sensor CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1455 of 4284

ENGINE CONTROL MODULE C2 (DIESEL) - BLACK 40 WAYCAV CIRCUIT FUNCTION

82 - -

83 - -

84 - -

85 - -

86 T753 20DG/YL IGNITION SWITCH OUTPUT (START)

87 - -

88 K35 20GY/YL EGR SOLENOID CONTROL

89 K35 20GY/YL EGR SOLENOID CONTROL

90 - -

91 - -

92 - -

93 - -

94 - -

95 - -

96 - -

97 - -

98 - -

99 - -

100 - -

101 - -

102 - -

103 - -

104 - -

105 - -

106 - -

107 - -

108 - -

109 - -

110 - -

111 - -

112 K119 20DB/LG CLUTCH PEDAL UPSTOP SWITCH SENSE

113 - -

114 - -

115 K14 14LB/BR FUEL INJECTOR NO. 4 CONTROL

116 K111 14DB/LB COMMON INJECTOR DRIVER

117 - -

118 K11 14WT/DB FUEL INJECTOR NO. 1 CONTROL

119 K12 14TN FUEL INJECTOR NO. 2 CONTROL

120 K13 14BR/LB FUEL INJECTOR NO. 3 CONTROL

121 - -

ENGINE COOLANT TEMP SENSOR (DIESEL) - BLUE 2 WAYCAV CIRCUIT FUNCTION

1 K2 20TN/BK ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

2 K900 20DB/DG SENSOR GROUND

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

236

CONNECTOR PINOUTS

Page 1456 of 4284

ENGINE OIL PRESSURE SENSOR (DIESEL) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

2 G6 20VT/GY ENGINE OIL PRESSURE SENSOR SIGNAL

3 K936 20BR/YL ENGINE OIL PRESSURE SENSOR GROUND

ENGINE OIL TEMPERATURE SENSOR (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K89 20DB/WT ENGINE OIL TEMPERATURE SENSOR SIGNAL

2 K900 20DB/OR SENSOR GROUND

FUEL HEATER (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 N1 16RD FUEL HEATER RELAY OUTPUT

