CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1711 of 4284

CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

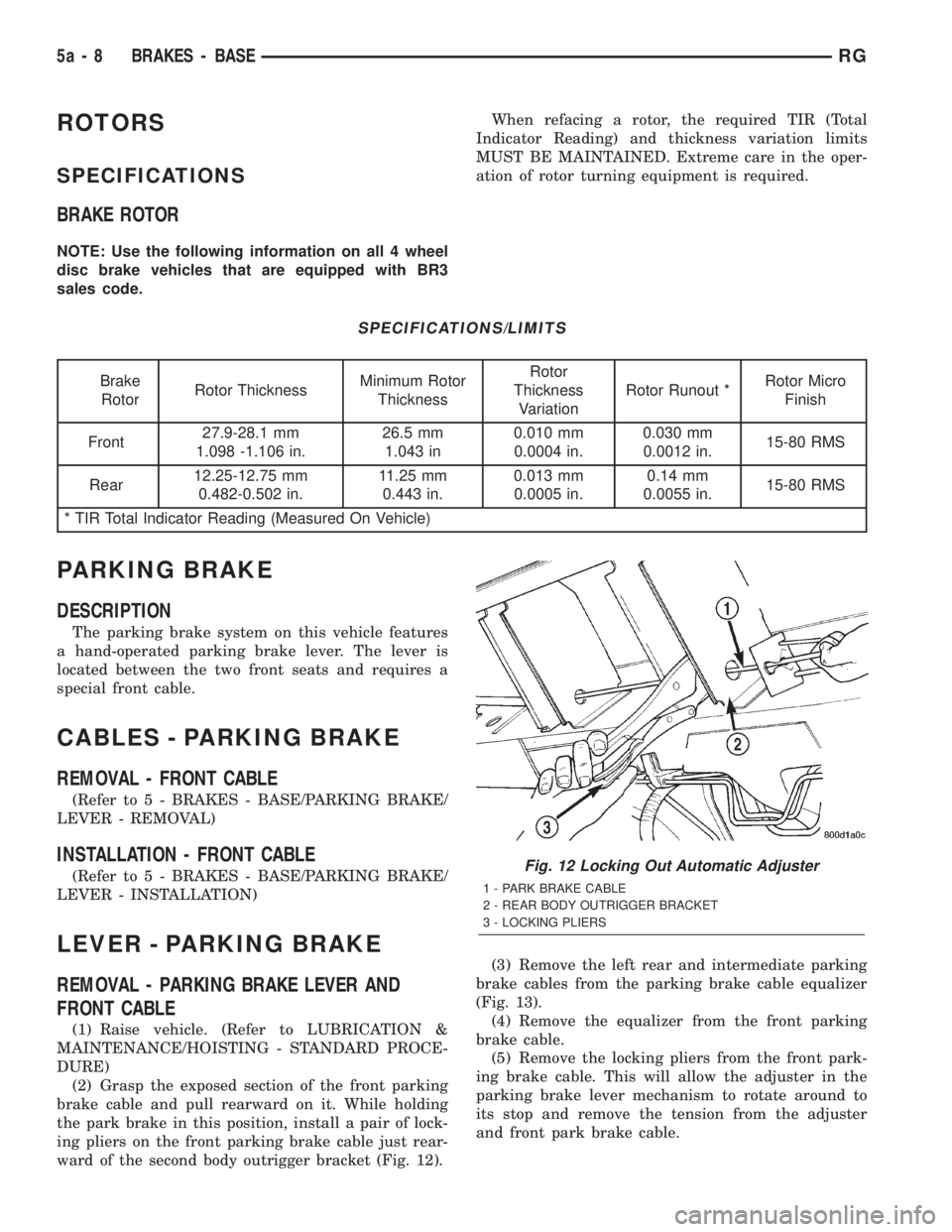

(8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 11).(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 6). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 5).

(12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION)

(13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(14) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(15) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(16) Install the battery, clamp and mounting nut.

(17) Install the positive battery cable on the bat-

tery.

(18) Install the negative battery cable on the bat-

tery.

(19) Install the battery thermal guard shield.

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(20) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(21) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(22) Road test vehicle to ensure proper operation

of the brakes.

