torque CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3332 of 4284

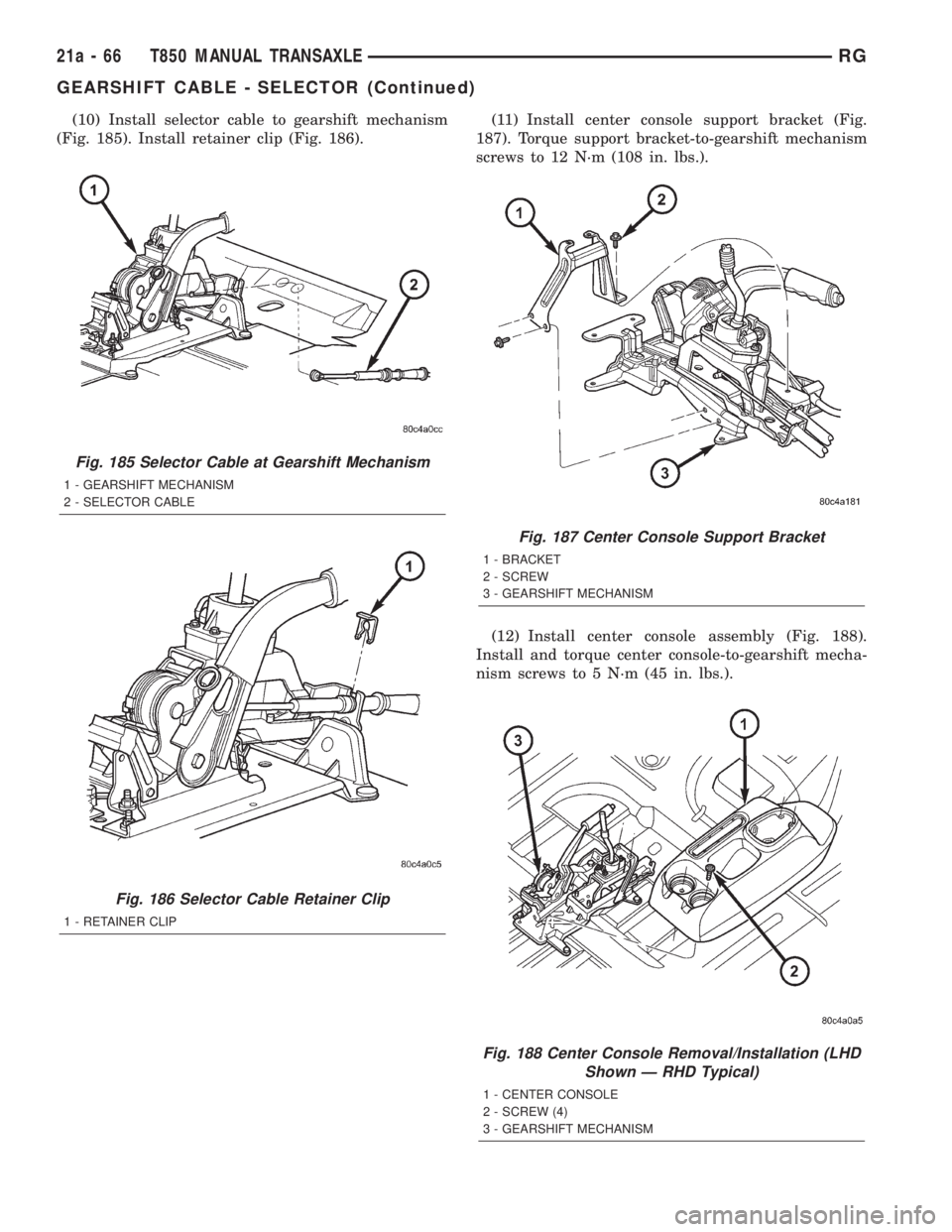

(10) Install selector cable to gearshift mechanism

(Fig. 185). Install retainer clip (Fig. 186).(11) Install center console support bracket (Fig.

187). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

(12) Install center console assembly (Fig. 188).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

Fig. 185 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 186 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 187 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

Fig. 188 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

21a - 66 T850 MANUAL TRANSAXLERG

GEARSHIFT CABLE - SELECTOR (Continued)