2 Z201 18RD GROUND

FUEL INJECTOR NO. 1 (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K111 14DB/LB COMMON INJECTOR DRIVER

2 K11 14WT/DB FUEL INJECTOR NO. 1 CONTROL

FUEL INJECTOR NO. 2 (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K111 14DB/LB COMMON INJECTOR DRIVER

2 K12 14TN FUEL INJECTOR NO. 2 CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

237

CONNECTOR PINOUTS

Page 1457 of 4284

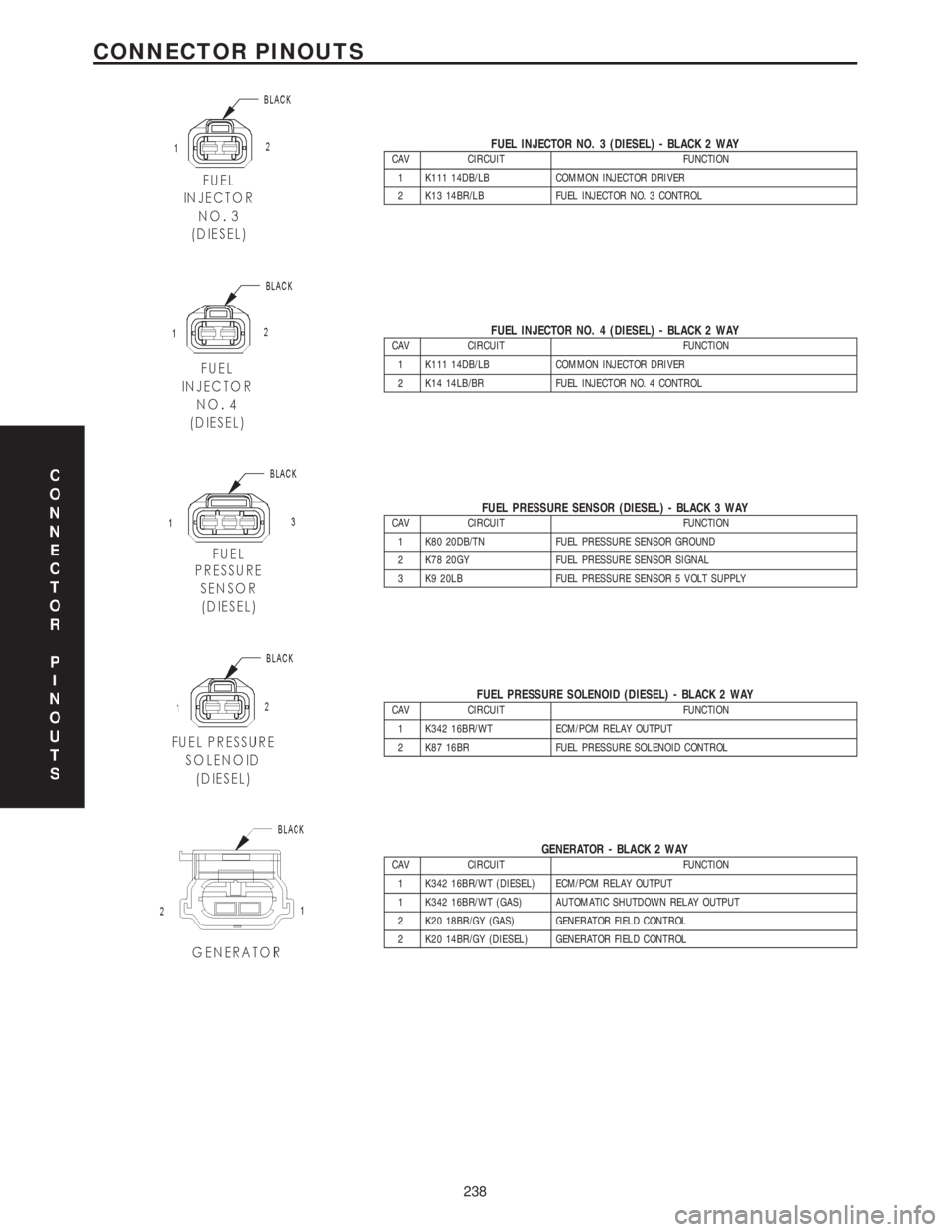

FUEL INJECTOR NO. 3 (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K111 14DB/LB COMMON INJECTOR DRIVER

2 K13 14BR/LB FUEL INJECTOR NO. 3 CONTROL

FUEL INJECTOR NO. 4 (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K111 14DB/LB COMMON INJECTOR DRIVER

2 K14 14LB/BR FUEL INJECTOR NO. 4 CONTROL

FUEL PRESSURE SENSOR (DIESEL) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 K80 20DB/TN FUEL PRESSURE SENSOR GROUND

