low beam CHRYSLER VOYAGER 2001 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1079 of 4284

LEFT FRONT DOOR LOCK MOTOR/AJAR SWITCH (EXCEPT BASE) - BLACK 4 WAYCAV CIRCUIT FUNCTION

1 G75 20VT LEFT FRONT DOOR AJAR SWITCH SENSE

2 Z75 20BK/VT GROUND

3 P1 20TN/LG LEFT FRONT DOOR UNLOCK DRIVER

4 P3 20TN/WT LEFT FRONT DOOR LOCK DRIVER

LEFT FRONT PARK/TURN SIGNAL LAMP (EXCEPT BUILT-UP-EXPORT) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 L61 18WT/LG LEFT FRONT TURN SIGNAL DRIVER

2 L77 18WT/BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

3 Z377 18BK/BR GROUND

LEFT FULL OPEN SWITCH (POWER SLIDING DOOR) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Q53 20OR LEFT FULL OPEN SWITCH SENSE

2 Z77 20BK/GY GROUND

LEFT HEADLAMP (EXCEPT BUILT-UP-EXPORT) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 L43 18WT/DB LEFT LOW BEAM DRIVER

2 Z343 18BK/LG GROUND

3 L33 18WT/LG LEFT HIGH BEAM DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1050

CONNECTOR PINOUTS

Page 1080 of 4284

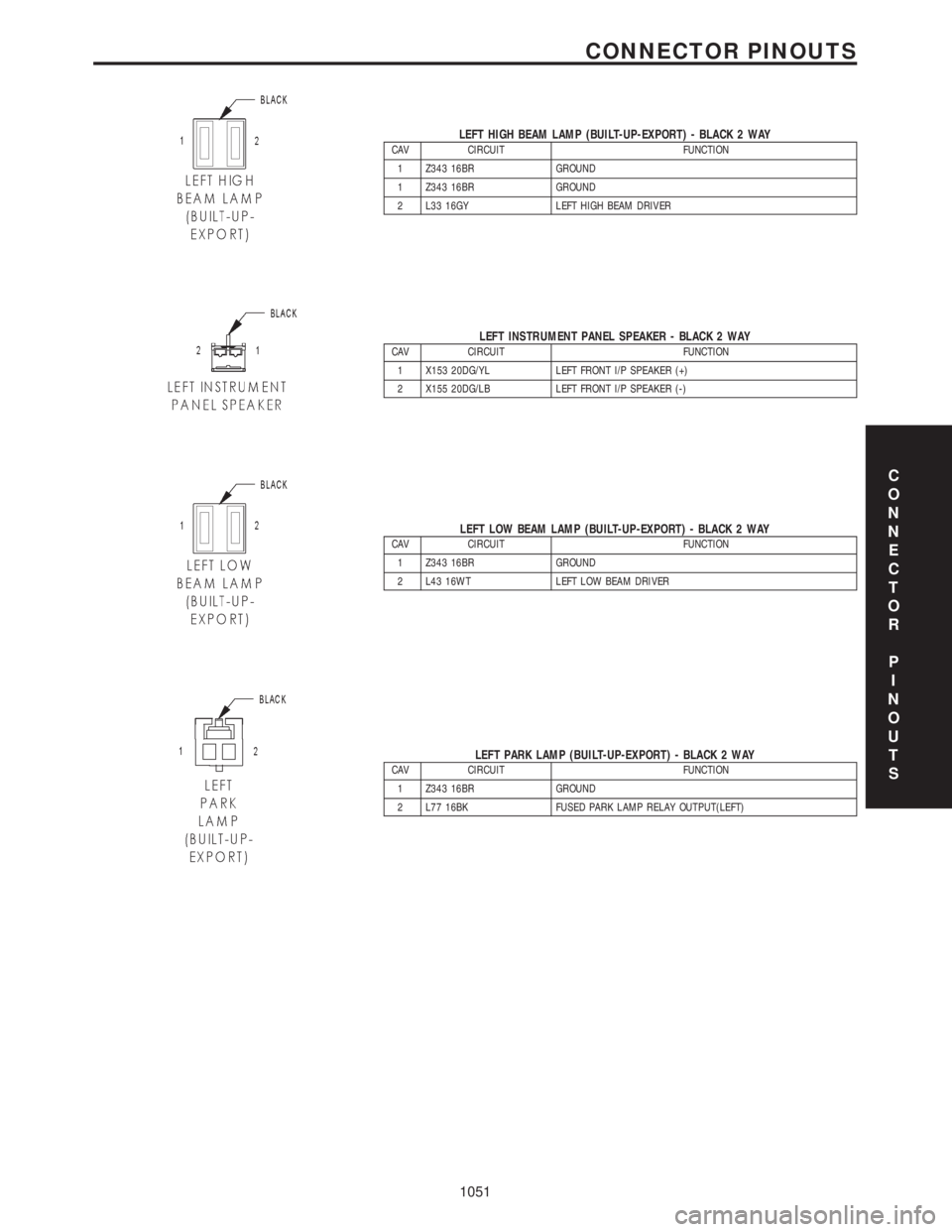

LEFT HIGH BEAM LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z343 16BR GROUND

1 Z343 16BR GROUND

2 L33 16GY LEFT HIGH BEAM DRIVER

LEFT INSTRUMENT PANEL SPEAKER - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 X153 20DG/YL LEFT FRONT I/P SPEAKER (+)

2 X155 20DG/LB LEFT FRONT I/P SPEAKER (-)

LEFT LOW BEAM LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z343 16BR GROUND