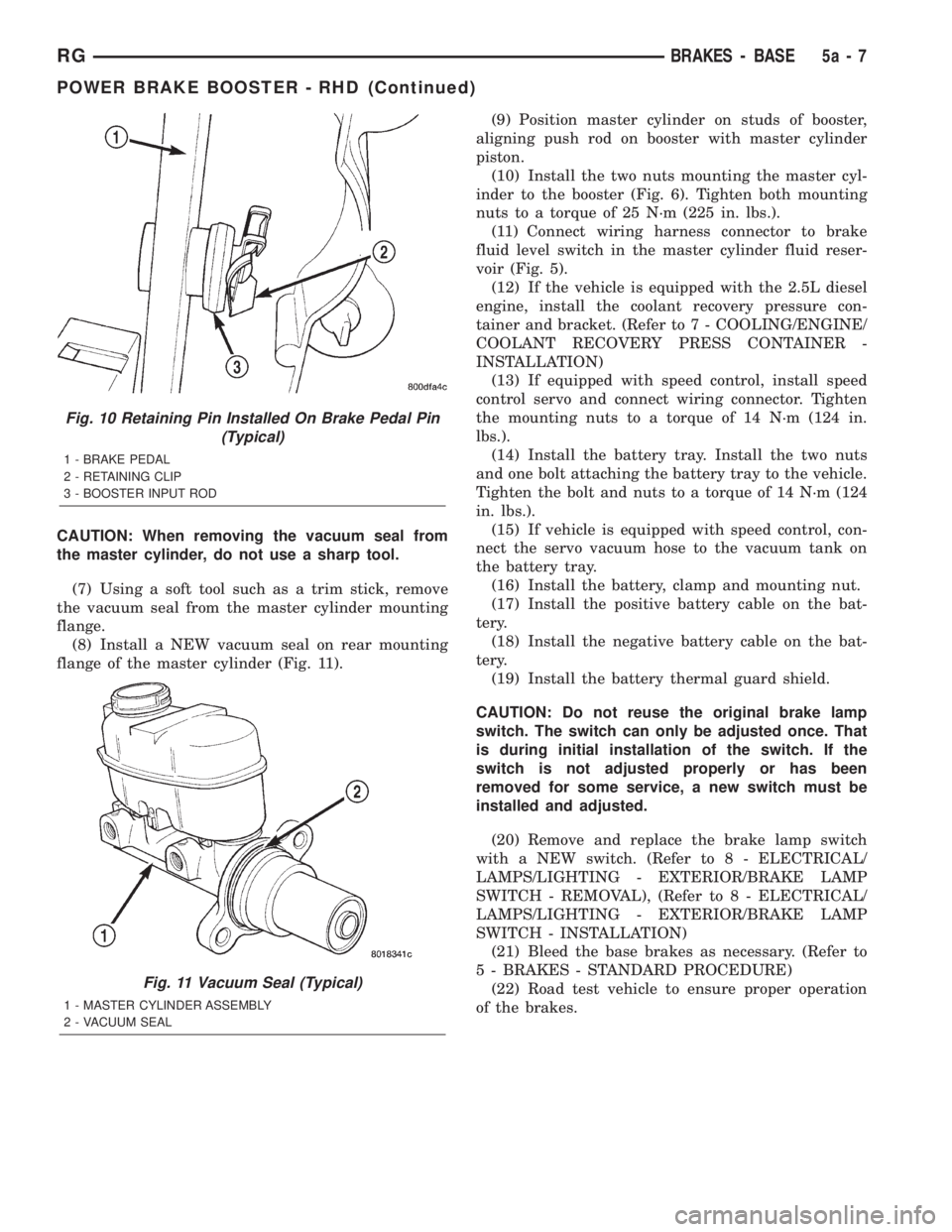

Fig. 10 Retaining Pin Installed On Brake Pedal Pin

(Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

Fig. 11 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

RGBRAKES - BASE5a-7

POWER BRAKE BOOSTER - RHD (Continued)

Page 1712 of 4284

ROTORS

SPECIFICATIONS

BRAKE ROTOR

NOTE: Use the following information on all 4 wheel

disc brake vehicles that are equipped with BR3

sales code.When refacing a rotor, the required TIR (Total

Indicator Reading) and thickness variation limits

MUST BE MAINTAINED. Extreme care in the oper-

ation of rotor turning equipment is required.

SPECIFICATIONS/LIMITS

Brake

RotorRotor ThicknessMinimum Rotor

ThicknessRotor

Thickness

VariationRotor Runout *Rotor Micro

Finish

Front27.9-28.1 mm

1.098 -1.106 in.26.5 mm

1.043 in0.010 mm

0.0004 in.0.030 mm

0.0012 in.15-80 RMS

Rear12.25-12.75 mm

0.482-0.502 in.11.25 mm

0.443 in.0.013 mm

0.0005 in.0.14 mm

0.0055 in.15-80 RMS

* TIR Total Indicator Reading (Measured On Vehicle)

PARKING BRAKE

DESCRIPTION

The parking brake system on this vehicle features

a hand-operated parking brake lever. The lever is

located between the two front seats and requires a

special front cable.

CABLES - PARKING BRAKE

REMOVAL - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - REMOVAL)

INSTALLATION - FRONT CABLE

(Refer to 5 - BRAKES - BASE/PARKING BRAKE/

LEVER - INSTALLATION)