2 K78 20GY FUEL PRESSURE SENSOR SIGNAL

3 K9 20LB FUEL PRESSURE SENSOR 5 VOLT SUPPLY

FUEL PRESSURE SOLENOID (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K342 16BR/WT ECM/PCM RELAY OUTPUT

2 K87 16BR FUEL PRESSURE SOLENOID CONTROL

GENERATOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K342 16BR/WT (DIESEL) ECM/PCM RELAY OUTPUT

1 K342 16BR/WT (GAS) AUTOMATIC SHUTDOWN RELAY OUTPUT

2 K20 18BR/GY (GAS) GENERATOR FIELD CONTROL

2 K20 14BR/GY (DIESEL) GENERATOR FIELD CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

238

CONNECTOR PINOUTS

Page 1459 of 4284

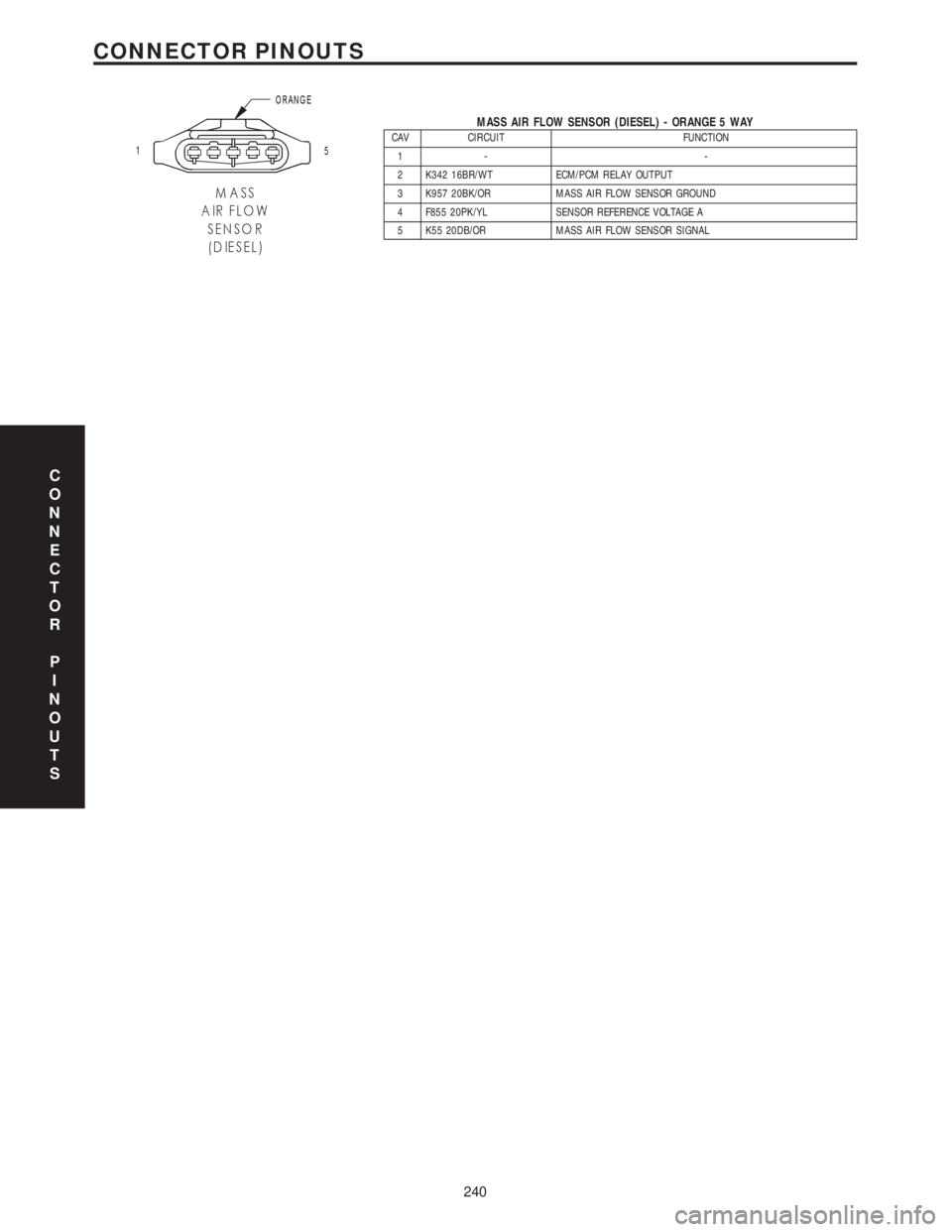

MASS AIR FLOW SENSOR (DIESEL) - ORANGE 5 WAYCAV CIRCUIT FUNCTION

1- -

2 K342 16BR/WT ECM/PCM RELAY OUTPUT

3 K957 20BK/OR MASS AIR FLOW SENSOR GROUND

4 F855 20PK/YL SENSOR REFERENCE VOLTAGE A

5 K55 20DB/OR MASS AIR FLOW SENSOR SIGNAL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

240

CONNECTOR PINOUTS

Page 1463 of 4284

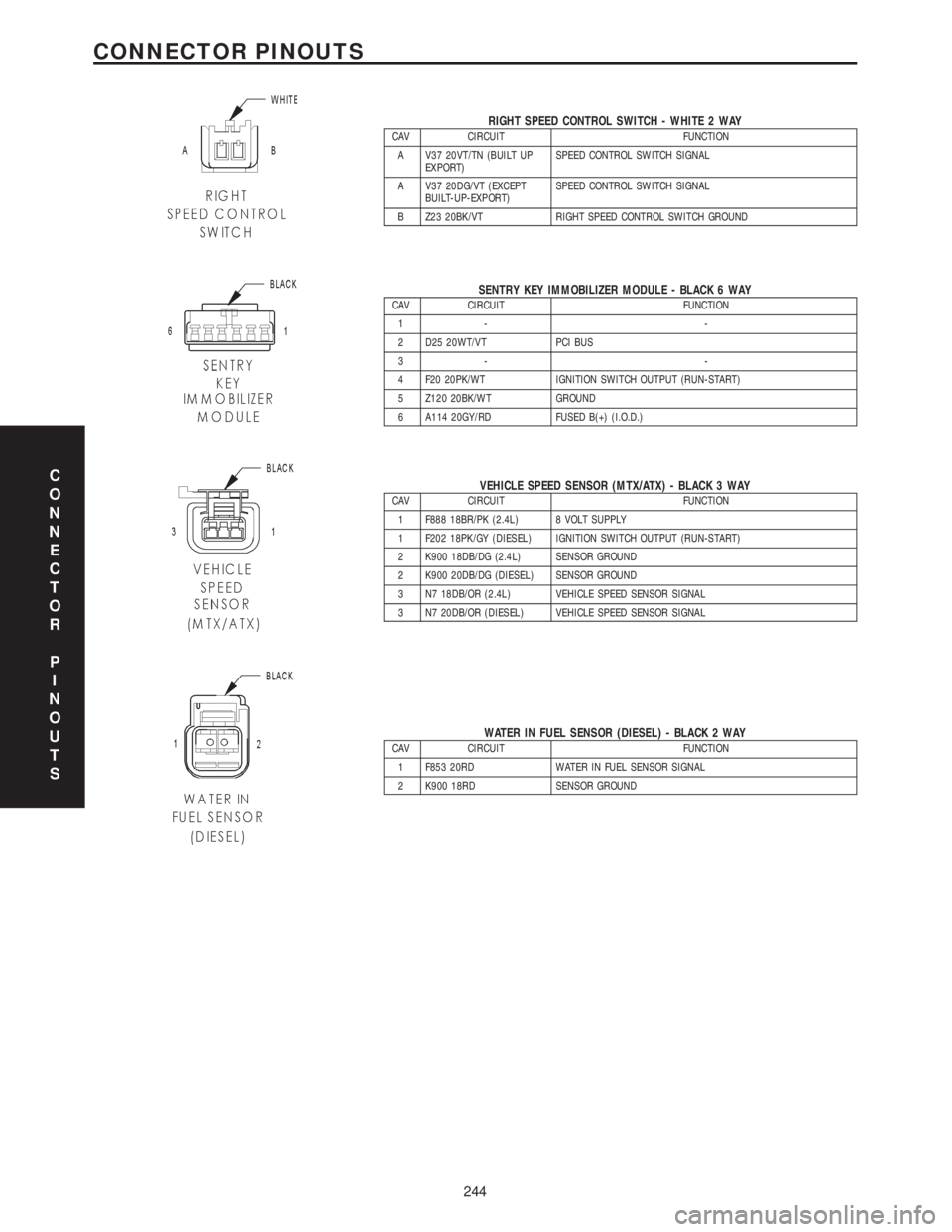

RIGHT SPEED CONTROL SWITCH - WHITE 2 WAYCAV CIRCUIT FUNCTION

A V37 20VT/TN (BUILT UP

EXPORT)SPEED CONTROL SWITCH SIGNAL

A V37 20DG/VT (EXCEPT

BUILT-UP-EXPORT)SPEED CONTROL SWITCH SIGNAL

B Z23 20BK/VT RIGHT SPEED CONTROL SWITCH GROUND

SENTRY KEY IMMOBILIZER MODULE - BLACK 6 WAYCAV CIRCUIT FUNCTION

1- -

2 D25 20WT/VT PCI BUS

3- -