2 L43 16WT LEFT LOW BEAM DRIVER

LEFT PARK LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z343 16BR GROUND

2 L77 16BK FUSED PARK LAMP RELAY OUTPUT(LEFT)

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1051

CONNECTOR PINOUTS

Page 1096 of 4284

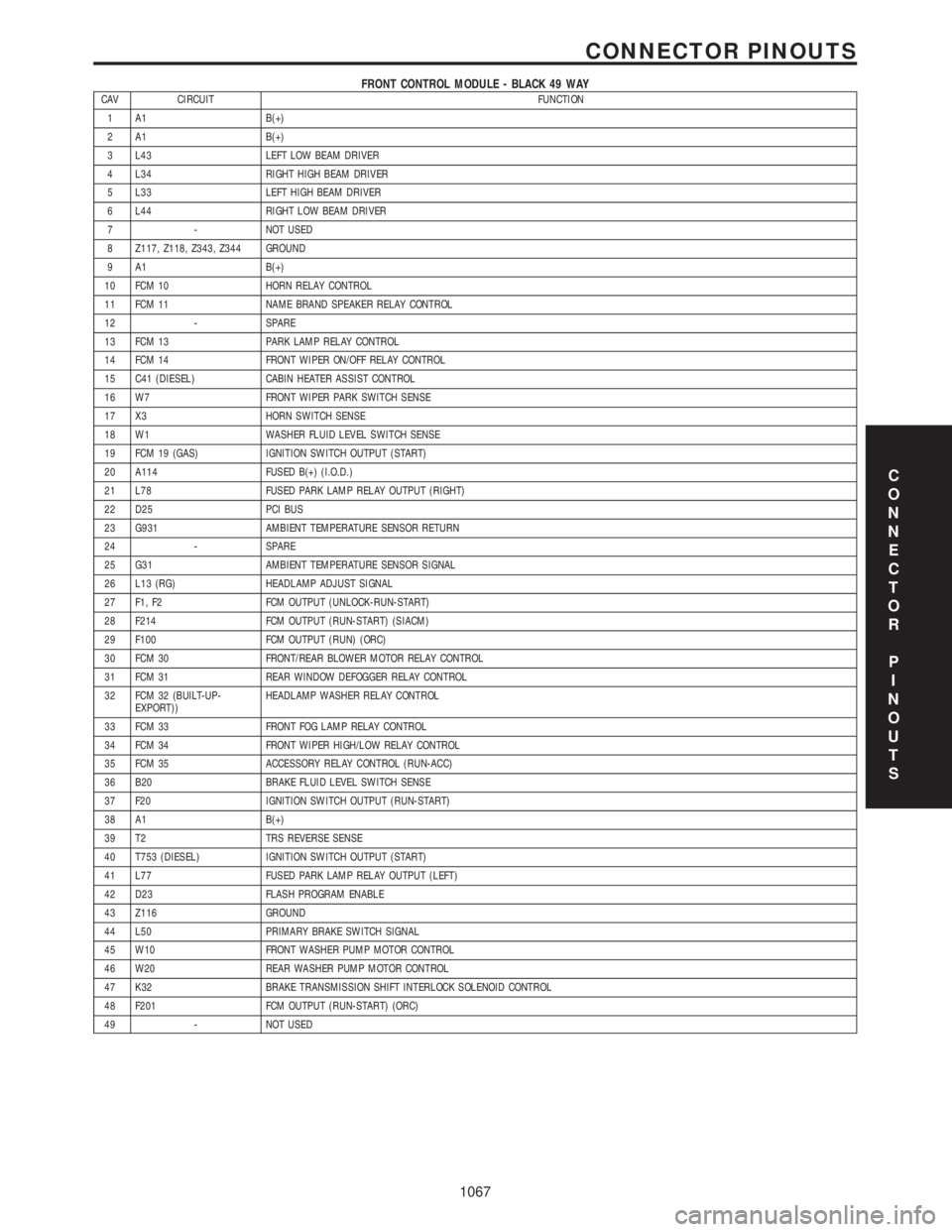

FRONT CONTROL MODULE - BLACK 49 WAYCAV CIRCUIT FUNCTION

1 A1 B(+)

2 A1 B(+)

3 L43 LEFT LOW BEAM DRIVER

4 L34 RIGHT HIGH BEAM DRIVER

5 L33 LEFT HIGH BEAM DRIVER

6 L44 RIGHT LOW BEAM DRIVER

7 - NOT USED

8 Z117, Z118, Z343, Z344 GROUND

9 A1 B(+)

10 FCM 10 HORN RELAY CONTROL

11 FCM 11 NAME BRAND SPEAKER RELAY CONTROL

12 - SPARE

13 FCM 13 PARK LAMP RELAY CONTROL

14 FCM 14 FRONT WIPER ON/OFF RELAY CONTROL

15 C41 (DIESEL) CABIN HEATER ASSIST CONTROL

16 W7 FRONT WIPER PARK SWITCH SENSE

17 X3 HORN SWITCH SENSE

18 W1 WASHER FLUID LEVEL SWITCH SENSE

19 FCM 19 (GAS) IGNITION SWITCH OUTPUT (START)

20 A114 FUSED B(+) (I.O.D.)

21 L78 FUSED PARK LAMP RELAY OUTPUT (RIGHT)

22 D25 PCI BUS

23 G931 AMBIENT TEMPERATURE SENSOR RETURN

24 - SPARE

25 G31 AMBIENT TEMPERATURE SENSOR SIGNAL

26 L13 (RG) HEADLAMP ADJUST SIGNAL

