torque CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2931 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding pivot bearing in front strut

assembly.7. Replace pivot bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on

cradle/crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling or

intermediate shaft worn, broken or

loose.3. Replace steering column coupling or

intermediate shaft.

4. Free play in steering column. 4. Check all components of the steering

column and repair or replace as required.

5. Worn lower control arm ball joints. 5. Replace lower control arm ball joints as

required.

6. Loose steering knuckle-to-ball joint

stud pinch bolt.6. Inspect pinch bolt, replace as necessary,

and tighten to specified torque.

7. Front wheel bearing loose or

worn.7. Replace hub and bearing as necessary.

8. Loose outer tie rod end. 8. Replace outer tie rod end that has

excessive free play.

9. Loose inner tie rod. 9. Replace power steering gear.

10. Defective steering gear rotary

valve.10. Replace power steering gear.

NOTE: * Steering shudder can be expected in new

vehicles and vehicles with recent steering systemrepairs. Shudder should dissipate after the vehicle

has been driven several weeks.

RSSTEERING19-7

STEERING (Continued)

Page 2932 of 4284

NOTE: ** To evaluate this condition, it may be nec-

essary to disconnect the coupling at the base of the

steering column. Turn the steering wheel and feel or

listen for internal rubbing in steering column. To

avoid damaging the column clockspring, note the

following. Before disconnecting coupling, place

tires in the straight-ahead position and center steer-

ing wheel. Once disconnected, DO NOT rotatesteering wheel more than one revolution in either

direction and place steering wheel in original loca-

tion before reconnecting coupling. If this position is

lost, the steering column clockspring must be

recentered following the procedure found within the

procedure for steering column installation in the

steering column section.

POWER STEERING FLUID

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH

VISIBLE LEAK.1. Loose power steering hose

fittings.1. Tighten the fitting to its specified torque.

2. Damaged or missing fitting seal,

gasket, or O-ring.2. Replace as necessary.

3. Power steering pump or power

steering gear leaking.3. Repair or replace the leaking component

as required.

AERATED FLUID. 1. Low fluid level.* 1. Fill power steering fluid reservoir to

proper level.

2. Air leak between power steering

fluid reservoir and pump.2. Inspect for proper sealing. Replace the

power steering pump (with reservoir).

3. Cracked power steering pump

housing.3. Replace the power steering pump.

RESERVOIR FLUID

OVERFLOW AND FLUID

THAT IS MILKY IN COLOR1. Water contamination. 1. Drain the power steering fluid from the

system. Flush the system with fresh clean

power steering fluid, drain, then refill to the

proper level.

NOTE: * Extremely cold temperatures may cause

power steering fluid aeration if the power steering

fluid level is low.

19 - 8 STEERINGRS

STEERING (Continued)

Page 2933 of 4284

SPECIFICATIONS

POWER STEERING FASTENER TORQUE

DESCRIPTION TORQUE

Power Steering Pump:

Flow Control Valve

Pressure Fitting75 N´m (55 ft. lbs.)

Mounting Bolts 54 N´m (40 ft. lbs.)

Rear Bracket To Engine

Mounting Bolts54 N´m (40 ft. lbs.)

Steering Gear:

Mounting Bolts 183 N´m (135 ft. lbs.)

Tie Rod Steering Knuckle

Nut75 N´m (55 ft. lbs.)

Tie Rod Jam Nut 75 N´m (55 ft. lbs.)

Coupling Pinch Bolt 28 N´m (250 in. lbs.)

Power Steering Fluid

Hoses:

Hose Tube Nuts 31 N´m (275 in. lbs.)

Routing Bracket Bolts 23 N´m (200 in. lbs.)