Page 3336 of 4284

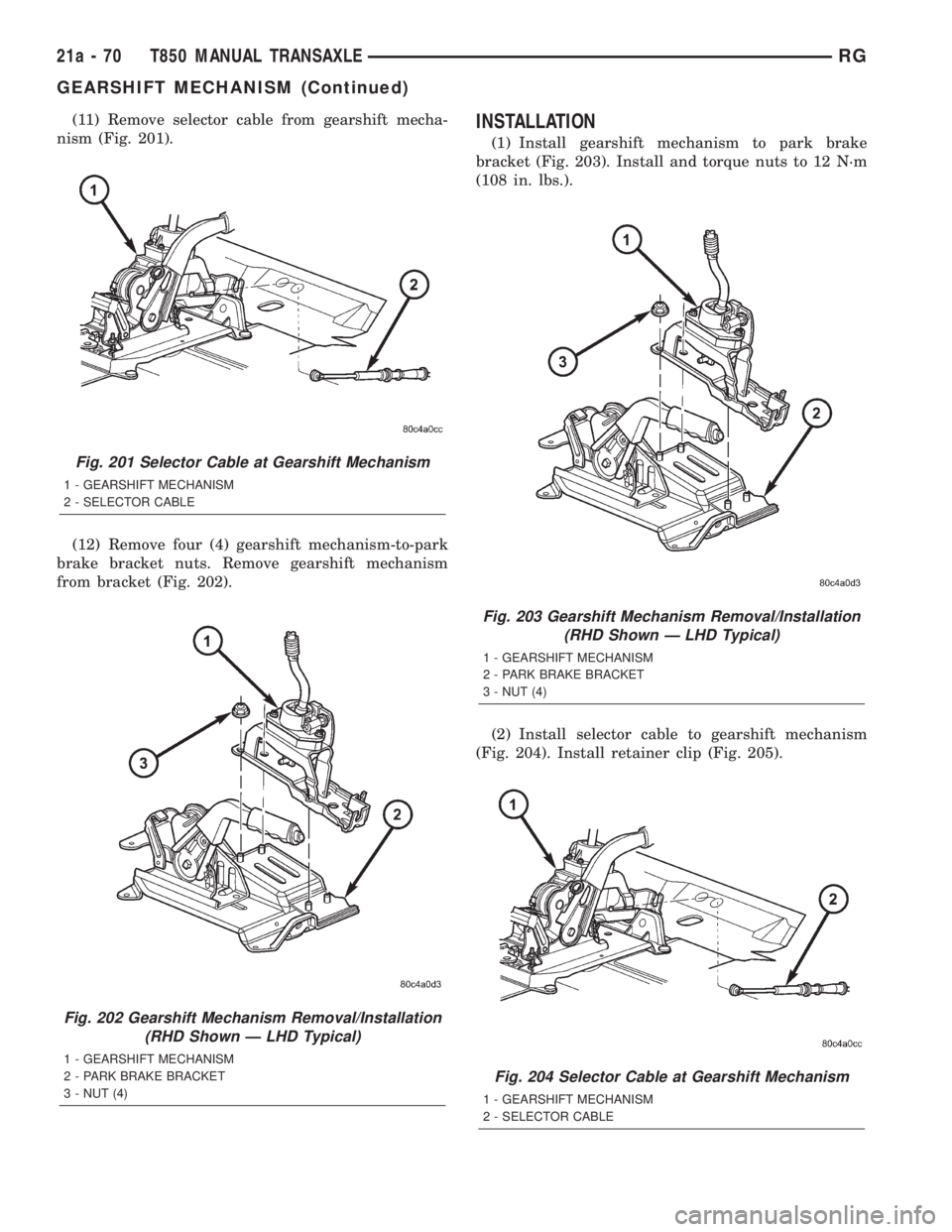

(11) Remove selector cable from gearshift mecha-

nism (Fig. 201).

(12) Remove four (4) gearshift mechanism-to-park

brake bracket nuts. Remove gearshift mechanism

from bracket (Fig. 202).INSTALLATION

(1) Install gearshift mechanism to park brake

bracket (Fig. 203). Install and torque nuts to 12 N´m

(108 in. lbs.).

(2) Install selector cable to gearshift mechanism

(Fig. 204). Install retainer clip (Fig. 205).

Fig. 201 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

Fig. 202 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 203 Gearshift Mechanism Removal/Installation

(RHD Shown Ð LHD Typical)

1 - GEARSHIFT MECHANISM

2 - PARK BRAKE BRACKET

3 - NUT (4)

Fig. 204 Selector Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - SELECTOR CABLE

21a - 70 T850 MANUAL TRANSAXLERG

GEARSHIFT MECHANISM (Continued)

