relay CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 42 of 4284

3.7.6 EXTERIOR LIGHTING BATTERY

SAVER

The BCM monitors the status of, and controls, the

Park Lamps, Headlamps and Fog Lamp relays. If

any exterior lamps are left ON after the ignition is

turned OFF, the BCM will turn them OFF after 3

minutes.

3.7.7 AUTO HEADLAMPS

This feature is available on vehicles equipped

with both the Electrocromatic Mirror (ECM) and

the Compass/Mini-Trip Computer (CMTC). When

the BCM detects a day/night signal from the CMTC,

an ECM is present and Auto Headlamp mode is

selected.

3.8 FRONT CONTROL MODULE

The Front Control Module (FCM) is an electrical

control and interface center located in the engine

compartment. When it is mated to the Power Dis-

tribution Center (PDC), it is referred to as the

Intelligent Power Module (IPM). The IPM, with its

fuses and relays provides power and signal distri-

bution throughout most of the vehicle. The FCM

receives both hard wire and digital electronic inputs

from the vehicle electrical system through the PDC.

Based on these inputs and the ignition switch

position, it provides direct power feeds and relay

control to some of the vehicles' most critical electri-

cal systems.

The Front Control Module provides the following

features:

Controlled power feeds:

²Front airbag system

²Side airbag system

²Headlamp power

²EATX module power (4 speed only)

²Front washer motor

²Rear washer motor

²Brake shift interlock system

Relay controls:

²Fog lamp relay (when equipped)

²Park lamp relay

²Front wiper on relay

²Front wiper high/low relay

²Accessory relay

²Horn relay

²Front & rear blower relay

²Name brand speakers (NBS) relay

²Electronic back light (EBL) run only relay

²Cabin heater relayElectrical inputs:

²Headlamp battery supplies1&2

²Module battery supply

²Power ground

²Ignition switch RUN or START position status

²Ignition switch START only status

²PCI Bus

²Stop lamp switch

²Horn switch

²Back-up switch

²Wiper park switch

²Washer fluid level switch

²Brake fluid level switch

²Ambient temperature sensor

²Right park lamp outage

²Left park lamp outage

²Battery IOD

²Battery (+) connection detection

²Flash reprogramming voltage

3.8.1 CONTROLLED POWER FEEDS

Front airbag system

The FCM provides power to the Occupant Re-

straint Control (ORC) system through two ªfuse-

lessº circuits (ORC RUN/START, and ORC RUN

only). These circuits are electronically controlled

and continuously monitored for malfunctions.

Power is supplied while the ignition switch is in the

RUN and START positions on pin 48 of the FCM

connector, and in the RUN only position on pin 29.

Side airbag system

The FCM provides power to the Side Impact

Airbag Control Module (SIACM) system through

one ªfuselessº circuit. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. Power is supplied in the ignition RUN and

START positions on pin 28 of the FCM connector.

Headlamp power

The headlamp switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it of a headlamp switch status

change. The FCM then turns on power to the

headlamps through four ªfuselessº circuits. These

circuits are electronically controlled and continu-

ously monitored for malfunctions. Power is supplied

to each filament in a separate circuit (RH low on pin

6, RH high on pin 4, LH low on pin 3 and LH high

on pin 5). For vehicles equipped with Daytime

Running Lamps (DRL), the FCM electronically

steps down the headlamp voltage to provide the

desired illumination.

13

GENERAL INFORMATION

Page 43 of 4284

EATX power

The electronic automatic 4 speed transmission

module is powered when the ignition switch is in

the UNLOCK, RUN or START positions. This cir-

cuit is electronically controlled and continuously

monitored for malfunctions. Power is supplied

through pin 27 of the FCM connector.

Front washer motor

The front washer switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it of a request to wash. The front

washer motor is then powered through low side

control inside the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. In addition, the FCM electronically protects

the washer motor from system voltages higher than

16 volts by automatically switching off the low side

circuit. The low side circuit is connected to pin 45 in

the FCM connector.

Rear washer motor

The rear washer switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it of a request to wash. The rear

washer motor is then powered through low side

control inside the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. In addition, the FCM electronically protects

the washer motor from system voltages higher than

16 volts by automatically switching off the low side

circuit. The low side circuit is connected to pin 46 in

the FCM connector.

Brake shift interlock system

The brake shift interlock solenoid receives power

from both high side and low side controls inside the

FCM. The high side control is on the same circuit as

the EATX module power, and the low side control

comes through pin 47 of the FCM connector. The

solenoid is controlled by the low side driver when

the brake pedal is pressed. Both circuits are contin-

uously monitored for malfunctions.

3.8.2 RELAY CONTROLS

Fog lamp relay

The fog lamp switch is a direct input to the BCM.

The BCM sends a PCI Bus message to the FCM

informing it to turn on the fog lamp relay. The fog

lamp relay is then powered through low side control

on pin 33 of the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. Fog lamp functionality is not equipped on all

vehicles. The FCM ªlearnsº that the vehicle is

equipped with fog lamps by reading the BCM PCI

Bus message.

Park lamp relay

The park lamp switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it to turn on the park lamp relay.

The park lamp relay is then powered through lowside control on pin 13 of the FCM. This circuit is

electronically controlled and continuously moni-

tored for malfunctions.

