torque CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3058 of 4284

ASSEMBLY

NOTE: The differential is serviced as an assembly.

Service is limited to bearing cups and cones. Any

other failure must be repaired by differential assem-

bly and transfer shaft replacement.

(1) Install shim and bearing cup using Tool 5052

and driver handle C-4171 (Fig. 152). Install bearing

cup into extension housing using Tool 6536 and

driver handle C-4171.

(2) Position bearing cone onto differential (Fig.

153), and install bearing cone using Tool 6536 and

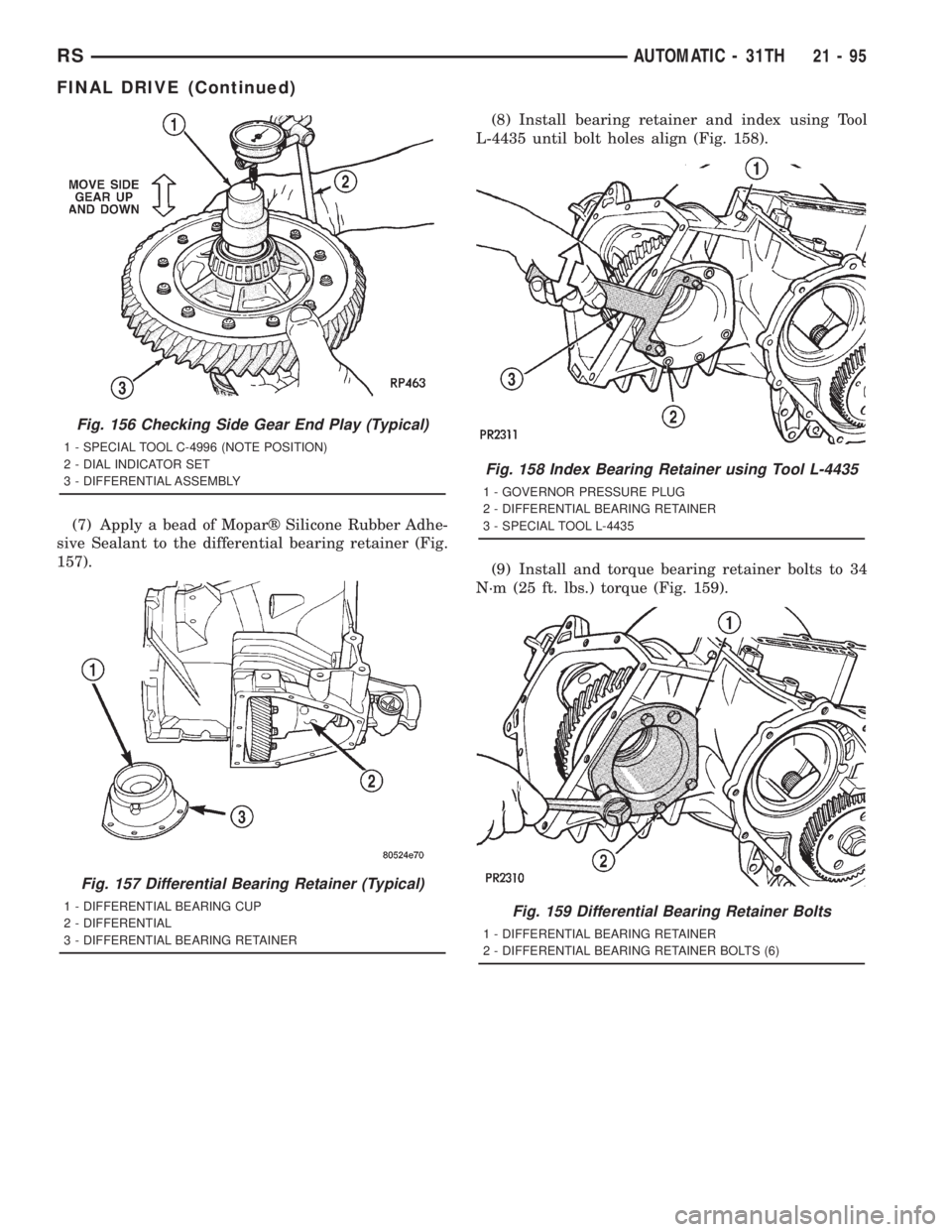

driver handle C-4171 (Fig. 154).(3) Measure side gear end play using dial indicator

C-3339 and Tool C-4996 (Fig. 155) (Fig. 156).Side

gear end play must be between 0.001 and 0.013

in.

(4) Apply a bead of Moparž Silicone Rubber Adhe-

sive Sealant to the adapter plate. Load differential

assembly into position and install adapter plate .

(5) Using Tool L-4435, index adapter plate until

bolt holes align.

(6) Install adapter plate-to-transaxle case bolts

and torque to 28 N´m (250 in. lbs.) torque.

Fig. 152 Bearing Retainer Bearing Cup Installation

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 5052

3 - DIFFERENTIAL BEARING RETAINER

Fig. 153 Position Bearing Cone Onto Differential

1 - DIFFERENTIAL ASSEMBLY

2 - DIFFERENTIAL BEARING

Fig. 154 Install Differential Bearing Cone

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL 6536

3 - DIFFERENTIAL ASSEMBLY

Fig. 155 Checking Side Gear End Play

1 - SPECIAL TOOL C-4996 (NOTE POSITION)

2 - DIAL INDICATOR SET

3 - DIFFERENTIAL ASSEMBLY

4 - SIDE GEAR

21 - 94 AUTOMATIC - 31THRS

FINAL DRIVE (Continued)