Page 3337 of 4284

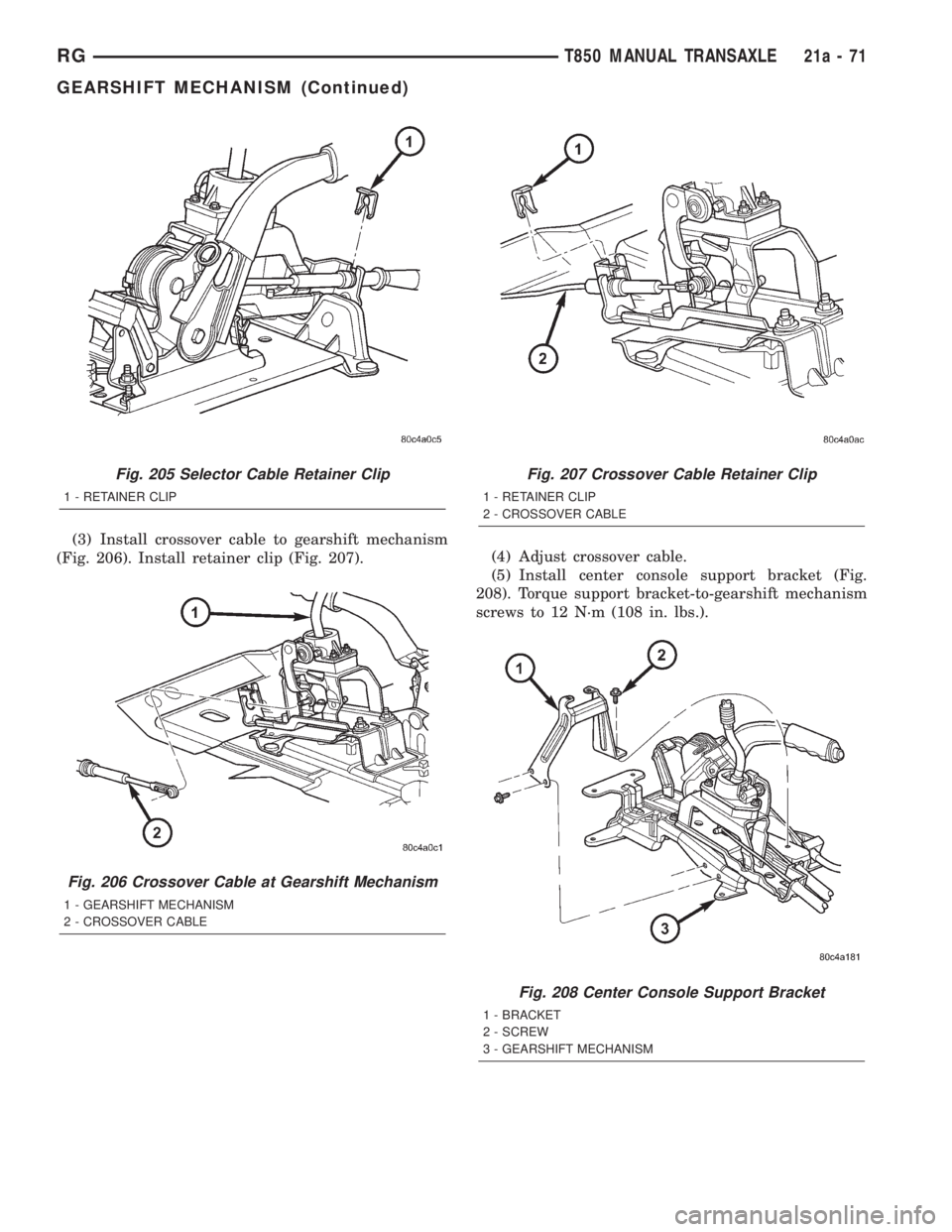

(3) Install crossover cable to gearshift mechanism

(Fig. 206). Install retainer clip (Fig. 207).(4) Adjust crossover cable.

(5) Install center console support bracket (Fig.

208). Torque support bracket-to-gearshift mechanism

screws to 12 N´m (108 in. lbs.).

Fig. 205 Selector Cable Retainer Clip

1 - RETAINER CLIP

Fig. 206 Crossover Cable at Gearshift Mechanism

1 - GEARSHIFT MECHANISM

2 - CROSSOVER CABLE

Fig. 207 Crossover Cable Retainer Clip

1 - RETAINER CLIP

2 - CROSSOVER CABLE

Fig. 208 Center Console Support Bracket

1 - BRACKET

2 - SCREW

3 - GEARSHIFT MECHANISM

RGT850 MANUAL TRANSAXLE21a-71

GEARSHIFT MECHANISM (Continued)

Page 3338 of 4284

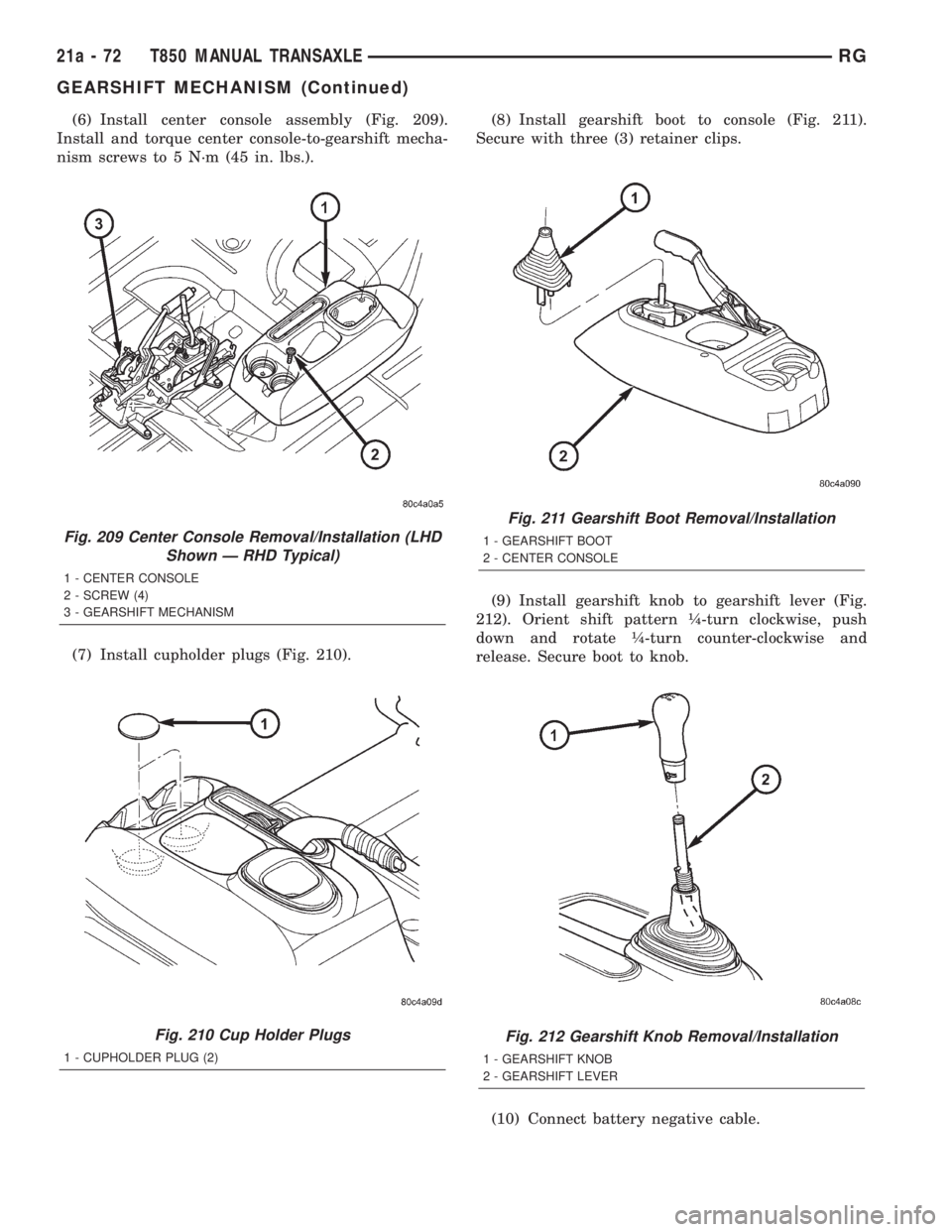

(6) Install center console assembly (Fig. 209).