27 F1, F2 FCM OUTPUT (UNLOCK-RUN-START)

28 F214 FCM OUTPUT (RUN-START) (SIACM)

29 F100 FCM OUTPUT (RUN) (ORC)

30 FCM 30 FRONT/REAR BLOWER MOTOR RELAY CONTROL

31 FCM 31 REAR WINDOW DEFOGGER RELAY CONTROL

32 FCM 32 (BUILT-UP-

EXPORT))HEADLAMP WASHER RELAY CONTROL

33 FCM 33 FRONT FOG LAMP RELAY CONTROL

34 FCM 34 FRONT WIPER HIGH/LOW RELAY CONTROL

35 FCM 35 ACCESSORY RELAY CONTROL (RUN-ACC)

36 B20 BRAKE FLUID LEVEL SWITCH SENSE

37 F20 IGNITION SWITCH OUTPUT (RUN-START)

38 A1 B(+)

39 T2 TRS REVERSE SENSE

40 T753 (DIESEL) IGNITION SWITCH OUTPUT (START)

41 L77 FUSED PARK LAMP RELAY OUTPUT (LEFT)

42 D23 FLASH PROGRAM ENABLE

43 Z116 GROUND

44 L50 PRIMARY BRAKE SWITCH SIGNAL

45 W10 FRONT WASHER PUMP MOTOR CONTROL

46 W20 REAR WASHER PUMP MOTOR CONTROL

47 K32 BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID CONTROL

48 F201 FCM OUTPUT (RUN-START) (ORC)

49 - NOT USED

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1067

CONNECTOR PINOUTS

Page 1108 of 4284

RIGHT FRONT PARK/TURN SIGNAL LAMP (EXCEPT BUILT-UP-EXPORT) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 L60 18WT/TN RIGHT FRONT TURN SIGNAL DRIVER