LEVER - PARKING BRAKE

REMOVAL - PARKING BRAKE LEVER AND

FRONT CABLE

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

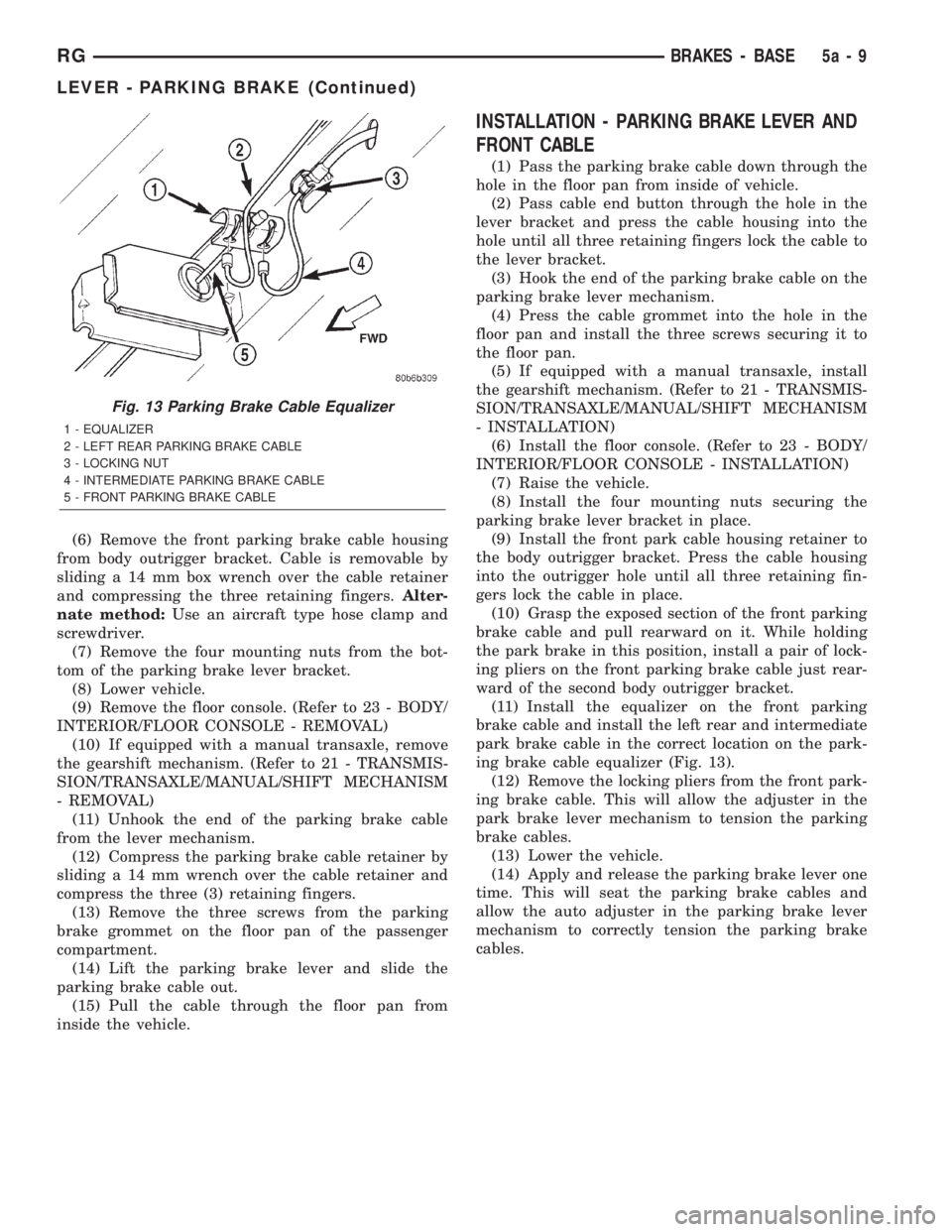

(2) Grasp the exposed section of the front parking

brake cable and pull rearward on it. While holding

the park brake in this position, install a pair of lock-

ing pliers on the front parking brake cable just rear-

ward of the second body outrigger bracket (Fig. 12).(3) Remove the left rear and intermediate parking

brake cables from the parking brake cable equalizer

(Fig. 13).

(4) Remove the equalizer from the front parking

brake cable.

(5) Remove the locking pliers from the front park-

ing brake cable. This will allow the adjuster in the

parking brake lever mechanism to rotate around to

its stop and remove the tension from the adjuster

and front park brake cable.

Fig. 12 Locking Out Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

5a - 8 BRAKES - BASERG

Page 1713 of 4284

(6) Remove the front parking brake cable housing

from body outrigger bracket. Cable is removable by

sliding a 14 mm box wrench over the cable retainer

and compressing the three retaining fingers.Alter-

nate method:Use an aircraft type hose clamp and

screwdriver.

(7) Remove the four mounting nuts from the bot-

tom of the parking brake lever bracket.

(8) Lower vehicle.

(9) Remove the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL)

(10) If equipped with a manual transaxle, remove

the gearshift mechanism. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/SHIFT MECHANISM

- REMOVAL)

(11) Unhook the end of the parking brake cable

from the lever mechanism.

(12) Compress the parking brake cable retainer by

sliding a 14 mm wrench over the cable retainer and

compress the three (3) retaining fingers.

(13) Remove the three screws from the parking

brake grommet on the floor pan of the passenger

compartment.

(14) Lift the parking brake lever and slide the

parking brake cable out.

(15) Pull the cable through the floor pan from

inside the vehicle.

INSTALLATION - PARKING BRAKE LEVER AND

FRONT CABLE

(1) Pass the parking brake cable down through the

hole in the floor pan from inside of vehicle.

(2) Pass cable end button through the hole in the

lever bracket and press the cable housing into the

hole until all three retaining fingers lock the cable to

the lever bracket.

(3) Hook the end of the parking brake cable on the

parking brake lever mechanism.

(4) Press the cable grommet into the hole in the

floor pan and install the three screws securing it to

the floor pan.

(5) If equipped with a manual transaxle, install

the gearshift mechanism. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/SHIFT MECHANISM

- INSTALLATION)

(6) Install the floor console. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION)

(7) Raise the vehicle.

(8) Install the four mounting nuts securing the

parking brake lever bracket in place.

(9) Install the front park cable housing retainer to

the body outrigger bracket. Press the cable housing

into the outrigger hole until all three retaining fin-

gers lock the cable in place.

(10) Grasp the exposed section of the front parking

brake cable and pull rearward on it. While holding

the park brake in this position, install a pair of lock-

ing pliers on the front parking brake cable just rear-

ward of the second body outrigger bracket.

(11) Install the equalizer on the front parking

brake cable and install the left rear and intermediate

park brake cable in the correct location on the park-

ing brake cable equalizer (Fig. 13).

(12) Remove the locking pliers from the front park-

ing brake cable. This will allow the adjuster in the

park brake lever mechanism to tension the parking

brake cables.

(13) Lower the vehicle.

(14) Apply and release the parking brake lever one

time. This will seat the parking brake cables and

allow the auto adjuster in the parking brake lever

mechanism to correctly tension the parking brake

cables.

Fig. 13 Parking Brake Cable Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

RGBRAKES - BASE5a-9

LEVER - PARKING BRAKE (Continued)

Page 1714 of 4284

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION...........................10

ICU (INTEGRATED CONTROL UNIT) - RHD

REMOVAL..............................10DISASSEMBLY...........................11

ASSEMBLY.............................12

INSTALLATION...........................13

BRAKES - ABS

DESCRIPTION - ANTILOCK BRAKE SYSTEM

Four-wheel disc antilock brakes are standard on all

models. The Mark 20e antilock brake system is used

on all models. Depending on whether the vehicle is a

left-hand drive (LHD) or right-hand drive (RHD)

model, the integrated control unit (ICU) is located in

one of two locations. On LHD models, the ICU is

mounted above the front suspension cradle/cross-

member below the master cylinder. On RHD models,

the ICU is located behind the front suspension cra-

dle/crossmember on the left side of the vehicle.

ICU (INTEGRATED CONTROL

UNIT) - RHD

REMOVAL - RHD

NOTE: Before proceeding, review all WARNINGS

AND CAUTIONS.

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. See Hoisting in the Lubrication

And Maintenance.

