low beam CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 523 of 4284

Symptom:

RIGHT HIGH BEAM HEADLAMP CIRCUIT SHORTED TO VOLT-

AGE

POSSIBLE CAUSES

FRONT CONTROL MODULE

GROUND CIRCUIT OPEN

HIGH BEAM AND LOW BEAM DRIVERS CIRCUITS SHORTED TOGETHER

RIGHT HEADLAMP

RIGHT HIGH BEAM DRIVER CIRCUIT SHORTED TO VOLTAGE

WIRING PROBLEM

WIRING HARNESS INSPECTION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Is this DTC present?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Using a 12-volt test light connected to 12-volts, check the Ground circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

3 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Disconnect the Front Control Module.

Measure the resistance between the Right High Beam Driver circuit and the Right

Low Beam Driver circuit at the Right Headlamp harness connector.

Is the resistance below 100.0 ohms?All

Ye s®Repair the Right High Beam Driver circuit for a short to the Right

Low Beam Driver circuit.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

494

EXTERIOR LIGHTING

Page 524 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Disconnect the Front Control Module.

Turn the ignition on.

Measure the voltage of the Right High Beam Driver circuit.

Is the voltage below 1.0 volt?All

Ye s®Go To 5

No®Repair the Right High Beam Driver circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Turn the Headlamps off.

Install a substitute Headlamp Bulb in place of the Right Headlamp Bulb.

Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Does the DRB display this DTC?All

Ye s®Go To 6

No®Replace the original Right Headlamp Bulb.

Perform BODY VERIFICATION TEST - VER 1.

6 Turn the ignition off.

Inspect the wiring and connectors associated with the Right High Beam Driver

circuit.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

7 Turn the ignition off.

NOTE: Visually inspect the related wiring harness and circuits. Look for

any chafed, pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

495

EXTERIOR LIGHTING

RIGHT HIGH BEAM HEADLAMP CIRCUIT SHORTED TO VOLTAGE Ð

Continued

Page 525 of 4284

Symptom:

RIGHT LOW BEAM HEADLAMP CIRCUIT OPEN

POSSIBLE CAUSES

FRONT CONTROL MODULE

GROUND CIRCUIT OPEN

RIGHT HEADLAMP

RIGHT LOW BEAM DRIVER CIRCUIT OPEN

WIRING HARNESS INSPECTION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Is this DTC present?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Using a 12-volt test light connected to 12-volts, check the Ground circuit.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

3 Turn the ignition off.

Disconnect the Right Headlamp.

Disconnect the Front Control Module from the Intelligent Power Module.

Measure the resistance of the Right Low Beam Driver circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 4

No®Repair the Right Low Beam Driver circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

496

EXTERIOR LIGHTING

Page 526 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Using a 12-volt test light connected to ground, check the Right Low Beam Driver

circuit in the Right Headlamp harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Turn the low beam headlamps on.

Does the test light illuminate brightly?All

Ye s®Replace the Right Headlamp Bulb.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off.

NOTE: Visually inspect the related wiring harness and circuits. Look for

any chafed, pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

497

EXTERIOR LIGHTING

RIGHT LOW BEAM HEADLAMP CIRCUIT OPEN ÐContinued

Page 527 of 4284

Symptom:

RIGHT LOW BEAM HEADLAMP CIRCUIT SHORTED TO GROUND

POSSIBLE CAUSES

FRONT CONTROL MODULE

RIGHT HEADLAMP

RIGHT LOW BEAM DRIVER CIRCUIT SHORTED TO GROUND

WIRING PROBLEM

WIRING HARNESS INSPECTION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Is this DTC present?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Disconnect the Right Headlamp.

Disconnect the Front Control Module from the Intelligent Power Module.

Measure the resistance between Ground and the Right Low Beam Driver circuit.

Is the resistance below 100.0 ohms?All

Ye s®Repair the Right Low Beam Driver circuit for a short to ground

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Turn the Headlamps off.

Install a substitute Headlamp Bulb in place of the Right Headlamp Bulb.

Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Does the DRB display this DTC?All

Ye s®Go To 4

No®Replace the original Right Headlamp Bulb.

Perform BODY VERIFICATION TEST - VER 1.

498

EXTERIOR LIGHTING

Page 528 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Inspect the wiring and connectors associated with the Right Low Beam Driver

circuit.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off.

