ignition CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 451 of 4284

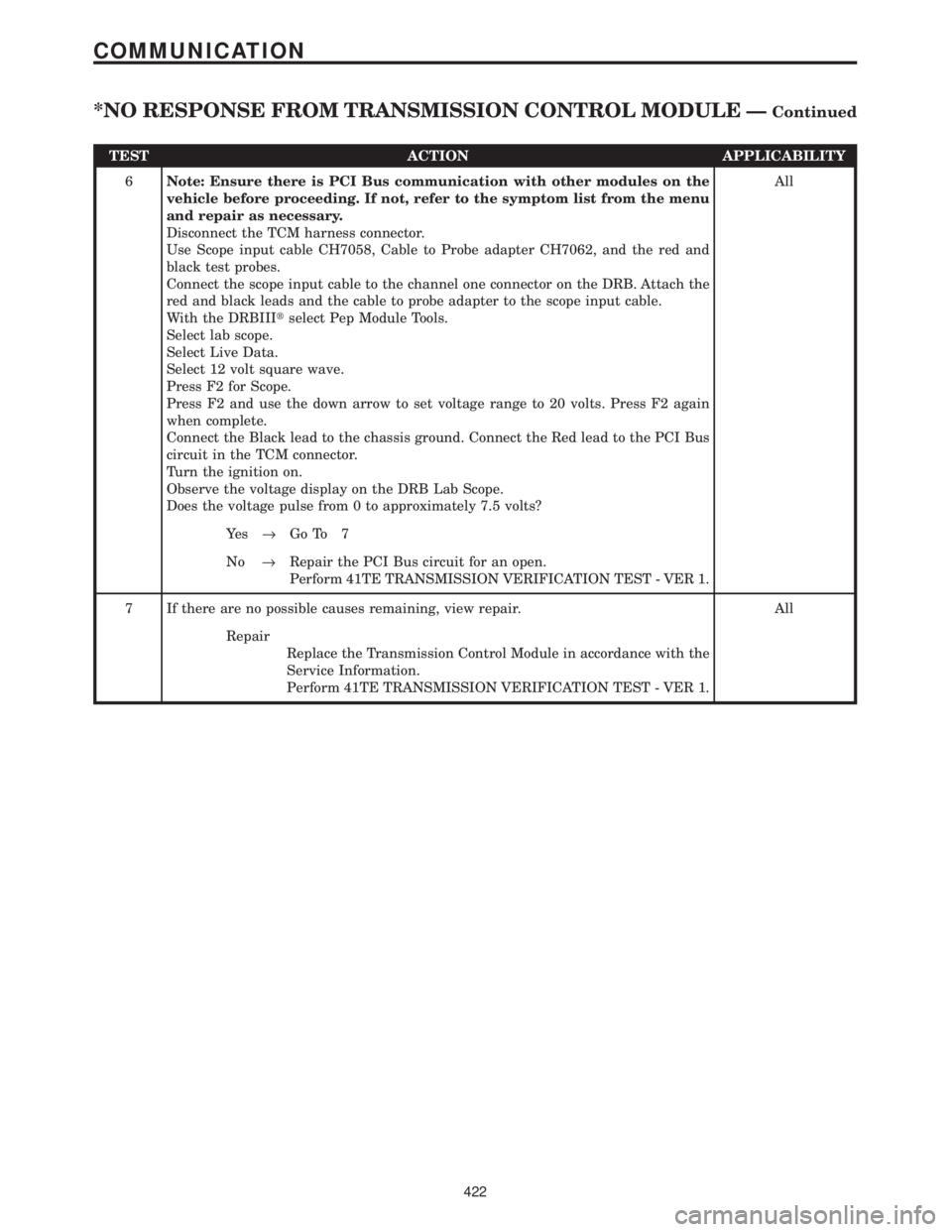

TEST ACTION APPLICABILITY

6Note: Ensure there is PCI Bus communication with other modules on the

vehicle before proceeding. If not, refer to the symptom list from the menu

and repair as necessary.

Disconnect the TCM harness connector.

Use Scope input cable CH7058, Cable to Probe adapter CH7062, and the red and

black test probes.

Connect the scope input cable to the channel one connector on the DRB. Attach the

red and black leads and the cable to probe adapter to the scope input cable.

With the DRBIIItselect Pep Module Tools.

Select lab scope.

Select Live Data.

Select 12 volt square wave.

Press F2 for Scope.

Press F2 and use the down arrow to set voltage range to 20 volts. Press F2 again

when complete.

Connect the Black lead to the chassis ground. Connect the Red lead to the PCI Bus

circuit in the TCM connector.

Turn the ignition on.

Observe the voltage display on the DRB Lab Scope.

