wheel torque CHRYSLER VOYAGER 2001 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1685 of 4284

(12) Install the wheel speed sensor on the hub/

bearing and adapter. Install the wheel speed sensor

attaching bolt (Fig. 89). Tighten the wheel speed sen-

sor attaching bolt to a torque of 12 N´m (105 in. lbs).

(13) Install the park brake cable into its mounting

hole in the adapter.Be sure all the locking tabs

on the park brake cable retainer are expanded

out to ensure the cable will not pull out of the

adapter.

(14) Install the end of the park brake cable on the

park brake actuator lever (Fig. 87).

NOTE: The horseshoe clip must be installed and

installed properly when the park brake cable is

installed in the adapter. The purpose of the horse-

shoe clip is to prevent park brake cable retainer

from moving in the adapter. If horseshoe clip is not

installed the park brake cable retainer will rattle in

the adapter.

(15) Install aNEWhorseshoe clip on the park

brake cable retainer (Fig. 87). The horseshoe clip is

installed between the retainer for the park brake

cable and the adapter. Horseshoe clip must be

installed with the curved end of the clip pointing

straight up and the edge of the curved end facing

toward the rear of the vehicle (Fig. 87).

(16) Remove the locking pliers (Fig. 83) from the

front park brake cable.

(17) Adjust the park brake drum-in-hat brake

shoes. (Refer to 5 - BRAKES/PARKING BRAKE/

SHOES - ADJUSTMENTS).

(18) Install the rotor on the hub/bearing.

(19) Carefully lower caliper and brake shoes over

rotor and onto the adapter using the reverse proce-

dure for removal (Fig. 85).

CAUTION: When installing guide pin bolts extreme

caution should be taken not to crossthread the cal-

iper guide pin bolts.

(20) Install the caliper guide pin bolts (Fig. 84).

Tighten the guide pin bolts to a torque of 22 N´m

(192 in. lbs.).

(21) Clean all foreign material off the threads of

the outer C/V joint stub shaft. Install the washer and

hub nut (Fig. 82) on the stub shaft of the outer C/V

joint.

(22) Set the parking brake.

(23) Tighten the hub nut to a torque of 244 N´m

(180 ft. lbs.).

(24) Install the spring washer (Fig. 81) on the stub

shaft of the outer C/V joint.

(25) Install the nut retainer and cotter pin (Fig.

80) on the stub shaft of the outer C/V joint.

(26) Install the wheel and tire assembly. Tighten

the wheel mounting stud nuts in proper sequenceuntil all nuts are torqued to half specification. Then

repeat the tightening sequence to the full specified

torque of 135 N´m (100 ft. lbs.).

(27) Lower vehicle.

(28) Fully apply and release the park brake pedal

one time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump the brake

pedal several times to insure the vehicle has a firm

brake pedal to adequately stop vehicle.

(29) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

ADJUSTMENT - PARKING BRAKE SHOES

CAUTION: Before adjusting the park brake shoes be

sure that the park brake pedal is in the fully

released position. If park brake pedal is not in the

fully released position, the park brake shoes can

not be accurately adjusted.

(1) Raise vehicle.

(2) Remove tire and wheel.