Install and torque center console-to-gearshift mecha-

nism screws to 5 N´m (45 in. lbs.).

(7) Install cupholder plugs (Fig. 210).(8) Install gearshift boot to console (Fig. 211).

Secure with three (3) retainer clips.

(9) Install gearshift knob to gearshift lever (Fig.

212). Orient shift pattern ò-turn clockwise, push

down and rotate ò-turn counter-clockwise and

release. Secure boot to knob.

(10) Connect battery negative cable.

Fig. 209 Center Console Removal/Installation (LHD

Shown Ð RHD Typical)

1 - CENTER CONSOLE

2 - SCREW (4)

3 - GEARSHIFT MECHANISM

Fig. 210 Cup Holder Plugs

1 - CUPHOLDER PLUG (2)

Fig. 211 Gearshift Boot Removal/Installation

1 - GEARSHIFT BOOT

2 - CENTER CONSOLE

Fig. 212 Gearshift Knob Removal/Installation

1 - GEARSHIFT KNOB

2 - GEARSHIFT LEVER

21a - 72 T850 MANUAL TRANSAXLERG

GEARSHIFT MECHANISM (Continued)

Page 3345 of 4284

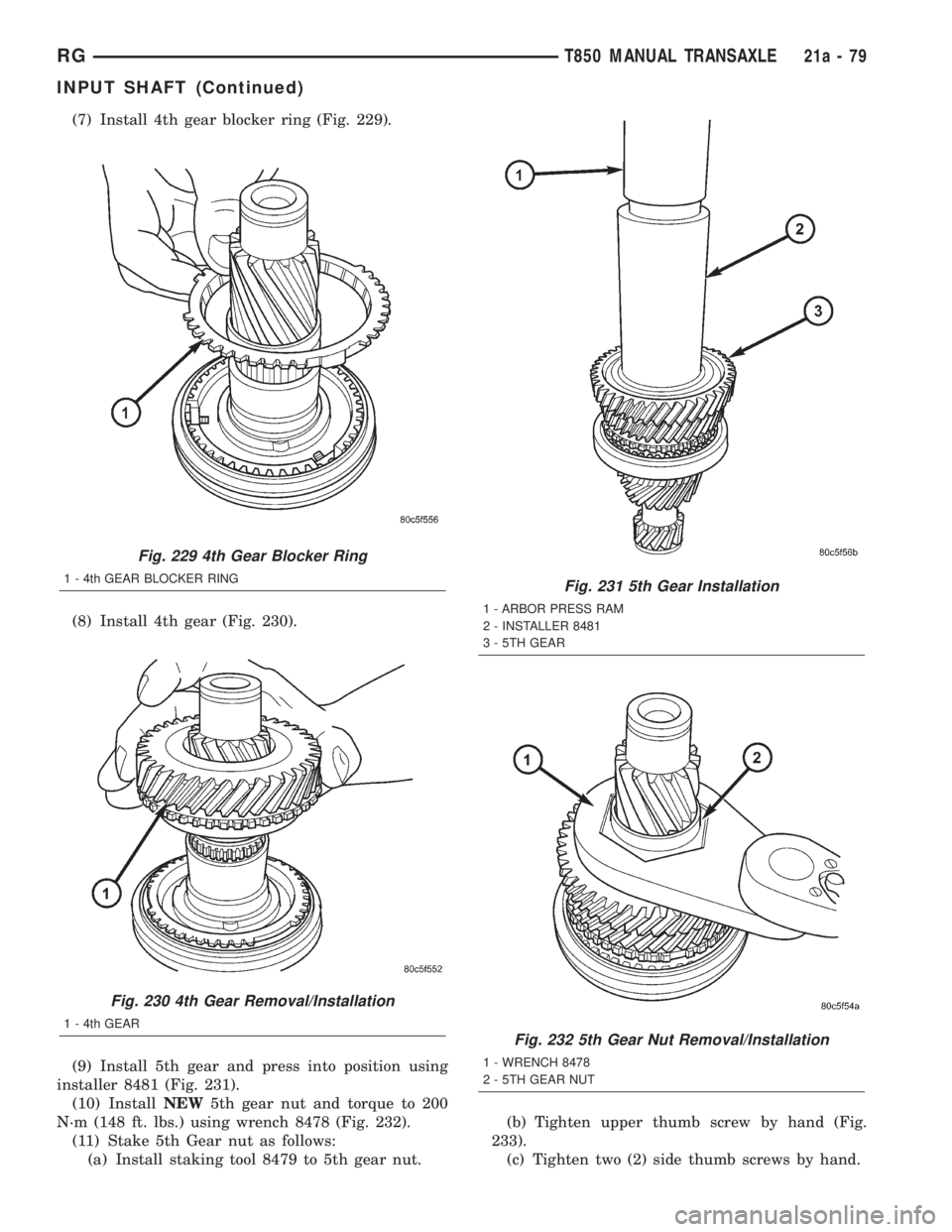

(7) Install 4th gear blocker ring (Fig. 229).

(8) Install 4th gear (Fig. 230).

(9) Install 5th gear and press into position using

installer 8481 (Fig. 231).

(10) InstallNEW5th gear nut and torque to 200

N´m (148 ft. lbs.) using wrench 8478 (Fig. 232).

