timing belt CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1797 of 4284

REMOVAL - WATER PUMP HOUSING

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove both outer and inner timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Disconnect water pump housing to thermostat

housing bypass hose (Fig. 16).

(5) Remove the water pump housing retaining

nuts (Fig. 17).

(6) Remove water pump housing from engine block

(Fig. 17).

CLEANING

Clean gasket mating surfaces as necessary.

INSTALLATION - WATER PUMP

(1) Clean gasket mating surfaces as necessary.

(2) Place water pump and gasket in place. Install

water pump retaining bolts (Fig. 15). Torque bolts to

24.4N´m.

(3) Install both inner and outer timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION).

(4) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).(5) Connect negative battery cable.

INSTALLATION - WATER PUMP HOUSING

(1) Clean mating serfaces of water pump housing

and engine block as necessary.

(2) Place new o-ring in groove in water pump

housing (Fig. 18).

(3) Be sure lower radiator hose tube o-ring is in

place.

(4) Install water pump housing on lower radiator

hose tube and push on mounting studs (Fig. 17).

Torque retaining nuts to 24.4N´m.

(5) Connect water pump housing to thermostat

housing bypass hose (Fig. 16).

(6) Install both inner and outer timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION).

(7) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(8) Connect negative battery cable.

Fig. 15 WATER PUMP LOCATION

1 - CYLINDER HEAD

2 - ENGINE BLOCK

3 - OIL COOLER

4 - OIL FILTER HOUSING

5 - WATER PUMP

Fig. 16 THERMOSTAT HOUSING LOCATION

1 - CYLINDER HEAD COVER

2 - THERMOSTAT HOUSING

3 - AIR BLEED

4 - WATER PUMP

5 - WATER PUMP HOUSING TO THERMOSTAT HOUSING

BYPASS HOSE

6 - E G R VA LV E

RGENGINE7a-23

WATER PUMP (Continued)

Page 1840 of 4284

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P1292 CNG Pressure Sensor Voltage Too

HighCompressed natural gas pressure sensor reading above

acceptable voltage.

P1293 CNG Pressure Sensor Voltage Too

LowCompressed natural gas pressure sensor reading below

acceptable voltage.

P1294 (M) Target Idle Not Reached Target RPM not achieved during drive idle condition.

Possible vacuum leak or IAC (AIS) lost steps.

P1295 No 5 Volts to TP Sensor Loss of a 5 volt feed to the Throttle Position Sensor has

been detected.

P1296 No 5 Volts to MAP Sensor Loss of a 5 volt feed to the MAP Sensor has been detected.

P1297 (M) No Change in MAP From Start To

RunNo difference is recognized between the MAP reading at

engine idle and the stored barometric pressure reading.

P1298 Lean Operation at Wide Open

ThrottleA prolonged lean condition is detected during Wide Open

Throttle.

P1299 (M) Vacuum Leak Found (IAC Fully

Seated)MAP Sensor signal does not correlate to Throttle Position

Sensor signal. Possible vacuum leak.

P1388 Auto Shutdown Relay Control Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P1389 No ASD Relay Output Voltage At

PCMNo Z1 or Z2 voltage sensed when the auto shutdown relay

is energized.

P1390 (M) Timing Belt Skipped 1 Tooth or More Relationship between Cam and Crank signals not correct.

P1391 (M) Intermittent Loss of CMP or CKP Loss of the Cam Position Sensor or Crank Position sensor

has occurred. For PL 2.0L

P1398 (M) Mis-Fire Adaptive Numerator at Limit PCM is unable to learn the Crank Sensor's signal in

preparation for Misfire Diagnostics. Probable defective Crank

Sensor.

P1399 Wait To Start Lamp Cicuit An open or shorted condition detected in the Wait to Start

Lamp circuit.

P1403 No 5 Volts to EGR Sensor Loss of 5v feed to the EGR position sensor.

P1476 Too Little Secondary Air Insufficient flow of secondary air injection detected during

aspirator test.(was P0411)

P1477 Too Much Secondary Air Excessive flow of secondary air injection detected during

aspirator test (was P0411).