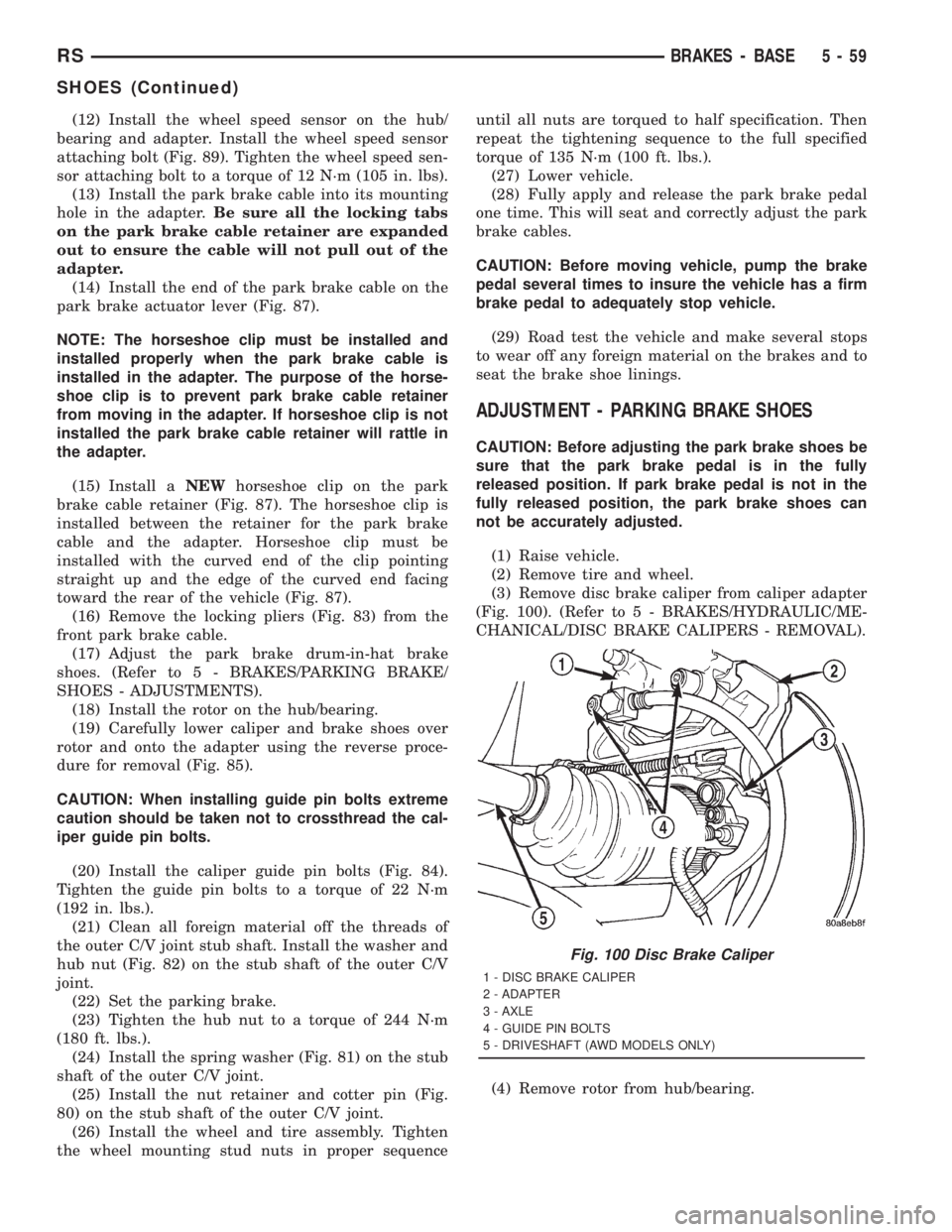

(3) Remove disc brake caliper from caliper adapter

(Fig. 100). (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - REMOVAL).

(4) Remove rotor from hub/bearing.

Fig. 100 Disc Brake Caliper

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

RSBRAKES - BASE5-59

SHOES (Continued)