2 L78 18WT/OR FUSED PARK LAMP RELAY OUTPUT (RIGHT)

3 Z378 18BK/TN GROUND

RIGHT FULL OPEN SWITCH (POWER SLIDING DOOR) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Q52 20OR RIGHT FULL OPEN SWITCH SENSE

2 Z76 20BK/YL GROUND

RIGHT HEADLAMP (EXCEPT BUILT-UP-EXPORT) - BLACK 3 WAYCAV CIRCUIT FUNCTION

1 L44 16WT/TN RIGHT LOW BEAM DRIVER

2 Z344 16BK/TN GROUND

3 L34 16WT/GY RIGHT HIGH BEAM DRIVER

RIGHT HIGH BEAM LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z344 16BR GROUND

1 Z344 16BR GROUND

2 L34 16GY RIGHT HIGH BEAM DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1079

CONNECTOR PINOUTS

Page 1109 of 4284

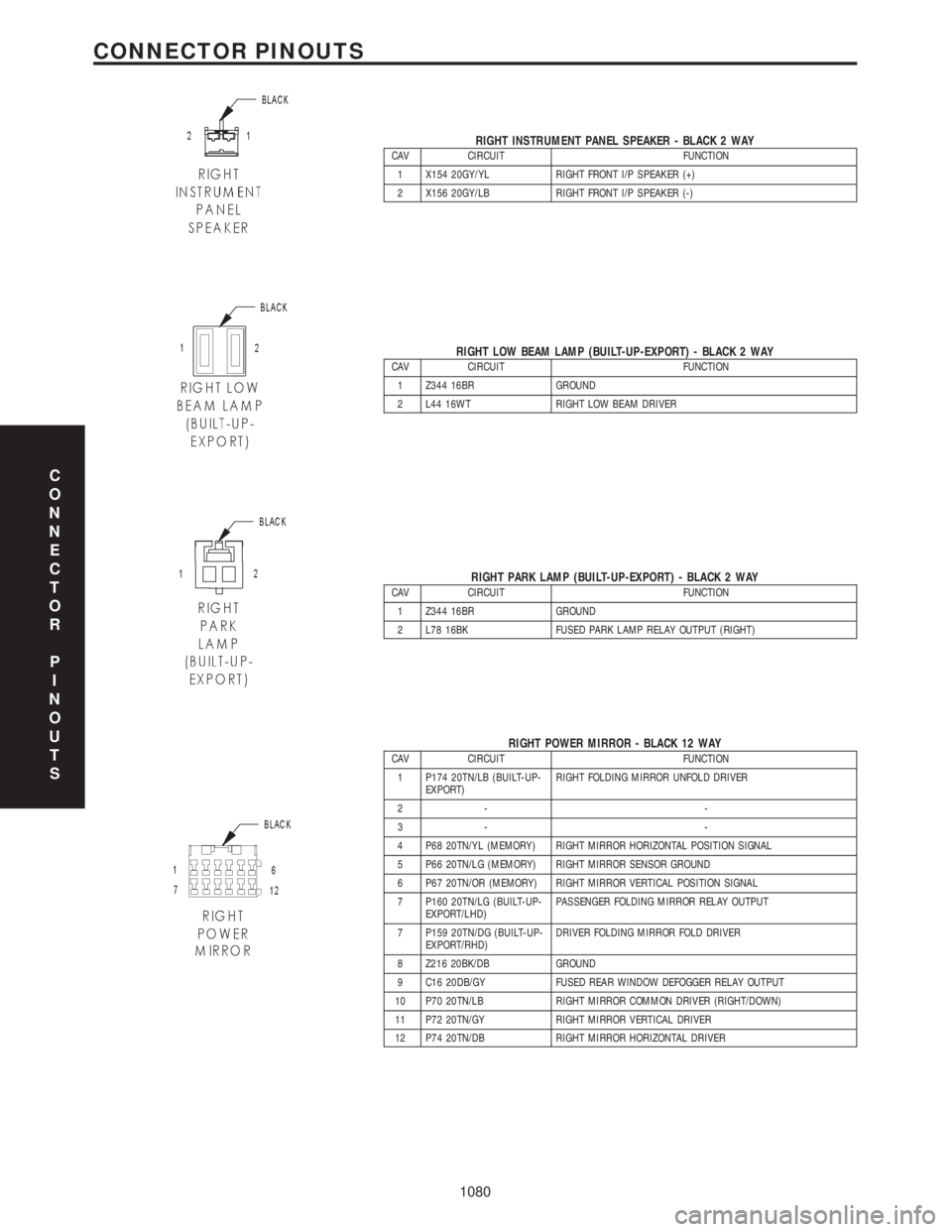

RIGHT INSTRUMENT PANEL SPEAKER - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 X154 20GY/YL RIGHT FRONT I/P SPEAKER (+)

2 X156 20GY/LB RIGHT FRONT I/P SPEAKER (-)

RIGHT LOW BEAM LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z344 16BR GROUND

2 L44 16WT RIGHT LOW BEAM DRIVER

RIGHT PARK LAMP (BUILT-UP-EXPORT) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 Z344 16BR GROUND

