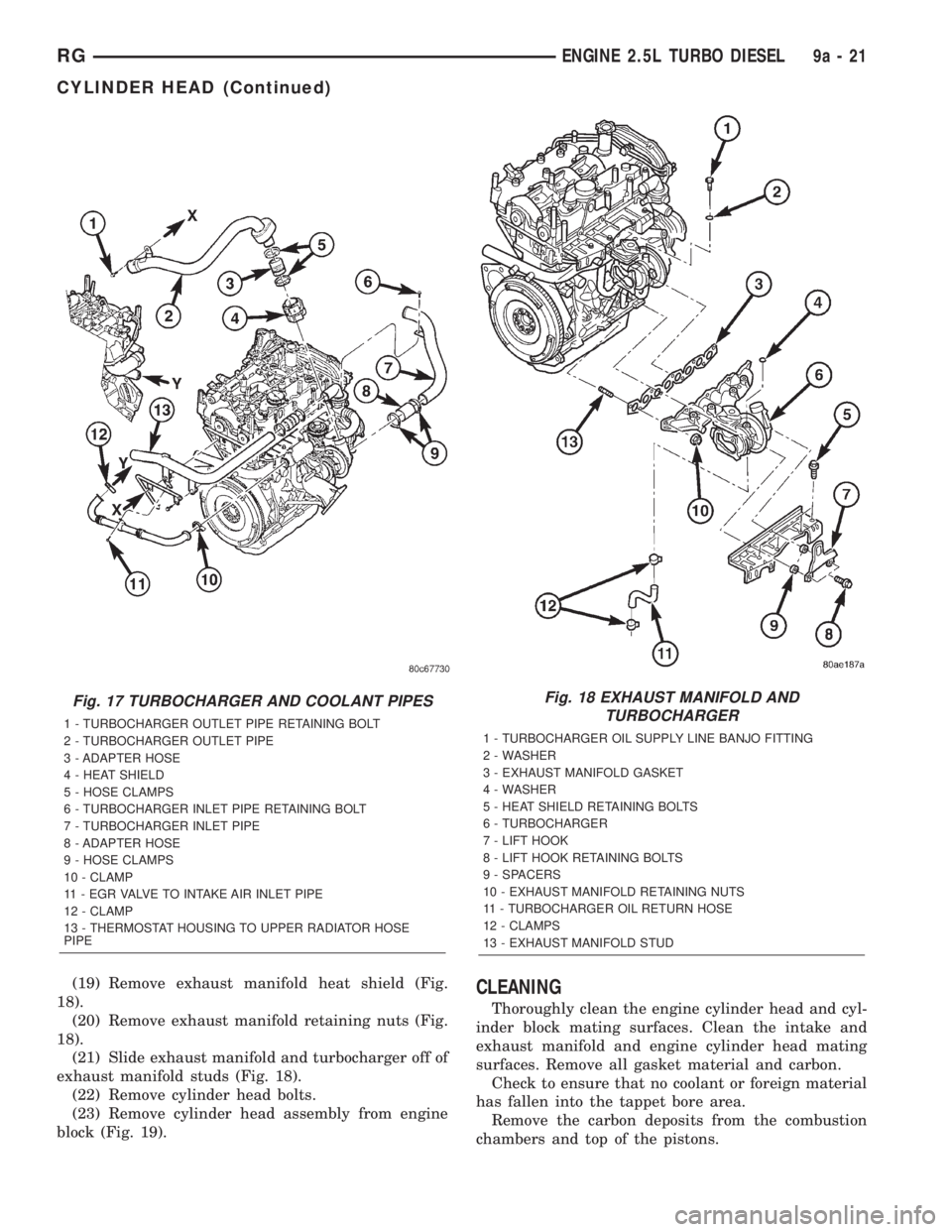

Fig. 17 TURBOCHARGER AND COOLANT PIPES

1 - TURBOCHARGER OUTLET PIPE RETAINING BOLT

2 - TURBOCHARGER OUTLET PIPE

3 - ADAPTER HOSE

4 - HEAT SHIELD

5 - HOSE CLAMPS

6 - TURBOCHARGER INLET PIPE RETAINING BOLT

7 - TURBOCHARGER INLET PIPE

8 - ADAPTER HOSE

9 - HOSE CLAMPS

10 - CLAMP

11 - EGR VALVE TO INTAKE AIR INLET PIPE

12 - CLAMP

13 - THERMOSTAT HOUSING TO UPPER RADIATOR HOSE

PIPE

Fig. 18 EXHAUST MANIFOLD AND

TURBOCHARGER

1 - TURBOCHARGER OIL SUPPLY LINE BANJO FITTING

2 - WASHER

3 - EXHAUST MANIFOLD GASKET

4 - WASHER

5 - HEAT SHIELD RETAINING BOLTS

6 - TURBOCHARGER

7 - LIFT HOOK

8 - LIFT HOOK RETAINING BOLTS

9 - SPACERS

10 - EXHAUST MANIFOLD RETAINING NUTS

11 - TURBOCHARGER OIL RETURN HOSE

12 - CLAMPS

13 - EXHAUST MANIFOLD STUD

RGENGINE 2.5L TURBO DIESEL9a-21

CYLINDER HEAD (Continued)

Page 2804 of 4284

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces.

The minimum cylinder head thickness is 89.95mm

(3.541 in.).

INSTALLATION

CAUTION: Piston protrusion must be measured to

determine cylinder head gasket thickness if one or

more cylinder liners have benn replaced (Refer to 9

- ENGINE/CYLINDER HEAD - STANDARD PROCE-

DURE).