Page 3059 of 4284

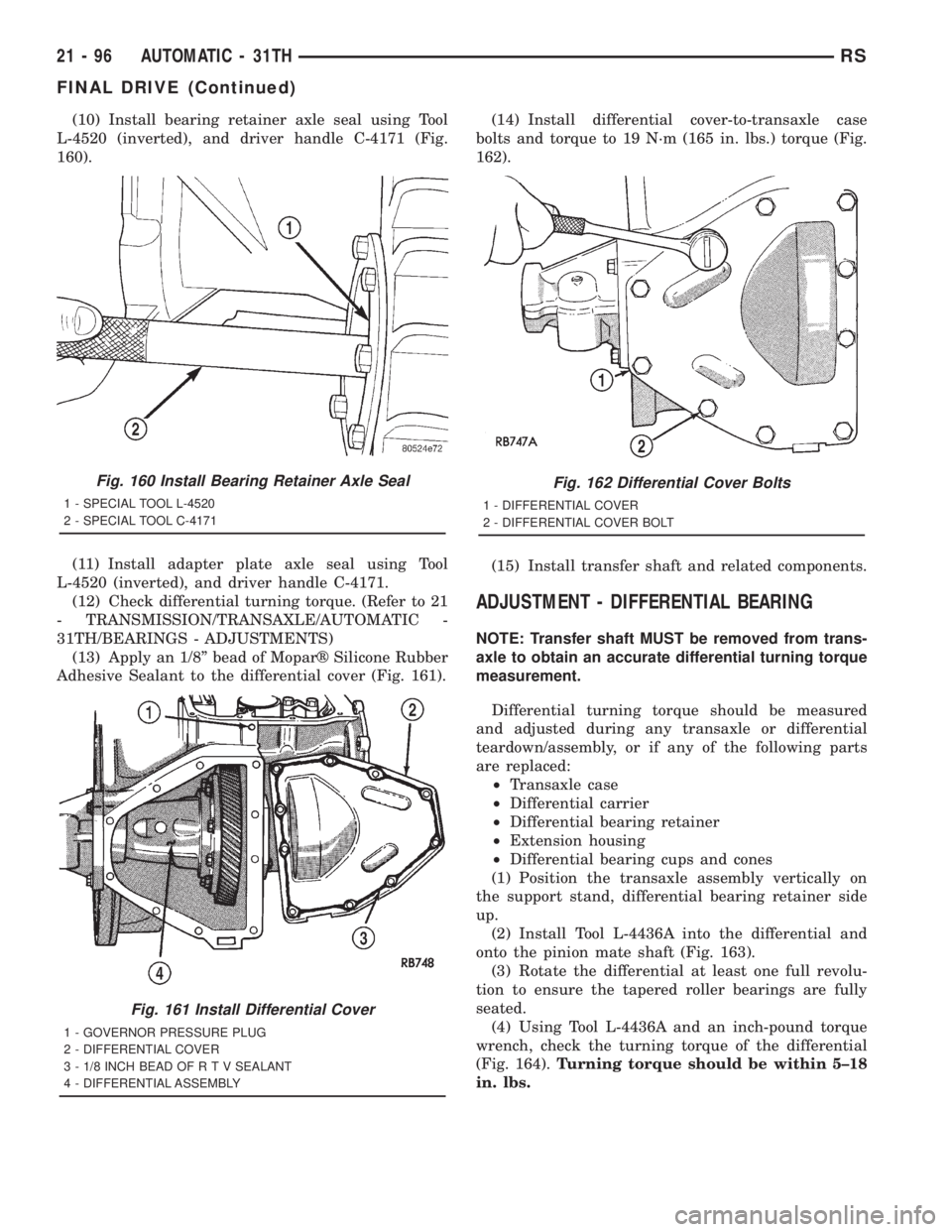

(7) Apply a bead of Moparž Silicone Rubber Adhe-

sive Sealant to the differential bearing retainer (Fig.

157).(8) Install bearing retainer and index using Tool

L-4435 until bolt holes align (Fig. 158).

(9) Install and torque bearing retainer bolts to 34

N´m (25 ft. lbs.) torque (Fig. 159).

Fig. 156 Checking Side Gear End Play (Typical)

1 - SPECIAL TOOL C-4996 (NOTE POSITION)

2 - DIAL INDICATOR SET

3 - DIFFERENTIAL ASSEMBLY

Fig. 157 Differential Bearing Retainer (Typical)

1 - DIFFERENTIAL BEARING CUP

2 - DIFFERENTIAL

3 - DIFFERENTIAL BEARING RETAINER

Fig. 158 Index Bearing Retainer using Tool L-4435

1 - GOVERNOR PRESSURE PLUG

2 - DIFFERENTIAL BEARING RETAINER

3 - SPECIAL TOOL L-4435

Fig. 159 Differential Bearing Retainer Bolts

1 - DIFFERENTIAL BEARING RETAINER

2 - DIFFERENTIAL BEARING RETAINER BOLTS (6)

RSAUTOMATIC - 31TH21-95

FINAL DRIVE (Continued)