Does the voltage pulse from 0 to approximately 7.5 volts?All

Ye s®Go To 7

No®Repair the PCI Bus circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

7 If there are no possible causes remaining, view repair. All

Repair

Replace the Transmission Control Module in accordance with the

Service Information.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

422

COMMUNICATION

*NO RESPONSE FROM TRANSMISSION CONTROL MODULE ÐContinued

Page 452 of 4284

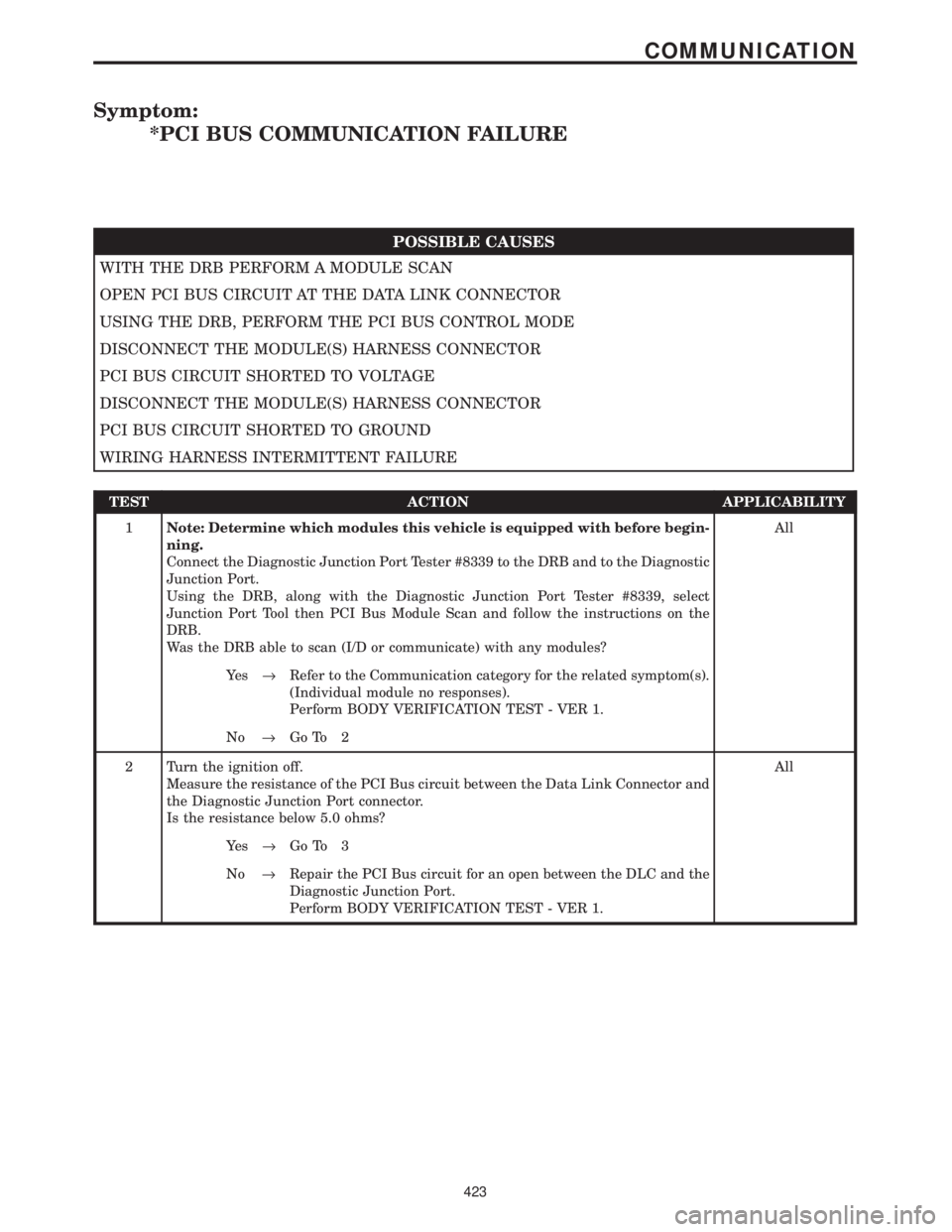

Symptom:

*PCI BUS COMMUNICATION FAILURE

POSSIBLE CAUSES

WITH THE DRB PERFORM A MODULE SCAN

OPEN PCI BUS CIRCUIT AT THE DATA LINK CONNECTOR

USING THE DRB, PERFORM THE PCI BUS CONTROL MODE

DISCONNECT THE MODULE(S) HARNESS CONNECTOR

PCI BUS CIRCUIT SHORTED TO VOLTAGE

DISCONNECT THE MODULE(S) HARNESS CONNECTOR

PCI BUS CIRCUIT SHORTED TO GROUND

WIRING HARNESS INTERMITTENT FAILURE

TEST ACTION APPLICABILITY

1Note: Determine which modules this vehicle is equipped with before begin-

ning.

Connect the Diagnostic Junction Port Tester #8339 to the DRB and to the Diagnostic

Junction Port.

Using the DRB, along with the Diagnostic Junction Port Tester #8339, select

Junction Port Tool then PCI Bus Module Scan and follow the instructions on the

DRB.

Was the DRB able to scan (I/D or communicate) with any modules?All

Ye s®Refer to the Communication category for the related symptom(s).

(Individual module no responses).

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

2 Turn the ignition off.

Measure the resistance of the PCI Bus circuit between the Data Link Connector and

the Diagnostic Junction Port connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 3

No®Repair the PCI Bus circuit for an open between the DLC and the

Diagnostic Junction Port.

Perform BODY VERIFICATION TEST - VER 1.

