ESP CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3806 of 4284

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second DTC could be set, making diagnosis of the

original problem more difficult.

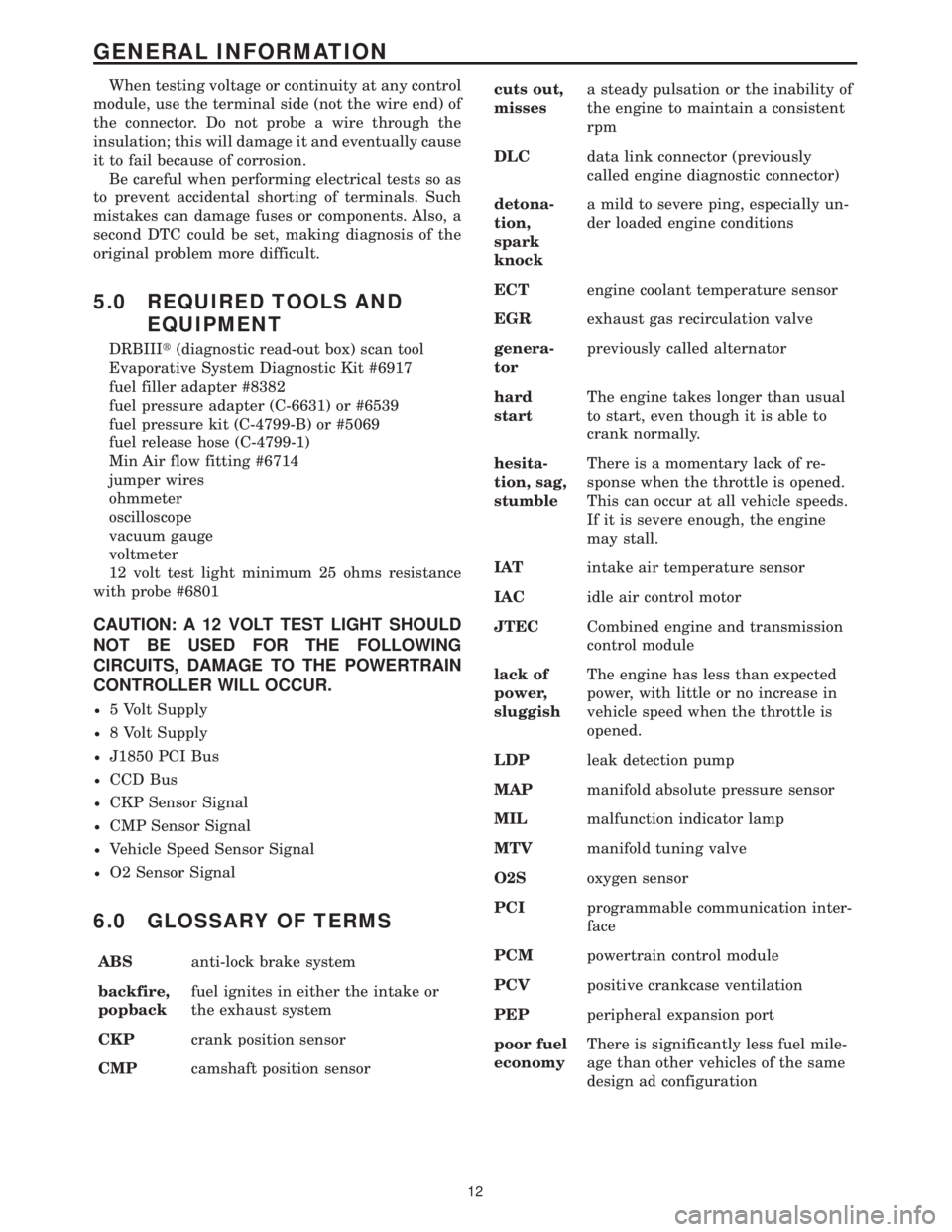

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

Evaporative System Diagnostic Kit #6917

fuel filler adapter #8382

fuel pressure adapter (C-6631) or #6539

fuel pressure kit (C-4799-B) or #5069

fuel release hose (C-4799-1)

Min Air flow fitting #6714

jumper wires

ohmmeter

oscilloscope

vacuum gauge

voltmeter

12 volt test light minimum 25 ohms resistance

with probe #6801

CAUTION: A 12 VOLT TEST LIGHT SHOULD

NOT BE USED FOR THE FOLLOWING

CIRCUITS, DAMAGE TO THE POWERTRAIN

CONTROLLER WILL OCCUR.

²5 Volt Supply

²8 Volt Supply

²J1850 PCI Bus

²CCD Bus

²CKP Sensor Signal

²CMP Sensor Signal

²Vehicle Speed Sensor Signal

²O2 Sensor Signal

6.0 GLOSSARY OF TERMS

ABSanti-lock brake system

backfire,

popbackfuel ignites in either the intake or

the exhaust system

CKPcrank position sensor

CMPcamshaft position sensorcuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector (previously

called engine diagnostic connector)

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECTengine coolant temperature sensor

EGRexhaust gas recirculation valve

genera-

torpreviously called alternator

hard

startThe engine takes longer than usual

to start, even though it is able to

crank normally.

hesita-

tion, sag,

stumbleThere is a momentary lack of re-

sponse when the throttle is opened.

