coolant CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3252 of 4284

Since there are four switches, there are 16 possible

combinations of open and closed switches (codes).

Seven of these codes are related to gear position and

three are recognized as ªbetween gearº codes. This

results in six codes which should never occur. These

are called ªinvalidº codes. An invalid code will result

in a DTC, and the TCM will then determine the shift

lever position based on pressure switch data. This

allows reasonably normal transmission operation

with a TRS failure.

TRS SWITCH STATES

SLP T42 T41 T3 T1

PCL CL CL OP

RCL OP OP OP

NCL CL OP CL

ODOP OP OP CL

3OP OP CL OP

LCL OP CL CL

TRANSMISSION TEMPERATURE SENSOR

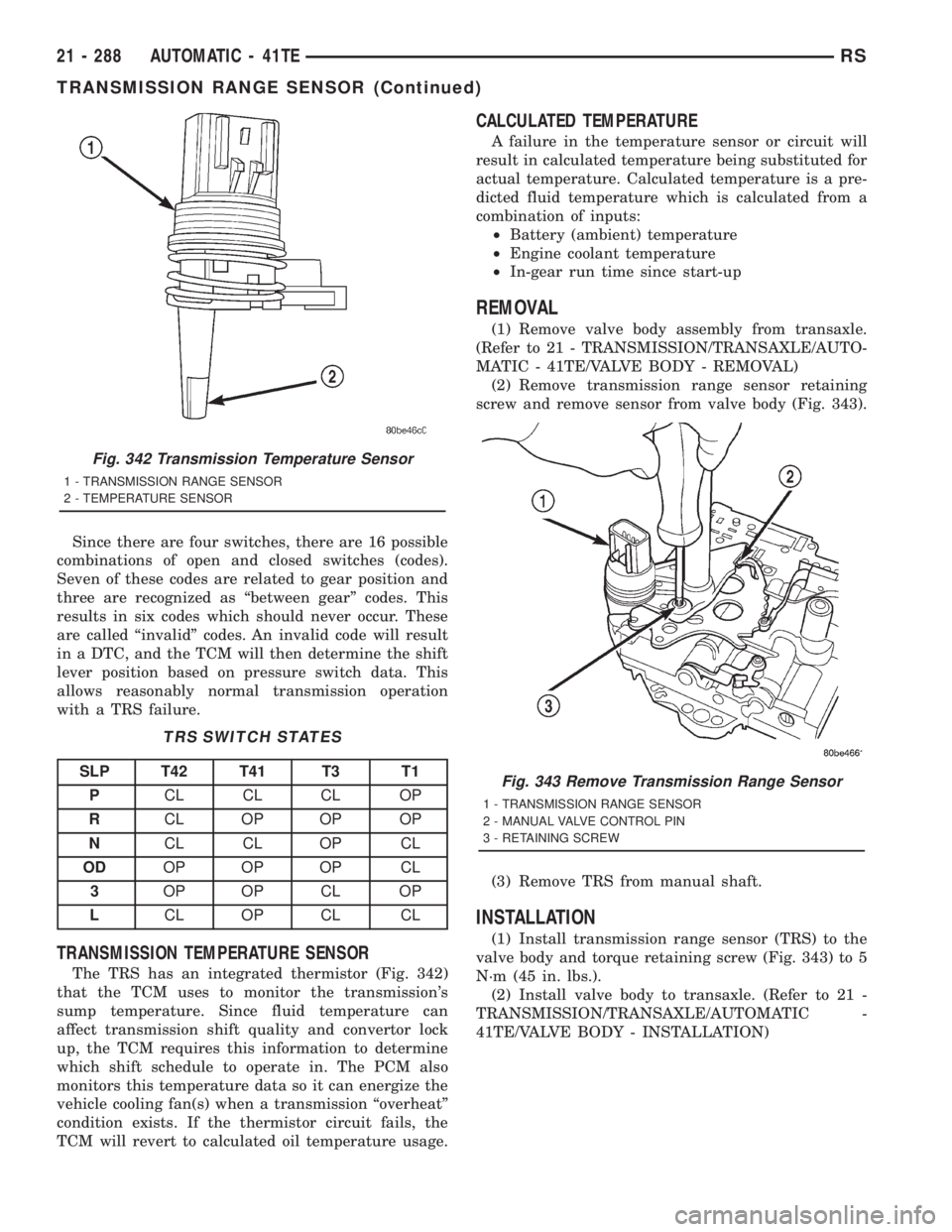

The TRS has an integrated thermistor (Fig. 342)

that the TCM uses to monitor the transmission's

sump temperature. Since fluid temperature can

affect transmission shift quality and convertor lock

up, the TCM requires this information to determine

which shift schedule to operate in. The PCM also

monitors this temperature data so it can energize the

vehicle cooling fan(s) when a transmission ªoverheatº

condition exists. If the thermistor circuit fails, the

TCM will revert to calculated oil temperature usage.