Page 1686 of 4284

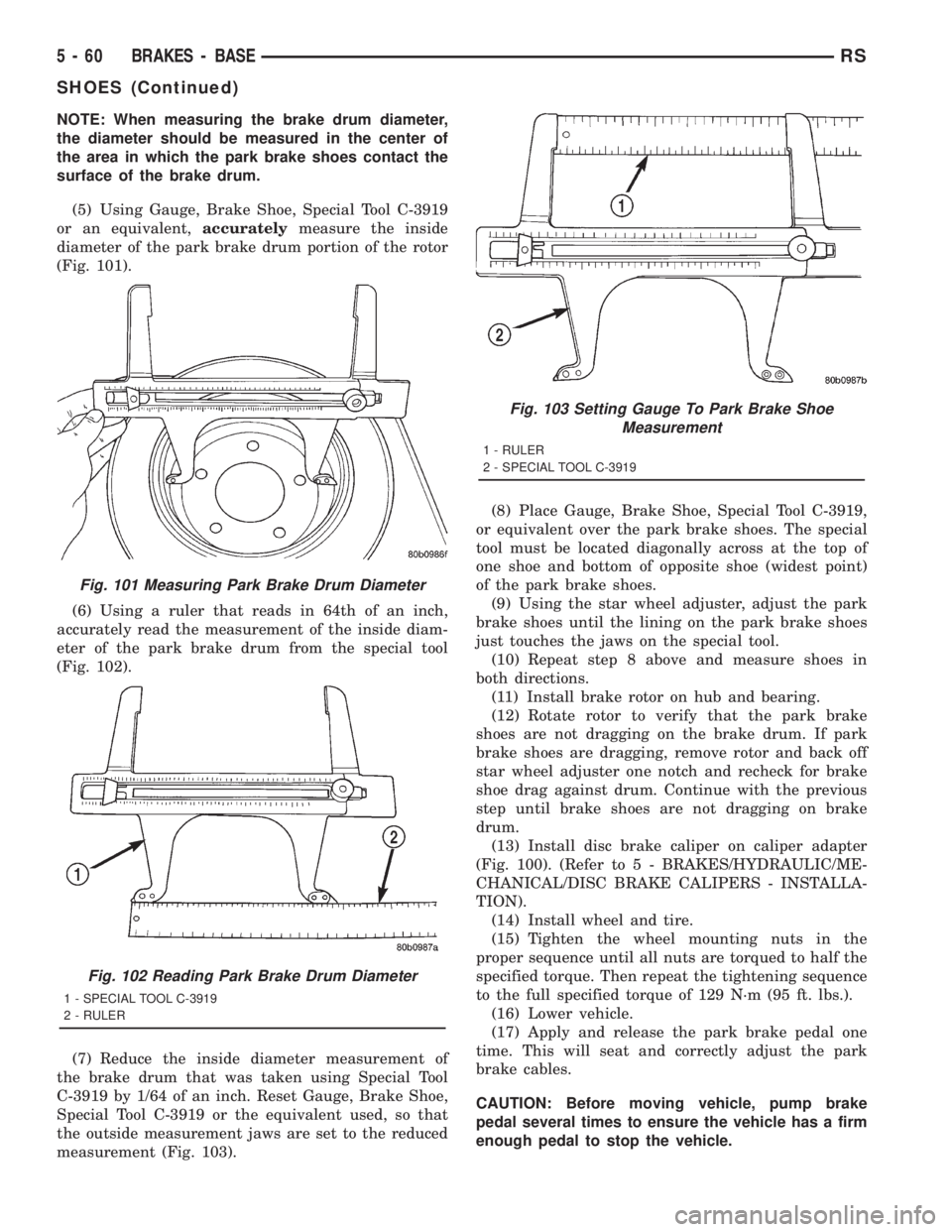

NOTE: When measuring the brake drum diameter,

the diameter should be measured in the center of

the area in which the park brake shoes contact the

surface of the brake drum.

(5) Using Gauge, Brake Shoe, Special Tool C-3919

or an equivalent,accuratelymeasure the inside

diameter of the park brake drum portion of the rotor

(Fig. 101).

(6) Using a ruler that reads in 64th of an inch,

accurately read the measurement of the inside diam-

eter of the park brake drum from the special tool

(Fig. 102).

(7) Reduce the inside diameter measurement of

the brake drum that was taken using Special Tool

C-3919 by 1/64 of an inch. Reset Gauge, Brake Shoe,

Special Tool C-3919 or the equivalent used, so that

the outside measurement jaws are set to the reduced

measurement (Fig. 103).(8) Place Gauge, Brake Shoe, Special Tool C-3919,

or equivalent over the park brake shoes. The special

tool must be located diagonally across at the top of

one shoe and bottom of opposite shoe (widest point)

of the park brake shoes.

(9) Using the star wheel adjuster, adjust the park

brake shoes until the lining on the park brake shoes

just touches the jaws on the special tool.

(10) Repeat step 8 above and measure shoes in

both directions.

(11) Install brake rotor on hub and bearing.

