wiring CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2023 of 4284

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

The RKE module is capable of retaining up to four

different Vehicle Access Codes.

OPERATION

Whenever the vehicle battery power is interrupted

the RKE Module will retain all vehicle access codes

in its memory. When replacing or adding a key fob

transmitter (maximum 4) a DRB IIItscan tool is

required to program the RKE Module to accept the

new Vehicle Access Code if a customer owned trans-

mitter is not available. Refer to Electrical, Remote

Keyless Entry Module, Standard Procedure - Pro-

gramming RKE Module or the Proper Body Diagnos-

tic Procedures manual.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Refer to the

proper Body Diagnostic Procedures Manual for test-

ing the Remote Keyless Entry system using a DRB

IIItscan tool. Also refer to other interrelated sys-

tems groups within this manual:

²Vehicle Theft Security System

²Power Seats

²Power Mirrors

STANDARD PROCEDURE - PROGRAMMING

RKE MODULE

(1) Using a functional key fob transmitter, unlock

the vehicle and disarm the Vehicle Theft Security

System.

(2) Insert ignition key into the ignition switch.

(3) Turn the ignition switch to RUN position with-

out starting engine.

(4) Using a functional key fob transmitter, press

and hold the UNLOCK button for a minimum five

seconds (maximum ten seconds).

(5) While still holding UNLOCK button, and

before ten seconds passes, press the PANIC button

and release both at the same time. A single chime

will sound to verify that the RKE module is set to

receive the new Vehicle Access Code(s).

(6) Within 30 seconds of the chime, press and

release the ªLOCKº and ªUNLOCKº buttons on the

transmitter at the same time. Then press any one of

the buttons. The BCM will sound an abbreviatedchime to acknowledge that the programming of the

transmitter has been completed and was successful.

(7) Repeat step 6 for all transmitters that will be

used with this vehicle (up to 4 total).

(8) Programming mode will last for 30 seconds. To

get out of programming mode sooner, turn the igni-

tion OFF. A single chime will sound to verify that the

RKE module will no longer accept additional Vehicle

Access Code(s).

(9) When Vehicle Access Code(s) programming is

complete, turn the ignition switch to the OFF posi-

tion and verify RKE system operation using each key

fob.

NOTE:

Only the two key fob transmitters that have been

programmed to the memory seat and mirror system

will operate it. If any key fob is replaced, the mem-

ory seat and mirror module will require program-

ming. (Refer to 8 - ELECTRICAL/POWER SEATS -

DIAGNOSIS AND TESTING).