This can occur at all vehicle speeds.

If it is severe enough, the engine

may stall.

IATintake air temperature sensor

IACidle air control motor

JTECCombined engine and transmission

control module

lack of

power,

sluggishThe engine has less than expected

power, with little or no increase in

vehicle speed when the throttle is

opened.

LDPleak detection pump

MAPmanifold absolute pressure sensor

MILmalfunction indicator lamp

MTVmanifold tuning valve

O2Soxygen sensor

PCIprogrammable communication inter-

face

PCMpowertrain control module

PCVpositive crankcase ventilation

PEPperipheral expansion port

poor fuel

economyThere is significantly less fuel mile-

age than other vehicles of the same

design ad configuration

12

GENERAL INFORMATION

Page 3807 of 4284

rough,

unstable,

or er-

ratic idle

stallingThe engine runs unevenly at idle

and causes the engine to shake if it

is severe enough. The engine idle

rpm may vary (called hunting). This

condition may cause stalling if it is

severe enough.

SBECsingle board engine controller

SKIMsentry key immobilizer module

SKISsentry key immobilizer systemstart &

stallThe engine starts but immediately

dies.

surgeengine rpm fluctuation without cor-

responding change in throttle posi-

tion sensor

TPSthrottle position sensor

TRStransmission range sensor

VSSvehicle speed sensor/signal

13

GENERAL INFORMATION

Page 3830 of 4284

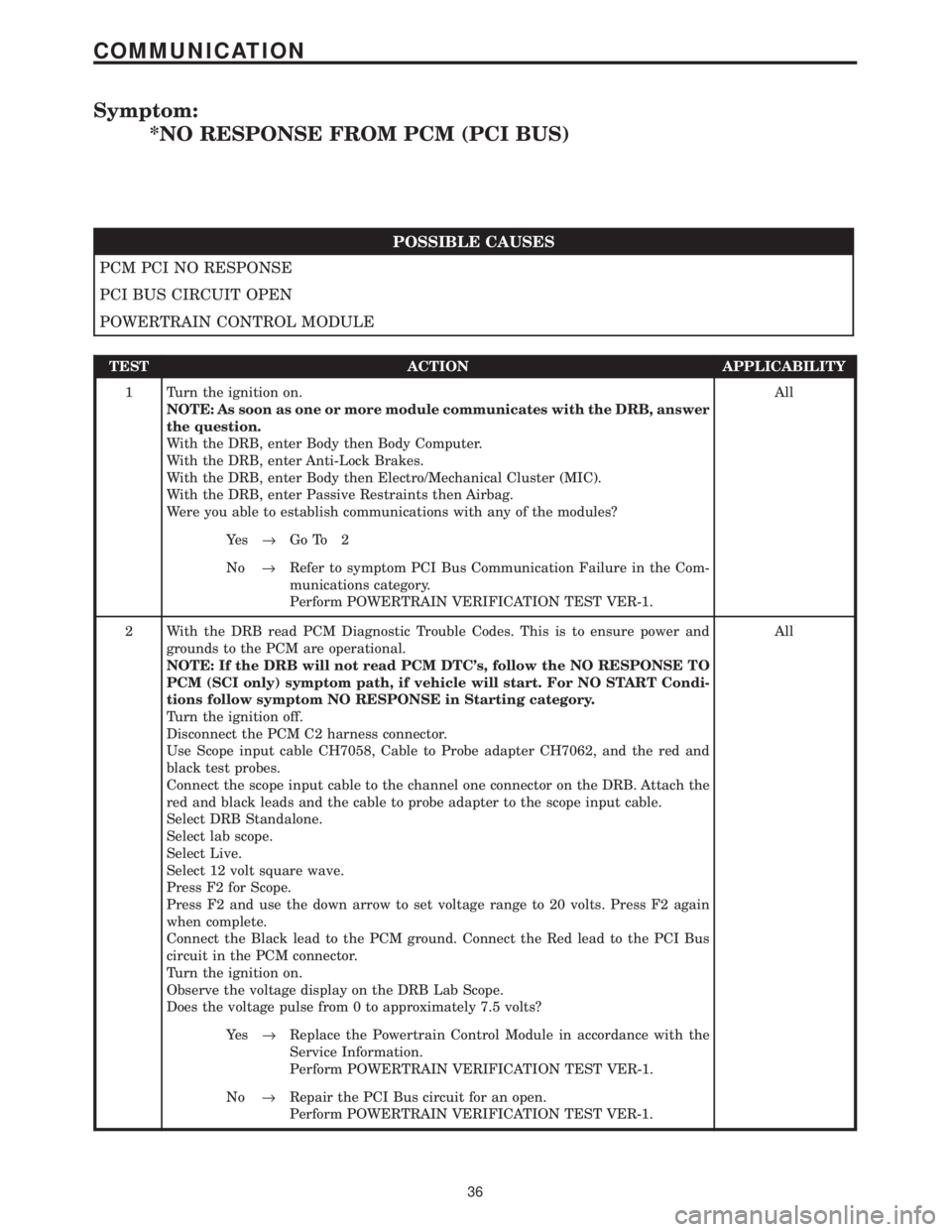

Symptom:

*NO RESPONSE FROM PCM (PCI BUS)

POSSIBLE CAUSES

PCM PCI NO RESPONSE

PCI BUS CIRCUIT OPEN

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

NOTE: As soon as one or more module communicates with the DRB, answer

the question.