(12) Rotate rotor to verify that the park brake

shoes are not dragging on the brake drum. If park

brake shoes are dragging, remove rotor and back off

star wheel adjuster one notch and recheck for brake

shoe drag against drum. Continue with the previous

step until brake shoes are not dragging on brake

drum.

(13) Install disc brake caliper on caliper adapter

(Fig. 100). (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - INSTALLA-

TION).

(14) Install wheel and tire.

(15) Tighten the wheel mounting nuts in the

proper sequence until all nuts are torqued to half the

specified torque. Then repeat the tightening sequence

to the full specified torque of 129 N´m (95 ft. lbs.).

(16) Lower vehicle.

(17) Apply and release the park brake pedal one

time. This will seat and correctly adjust the park

brake cables.

CAUTION: Before moving vehicle, pump brake

pedal several times to ensure the vehicle has a firm

enough pedal to stop the vehicle.

Fig. 101 Measuring Park Brake Drum Diameter

Fig. 102 Reading Park Brake Drum Diameter

1 - SPECIAL TOOL C-3919

2 - RULER

Fig. 103 Setting Gauge To Park Brake Shoe

Measurement

1 - RULER

2 - SPECIAL TOOL C-3919

5 - 60 BRAKES - BASERS

SHOES (Continued)

Page 1697 of 4284

SPECIFICATIONS

SPECIFICATIONS - ABS FASTENER TORQUE

(Refer to 5 - BRAKES - BASE - SPECIFICA-

TIONS)

TONE WHEEL RUNOUT

DESCRIPTION SPECIFICATION

Front Tone Wheel

Maximum Runout0.15 mm (0.006 in.)

Rear Tone Wheel

Maximum Runout0.15 mm (0.006 in.)

WHEEL SPEED SENSOR AIR GAP

DESCRIPTION SPECIFICATION

Front Sensor0.35 ± 1.20 mm

0.014 ± 0.047 in.

Rear Sensor0.40 ± 1.20 mm

0.016 ± 0.047 in.

FRONT WHEEL SPEED

SENSOR

REMOVAL - WHEEL SPEED SENSOR (FRONT)

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove the tire and wheel assembly.

(3) Remove the sensor cable routing clamp screws.

CAUTION: When disconnecting the wheel speed

sensor from vehicle wiring harness, be careful not

to damage pins on connector

(4) Remove speed sensor cable grommets from

intermediate bracket on strut.

(5) Disconnect speed sensor cable from vehicle wir-

ing harness behind fender well shield.