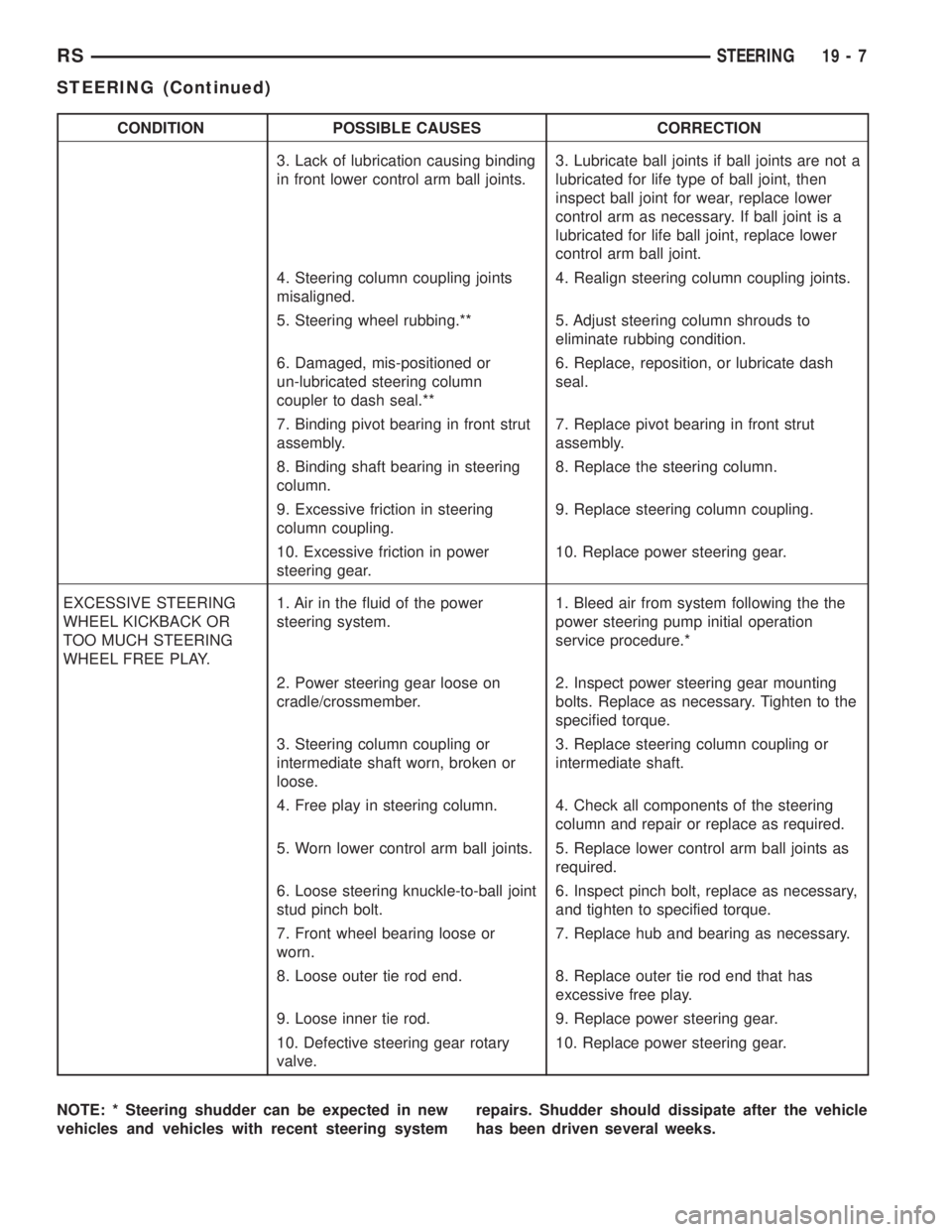

SPECIAL TOOLS

POWER STEERING

Power Steering Analyzer 6815

Adapters, Power Steering Analyzer 6893

HOSE, POWER STEERING ANALYZER 6959

RSSTEERING19-9

Page 2938 of 4284

(16) Install the steering wheel retaining nut.

Tighten the nut to 61 N´m (45 ft. lbs.)

(17) Install the airbag (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(18) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(19) Install the parking brake handle link.

(20) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

(21) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(22) Install the upper shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - INSTAL-

LATION).

(23) Install the traction off switch.

(24) Install the lower shroud.

SPECIFICATIONS

COLUMN TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Steering Wheel Retaining

Nut61 45 Ð

Steering Column Mounting

Bracket Attaching Nuts12 Ð 105

Steering Column Coupling

Pinch Bolt28 Ð 250

Steering Column Airbag

Module Attaching Nuts11 Ð 100

KEY/LOCK CYLINDER

DESCRIPTION

The lock cylinder is inserted in the end of the

housing opposite the ignition switch.

OPERATION

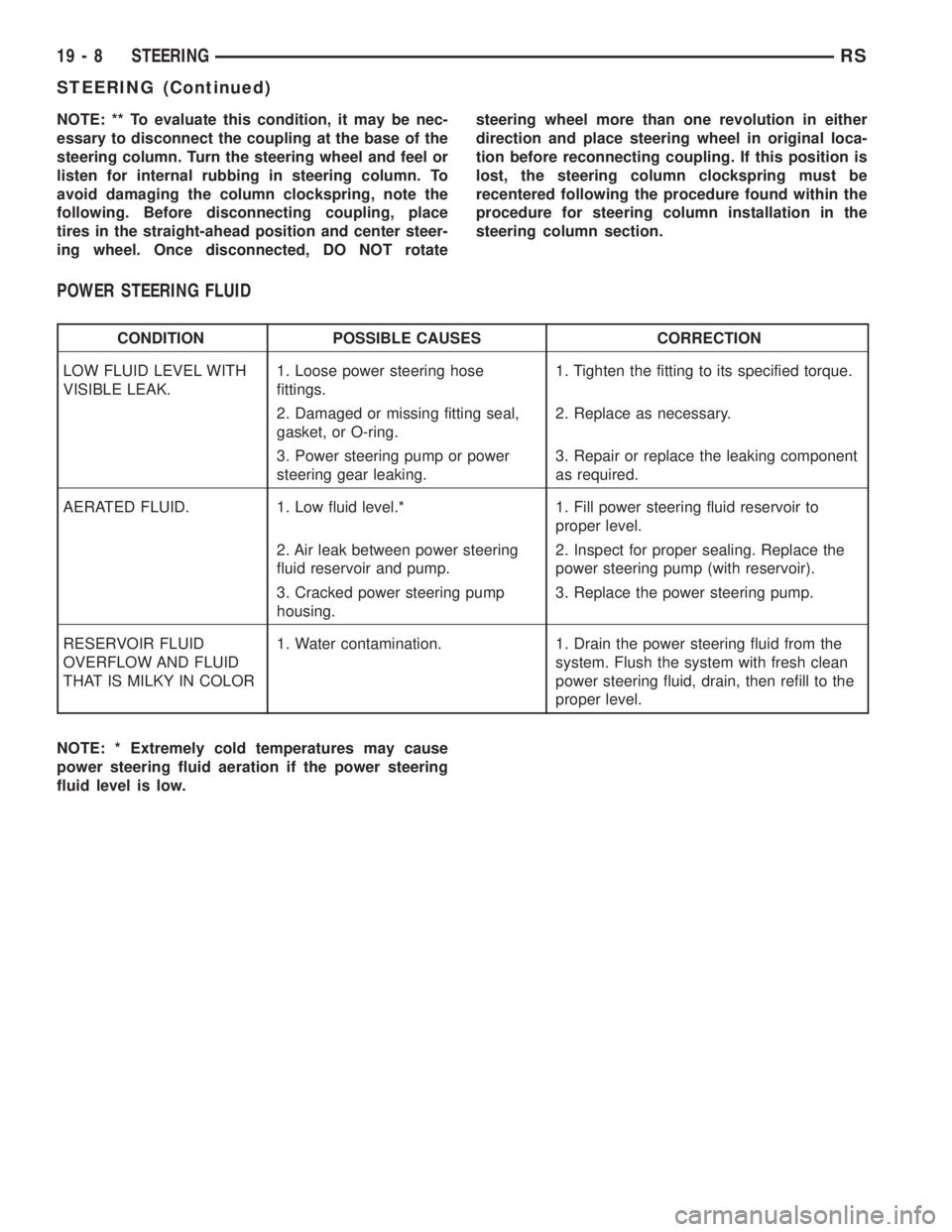

The ignition key rotates the cylinder to 5 different

detents (Fig. 7) :

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove steering column cover retaining

screws.