With the DRB, enter Body then Body Computer.

With the DRB, enter Anti-Lock Brakes.

With the DRB, enter Body then Electro/Mechanical Cluster (MIC).

With the DRB, enter Passive Restraints then Airbag.

Were you able to establish communications with any of the modules?All

Ye s®Go To 2

No®Refer to symptom PCI Bus Communication Failure in the Com-

munications category.

Perform POWERTRAIN VERIFICATION TEST VER-1.

2 With the DRB read PCM Diagnostic Trouble Codes. This is to ensure power and

grounds to the PCM are operational.

NOTE: If the DRB will not read PCM DTC's, follow the NO RESPONSE TO

PCM (SCI only) symptom path, if vehicle will start. For NO START Condi-

tions follow symptom NO RESPONSE in Starting category.

Turn the ignition off.

Disconnect the PCM C2 harness connector.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and the red and

black test probes.

Connect the scope input cable to the channel one connector on the DRB. Attach the

red and black leads and the cable to probe adapter to the scope input cable.

Select DRB Standalone.

Select lab scope.

Select Live.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts. Press F2 again

when complete.

Connect the Black lead to the PCM ground. Connect the Red lead to the PCI Bus

circuit in the PCM connector.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?All

Ye s®Replace the Powertrain Control Module in accordance with the

Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Repair the PCI Bus circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

36

COMMUNICATION

Page 3831 of 4284

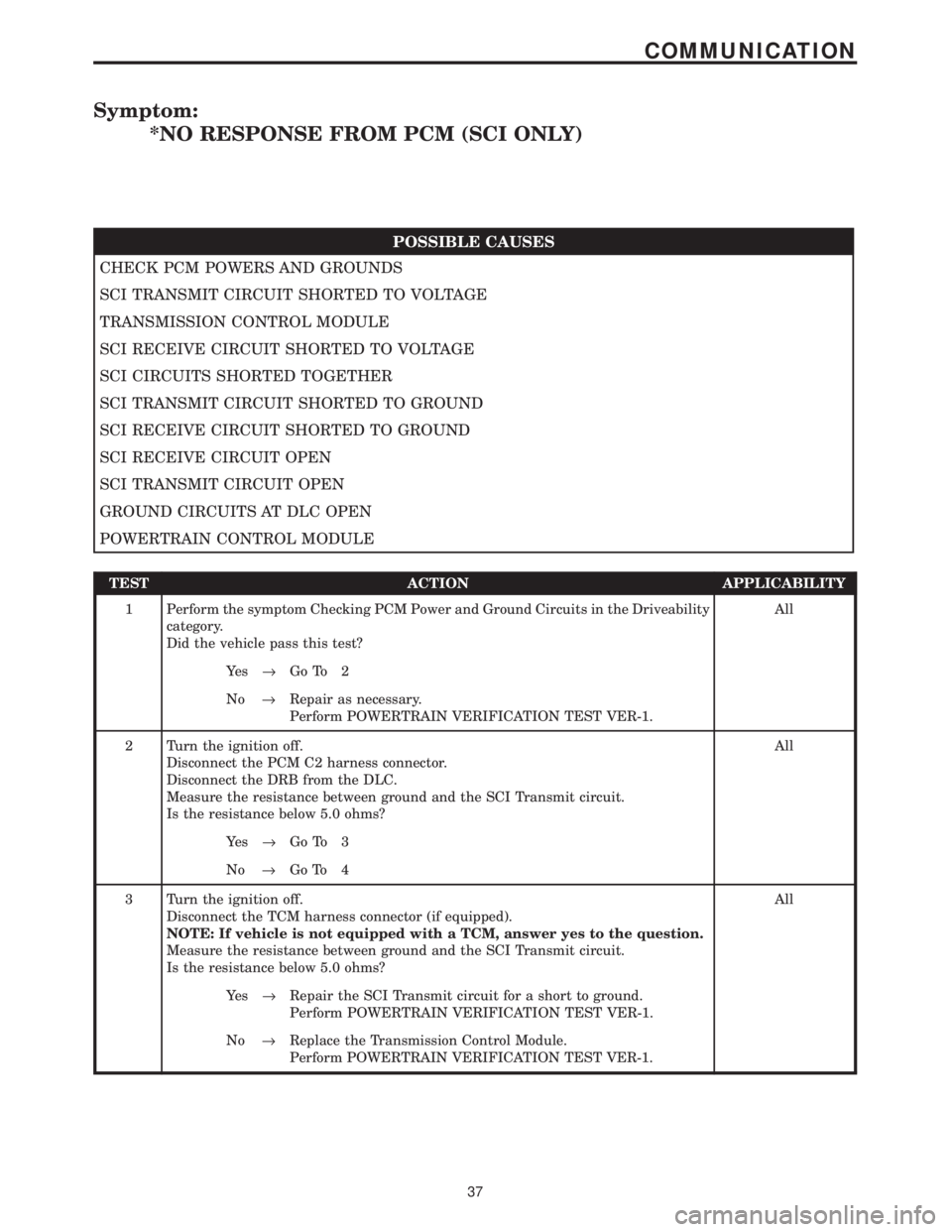

Symptom:

