wiring CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3902 of 4284

Symptom:

P0320-NO CRANK REFERENCE SIGNAL AT PCM

When Monitored and Set Condition:

P0320-NO CRANK REFERENCE SIGNAL AT PCM

When Monitored: Engine cranking.

Set Condition: No CKP signal is present during engine cranking, and at least 8 camshaft

position sensor signals have occurred.

POSSIBLE CAUSES

CHECKING INTERMITTENT CKP SIGNAL WITH LAB

CHECKING INTERMITTENT CMP SIGNAL WITH LAB

CHECKING INTERMITTENT WIRING WITH LAB SCOPE

INTERMITTENT CONDITION

8 VOLT SUPPLY CIRCUIT SHORTED TO GROUND

8 VOLT SUPPLY CIRCUIT OPEN

8 VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

CKP SENSOR SIGNAL CIRCUIT SHORTED GROUND

CKP SENSOR SIGNAL CIRCUIT OPEN

CKP SENSOR SIGNAL CIRCUIT SHORTED TO VOLTAGE

CKP SENSOR SIGNAL SHORTED TO 8 VOLT SUPPLY CIRCUIT

SENSOR GROUND CIRCUIT OPEN

PCM - 8 VOLT SUPPLY

PCM - CKP SENSOR SIGNAL

CRANKSHAFT POSITION SENSOR

TEST ACTION APPLICABILITY

1 With the DRBIIIt, read the Current CKP State while cranking the engine.

Does the DRBIIItdisplay Current CKP State Present while cranking the engine.All

Ye s®Go To 2

No®Go To 6

108

DRIVEABILITY - GAS

Page 3903 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition off.

With the DRBIIItlab scope probe and the Miller special tool #6801, backprobe the

CKP Signal circuit in the PCM harness connector.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Turn the ignition on. (do not start the engine)

Observe the lab scope screen.

Look for any pulses generated by the CKP Sensor.

Did the CKP Sensor generate any pulses?All

Ye s®Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

3 Turn the ignition off.

With the DRBIIItlab scope probe and the Miller special tool #6801, backprobe the

CMP Signal circuit in the PCM harness connector.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Turn the ignition on. (do not start the engine)

Observe the lab scope screen.

Look for any pulses generated by the CMP Sensor.

Did the CMP Sensor generate any pulses?All

Ye s®Replace the Camshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Turn the ignition off.

With the DRBIIItlab scope probe and the Miller special tool #6801, backprobe the

CKP Signal circuit in the PCM harness connector.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Start the engine.

Observe the lab scope screen while wiggling the wiring harness and connectors.