(3) Remove screws holding steering column

shrouds and remove lower shroud.

(4) Place key cylinder in RUN position. Depress

lock cylinder retaining tab on the bottom of the lock

housing and remove key cylinder.

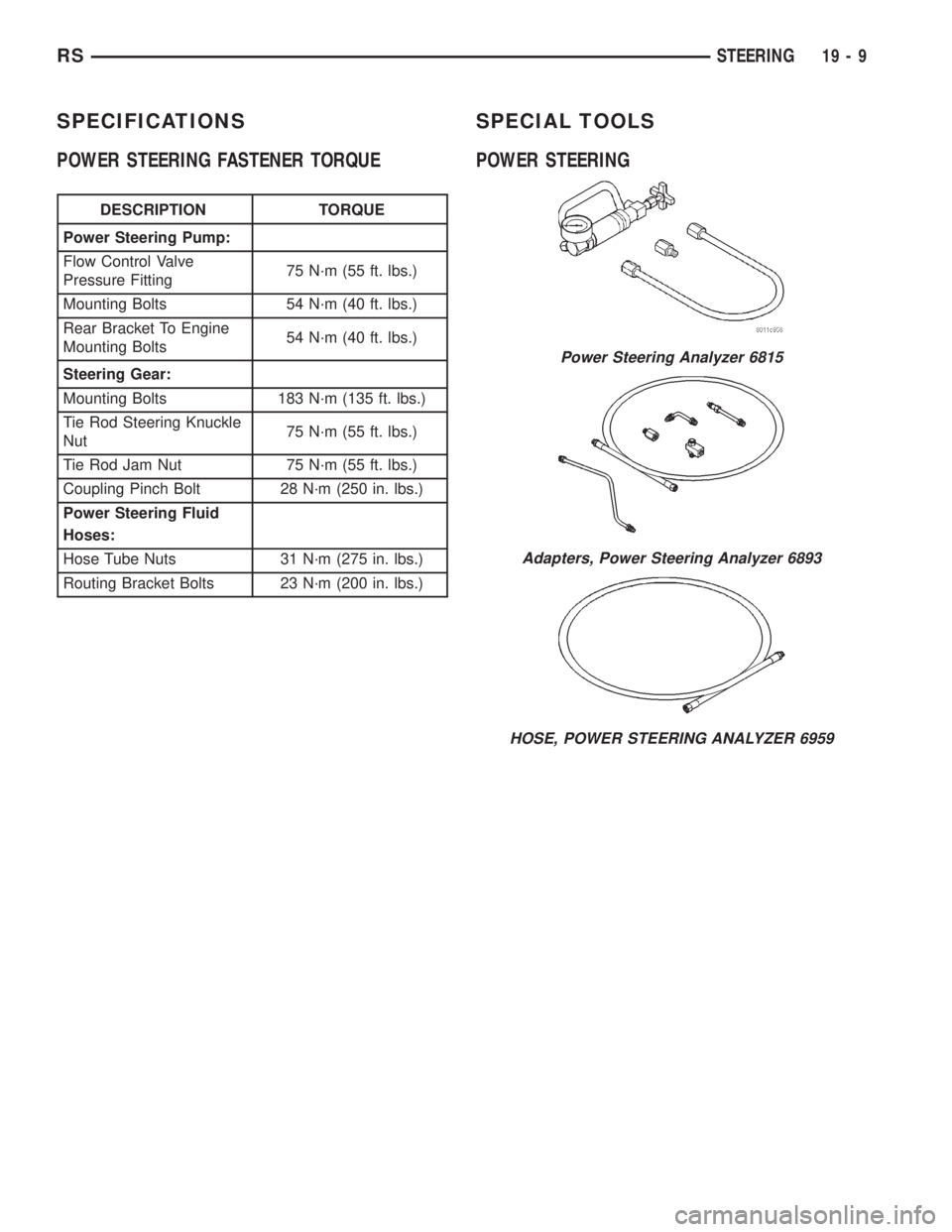

INSTALLATION

(1) Install key in lock cylinder. Turn key to run

position (retaining tab on lock cylinder can be

depressed).

(2) The shaft at the end of the lock cylinder aligns

with the socket in the end of the housing. To align

the socket with the lock cylinder, ensure the socket is

in the Run position (Fig. 8) .

Fig. 7 Ignition Lock Cylinder Detents

Fig. 8 Socket in Lock Cylinder Housing

1 - LOCK CYLINDER HOUSING

2 - SOCKET

19 - 14 COLUMNRS

COLUMN (Continued)

Page 2945 of 4284

(4) Install steering gear assembly on the front sus-

pension cradle. Install the 3 steering gear mounting

bolts and nuts (Fig. 7).

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Tighten the 3 steering gear to suspension cra-

dle mounting bolts to a torque of 183 N´m (135 ft.

lbs.).

(6) Attach the power steering fluid pressure and

return lines (Fig. 6) to the proper fittings on the

steering gear. Tighten the power steering fluid line

tube nuts to a torque of 31 N´m (275 in. lbs.).