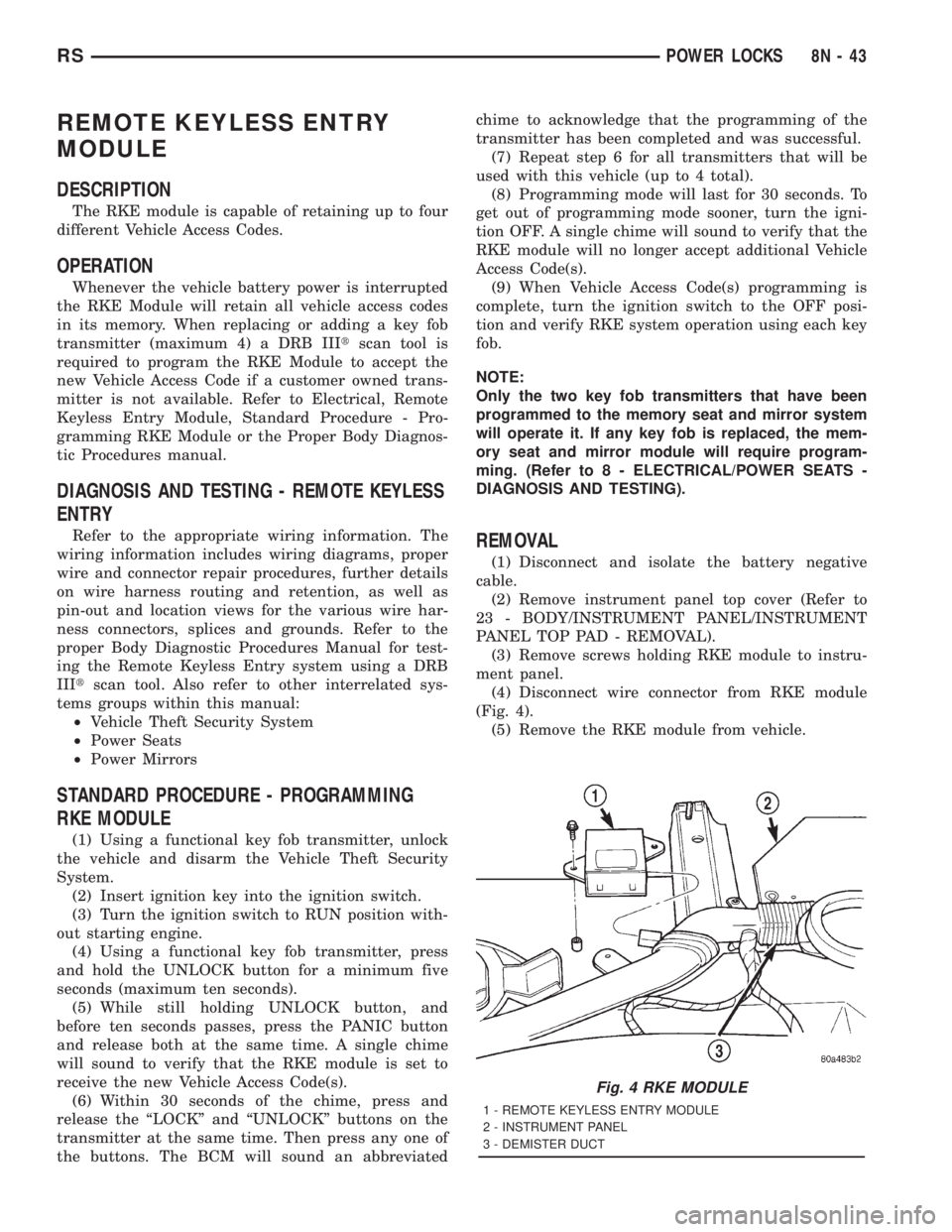

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel top cover (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP PAD - REMOVAL).

(3) Remove screws holding RKE module to instru-

ment panel.

(4) Disconnect wire connector from RKE module

(Fig. 4).

(5) Remove the RKE module from vehicle.

Fig. 4 RKE MODULE

1 - REMOTE KEYLESS ENTRY MODULE

2 - INSTRUMENT PANEL

3 - DEMISTER DUCT

RSPOWER LOCKS8N-43

Page 2025 of 4284

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION...........................45

OPERATION.............................45

DIAGNOSIS AND TESTING.................45

POWER MIRRORS......................45

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION...........................46

OPERATION.............................46

DIAGNOSIS AND TESTING.................47AUTOMATIC DAY/NIGHT MIRROR..........47

REMOTE SWITCH

DIAGNOSIS AND TESTING.................48

REMOTE SWITCH......................48

REMOVAL..............................48

INSTALLATION...........................48

SIDEVIEW MIRROR

REMOVAL..............................48

POWER MIRRORS

DESCRIPTION

If equipped with power mirrors, the control switch

is located on the instrument panel to the left of the

headlamp switch.

OPERATION

The power mirrors are connected to battery feed at

all times. Each mirror head contains two electric

motors, two drive mechanisms, an electric heating

element, and the mirror glass. If the vehicle is

equipped with the optional memory system, each

mirror head also contains both a horizontal and a

vertical motor position sensor. One motor and drive

controls mirror up-and-down movement, and the

other controls right-and-left movement.

An optional driver side outside electrochromic mir-

ror is able to automatically change its reflectance

level. This mirror is controlled by the circuitry of the

automatic day/night inside rear view mirror. A thin

layer of electrochromic material between two pieces

of conductive glass make up the face of the mirror.

Two photocell sensors on the inside rear view mirror

are used to monitor light levels and adjust the reflec-tance of both the inside and driver side outside mir-

rors. This change in reflectance helps to reduce the

glare of headlamps approaching the vehicle from the

rear. (Refer to 8 - ELECTRICAL/POWER MIRRORS/

AUTOMATIC DAY / NIGHT MIRROR - DESCRIP-

TION) for more information on this system.

The motors which operate the mirrors are part of

the mirror assembly and cannot be serviced sepa-

rately.

DIAGNOSIS AND TESTING - POWER MIRRORS

(1) Remove Power Mirror Switch. (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(2) Disconnect wiring harness connector to the

power mirror switch and headlamp switch.

(3) Using two jumper wires:

²Connect one to a 12-volt source

²Connect the other to a good body ground

²Refer to the Mirror Test Chart for wire hookups

at the switch connector (Fig. 1).

(4) If results shown in table are not obtained,

check for broken or shorted circuit, or replace mirror

assembly as necessary.

RSPOWER MIRRORS8N-45

Page 2027 of 4284

The driver side automatic dimming mirror is stan-

dard with the automatic dimming inside mirror. The

signal to control the dimming of that mirror is gen-

erated by the automatic day/night inside rear view

mirror circuitry. That signal is then delivered to the

driver side outside rear view mirror on a hard wired

circuit.

The automatic day/night mirror cannot be

repaired. If faulty or damaged, the entire inside rear

view mirror assembly must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC

DAY/NIGHT MIRROR

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(1) Check the fuse in the intelligent power module.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the intelli-

gent power module. If OK, go to Step 3. If not OK,

repair the open circuit to the ignition switch as

required.

(3) Unplug the wire harness connector from the

automatic day/night mirror. Check for battery voltage

at the fused ignition switch output circuit cavity of

the automatic day/night mirror wire harness connec-

tor. If OK, go to Step 4. If not OK, repair the open

circuit to the junction block as required.

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

(5) Turn the ignition switch to the On position. Set

the parking brake. Place the transmission gear selec-

tor lever in the Reverse position. Check for battery

voltage at the backup lamp switch output circuit cav-ity of the automatic day/night mirror wire harness

connector. If voltage is present, reinstall the auto-

matic day/night mirror wire harness connector and

go to Step 6. If not OK, repair the open circuit as

required.