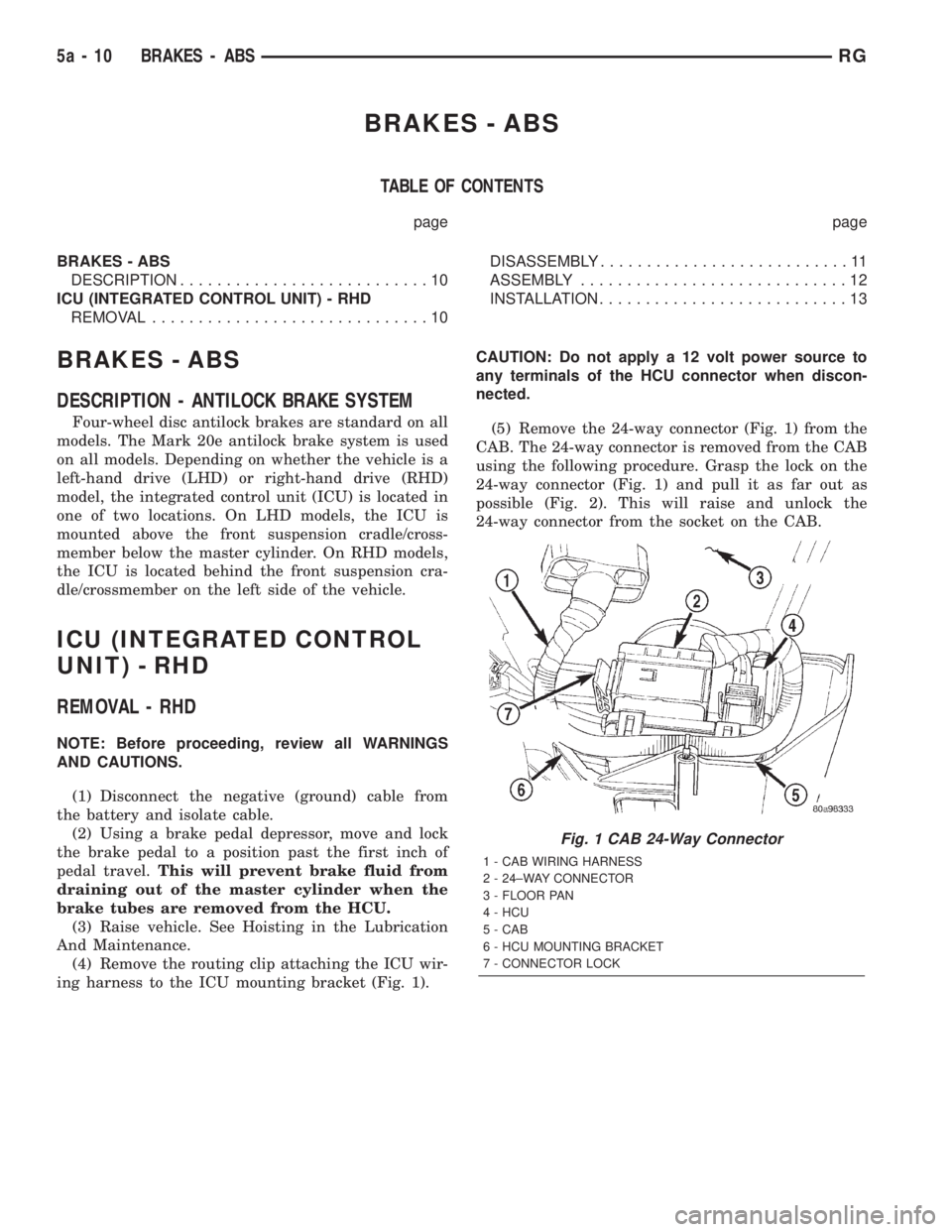

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 1).CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