P1478 (M) Battery Temp Sensor Volts Out of

LimitInternal temperature sensor input voltage out of an

acceptable range.

P1479 Transmission Fan Relay Circuit An open or shorted condition detected in the transmission

fan relay circuit.

P1480 PCV Solenoid Circuit An open or shorted condition detected in the PCV solenoid

circuit.

P1482 Catalyst Temperature Sensor Circuit

Shorted LowCatalyst temperature sensor circuit shorted low.

P1483 Catalyst Temperature Sensor Circuit

Shorted High.Catalyst temperature sensor circuit shorted high.

P1484 Catalytic Converter Overheat

DetectedA catalyst overheat condition has been detected by the

catalyst temperature sensor.

8E - 16 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

Page 2626 of 4284

CLEANING..............................35

INSPECTION............................35

CONNECTING ROD BEARINGS

STANDARD PROCEDURE..................35

CONNECTING ROD - FITTING.............35

CRANKSHAFT

DESCRIPTION...........................36

OPERATION.............................36

STANDARD PROCEDURE..................36

CRANKSHAFT END-PLAY................36

REMOVAL..............................36

INSPECTION............................37

INSTALLATION...........................37

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE..................38

MAIN BEARING - FITTING................38

CRANKSHAFT OIL SEAL - FRONT

REMOVAL..............................40

INSTALLATION...........................40

CRANKSHAFT OIL SEAL - REAR

REMOVAL..............................41

INSTALLATION...........................41

PISTON & CONNECTING ROD

DESCRIPTION...........................42

OPERATION.............................42

REMOVAL..............................42

INSTALLATION...........................43

PISTON RINGS

STANDARD PROCEDURE..................44

PISTON RING - FITTING.................44

VIBRATION DAMPER

REMOVAL..............................46

INSTALLATION...........................46

STRUCTURAL COLLAR

REMOVAL..............................46

INSTALLATION...........................46

ENGINE MOUNTING

DESCRIPTION...........................47

FRONT MOUNT

REMOVAL..............................47

INSTALLATION...........................47

LEFT MOUNT

REMOVAL..............................47

INSTALLATION...........................48

REAR MOUNT

REMOVAL..............................48

INSTALLATION...........................48

RIGHT MOUNT

REMOVAL..............................50

INSTALLATION...........................50

LUBRICATION

DESCRIPTION...........................50

OPERATION.............................50

DIAGNOSIS AND TESTING.................50

ENGINE OIL PRESSURE CHECKING........50

OIL

STANDARD PROCEDURE..................51ENGINE OIL LEVEL CHECK...............51

ENGINE OIL CHANGE...................51

OIL FILTER

DESCRIPTION...........................51

REMOVAL..............................51

INSTALLATION...........................52

OIL PAN

REMOVAL..............................52

INSTALLATION...........................52

OIL PUMP

REMOVAL..............................52

DISASSEMBLY...........................53

CLEANING..............................53

INSPECTION............................53

ASSEMBLY.............................55

INSTALLATION...........................55

INTAKE MANIFOLD

DESCRIPTION...........................56

OPERATION.............................56

DIAGNOSIS AND TESTING.................56

INTAKE MANIFOLD LEAKS...............56

INTAKE MANIFOLD - UPPER

REMOVAL..............................56

INSPECTION............................57

INSTALLATION...........................57

INTAKE MANIFOLD - LOWER

REMOVAL..............................58

INSPECTION............................58

INSTALLATION...........................58

EXHAUST MANIFOLD

DESCRIPTION...........................59

OPERATION.............................59

REMOVAL..............................59

CLEANING..............................59

INSPECTION............................59

INSTALLATION...........................59

TIMING BELT COVER(S)

REMOVAL..............................60

INSTALLATION...........................61

TIMING BELT AND SPROCKET(S)