(6) Place the transmission gear selector lever in

the Neutral position. Place the automatic day/night

mirror switch in the On (LED in the switch is

lighted) position. Cover the forward facing ambient

photocell sensor to keep out any ambient light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The automatic day/night mir-

ror should darken. The automatic day/night mirror

should darken within 2 minutes if testing for the

first time. For immediate response, turn the vehicle

OFF and back ON with the forward-facing light sen-

sor still covered. This defeats the day-detect logic. If

OK, go to Step 8. If not OK, replace the faulty mirror

unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty mirror

unit.

Bench testing both mirrors can be done, of care is

exercised. For an inside mirror, the pin closest to he

mount is 12V (+), the next is 12V (-). The third is

reverse override. The fourth is outside mirror (+),

and the fifth is outside mirror (-).Do not apply 12

volts to the fourth and fifth pins.With 12 volts

on pins 1 and 2, the mirror can be tested by blocking

the rear sensor and shining a light into the forward

sensor. For an outside mirror, there is a 2±pin con-

nector. Applying 1.2 volts will cause the mirror to

dim. If the mirror does not dim, the entire glass

assembly can be replaced just as it is when the glass

is broken.

WARNING: Do not apply 12 volts to the outside mir-

ror. Damage to the mirror will result.

RSPOWER MIRRORS8N-47

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 2028 of 4284

REMOTE SWITCH

DIAGNOSIS AND TESTING - REMOTE SWITCH

(1) Remove power mirror switch. (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(2) Disconnect wiring harness at switch connector.

(3) Using a ohmmeter, test for continuity between

the terminals of the switch (Fig. 2).

(4) If results shown in the table are not obtained,

replace the switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel lower cover.

(3) From behind headlamp switch assembly,

depress retaining tabs and push switch from instru-

ment panel.

(4) Disconnect wire connector from power mirror

switch.

(5) Disengage lock tabs above and below the mir-

ror switch.

(6) Remove power mirror switch from headlamp

switch bezel.

INSTALLATION

(1) Install power mirror switch to the headlamp

switch bezel.

(2) Connect wire connector to the power mirror

switch.

(3) Insert headlamp switch assembly into instru-

ment panel.

(4) Install instrument panel lower cover.

(5) Connect battery negative cable.

SIDEVIEW MIRROR

REMOVAL

For service procedures, (Refer to 23 - BODY/EXTE-

RIOR/SIDE VIEW MIRROR - REMOVAL).

Fig. 2 Mirror Switch Test

MIRROR SWITCH CONTINUITY

MIRROR SELECT SWITCH IN ªLEFTº POSITION

Move Button Continuity Between

UP PIN 9 - PIN 12,

PIN 6 - PIN 11,

PIN 9 - PIN 13

LEFT PIN 9 - PIN 7,

PIN 6 - PIN 11,

PIN 9 - PIN 8

DOWN PIN 9 - PIN 6,

PIN 12 - PIN 11,

PIN 13 - PIN 11

RIGHT PIN 9 - PIN 6,

PIN 7 - PIN 11,

PIN 8 - PIN 11

MIRROR SELECT SWITCH IN ªRIGHTº POSITION

Move Button Continuity Between

UP PIN 9 - PIN 13,

PIN 1 - PIN 11,

PIN 9 - PIN 12

LEFT PIN 9 - PIN 8,

PIN 1 - PIN 11,

PIN 9 - PIN 7

DOWN PIN 9 - PIN 1,

PIN 13 - PIN 11,

PIN 12 - PIN 11

RIGHT PIN 9 - PIN 1,

PIN 8 - PIN 11,

PIN 7 - PIN 11

LAMP PIN5-PIN11

8N - 48 POWER MIRRORSRS

Page 2030 of 4284

A eight-way power seat is standard on highline

models and optional on others. This option includes a

six-way adjustable seat cushion track and a two-way

power seat back.

The eight-way power seat is also available with the

heated seat and memory seat system that automati-

cally positions the power seat for two different driv-

ers. Refer toHeated Seat Systemfor more

information on the heated seat option. Refer toMem-

ory Systemin the Memory System section of this

group for more information on the memory system.

The power seat system includes the following com-

ponents:

²Power seat recliner

²Power seat switch

²Power seat track.

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Heated Seat Module (MHSM)

²Memory set switch

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

²Programmable Communications Interface (PCI)

data bus network

Refer to Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions and opera-

tions for the major components in the power seat

system and memory seat system.

DESCRIPTION - MEMORY SEAT SYSTEM

An electronic memory and heated seat system is

available on some models. The memory system is

able to store and recall the driver side power seat

positions (including the power recliner position), and

both outside power mirror positions for two drivers.

For vehicles with a radio and heated / memory seat

system connected to the Programmable Communica-

tions Interface (PCI) data bus network, the memory

system is also able to store and recall radio station

presets for two drivers. The memory system also will

store and recall the last station listened to for each

driver, even if it is not one of the preset stations.

The memory system will automatically return to

all of these settings when the corresponding num-

bered and button of the memory switch on the driver

side seat side shield is depressed, or when the doors

are unlocked using the Remote Keyless Entry (RKE)

transmitter. A customer programmable feature of the

memory system allows the RKE recall of memory fea-

tures to be disabled in cases where there are more

than two drivers of the vehicle.

A Memory Heated Seat Module (MHSM) is used on

some models to control and integrate the many elec-tronic functions and features included in the memory

/ heated seat system.

The memory system includes the following compo-

nents:

²Heated seat switch

²Memory heated seat module (MHSM)

²Memory switch

²Position potentiometers on both outside power

mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Radio receiver (if PCI data bus capable).