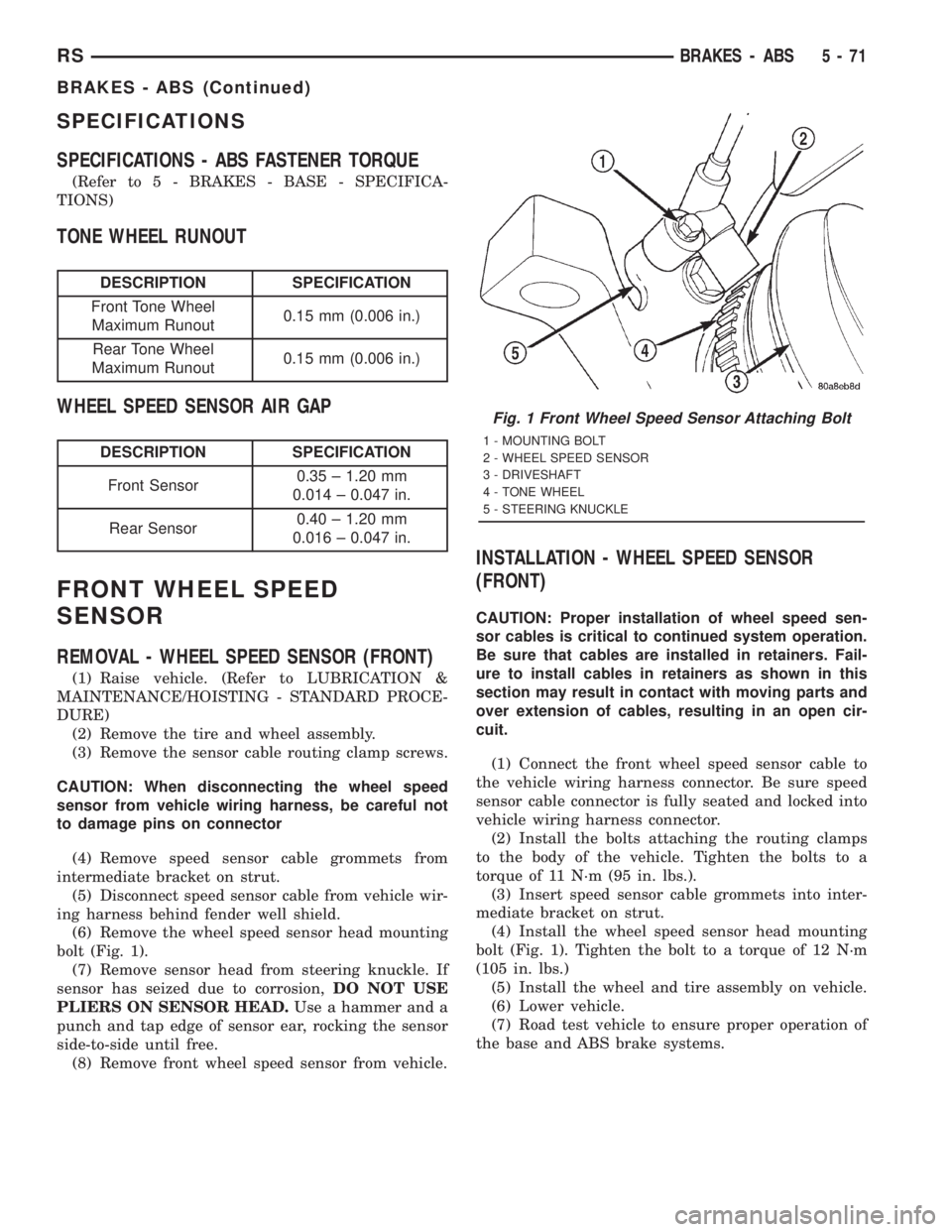

(6) Remove the wheel speed sensor head mounting

bolt (Fig. 1).

(7) Remove sensor head from steering knuckle. If

sensor has seized due to corrosion,DO NOT USE

PLIERS ON SENSOR HEAD.Use a hammer and a

punch and tap edge of sensor ear, rocking the sensor

side-to-side until free.

(8) Remove front wheel speed sensor from vehicle.

INSTALLATION - WHEEL SPEED SENSOR

(FRONT)

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as shown in this

section may result in contact with moving parts and

over extension of cables, resulting in an open cir-

cuit.

(1) Connect the front wheel speed sensor cable to

the vehicle wiring harness connector. Be sure speed

sensor cable connector is fully seated and locked into

vehicle wiring harness connector.

(2) Install the bolts attaching the routing clamps

to the body of the vehicle. Tighten the bolts to a

torque of 11 N´m (95 in. lbs.).

(3) Insert speed sensor cable grommets into inter-

mediate bracket on strut.

(4) Install the wheel speed sensor head mounting

bolt (Fig. 1). Tighten the bolt to a torque of 12 N´m

(105 in. lbs.)

(5) Install the wheel and tire assembly on vehicle.

(6) Lower vehicle.

(7) Road test vehicle to ensure proper operation of

the base and ABS brake systems.

Fig. 1 Front Wheel Speed Sensor Attaching Bolt

1 - MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - DRIVESHAFT

4 - TONE WHEEL

5 - STEERING KNUCKLE

RSBRAKES - ABS5-71

BRAKES - ABS (Continued)

Page 1698 of 4284

REAR WHEEL SPEED SENSOR

-AWD

REMOVAL - WHEEL SPEED SENSOR

(REAR-AWD)

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

CAUTION: When disconnecting speed sensor cable

from vehicle wiring harness be careful not to dam-

age pins on the electrical connectors. Also, inspect

connectors for any signs of previous damage.