Front wiper on relay

The front wiper switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it to turn on the front wiper on

relay. The front wiper on relay is then powered

through low side control on pin 14 of the FCM. This

circuit is electronically controlled and continuously

monitored for malfunctions.

Front wiper high/low relay

The front wiper switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it to turn on the front wiper high/

low relay. The relay switches power between the low

speed and high speed windings of the wiper motor.

The front wiper high/low relay is powered through

low side control on pin 34 of the FCM. This circuit is

electronically controlled and continuously moni-

tored for malfunctions.

Accessory relay

The accessory relay works in conjunction with the

FCM's power accessory delay feature to control the

operation of the radio, power windows, washer

motors, wiper motors and power outlet. The acces-

sory relay is turned on through low side control on

pin 35 of the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. Depending on the ignition switch position,

the accessory relay will remain on or will time-out

and turn off. The accessory relay remains on in the

RUN and ACCY positions of the ignition switch. In

the UNLK and OFF positions, the relay will remain

energized for 45 seconds then turn off. During this

time-out period, if the driver or passenger doors are

opened, the relay will turn off immediately. While

the ignition switch is in the START position, the

relay will also drop-out, then resume operation.

Accessory relay operation is most noticeable by

observing the operation of the radio or blower

functions.

Horn relay

The horn relay operates through a direct wire

input to the FCM from the horn switch (FCM pin

17) , or a PCI Bus message from the BCM. The relay

responds to the horn switch, remote door lock and

VTA alarm functions. The horn relay is powered

through low side control on pin 10 of the FCM.

Under normal operating conditions, if the horn is

pressed for longer than 30 seconds, the FCM will

automatically deactivate the horn to prevent dam-

age to it. The FCM will re-activate control of the

relay after a 25 second cool-down period. This

circuit is electronically controlled and continuously

monitored for malfunctions.

14

GENERAL INFORMATION

Page 44 of 4284

Front and rear blower relay

The blower control switch is part of the Automatic

Temperature Control (ATC) or A/C-Heater Control

Module, (Manual Temp). When the blower switch is

turned on, the ATC or A/C-Heater Control Module

sends a PCI Bus message to the FCM. The front and

rear blower relay is then powered through low side

control on pin 30 of the FCM. The relay provides the

high side to the blower motor, and the blower speed

is governed through low side control in the ATC or

A/C-Heater Control Module. This circuit is electron-

ically controlled and continuously monitored for

malfunctions.

Name Brand Speakers (NBS) relay

The NBS relay operates through the vehicle bus

interface between the radio and the FCM. When the

radio is turned on, the radio sends a PCI Bus

message to the FCM. The NBS relay is then pow-

ered on through low side control on pin 11 of the

FCM. The relay supplies power to the amplified

speaker, and ground is supplied through the radio.

This circuit is electronically controlled and contin-

uously monitored for malfunctions.

Electronic Back Light (EBL) relay

The rear defrost switch is part of the Automatic

Temperature Control or A/C-Heater Control Module

(Manual Temp). When the ignition switch is in the

RUN position and the rear defrost switch is turned

on, the ATC or A/C-Heater Control Module sends a

PCI Bus message to the FCM. The EBL run only

relay is then powered through low side control on

pin 31 of the FCM. The relay provides the high side

to the rear window defrost grid, and ground is

attached to the vehicle body. The FCM will only

allow the rear defrost to operate in the RUN posi-

tion. This circuit is electronically controlled and

continuously monitored for malfunctions.

Cabin Heater Relay

When the ignition is in Run, the FCM monitors

the PCI bus for the Cabin Heater Activation re-

quest. The A/C ± Heater Control Module initiates

this request only when all conditions for Cabin

Heater activation are favorable. The request carries

the status bit that the FCM requires to activate its

Cabin Heater Assist Control output. This output is

a low side driver (coming from FCM pin 15) which

supplies a ground signal to the Cabin Heater (pin

5). When the Cabin Heater receives this ground

signal input, it interprets this as an activation

signal. The FCM low side driver is also capable of

diagnostic sensing. The driver will sense an open

circuit when the driver is off, and will sense a short

to voltage when the driver is on. The FCM will set

DTCs for both of these types of faults. For addi-

tional information, refer to Cabin Heater under

General Information and Diagnostic Procedures in

the manual.3.8.3 ELECTRICAL INPUTS

Headlamp battery supplies1&2Ð12 volt

input on pins 1 and 2. Battery supply voltage for

switching headlamp circuits only.

Module battery supply Ð12 volt input on pin 9.

Battery supply voltage for all other FCM opera-

tions.

Power ground ÐGround source on pin 8 for all

FCM operations.

Ignition switch RUN or START position status

Ð12 volt input on pin 37. Allows the FCM to

determine the ignition switch status for related

FCM operations.

Ignition switch START only status Ð12 volt

input on pin 19. Allows the FCM to discriminate

between RUN/START input and START for related

FCM operations.

PCI Bus ÐApproximately 7.5 volt input on pin 22.

Allows the FCM to communicate with other mod-

ules on the vehicle bus.

Stop lamp Switch status Ð12 volt input on pin

44. Provides for brake shift interlock function.

Horn Switch ÐGround input on pin 17. Primary

means for engaging the horn.

Back-up switch ÐGround input on pin 39. Input

is converted to a PCI Bus status message for use by

other modules.

Wiper park switch ÐGround input on pin 16.