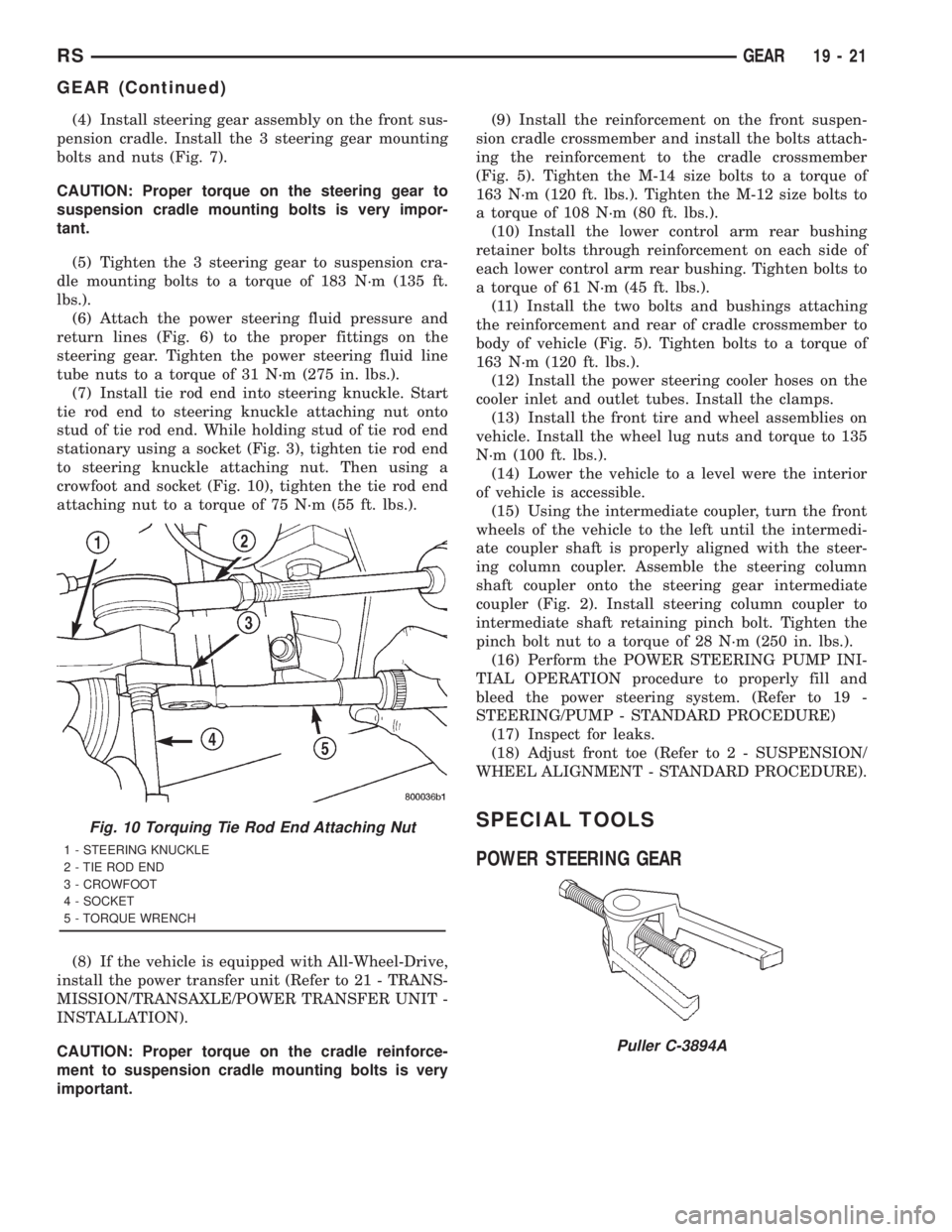

(7) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 3), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 10), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(8) If the vehicle is equipped with All-Wheel-Drive,

install the power transfer unit (Refer to 21 - TRANS-

MISSION/TRANSAXLE/POWER TRANSFER UNIT -

INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.(9) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 5). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(10) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(11) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 5). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(12) Install the power steering cooler hoses on the

cooler inlet and outlet tubes. Install the clamps.

(13) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 135

N´m (100 ft. lbs.).

(14) Lower the vehicle to a level were the interior

of vehicle is accessible.

(15) Using the intermediate coupler, turn the front

wheels of the vehicle to the left until the intermedi-

ate coupler shaft is properly aligned with the steer-

ing column coupler. Assemble the steering column

shaft coupler onto the steering gear intermediate

coupler (Fig. 2). Install steering column coupler to

intermediate shaft retaining pinch bolt. Tighten the

pinch bolt nut to a torque of 28 N´m (250 in. lbs.).

(16) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(17) Inspect for leaks.

(18) Adjust front toe (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

SPECIAL TOOLS

POWER STEERING GEARFig. 10 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

Puller C-3894A

RSGEAR19-21

GEAR (Continued)