REMOVAL..............................61

CLEANING..............................62

INSTALLATION...........................62

TIMING BELT TENSIONER & PULLEY

REMOVAL..............................64

INSTALLATION...........................65

BALANCE SHAFT

DESCRIPTION...........................66

OPERATION.............................66

REMOVAL..............................66

INSTALLATION...........................67

BALANCE SHAFT CARRIER

REMOVAL..............................70

INSTALLATION...........................70

BALANCE SHAFT CHAIN

REMOVAL..............................70

INSTALLATION...........................70

9 - 2 ENGINE 2.4LRS

Page 2629 of 4284

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

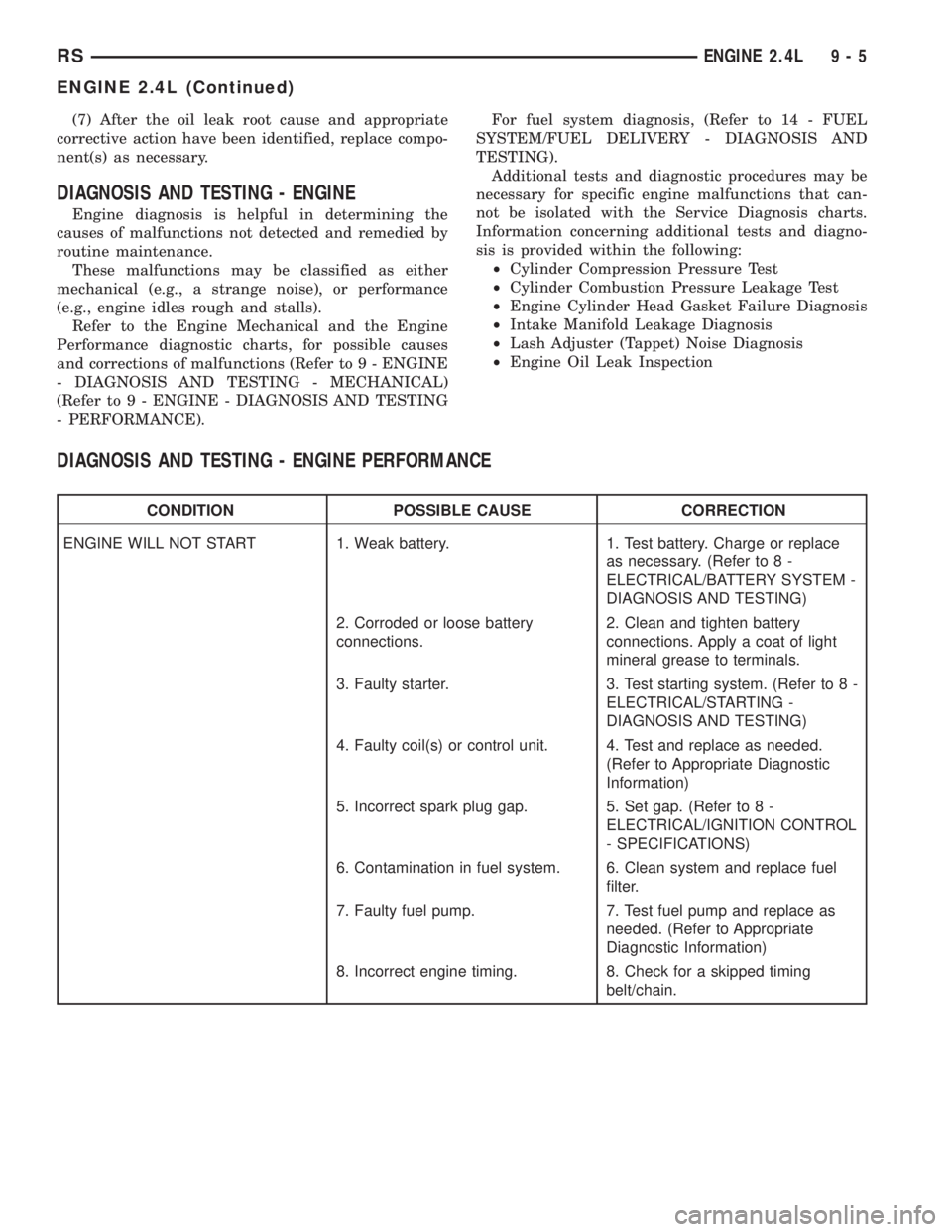

DIAGNOSIS AND TESTING - ENGINE

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Lash Adjuster (Tappet) Noise Diagnosis

²Engine Oil Leak Inspection

DIAGNOSIS AND TESTING - ENGINE PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery. 1. Test battery. Charge or replace

as necessary. (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM -

DIAGNOSIS AND TESTING)

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Faulty starter. 3. Test starting system. (Refer to 8 -

ELECTRICAL/STARTING -

DIAGNOSIS AND TESTING)

4. Faulty coil(s) or control unit. 4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Incorrect spark plug gap. 5. Set gap. (Refer to 8 -

ELECTRICAL/IGNITION CONTROL

- SPECIFICATIONS)

6. Contamination in fuel system. 6. Clean system and replace fuel

filter.