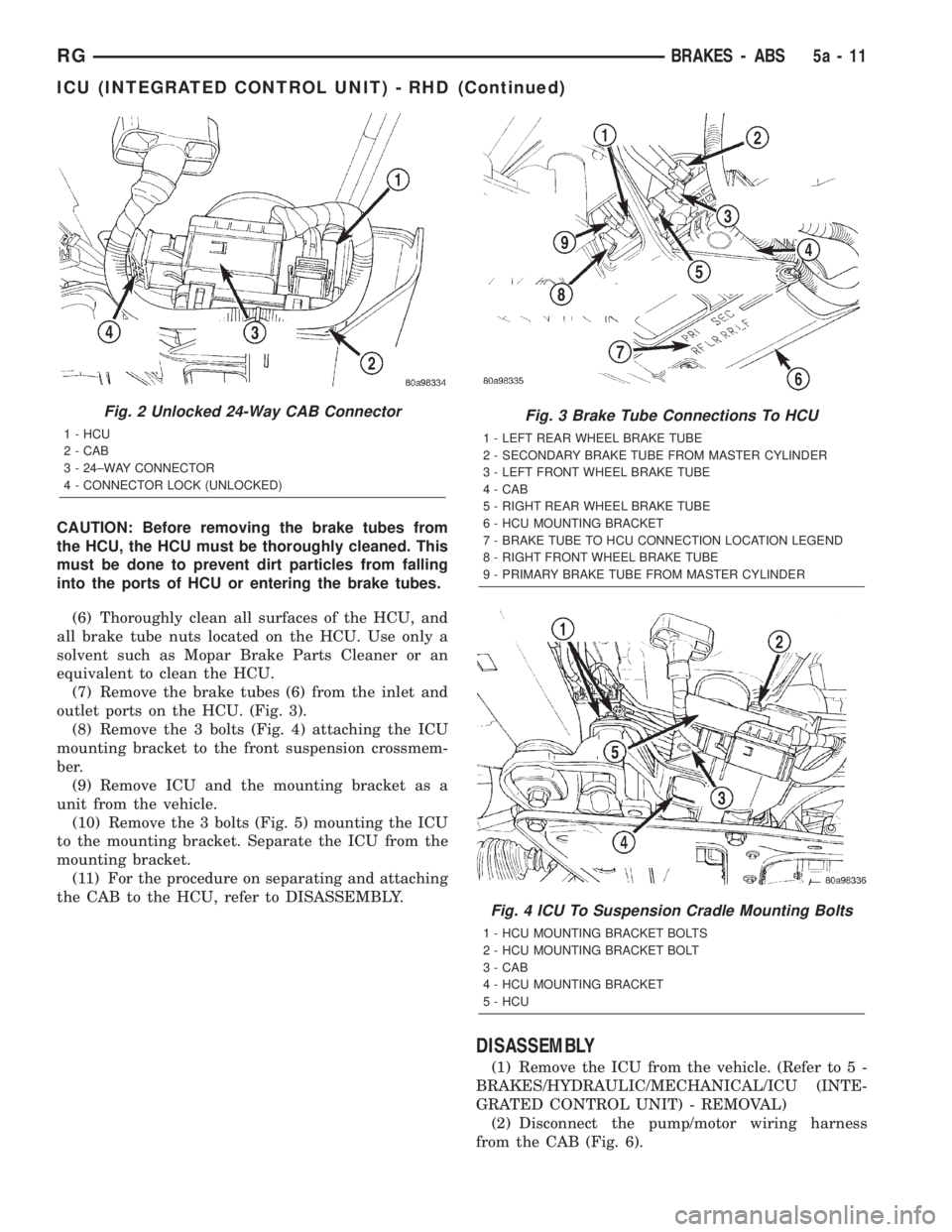

(5) Remove the 24-way connector (Fig. 1) from the

CAB. The 24-way connector is removed from the CAB

using the following procedure. Grasp the lock on the

24-way connector (Fig. 1) and pull it as far out as

possible (Fig. 2). This will raise and unlock the

24-way connector from the socket on the CAB.

Fig. 1 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

5a - 10 BRAKES - ABSRG

Page 1715 of 4284

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

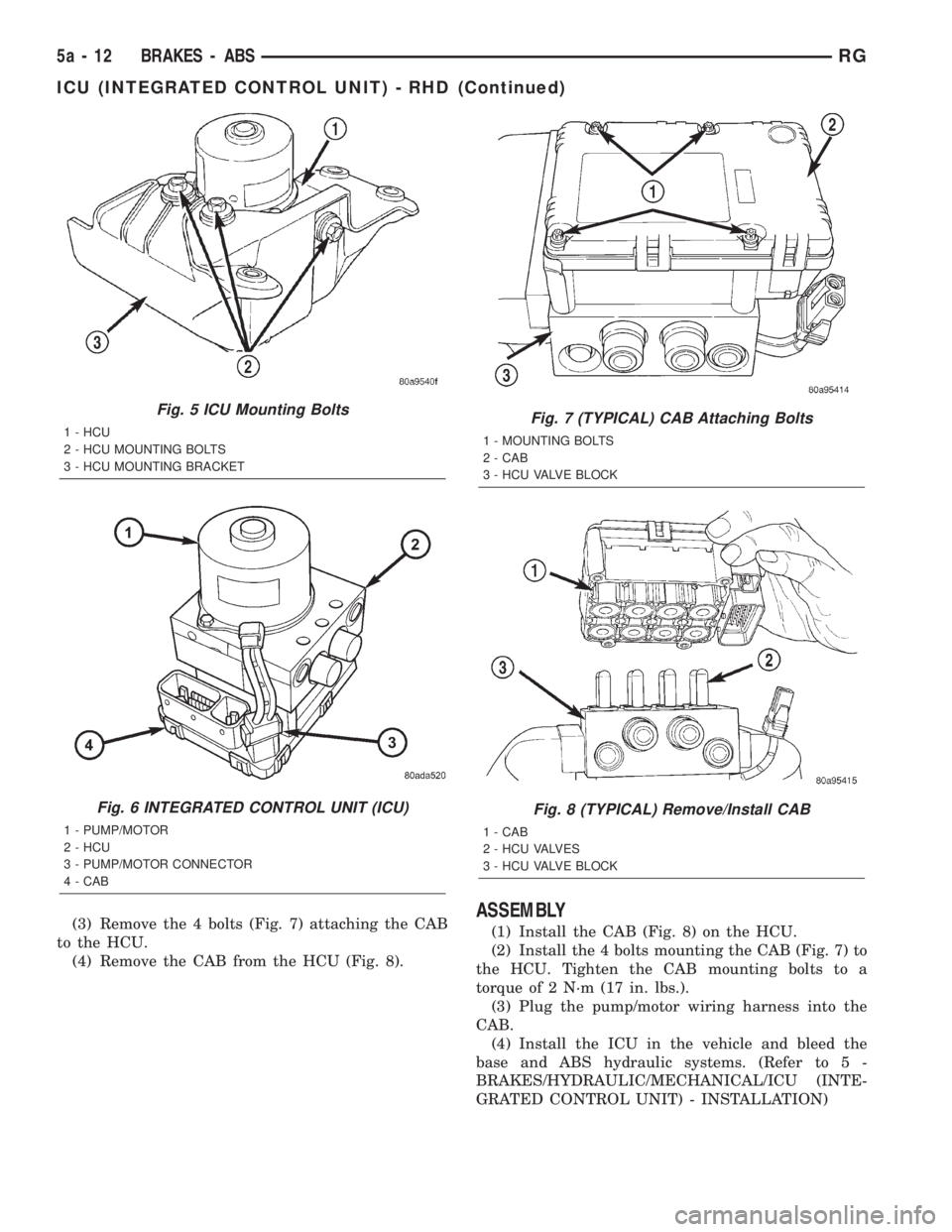

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 3).

(8) Remove the 3 bolts (Fig. 4) attaching the ICU

mounting bracket to the front suspension crossmem-

ber.

(9) Remove ICU and the mounting bracket as a

unit from the vehicle.