Were there any irregularities in the lab scope pattern?All

Ye s®Check the harness connectors carefully. If OK, replace the Crank-

shaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

109

DRIVEABILITY - GAS

P0320-NO CRANK REFERENCE SIGNAL AT PCM ÐContinued

Page 3904 of 4284

TEST ACTION APPLICABILITY

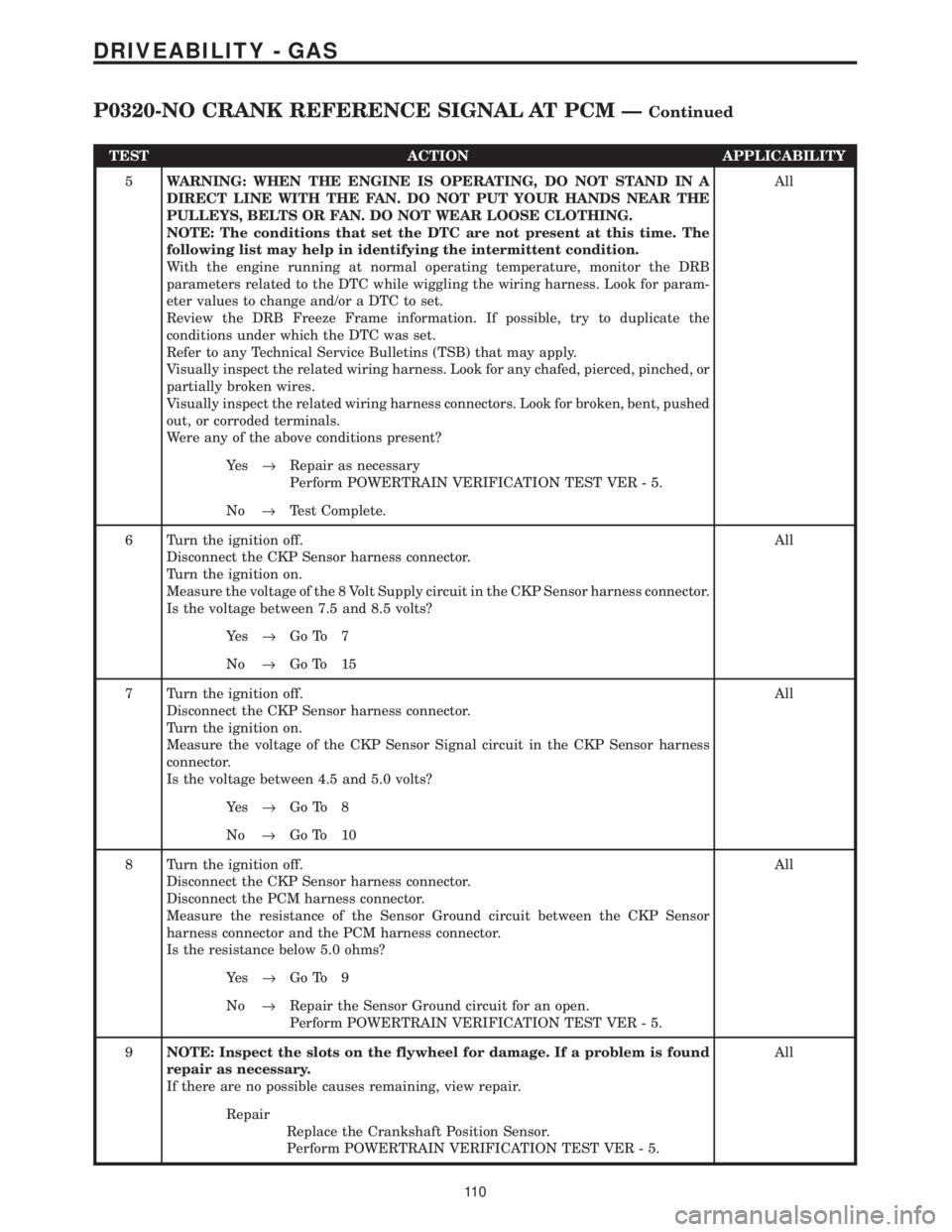

5WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

6 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Turn the ignition on.

Measure the voltage of the 8 Volt Supply circuit in the CKP Sensor harness connector.

Is the voltage between 7.5 and 8.5 volts?All

Ye s®Go To 7

No®Go To 15

7 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Turn the ignition on.

Measure the voltage of the CKP Sensor Signal circuit in the CKP Sensor harness

connector.

Is the voltage between 4.5 and 5.0 volts?All

Ye s®Go To 8

No®Go To 10

8 Turn the ignition off.

Disconnect the CKP Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Sensor Ground circuit between the CKP Sensor

harness connector and the PCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 9

No®Repair the Sensor Ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

9NOTE: Inspect the slots on the flywheel for damage. If a problem is found

repair as necessary.

If there are no possible causes remaining, view repair.All

Repair

Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

11 0

DRIVEABILITY - GAS

P0320-NO CRANK REFERENCE SIGNAL AT PCM ÐContinued

Page 3909 of 4284

TEST ACTION APPLICABILITY

8WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

11 5

DRIVEABILITY - GAS

P0325-KNOCK SENSOR #1 CIRCUIT ÐContinued

Page 3910 of 4284

Symptom:

P0340-NO CAM SIGNAL AT PCM

When Monitored and Set Condition:

P0340-NO CAM SIGNAL AT PCM

When Monitored: Engine cranking/running. Battery voltage greater than 10 volts.

Set Condition: At least 5 seconds or 2.5 engine revolutions have elapsed with crankshaft

position sensor signals present but no camshaft position sensor signal.