*NO RESPONSE FROM PCM (SCI ONLY)

POSSIBLE CAUSES

CHECK PCM POWERS AND GROUNDS

SCI TRANSMIT CIRCUIT SHORTED TO VOLTAGE

TRANSMISSION CONTROL MODULE

SCI RECEIVE CIRCUIT SHORTED TO VOLTAGE

SCI CIRCUITS SHORTED TOGETHER

SCI TRANSMIT CIRCUIT SHORTED TO GROUND

SCI RECEIVE CIRCUIT SHORTED TO GROUND

SCI RECEIVE CIRCUIT OPEN

SCI TRANSMIT CIRCUIT OPEN

GROUND CIRCUITS AT DLC OPEN

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Perform the symptom Checking PCM Power and Ground Circuits in the Driveability

category.

Did the vehicle pass this test?All

Ye s®Go To 2

No®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER-1.

2 Turn the ignition off.

Disconnect the PCM C2 harness connector.

Disconnect the DRB from the DLC.

Measure the resistance between ground and the SCI Transmit circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 3

No®Go To 4

3 Turn the ignition off.

Disconnect the TCM harness connector (if equipped).

NOTE: If vehicle is not equipped with a TCM, answer yes to the question.

Measure the resistance between ground and the SCI Transmit circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the SCI Transmit circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Replace the Transmission Control Module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

37

COMMUNICATION

Page 3832 of 4284

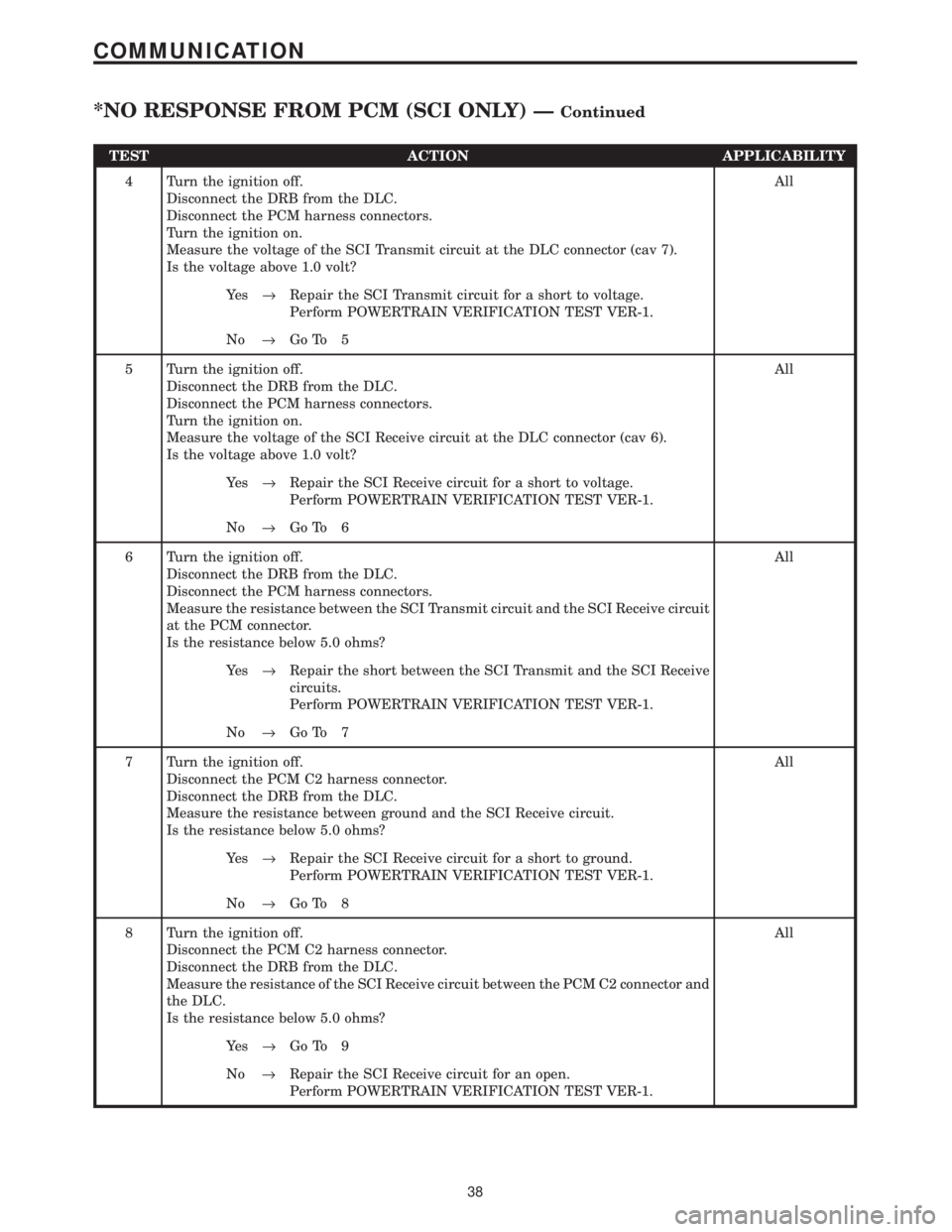

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the PCM harness connectors.

Turn the ignition on.

Measure the voltage of the SCI Transmit circuit at the DLC connector (cav 7).