CALCULATED TEMPERATURE

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

REMOVAL

(1) Remove valve body assembly from transaxle.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 41TE/VALVE BODY - REMOVAL)

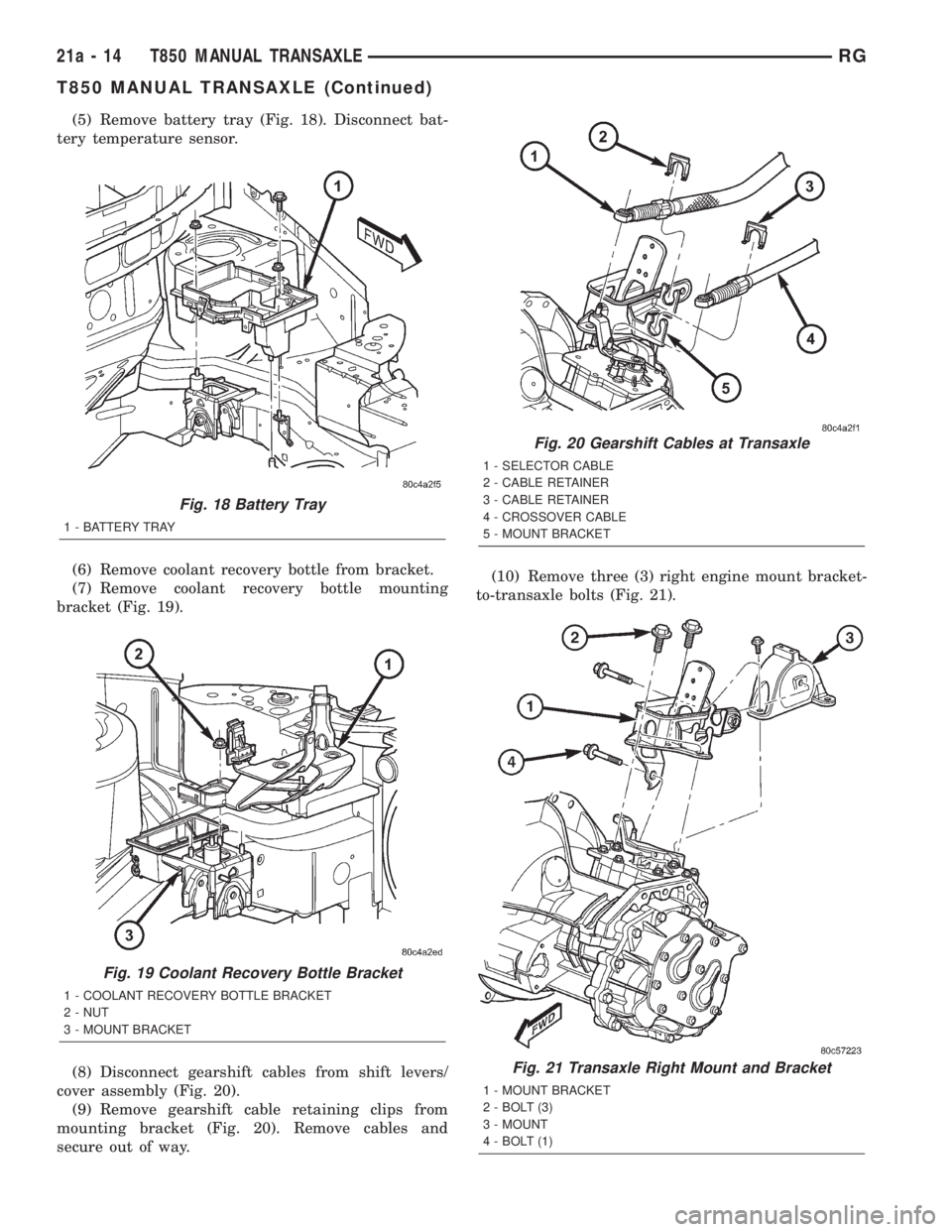

(2) Remove transmission range sensor retaining

screw and remove sensor from valve body (Fig. 343).

(3) Remove TRS from manual shaft.

INSTALLATION

(1) Install transmission range sensor (TRS) to the

valve body and torque retaining screw (Fig. 343) to 5

N´m (45 in. lbs.).