Used to determine park placement of wipers. Also

used as feedback to FCM to determine correct

operating mode of wipers.

Washer fluid level switch ÐGround input to

pull-up on pin 18. Ground is switched into the

circuit when washer bottle fluid level is low.

Brake fluid level switch ÐGround input to

pull-up on pin 36. Ground is switched into the

circuit when brake fluid level is low.

Ambient temperature sensor ÐResistive input

to pull-up on pin 25. Corresponding voltage level is

converted to a PCI Bus message for use by other

modules on the bus.

Right park lamp outage Ð12 volt input on pin

21. Used to determine if right park lamp circuit is

operating properly.

Left park lamp outage Ð12 volt input on pin 41.

Used to determine if left park lamp circuit is

operating properly.

Battery IOD Ð12 volt input on pin 20. The FCM

enters a low power consumption mode when the

ignition is turned OFF. This low current draw

battery supply keeps the microprocessor function-

ing in the low power mode.

Battery (+) connection detection Ð12 volt

input on pin 38. The battery connection on the PDC

incorporates the use of an internal switch to deter-

mine if the connector is properly mated and the

Connector Positive Assurance (CPA) is engaged. If

15

GENERAL INFORMATION

Page 45 of 4284

the CPA is not properly engaged, a voltage on pin 38

will be interpreted as an unseated connector and a

fault will set.

Flash programming voltage Ð20 volt input on

pin 42. When a DRBIIItis connected and the

proper flash reprogramming sequence is selected,

the 20 volt signal will be applied through pin 42.

3.9 HEATING & A/C

3.9.1 AUTOMATIC TEMPERATURE

CONTROL (ATC)

3.9.1.1 CABIN HEATER

For vehicles equipped with a diesel engine, a

Cabin Heater is used in conjunction with the HVAC

system. The Cabin Heater is designed to supply the

vehicle's occupants with heat prior to the engine

reaching operating temperature. For additional in-

formation on this system, refer to Cabin Heater

under General Information and Diagnostic Proce-

dures in this manual.

3.9.1.2 SYSTEM OPERATION

The Automatic Temperature Control (ATC) sys-

tem provides fully adjustable three zone climate

control; Driver front zone, Passenger Front zone

and Rear zone. The following is a list of ATC

controls and features:

± a POWER button which allows the operator to

turn the system completely off.

± AUTO HIGH/LOW switch allows the operator

to select what rate (fan speed) the system will

provide the selected comfort level.

± DRIVER, REAR and PASSENGER rocker

switches to select desired temperature for each

zone.

± Recirculation button allows cooling air to be

recirculated which maximizes cooling ability.

± A/C select button allows the operator to turn

the A/C compressor off.

± Defroster button allows the operator to turn on

the defroster independently during automatic

control.

± Fan control rotary switch for selecting fan

speed.

± Mode rotary switch for selecting heating/

cooling direction.

± REAR SYSTEM rotary switch for activating

the Rear ATC Switch allowing intermediate

passenger control over rear climate control.

3.9.1.3 BLOWER MOTOR OPERATION

The Automatic Temperature Control (ATC) front

and rear blower control provides continuously vari-

able control of air flow rate to meet occupant

comfort requirements. Pulse width modulation of

the blower motor power allows the front and rear

blower to operate at any speed from off to full speed.

When front or rear blower operation is required, the

ATC sends a PCI Bus message to the Front Control

Module (FCM) requesting blower relay ON. The

FCM provides a ground for the front and rear

blower motor relay coils, activating both relays. The

front and rear blower relays provide 12 volts to

their respective blower motor power modules. Each

module provides a 12 volt blower motor control

signal to the ATC. The ATC provides a pulse width

modulated (duty-cycle) ground signal to this circuit

based on climate requirements. The higher voltage

on the signal circuit (less duty-cycle ground) the

lower the blower speed request. The lower voltage

on the signal circuit (more duty-cycle ground) the

higher the blower speed request.

3.9.1.4 INFRARED SENSORS

The ATC system uses infrared (I/R) sensors to

monitor and control oocupant comfort levels. This

sensing system replaces interior air temperature

and solar sensors which required complex control

programs to maintain occupant comfort levels. The

front I/R sensor is located in the instrument panel

center bezel outlet. The rear I/R sensor is located in

the rear overhead mounted ATC switch.

3.9.1.5 REAR ATC SWITCH

The rear ATC switch is mounted in the headliner.

The switch contains a rotary adjustment for fan

speed, a rotary adjustment for mode selection, a

push button switch for temperature selection and a

digital display of the selected temperature.

3.9.1.6 COOLDOWN TESTING

The ATC provides a feature referred to as a

Cooldown Test. This test is initiated using the

DRBIIItand is designed to check the performance

of the air conditioning system. The ATC will not

perform this test if the ambient air temperature is

below 12ÉC (53ÉF). During the test, the ATC com-

pares the ambient air temperature to the evapora-

tor temperature sensor. To pass the cooldown test,

the evap temperature sensor must drop -6ÉC (20ÉF)

below ambient temperature within 2 minutes of

start of test. At the completion of the cooldown test

the DRBIIItwill display one of the following mes-

sages indicating test outcome:

± Cooldown Test Passed

± Cooldown Test Failed

16

GENERAL INFORMATION

Page 47 of 4284

3.9.2.8 HVAC SYSTEM RELAYS

The Integrated Power Module (IPM) houses and

provides power to the A/C Clutch Relay and Front

Blower Motor Relay.