Is the voltage above 1.0 volt?All

Ye s®Repair the SCI Transmit circuit for a short to voltage.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 5

5 Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the PCM harness connectors.

Turn the ignition on.

Measure the voltage of the SCI Receive circuit at the DLC connector (cav 6).

Is the voltage above 1.0 volt?All

Ye s®Repair the SCI Receive circuit for a short to voltage.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the PCM harness connectors.

Measure the resistance between the SCI Transmit circuit and the SCI Receive circuit

at the PCM connector.

Is the resistance below 5.0 ohms?All

Ye s®Repair the short between the SCI Transmit and the SCI Receive

circuits.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 7

7 Turn the ignition off.

Disconnect the PCM C2 harness connector.

Disconnect the DRB from the DLC.

Measure the resistance between ground and the SCI Receive circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the SCI Receive circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 8

8 Turn the ignition off.

Disconnect the PCM C2 harness connector.

Disconnect the DRB from the DLC.

Measure the resistance of the SCI Receive circuit between the PCM C2 connector and

the DLC.

Is the resistance below 5.0 ohms?All

Ye s®Go To 9

No®Repair the SCI Receive circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

38

COMMUNICATION

*NO RESPONSE FROM PCM (SCI ONLY) ÐContinued

Page 3833 of 4284

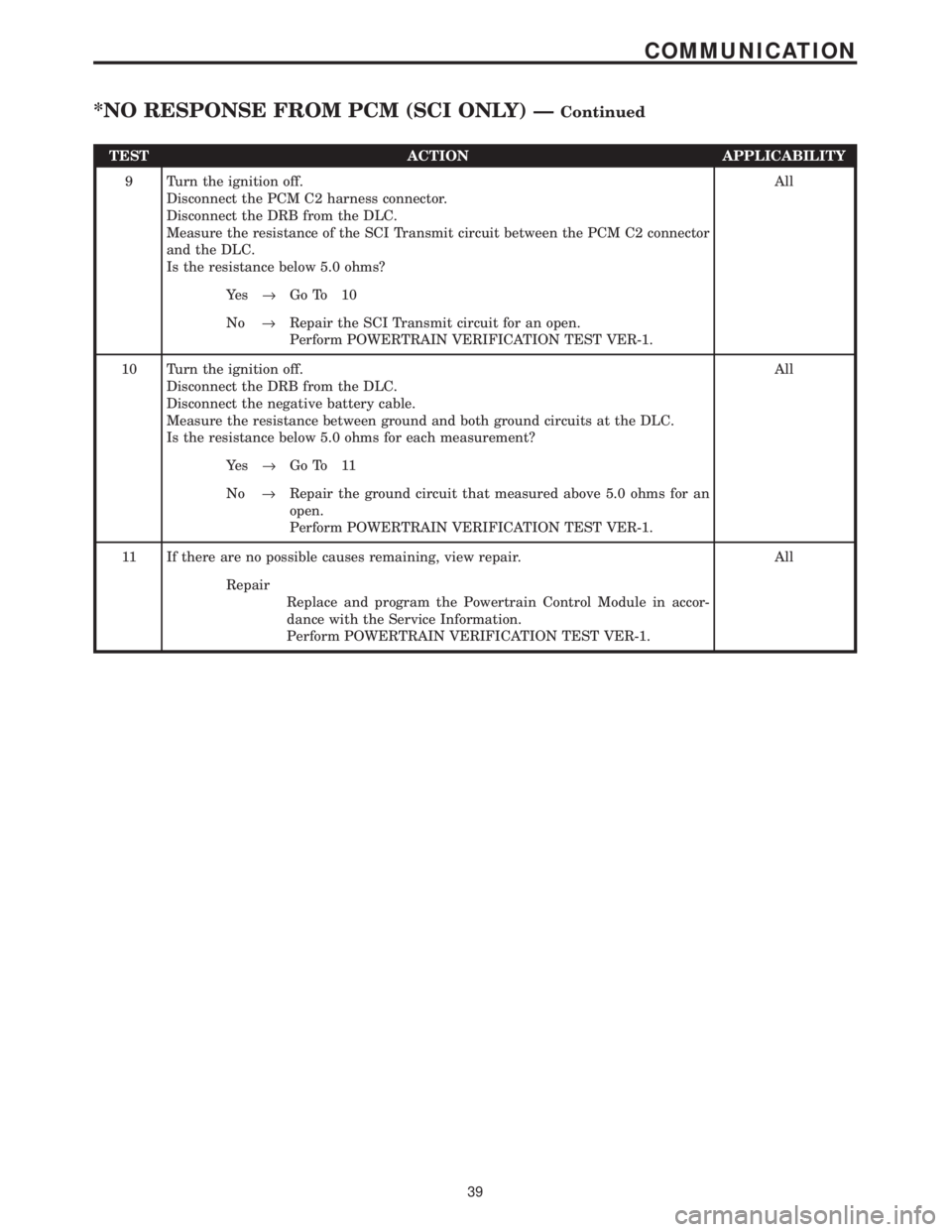

TEST ACTION APPLICABILITY

9 Turn the ignition off.

Disconnect the PCM C2 harness connector.

Disconnect the DRB from the DLC.

Measure the resistance of the SCI Transmit circuit between the PCM C2 connector

and the DLC.