POSSIBLE CAUSES

CHECKING INTERMITTENT CKP SIGNAL WITH LAB

CHECKING INTERMITTENT CMP SIGNAL WITH LAB

CHECKING INTERMITTENT WIRING WITH LAB SCOPE

INTERMITTENT CONDITION

8 VOLT SUPPLY CIRCUIT SHORTED TO GROUND

8 VOLT SUPPLY CIRCUIT OPEN

8 VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

CMP SENSOR SIGNAL CIRCUIT SHORTED GROUND

CMP SENSOR SIGNAL CIRCUIT OPEN

CMP SENSOR SIGNAL CIRCUIT SHORTED TO VOLTAGE

CMP SENSOR SIGNAL SHORTED TO 8 VOLT SUPPLY CIRCUIT

SENSOR GROUND CIRCUIT OPEN

PCM - 8 VOLT SUPPLY

PCM - CMP SENSOR SIGNAL

CAMSHAFT POSITION SENSOR

TEST ACTION APPLICABILITY

1 With the DRBIIIt, read the Current CMP State while cranking the engine.

Does the DRBIIItdisplay Current CMP State Present while cranking the engine.All

Ye s®Go To 2

No®Go To 6

11 6

DRIVEABILITY - GAS

Page 3911 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition off.

With the DRBIIItlab scope probe and the Miller special tool #6801, backprobe the

CKP Signal circuit in the PCM harness connector.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Turn the ignition on. (do not start the engine)

Observe the lab scope screen.

Look for any pulses generated by the CKP Sensor.

Did the CKP Sensor generate any pulses?All

Ye s®Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

3 Turn the ignition off.

With the DRBIIItlab scope probe and the Miller special tool #6801, backprobe the

CMP Signal circuit in the PCM harness connector.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Turn the ignition on. (do not start the engine)

Observe the lab scope screen.

Look for any pulses generated by the CMP Sensor.

Did the CMP Sensor generate any pulses?All

Ye s®Replace the Camshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Turn the ignition off.

With the DRBIIItlab scope probe and the Miller special tool #6801, backprobe the

CMP Signal circuit in the PCM harness connector.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

Start the engine.

Observe the lab scope screen while wiggling the wiring harness and connectors.

Were there any irregularities in the lab scope pattern?All

Ye s®Check the harness connectors carefully. If OK, replace the Cam-

shaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

11 7

DRIVEABILITY - GAS

P0340-NO CAM SIGNAL AT PCM ÐContinued

Page 3912 of 4284

TEST ACTION APPLICABILITY

5WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

6 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Measure the voltage of the 8 Volt Supply circuit in the CMP Sensor harness

connector.

Is the voltage between 7.5 and 8.5 volts?All

Ye s®Go To 7

No®Go To 15

7 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Turn the ignition on.

Measure the voltage of the CMP Sensor Signal circuit in the CMP Sensor harness

connector.

Is the voltage between 4.5 and 5.0 volts?All

Ye s®Go To 8

No®Go To 10

8 Turn the ignition off.

Disconnect the CMP Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Sensor Ground circuit between the CMP Sensor

harness connector and the PCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 9

No®Repair the Sensor Ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

11 8

DRIVEABILITY - GAS

P0340-NO CAM SIGNAL AT PCM ÐContinued

Page 3917 of 4284

TEST ACTION APPLICABILITY

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

123

DRIVEABILITY - GAS

P0351-IGNITION COIL #1 PRIMARY CIRCUIT ÐContinued

Page 3921 of 4284

TEST ACTION APPLICABILITY

12NOTE: Inspect the exhaust system for leaks.

WARNING: KEEP CLEAR OF THE ENGINE'S MOVING PARTS.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

127

DRIVEABILITY - GAS

P0401 - EGR SYSTEM FAILURE ÐContinued

Page 3924 of 4284

TEST ACTION APPLICABILITY

8NOTE: Inspect the exhaust system for leaks.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

130

DRIVEABILITY - GAS

P0403 - EGR SOLENOID CIRCUIT ÐContinued