(2) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE/VALVE BODY - INSTALLATION)

Fig. 342 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

Fig. 343 Remove Transmission Range Sensor

1 - TRANSMISSION RANGE SENSOR

2 - MANUAL VALVE CONTROL PIN

3 - RETAINING SCREW

21 - 288 AUTOMATIC - 41TERS

TRANSMISSION RANGE SENSOR (Continued)

Page 3280 of 4284

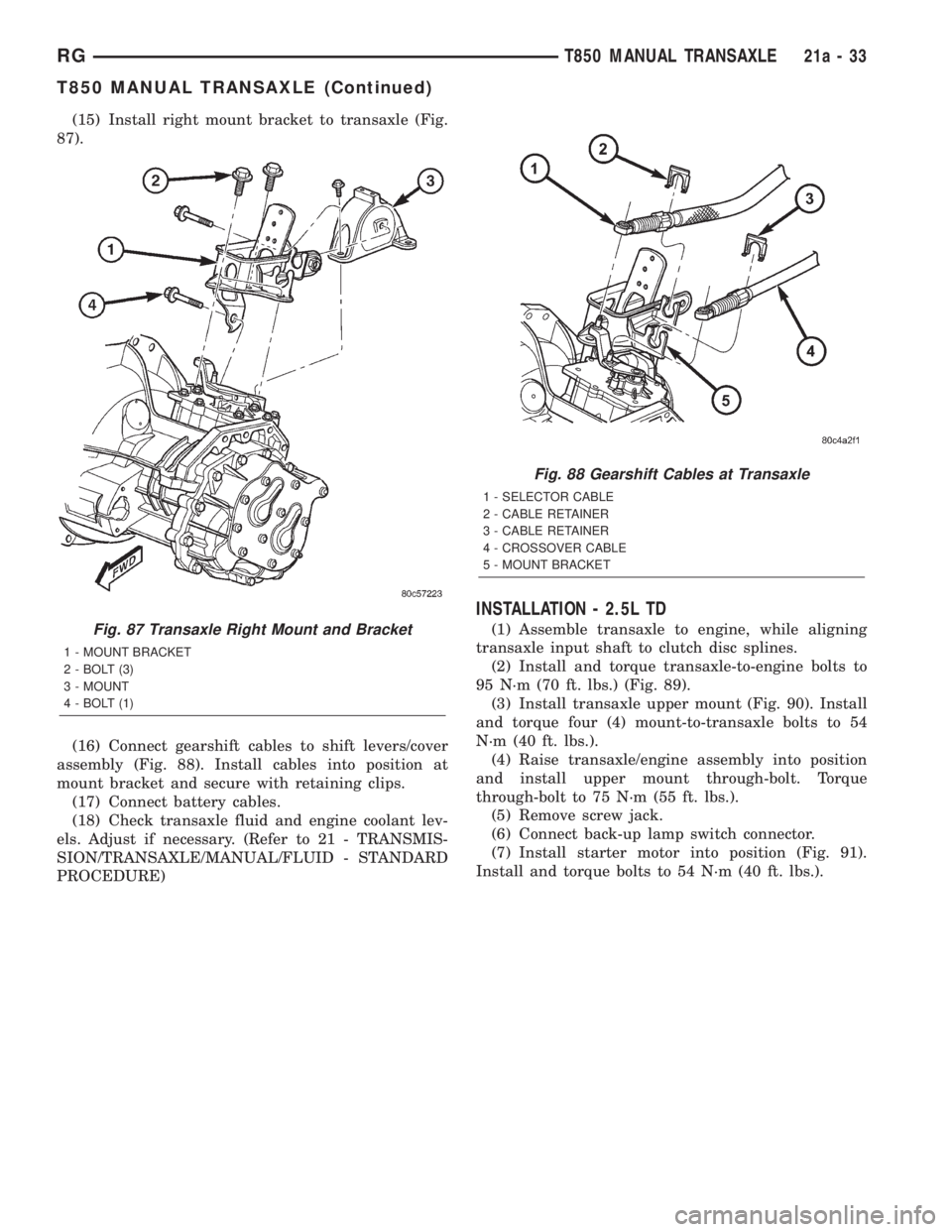

(5) Remove battery tray (Fig. 18). Disconnect bat-

tery temperature sensor.

(6) Remove coolant recovery bottle from bracket.

(7) Remove coolant recovery bottle mounting

bracket (Fig. 19).

(8) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 20).

(9) Remove gearshift cable retaining clips from

mounting bracket (Fig. 20). Remove cables and

secure out of way.(10) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 21).

Fig. 18 Battery Tray

1 - BATTERY TRAY

Fig. 19 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 20 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 21 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

21a - 14 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3299 of 4284

(15) Install right mount bracket to transaxle (Fig.

87).

(16) Connect gearshift cables to shift levers/cover

assembly (Fig. 88). Install cables into position at

mount bracket and secure with retaining clips.

(17) Connect battery cables.

(18) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

INSTALLATION - 2.5L TD

(1) Assemble transaxle to engine, while aligning

transaxle input shaft to clutch disc splines.

(2) Install and torque transaxle-to-engine bolts to

95 N´m (70 ft. lbs.) (Fig. 89).

(3) Install transaxle upper mount (Fig. 90). Install

and torque four (4) mount-to-transaxle bolts to 54

N´m (40 ft. lbs.).

(4) Raise transaxle/engine assembly into position

and install upper mount through-bolt. Torque

through-bolt to 75 N´m (55 ft. lbs.).