Page 2947 of 4284

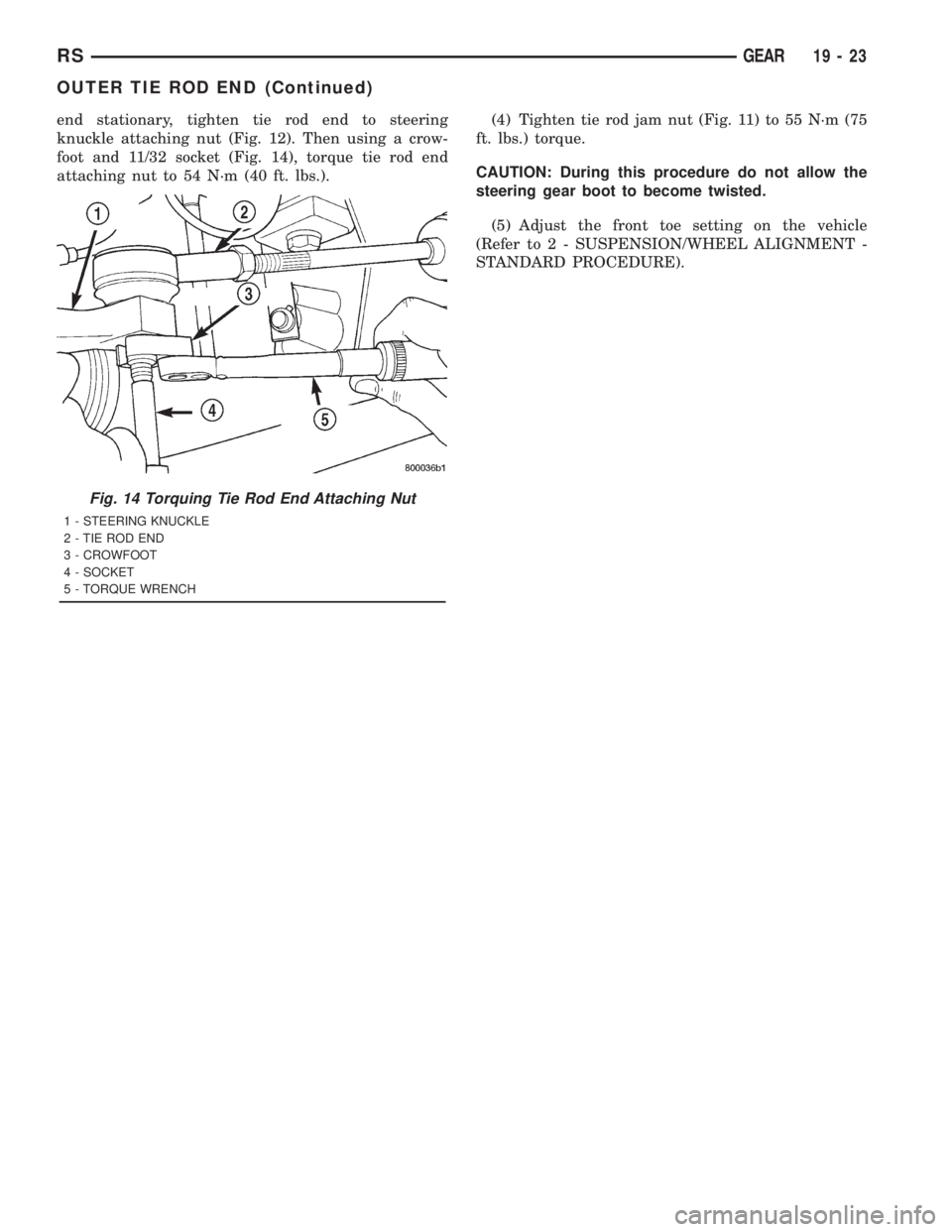

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 12). Then using a crow-

foot and 11/32 socket (Fig. 14), torque tie rod end

attaching nut to 54 N´m (40 ft. lbs.).(4) Tighten tie rod jam nut (Fig. 11) to 55 N´m (75

ft. lbs.) torque.

CAUTION: During this procedure do not allow the

steering gear boot to become twisted.

(5) Adjust the front toe setting on the vehicle

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

Fig. 14 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

RSGEAR19-23

OUTER TIE ROD END (Continued)

Page 2953 of 4284

INSTALLATION - PUMP (2.4L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket (Fig. 7), then install the nut and

bolt attaching the front bracket to the cast bracket

(Fig. 8).Do not fully tighten at this time..

(3) Install the rear nut (Fig. 7).

(4) Install the power steering pump drive belt on

pulley and adjust (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - INSTALLATION).(5) Tighten the two adjustment slot bolts and the

one pivot bolt to 54 N´m (40 ft.lbs.) torque.

(6) Install the accessory drive splash shield.

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(7) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 6). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(8) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 6).Be sure hose clamps are properly

reinstalled.

(9) Install the power steering fluid supply hose on

the power steering pump fluid fitting.Be sure hose

is clear of accessory drive belts all hose clamps

are properly reinstalled.

(10) When used, properly position the protective

heat sleeve on the power steering return hose. Tie

strap the heat sleeve to the power steering hose to

keep in it's proper position.

(11) Install the exhaust system (Fig. 4). Install all

exhaust system isolators/hangers on the exhaust sys-

tem brackets, then the four bolts and flag nuts (Fig.

3).

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness.

(13) Lower vehicle.

(14) Connect the negative battery cable on the

negative battery post.

(15) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(16) Inspect for leaks.

INSTALLATION - PUMP (3.3L/3.8L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

engine compartment of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket.