3.9.2.9 EVAPORATOR TEMPERATURE

SENSOR

An evaporator temperature sensor, located on the

A/C expansion valve under the hood, replaces the

previously used fin sensor.

3.9.2.10 A/C ± HEATER CONTROL

MODULE, SWITCH OPERATION

Power Switch

The Power Switch is a momentary contact switch.

The switch LED illuminates when the switch is on.

The Power Switch setting is remembered during

power down.

Rear Window Defogger Switch

The Rear Window Defogger Switch is a momen-

tary contact switch. Toggling the switch results in

the A/C ± Heater Control Module sending a change

of state message to the FCM to provide rear window

defogger activation or deactivation respectively.

The switch LED illuminates when the switch is on.

Recirculation Switch

The Recirculation Switch is a momentary contact

switch. Toggling the switch on results in the A/C ±

Heater Control Module signaling the actuator to

close the fresh-air door. Toggling the switch off

results in the A/C ± Heater Control Module signal-

ing the actuator to open the fresh-air door. The

switch LED illuminates when the switch is on.

When the Power Switch is off, the A/C ± Heater

Control Module closes the fresh-air door to prevent

outside air from entering the passenger compart-

ment. The recirculation mode will cancel whenever

defrost is requested. Pressing the Recirculation

Switch while in defrost mode will illuminate the

Recirculation Switch LED, but only while the but-

ton is pressed. Under this circumstance, the recir-

culation request will be denied and the fresh-air

door will remain in the fresh position. All door

positions are determined relative to the number of

commutator pulses required to provide full travel of

the door. On command, the A/C ± Heater Control

Module runs the actuator for the number of pulses

corresponding to the desired door position.

A/C Switch

The A/C Switch is a momentary contact switch.

Toggling the switch results in the A/C ± Heater

Control Module sending a change of state message

to the Powertrain Control Module (PCM ± gasoline)or Engine Control Module (ECM ± diesel) to provide

A/C compressor clutch activation or deactivation

respectively. The A/C ± Heater Control Module will

only provide this request if EVAP function is found

acceptable. The Power Switch must be on to make

the A/C switch active. The switch LED illuminates

when the switch is on. The A/C Switch setting is

remembered during power down.

Blower Switch

The rotary Blower Switch has five positions, Low,

M1, M2, M3, and High. The Power Switch must be

on to make the Blower Switch active. Toggling the

Power Switch results in the A/C ± Heater Control

Module sending a request to the FCM to provide

blower motor activation or deactivation respec-

tively.

Blend Switch ± Single Zone

The single rotary Blend Switch has multiple

detents to control the full range of temperature that

the system can produce in any mode. Rotating the

switch results in the A/C ± Heater Control Module

signaling the actuator to move the blend door. All

door positions are determined relative to the num-

ber of commutator pulses required to provide full

travel of the door. On command, the A/C ± Heater

Control Module runs the actuator for the number of

pulses corresponding to the desired door position.

Blend Switch ± Dual Zone

The dual sliding Blend Switches have multiple

detents to control the full range of temperature that

the system can produce an any mode. The upper

slide pot controls the driver-side blend door, while

the lower slide pot controls the passenger-side

blend door. Sliding the switch results in the A/C ±

Heater Control Module signaling the actuator to

move the blend door. All door positions are deter-

mined relative to the number of commutator pulses

required to provide full travel of the door. On

command, the A/C ± Heater Control Module runs

the actuator for the number of pulses corresponding

to the desired door position.

Mode Switch

The single rotary Mode Switch has 13 detents to

either direct airflow to the panel outlets, a mix of

floor and panel outlets, floor outlets, a mix of floor

and defrost outlets, or defrost outlets. Rotating the

switch results in the A/C ± Heater Control Module

signaling the actuator to move the mode door. All

door positions are determined relative to the num-

ber of commutator pulses required to provide full

travel of the door. On command, the A/C ± Heater

Control Module runs the actuator for the number of

pulses corresponding to the desired door position.

18

GENERAL INFORMATION

Page 54 of 4284

opening either front door, the Body Control Module

will unfold the mirrors in the following manner

depending on which front door is opened. If the

driver door is opened, only the driver side mirror

will unfold. If the passenger door is opened, both

mirrors will unfold. The passenger mirror is pre-

vented from unfolding when the driver 's door is

opened by the Passenger Folding Mirror Relay,

which opens the driver circuit to the passenger side

mirror.

3.17 POWER LIFTGATE SYSTEM

3.17.1 POWER LIFTGATE

The power liftgate (PLG) system is activated

through the use of the following: remote keyless

entry (RKE), overhead console switches, outside

liftgate handle switch or the DRBIIIt. These inputs

are hardwired to the body control module (BCM)

and can be monitored with a diagnostic tool. The

BCM will send the message via PCI bus to the

power liftgate module (PLGM). The liftgate must be

in the full open or full closed position to operate.

Once the BCM sends a button activation message to

the PLGM, the module shall read all inputs, out-

puts and vehicle conditions to determine whether it

shall open, close or inhibit the PLG operation. Once

the PLGM determines the vehicle conditions are

safe for operation, the PLGM will initiate a chime

for 2 seconds prior to the liftgate activation and 2

seconds during the open or close cycle.