(5) Remove screw jack.

(6) Connect back-up lamp switch connector.

(7) Install starter motor into position (Fig. 91).

Install and torque bolts to 54 N´m (40 ft. lbs.).Fig. 87 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

Fig. 88 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

RGT850 MANUAL TRANSAXLE21a-33

T850 MANUAL TRANSAXLE (Continued)

Page 3302 of 4284

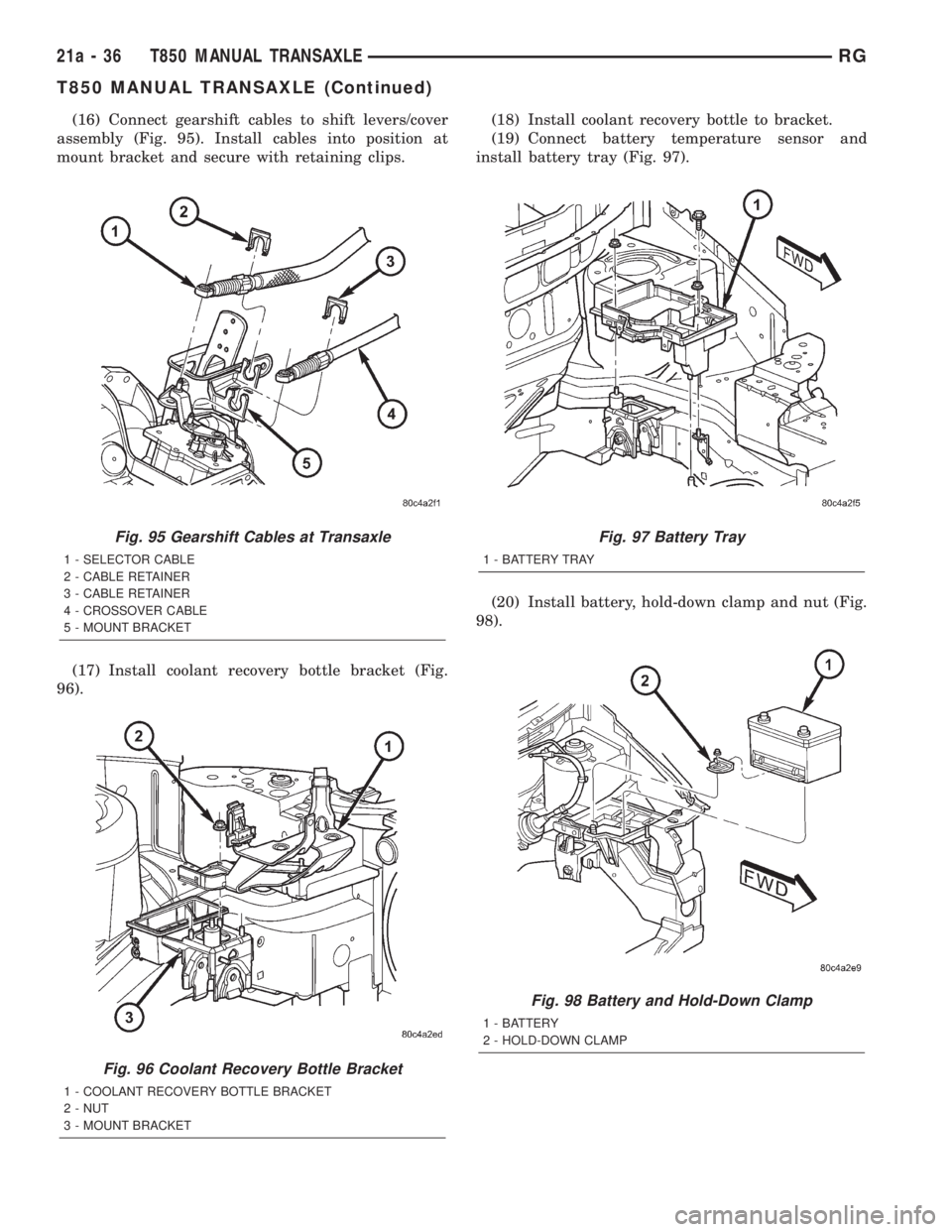

(16) Connect gearshift cables to shift levers/cover

assembly (Fig. 95). Install cables into position at

mount bracket and secure with retaining clips.

(17) Install coolant recovery bottle bracket (Fig.

96).(18) Install coolant recovery bottle to bracket.

(19) Connect battery temperature sensor and

install battery tray (Fig. 97).

(20) Install battery, hold-down clamp and nut (Fig.

98).