4 F20 20PK/WT IGNITION SWITCH OUTPUT (RUN-START)

5 Z120 20BK/WT GROUND

6 A114 20GY/RD FUSED B(+) (I.O.D.)

VEHICLE SPEED SENSOR (MTX/ATX) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 F888 18BR/PK (2.4L) 8 VOLT SUPPLY

1 F202 18PK/GY (DIESEL) IGNITION SWITCH OUTPUT (RUN-START)

2 K900 18DB/DG (2.4L) SENSOR GROUND

2 K900 20DB/DG (DIESEL) SENSOR GROUND

3 N7 18DB/OR (2.4L) VEHICLE SPEED SENSOR SIGNAL

3 N7 20DB/OR (DIESEL) VEHICLE SPEED SENSOR SIGNAL

WATER IN FUEL SENSOR (DIESEL) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 F853 20RD WATER IN FUEL SENSOR SIGNAL

2 K900 18RD SENSOR GROUND

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

244

CONNECTOR PINOUTS

Page 1523 of 4284

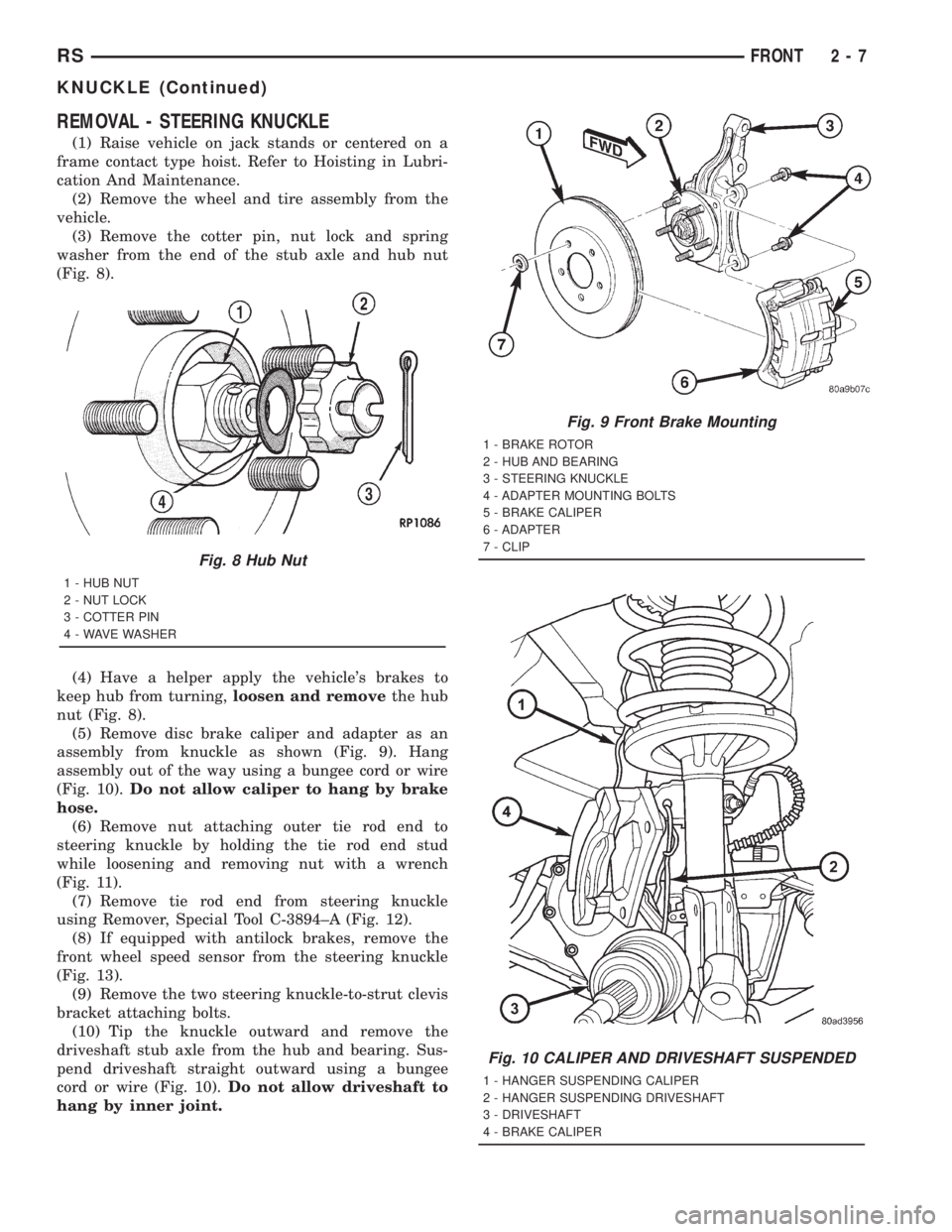

REMOVAL - STEERING KNUCKLE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. Refer to Hoisting in Lubri-

cation And Maintenance.

(2) Remove the wheel and tire assembly from the

vehicle.

(3) Remove the cotter pin, nut lock and spring

washer from the end of the stub axle and hub nut

(Fig. 8).

(4) Have a helper apply the vehicle's brakes to

keep hub from turning,loosen and removethe hub

nut (Fig. 8).

(5) Remove disc brake caliper and adapter as an

assembly from knuckle as shown (Fig. 9). Hang

assembly out of the way using a bungee cord or wire

(Fig. 10).Do not allow caliper to hang by brake

hose.