Certain functions and features of the memory system

rely upon resources shared with other electronic mod-

ules in the vehicle over the Programmable Communica-

tions Interface (PCI) J1850 data bus network. The PCI

data bus network allows the sharing of sensor informa-

tion. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor cur-

rent loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and allows

the addition of many new feature capabilities. For diag-

nosis of these electronic modules or of the PCI data bus

network, the use of a DRBtscan tool and the proper

Diagnostic Procedures manual are recommended.

The other electronic modules that may affect mem-

ory system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²

Electronic Vehicle Information Center (EVIC)

- Refer toElectronic Vehicle Information Center

in Overhead Console Systems for more information.

²Powertrain Control Module (PCM)- Refer to

Powertrain Control Modulein Electronic Control

Modules for more information.

²Radio Receiver- Refer toRadio Receiverin

Audio Systems for more information.

Refer toHeated Seat Systemfor more informa-

tion on the heated seat system. Refer toRemote

Keyless Entry Systemin Power Lock Systems for

more information on the RKE system. Refer to

Power Mirrorin Power Mirrors for more informa-

tion on the mirror position potentiometers. Refer to

Power Seat TrackandPower Seat Reclinerin

the Power Seat System section of this group for more

information on the driver side power seat position

potentiometers.

Refer toPower Seatin the Contents of Wiring

Diagrams for complete circuit diagrams. Following

are general descriptions of the remaining major com-

ponents in the factory-installed memory system.

OPERATION - POWER SEAT SYSTEM

The power seat system allows the driver and/or

front passenger seating positions to be adjusted elec-

8N - 50 POWER SEATSRS

POWER SEATS (Continued)

Page 2031 of 4284

trically and independently using the separate power

seat switches found on the outboard seat cushion

side shield of each front seat. See the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

The Memory Seat/Mirror Module (MSMM) will

drive a maximum of 2 motors at a time in a given

direction. If conflicting directions are requested, the

priority for response will be as follows:

²Seat Track Rearward

²Seat Front Down

²Seat Rear Down

²Recliner Rearward

²Seat Track Forward

²Seat Front Up

²Seat Rear Up

²Recliner Forward

The inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated.

Soft stops are incorporated to prevent the motor

from being driven into a stall. Should the seat have

restricted travel, refer to Resetting Soft Stops in this

section.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory system. For diagnosis of the MSM, the

PCI data bus, or the other electronic modules on the

PCI data bus that provide inputs and outputs for the

memory system, the use of a DRBtscan tool and the

proper Diagnostic Procedures manual are recom-

mended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer toElectronic Vehicle Informa-

tion Centerin Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seatsystem. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBtscan tool

and the proper Diagnostic Procedures manual. The

DRBtscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all of the power seat system wire harness connections

and pins cleaned and tightened to ensure proper cir-

cuit continuity and ground paths. For complete cir-

cuit diagrams, refer toPower Seatin Wiring

Diagrams.

With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits.

DIAGNOSIS AND TESTING - MEMORY SYSTEM

CHECK AND RESET SOFT STOPS

To check and reset the power memory seat soft

stops, use the power seat control switches to move

the seat in one direction to the end of travel, allow a

couple of seconds before re-energizing the seat in the

same direction until it stops and for three additional

seconds after it stops. (The amount the seat moved

RSPOWER SEATS8N-51

POWER SEATS (Continued)

Page 2032 of 4284

upon the second energizing is the amount the soft

stops have been reprogrammed.

Repeat this procedure for each direction of seat

movement (One at a time).

NOTE: Checking and resetting of the power mem-

ory seat soft stops will not affect the customer's

programmed positions.

DIAGNOSIS AND TESTING MEMORY SYSTEM

In order to obtain conclusive testing of the memory

system, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the memory system requires the use of a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual. The DRB IIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the memory system is receiving the proper hard

wired inputs and relaying the proper hard wired out-

puts to perform its functions.

Following are diagnostic routines that are built

into the module which can be performed without the

use of a diagnostic scan tool. Refer to Wiring Dia-

grams for complete circuit schematic or connector

pin-out information.

DIAGNOSTIC MODE 1

Diagnostic Mode 1 clears soft limits and sets mem-

ory selector switches (1 and 2) to predetermined val-

ues.

ACTIVATION-Press and hold the S and 1 buttons

for 5 seconds to enter diagnostic mode 1. This mode

is exited at the completion of the mode 1 tasks or

upon grounding the DATA G87 circuit input to the

module.

Mode 1 will:

²Clear all soft limits to their default hard limit

values

²Load memory 1 with default settings corre-

sponding to horizontal rearward, front down, rear

down, and recliner rearward positions

²Load memory 2 with default settings corre-

sponding to horizontal forward, front up, rear up,

and recliner forward positions

DIAGNOSTIC MODE 2

Diagnostic mode 2 provides a way to determine if

the seat/mirror motors and position sensors are con-

nected properly.

ACTIVATION-Press and hold the S and 2 buttons

for 5 seconds to enter diagnostic mode 2. This modeis exited after 5 seconds of switch inactivity or upon

grounding the DATA G87 circuit input by moving the

transmission out of the PARK position.