Fig. 95 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 96 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 97 Battery Tray

1 - BATTERY TRAY

Fig. 98 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

21a - 36 T850 MANUAL TRANSAXLERG

T850 MANUAL TRANSAXLE (Continued)

Page 3303 of 4284

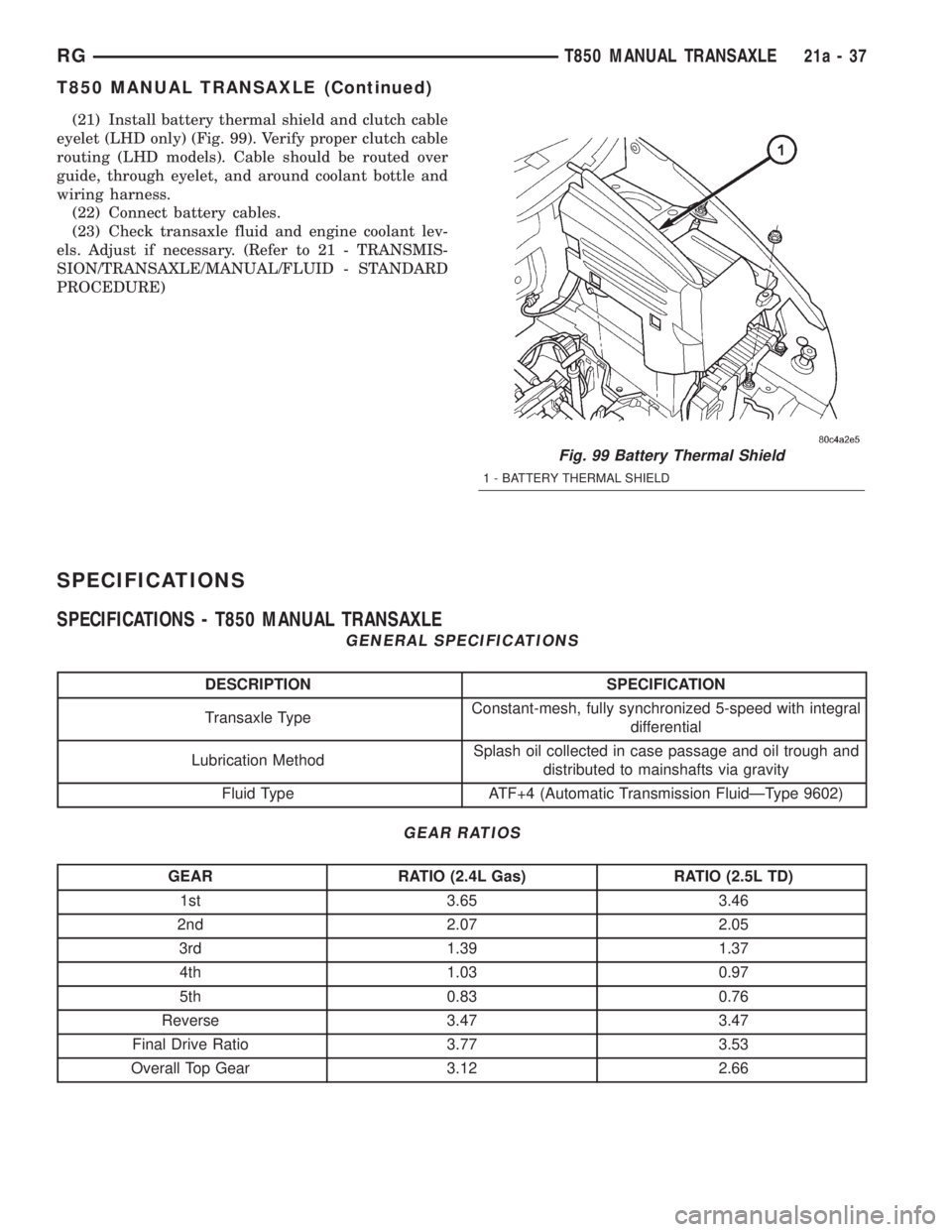

(21) Install battery thermal shield and clutch cable

eyelet (LHD only) (Fig. 99). Verify proper clutch cable

routing (LHD models). Cable should be routed over

guide, through eyelet, and around coolant bottle and

wiring harness.

(22) Connect battery cables.

(23) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

SPECIFICATIONS

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.46

2nd 2.07 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.53

Overall Top Gear 3.12 2.66

Fig. 99 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RGT850 MANUAL TRANSAXLE21a-37

T850 MANUAL TRANSAXLE (Continued)