(3) Install the 3 front and 1 rear power steering

pump mounting bolts (Fig. 9). Remember to place

spacer between pump and rear mounting bracket

when installing rear mounting bolt. Tighten the

power steering pump mounting bolts to a torque of

54 N´m (40 ft. lbs.).

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

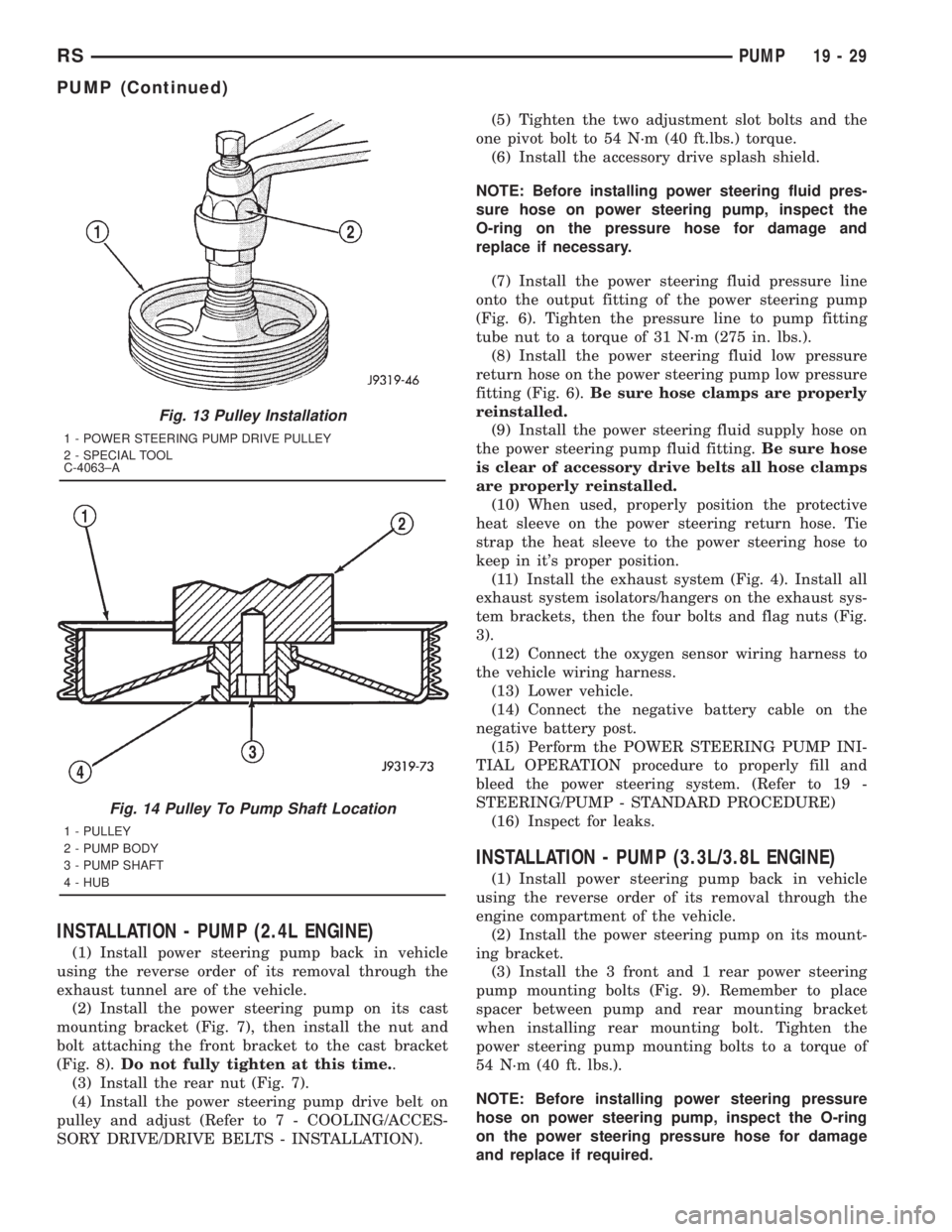

Fig. 13 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL

C-4063±A

Fig. 14 Pulley To Pump Shaft Location

1 - PULLEY

2 - PUMP BODY

3 - PUMP SHAFT

4 - HUB

RSPUMP19-29

PUMP (Continued)

Page 2954 of 4284

(4) Install the power steering fluid pressure line

into the pressure output fitting of the power steering

pump (Fig. 11). Tighten the pressure line to pump fit-

ting tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid low-pressure

return hose on the power steering pump low pressure

fitting (Fig. 11).Be sure hose clamps are prop-

erly reinstalled.

(6) Raise the vehicle.

(7) Install the routing clip on the engine for the

pressure hose (Fig. 10).

(8) Tighten the pump thru-bolt (Fig. 9). Tighten to

54 N´m (40 ft. lbs.) torque.

(9) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(10) Install the drive belt splash shield.

(11) Lower the vehicle.

(12) Install the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(13) Connect the negative battery cable on the

negative battery post.

(14) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(15) Inspect for leaks.

SPECIAL TOOLS

POWER STEERING PUMP

FLUID

STANDARD PROCEDURE - POWER STEERING

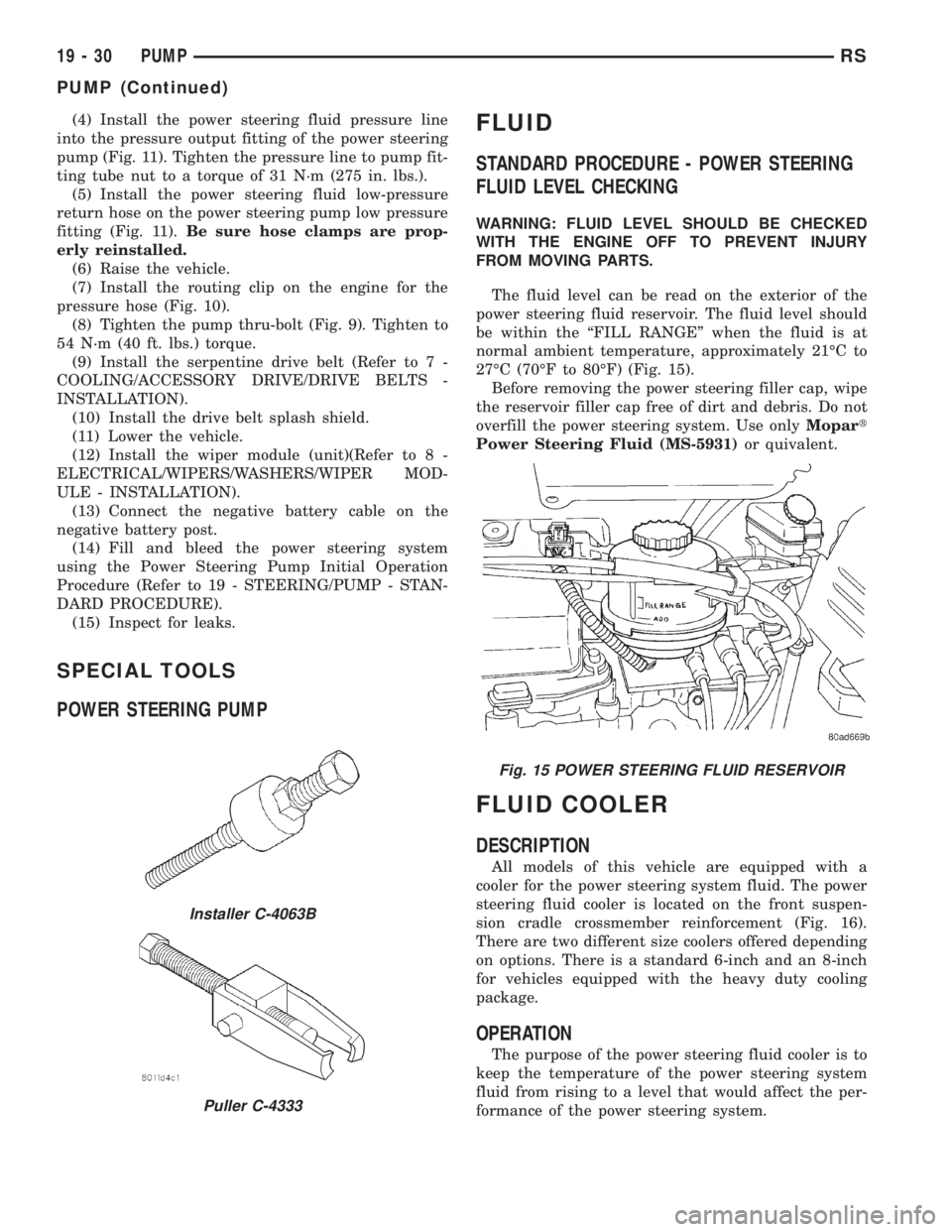

FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT INJURY

FROM MOVING PARTS.