(11) Stake 5th Gear nut as follows:

(a) Install staking tool 8479 to 5th gear nut.(b) Tighten upper thumb screw by hand (Fig.

233).

(c) Tighten two (2) side thumb screws by hand.

Fig. 229 4th Gear Blocker Ring

1 - 4th GEAR BLOCKER RING

Fig. 230 4th Gear Removal/Installation

1 - 4th GEAR

Fig. 231 5th Gear Installation

1 - ARBOR PRESS RAM

2 - INSTALLER 8481

3 - 5TH GEAR

Fig. 232 5th Gear Nut Removal/Installation

1 - WRENCH 8478

2 - 5TH GEAR NUT

RGT850 MANUAL TRANSAXLE21a-79

INPUT SHAFT (Continued)

Page 3362 of 4284

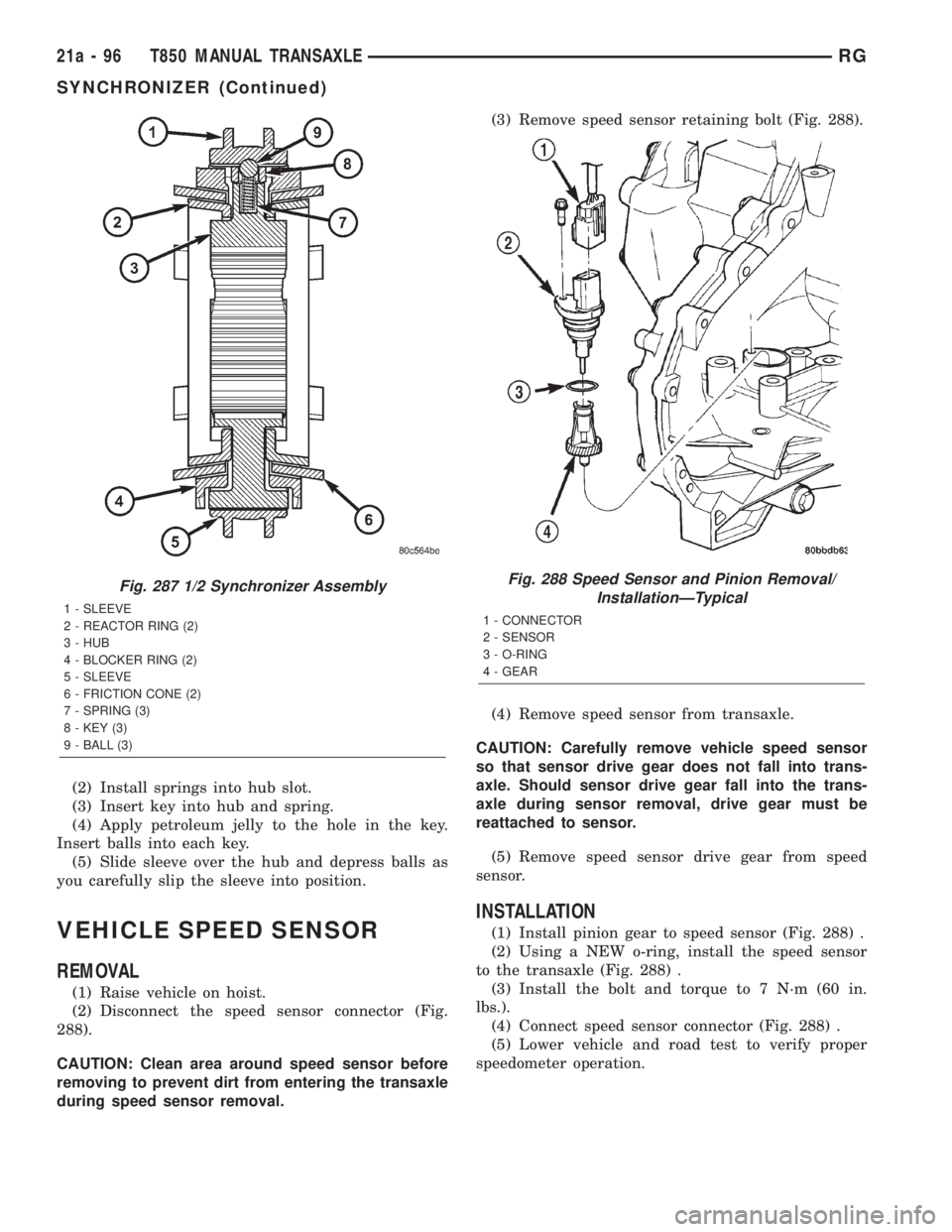

(2) Install springs into hub slot.

(3) Insert key into hub and spring.

(4) Apply petroleum jelly to the hole in the key.

Insert balls into each key.

(5) Slide sleeve over the hub and depress balls as

you carefully slip the sleeve into position.

VEHICLE SPEED SENSOR

REMOVAL

(1) Raise vehicle on hoist.

(2) Disconnect the speed sensor connector (Fig.

288).

CAUTION: Clean area around speed sensor before

removing to prevent dirt from entering the transaxle

during speed sensor removal.(3) Remove speed sensor retaining bolt (Fig. 288).

(4) Remove speed sensor from transaxle.

CAUTION: Carefully remove vehicle speed sensor

so that sensor drive gear does not fall into trans-

axle. Should sensor drive gear fall into the trans-

axle during sensor removal, drive gear must be

reattached to sensor.

(5) Remove speed sensor drive gear from speed

sensor.

INSTALLATION

(1) Install pinion gear to speed sensor (Fig. 288) .

(2) Using a NEW o-ring, install the speed sensor

to the transaxle (Fig. 288) .

(3) Install the bolt and torque to 7 N´m (60 in.

lbs.).