Page 3060 of 4284

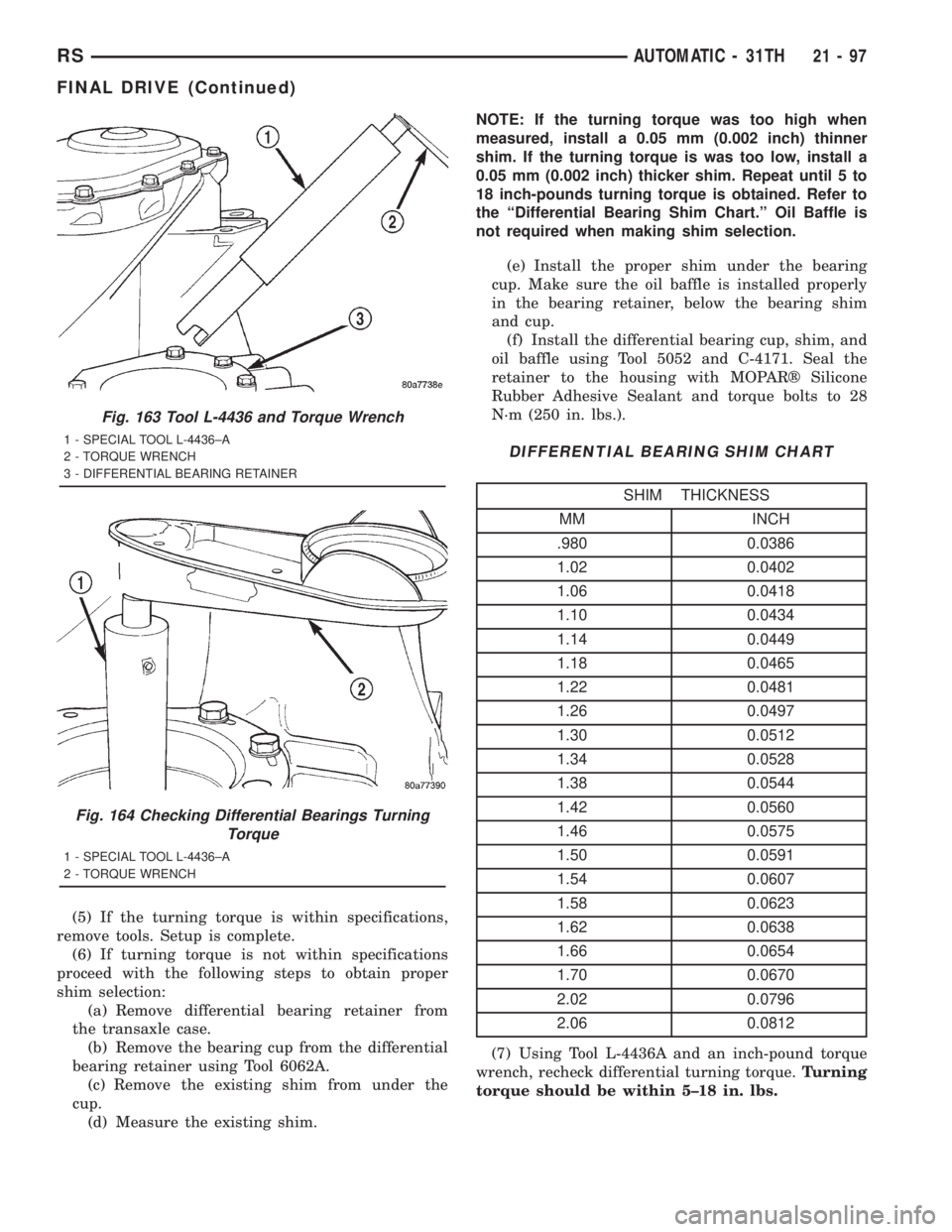

(10) Install bearing retainer axle seal using Tool

L-4520 (inverted), and driver handle C-4171 (Fig.

160).

(11) Install adapter plate axle seal using Tool

L-4520 (inverted), and driver handle C-4171.

(12) Check differential turning torque. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/BEARINGS - ADJUSTMENTS)

(13) Apply an 1/8º bead of Moparž Silicone Rubber

Adhesive Sealant to the differential cover (Fig. 161).(14) Install differential cover-to-transaxle case

bolts and torque to 19 N´m (165 in. lbs.) torque (Fig.

162).

(15) Install transfer shaft and related components.

ADJUSTMENT - DIFFERENTIAL BEARING

NOTE: Transfer shaft MUST be removed from trans-

axle to obtain an accurate differential turning torque

measurement.

Differential turning torque should be measured

and adjusted during any transaxle or differential

teardown/assembly, or if any of the following parts

are replaced:

²Transaxle case

²Differential carrier

²Differential bearing retainer

²Extension housing

²Differential bearing cups and cones

(1) Position the transaxle assembly vertically on

the support stand, differential bearing retainer side

up.

(2) Install Tool L-4436A into the differential and

onto the pinion mate shaft (Fig. 163).

(3) Rotate the differential at least one full revolu-

tion to ensure the tapered roller bearings are fully

seated.

(4) Using Tool L-4436A and an inch-pound torque

wrench, check the turning torque of the differential

(Fig. 164).Turning torque should be within 5±18

in. lbs.

Fig. 160 Install Bearing Retainer Axle Seal

1 - SPECIAL TOOL L-4520

2 - SPECIAL TOOL C-4171

Fig. 161 Install Differential Cover

1 - GOVERNOR PRESSURE PLUG

2 - DIFFERENTIAL COVER

3 - 1/8 INCH BEAD OF R T V SEALANT

4 - DIFFERENTIAL ASSEMBLY

Fig. 162 Differential Cover Bolts

1 - DIFFERENTIAL COVER

2 - DIFFERENTIAL COVER BOLT

21 - 96 AUTOMATIC - 31THRS

FINAL DRIVE (Continued)

Page 3061 of 4284

(5) If the turning torque is within specifications,

remove tools. Setup is complete.

(6) If turning torque is not within specifications

proceed with the following steps to obtain proper

shim selection:

(a) Remove differential bearing retainer from

the transaxle case.

(b) Remove the bearing cup from the differential

bearing retainer using Tool 6062A.

(c) Remove the existing shim from under the

cup.

(d) Measure the existing shim.NOTE: If the turning torque was too high when

measured, install a 0.05 mm (0.002 inch) thinner

shim. If the turning torque is was too low, install a

0.05 mm (0.002 inch) thicker shim. Repeat until 5 to

18 inch-pounds turning torque is obtained. Refer to

the ªDifferential Bearing Shim Chart.º Oil Baffle is

not required when making shim selection.

(e) Install the proper shim under the bearing

cup. Make sure the oil baffle is installed properly

in the bearing retainer, below the bearing shim

and cup.

(f) Install the differential bearing cup, shim, and

oil baffle using Tool 5052 and C-4171. Seal the

retainer to the housing with MOPARž Silicone

Rubber Adhesive Sealant and torque bolts to 28

N´m (250 in. lbs.).

DIFFERENTIAL BEARING SHIM CHART

SHIM THICKNESS

MM INCH

.980 0.0386

1.02 0.0402

1.06 0.0418

1.10 0.0434

1.14 0.0449

1.18 0.0465

1.22 0.0481

1.26 0.0497

1.30 0.0512

1.34 0.0528

1.38 0.0544

1.42 0.0560

1.46 0.0575

1.50 0.0591

1.54 0.0607

1.58 0.0623

1.62 0.0638

1.66 0.0654

1.70 0.0670

2.02 0.0796

2.06 0.0812

(7) Using Tool L-4436A and an inch-pound torque

wrench, recheck differential turning torque.Turning

torque should be within 5±18 in. lbs.

Fig. 163 Tool L-4436 and Torque Wrench

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

3 - DIFFERENTIAL BEARING RETAINER

Fig. 164 Checking Differential Bearings Turning

Torque

1 - SPECIAL TOOL L-4436±A

2 - TORQUE WRENCH

RSAUTOMATIC - 31TH21-97

FINAL DRIVE (Continued)

Page 3062 of 4284

FLUID

STANDARD PROCEDURE - FLUID LEVEL AND

CONDITION CHECK

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

FLUID LEVEL CHECK

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. This will assure complete oil level sta-

bilization between differential and transmis-

sion.The fluid should be at normal operating

temperature (approximately 82 C. or 180 F.). The

fluid level is correct if it is in the HOT region (cross-

hatched area) on the fluid level indicator (Fig. 165).