7. Faulty fuel pump. 7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Incorrect engine timing. 8. Check for a skipped timing

belt/chain.

RSENGINE 2.4L9-5

ENGINE 2.4L (Continued)

Page 2643 of 4284

SPECIFICATIONS - TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Balance Shaft Carrier to

BlockÐBolts54 40 Ð

Balance Shaft Gear

CoverÐDouble Ended

Fastener12 Ð 105

Balance Shaft SprocketÐ

Bolt28 Ð 250

Balance Shaft Chain

TensionerÐBolts12 Ð 105

Balance Shaft Carrier

CoverÐBolts12 Ð 105

Camshaft SprocketÐBolt 101 75 Ð

Connecting Rod

CapÐBolts27 +

1¤4

turn20

+1¤4

turnÐ

Crankshaft Main Bearing

Cap/Bedplate

ÐM8 Bolts 34 250

ÐM11 Bolts 41 +

1¤4

Turn30

+1¤4

TurnÐ

Crankshaft Damper 136 100 Ð

Cylinder HeadÐBolts (Refer to 9 - ENGINE/

CYLINDER HEAD -

INSTALLATION)

Cylinder Head CoverÐ

Bolts12 Ð 105

Flex Plate to Crankshaft 95 70 Ð

Engine Mount Bracket

RightÐBolts61 45 Ð

Engine MountingÐBolts (Refer to 9 ENGINE/

ENGINE MOUNTING)

Exhaust Manifold to

Cylinder HeadÐBolts23 Ð 200

Exhaust Manifold Heat

ShieldÐBolts12 Ð 105

Intake Manifold - Lower

ÐBolts28 Ð 250

Intake Manifold -

UpperÐBolts12 Ð 105

Oil Filter 20 15 Ð

Oil PanÐBolts 12 Ð 105

Oil Pan DrainÐPlug 27 20 Ð

Oil Pump to BlockÐBolts 28 Ð 250

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Oil Pump Cover

PlateÐBolts12 Ð 105

Oil Pump Pick-up

TubeÐBolt28 20 Ð

Oil Pump Relief

ValveÐCap41 30 Ð

Spark Plugs 28 Ð 250

Structural Collar (Refer to 9 - ENGINE/

ENGINE BLOCK/

STRUCTURAL COVER -

INSTALLATION)

Timing Belt Covers

- Front Covers to Rear

CoverÐBolts7Ð60

- Rear CoverÐBolts 7 Ð 60

ÐBolts 28 Ð 250

Timing Belt Tensioner

AssemblyÐBolts61 45 Ð

SPECIAL TOOLS

2.4L ENGINE

Puller 1026

Crankshaft Damper Removal Insert 6827-A

RSENGINE 2.4L9-19

SPECIFICATIONS (Continued)

Page 2648 of 4284

(6) Remove heater tube support bracket from cyl-

inder head.

(7) Disconnect radiator upper and heater supply

hoses from intake manifold water outlet connections.

(8) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Raise vehicle and remove exhaust pipe from

manifold.

(10) Remove power steering pump reservoir and

line support bracket from lower intake manifold and

set aside. Do not disconnect lines.

(11) Remove ignition coil and wires from engine.

(12) Disconnect cam sensor and fuel injector wir-

ing connectors.

(13) Remove timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL)

(14) Remove timing belt idler pulley and rear tim-

ing belt cover. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT / CHAIN COVER(S) -

REMOVAL)

(15) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(16) Remove camshafts (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: Identify rocker arm position to ensure cor-

rect re-installation in original position, if reused.