NOTE: Visually inspect the related wiring harness and circuits. Look for

any chafed, pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

499

EXTERIOR LIGHTING

RIGHT LOW BEAM HEADLAMP CIRCUIT SHORTED TO GROUND Ð

Continued

Page 529 of 4284

Symptom:

RIGHT LOW BEAM HEADLAMP CIRCUIT SHORTED TO VOLTAGE

POSSIBLE CAUSES

FRONT CONTROL MODULE

GROUND CIRCUIT OPEN

HIGH BEAM AND LOW BEAM DRIVERS CIRCUITS SHORTED TOGETHER

RIGHT HEADLAMP

RIGHT LOW BEAM DRIVER CIRCUIT SHORTED TO VOLTAGE

WIRING PROBLEM

WIRING HARNESS INSPECTION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Is this DTC present?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Using a 12-volt test light connected to 12-volts, check the Ground circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

3 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Disconnect the Front Control Module.

Measure the resistance between the Right High Beam Driver circuit and the Right

Low Beam Driver circuit at the Right Headlamp harness connector.

Is the resistance below 100.0 ohms?All

Ye s®Repair the Right High Beam Driver circuit for a short to the Right

Low Beam Driver circuit.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

500

EXTERIOR LIGHTING

Page 530 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the Right Headlamp harness connector.

Disconnect the Front Control Module.

Turn the ignition on.

Measure the voltage of the Right Low Beam Driver circuit.

Is the voltage below 1.0 volt?All

Ye s®Go To 5

No®Repair the Right Low Beam Driver circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Turn the Headlamps off.

Install a substitute Headlamp Bulb in place of the Right Headlamp Bulb.

Turn the ignition on.

With the DRB, erase the Front Control Module DTC's.

Turn the headlamps on.

Switch the headlamps between high beam and low beam several times, pausing for

5 seconds in each position.

With the DRB, read Front Control Module DTC's.

Does the DRB display this DTC?All

Ye s®Go To 6

No®Replace the original Right Headlamp Bulb.

Perform BODY VERIFICATION TEST - VER 1.