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming can also result in fluid escaping from the

transaxle dipstick where it may be mistaken for a

leak.Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

If there is any doubt about its condition, drain out a

sample for a double check.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is needed.

Be sure to examine the fluid on the dipstick closely.

If there is any doubt about its condition, drain out a

sample for a double check.

Moparž ATF+4 (Automatic Transmission Fluid-

Type 9602) when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown. This is normal. A dark brown/black fluid

accompanied with a burnt odor and/or deterioration

in shift quality may indicate fluid deterioration or

transmission component failure.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

STANDARD PROCEDURE - FLUID AND FILTER

CHANGE

NOTE: For the recommended maintenance (fluid/fil-

ter change) intervals for this transaxle, (Refer to

LUBRICATION & MAINTENANCE/MAINTENANCE

SCHEDULES - DESCRIPTION)

NOTE: Only fluids of the type labeled Moparž

ATF+4 (Automatic Transmission Fluid) Type 9602

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist. Place a drain con-

tainer with a large opening, under transaxle oil pan.

Fig. 165 Fluid Level Indicator Markings

1 - TRANSAXLE DIPSTICK

21 - 98 AUTOMATIC - 31THRS

Page 3063 of 4284

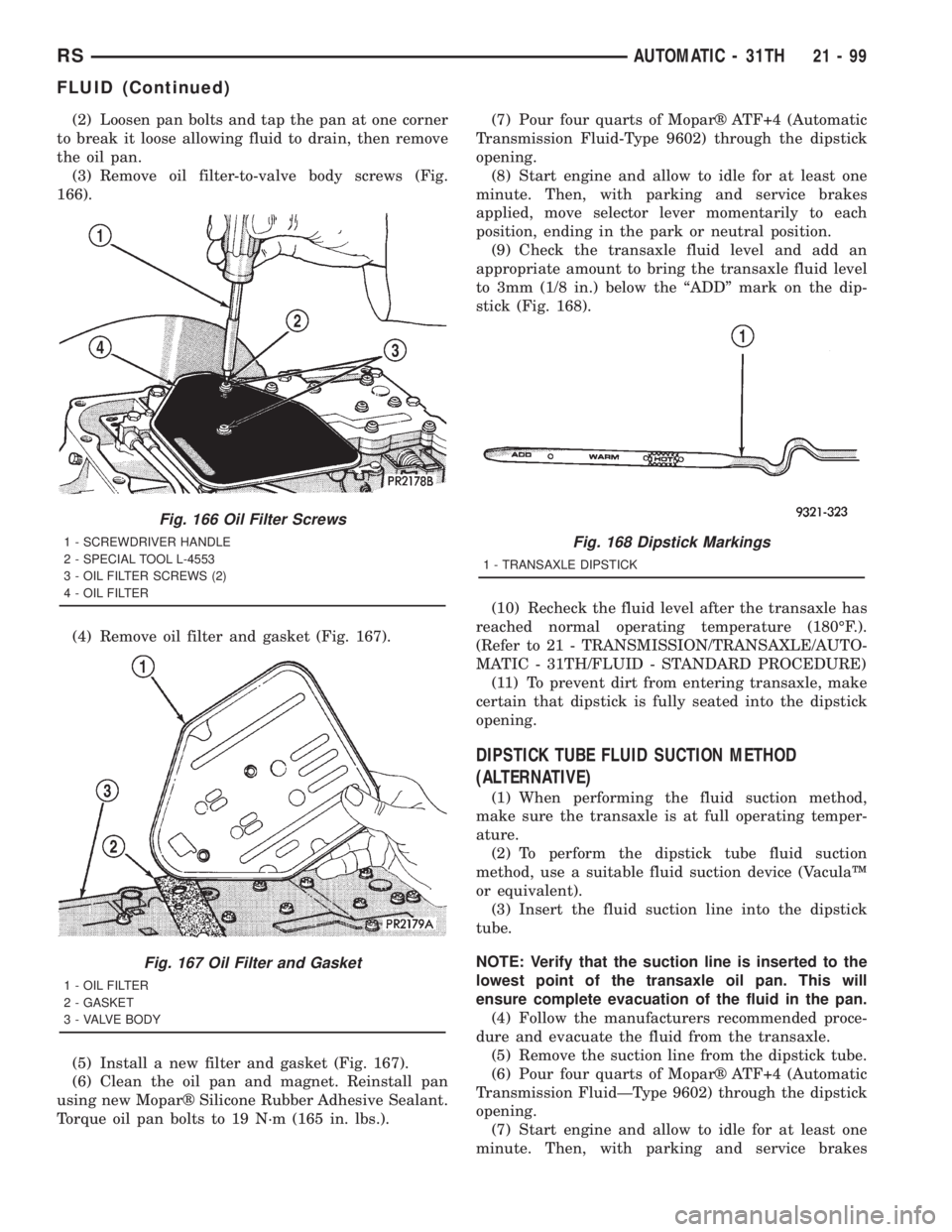

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Remove oil filter-to-valve body screws (Fig.

166).

(4) Remove oil filter and gasket (Fig. 167).

(5) Install a new filter and gasket (Fig. 167).

(6) Clean the oil pan and magnet. Reinstall pan

using new Moparž Silicone Rubber Adhesive Sealant.

Torque oil pan bolts to 19 N´m (165 in. lbs.).(7) Pour four quarts of Moparž ATF+4 (Automatic

Transmission Fluid-Type 9602) through the dipstick

opening.

(8) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

applied, move selector lever momentarily to each

position, ending in the park or neutral position.

(9) Check the transaxle fluid level and add an

appropriate amount to bring the transaxle fluid level

to 3mm (1/8 in.) below the ªADDº mark on the dip-

stick (Fig. 168).

(10) Recheck the fluid level after the transaxle has

reached normal operating temperature (180ÉF.).

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-

MATIC - 31TH/FLUID - STANDARD PROCEDURE)

(11) To prevent dirt from entering transaxle, make

certain that dipstick is fully seated into the dipstick

opening.