The fluid level can be read on the exterior of the

power steering fluid reservoir. The fluid level should

be within the ªFILL RANGEº when the fluid is at

normal ambient temperature, approximately 21ÉC to

27ÉC (70ÉF to 80ÉF) (Fig. 15).

Before removing the power steering filler cap, wipe

the reservoir filler cap free of dirt and debris. Do not

overfill the power steering system. Use onlyMopart

Power Steering Fluid (MS-5931)or quivalent.

FLUID COOLER

DESCRIPTION

All models of this vehicle are equipped with a

cooler for the power steering system fluid. The power

steering fluid cooler is located on the front suspen-

sion cradle crossmember reinforcement (Fig. 16).

There are two different size coolers offered depending

on options. There is a standard 6-inch and an 8-inch

for vehicles equipped with the heavy duty cooling

package.

OPERATION

The purpose of the power steering fluid cooler is to

keep the temperature of the power steering system

fluid from rising to a level that would affect the per-

formance of the power steering system.

Installer C-4063B

Puller C-4333

Fig. 15 POWER STEERING FLUID RESERVOIR

19 - 30 PUMPRS

PUMP (Continued)

Page 2960 of 4284

INSTALLATION - RHD GEAR

(1) Install the steering gear up in the front sus-

pension cradle crossmember, leaving room to install

intermediate coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

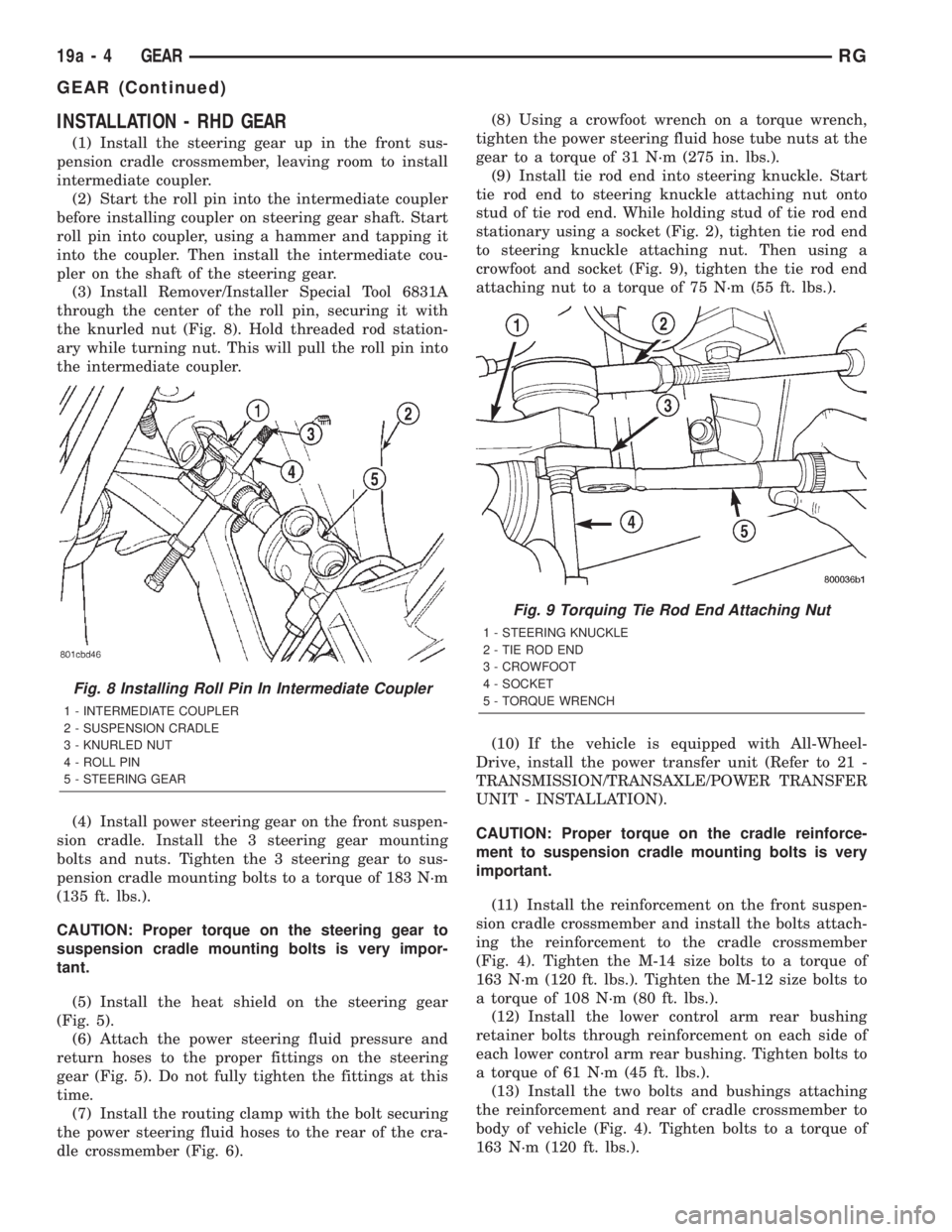

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 8). Hold threaded rod station-

ary while turning nut. This will pull the roll pin into

the intermediate coupler.