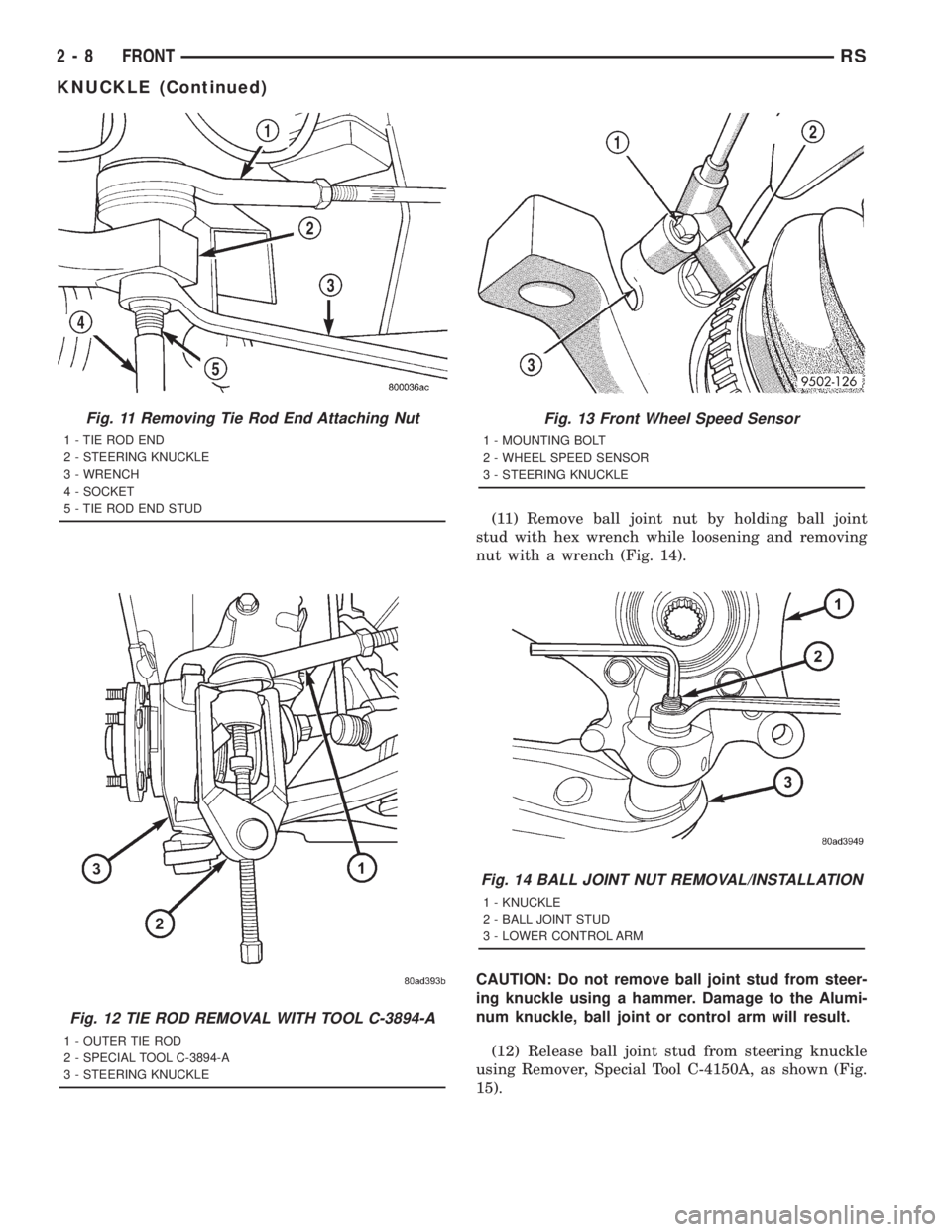

(6) Remove nut attaching outer tie rod end to

steering knuckle by holding the tie rod end stud

while loosening and removing nut with a wrench

(Fig. 11).

(7) Remove tie rod end from steering knuckle

using Remover, Special Tool C-3894±A (Fig. 12).

(8) If equipped with antilock brakes, remove the

front wheel speed sensor from the steering knuckle

(Fig. 13).

(9) Remove the two steering knuckle-to-strut clevis

bracket attaching bolts.

(10) Tip the knuckle outward and remove the

driveshaft stub axle from the hub and bearing. Sus-

pend driveshaft straight outward using a bungee

cord or wire (Fig. 10).Do not allow driveshaft to

hang by inner joint.

Fig. 8 Hub Nut

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - WAVE WASHER

Fig. 9 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 10 CALIPER AND DRIVESHAFT SUSPENDED

1 - HANGER SUSPENDING CALIPER

2 - HANGER SUSPENDING DRIVESHAFT

3 - DRIVESHAFT

4 - BRAKE CALIPER

RSFRONT2-7

KNUCKLE (Continued)

Page 1524 of 4284

(11) Remove ball joint nut by holding ball joint

stud with hex wrench while loosening and removing

nut with a wrench (Fig. 14).

CAUTION: Do not remove ball joint stud from steer-

ing knuckle using a hammer. Damage to the Alumi-

num knuckle, ball joint or control arm will result.

(12) Release ball joint stud from steering knuckle

using Remover, Special Tool C-4150A, as shown (Fig.

15).