(4) Connect speed sensor connector (Fig. 288) .

(5) Lower vehicle and road test to verify proper

speedometer operation.

Fig. 287 1/2 Synchronizer Assembly

1 - SLEEVE

2 - REACTOR RING (2)

3 - HUB

4 - BLOCKER RING (2)

5 - SLEEVE

6 - FRICTION CONE (2)

7 - SPRING (3)

8 - KEY (3)

9 - BALL (3)

Fig. 288 Speed Sensor and Pinion Removal/

InstallationÐTypical

1 - CONNECTOR

2 - SENSOR

3 - O-RING

4 - GEAR

21a - 96 T850 MANUAL TRANSAXLERG

SYNCHRONIZER (Continued)

Page 3370 of 4284

(3) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

This will hold the wheel cover in place.(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRES

DESCRIPTION - TIRE

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

²Operating vehicle with over or under inflated

tire pressures

Radial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 17).

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

22 - 8 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

Page 3374 of 4284

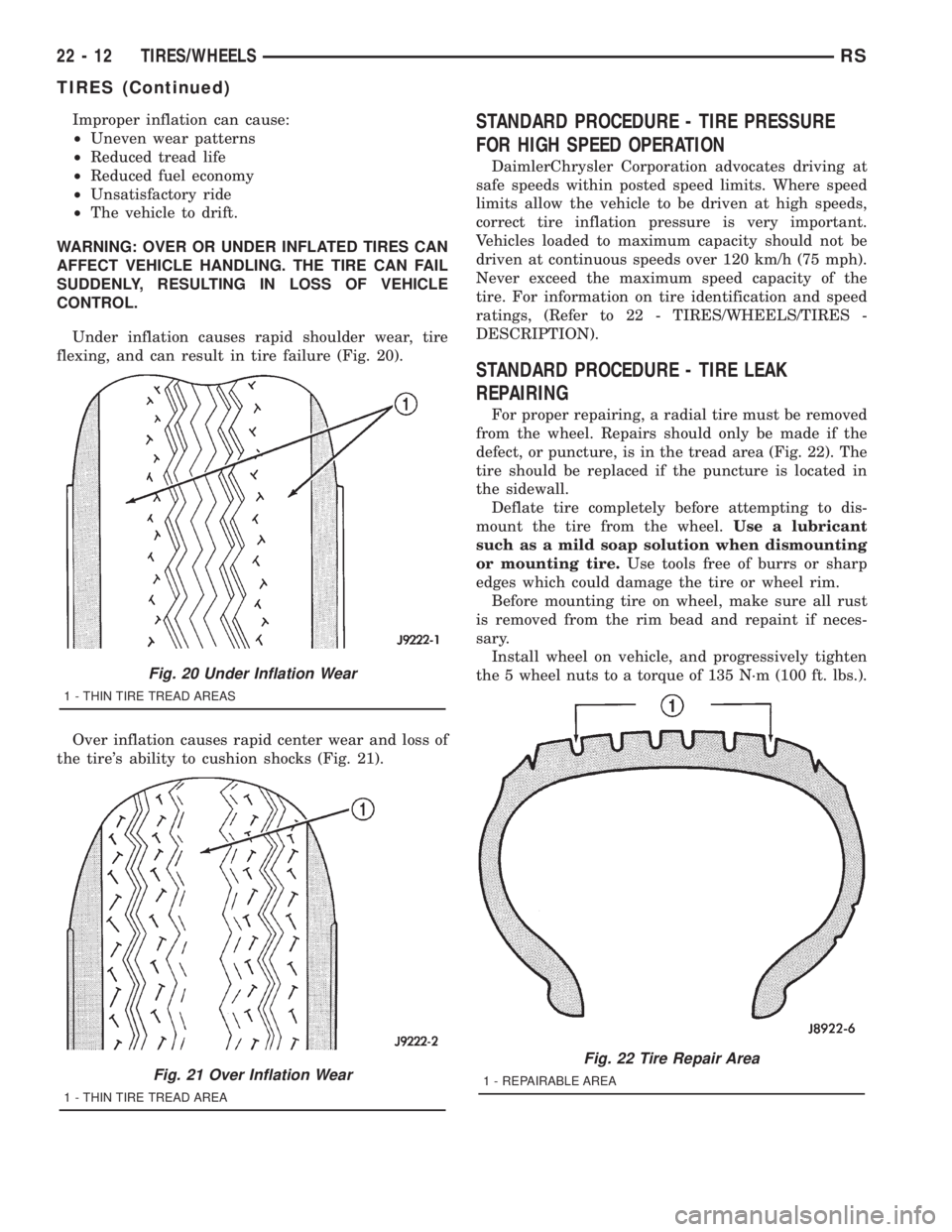

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 20).

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 21).STANDARD PROCEDURE - TIRE PRESSURE

FOR HIGH SPEED OPERATION

DaimlerChrysler Corporation advocates driving at

safe speeds within posted speed limits. Where speed

limits allow the vehicle to be driven at high speeds,

correct tire inflation pressure is very important.

Vehicles loaded to maximum capacity should not be

driven at continuous speeds over 120 km/h (75 mph).

Never exceed the maximum speed capacity of the

tire. For information on tire identification and speed

ratings, (Refer to 22 - TIRES/WHEELS/TIRES -

DESCRIPTION).