Mode 2 will:

²Place the seat and mirror motors at their mid-

point

²When a single axis of seat or mirror motion is

requested by pressing a switch, the corresponding

motor is energized. This tests switch input and motor

output

DRIVER SEAT SWITCH

DESCRIPTION

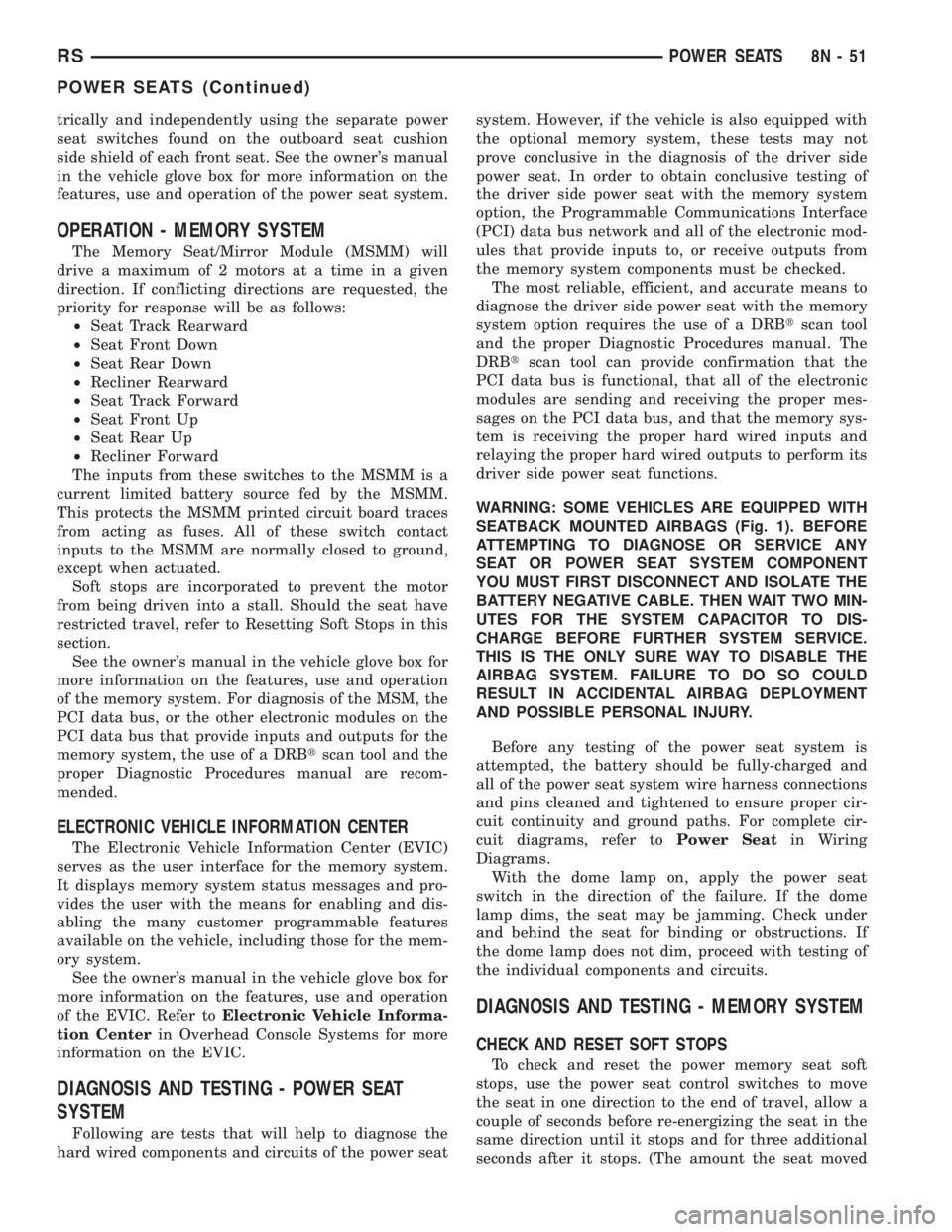

Vehicles equipped with power seats utilize a eight-

way power seat switch. This eight-way power seat

switch features two knobs ganged together on the

outboard seat cushion side shield (Fig. 2).

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

The power seat tracks can be adjusted in eight dif-

ferent ways using the power seat switches. See the

owner's manual in the vehicle glove box for more

information on the power seat switch functions and

the seat adjusting procedures.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

Fig. 2 Power Seat Switch - Typical

8N - 52 POWER SEATSRS

POWER SEATS (Continued)

Page 2034 of 4284

(7) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield.

(2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.).

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Reconnect the battery negative cable.

MEMORY SET SWITCH

DESCRIPTION

Vehicles equipped with the memory system have a

memory switch mounted to the driver side front door

trim panel. This switch is used to set and recall all of

the memory system settings for up to two drivers.

The memory switch is a resistor multiplexed unit

that is hard wired to the Body Control Module

(BCM). The BCM sends out the memory system set

and recall requests to the other electronic modules

over the Programmable Communications Interface

(PCI) data bus.

The memory switch cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced. For

complete circuit diagrams, refer toWiring Dia-

grams.