Page 3321 of 4284

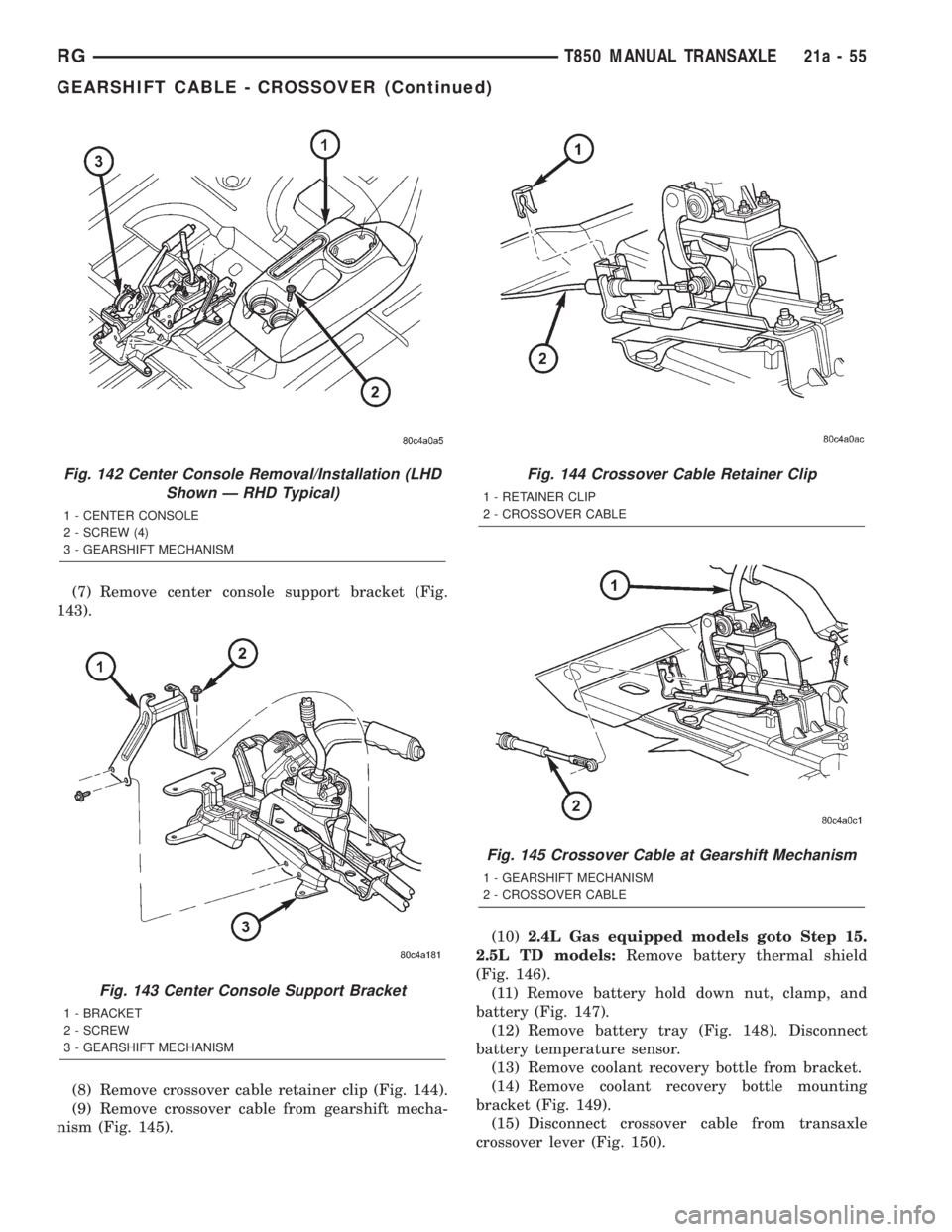

(7) Remove center console support bracket (Fig.

143).

(8) Remove crossover cable retainer clip (Fig. 144).

(9) Remove crossover cable from gearshift mecha-

nism (Fig. 145).(10)2.4L Gas equipped models goto Step 15.