DIPSTICK TUBE FLUID SUCTION METHOD

(ALTERNATIVE)

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

(2) To perform the dipstick tube fluid suction

method, use a suitable fluid suction device (VaculaŸ

or equivalent).

(3) Insert the fluid suction line into the dipstick

tube.

NOTE: Verify that the suction line is inserted to the

lowest point of the transaxle oil pan. This will

ensure complete evacuation of the fluid in the pan.

(4) Follow the manufacturers recommended proce-

dure and evacuate the fluid from the transaxle.

(5) Remove the suction line from the dipstick tube.

(6) Pour four quarts of Moparž ATF+4 (Automatic

Transmission FluidÐType 9602) through the dipstick

opening.

(7) Start engine and allow to idle for at least one

minute. Then, with parking and service brakes

Fig. 166 Oil Filter Screws

1 - SCREWDRIVER HANDLE

2 - SPECIAL TOOL L-4553

3 - OIL FILTER SCREWS (2)

4 - OIL FILTER

Fig. 167 Oil Filter and Gasket

1 - OIL FILTER

2 - GASKET

3 - VALVE BODY

Fig. 168 Dipstick Markings

1 - TRANSAXLE DIPSTICK

RSAUTOMATIC - 31TH21-99

FLUID (Continued)

Page 3068 of 4284

pressure. Generally governor pressure ranges from

0-100 psi from idle to maximum speed, and rises pro-

portionally with the increase in output shaft speed.

Governor pressure and throttle pressure are acting

upon the shift valves to determine when a shift will

occur. Governor pressure is a direct indication of road

speed, and throttle pressure is an indication of

engine load. When both parameters have been met

by the throttle and governor pressures, an upshift or

downshift will occur.

CLEANING

Thoroughly clean all the governor parts in a suit-

able cleaning solution but do not use any type of

caustic cleaning agents.

The governor weight components and the governor

valve, must slide freely in their bores when clean and

dry. Minor surface scratches and burrs can be

smoothed with crocus cloth.

INSPECTION

The aluminum governor valve and outer weight

have a hard coating on them. Check condition of this

coating carefully. Do not reuse either part if the coat-

ing is damaged.

Inspect the governor weight spring for distortion.

Replace the spring, if distorted, collapsed, or broken.

Clean the filter in solvent and dry it with compressedair. Replace the filter, if damaged. Inspect the park

gear for chipped or worn gear teeth or damaged ring

grooves. Replace the gear, if damaged.

Check the teeth on the park gear for wear or dam-

age. Replace the gear if necessary. Inspect the metal

seal rings on the park gear hub. Replace the rings

only if severely worn, or broken.

OIL PUMP

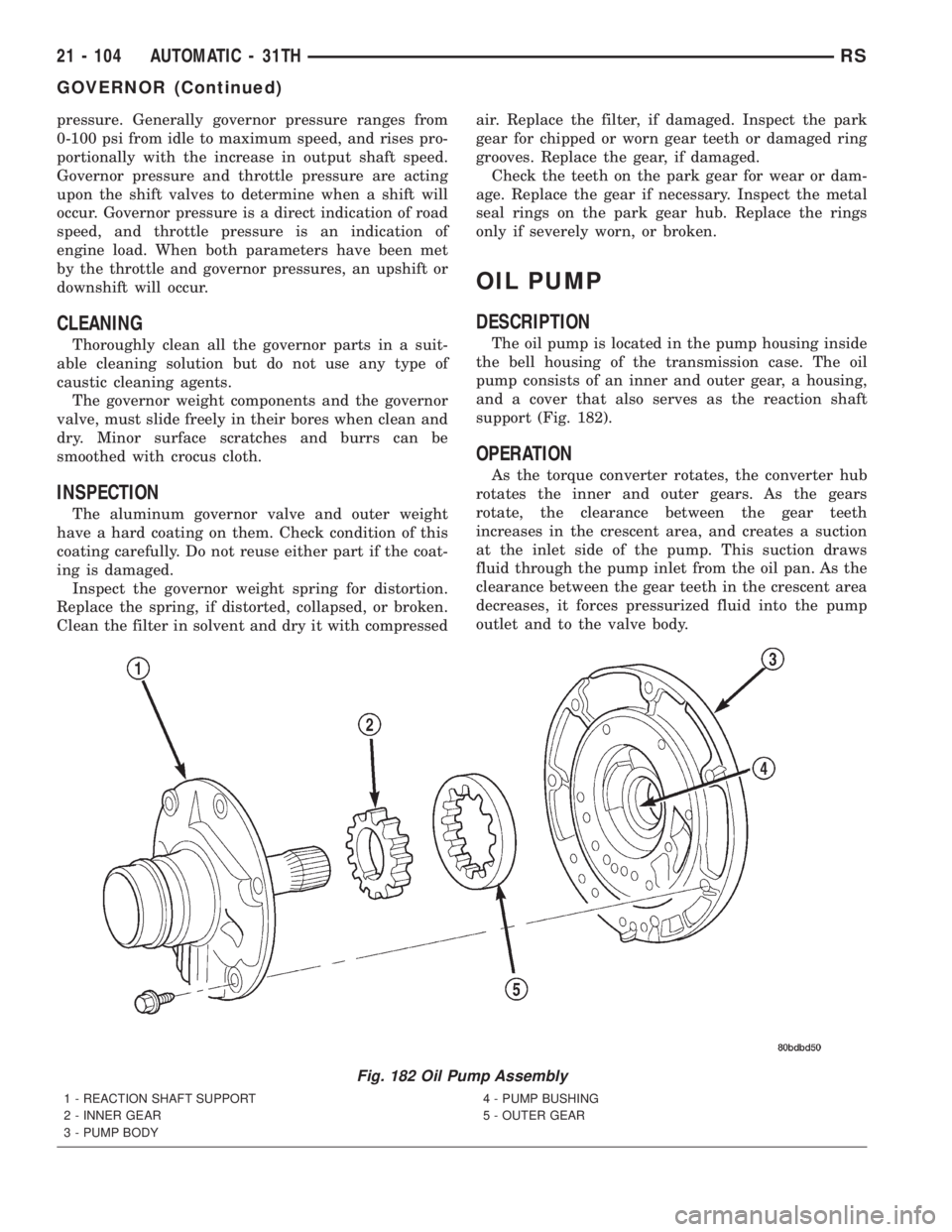

DESCRIPTION

The oil pump is located in the pump housing inside

the bell housing of the transmission case. The oil

pump consists of an inner and outer gear, a housing,

and a cover that also serves as the reaction shaft

support (Fig. 182).