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. The Driver 1 and Driver

2 buttons are back-lit with Light-Emitting Diodes

(LED) for visibility, and are also color-coded to coin-

cide with the color-coded Driver 1 and Driver 2

Remote Keyless Entry (RKE) transmitters. The

Driver 1 memory switch button and RKE transmitter

are black, and the Driver 2 memory switch button

and RKE transmitter are gray. The memory switch

Set button also has an LED that will illuminate and

flash to indicate that the memory system is in the set

mode. This LED will automatically be extinguished

when a set request has been successfully completed.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch.

DIAGNOSIS AND TESTING - MEMORY SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front door trim panel

switch bezel. Using a small thin bladed pry tool, gen-

tly pry the switch bezel away from the door trim

panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Use an ohmmeter to test the resistances of the

memory switch in each switch position. See the Mem-

ory Switch Test chart. If OK, refer toMemory Sys-

temin the Diagnosis and Testing section of this

group. If not OK, replace the faulty memory switch.

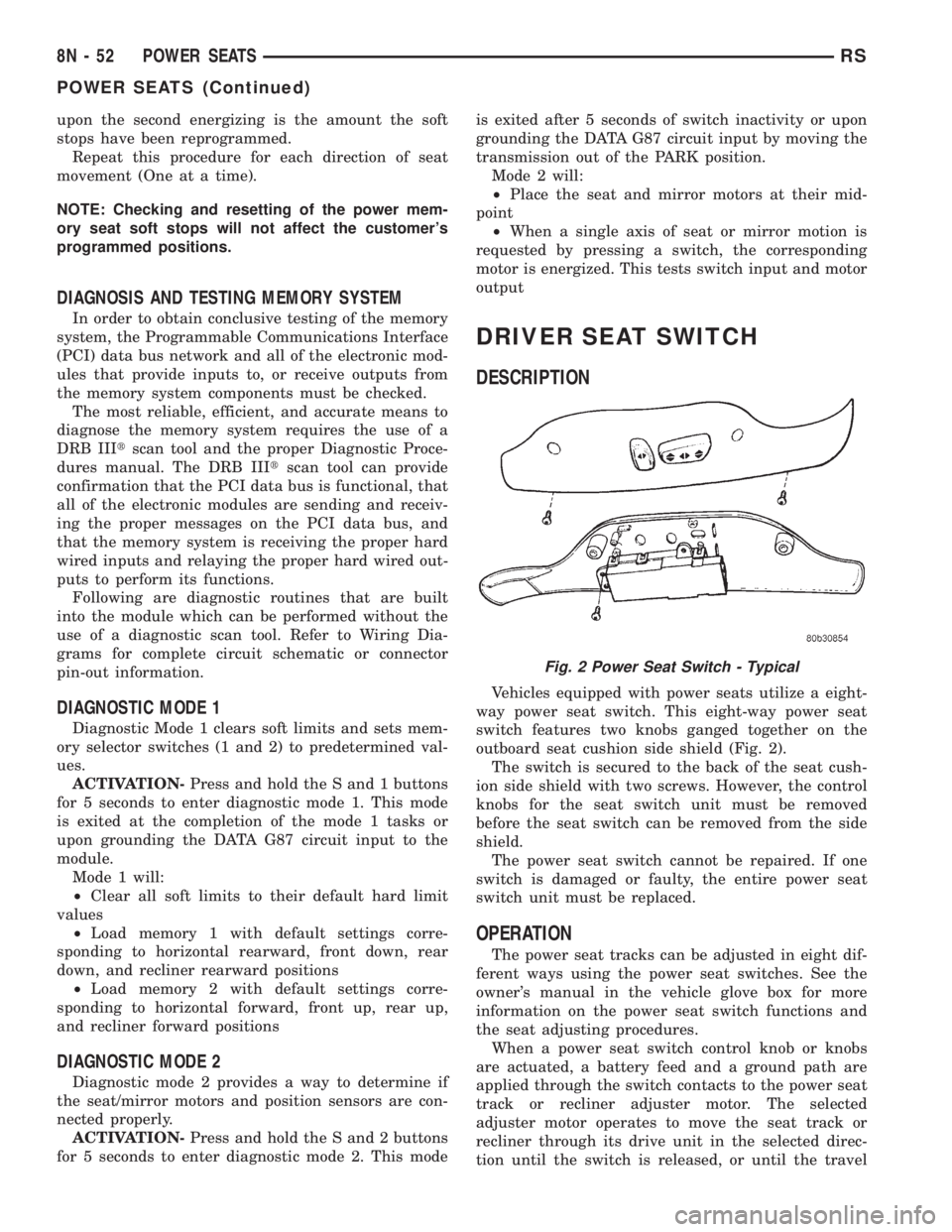

MEMORY SWITCH TEST

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEEN

PINSRESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24560 1%

(24.56 k)

MEMORY 1 1&2 6830 1%

(6.83 k)

MEMORY 2 1&2 2090 1%

(2.09 k)

SET 1&2 4490 1%

(4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-

bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel.

(5) Remove the memory switch.

INSTALLATION

(1)Position the memory switch and install and

tighten the two screws that secure the memory switch

to the back of the driver side front door trim panel

switch bezel. Tighten the screws to 2.2 N´m (20 in. lbs.).

(2) Reconnect the memory switch wire harness

connector to the memory switch.

(3) Install the trim panel switch bezel onto the

driver side front door.

(4) Reconnect the battery negative cable.