Fig. 11 Removing Tie Rod End Attaching Nut

1 - TIE ROD END

2 - STEERING KNUCKLE

3 - WRENCH

4 - SOCKET

5 - TIE ROD END STUD

Fig. 12 TIE ROD REMOVAL WITH TOOL C-3894-A

1 - OUTER TIE ROD

2 - SPECIAL TOOL C-3894-A

3 - STEERING KNUCKLE

Fig. 13 Front Wheel Speed Sensor

1 - MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - STEERING KNUCKLE

Fig. 14 BALL JOINT NUT REMOVAL/INSTALLATION

1 - KNUCKLE

2 - BALL JOINT STUD

3 - LOWER CONTROL ARM

2 - 8 FRONTRS

KNUCKLE (Continued)

Page 1526 of 4284

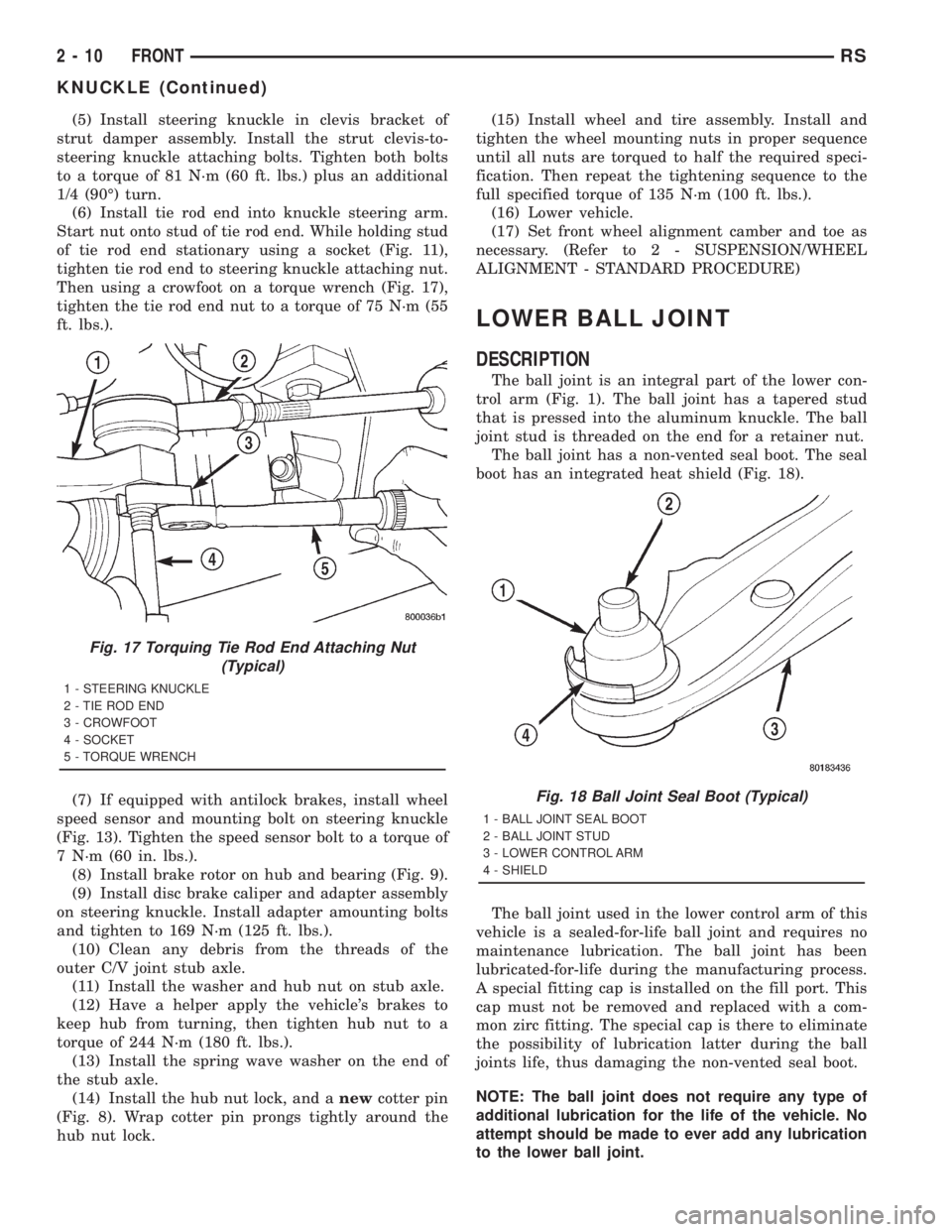

(5) Install steering knuckle in clevis bracket of

strut damper assembly. Install the strut clevis-to-

steering knuckle attaching bolts. Tighten both bolts

to a torque of 81 N´m (60 ft. lbs.) plus an additional

1/4 (90É) turn.

(6) Install tie rod end into knuckle steering arm.

Start nut onto stud of tie rod end. While holding stud

of tie rod end stationary using a socket (Fig. 11),

tighten tie rod end to steering knuckle attaching nut.

Then using a crowfoot on a torque wrench (Fig. 17),

tighten the tie rod end nut to a torque of 75 N´m (55

ft. lbs.).

(7) If equipped with antilock brakes, install wheel

speed sensor and mounting bolt on steering knuckle

(Fig. 13). Tighten the speed sensor bolt to a torque of

7 N´m (60 in. lbs.).

(8) Install brake rotor on hub and bearing (Fig. 9).

(9) Install disc brake caliper and adapter assembly

on steering knuckle. Install adapter amounting bolts

and tighten to 169 N´m (125 ft. lbs.).

(10) Clean any debris from the threads of the

outer C/V joint stub axle.

(11) Install the washer and hub nut on stub axle.

(12) Have a helper apply the vehicle's brakes to

keep hub from turning, then tighten hub nut to a

torque of 244 N´m (180 ft. lbs.).

(13) Install the spring wave washer on the end of

the stub axle.