OPERATION

As the torque converter rotates, the converter hub

rotates the inner and outer gears. As the gears

rotate, the clearance between the gear teeth

increases in the crescent area, and creates a suction

at the inlet side of the pump. This suction draws

fluid through the pump inlet from the oil pan. As the

clearance between the gear teeth in the crescent area

decreases, it forces pressurized fluid into the pump

outlet and to the valve body.

Fig. 182 Oil Pump Assembly

1 - REACTION SHAFT SUPPORT

2 - INNER GEAR

3 - PUMP BODY4 - PUMP BUSHING

5 - OUTER GEAR

21 - 104 AUTOMATIC - 31THRS

GOVERNOR (Continued)

Page 3069 of 4284

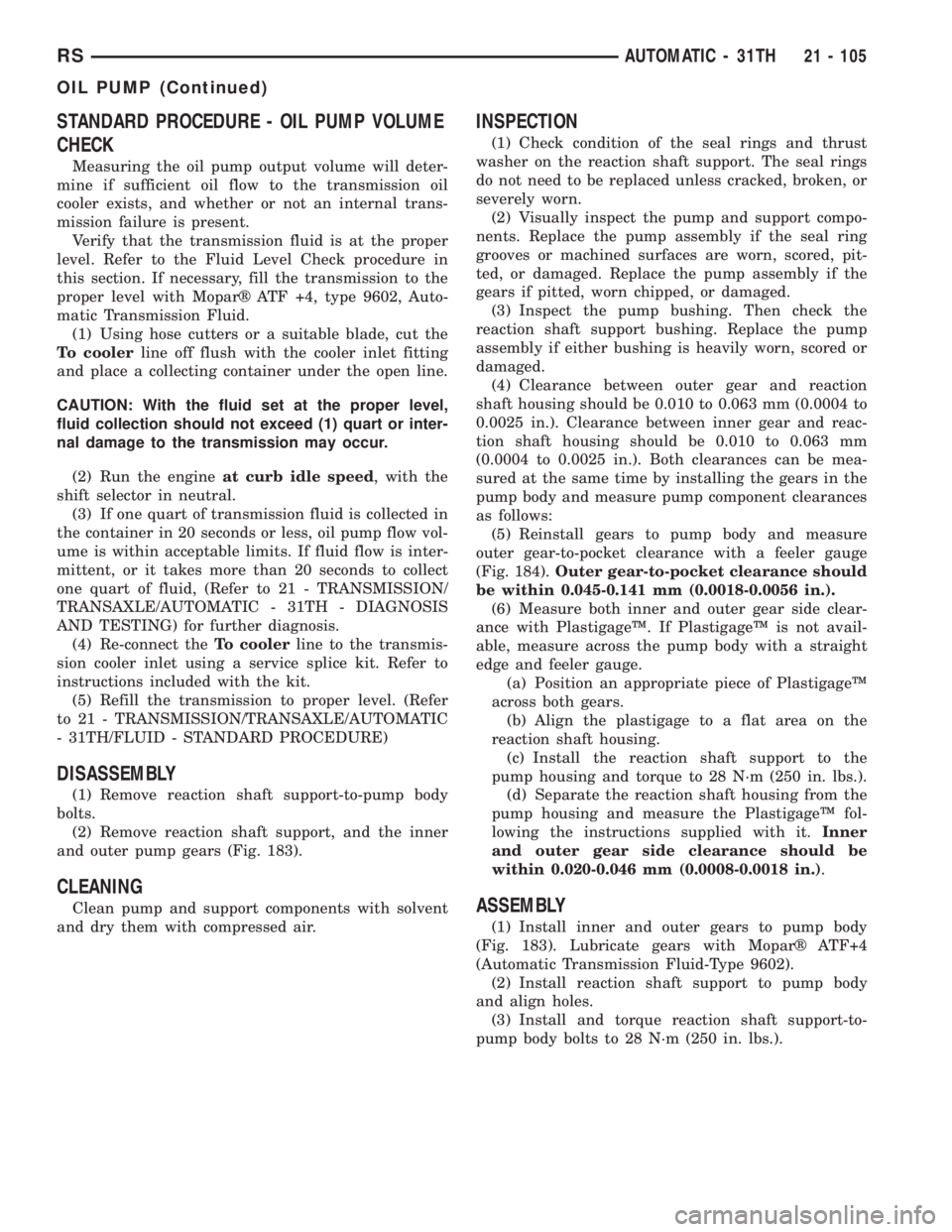

STANDARD PROCEDURE - OIL PUMP VOLUME

CHECK

Measuring the oil pump output volume will deter-

mine if sufficient oil flow to the transmission oil

cooler exists, and whether or not an internal trans-

mission failure is present.

Verify that the transmission fluid is at the proper

level. Refer to the Fluid Level Check procedure in

this section. If necessary, fill the transmission to the

proper level with Moparž ATF +4, type 9602, Auto-

matic Transmission Fluid.

(1) Using hose cutters or a suitable blade, cut the

To coolerline off flush with the cooler inlet fitting

and place a collecting container under the open line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If one quart of transmission fluid is collected in

the container in 20 seconds or less, oil pump flow vol-

ume is within acceptable limits. If fluid flow is inter-

mittent, or it takes more than 20 seconds to collect

one quart of fluid, (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 31TH - DIAGNOSIS

AND TESTING) for further diagnosis.

(4) Re-connect theTo coolerline to the transmis-

sion cooler inlet using a service splice kit. Refer to

instructions included with the kit.

(5) Refill the transmission to proper level. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 31TH/FLUID - STANDARD PROCEDURE)

DISASSEMBLY

(1) Remove reaction shaft support-to-pump body

bolts.

(2) Remove reaction shaft support, and the inner

and outer pump gears (Fig. 183).

CLEANING

Clean pump and support components with solvent

and dry them with compressed air.

INSPECTION

(1) Check condition of the seal rings and thrust

washer on the reaction shaft support. The seal rings

do not need to be replaced unless cracked, broken, or

severely worn.