NOTE: If cylinder liner(s) have not been removed,

the same thickness head gasket that was removed

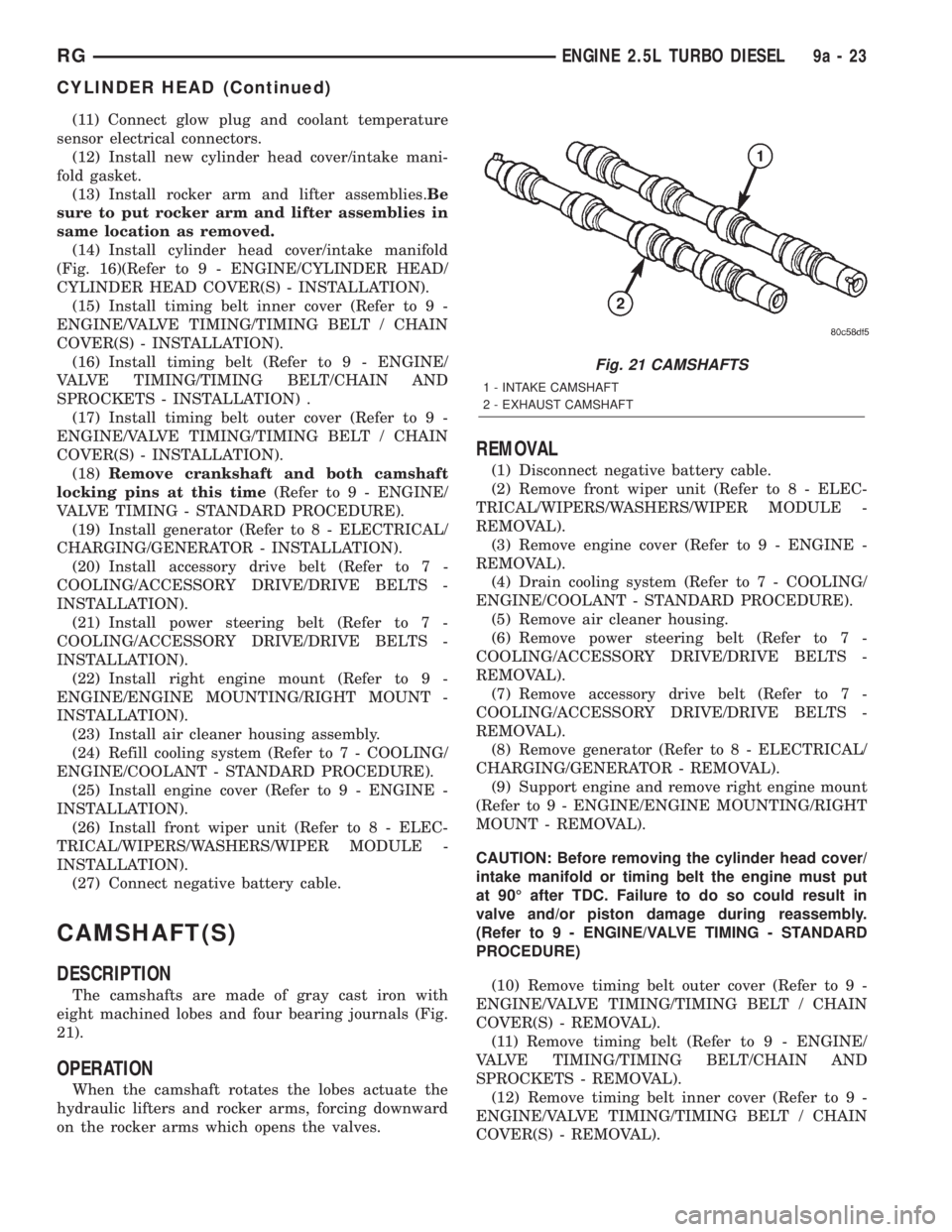

can be used.(1) Clean and inspect gasket mating surfaces.

(2) Position correct head gasket on engine block.

(3) Place cylinder head on engine block (Fig. 19).

CAUTION: New cylinder head bolts must be uesd.

(4) Tighten cylinder head bolts following procedure

below.

Cylinder Head Bolt Torquing Procedure

(1) Lubricate cylinder head bolts with engine oil.

(2) Torque bolts to 30N´m in numerical starting

with bolt #1 (Fig. 20).

(3) Tighten all bolts an additional 50É, starting

with bolt #4 then 5-6-7-8-9-10-1-2-3-11-12-13-14-15-

16-17-18 (Fig. 20).

(4) Finally tighten all bolts an additional 75É in

numerical order starting with bolt #1 (Fig. 20).

(5) Slide exhaust manifold and turbocharger on

exhaust manifold studs (Fig. 18).

(6) Install exhaust manifold retaining nuts. Torque

nuts to 32.4N´m.

(7) Install exhaust manifold heat shield (Fig. 18).

Torque bolts to 27.5N´m.

(8) Install turbocharger outlet to charge air cooler

pipe (Fig. 17).

(9) Install thermostat housing to upper radiator

hose pipe (Fig. 17). Install retaining bolt and torque

to 47.1N´m.

(10) Install coolant recovery pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

Fig. 19 CYLINDER HEAD ASSEMBLY

1 - VALVE SPRING

2 - CYLINDER HEAD BOLT

3 - GLOW PLUG

4 - COOLANT TEMPERATURE SENSOR

5 - CYLINDER HEAD ALIGNMENT DOWEL

6 - CYLINDER BLOCK

7 - CYLINDER LINER

8 - ENGINE BLOCK DECK

9 - CYLINDER HEAD GASKET

10 - CYLINDER HEAD

11 - ROCKER ARM AND LIFTER ASSEMBLY

Fig. 20 CYLINDER HEAD TORQUE SEQUENCE

9a - 22 ENGINE 2.5L TURBO DIESELRG

CYLINDER HEAD (Continued)

Page 2805 of 4284

(11) Connect glow plug and coolant temperature

sensor electrical connectors.

(12) Install new cylinder head cover/intake mani-

fold gasket.

(13) Install rocker arm and lifter assemblies.Be

sure to put rocker arm and lifter assemblies in

same location as removed.

(14) Install cylinder head cover/intake manifold

(Fig. 16)(Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - INSTALLATION).

(15) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(16) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(17) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(18)Remove crankshaft and both camshaft

locking pins at this time(Refer to 9 - ENGINE/

VALVE TIMING - STANDARD PROCEDURE).

(19) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(20) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(21) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(22) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(23) Install air cleaner housing assembly.

(24) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(25) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(26) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(27) Connect negative battery cable.

CAMSHAFT(S)

DESCRIPTION

The camshafts are made of gray cast iron with

eight machined lobes and four bearing journals (Fig.

21).

OPERATION

When the camshaft rotates the lobes actuate the

hydraulic lifters and rocker arms, forcing downward

on the rocker arms which opens the valves.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Remove air cleaner housing.

(6) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(8) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(9) Support engine and remove right engine mount

(Refer to 9 - ENGINE/ENGINE MOUNTING/RIGHT

MOUNT - REMOVAL).