8N - 54 POWER SEATSRS

DRIVER SEAT SWITCH (Continued)

Page 2037 of 4284

DIAGNOSIS AND TESTING - POWER SEAT

RECLINER

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBtscan tool

and the proper Diagnostic Procedures manual. The

DRBtscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

Actuate the power seat recliner switch to move the

power seat recliner adjuster in each direction. The

power seat recliner adjuster should move in both

directions. If the power seat recliner adjuster fails to

operate in only one direction, move the adjuster a

short distance in the opposite direction and test

again to be certain that the adjuster is not at its

travel limit. If the power seat recliner adjuster still

fails to operate in only one direction, refer toPower

Seat Switchin the Diagnosis and Testing section of

this group. If the power recliner adjuster fails to

operate in either direction, perform the following

tests. For complete circuit diagrams, refer toPower

Seatin Wiring Diagrams.

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toPower

Seat Switchin the Diagnosis and Testing section of

this group. If the switch tests OK, test the circuits of

the power seat wire harness between the power seat

recliner adjuster motor and the power seat switch for

shorts or opens. If the circuits check OK, replace the

faulty power seat recliner unit. If the circuits are not

OK, repair the power seat wire harness as required.

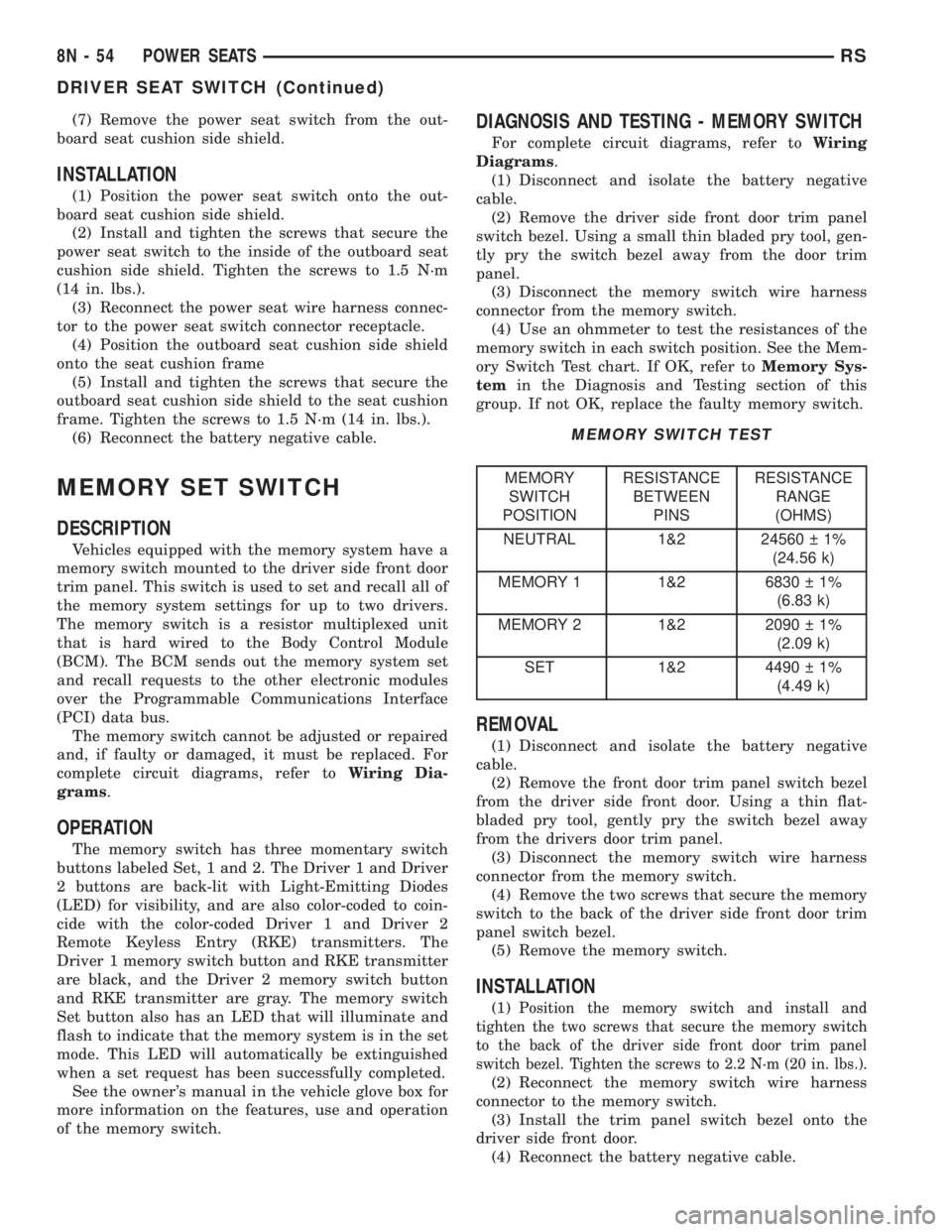

Fig. 8 Power Seat Recliner and Track - Typical

1 - SEAT BACK FRAME

2 - SEAT CUSHION PAD

3 - POWER RECLINER

4 - SEAT CUSHION FRAME

5 - SHIELD

6 - POWER SEAT TRACK ADJUSTER

RSPOWER SEATS8N-57

RECLINER MOTOR (Continued)

Page 2039 of 4284

fails to operate in more than one direction, perform

the following tests. For complete circuit diagrams,

refer toPower Seatin Wiring Diagrams.