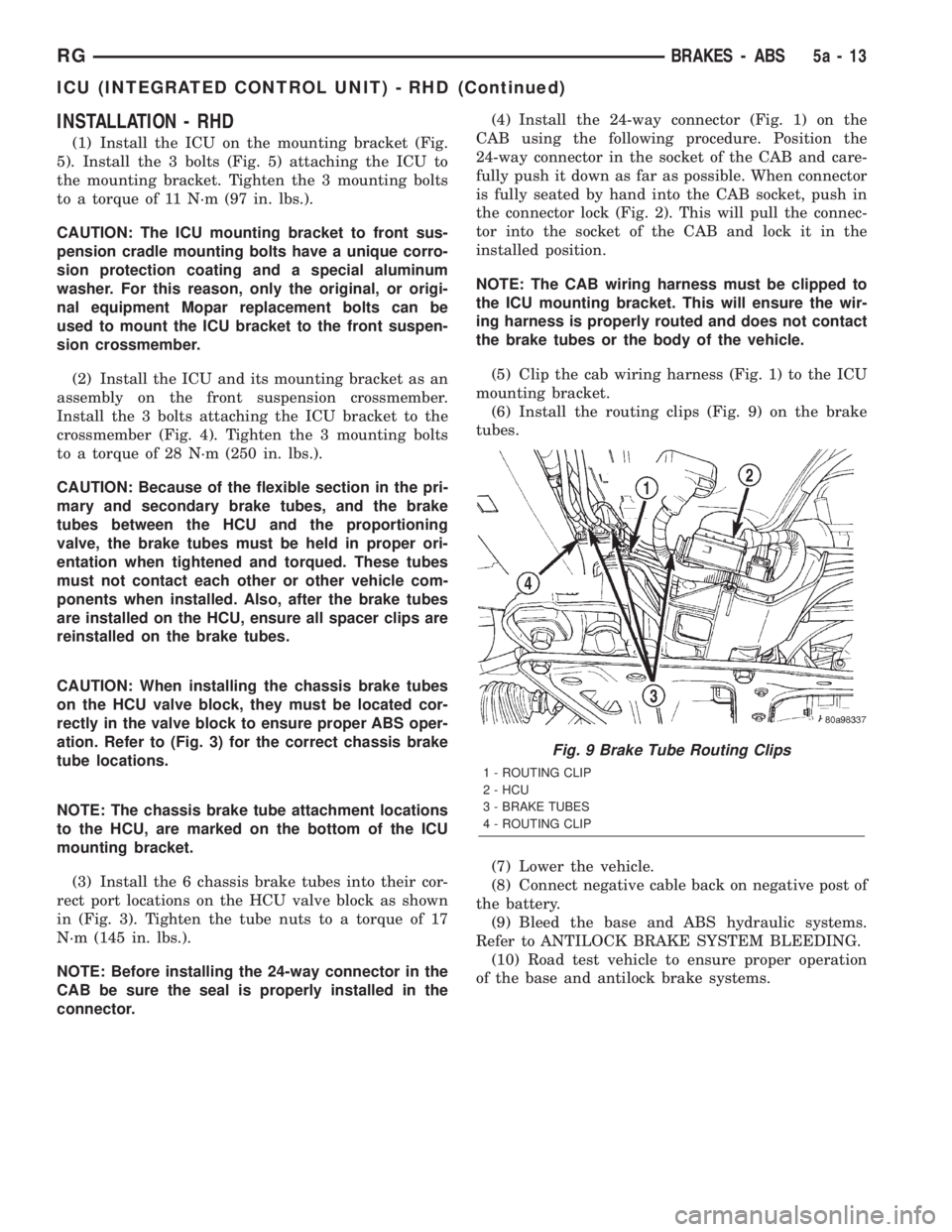

(10) Remove the 3 bolts (Fig. 5) mounting the ICU

to the mounting bracket. Separate the ICU from the

mounting bracket.

(11) For the procedure on separating and attaching

the CAB to the HCU, refer to DISASSEMBLY.

DISASSEMBLY

(1) Remove the ICU from the vehicle. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - REMOVAL)

(2) Disconnect the pump/motor wiring harness

from the CAB (Fig. 6).

Fig. 2 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 3 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

Fig. 4 ICU To Suspension Cradle Mounting Bolts

1 - HCU MOUNTING BRACKET BOLTS

2 - HCU MOUNTING BRACKET BOLT

3 - CAB

4 - HCU MOUNTING BRACKET

5 - HCU

RGBRAKES - ABS5a-11

ICU (INTEGRATED CONTROL UNIT) - RHD (Continued)

Page 1716 of 4284

(3) Remove the 4 bolts (Fig. 7) attaching the CAB

to the HCU.

(4) Remove the CAB from the HCU (Fig. 8).ASSEMBLY

(1) Install the CAB (Fig. 8) on the HCU.

(2) Install the 4 bolts mounting the CAB (Fig. 7) to

the HCU. Tighten the CAB mounting bolts to a

torque of 2 N´m (17 in. lbs.).

(3) Plug the pump/motor wiring harness into the

CAB.

(4) Install the ICU in the vehicle and bleed the

base and ABS hydraulic systems. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - INSTALLATION)

Fig. 5 ICU Mounting Bolts

1 - HCU

2 - HCU MOUNTING BOLTS

3 - HCU MOUNTING BRACKET

Fig. 6 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 7 (TYPICAL) CAB Attaching Bolts

1 - MOUNTING BOLTS

2 - CAB

3 - HCU VALVE BLOCK

Fig. 8 (TYPICAL) Remove/Install CAB

1 - CAB

2 - HCU VALVES

3 - HCU VALVE BLOCK

5a - 12 BRAKES - ABSRG

ICU (INTEGRATED CONTROL UNIT) - RHD (Continued)

Page 1717 of 4284

INSTALLATION - RHD

(1) Install the ICU on the mounting bracket (Fig.

5). Install the 3 bolts (Fig. 5) attaching the ICU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The ICU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the ICU bracket to the front suspen-

sion crossmember.

(2) Install the ICU and its mounting bracket as an

assembly on the front suspension crossmember.

Install the 3 bolts attaching the ICU bracket to the

crossmember (Fig. 4). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 3) for the correct chassis brake

tube locations.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the ICU

mounting bracket.

(3) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 3). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 24-way connector in the

CAB be sure the seal is properly installed in the

connector.(4) Install the 24-way connector (Fig. 1) on the

CAB using the following procedure. Position the

24-way connector in the socket of the CAB and care-

fully push it down as far as possible. When connector

is fully seated by hand into the CAB socket, push in

the connector lock (Fig. 2). This will pull the connec-

tor into the socket of the CAB and lock it in the

installed position.