During an opening or closing cycle, the PLGM can

detect an obstacle present should it meet sufficient

resistance by the hall effect sensors (integrated in

the gear motor assembly GMA).

During an open cycle, multiple liftgate activa-

tions (RKE, overhead console, B pillar) are ignored

until the liftgate reaches the full open position.

However, during a close cycle, a 2nd liftgate activa-

tion (RKE, overhead console, B pillar) will reverse

the liftgate to the full open position.

If the engine is cranked during a power open/close

the PLG will pause then resume after engine crank-

ing. In addition, if the vehicle is placed in gear

during an open cycle, the PLG shall reverse direc-

tion and begin closing. If the vehicle is placed in

gear during a closing cycle, the PLG shall continue

closing until fully closed. If the outside handle is

activated during an open cycle, the PLG will become

a full manual liftgate. If the outside handle is

activated during a close cycle, the PLG shall reverse

direction of travel to the full open position.

3.17.2 DIAGNOSTIC FEATURES

The PLG can be flashed on vehicle via PCI bus

with a DRBIIItdiagnostic tool. The DRBIIItcanread all inputs, actuate all outputs, read module

information, and read diagnostic trouble codes. As a

reminder, some DTC's can be set during normal

PLG operation.

3.17.3 SYSTEM INHIBITORS

1. Battery voltage too high or too low (above 16V,

below 9.5V)

2. Vehicle in gear

3. Vehicle speed > 0 mph/km/h

4. Outside temperature too high, above 143ÉF

(62ÉC) or too low, below -12ÉF (-24ÉC).

5. O/H console lockout will inhibit the B pillar

switches only.

6. Liftgate locked will inhibit all interior switches

from opening (overhead console). A locked lift-

gate can be power closed.

7. Pinch Sensor switch stuck shall inhibit the

power close feature.

3.18 POWER SLIDING DOOR SYSTEM

3.18.1 POWER SLIDING DOOR

The Power Sliding Door (PSD) system is acti-

vated through the use of the following: Remote

Keyless Entry (RKE), overhead console switches, B

pillar switches or the DRBIIIt. These inputs are

hardwired to the body control module (BCM) and

can be monitored with a diagnostic tool. The BCM

will send the message via PCI bus to the power

sliding door module (PSDM). The sliding door must

be in the full open or full closed position to operate.

Once the BCM sends a button activation message to

the PSDM, the module shall read all inputs, out-

puts and vehicle conditions to determine whether it

shall open, close or inhibit the PSD operation.

During an opening or closing cycle, the PSDM can

detect an obstacle present should it meet sufficient

resistance by the hall effect sensors (integrated in

the drive motor).

During an open cycle, multiple door activations

(RKE, overhead console, B pillar) are ignored until

the door reaches the full open position. However,

during a close cycle, a 2nd door activation (RKE,

overhead console, B pillar) will reverse the door to

the full open position.

If the engine is cranked during a power open/close

the PSD will pause then resume after engine crank-

ing. In addition, if the vehicle is placed in gear

during an open cycle, the PSD shall reverse direc-

tion and begin closing. If the vehicle is placed in

gear during a closing cycle, the PSD shall continue

closing until fully closed.

If the inside or outside handle is activated during

an open or close cycle, the PSD will become a full

25

GENERAL INFORMATION

Page 55 of 4284

manual sliding door. When the child lock out switch

is on, the B pillar switches are disabled.

There is only one part number for the power

sliding door module (PSDM). The driver sliding

door harness has an additional ground circuit which

will identify it as the driver side. This eliminates

the need for a left and a right side module.

3.18.2 DIAGNOSTIC FEATURES

The PSDM can be flashed on vehicle via PCI bus

with a DRBIIItdiagnostic tool. The DRBIIItcan

read all inputs, actuate all outputs, read module

information, and read diagnostic trouble codes. As a

reminder, some DTC's can be set during normal

PSD operation.

3.18.3 SYSTEM INHIBITORS

1. Battery voltage too high or too low (above 16V,

below 9.5V)

2. Vehicle in gear

3. Vehicle speed > 0 mph/km/h

4. Child locks enabled inhibit the B pillar switch

operation

5. O/H console lockout will inhibit the B pillar

switches

6. Doors locked will inhibit all interior switches

from opening (Overhead Console, B Pillar). A

locked sliding door can be power closed.

3.19 REAR WINDOW DEFOG/HEATED

MIRROR/FRONT WIPER DE-ICE

The defroster button located on the HVAC control

controls the rear window defogger, heated side view

mirrors and front wiper de-icer grid. In addition the

front wiper de-ice function is turned on when front

defog/defrost mode is selected.

When the defroster button is pushed, the HVAC

control sends a bus message over the PCI bus to the

Front Control Module (FCM) which controls the

Rear Window Defogger relay. The defroster LED

will illuminate when the defroster function is on.

The defroster will function for 10 minutes or can be

cycled off sooner by pressing the defroster button

again. The front wiper de-icer grid receives its 12

volts from the accessory relay through fuse 11 and

the HVAC control module supplies the grid ground.