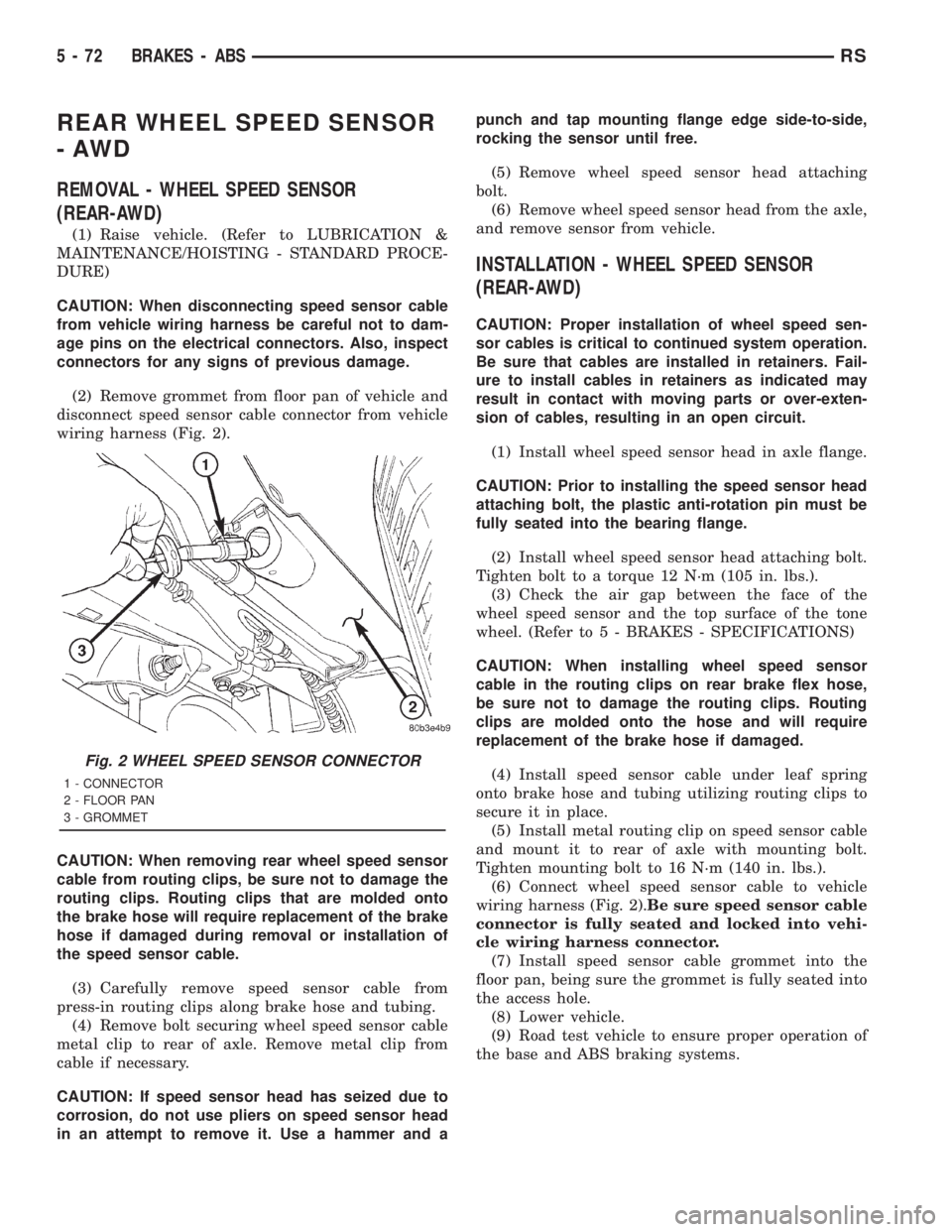

(2) Remove grommet from floor pan of vehicle and

disconnect speed sensor cable connector from vehicle

wiring harness (Fig. 2).

CAUTION: When removing rear wheel speed sensor

cable from routing clips, be sure not to damage the

routing clips. Routing clips that are molded onto

the brake hose will require replacement of the brake

hose if damaged during removal or installation of

the speed sensor cable.

(3) Carefully remove speed sensor cable from

press-in routing clips along brake hose and tubing.