423

COMMUNICATION

Page 453 of 4284

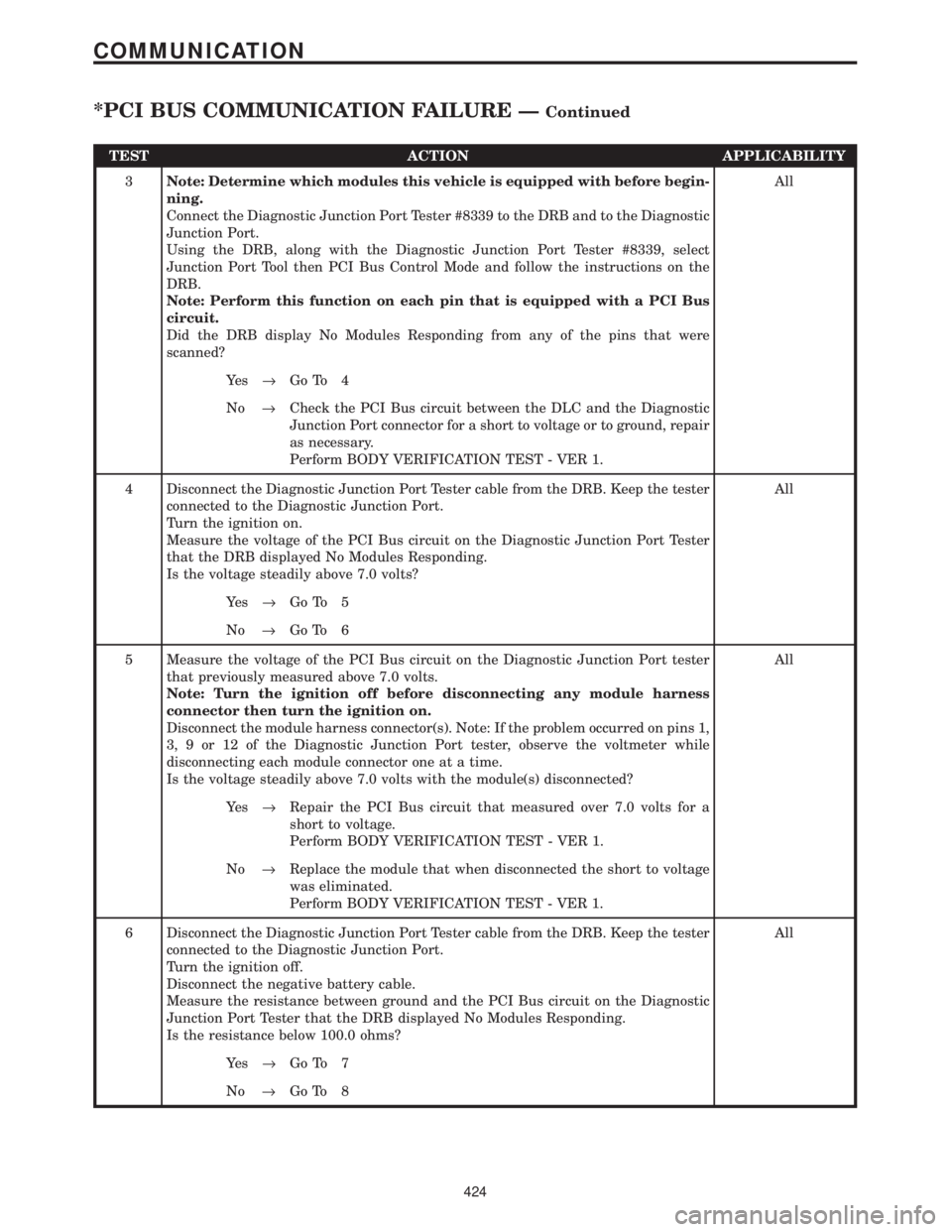

TEST ACTION APPLICABILITY

3Note: Determine which modules this vehicle is equipped with before begin-

ning.

Connect the Diagnostic Junction Port Tester #8339 to the DRB and to the Diagnostic

Junction Port.

Using the DRB, along with the Diagnostic Junction Port Tester #8339, select

Junction Port Tool then PCI Bus Control Mode and follow the instructions on the

DRB.

Note: Perform this function on each pin that is equipped with a PCI Bus

circuit.

Did the DRB display No Modules Responding from any of the pins that were

scanned?All

Ye s®Go To 4

No®Check the PCI Bus circuit between the DLC and the Diagnostic

Junction Port connector for a short to voltage or to ground, repair

as necessary.

Perform BODY VERIFICATION TEST - VER 1.

4 Disconnect the Diagnostic Junction Port Tester cable from the DRB. Keep the tester

connected to the Diagnostic Junction Port.

Turn the ignition on.

Measure the voltage of the PCI Bus circuit on the Diagnostic Junction Port Tester

that the DRB displayed No Modules Responding.

Is the voltage steadily above 7.0 volts?All

Ye s®Go To 5

No®Go To 6

5 Measure the voltage of the PCI Bus circuit on the Diagnostic Junction Port tester

that previously measured above 7.0 volts.

Note: Turn the ignition off before disconnecting any module harness

connector then turn the ignition on.

Disconnect the module harness connector(s). Note: If the problem occurred on pins 1,

3, 9 or 12 of the Diagnostic Junction Port tester, observe the voltmeter while

disconnecting each module connector one at a time.

Is the voltage steadily above 7.0 volts with the module(s) disconnected?All

Ye s®Repair the PCI Bus circuit that measured over 7.0 volts for a

short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the module that when disconnected the short to voltage

was eliminated.

Perform BODY VERIFICATION TEST - VER 1.

6 Disconnect the Diagnostic Junction Port Tester cable from the DRB. Keep the tester

connected to the Diagnostic Junction Port.

Turn the ignition off.

Disconnect the negative battery cable.

Measure the resistance between ground and the PCI Bus circuit on the Diagnostic

Junction Port Tester that the DRB displayed No Modules Responding.