NOTE: The CAB wiring harness must be clipped to

the ICU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(5) Clip the cab wiring harness (Fig. 1) to the ICU

mounting bracket.

(6) Install the routing clips (Fig. 9) on the brake

tubes.

(7) Lower the vehicle.

(8) Connect negative cable back on negative post of

the battery.

(9) Bleed the base and ABS hydraulic systems.

Refer to ANTILOCK BRAKE SYSTEM BLEEDING.

(10) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

Fig. 9 Brake Tube Routing Clips

1 - ROUTING CLIP

2 - HCU

3 - BRAKE TUBES

4 - ROUTING CLIP

RGBRAKES - ABS5a-13

ICU (INTEGRATED CONTROL UNIT) - RHD (Continued)

Page 1718 of 4284

Page 1719 of 4284

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

DESCRIPTION...........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CLUTCH

SYSTEM..............................4

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT.........................7

DIAGNOSIS AND TESTING - CLUTCH

COVER AND DISC RUNOUT...............7

DIAGNOSIS AND TESTING - CLUTCH

CHATTER COMPLAINTS..................7

SPECIAL TOOLS..........................7

CLUTCH RELEASE CABLE - LHD

REMOVAL...............................7

INSTALLATION...........................9

CLUTCH RELEASE LEVER AND BEARING

REMOVAL..............................11INSTALLATION..........................12

MASTER CYLINDER - RHD

REMOVAL..............................13

INSTALLATION..........................14

MODULAR CLUTCH ASSY - 2.4L GAS

REMOVAL..............................14

INSTALLATION..........................15

SLAVE CYLINDER - RHD

REMOVAL..............................15

INSTALLATION..........................15

CLUTCH DISC AND PRESSURE PLATE - 2.5L

TD

REMOVAL..............................15

INSTALLATION..........................15

FLYWHEEL

REMOVAL..............................16

INSTALLATION..........................16

CLUTCH

DESCRIPTION

CLUTCH COMPONENTS

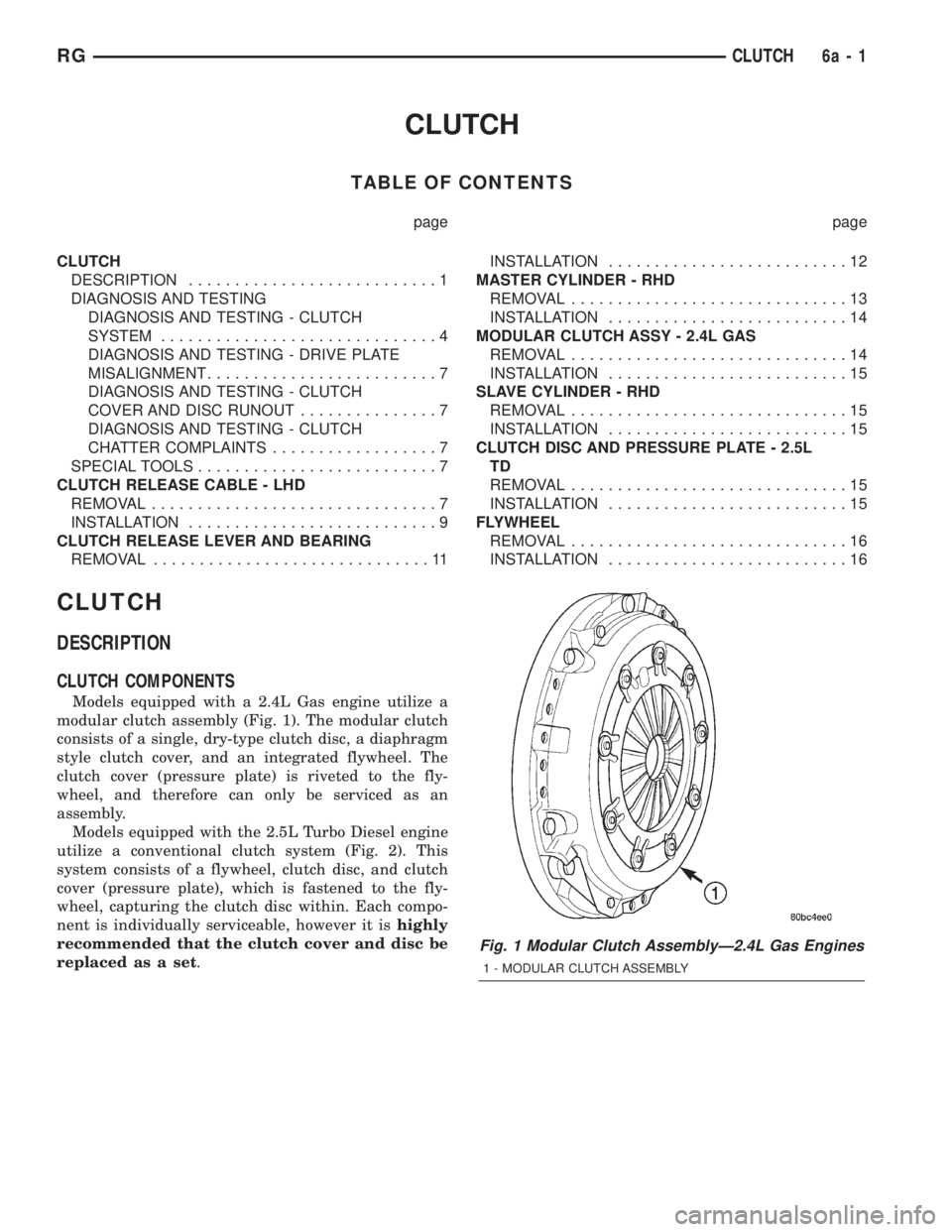

Models equipped with a 2.4L Gas engine utilize a

modular clutch assembly (Fig. 1). The modular clutch

consists of a single, dry-type clutch disc, a diaphragm

style clutch cover, and an integrated flywheel. The

clutch cover (pressure plate) is riveted to the fly-

wheel, and therefore can only be serviced as an

assembly.