CAUTION: Before removing the cylinder head cover/

intake manifold or timing belt the engine must put

at 90É after TDC. Failure to do so could result in

valve and/or piston damage during reassembly.

(Refer to 9 - ENGINE/VALVE TIMING - STANDARD

PROCEDURE)

(10) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(11) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(12) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 21 CAMSHAFTS

1 - INTAKE CAMSHAFT

2 - EXHAUST CAMSHAFT

RGENGINE 2.5L TURBO DIESEL9a-23

CYLINDER HEAD (Continued)

Page 2806 of 4284

(13) Remove cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(14) With cylinder head cover/intake manifold on

work bench, remove plugs at rear of cylinder head

cover/intake manifold.

(15) Remove camshaft oil seals (Fig. 22).

(16) Remove snapring and thrust washer from

camshaft (Fig. 22).

(17) Slide camshaft through access hole at rear of

cylinder head cover/intake manifold.

INSTALLATION

(1) Lubricate the camshafts with MopartEngine

Oil Supplement, or equivalent.

(2) Carefully install camshafts into access holes in

rear of cylinder head cover/intake manifold.

(3) Install thrust washer, snapring, and camshaft

oil seal (Fig. 22).

(4) Install access hole plugs and gaskets at rear of

cylinder head cover/intake manifold. Torque plugs to

80N´m.

(5) Install cylinder head cover/intake manifold on

engine block (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).(6) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(8) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(9) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(10) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(11) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install air cleaner housing.

(14) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(15) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(16) Connect negative battery cable.

CYLINDER HEAD COVER(S)

DESCRIPTION

The cylinder head cover is made of cast aluminum

and is also the intake manifold on this engine (Fig.

23).

REMOVAL

CAUTION: Before removing the cylinder head cover/

intake manifold the engine must put at 90É after

TDC. Failure to do so could result in valve and/or

piston damage during reassembly. (Refer to 9 -

ENGINE/VALVE TIMING - STANDARD PROCEDURE)

(1) Disconnect negative battery cable.

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Rotate engine until 90É after TDC is reached.

Install both camshaft locking pins and the crankshaft

locking pin. (Refer to 9 - ENGINE/VALVE TIMING -

STANDARD PROCEDURE)

(6) Remove air cleaner housing assembly.

Fig. 22 CAMSHAFT ASSEMBLY

1 - INTAKE CAMSHAFT

2 - SNAPRING

3 - CAMSHAFT OIL SEAL

4 - THRUST WASHER

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

6 - EXHAUST MANIFOLD

9a - 24 ENGINE 2.5L TURBO DIESELRG

CAMSHAFT(S) (Continued)

Page 2809 of 4284

(4) Install turbo inlet tube retaining bolt at intake

manifold. Torque bolt to 27.5 N´m.

(5) Connect oil separator outlet hose at separator.

(6) Install oil dipstick tube retaining bolt at intake

manifold inlet. Torque bolt to 10 N´m.

(7) Install power steering pump reservoir in

bracket.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install fuel injectors and fuel injector supply

lines (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/FUEL INJECTOR - INSTALLATION).

(10) Connect vacuum lines at EGR solenoid.

(11) Clip wiring harness retainers on studs on fuel

rail (Fig. 24).

(12) Connect camshaft position sensor, boost pres-

sure/intake air temperature sensor, EGR solenoid,

and fuel pressure sensor electrical connectors (Fig.

24).

(13) Install inner timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(14) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(15) Install outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(16) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(17) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(20) Install air cleaner housing assembly.

(21) Remove crankshaft and both camshaft locking

pins (Refer to 9 - ENGINE/VALVE TIMING - STAN-

DARD PROCEDURE).

(22) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(23) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(24) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(25) Connect negative battery cable.

Fig. 27 CYLINDER HEAD COVER/INTAKE

MANIFOLD ALIGNMENT STUDS VM.1066

1 - CYLINDER HEAD COVER/INTAKE MANIFOLD ALIGNMENT

STUDS VM.1066

2 - CYLINDER HEAD

Fig. 28 CYLINDER HEAD COVER/INTAKE

MANIFOLD TIGHTENING SEQUENCE

RGENGINE 2.5L TURBO DIESEL9a-27

CYLINDER HEAD COVER(S) (Continued)

Page 2811 of 4284

INSTALLATION

(1) Clean and inspect gasket sealing surfaces.