6 Turn the ignition off.

Inspect the wiring and connectors associated with the Right Low Beam Driver

circuit.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

7 Turn the ignition off.

NOTE: Visually inspect the related wiring harness and circuits. Look for

any chafed, pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

501

EXTERIOR LIGHTING

RIGHT LOW BEAM HEADLAMP CIRCUIT SHORTED TO VOLTAGE Ð

Continued

Page 988 of 4284

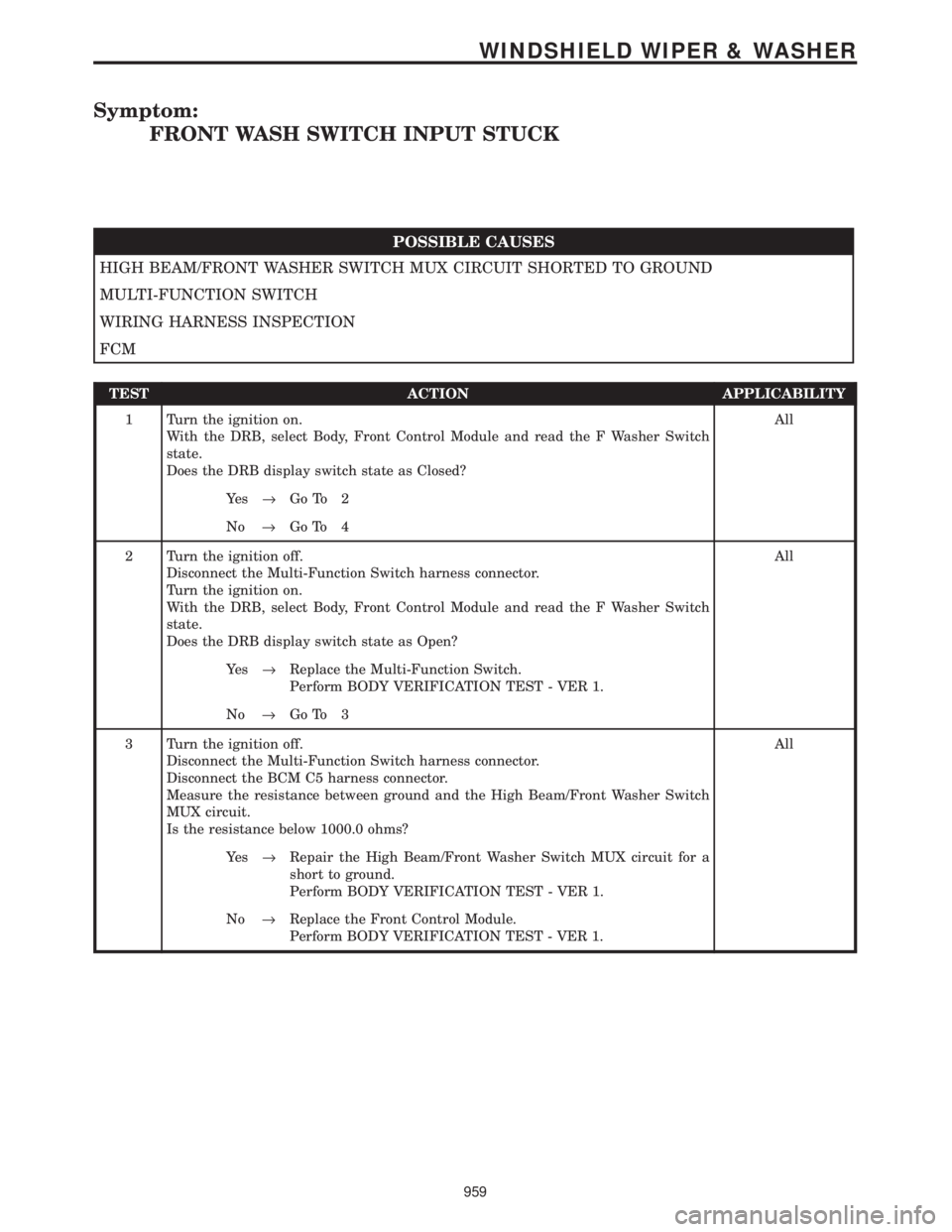

Symptom:

FRONT WASH SWITCH INPUT STUCK

POSSIBLE CAUSES

HIGH BEAM/FRONT WASHER SWITCH MUX CIRCUIT SHORTED TO GROUND

MULTI-FUNCTION SWITCH

WIRING HARNESS INSPECTION

FCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRB, select Body, Front Control Module and read the F Washer Switch

state.

Does the DRB display switch state as Closed?All

Ye s®Go To 2

No®Go To 4

2 Turn the ignition off.

Disconnect the Multi-Function Switch harness connector.

Turn the ignition on.

With the DRB, select Body, Front Control Module and read the F Washer Switch

state.

Does the DRB display switch state as Open?All

Ye s®Replace the Multi-Function Switch.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Disconnect the Multi-Function Switch harness connector.

Disconnect the BCM C5 harness connector.

Measure the resistance between ground and the High Beam/Front Washer Switch

MUX circuit.