Is the resistance below 100.0 ohms?All

Ye s®Go To 7

No®Go To 8

424

COMMUNICATION

*PCI BUS COMMUNICATION FAILURE ÐContinued

Page 454 of 4284

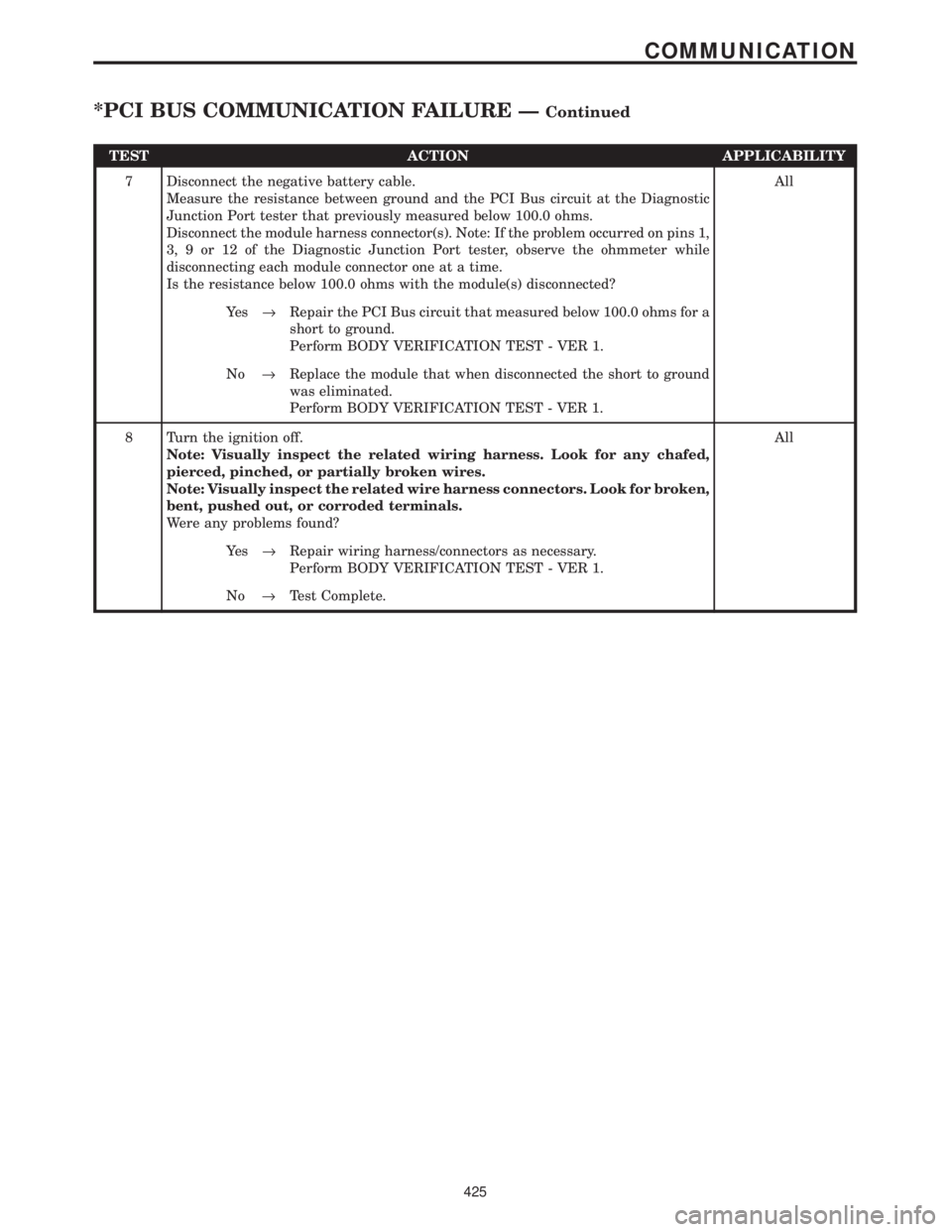

TEST ACTION APPLICABILITY

7 Disconnect the negative battery cable.

Measure the resistance between ground and the PCI Bus circuit at the Diagnostic

Junction Port tester that previously measured below 100.0 ohms.

Disconnect the module harness connector(s). Note: If the problem occurred on pins 1,

3, 9 or 12 of the Diagnostic Junction Port tester, observe the ohmmeter while

disconnecting each module connector one at a time.

Is the resistance below 100.0 ohms with the module(s) disconnected?All

Ye s®Repair the PCI Bus circuit that measured below 100.0 ohms for a

short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the module that when disconnected the short to ground

was eliminated.

Perform BODY VERIFICATION TEST - VER 1.

8 Turn the ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

Note: Visually inspect the related wire harness connectors. Look for broken,

bent, pushed out, or corroded terminals.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

425

COMMUNICATION

*PCI BUS COMMUNICATION FAILURE ÐContinued

Page 469 of 4284

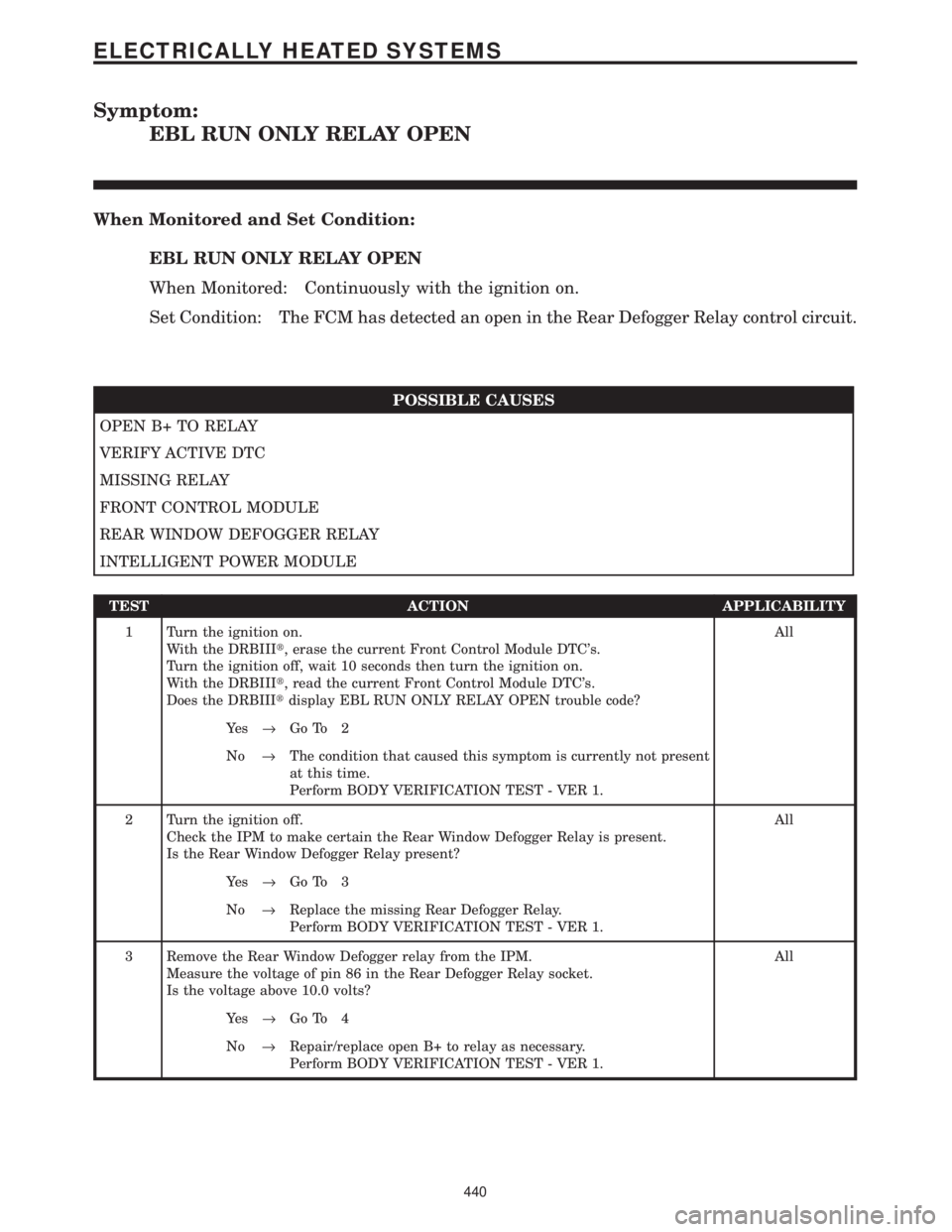

Symptom:

EBL RUN ONLY RELAY OPEN

When Monitored and Set Condition:

EBL RUN ONLY RELAY OPEN

When Monitored: Continuously with the ignition on.

Set Condition: The FCM has detected an open in the Rear Defogger Relay control circuit.

POSSIBLE CAUSES

OPEN B+ TO RELAY

VERIFY ACTIVE DTC

MISSING RELAY

FRONT CONTROL MODULE

REAR WINDOW DEFOGGER RELAY

INTELLIGENT POWER MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase the current Front Control Module DTC's.