3.20 VEHICLE THEFT SECURITY SYSTEM

3.20.1 BASE ALARM SYSTEM

The Vehicle Theft Security System (VTSS) is part

of the Body Control Module (BCM). The BCM

monitors the vehicle doors, liftgate, hood, and theignition for unauthorized operation. The alarm ac-

tivates by sounding the horn, flashing the head-

lamps and the VTSS indicator lamp. The VTSS does

not prevent engine operation, this is done with the

Sentry Key Immobilizer Module (SKIM). Passive

arming occurs in one of two ways. Upon normal

vehicle exit by removing the ignition key, opening

the driver door, locking the doors with the power

lock, and closing the driver door, or by removing the

ignition key, opening the driver door, closing the

driver door, and locking the doors with the Remote

Keyless Entry (RKE) transmitter. The VTSS indi-

cator lamp will flash for approximately 15 seconds

during the arming process. If there is no interrup-

tion during the arming process, upon completion

the VTSS indicator lamp will flash at a slower rate.

When the BCM receives an input to trigger the

alarm, the BCM will control the outputs of the

headlamps, horn, and VTSS lamp for approxi-

mately 18 minutes.

Arming (Active and Passive)

Active arming occurs when the RKE transmitter

is used to lock the vehicle doors, whether the doors

are open or closed. The arming process is complete

only after all doors are closed.

Passive arming occurs when the ignition key is

removed, the driver door is opened, and the doors

are locked with the power door lock switch, and the

door is closed.

Disarming (Active and Passive)

Active disarming occurs when the RKE transmit-

ter is used to unlock the vehicle doors. This disarm-

ing will also halt the alarm once it has been acti-

vated.

Passive disarming occurs upon normal vehicle

entry (unlocking driver door with the key). This

disarming will also halt the alarm once it has been

activated.

Tamper Alert

The VTSS tamper alert will sound the horn three

times upon disarming to indicate a tamper condi-

tion has occurred.

Manual Override

The system will not arm if the doors are locked

using the manual lock control or if the locks are

actuated by an inside occupant after the doors are

closed.

Diagnosis

For complaints about the Vehicle Theft Alarm

triggering on its own, use the DRBIIItand read the

Last VTSS Cause status.

26

GENERAL INFORMATION

Page 56 of 4284

NOTE: A POWERTRAIN CONTROL MODULE

FROM A VEHICLE EQUIPPED WITH A

VEHICLE THEFT SECURITY SYSTEM

CANNOT BE USED IN A VEHICLE THAT IS

NOT EQUIPPED WITH A VEHICLE THEFT

SECURITY SYSTEM IF THE VTSS INDICATOR

LAMP COMES ON AFTER IGNITION ON AND

STAYS ON, THE PCI BUS COMMUNICATION

WITH THE POWERTRAIN CONTROL

MODULE HAS POSSIBLY BEEN LOST.

3.20.2 THATCHAM ALARM SYSTEM

The Thatcham Alarm Module monitors the vehi-

cle doors, liftgate, hood and the interior of the

vehicle for unauthorized operation. The vehicle

doors, liftgate, and hood use ajar switches as inputs

to the BCM to indicate their current status. The

interior of the vehicle is secured by the use of

Intrusion Sensors. The Intrusion Sensors are used

as inputs to the RKE/Thatcham Alarm Module to

report any motion in the interior of the vehicle. The

alarm activates by sounding the siren, flashing the

hazard lamps, and the VTSS Indicator Lamp.

Arming

Before arming, all doors, liftgate, and the hood

must be completely closed. The system can then be

armed by following a normal exit sequence, of

opening the door and then locking the doors with

the door lock switch and then closing the door. The

system can also be armed by opening the door,

closing the door and then locking the doors with the

RKE transmitter.

Disarming

To disarm the alarm system, the RKE transmit-

ter is used. The RKE transmitter will unlock the

vehicle doors and disarm the alarm system. The

RKE transmitter can also be used to halt the alarm

once it has been activated.

3.21 WIPER SYSTEM

3.21.1 FRONT WIPER

The front wiper/washer system consists of the

following features: lo-hi-speed, mist wipers, inter-

mittent wipers and wipe after wash. The front

wiper system is only active when the ignition switch

is in the RUN/ACC position. The vehicle operator

selects the front wiper function using the front

wiper switch (a resistive multiplexed stalk switch)

which is integral to the Multi-Function Switch. The

front wiper switch is hardwired to the Body Control

Module (BCM). Upon receiving a wiper switch sig-

nal, the BCM sends a PCI Bus message to the Front

Control Module (FCM). The FCM controls the ON/OFF relay, the HIGH/LOW relay and the front and

rear washer pump motors.

The Wiper system utilizes the BCM to control the

on/off and hi/low relays for the low and hi speed

wiper functions, intermittent wiper delay as the

switch position changes, pulse wipe, wipe after

wash mode and wiper motor functions. The BCM

uses the vehicle speed input to double the usual

delay time below 10 MPH (6 KPH).

3.21.2 SPEED SENSITIVE INTERMITTENT

WIPE MODE

There are 5 individual delay time settings with a

minimum delay of 1.7 seconds to a maximum of 18.4

seconds. When the vehicle speed is under 10 MPH

(6 KPM), the delay time is doubled, providing a

delay range of 3.4 seconds to 36.8 seconds.

3.21.3 PULSE WIPE

When the wiper is in the off position and the

driver presses the wash button for more than .062

seconds, but less than .5 seconds, 2 wipe cycles in

low speed mode will be provided.

3.21.4 PARK AFTER IGNITION OFF

Because the wiper relays are powered from the

battery, the BCM can run the wipers to park after

the ignition is turned off.