STANDARD PROCEDURE - TIRE LEAK

REPAIRING

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 22). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before attempting to dis-

mount the tire from the wheel.Use a lubricant

such as a mild soap solution when dismounting

or mounting tire.Use tools free of burrs or sharp

edges which could damage the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and progressively tighten

the 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

Fig. 20 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

Fig. 21 Over Inflation Wear

1 - THIN TIRE TREAD AREA

Fig. 22 Tire Repair Area

1 - REPAIRABLE AREA

22 - 12 TIRES/WHEELSRS

TIRES (Continued)

Page 3376 of 4284

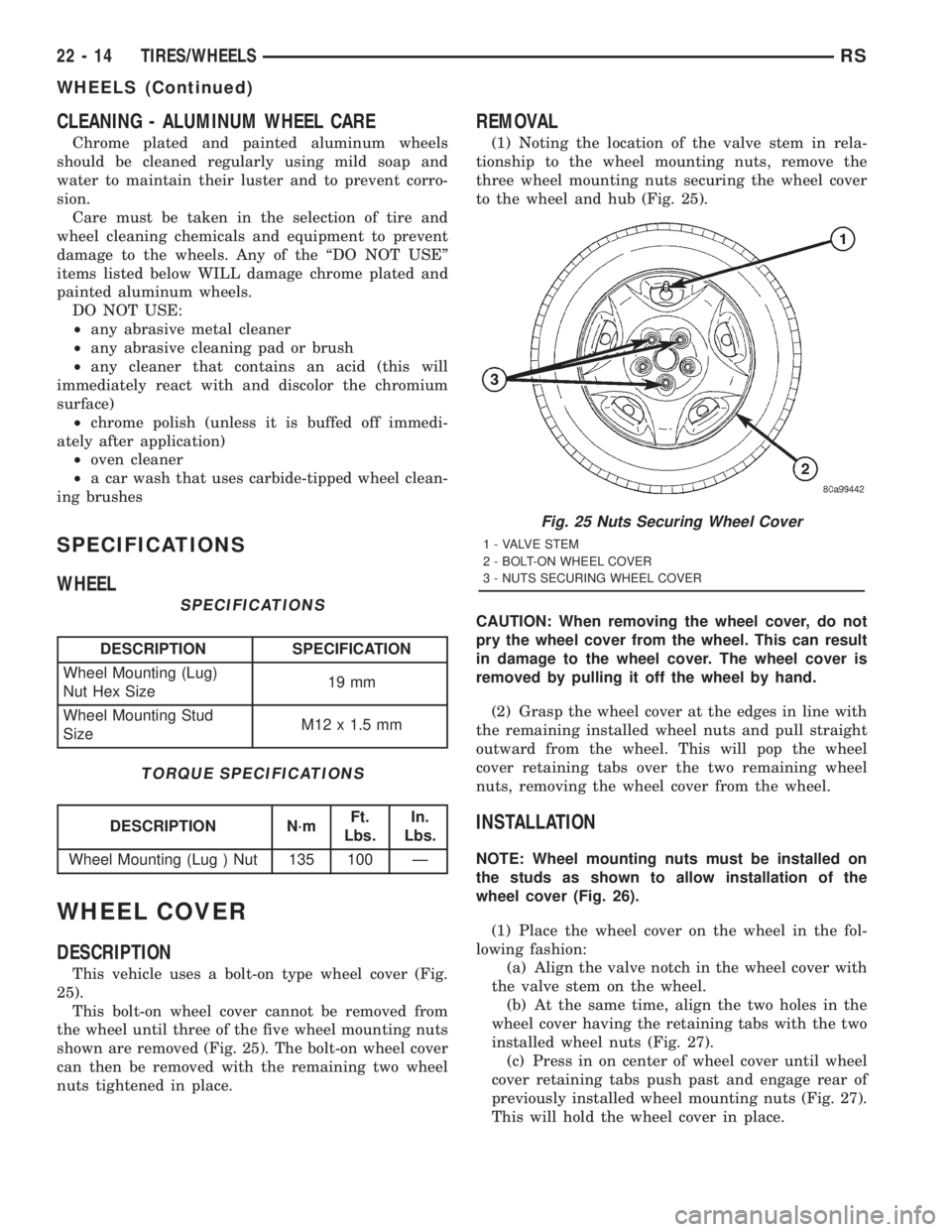

CLEANING - ALUMINUM WHEEL CARE

Chrome plated and painted aluminum wheels

should be cleaned regularly using mild soap and

water to maintain their luster and to prevent corro-

sion.

Care must be taken in the selection of tire and

wheel cleaning chemicals and equipment to prevent

damage to the wheels. Any of the ªDO NOT USEº

items listed below WILL damage chrome plated and

painted aluminum wheels.

DO NOT USE:

²any abrasive metal cleaner

²any abrasive cleaning pad or brush

²any cleaner that contains an acid (this will

immediately react with and discolor the chromium

surface)

²chrome polish (unless it is buffed off immedi-

ately after application)

²oven cleaner

²a car wash that uses carbide-tipped wheel clean-

ing brushes

SPECIFICATIONS

WHEEL

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Wheel Mounting (Lug)

Nut Hex Size19 mm

Wheel Mounting Stud

SizeM12 x 1.5 mm

TORQUE SPECIFICATIONS

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Wheel Mounting (Lug ) Nut 135 100 Ð

WHEEL COVER

DESCRIPTION

This vehicle uses a bolt-on type wheel cover (Fig.

25).

This bolt-on wheel cover cannot be removed from

the wheel until three of the five wheel mounting nuts

shown are removed (Fig. 25). The bolt-on wheel cover

can then be removed with the remaining two wheel

nuts tightened in place.

REMOVAL

(1) Noting the location of the valve stem in rela-

tionship to the wheel mounting nuts, remove the

three wheel mounting nuts securing the wheel cover

to the wheel and hub (Fig. 25).

CAUTION: When removing the wheel cover, do not

pry the wheel cover from the wheel. This can result

in damage to the wheel cover. The wheel cover is

removed by pulling it off the wheel by hand.