(2) Visually inspect the pump and support compo-

nents. Replace the pump assembly if the seal ring

grooves or machined surfaces are worn, scored, pit-

ted, or damaged. Replace the pump assembly if the

gears if pitted, worn chipped, or damaged.

(3) Inspect the pump bushing. Then check the

reaction shaft support bushing. Replace the pump

assembly if either bushing is heavily worn, scored or

damaged.

(4) Clearance between outer gear and reaction

shaft housing should be 0.010 to 0.063 mm (0.0004 to

0.0025 in.). Clearance between inner gear and reac-

tion shaft housing should be 0.010 to 0.063 mm

(0.0004 to 0.0025 in.). Both clearances can be mea-

sured at the same time by installing the gears in the

pump body and measure pump component clearances

as follows:

(5) Reinstall gears to pump body and measure

outer gear-to-pocket clearance with a feeler gauge

(Fig. 184).Outer gear-to-pocket clearance should

be within 0.045-0.141 mm (0.0018-0.0056 in.).

(6) Measure both inner and outer gear side clear-

ance with PlastigageŸ. If PlastigageŸ is not avail-

able, measure across the pump body with a straight

edge and feeler gauge.

(a) Position an appropriate piece of PlastigageŸ

across both gears.

(b) Align the plastigage to a flat area on the

reaction shaft housing.

(c) Install the reaction shaft support to the

pump housing and torque to 28 N´m (250 in. lbs.).

(d) Separate the reaction shaft housing from the

pump housing and measure the PlastigageŸ fol-

lowing the instructions supplied with it.Inner

and outer gear side clearance should be

within 0.020-0.046 mm (0.0008-0.0018 in.).

ASSEMBLY

(1) Install inner and outer gears to pump body

(Fig. 183). Lubricate gears with Moparž ATF+4

(Automatic Transmission Fluid-Type 9602).

(2) Install reaction shaft support to pump body

and align holes.

(3) Install and torque reaction shaft support-to-

pump body bolts to 28 N´m (250 in. lbs.).

RSAUTOMATIC - 31TH21 - 105

OIL PUMP (Continued)

Page 3081 of 4284

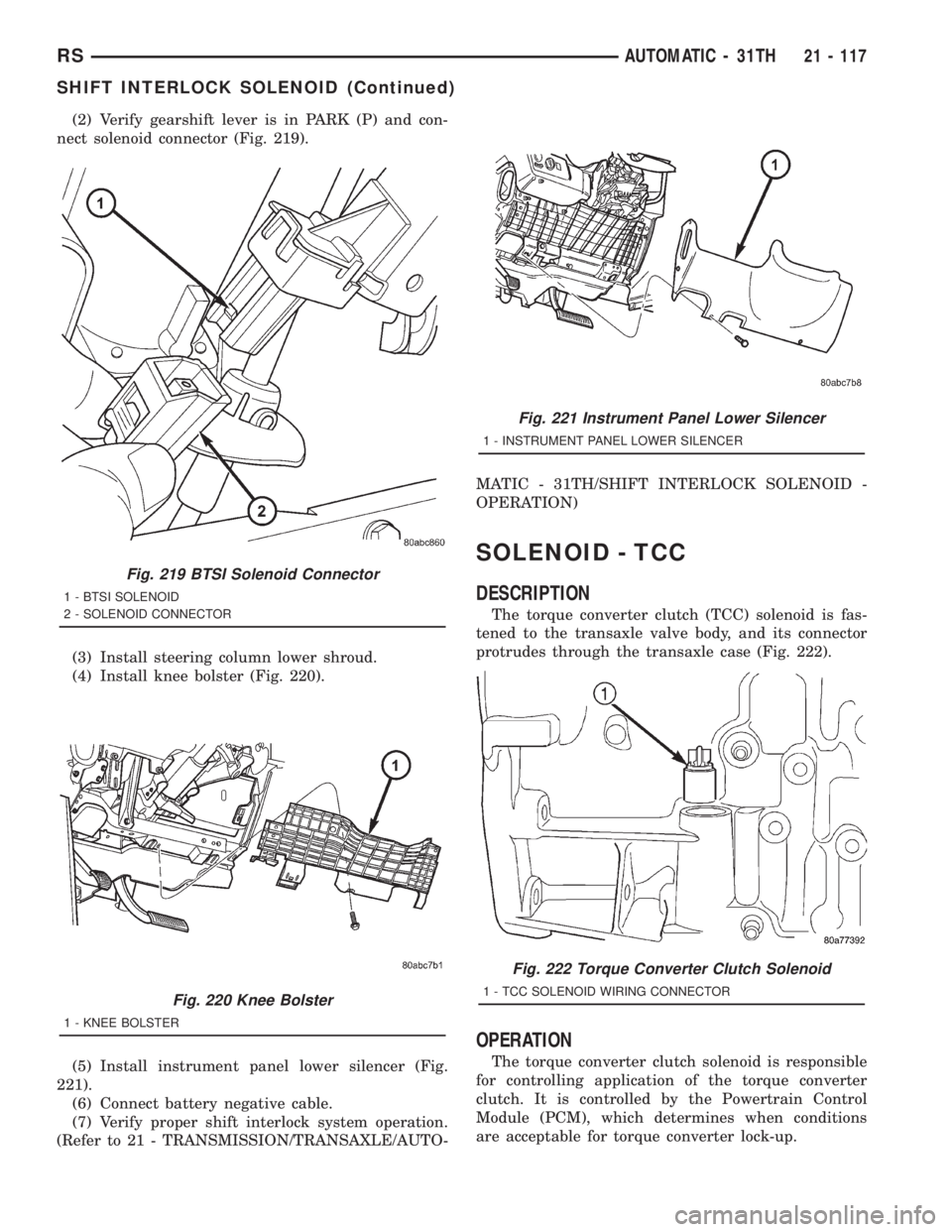

(2) Verify gearshift lever is in PARK (P) and con-

nect solenoid connector (Fig. 219).

(3) Install steering column lower shroud.

(4) Install knee bolster (Fig. 220).

(5) Install instrument panel lower silencer (Fig.

221).

(6) Connect battery negative cable.