(4) Remove bolt securing wheel speed sensor cable

metal clip to rear of axle. Remove metal clip from

cable if necessary.

CAUTION: If speed sensor head has seized due to

corrosion, do not use pliers on speed sensor head

in an attempt to remove it. Use a hammer and apunch and tap mounting flange edge side-to-side,

rocking the sensor until free.

(5) Remove wheel speed sensor head attaching

bolt.

(6) Remove wheel speed sensor head from the axle,

and remove sensor from vehicle.

INSTALLATION - WHEEL SPEED SENSOR

(REAR-AWD)

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as indicated may

result in contact with moving parts or over-exten-

sion of cables, resulting in an open circuit.

(1) Install wheel speed sensor head in axle flange.

CAUTION: Prior to installing the speed sensor head

attaching bolt, the plastic anti-rotation pin must be

fully seated into the bearing flange.

(2) Install wheel speed sensor head attaching bolt.

Tighten bolt to a torque 12 N´m (105 in. lbs.).

(3) Check the air gap between the face of the

wheel speed sensor and the top surface of the tone

wheel. (Refer to 5 - BRAKES - SPECIFICATIONS)

CAUTION: When installing wheel speed sensor

cable in the routing clips on rear brake flex hose,

be sure not to damage the routing clips. Routing

clips are molded onto the hose and will require

replacement of the brake hose if damaged.

(4) Install speed sensor cable under leaf spring

onto brake hose and tubing utilizing routing clips to

secure it in place.

(5) Install metal routing clip on speed sensor cable

and mount it to rear of axle with mounting bolt.

Tighten mounting bolt to 16 N´m (140 in. lbs.).

(6) Connect wheel speed sensor cable to vehicle

wiring harness (Fig. 2).Be sure speed sensor cable

connector is fully seated and locked into vehi-

cle wiring harness connector.

(7) Install speed sensor cable grommet into the

floor pan, being sure the grommet is fully seated into

the access hole.

(8) Lower vehicle.

(9) Road test vehicle to ensure proper operation of

the base and ABS braking systems.

Fig. 2 WHEEL SPEED SENSOR CONNECTOR

1 - CONNECTOR

2 - FLOOR PAN

3 - GROMMET

5 - 72 BRAKES - ABSRS

Page 1704 of 4284

(2) Inside the vehicle, install the remaining 2

mounting bolts attaching the ICU to the mounting

bracket (Fig. 11). Tighten all 3 mounting bolts to a

torque of 11 N´m (97 in. lbs.).

(3) Install the dash seal and three mounting

screws (Fig. 10).

(4) Install the silencer on top of the dash seal (Fig.

10).

(5) Connect the steering shaft coupling and install

the pinch bolt (Fig. 10). Tighten the pinch bolt to 28

N´m (250 in. lbs.).

(6) Install the silencer panel below the steering

column under the instrument panel.

(7) Remove the steering wheel holder.

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, the brake tubes

must be held in proper orientation when tightened

and torqued. These tubes must not contact each

other or other vehicle components when installed.

Also, after the brake tubes are installed on the HCU,

ensure all spacer clips are reinstalled on the brake

tubes.

(8) Install the primary and secondary brake tubes

into their correct port locations on the HCU valve

block (Fig. 9). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the CAB.

(9) Install the (4) chassis brake tubes into their

correct port locations on the HCU valve block as

shown (Fig. 9). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).NOTE: Before installing the 24±way connector in

the CAB be sure the seal is properly installed in the

connector.

(10) Install the 24±way connector on the CAB by,

first, positioning the 24±way connector in the socket

of the CAB and carefully pushing it down as far as

possible. Once connector is fully seated by hand into

the CAB socket, push down on connector lock. This

will pull the connector into the socket of the CAB

and lock it in the installed position.

(11) Install any routing clips on the brake tubes.

(12) Remove the brake pedal holder.

(13) Install the speed control servo with its mount-

ing nuts.

(14) Connect the wiring harness to the speed con-

trol servo.

(15) Install the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION).

(16) Install the screw securing the coolant filler

neck to the battery tray.

(17) Reconnect the vacuum hose connector at the

tank built into the battery tray.