Is the resistance below 5.0 ohms?All

Ye s®Go To 10

No®Repair the SCI Transmit circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

10 Turn the ignition off.

Disconnect the DRB from the DLC.

Disconnect the negative battery cable.

Measure the resistance between ground and both ground circuits at the DLC.

Is the resistance below 5.0 ohms for each measurement?All

Ye s®Go To 11

No®Repair the ground circuit that measured above 5.0 ohms for an

open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

11 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

39

COMMUNICATION

*NO RESPONSE FROM PCM (SCI ONLY) ÐContinued

Page 3834 of 4284

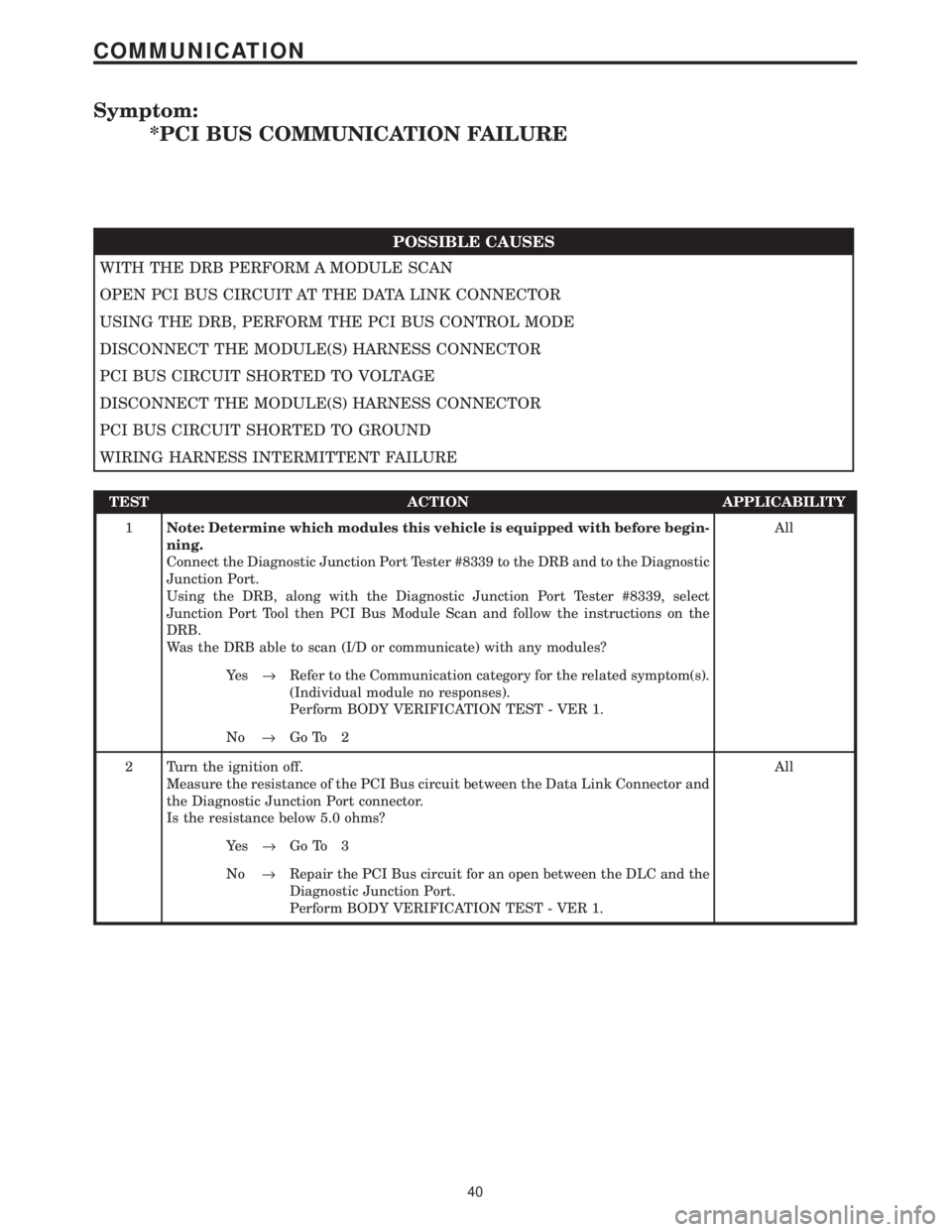

Symptom:

*PCI BUS COMMUNICATION FAILURE

POSSIBLE CAUSES

WITH THE DRB PERFORM A MODULE SCAN

OPEN PCI BUS CIRCUIT AT THE DATA LINK CONNECTOR

USING THE DRB, PERFORM THE PCI BUS CONTROL MODE

DISCONNECT THE MODULE(S) HARNESS CONNECTOR

PCI BUS CIRCUIT SHORTED TO VOLTAGE

DISCONNECT THE MODULE(S) HARNESS CONNECTOR

PCI BUS CIRCUIT SHORTED TO GROUND

WIRING HARNESS INTERMITTENT FAILURE

TEST ACTION APPLICABILITY

1Note: Determine which modules this vehicle is equipped with before begin-

ning.

Connect the Diagnostic Junction Port Tester #8339 to the DRB and to the Diagnostic

Junction Port.