Turn the ignition off, wait 10 seconds then turn the ignition on.

With the DRBIIIt, read the current Front Control Module DTC's.

Does the DRBIIItdisplay EBL RUN ONLY RELAY OPEN trouble code?All

Ye s®Go To 2

No®The condition that caused this symptom is currently not present

at this time.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Check the IPM to make certain the Rear Window Defogger Relay is present.

Is the Rear Window Defogger Relay present?All

Ye s®Go To 3

No®Replace the missing Rear Defogger Relay.

Perform BODY VERIFICATION TEST - VER 1.

3 Remove the Rear Window Defogger relay from the IPM.

Measure the voltage of pin 86 in the Rear Defogger Relay socket.

Is the voltage above 10.0 volts?All

Ye s®Go To 4

No®Repair/replace open B+ to relay as necessary.

Perform BODY VERIFICATION TEST - VER 1.

440

ELECTRICALLY HEATED SYSTEMS

Page 470 of 4284

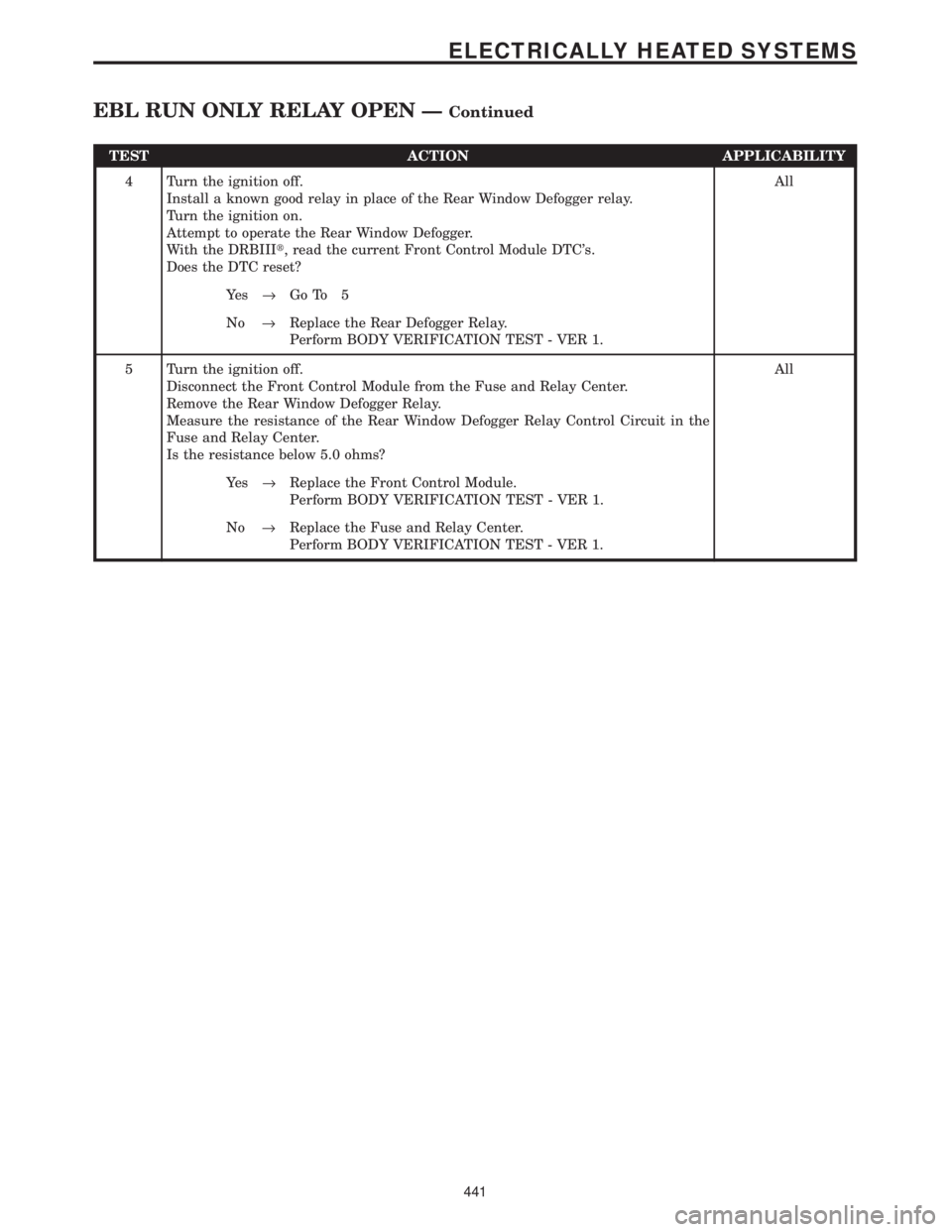

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Install a known good relay in place of the Rear Window Defogger relay.

Turn the ignition on.

Attempt to operate the Rear Window Defogger.

With the DRBIIIt, read the current Front Control Module DTC's.

Does the DTC reset?All

Ye s®Go To 5

No®Replace the Rear Defogger Relay.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Disconnect the Front Control Module from the Fuse and Relay Center.

Remove the Rear Window Defogger Relay.

Measure the resistance of the Rear Window Defogger Relay Control Circuit in the

Fuse and Relay Center.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Fuse and Relay Center.

Perform BODY VERIFICATION TEST - VER 1.