(14) Install the hub nut lock, and anewcotter pin

(Fig. 8). Wrap cotter pin prongs tightly around the

hub nut lock.(15) Install wheel and tire assembly. Install and

tighten the wheel mounting nuts in proper sequence

until all nuts are torqued to half the required speci-

fication. Then repeat the tightening sequence to the

full specified torque of 135 N´m (100 ft. lbs.).

(16) Lower vehicle.

(17) Set front wheel alignment camber and toe as

necessary. (Refer to 2 - SUSPENSION/WHEEL

ALIGNMENT - STANDARD PROCEDURE)

LOWER BALL JOINT

DESCRIPTION

The ball joint is an integral part of the lower con-

trol arm (Fig. 1). The ball joint has a tapered stud

that is pressed into the aluminum knuckle. The ball

joint stud is threaded on the end for a retainer nut.

The ball joint has a non-vented seal boot. The seal

boot has an integrated heat shield (Fig. 18).

The ball joint used in the lower control arm of this

vehicle is a sealed-for-life ball joint and requires no

maintenance lubrication. The ball joint has been

lubricated-for-life during the manufacturing process.

A special fitting cap is installed on the fill port. This

cap must not be removed and replaced with a com-

mon zirc fitting. The special cap is there to eliminate

the possibility of lubrication latter during the ball

joints life, thus damaging the non-vented seal boot.

NOTE: The ball joint does not require any type of

additional lubrication for the life of the vehicle. No

attempt should be made to ever add any lubrication

to the lower ball joint.

Fig. 17 Torquing Tie Rod End Attaching Nut

(Typical)

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

Fig. 18 Ball Joint Seal Boot (Typical)

1 - BALL JOINT SEAL BOOT

2 - BALL JOINT STUD

3 - LOWER CONTROL ARM

4 - SHIELD

2 - 10 FRONTRS

KNUCKLE (Continued)

Page 1536 of 4284

arately for each corner or side of the vehicle depend-

ing on optional equipment and type of vehicle

service. If the coil springs require replacement, be

sure that the springs are replaced with springs meet-

ing the correct load rating and spring rate for the

vehicle and its specific options.

OPERATION - STRUT ASSEMBLY

The strut assembly cushions the ride of the vehicle,

controlling vibration, along with jounce and rebound

of the suspension.

The coil spring controls ride quality and maintains

proper ride height.

The spring isolators isolate the coil spring at the

top and bottom from coming into metal-to-metal con-

tact with the upper seat and strut.

The jounce bumper limits suspension travel and

metal-to-metal contact under full jounce condition.

The strut dampens jounce and rebound motions of

the coil spring and suspension.

During steering maneuvers, the strut assembly

(through a pivot bearing in the upper strut mount)

and steering knuckle (through the lower ball joint)

turn as an assembly.

DIAGNOSIS AND TESTING - STRUT ASSEMBLY

(FRONT)

(1) Inspect for damaged or broken coil springs

(Fig. 39).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 39).

(3) Inspect the coil spring isolator on the lower

spring seat for any signs of damage or deterioration.

(4) Lift dust boot (Fig. 40) and inspect strut

assembly for evidence of fluid running from the

upper end of fluid reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage

between the strut rod and strut shaft seal is not

unusual and does not affect performance of the strut

assembly (Fig. 40). Also inspect jounce bumpers for

signs of damage or deterioration.

REMOVAL - STRUT ASSEMBLY

WARNING: DO NOT REMOVE THE NUT FROM THE

STRUT ROD WHILE STRUT ASSEMBLY IS

INSTALLED IN VEHICLE, OR BEFORE STRUT

ASSEMBLY SPRING IS COMPRESSED.

(1) Raise the vehicle. See Hoisting in Lubrication

and Maintenance.

(2) Remove the wheel and tire assembly from loca-

tion on front of vehicle requiring strut removal.(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

(4) Remove the hydraulic brake hose routing

bracket and the speed sensor cable routing bracket

from the strut damper brackets (Fig. 41).

Fig. 40 Strut Assembly Leakage Inspection (Typical)

1 - DUST BOOT

2 - STRUT SHAFT

3 - STRUT FLUID RESERVOIR

4 - INSPECT THIS AREA FOR EVIDENCE OF EXCESSIVE FLUID

LEAKAGE

Fig. 41 Brake Hose And Speed Sensor Cable

Routing

1 - STRUT DAMPER

2 - WHEEL SPEED SENSOR CABLE

3 - ROUTING BRACKET

4 - HYDRAULIC BRAKE HOSE

5 - ATTACHING BOLT

6 - ROUTING BRACKET

2 - 20 FRONTRS

STRUT (Continued)

Page 1546 of 4284

body, Install the mounting bolts (Fig. 3). Tighten the

four mounting bolts to 61 N´m (45 ft. lbs.) torque.

(9) Raise or lower the jack until shock absorber

lower eye aligns with threads in axle housing. Install

shock absorber lower mounting bolt. Do not fully

tighten bolt at this time.

(10) Lower the vehicle and remove hoist arms and

block of wood from under vehicle.

(11) Tighten the spring front pivot bolt to 156 N´m

(115 ft. lbs.) torque.

(12) Tighten the lower shock absorber mounting

bolt to 102 N´m (75 ft. lbs.) torque.