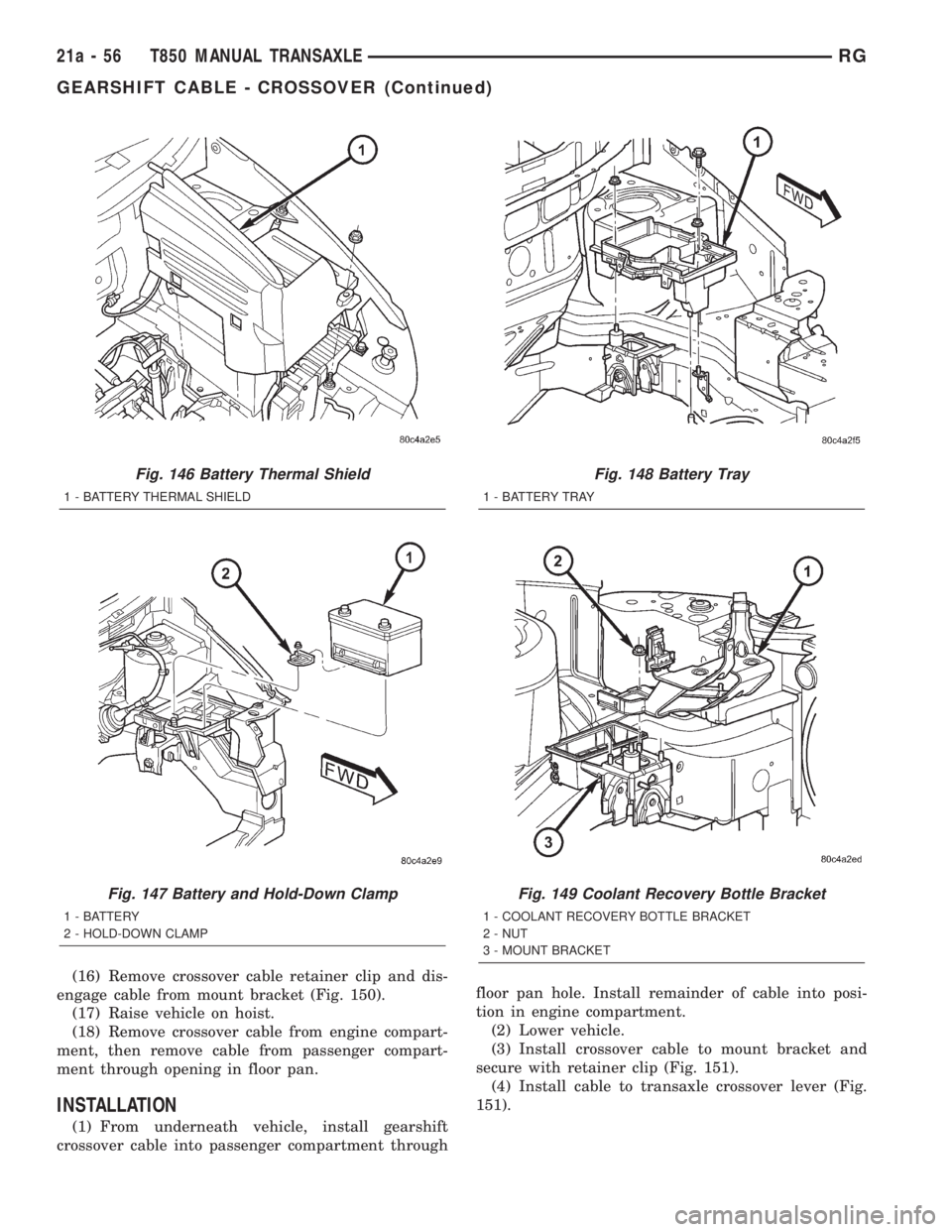

2.5L TD models:Remove battery thermal shield

(Fig. 146).

(11) Remove battery hold down nut, clamp, and

battery (Fig. 147).

(12) Remove battery tray (Fig. 148). Disconnect

battery temperature sensor.

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 149).

(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 150).

Fig. 142 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 143 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 144 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 145 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

RGT850 MANUAL TRANSAXLE21a-55

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3322 of 4284

(16) Remove crossover cable retainer clip and dis-

engage cable from mount bracket (Fig. 150).

(17) Raise vehicle on hoist.

(18) Remove crossover cable from engine compart-

ment, then remove cable from passenger compart-

ment through opening in floor pan.

INSTALLATION

(1) From underneath vehicle, install gearshift

crossover cable into passenger compartment throughfloor pan hole. Install remainder of cable into posi-

tion in engine compartment.

(2) Lower vehicle.

(3) Install crossover cable to mount bracket and

secure with retainer clip (Fig. 151).

(4) Install cable to transaxle crossover lever (Fig.

151).

Fig. 146 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 147 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