441

ELECTRICALLY HEATED SYSTEMS

EBL RUN ONLY RELAY OPEN ÐContinued

Page 471 of 4284

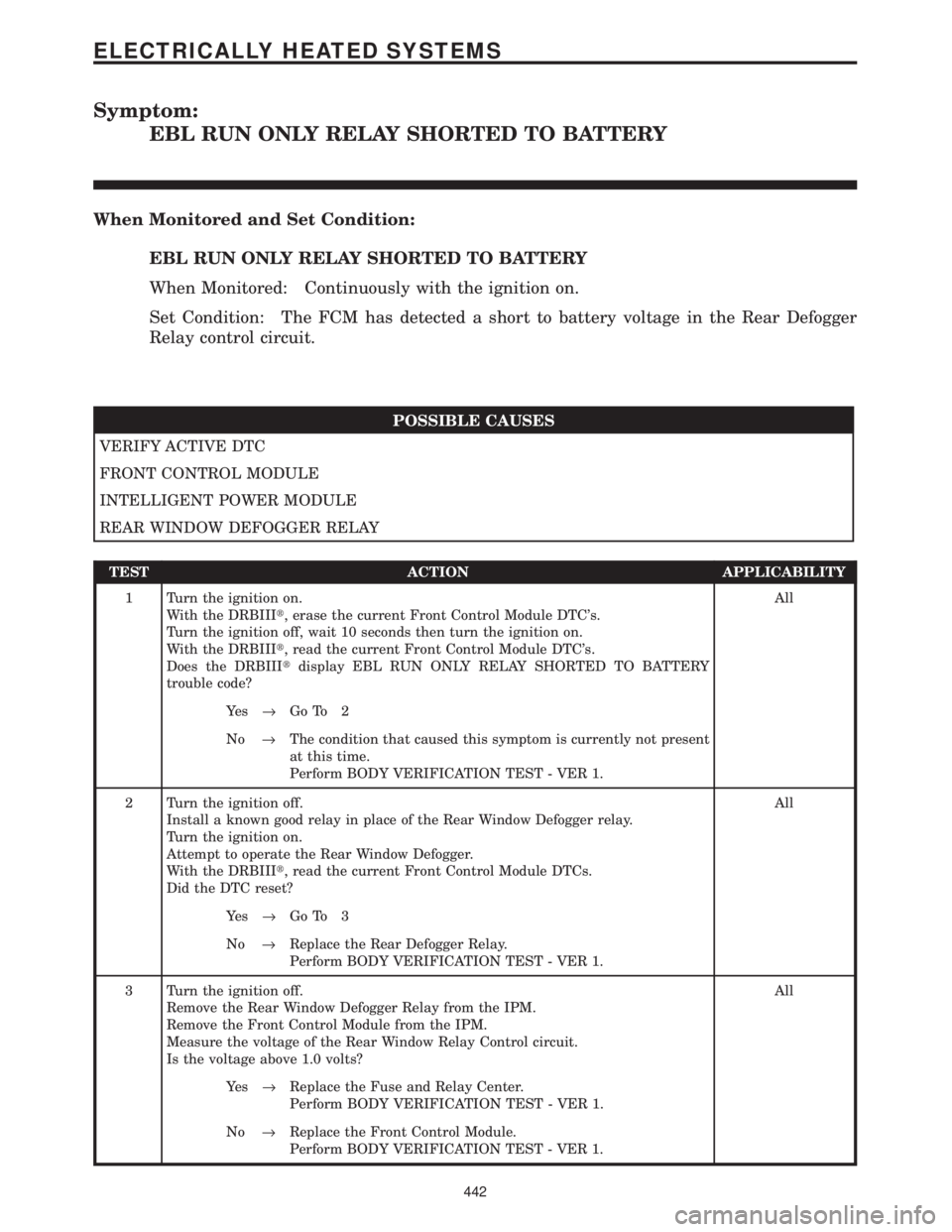

Symptom:

EBL RUN ONLY RELAY SHORTED TO BATTERY

When Monitored and Set Condition:

EBL RUN ONLY RELAY SHORTED TO BATTERY

When Monitored: Continuously with the ignition on.

Set Condition: The FCM has detected a short to battery voltage in the Rear Defogger

Relay control circuit.

POSSIBLE CAUSES

VERIFY ACTIVE DTC

FRONT CONTROL MODULE

INTELLIGENT POWER MODULE

REAR WINDOW DEFOGGER RELAY

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase the current Front Control Module DTC's.

Turn the ignition off, wait 10 seconds then turn the ignition on.

With the DRBIIIt, read the current Front Control Module DTC's.

Does the DRBIIItdisplay EBL RUN ONLY RELAY SHORTED TO BATTERY

trouble code?All

Ye s®Go To 2

No®The condition that caused this symptom is currently not present

at this time.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Install a known good relay in place of the Rear Window Defogger relay.

Turn the ignition on.

Attempt to operate the Rear Window Defogger.

With the DRBIIIt, read the current Front Control Module DTCs.

Did the DTC reset?All

Ye s®Go To 3

No®Replace the Rear Defogger Relay.

Perform BODY VERIFICATION TEST - VER 1.

3 Turn the ignition off.

Remove the Rear Window Defogger Relay from the IPM.

Remove the Front Control Module from the IPM.

Measure the voltage of the Rear Window Relay Control circuit.

Is the voltage above 1.0 volts?All

Ye s®Replace the Fuse and Relay Center.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