(7) Verify proper shift interlock system operation.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-MATIC - 31TH/SHIFT INTERLOCK SOLENOID -

OPERATION)

SOLENOID - TCC

DESCRIPTION

The torque converter clutch (TCC) solenoid is fas-

tened to the transaxle valve body, and its connector

protrudes through the transaxle case (Fig. 222).

OPERATION

The torque converter clutch solenoid is responsible

for controlling application of the torque converter

clutch. It is controlled by the Powertrain Control

Module (PCM), which determines when conditions

are acceptable for torque converter lock-up.

Fig. 219 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

Fig. 220 Knee Bolster

1 - KNEE BOLSTER

Fig. 221 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 222 Torque Converter Clutch Solenoid

1 - TCC SOLENOID WIRING CONNECTOR

RSAUTOMATIC - 31TH21 - 117

SHIFT INTERLOCK SOLENOID (Continued)

Page 3082 of 4284

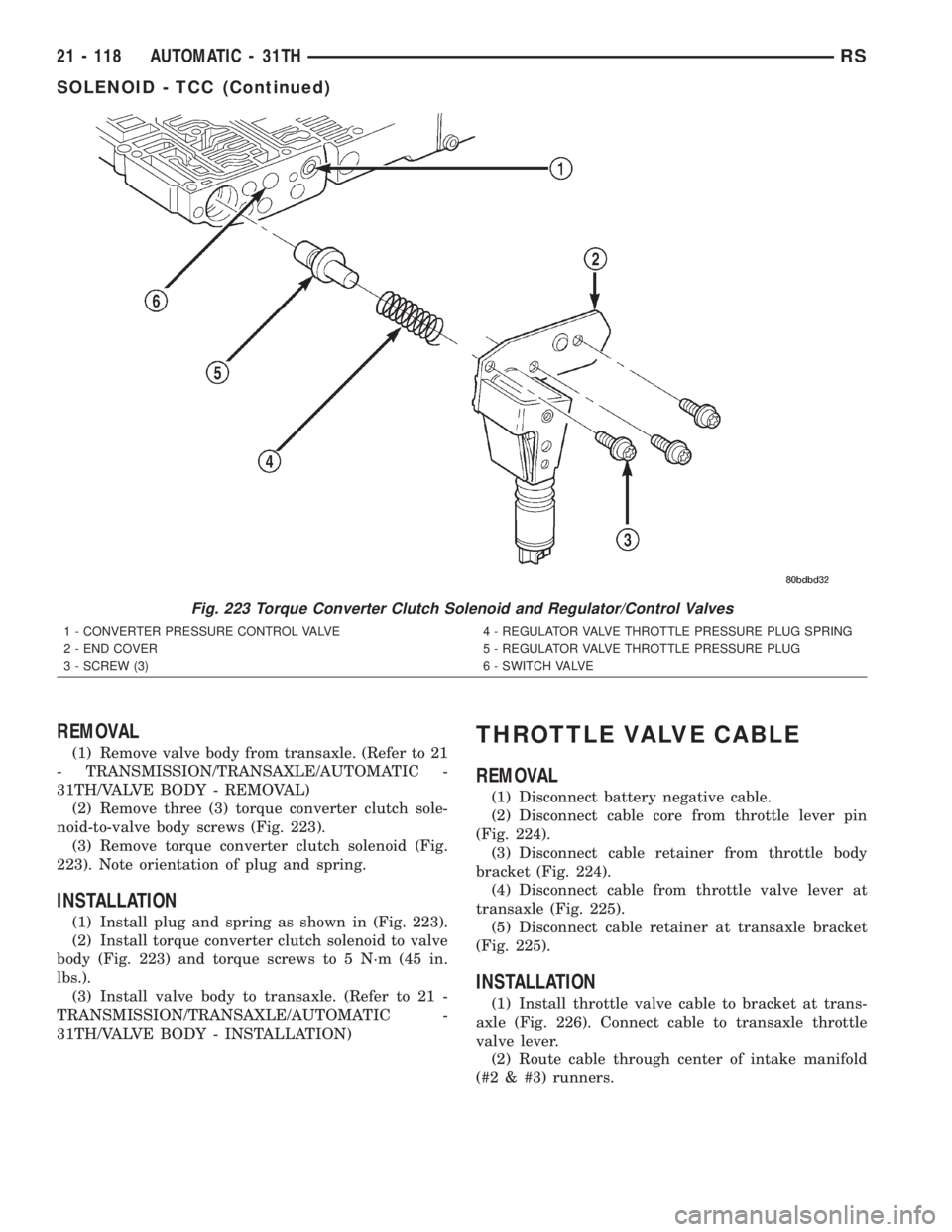

REMOVAL

(1) Remove valve body from transaxle. (Refer to 21

- TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/VALVE BODY - REMOVAL)

(2) Remove three (3) torque converter clutch sole-

noid-to-valve body screws (Fig. 223).

(3) Remove torque converter clutch solenoid (Fig.

223). Note orientation of plug and spring.

INSTALLATION

(1) Install plug and spring as shown in (Fig. 223).

(2) Install torque converter clutch solenoid to valve

body (Fig. 223) and torque screws to 5 N´m (45 in.

lbs.).

(3) Install valve body to transaxle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/VALVE BODY - INSTALLATION)

THROTTLE VALVE CABLE

REMOVAL

(1) Disconnect battery negative cable.

(2) Disconnect cable core from throttle lever pin

(Fig. 224).

(3) Disconnect cable retainer from throttle body

bracket (Fig. 224).

(4) Disconnect cable from throttle valve lever at

transaxle (Fig. 225).

(5) Disconnect cable retainer at transaxle bracket

(Fig. 225).

INSTALLATION

(1) Install throttle valve cable to bracket at trans-

axle (Fig. 226). Connect cable to transaxle throttle

valve lever.

(2) Route cable through center of intake manifold

(#2 & #3) runners.

Fig. 223 Torque Converter Clutch Solenoid and Regulator/Control Valves

1 - CONVERTER PRESSURE CONTROL VALVE

2 - END COVER

3 - SCREW (3)4 - REGULATOR VALVE THROTTLE PRESSURE PLUG SPRING

5 - REGULATOR VALVE THROTTLE PRESSURE PLUG

6 - SWITCH VALVE

21 - 118 AUTOMATIC - 31THRS

SOLENOID - TCC (Continued)