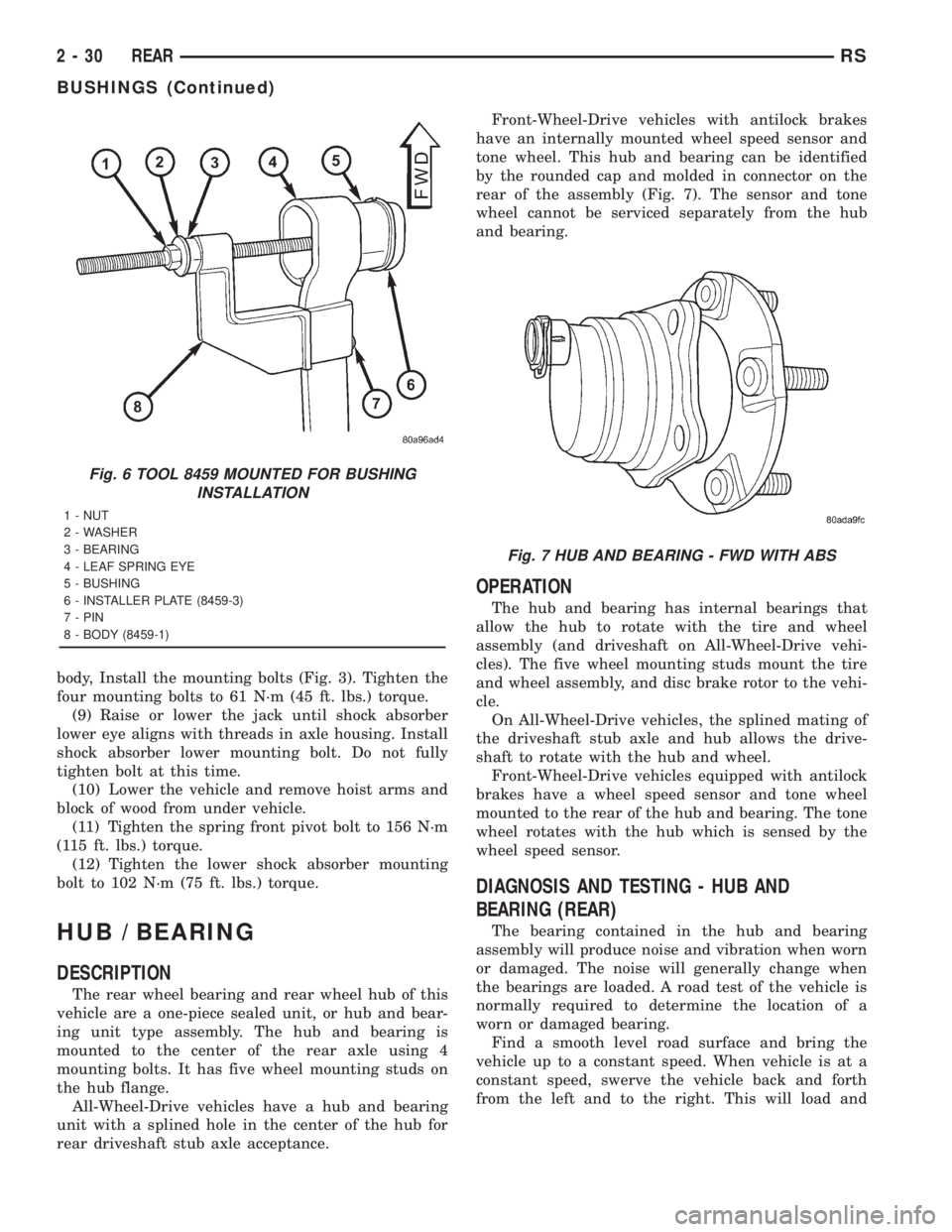

HUB / BEARING

DESCRIPTION

The rear wheel bearing and rear wheel hub of this

vehicle are a one-piece sealed unit, or hub and bear-

ing unit type assembly. The hub and bearing is

mounted to the center of the rear axle using 4

mounting bolts. It has five wheel mounting studs on

the hub flange.

All-Wheel-Drive vehicles have a hub and bearing

unit with a splined hole in the center of the hub for

rear driveshaft stub axle acceptance.Front-Wheel-Drive vehicles with antilock brakes

have an internally mounted wheel speed sensor and

tone wheel. This hub and bearing can be identified

by the rounded cap and molded in connector on the

rear of the assembly (Fig. 7). The sensor and tone

wheel cannot be serviced separately from the hub

and bearing.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the tire and wheel

assembly (and driveshaft on All-Wheel-Drive vehi-

cles). The five wheel mounting studs mount the tire

and wheel assembly, and disc brake rotor to the vehi-

cle.

On All-Wheel-Drive vehicles, the splined mating of

the driveshaft stub axle and hub allows the drive-

shaft to rotate with the hub and wheel.

Front-Wheel-Drive vehicles equipped with antilock

brakes have a wheel speed sensor and tone wheel

mounted to the rear of the hub and bearing. The tone

wheel rotates with the hub which is sensed by the

wheel speed sensor.

DIAGNOSIS AND TESTING - HUB AND

BEARING (REAR)

The bearing contained in the hub and bearing

assembly will produce noise and vibration when worn

or damaged. The noise will generally change when

the bearings are loaded. A road test of the vehicle is

normally required to determine the location of a

worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

Fig. 6 TOOL 8459 MOUNTED FOR BUSHING

INSTALLATION

1 - NUT

2 - WASHER

3 - BEARING

4 - LEAF SPRING EYE

5 - BUSHING

6 - INSTALLER PLATE (8459-3)

7 - PIN

8 - BODY (8459-1)

Fig. 7 HUB AND BEARING - FWD WITH ABS

2 - 30 REARRS

BUSHINGS (Continued)