2 L78 16BK FUSED PARK LAMP RELAY OUTPUT (RIGHT)

RIGHT POWER MIRROR - BLACK 12 WAYCAV CIRCUIT FUNCTION

1 P174 20TN/LB (BUILT-UP-

EXPORT)RIGHT FOLDING MIRROR UNFOLD DRIVER

2- -

3- -

4 P68 20TN/YL (MEMORY) RIGHT MIRROR HORIZONTAL POSITION SIGNAL

5 P66 20TN/LG (MEMORY) RIGHT MIRROR SENSOR GROUND

6 P67 20TN/OR (MEMORY) RIGHT MIRROR VERTICAL POSITION SIGNAL

7 P160 20TN/LG (BUILT-UP-

EXPORT/LHD)PASSENGER FOLDING MIRROR RELAY OUTPUT

7 P159 20TN/DG (BUILT-UP-

EXPORT/RHD)DRIVER FOLDING MIRROR FOLD DRIVER

8 Z216 20BK/DB GROUND

9 C16 20DB/GY FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

10 P70 20TN/LB RIGHT MIRROR COMMON DRIVER (RIGHT/DOWN)

11 P72 20TN/GY RIGHT MIRROR VERTICAL DRIVER

12 P74 20TN/DB RIGHT MIRROR HORIZONTAL DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1080

CONNECTOR PINOUTS

Page 1483 of 4284

FASTENER USAGE

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 4) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 4 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RGINTRODUCTION5a