Using the DRB, along with the Diagnostic Junction Port Tester #8339, select

Junction Port Tool then PCI Bus Module Scan and follow the instructions on the

DRB.

Was the DRB able to scan (I/D or communicate) with any modules?All

Ye s®Refer to the Communication category for the related symptom(s).

(Individual module no responses).

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2 Turn the ignition off.

Measure the resistance of the PCI Bus circuit between the Data Link Connector and

the Diagnostic Junction Port connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 3

No®Repair the PCI Bus circuit for an open between the DLC and the

Diagnostic Junction Port.

Perform BODY VERIFICATION TEST - VER 1.

40

COMMUNICATION

Page 3835 of 4284

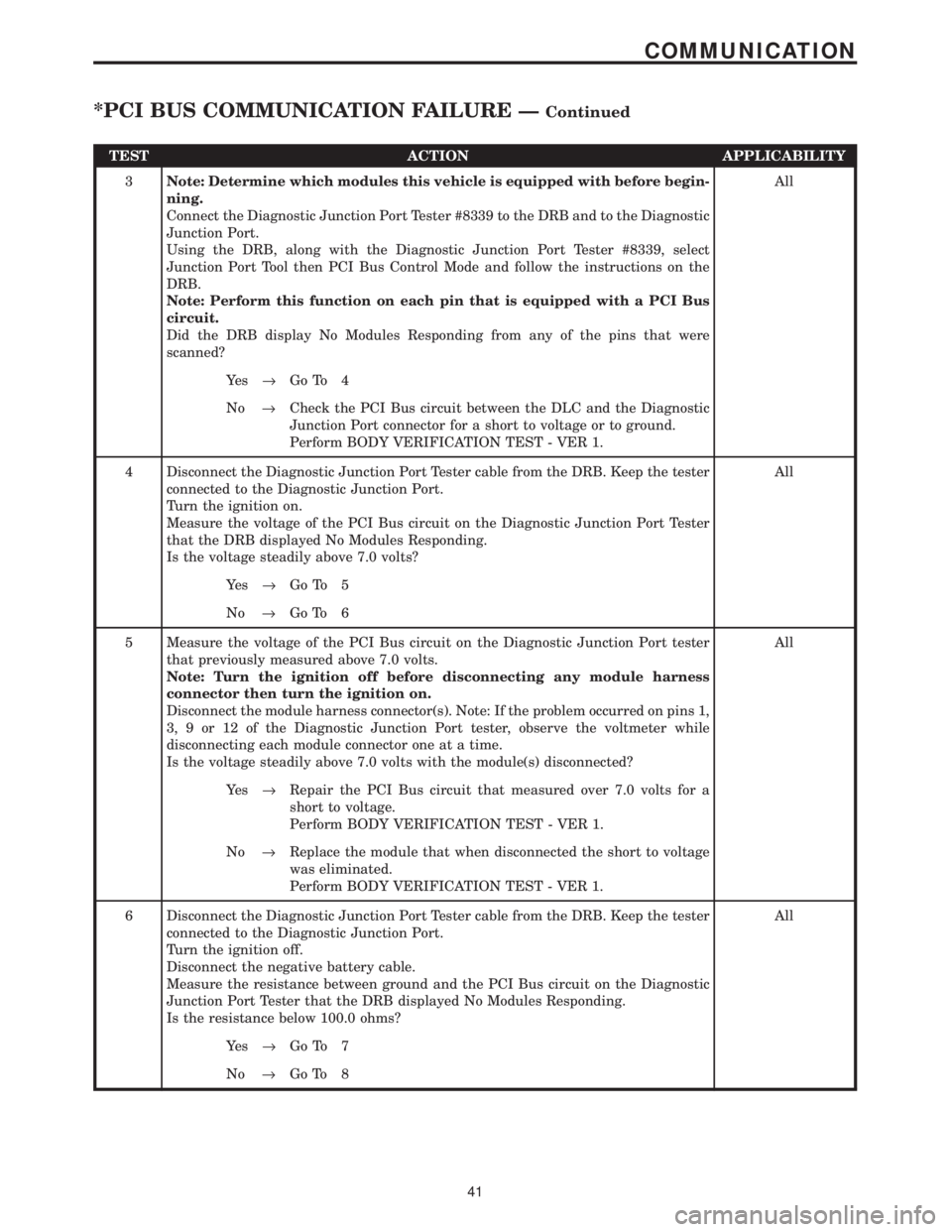

TEST ACTION APPLICABILITY

3Note: Determine which modules this vehicle is equipped with before begin-

ning.

Connect the Diagnostic Junction Port Tester #8339 to the DRB and to the Diagnostic

Junction Port.

Using the DRB, along with the Diagnostic Junction Port Tester #8339, select

Junction Port Tool then PCI Bus Control Mode and follow the instructions on the

DRB.

Note: Perform this function on each pin that is equipped with a PCI Bus

circuit.

Did the DRB display No Modules Responding from any of the pins that were

scanned?All

Ye s®Go To 4

No®Check the PCI Bus circuit between the DLC and the Diagnostic

Junction Port connector for a short to voltage or to ground.

Perform BODY VERIFICATION TEST - VER 1.

4 Disconnect the Diagnostic Junction Port Tester cable from the DRB. Keep the tester

connected to the Diagnostic Junction Port.

Turn the ignition on.