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toPower

Seat Switchin the Diagnosis and Testing section of

this group. If the switch tests OK, test the circuits of

the power seat wire harness between the inoperative

power seat track adjuster motor and the power seat

switch for shorts or opens. If the circuits check OK,

replace the faulty power seat track unit. If the cir-

cuits are not OK, repair the power seat wire harness

as required.

REMOVAL

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

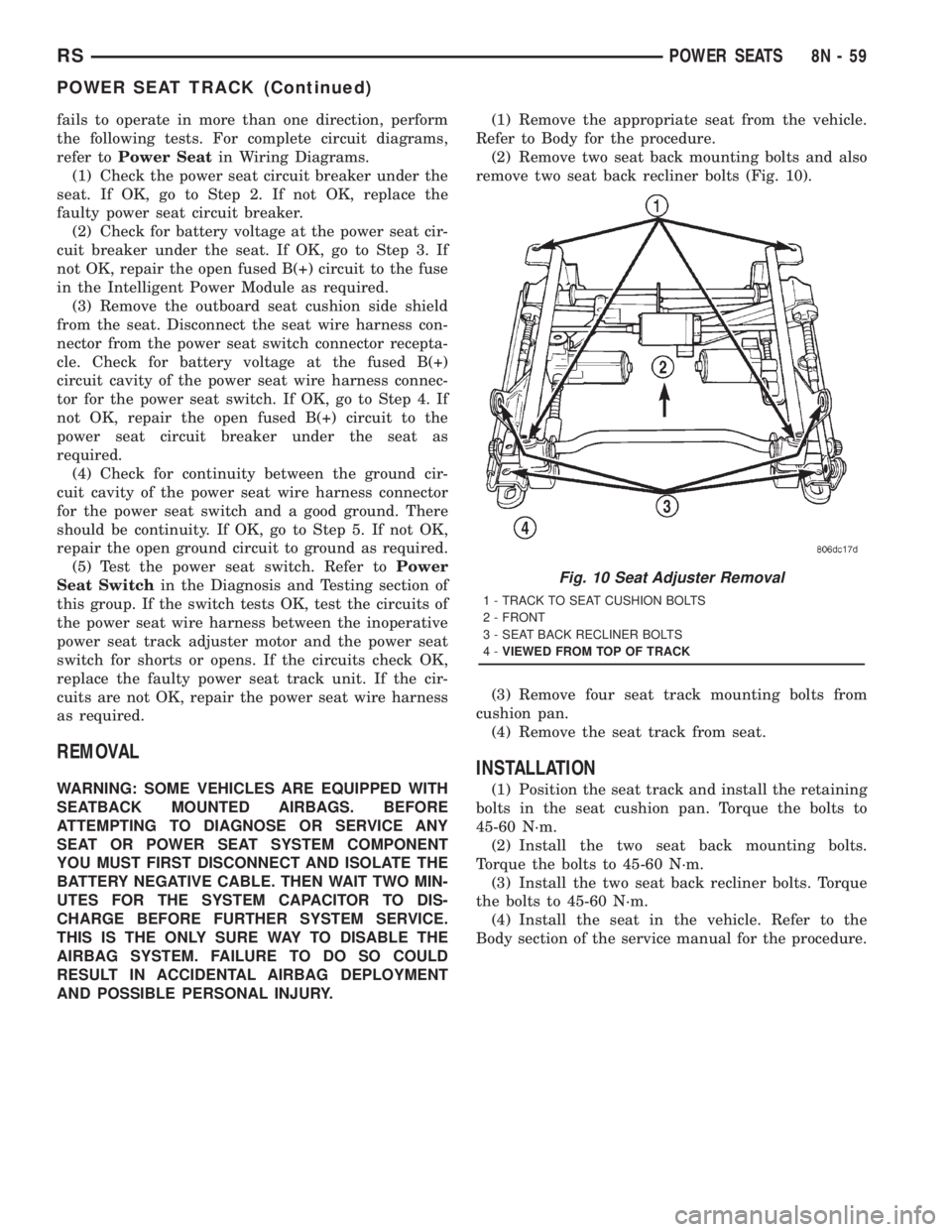

AND POSSIBLE PERSONAL INJURY.(1) Remove the appropriate seat from the vehicle.

Refer to Body for the procedure.

(2) Remove two seat back mounting bolts and also

remove two seat back recliner bolts (Fig. 10).

(3) Remove four seat track mounting bolts from

cushion pan.

(4) Remove the seat track from seat.

INSTALLATION

(1) Position the seat track and install the retaining

bolts in the seat cushion pan. Torque the bolts to

45-60 N´m.

(2) Install the two seat back mounting bolts.

Torque the bolts to 45-60 N´m.

(3) Install the two seat back recliner bolts. Torque

the bolts to 45-60 N´m.

(4) Install the seat in the vehicle. Refer to the

Body section of the service manual for the procedure.

Fig. 10 Seat Adjuster Removal

1 - TRACK TO SEAT CUSHION BOLTS

2 - FRONT

3 - SEAT BACK RECLINER BOLTS

4-VIEWED FROM TOP OF TRACK

RSPOWER SEATS8N-59

POWER SEAT TRACK (Continued)