Page 1763 of 4284

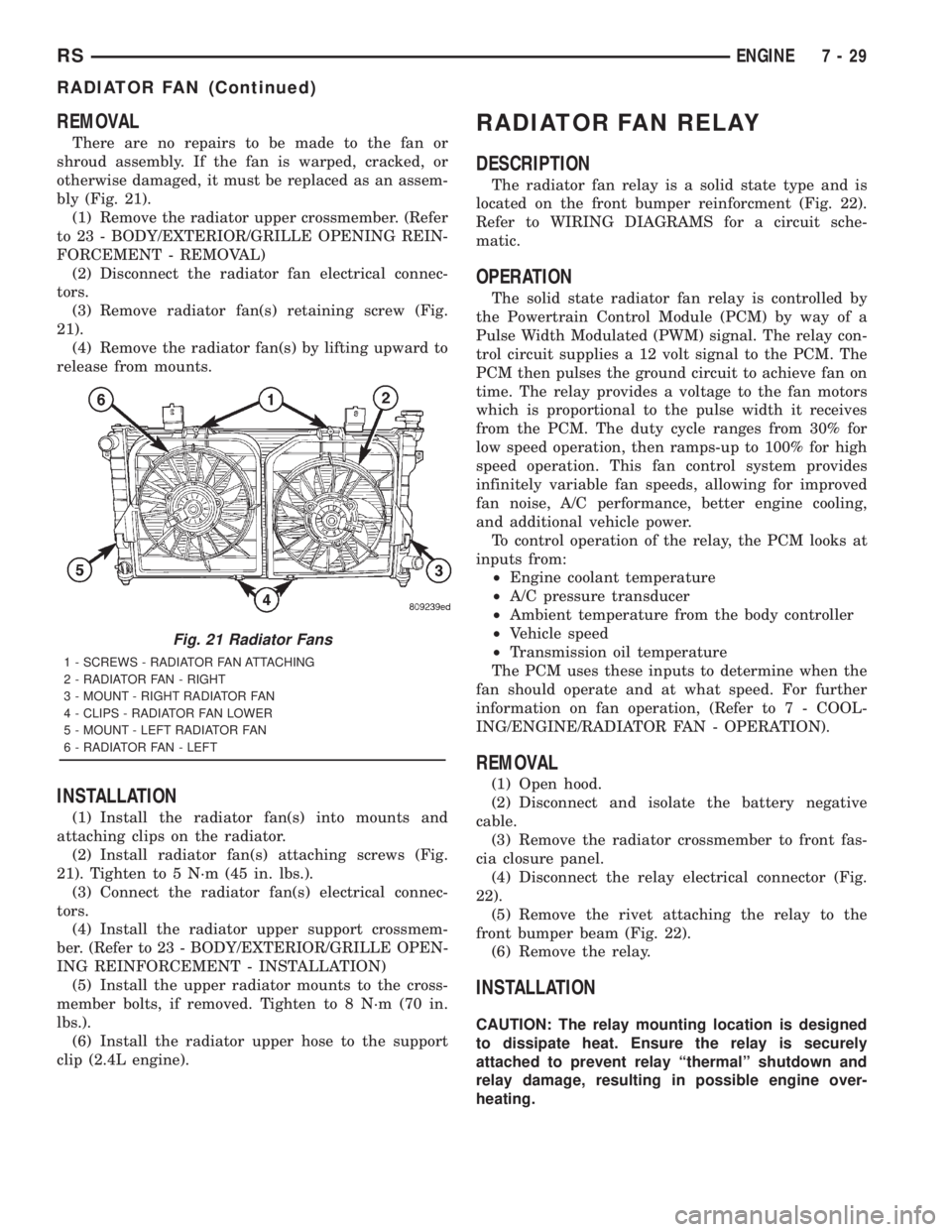

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assem-

bly (Fig. 21).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REIN-

FORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connec-

tors.

(3) Remove radiator fan(s) retaining screw (Fig.

21).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

21). Tighten to 5 N´m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connec-

tors.

(4) Install the radiator upper support crossmem-

ber. (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - INSTALLATION)

(5) Install the upper radiator mounts to the cross-

member bolts, if removed. Tighten to 8 N´m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

RADIATOR FAN RELAY

DESCRIPTION

The radiator fan relay is a solid state type and is

located on the front bumper reinforcment (Fig. 22).

Refer to WIRING DIAGRAMS for a circuit sche-

matic.

OPERATION

The solid state radiator fan relay is controlled by

the Powertrain Control Module (PCM) by way of a

Pulse Width Modulated (PWM) signal. The relay con-

trol circuit supplies a 12 volt signal to the PCM. The

PCM then pulses the ground circuit to achieve fan on

time. The relay provides a voltage to the fan motors

which is proportional to the pulse width it receives

from the PCM. The duty cycle ranges from 30% for

low speed operation, then ramps-up to 100% for high

speed operation. This fan control system provides

infinitely variable fan speeds, allowing for improved

fan noise, A/C performance, better engine cooling,

and additional vehicle power.

To control operation of the relay, the PCM looks at

inputs from:

²Engine coolant temperature

²A/C pressure transducer

²Ambient temperature from the body controller

²Vehicle speed

²Transmission oil temperature

The PCM uses these inputs to determine when the

fan should operate and at what speed. For further

information on fan operation, (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - OPERATION).

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the radiator crossmember to front fas-

cia closure panel.