442

ELECTRICALLY HEATED SYSTEMS

Page 472 of 4284

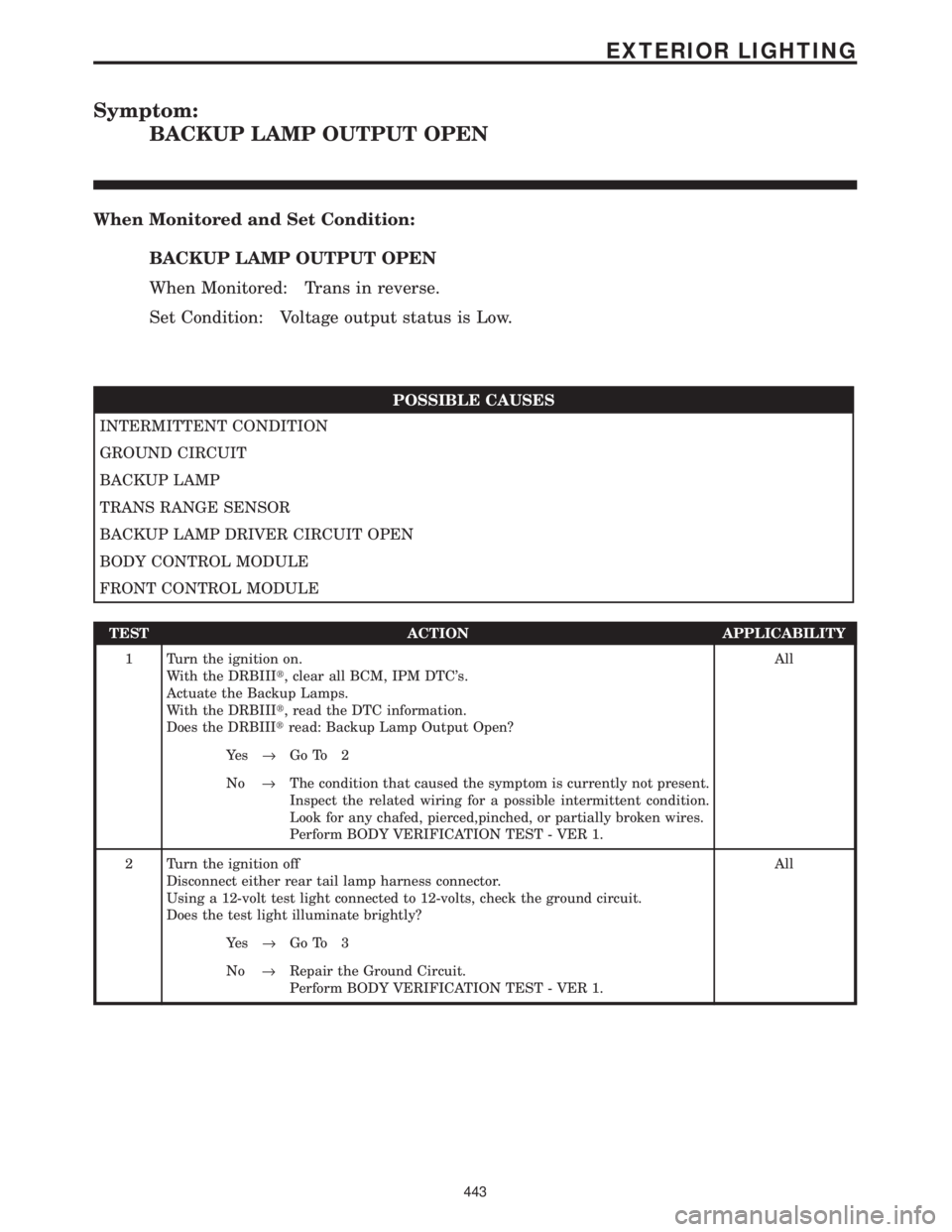

Symptom:

BACKUP LAMP OUTPUT OPEN

When Monitored and Set Condition:

BACKUP LAMP OUTPUT OPEN

When Monitored: Trans in reverse.

Set Condition: Voltage output status is Low.

POSSIBLE CAUSES

INTERMITTENT CONDITION

GROUND CIRCUIT

BACKUP LAMP

TRANS RANGE SENSOR

BACKUP LAMP DRIVER CIRCUIT OPEN

BODY CONTROL MODULE

FRONT CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, clear all BCM, IPM DTC's.

Actuate the Backup Lamps.

With the DRBIIIt, read the DTC information.

Does the DRBIIItread: Backup Lamp Output Open?All

Ye s®Go To 2

No®The condition that caused the symptom is currently not present.

Inspect the related wiring for a possible intermittent condition.

Look for any chafed, pierced,pinched, or partially broken wires.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off

Disconnect either rear tail lamp harness connector.

Using a 12-volt test light connected to 12-volts, check the ground circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Ground Circuit.

Perform BODY VERIFICATION TEST - VER 1.

443

EXTERIOR LIGHTING

Page 473 of 4284

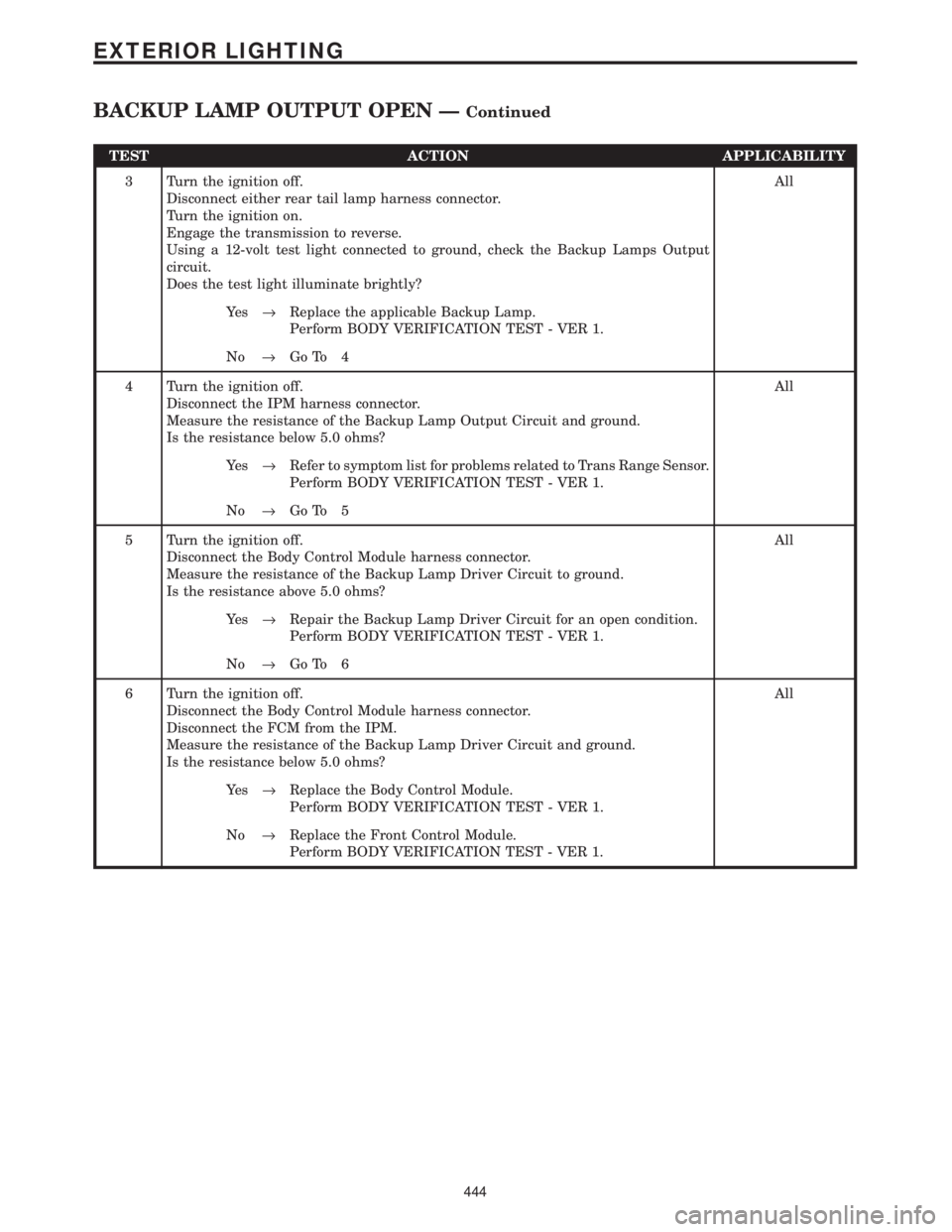

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect either rear tail lamp harness connector.