3.21.5 WIPE AFTER WASH

When the driver presses the wash button for over

.5 seconds and releases it, the wiper will continue to

run for 2 additional wipe cycles.

3.21.6 REAR WIPER

The rear wiper/washer system consists of the

following features: mist wipers, intermittent wipers

and wipe after wash. The rear wiper system is only

active when the ignition switch is in the RUN/ACC

position. The vehicle operator selects the rear wiper

function using one of the three buttons on the dash

mounted rear wiper switch. The rear wiper switch

is hardwired to the Body Control Module (BCM).

Upon receiving a wiper switch signal, the BCM

provides 12 volts to the rear wiper motor. Rear

washer occurs when the BCM receives a rear

washer switch ON input. The BCM sends a PCI Bus

message to the FCM requesting rear washer on.

The FCM activates the rear washer by providing a

ground for the rear washer motor.

3.21.7 SPEED SENSITIVE INTERMITTENT

WIPE MODE

The delay setting of the rear wiper system is

based solely on the vehicle speed. The delay time is

27

GENERAL INFORMATION

Page 236 of 4284

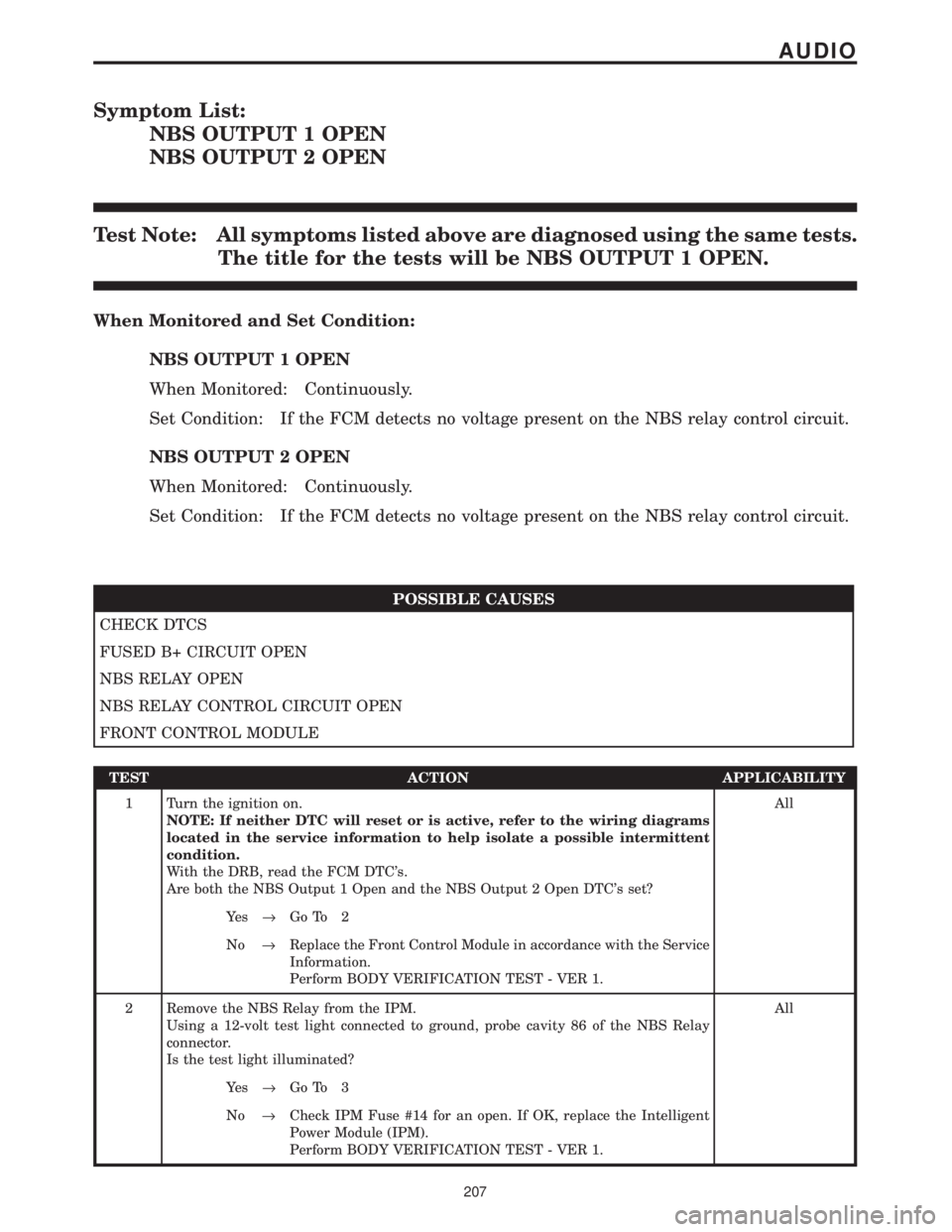

Symptom List:

NBS OUTPUT 1 OPEN

NBS OUTPUT 2 OPEN

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be NBS OUTPUT 1 OPEN.

When Monitored and Set Condition:

NBS OUTPUT 1 OPEN

When Monitored: Continuously.

Set Condition: If the FCM detects no voltage present on the NBS relay control circuit.

NBS OUTPUT 2 OPEN

When Monitored: Continuously.

Set Condition: If the FCM detects no voltage present on the NBS relay control circuit.