Measure the voltage of the PCI Bus circuit on the Diagnostic Junction Port Tester

that the DRB displayed No Modules Responding.

Is the voltage steadily above 7.0 volts?All

Ye s®Go To 5

No®Go To 6

5 Measure the voltage of the PCI Bus circuit on the Diagnostic Junction Port tester

that previously measured above 7.0 volts.

Note: Turn the ignition off before disconnecting any module harness

connector then turn the ignition on.

Disconnect the module harness connector(s). Note: If the problem occurred on pins 1,

3, 9 or 12 of the Diagnostic Junction Port tester, observe the voltmeter while

disconnecting each module connector one at a time.

Is the voltage steadily above 7.0 volts with the module(s) disconnected?All

Ye s®Repair the PCI Bus circuit that measured over 7.0 volts for a

short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the module that when disconnected the short to voltage

was eliminated.

Perform BODY VERIFICATION TEST - VER 1.

6 Disconnect the Diagnostic Junction Port Tester cable from the DRB. Keep the tester

connected to the Diagnostic Junction Port.

Turn the ignition off.

Disconnect the negative battery cable.

Measure the resistance between ground and the PCI Bus circuit on the Diagnostic

Junction Port Tester that the DRB displayed No Modules Responding.

Is the resistance below 100.0 ohms?All

Ye s®Go To 7

No®Go To 8

41

COMMUNICATION

*PCI BUS COMMUNICATION FAILURE ÐContinued

Page 3853 of 4284

Symptom:

P0121-TPS VOLTAGE DOES NOT AGREE WITH MAP

When Monitored and Set Condition:

P0121-TPS VOLTAGE DOES NOT AGREE WITH MAP

When Monitored: With the engine running and no MAP Sensor or TP Sensor DTC's set.

Engine speed must be greater than 1600 RPM.

Set Condition: When the manifold vacuum is low, the TP sensor signal should be high.

Conversely, when manifold vacuum is high, the TP sensor signal should be low. If the MAP

Sensor and TP Sensor do not respond within 4 seconds as stated above, a DTC will be set.

POSSIBLE CAUSES

INTERMITTENT CONDITION

HIGH RESISTANCE IN 5 VOLT SUPPLY CIRCUIT

HIGH RESISTANCE TO GROUND IN 5 VOLT SUPPLY CIRCUIT

MAP SENSOR

HIGH RESISTANCE IN MAP SENSOR SIGNAL CIRCUIT

HIGH RESISTANCE TO GROUND IN MAP SENSOR SIGNAL CIRCUIT

HIGH RESISTANCE IN SENSOR GROUND CIRCUIT

PCM

HIGH RESISTANCE IN 5 VOLT SUPPLY CIRCUIT

HIGH RESISTANCE TO GROUND IN 5 VOLT SUPPLY CIRCUIT

TP SENSOR

HIGH RESISTANCE IN TP SENSOR SIGNAL CIRCUIT

HIGH RESISTANCE TO GROUND IN THROTTLE POSITION SENSOR SIGNAL CIRCUIT

HIGH RESISTANCE IN SENSOR GROUND CIRCUIT

PCM

TEST ACTION APPLICABILITY

1NOTE: Diagnose any TP Sensor or MAP Sensor component DTC first before

continuing.

NOTE: If the P0500 - No Vehicle Speed Signal is set long with this DTC, refer

to the P0500 diagnostics before continuing.

NOTE: The throttle plate and linkage should be free from binding and

carbon build up.

NOTE: Ensure the throttle plate is at the idle position.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 18

59

DRIVEABILITY - GAS

Page 3873 of 4284

Symptom List:

P0133-1/1 O2 SENSOR SLOW RESPONSE

P0139-1/2 O2 SENSOR SLOW RESPONSE

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0133-1/1 O2 SENSOR SLOW

RESPONSE.

When Monitored and Set Condition:

P0133-1/1 O2 SENSOR SLOW RESPONSE

When Monitored: Start and drive vehicle greater than 10 MPH with throttle open for a

minimum 200 seconds. Coolant greater than 70ÉC (158ÉF). EVAP Purge is active. Test

performs in idle drive.

Set Condition: The oxygen sensor signal voltage is switching from below 0.39 volts to

above 0.58 volts and back fewer times than required in 60 seconds. Two trip fault..

P0139-1/2 O2 SENSOR SLOW RESPONSE

When Monitored: Start engine. Allow engine to idle. For 1st part of test, if limits are

exceeded, test passes. If not, 2nd part of test runs. Engine running for grater than 295

seconds. amb/batt temp >44ÉF, Baro >22.139HG, MAP >13.8 & <21.69HG, RPM >1400 &

<2500 (4cylinder) RPM > 1120 & <1950(6 cylinder) and vss >22 and < 60 MPH.

Set Condition: The oxygen sensor signal voltage is has not switched below 0.35 volts to

above 0.53 volts in 411 seconds of engine run. Two trip fault.

POSSIBLE CAUSES

INTERMITTENT CONDITION

EXHAUST LEAK

O2 SENSOR SIGNAL CIRCUIT VOLTAGE DROP

O2 SENSOR GROUND CIRCUIT VOLTAGE DROP

O2 SENSOR

TEST ACTION APPLICABILITY

1NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 6

79

DRIVEABILITY - GAS