Turn the ignition on.

Engage the transmission to reverse.

Using a 12-volt test light connected to ground, check the Backup Lamps Output

circuit.

Does the test light illuminate brightly?All

Ye s®Replace the applicable Backup Lamp.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the IPM harness connector.

Measure the resistance of the Backup Lamp Output Circuit and ground.

Is the resistance below 5.0 ohms?All

Ye s®Refer to symptom list for problems related to Trans Range Sensor.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

Disconnect the Body Control Module harness connector.

Measure the resistance of the Backup Lamp Driver Circuit to ground.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Backup Lamp Driver Circuit for an open condition.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6 Turn the ignition off.

Disconnect the Body Control Module harness connector.

Disconnect the FCM from the IPM.

Measure the resistance of the Backup Lamp Driver Circuit and ground.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

444

EXTERIOR LIGHTING

BACKUP LAMP OUTPUT OPEN ÐContinued

Page 474 of 4284

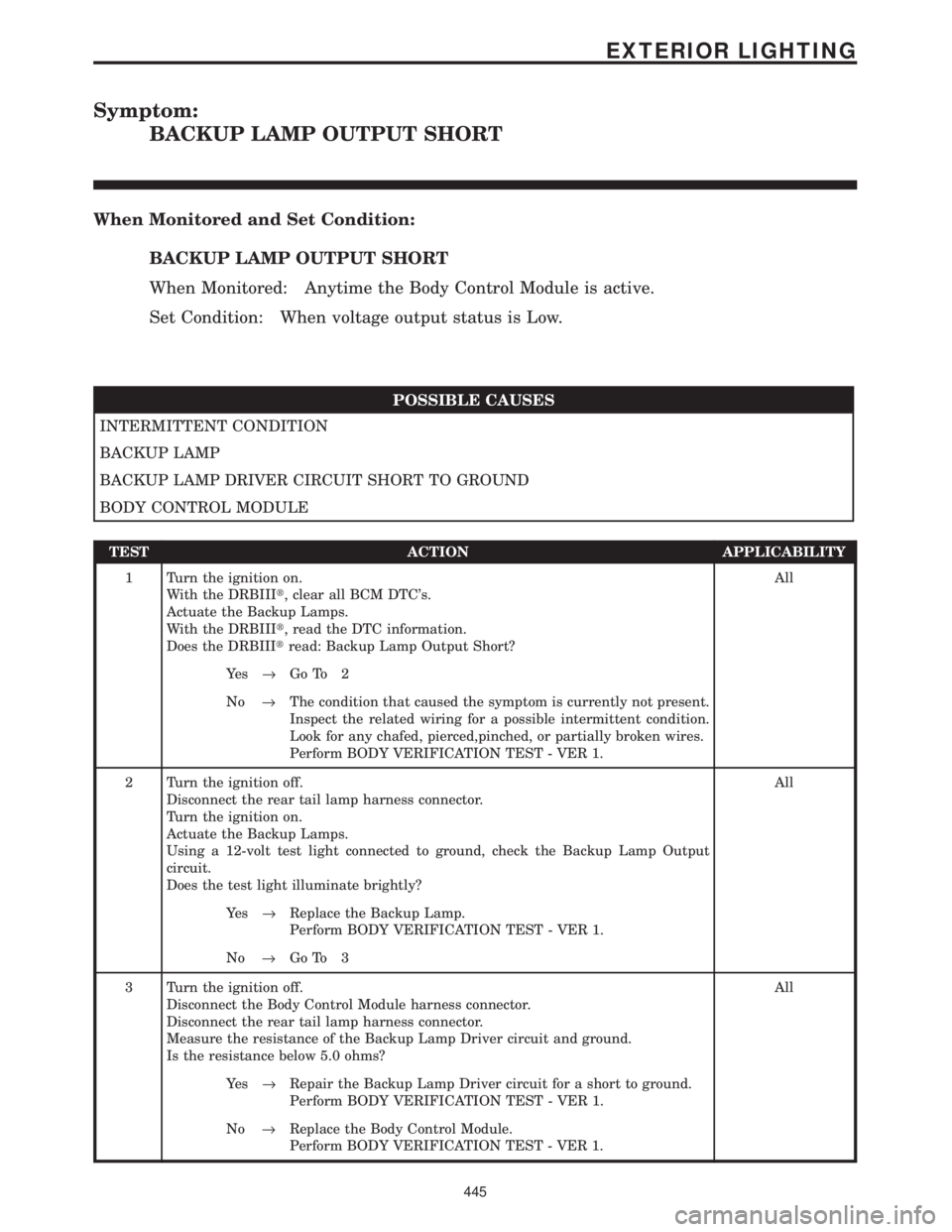

Symptom:

BACKUP LAMP OUTPUT SHORT

When Monitored and Set Condition:

BACKUP LAMP OUTPUT SHORT

When Monitored: Anytime the Body Control Module is active.

Set Condition: When voltage output status is Low.

POSSIBLE CAUSES

INTERMITTENT CONDITION

BACKUP LAMP

BACKUP LAMP DRIVER CIRCUIT SHORT TO GROUND

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, clear all BCM DTC's.

Actuate the Backup Lamps.

With the DRBIIIt, read the DTC information.

Does the DRBIIItread: Backup Lamp Output Short?All

Ye s®Go To 2

No®The condition that caused the symptom is currently not present.

Inspect the related wiring for a possible intermittent condition.

Look for any chafed, pierced,pinched, or partially broken wires.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Disconnect the rear tail lamp harness connector.

Turn the ignition on.

Actuate the Backup Lamps.

Using a 12-volt test light connected to ground, check the Backup Lamp Output

circuit.

Does the test light illuminate brightly?All

Ye s®Replace the Backup Lamp.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Disconnect the Body Control Module harness connector.

Disconnect the rear tail lamp harness connector.

Measure the resistance of the Backup Lamp Driver circuit and ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Backup Lamp Driver circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

445

EXTERIOR LIGHTING