(2) Install new gasket on cylinder head.

(3) Lubricate lifter ball end of lifter(s), valve(s),

and rocker arm roller(s) with MopartEngine Oil

Supplement or equivlalent.

(4) Connect rocker arm(s) to lifter and reposition

on valve(s) (Fig. 31).

(5) Install cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - INSTALLATION).(6) Install inner timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(8) Install outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(9) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(10) Install air cleaner housing assembly.

(11) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(12) Connect negative battery cable.

Fig. 30 CYLINDER HEAD ASSEMBLY

1 - VALVE SPRING

2 - CYLINDER HEAD BOLT

3 - GLOW PLUG

4 - COOLANT TEMPERATURE SENSOR

5 - CYLINDER HEAD ALIGNMENT DOWEL

6 - CYLINDER BLOCK

7 - CYLINDER LINER

8 - ENGINE BLOCK DECK

9 - CYLINDER HEAD GASKET

10 - CYLINDER HEAD

11 - ROCKER ARM AND LIFTER ASSEMBLY

Fig. 31 ROCKER ARM ASSEMBLY

1 - ROCKER ARM ASSEMBLY

2 - CYLINDER HEAD COVER/INTAKE MANIFOLD

3 - HYDRAULIC LIFTER

4 - CYLINDER HEAD

5 - VALVE

RGENGINE 2.5L TURBO DIESEL9a-29

ROCKER ARMS (Continued)

Page 2812 of 4284

HYDRAULIC LIFTERS

DESCRIPTION

Valve lash is controlled by hydraulic tappets

located inside the cylinder head, in tappet bores

below the camshafts (Fig. 32).

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(3) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(4) Support engine and remove right engine mount

(Refer to 9 - ENGINE/ENGINE MOUNTING/RIGHT

MOUNT - REMOVAL).(5) Remove outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

CAUTION: Before removing the cylinder head cover/

intake manifold or the timing belt the engine must

put at 90É after TDC. Failure to do so could result in

valve and/or piston damage during reassembly.

(Refer to 9 - ENGINE/VALVE TIMING - STANDARD

PROCEDURE)

(6) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(7) Remove inner timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(8) Remove cylinder head cover/intake manifold

(Fig. 33)(Refer to 9 - ENGINE/CYLINDER HEAD/

CYLINDER HEAD COVER(S) - REMOVAL).

(9) Remove rocker arm and lifter assemblies from

lifter bores.

Fig. 32 CYLINDER HEAD ASSEMBLY

1 - VALVE SPRING

2 - CYLINDER HEAD BOLT

3 - GLOW PLUG

4 - COOLANT TEMPERATURE SENSOR

5 - CYLINDER HEAD ALIGNMENT DOWEL

6 - CYLINDER BLOCK

7 - CYLINDER LINER

8 - ENGINE BLOCK DECK

9 - CYLINDER HEAD GASKET

10 - CYLINDER HEAD

11 - ROCKER ARM AND LIFTER ASSEMBLY

Fig. 33 CYLINDER HEAD COVER/INTAKE

MANIFOLD

1 - CYLINDER HEAD COVER/INTAKE MANIFOLD BOLTS(LONG)

2 - CYLINDER HEAD COVER/INTAKE MANIFOLD

3 - CYLINDER HEAD

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD GASKET

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

BOLTS(SHORT)

9a - 30 ENGINE 2.5L TURBO DIESELRG

Page 2833 of 4284

REMOVAL

(1) Remove engine oil pan (Refer to 9 - ENGINE/

LUBRICATION/OIL PAN - REMOVAL).

(2) Using special tool VM.1054, remove oil pres-

sure relief valve from engine block (Fig. 75).

INSTALLATION

(1) Thoroughly clean all components and relief

valve pocket in cylinder block.

(2) Lubricate all oil pressure relief valve compo-

nents with engine oil.

(3) Install oil pressure relief valve plunger, spring,

and cap.(4) Using special tool VM.1059, push oil pressure

relief valve cap in untill flush with engine block (Fig.

76).