Fig. 148 Battery Tray

1 - BATTERY TRAY

Fig. 149 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

21a - 56 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3323 of 4284

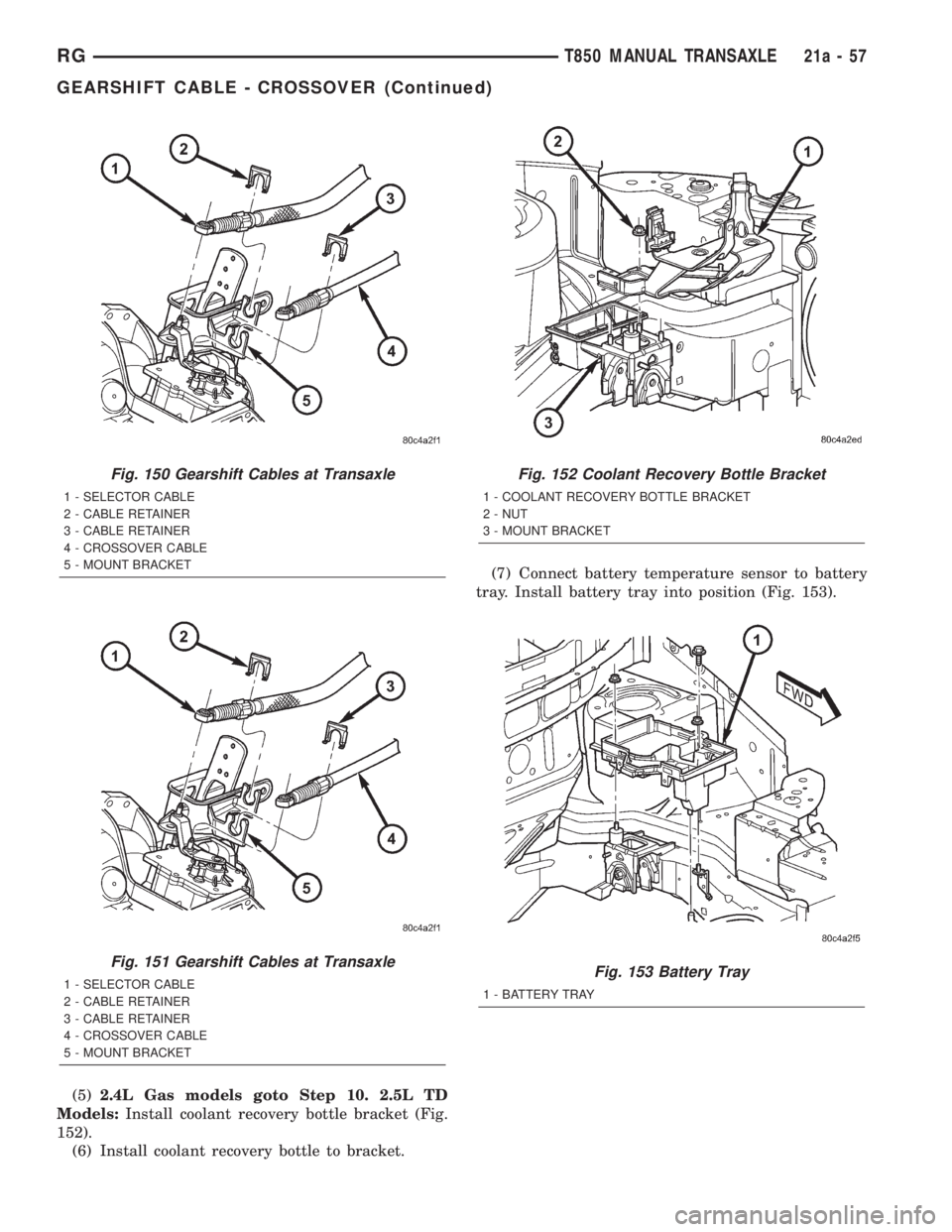

(5)2.4L Gas models goto Step 10. 2.5L TD

Models:Install coolant recovery bottle bracket (Fig.

152).

(6) Install coolant recovery bottle to bracket.(7) Connect battery temperature sensor to battery

tray. Install battery tray into position (Fig. 153).

Fig. 150 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 151 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 152 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 153 Battery Tray

1 - BATTERY TRAY

RGT850 MANUAL TRANSAXLE21a-57

GEARSHIFT CABLE - CROSSOVER (Continued)

Page 3329 of 4284

(8) Remove selector cable retainer clip (Fig. 173).

(9) Remove selector cable from gearshift mecha-

nism (Fig. 174).

(10)2.4L Gas models goto Step 15. 2.5L TD

Models:Remove battery thermal shield (Fig. 175).

(11) Remove battery hold down nut, clamp, and

battery (Fig. 176).

(12) Remove battery tray (Fig. 177). Disconnect

battery temperature sensor.

(13) Remove coolant recovery bottle from bracket.

(14) Remove coolant recovery bottle mounting

bracket (Fig. 178).(15) Disconnect crossover cable from transaxle

crossover lever (Fig. 179).

(16) Remove crossover cable retainer clip and dis-

engage cable from mount bracket (Fig. 179).

(17) Raise vehicle on hoist.

(18) Remove selector cable from engine compart-

ment, then remove cable from passenger compart-

ment through opening in floor pan.

Fig. 173 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 174 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 175 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

Fig. 176 Battery and Hold-Down Clamp

1 - BATTERY

2 - HOLD-DOWN CLAMP

RGT850 MANUAL TRANSAXLE21a-63

GEARSHIFT CABLE - SELECTOR (Continued)

Page 3330 of 4284

INSTALLATION

(1) From underneath vehicle, install gearshift

selector cable into passenger compartment through

floor pan hole. Install remainder of cable into posi-

tion in engine compartment.

(2) Lower vehicle.

(3) Install selector cable to mount bracket and

secure with retainer clip (Fig. 180).(4) Install cable to transaxle selector lever (Fig.

180).

Fig. 177 Battery Tray

1 - BATTERY TRAY

Fig. 178 Coolant Recovery Bottle Bracket

1 - COOLANT RECOVERY BOTTLE BRACKET

2 - NUT

3 - MOUNT BRACKET

Fig. 179 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

Fig. 180 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

21a - 64 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - SELECTOR (Continued)