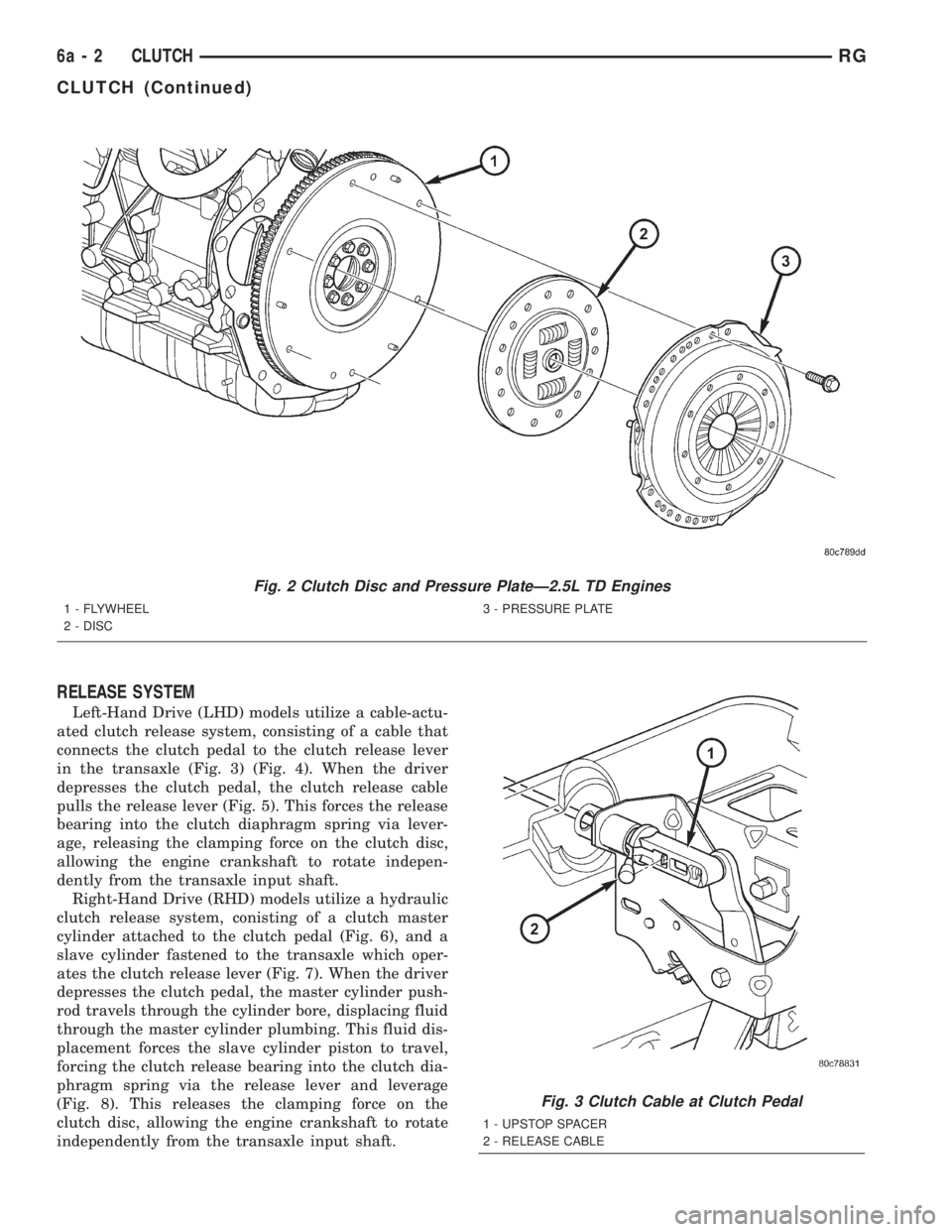

Models equipped with the 2.5L Turbo Diesel engine

utilize a conventional clutch system (Fig. 2). This

system consists of a flywheel, clutch disc, and clutch

cover (pressure plate), which is fastened to the fly-

wheel, capturing the clutch disc within. Each compo-

nent is individually serviceable, however it ishighly

recommended that the clutch cover and disc be

replaced as a set.

Fig. 1 Modular Clutch AssemblyÐ2.4L Gas Engines

1 - MODULAR CLUTCH ASSEMBLY

RGCLUTCH6a-1

Page 1720 of 4284

RELEASE SYSTEM

Left-Hand Drive (LHD) models utilize a cable-actu-

ated clutch release system, consisting of a cable that

connects the clutch pedal to the clutch release lever

in the transaxle (Fig. 3) (Fig. 4). When the driver

depresses the clutch pedal, the clutch release cable

pulls the release lever (Fig. 5). This forces the release

bearing into the clutch diaphragm spring via lever-

age, releasing the clamping force on the clutch disc,

allowing the engine crankshaft to rotate indepen-

dently from the transaxle input shaft.

Right-Hand Drive (RHD) models utilize a hydraulic

clutch release system, conisting of a clutch master

cylinder attached to the clutch pedal (Fig. 6), and a

slave cylinder fastened to the transaxle which oper-

ates the clutch release lever (Fig. 7). When the driver

depresses the clutch pedal, the master cylinder push-

rod travels through the cylinder bore, displacing fluid

through the master cylinder plumbing. This fluid dis-

placement forces the slave cylinder piston to travel,

forcing the clutch release bearing into the clutch dia-

phragm spring via the release lever and leverage

(Fig. 8). This releases the clamping force on the

clutch disc, allowing the engine crankshaft to rotate

independently from the transaxle input shaft.

Fig. 2 Clutch Disc and Pressure PlateÐ2.5L TD Engines

1 - FLYWHEEL

2 - DISC3 - PRESSURE PLATE

Fig. 3 Clutch Cable at Clutch Pedal

1 - UPSTOP SPACER

2 - RELEASE CABLE

6a - 2 CLUTCHRG

CLUTCH (Continued)