(17) Remove rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - REMOVAL)

(18) Remove cylinder head bolts in REVERSE

sequence of tightening (Fig. 19).

(19) Remove cylinder head from engine block.

(20) Inspect and clean cylinder head. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSPECTION) (Refer

to 9 - ENGINE/CYLINDER HEAD - CLEANING)

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Remove all gasket material from cylinder head and

block. (Refer to 9 - ENGINE - STANDARD PROCE-

DURE) Be careful not to gouge or scratch the alumi-

num head sealing surface.

Clean all engine oil passages.

INSPECTION

(1) Cylinder head must be flat within 0.1 mm

(0.004 in.) (Fig. 14).

(2) Inspect camshaft bearing journals for scoring.

(3) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(4) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 15). (Refer to 9 - ENGINE - SPECIFICA-

TIONS) Replace guides if they are not within

specification.

(5) Check valve guide height (Fig. 16).

INSTALLATION - CYLINDER HEAD

NOTE: The Cylinder head bolts should be examined

BEFORE reuse. If the threads are necked down, the

bolts must be replaced (Fig. 17).

Fig. 14 Checking Cylinder Head Flatness

1 - FEELER GAUGE

2 - STRAIGHT EDGE

Fig. 15 Checking Wear on Valve GuideÐTypical

1-TOP

2 - MIDDLE

3 - BOTTOM

4 - CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

9 - 24 ENGINE 2.4LRS

CYLINDER HEAD (Continued)

Page 2649 of 4284

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale, the bolt should be replaced.

(1) Before installing the bolts, the threads should

be coated with engine oil.

(2) Position cylinder head gasket on engine block

(Fig. 18).

(3) Install cylinder head on engine block.

(4) Tighten the cylinder head bolts in the sequence

shown in (Fig. 19). Using the 4 step torque turn

method, tighten according to the following values:

²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

²Third All to 68 N´m (50 ft. lbs.)

CAUTION: Do not use a torque wrench for the fol-

lowing step.

²Fourth Turn an additional 1/4 Turn,(5) Install rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - INSTALLA-

TION)

(6) Install camshafts. (Refer to 9 - ENGINE/CYL-

INDER HEAD/CAMSHAFT(S) - INSTALLATION).

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and timing belt

idler pulley. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - INSTALLATION)

(10) Connect cam sensor and fuel injectors wiring

connectors.

(11) Install ignition coil and wires. Connect igni-

tion coil wiring connector.

(12) Install power steering pump reservoir and

line support bracket to cylinder head.

Fig. 16 Valve Guide Height

1 - VALVE GUIDE

2 - 13.25 - 13.75 MM (0.521 - 0.541 IN.)

3 - SPRING SEAT

Fig. 17 Checking Bolts for

1 - STRETCHED BOLT

2 - THREADS ARE NOT STRAIGHT ON LINE

3 - THREADS ARE STRAIGHT ON LINE

4 - UNSTRETCHED BOLT

Fig. 18 Cylinder Head Gasket Positioning

1 - PART NUMBER FACES UP

2 - NO. 1 CYLINDER

Fig. 19 Cylinder Head Tightening Sequence

RSENGINE 2.4L9-25

CYLINDER HEAD (Continued)

Page 2650 of 4284

(13) Raise vehicle and install the exhaust pipe to

the manifold.

(14) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(15) Install heater tube support bracket to cylinder

head.

(16) Connect radiator upper and heater hoses to

intake manifold water outlet connections.

(17) Install upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

(18) Using new gaskets, install EGR tube and

tighten fasteners to 11 N´m (95 in. lbs.).

(19) Install air inlet tube and housing.

(20) Connect all vacuum lines, electrical wiring,

ground straps and fuel line.

(21) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(22) Connect battery negative cable.

CAMSHAFT OIL SEAL(S)

REMOVAL

(1) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(2) Hold each camshaft sprocket with Special Tool

6847 while removing center bolt (Fig. 20).

(3) Remove camshaft sprockets.

(4) Remove rear timing belt cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(5) Remove camshaft seal using Special Tool

C-4679-A (Fig. 21).

CAUTION: Do not nick shaft seal surface or seal

bore.