Is the resistance below 1000.0 ohms?All

Ye s®Repair the High Beam/Front Washer Switch MUX circuit for a

short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

959

WINDSHIELD WIPER & WASHER

Page 1073 of 4284

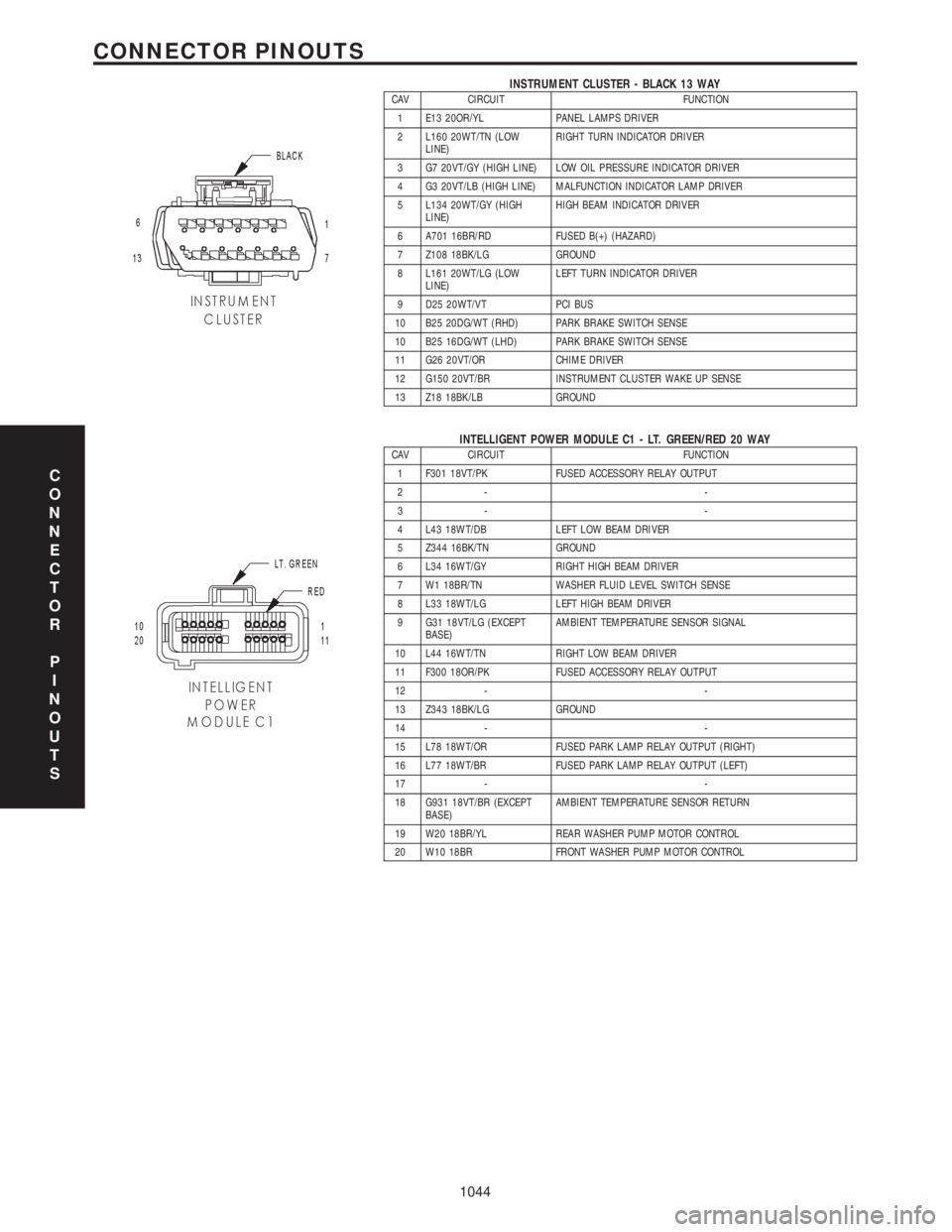

INSTRUMENT CLUSTER - BLACK 13 WAYCAV CIRCUIT FUNCTION

1 E13 20OR/YL PANEL LAMPS DRIVER

2 L160 20WT/TN (LOW

LINE)RIGHT TURN INDICATOR DRIVER

3 G7 20VT/GY (HIGH LINE) LOW OIL PRESSURE INDICATOR DRIVER

4 G3 20VT/LB (HIGH LINE) MALFUNCTION INDICATOR LAMP DRIVER

5 L134 20WT/GY (HIGH

LINE)HIGH BEAM INDICATOR DRIVER

6 A701 16BR/RD FUSED B(+) (HAZARD)

7 Z108 18BK/LG GROUND

8 L161 20WT/LG (LOW

LINE)LEFT TURN INDICATOR DRIVER

9 D25 20WT/VT PCI BUS

10 B25 20DG/WT (RHD) PARK BRAKE SWITCH SENSE

10 B25 16DG/WT (LHD) PARK BRAKE SWITCH SENSE

11 G26 20VT/OR CHIME DRIVER

12 G150 20VT/BR INSTRUMENT CLUSTER WAKE UP SENSE

13 Z18 18BK/LB GROUND

INTELLIGENT POWER MODULE C1 - LT. GREEN/RED 20 WAYCAV CIRCUIT FUNCTION

1 F301 18VT/PK FUSED ACCESSORY RELAY OUTPUT

2- -

3- -

4 L43 18WT/DB LEFT LOW BEAM DRIVER

5 Z344 16BK/TN GROUND

6 L34 16WT/GY RIGHT HIGH BEAM DRIVER

7 W1 18BR/TN WASHER FLUID LEVEL SWITCH SENSE

8 L33 18WT/LG LEFT HIGH BEAM DRIVER

9 G31 18VT/LG (EXCEPT

BASE)AMBIENT TEMPERATURE SENSOR SIGNAL

10 L44 16WT/TN RIGHT LOW BEAM DRIVER

11 F300 18OR/PK FUSED ACCESSORY RELAY OUTPUT

12 - -

13 Z343 18BK/LG GROUND

14 - -

15 L78 18WT/OR FUSED PARK LAMP RELAY OUTPUT (RIGHT)

16 L77 18WT/BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

17 - -

18 G931 18VT/BR (EXCEPT

BASE)AMBIENT TEMPERATURE SENSOR RETURN

19 W20 18BR/YL REAR WASHER PUMP MOTOR CONTROL

20 W10 18BR FRONT WASHER PUMP MOTOR CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1044

CONNECTOR PINOUTS