POSSIBLE CAUSES

CHECK DTCS

FUSED B+ CIRCUIT OPEN

NBS RELAY OPEN

NBS RELAY CONTROL CIRCUIT OPEN

FRONT CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

NOTE: If neither DTC will reset or is active, refer to the wiring diagrams

located in the service information to help isolate a possible intermittent

condition.

With the DRB, read the FCM DTC's.

Are both the NBS Output 1 Open and the NBS Output 2 Open DTC's set?All

Ye s®Go To 2

No®Replace the Front Control Module in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

2 Remove the NBS Relay from the IPM.

Using a 12-volt test light connected to ground, probe cavity 86 of the NBS Relay

connector.

Is the test light illuminated?All

Ye s®Go To 3

No®Check IPM Fuse #14 for an open. If OK, replace the Intelligent

Power Module (IPM).

Perform BODY VERIFICATION TEST - VER 1.

207

AUDIO

Page 237 of 4284

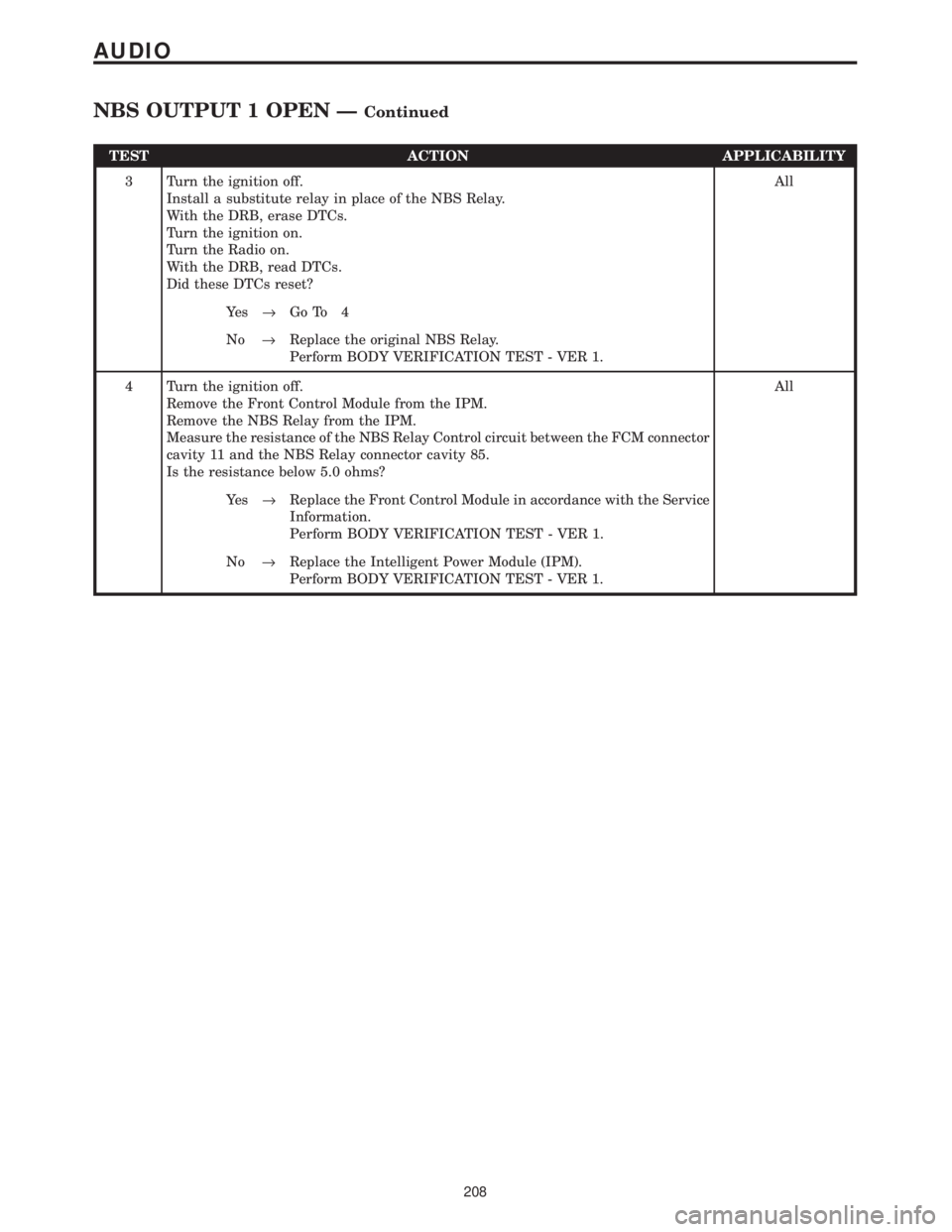

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Install a substitute relay in place of the NBS Relay.

With the DRB, erase DTCs.

Turn the ignition on.

Turn the Radio on.

With the DRB, read DTCs.

Did these DTCs reset?All

Ye s®Go To 4

No®Replace the original NBS Relay.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Remove the Front Control Module from the IPM.

Remove the NBS Relay from the IPM.

Measure the resistance of the NBS Relay Control circuit between the FCM connector

cavity 11 and the NBS Relay connector cavity 85.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Front Control Module in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Intelligent Power Module (IPM).

Perform BODY VERIFICATION TEST - VER 1.

208

AUDIO

NBS OUTPUT 1 OPEN ÐContinued