(5) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

OIL COOLER & LINES

REMOVAL

(1) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Raise vehicle on hoist.

(3) Remove oil filter cap and filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER - REMOVAL).

(4) Remove oil filter housing retaining nut and

housing (Fig. 77).

(5) Disconnect coolant hoses at cooler (Fig. 78).

(6) Remove oil cooler retaining bolt at engine block

(Fig. 78).

Fig. 75 OIL PRESSURE RELIEF VALVE REMOVAL

1 - VM.1054

2 - OIL PRESSURE RELIEF VALVE

3 - ENGINE BLOCK

4 - OIL PUMP

Fig. 76 OIL PRESSURE RELIEF VALVE

INSTALLATION

1 - VM.1059

2 - OIL PRESSURE RELIEF VALVE

3 - ENGINE BLOCK

4 - OIL PUMP

RGENGINE 2.5L TURBO DIESEL9a-51

OIL PRESSURE RELIEF VALVE (Continued)

Page 2834 of 4284

(7) Remove oil cooler retaining stud and remove oil

cooler from engine block (Fig. 78).

INSTALLATION

(1) Clean oil cooler and engine block sealing sur-

faces.

(2) Install oil cooler, retaining bolt, and stud (Fig.

78). Torque retaining bolt to 47.1N´m and stud to

50N´m.

(3) Connect coolant hoses at cooler (Fig. 78).

(4) Install oil filter housing and retaining nut (Fig.

77).

(5) Install oil filter cartridge and oil filter cap

(Refer to 9 - ENGINE/LUBRICATION/OIL FILTER -

INSTALLATION).

(6) Lower vehicle.

(7) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(8) Start engine and check for leaks.

(9) Check and adjust oil level as necessary.

OIL FILTER

DESCRIPTION

The oil filter used on this engine is a cartridge

style filter (Fig. 79).

Fig. 77 OIL FILTER HOUSING RETAINING NUT

1 - OIL FILTER HOUSING

2 - OIL FILTER HOUSING RETAINING NUT

3 - OIL COOLER

Fig. 78 WATER PUMP AND OIL COOLER

ASSEMBLIES

1 - WATER PUMP HOUSING STUDS

2 - WATER PUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

Fig. 79 OIL FILTER ASSEMBLY

1 - OIL FILTER CAP

2 - DRAIN PLUG

3 - OIL FILTER CARTRIDGE

9a - 52 ENGINE 2.5L TURBO DIESELRG

OIL COOLER & LINES (Continued)

Page 2837 of 4284

(6) Remove plug in cylinder head cover/intake

manifold and insert VM.1053 to lock exhaust cam-

shaft in position (Fig. 84).

(7) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(8) Remove plug in cylinder head cover/intake

manifold and insert VM.1052 to lock intake camshaft

in position (Fig. 85).

(9) At this point the timing belt can be removed

for service.

(10) After engine service is completed and timing

belt reinstalled, remove both camshaft locking pins

from cylinder head cover/intake manifold.

(11) Install both camshaft access plugs.

(12) Remove 90É after TDC engine locking pin.

(13) Install starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLA-

TION).

(14) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).(15) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(16) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(17) Connect negative battery cable.

BALANCE SHAFT

DESCRIPTION

The 2.5L Common Rail Diesel engine is equipped

with two nodular cast iron balance shafts in a cast

aluminum carrier. The balance shaft assembly is

mounted to the engine block (Fig. 86).

Fig. 84 EXHAUST CAMSHAFT LOCKING PIN

VM.1053

1 - EXHAUST MANIFOLD HEAT SHIELD

2 - EXHAUST CAMSHAFT LOCKING PIN VM.1053

3 - COOLANT TUBE FROM THERMOSTAT HOUSING TO UPPER

RADIATOR HOSE

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD

Fig. 85 INTAKE CAMSHAFT LOCKING PIN VM.1052

1 - TIMING BELT INNER COVER

2 - GLOW PLUG ELECTRICAL CONNECTOR

3 - CYLINDER HEAD COVER/INTAKE MANIFOLD

4 - FUEL RAIL

5 - INTAKE CAMSHAFT LOCKING PIN VM.1052

RGENGINE 2.5L TURBO DIESEL9a-55

VALVE TIMING (Continued)