(4) Install power steering gear on the front suspen-

sion cradle. Install the 3 steering gear mounting

bolts and nuts. Tighten the 3 steering gear to sus-

pension cradle mounting bolts to a torque of 183 N´m

(135 ft. lbs.).

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Install the heat shield on the steering gear

(Fig. 5).

(6) Attach the power steering fluid pressure and

return hoses to the proper fittings on the steering

gear (Fig. 5). Do not fully tighten the fittings at this

time.

(7) Install the routing clamp with the bolt securing

the power steering fluid hoses to the rear of the cra-

dle crossmember (Fig. 6).(8) Using a crowfoot wrench on a torque wrench,

tighten the power steering fluid hose tube nuts at the

gear to a torque of 31 N´m (275 in. lbs.).

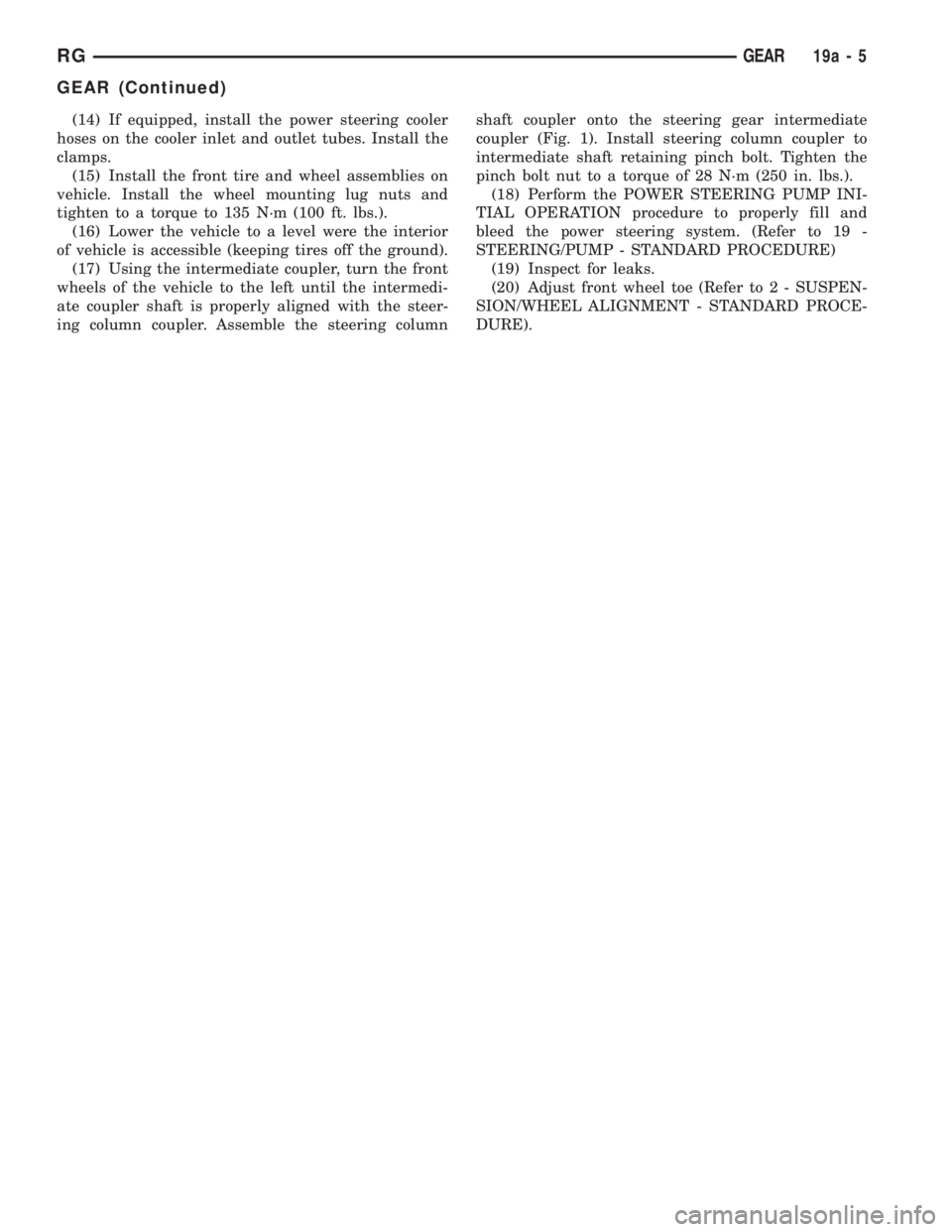

(9) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 2), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 9), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(10) If the vehicle is equipped with All-Wheel-

Drive, install the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(11) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 4). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(12) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(13) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 4). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

Fig. 8 Installing Roll Pin In Intermediate Coupler

1 - INTERMEDIATE COUPLER

2 - SUSPENSION CRADLE

3 - KNURLED NUT

4 - ROLL PIN

5 - STEERING GEAR

Fig. 9 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

19a - 4 GEARRG

GEAR (Continued)

Page 2961 of 4284

(14) If equipped, install the power steering cooler

hoses on the cooler inlet and outlet tubes. Install the

clamps.

(15) Install the front tire and wheel assemblies on

vehicle. Install the wheel mounting lug nuts and

tighten to a torque to 135 N´m (100 ft. lbs.).

(16) Lower the vehicle to a level were the interior

of vehicle is accessible (keeping tires off the ground).

(17) Using the intermediate coupler, turn the front

wheels of the vehicle to the left until the intermedi-

ate coupler shaft is properly aligned with the steer-

ing column coupler. Assemble the steering columnshaft coupler onto the steering gear intermediate

coupler (Fig. 1). Install steering column coupler to

intermediate shaft retaining pinch bolt. Tighten the

pinch bolt nut to a torque of 28 N´m (250 in. lbs.).

(18) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(19) Inspect for leaks.

(20) Adjust front wheel toe (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

RGGEAR19a-5

GEAR (Continued)