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

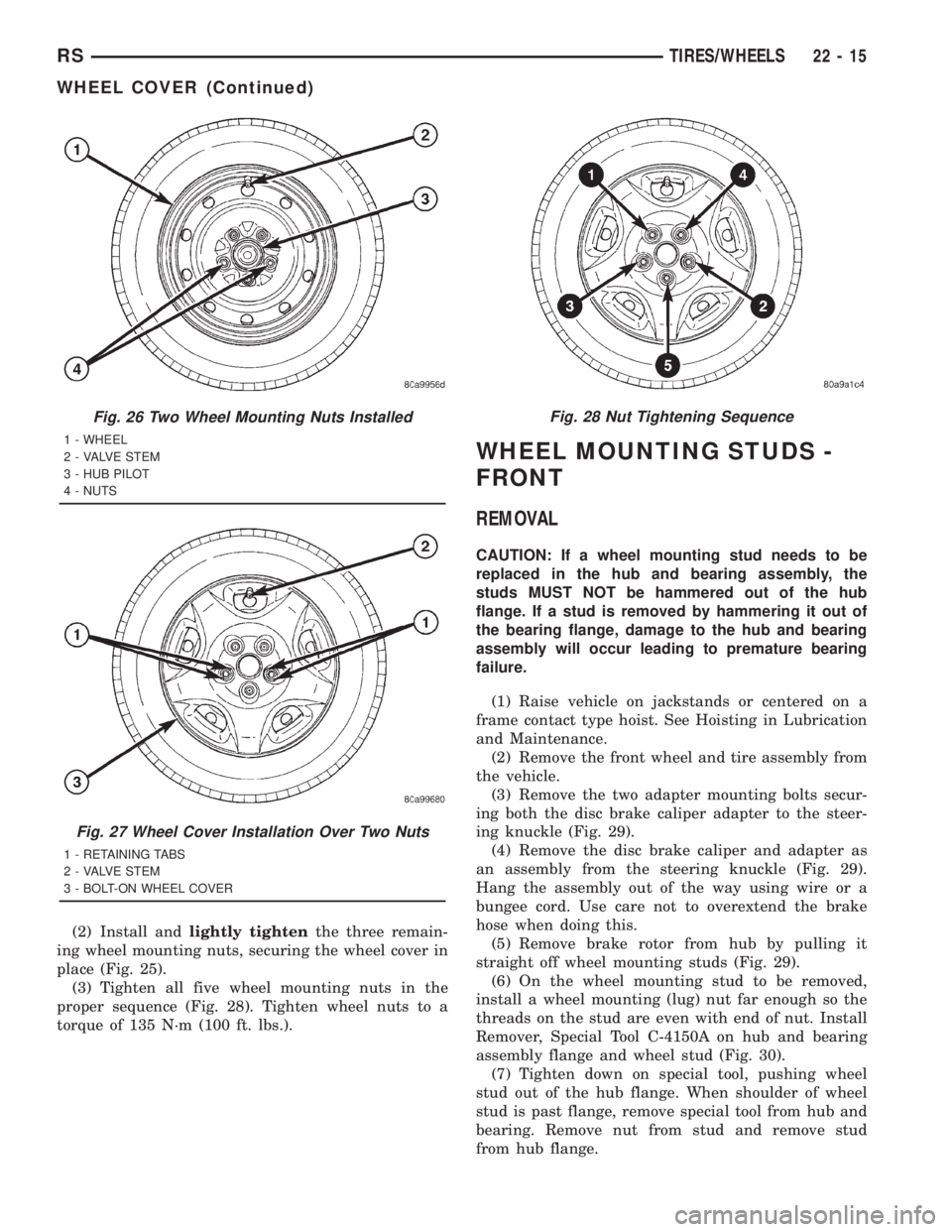

INSTALLATION

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 26).

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 27).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 27).

This will hold the wheel cover in place.

Fig. 25 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

22 - 14 TIRES/WHEELSRS

WHEELS (Continued)

Page 3377 of 4284

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 25).

(3) Tighten all five wheel mounting nuts in the

proper sequence (Fig. 28). Tighten wheel nuts to a

torque of 135 N´m (100 ft. lbs.).

WHEEL MOUNTING STUDS -

FRONT

REMOVAL

CAUTION: If a wheel mounting stud needs to be

replaced in the hub and bearing assembly, the

studs MUST NOT be hammered out of the hub

flange. If a stud is removed by hammering it out of

the bearing flange, damage to the hub and bearing

assembly will occur leading to premature bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the front wheel and tire assembly from

the vehicle.

(3) Remove the two adapter mounting bolts secur-

ing both the disc brake caliper adapter to the steer-

ing knuckle (Fig. 29).

(4) Remove the disc brake caliper and adapter as

an assembly from the steering knuckle (Fig. 29).

Hang the assembly out of the way using wire or a

bungee cord. Use care not to overextend the brake

hose when doing this.

(5) Remove brake rotor from hub by pulling it

straight off wheel mounting studs (Fig. 29).

(6) On the wheel mounting stud to be removed,

install a wheel mounting (lug) nut far enough so the

threads on the stud are even with end of nut. Install

Remover, Special Tool C-4150A on hub and bearing

assembly flange and wheel stud (Fig. 30).

(7) Tighten down on special tool, pushing wheel

stud out of the hub flange. When shoulder of wheel

stud is past flange, remove special tool from hub and

bearing. Remove nut from stud and remove stud

from hub flange.

Fig. 26 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 27 Wheel Cover Installation Over Two Nuts

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 28 Nut Tightening Sequence

RSTIRES/WHEELS22-15

WHEEL COVER (Continued)