(4) Disconnect the relay electrical connector (Fig.

22).

(5) Remove the rivet attaching the relay to the

front bumper beam (Fig. 22).

(6) Remove the relay.

INSTALLATION

CAUTION: The relay mounting location is designed

to dissipate heat. Ensure the relay is securely

attached to prevent relay ªthermalº shutdown and

relay damage, resulting in possible engine over-

heating.

Fig. 21 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

RSENGINE7-29

RADIATOR FAN (Continued)

Page 1942 of 4284

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

LAMP SYSTEMS

RS vehicles use lighting on the interior and exte-

rior of the vehicle for illuminating and indicating

purposes. Lighting circuits are protected by fuses.

Lighting circuits require an overload protected power

source, on/off device, lamps and body ground to oper-

ate properly. Plastic lamps require a wire in the har-

ness to supply body ground to the lamp socket.

Replace sockets and bulbs that are corroded.

Some of the interior and exterior lighting functions

are governed by the Body Control Module. The head-

lamp, dome, and the door ajar switches provide sig-

nals to the Body Control Module. The Body Control

Module in turn sends a J1850 message to the Front

Control Module (FCM) to enable the necessary driv-

ers to set the required illumination configuration.

Wire connectors can make intermittent contact or

become corroded. Before coupling wire connectors,

inspect the terminals inside the connector. Male termi-

nals should not be bent or disengaged from the insu-

lator. Female terminals should not be sprung open or

disengaged from the insulator. Bent and sprung termi-

nals can be repaired using needle nose pliers and pick

tool. Corroded terminals appear chalky or green. Cor-

roded terminals should be replaced to avoid recur-

rence of the problem symptoms.

Begin electrical system failure diagnosis by testing

related fuses in the fuse block and intelligent power

module. Verify that bulbs are in good condition and

test continuity of the circuit ground. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

AUTOMATIC HEADLAMP SYSTEM

The Automatic Headlamp system turns the instru-

mentation and exterior illumination lamps ON when

the ambient light levels are Night and OFF when

light levels are Day.

DAYTIME RUNNING LAMPS

Operating the high-beam headlamps at reduced

power provides daytime running lamps, which are

required on all new Canadian vehicles.

HEADLAMPS ON WITH WINDSHIELD WIPERS

For vehicles equipped with the Automatic Head-

lamp System, the instrumentation and exterior illu-

mination lamps will be turned ON when theheadlamp switch is in the AUTO position, RPM >

450 and the windshield wipers have been in the

intermittent, low or high mode of operation for more

than ten seconds. When the windshield wipers are

turned OFF the Body Control Module will determine

if the instrumentation and exterior illumination

lamps should remain ON base upon the current

ambient light level.

HEADLAMP SYSTEM

The configuration of the headlamp system of head-

lamps, park lamps and fog lamps is determined by

the BCM. The BCM determines the lighting configu-

ration as a result of the inputs from the ignition

switch, headlamp switch and multifunction switch. A

J1850 is transmitted from the BCM to the FCM to

enable the necessary drivers to set the illumination

configuration. Four wires are connected between the

headlamp switch and the BCM. The first wire con-

tains information regarding the position of the head-

lamp switch (Off, Automatic Headlamps, Automatic

Headlamp switch fog, Park with Fog, Head, or Head

with Fog Lamps). The second wire contains informa-

tion regarding the position of the dimmer switch

(Dome Lamp, Daytime Brightness, Dimming Level or

Off). The third wire is a dedicated signal return

(ground) wire. The fourth wire provides power to the

front fog lamp indicator.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is controlled by

the Body Control Module (BCM) via a J1850 message

transmitted by the BCM to the FCM to turn off the

headlamps.

OPERATION

AUTOMATIC HEADLAMP SYSTEM

Automatic headlamps are controlled by the Body

Control Module (BCM). With the headlamp switch in

the AUTO position, the BCM will control the head-

lamp, parking, side marker, tail and instrumentation

lamps based on ambient light levels. Ambient light

levels are monitored by the BCM using the Day/

Night signal and Electrochromatic Mirror (ECM)

present from the Compass Mini Trip (CMTC) located

on the front windshield in front of the rear view mir-

ror (ECM). Ambient light readings are averaged to

limit cycling the lamps ON and OFF when passing

through areas with varying light levels. The auto-

matic headlamps will only function when the engine

is running with RPM > 450. When the headlamp

switch is in the AUTO position (Automatic mode), the

Headlamp Time Delay system will function when the

ignition switch is placed in any position other than

run/start.