INSTALLATION

(1) Shaft seal surface must be free of varnish, dirt

or nicks. Polish with 400 grit paper if necessary.

(2) Install camshaft seals into cylinder head using

Special Tool MD-998306 until flush with head (Fig.

22).

(3) Install timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(4) Install camshaft sprockets. Hold each sprocket

with Special Tool 6847 and tighten center bolt to 101

N´m (75 ft. lbs.) (Fig. 20).

(5) Install timing belt and front covers. (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION) (Refer to 9 -ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

CAMSHAFT(S)

DESCRIPTION

Both nodular iron camshafts have six bearing jour-

nal surfaces and two cam lobes per cylinder (Fig. 23).

Flanges at the rear journals control camshaft end

play. Provision for a cam position sensor is located on

the intake camshaft on the rear of the cylinder head.

A hydrodynamic oil seal is used for oil control at the

front of the camshaft.

Fig. 20 Camshaft Sprocket - Removal/Installation

1 - SPECIAL TOOL 6847

Fig. 21 Camshaft Oil Seal - Removal With C-4679-A

1 - SPECIAL TOOL C-4679

9 - 26 ENGINE 2.4LRS

CYLINDER HEAD (Continued)

Page 2651 of 4284

OPERATION

The camshaft is driven by the crankshaft via drive

sprockets and belt. The camshaft has precisely

machined lobes to provide accurate valve timing and

duration.

STANDARD PROCEDURES - CAMSHAFT

END-PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTcam follower assemblies. Install rear cam

caps and tighten screws to specified torque.

(2) Using a suitable tool, move camshaft as far

rearward as it will go.

(3) Zero dial indicator (Fig. 24).

(4) Move camshaft as far forward as it will go.

(5) Record reading on dial indicator. For end play

specification, (Refer to 9 - ENGINE - SPECIFICA-

TIONS).

(6) If end play is excessive, check cylinder head

and camshaft for wear; replace as necessary.

REMOVAL

(1) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(2) Remove camshaft position sensor and camshaft

target magnet. (Refer to 8 - ELECTRICAL/IGNI-

TION CONTROL/CAMSHAFT POSITION SENSOR -

REMOVAL)

(3) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(4) Remove camshaft sprockets and timing belt

rear cover. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - REMOVAL)

(5) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 25).

(6) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 26) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

Fig. 22 Camshaft Seal - Installation

1 - SPECIAL TOOL MD 998306

Fig. 23 Camshafts

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

Fig. 24 Camshaft End Play - Typical

RSENGINE 2.4L9-27

CAMSHAFT(S) (Continued)

Page 2653 of 4284

NOTE: Bearing end caps must be installed before

seals can be installed.

(5) Install camshaft oil seals. (Refer to 9 -

ENGINE/CYLINDER HEAD/CAMSHAFT OIL

SEAL(S) - INSTALLATION)

(6) Install camshaft target magnet and camshaft

position sensor.

(7) Install cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION)

(8) Install timing belt rear cover and camshaft

sprocket. (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT / CHAIN COVER(S) - INSTALLA-

TION)

(9) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

CYLINDER HEAD COVER

REMOVAL

(1) Remove upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(2) Remove upper manifold support bracket.

(3) Remove ignition coil and spark plug wires.

(4) Disconnect PCV and make-up air hoses from

cylinder head cover.

(5) Remove cylinder head cover bolts.

(6) Remove cylinder head cover from cylinder

head.

CLEANING

Clean cylinder head and cover mating surfaces

using a suitable solvent.

INSPECTION

Inspect cover rails for flatness.

INSTALLATION

NOTE: Replace spark plug well seals and bolt

assemblies when installing a new cylinder head

cover gasket.

(1) Install new cylinder head cover gaskets and

spark plug well seals (Fig. 30).

(2) Replace cylinder head cover bolt assemblies

(Fig. 31).

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

Fig. 29 Camshaft Bearing Cap Sealing

1 - 1.5 mm (.060 in.) DIAMETER BEAD OF MOPAR GASKET

MAKER

Fig. 30 Spark Plug Well Seals

Fig. 31 Cylinder Head Cover Bolt Assembly

RSENGINE 2.4L9-29

CAMSHAFT(S) (Continued)