8L - 2 LAMPS/LIGHTING - EXTERIORRS

Page 1943 of 4284

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the Front Control Module (FCM).

HEADLAMP SYSTEM

The headlamp system will default to headlamps

ON position when ignition switch is ON and when an

open or short circuit failure occurs on the headlamp

switch input. The system will return to normal oper-

ation when the open or short is repaired. A fault will

be reported by the BCM when a failure occurs on the

dimmer or headlamp switch input.

If the exterior lamps are ON and the headlamp

switch is in any position other than OFF or AUTO

and with the ignition switch OFF (LOCK) after 3

minutes the BCM sends a message via J1850 to the

FCM informing the FCM to turn off the headlamps,

park lamps and fog lamps. This feature prevents the

vehicle battery from being discharged when the vehi-

cle lights have been left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The BCM will allow

the headlamps to remain ON for 90 seconds (config-

urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then both the headlamps and park lamps

(including panel dimming) will be ON). Refer to the

Owner's Manual for more information.

If the headlamp switch is in the Auto Headlamp

Position, the headlamps are ON due to the night sig-

nal from the CMTC and the ignition switch is in any

position other than run/start, the BCM shall enter a

90 second (configurable) Auto Headlamps time delay

mode. If the key is in the ignition during the head-

lamp time delay mode, then both the headlamps and

park lamps (including panel dimming) will be ON. If

the key is not in the ignition, then only the head-

lamps will be ON. The BCM will allow the head-

lamps to remain ON for 90 seconds before they

automatically turn OFF. Refer to the Owner's Man-

ual for more information.

LAMP OUTAGE

If one or more of the following lamps (Low and/or

High beams) are out, then a ªlamps outº indicator

located in the cluster will illuminate.

OPTICAL HORN/HIGH BEAMS

When the multifunction switch is pulled to the first

detent (optical horn) signal, the headlamps are ON,

key-in the ignition the BCM shall send a message via

J1850 to the FCM to turn on the headlamps drivers

to illuminate all four filaments (Low and High

beams). When the multifunction switch is pulled to

the second detent (high beam) signal and the head-

lamps are ON, the BCM shall send a message via

J1850 to the FCM to turn on the headlamps drivers.

The High Beams are illuminated and the Low Beams

and Fog Lamps (if ON) are extinguished. If the head-

lamps were in the high beam configuration when

power was removed from the headlamps, the head-

lamps will be configured as low beam the next time

they are activated.

DIAGNOSIS AND TESTING

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, fuses, charging system, headlamp bulbs,

wire connectors, relay, high beam switch, dimmer

switch, and headlamp switch. Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

RSLAMPS/LIGHTING - EXTERIOR8L-3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 1952 of 4284

HEADLAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the three retaining screws (Fig. 11).

(3) Disconnect the wiring harness from the bulbs

(Fig. 12).(4) Remove wire harness retainer from back of

headlamp unit.

(5) Remove the headlamp unit.INSTALLATION

(1) Reconnect wire harness to the bulbs.

(2) Install wire harness retainer to headlamp unit.

(3) Install the three retaining screws.

(4) Reconnect the battery negative cable.

ADJUSTMENT

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is loaded as the vehi-

cle is routinely used.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens (Fig. 13).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall.

(3) Rock vehicle side-to-side three times and allow

suspension to stabilize.

(4) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(5) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

Fig. 11 HEADLAMP FASTENERS

1 - HEADLAMP RETAINING SCREW

2 - HEADLAMP UNIT

Fig. 12 HEADLAMP ASSEMBLY

1 - HEADLAMP UNIT

2 - HEADLAMP BULB

3 - PARK/TURN SIGNAL BULB

4 - WIRE HARNESS RETAINER

8L - 12 LAMPS/LIGHTING - EXTERIORRS