(18) Install the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION).

(19) Install the battery shield.

(20) Remove the brake pedal holder.

(21) Connect negative cable back on negative post

of the battery.

(22) Bleed the Base and ABS brake hydraulic sys-

tems (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(23) Road test vehicle to ensure proper operation

of the base and antilock brake systems.

5 - 78 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

Page 1705 of 4284

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 10

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DESCRIPTION............................1

HYDRAULIC/MECHANICAL

DESCRIPTION............................1

FLUID

STANDARD PROCEDURE...................1

BRAKE FLUID LEVEL CHECKING...........1

MASTER CYLINDER - RHD

DESCRIPTION............................2

REMOVAL...............................2

INSTALLATION............................3

PEDAL TORQUE SHAFT

REMOVAL...............................3

INSTALLATION............................4POWER BRAKE BOOSTER - RHD

REMOVAL...............................4

INSTALLATION............................6

ROTORS

SPECIFICATIONS.........................8

PARKING BRAKE

DESCRIPTION............................8

CABLES - PARKING BRAKE

REMOVAL...............................8

INSTALLATION............................8

LEVER - PARKING BRAKE

REMOVAL...............................8

INSTALLATION............................9

BRAKES - BASE

DESCRIPTION - BASE BRAKES

Four-Wheel Disc Antilock Brakes are standard on

all models.

HYDRAULIC/MECHANICAL

DESCRIPTION - DISC BRAKES

All vehicles are equipped with Four-Wheel-Disc

brakes. Both 15º (BRE) and 16º (BR3) disc/disc brake

systems are available. The disc brakes are manufac-

tured by Continental Teves. The BR3 system is stan-

dard equipment on all-wheel drive and all right-hand

drive models. It is optional on other models.

The BR3 system features larger, externally vented

front brake rotors.

Although there are different disc/disc systems, they

are serviced using the same service procedures. Some

specifications differ.

FLUID

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING

Right hand drive vehicles feature a brake fluid res-

ervoir with the same markings as left hand drive res-

ervoirs.

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Fluid reservoirs are marked with the words FULL

and ADD to indicate proper brake fluid fill level of

the master cylinder.

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.

Use only Mopartbrake fluid or equivalent from a

sealed container. Brake fluid must conform to DOT 3

specifications (DOT 4 or DOT 4+ are acceptable).

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

RGBRAKES5a-1

Page 1725 of 4284

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder

²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

DIAGNOSIS AND TESTING - CLUTCH COVER

AND DISC RUNOUT

Check condition of the clutch cover before installa-

tion. A warped cover or diaphragm spring will cause

grab and/or incomplete release or engagement. Use

care when handling the clutch assembly. Impact can

distort the cover, diaphragm spring, and release fin-

gers.

DIAGNOSIS AND TESTING - CLUTCH CHATTER

COMPLAINTS

For all clutch chatter complaints, perform the fol-

lowing:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further.

(2) If chatter persists, check hydraulic clutch

release system is functioning properly.

(3) Check for loose connections in drivetrain. Cor-

rect any problems and determine if clutch chatter

complaints have been satisfied. If not:

(a) Remove transaxle.

(b) Check to see if the release bearing is sticky

or binding. Replace bearing, if needed.

(c) Check linkage for excessive wear on the pivot

stud and fork fingers. Replace all worn parts.

(d) Check clutch assembly for contamination

(dirt, oil). Replace clutch assembly, if required.

(e) Check to see if the clutch disc hub splines

are damaged. Replace with new clutch assembly, if

necessary.

(f) Check input shaft splines for damage.

Replace, if necessary.

(g) Check for uneven wear on clutch fingers.

(h) Check for broken clutch cover diaphragm

spring fingers. Replace with new clutch assembly,

if necessary.

SPECIAL TOOLS

SPECIAL TOOLS - T850 TRANSAXLE

CLUTCH RELEASE CABLE -

LHD

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3)Diesel models:Remove underbody splash

shield.

(4) Remove clutch bellhousing cap.

(5) Some models will have a clutch cable retainer

clip at the transaxle to secure it to the case (Fig. 9).

If retainer clip is installed, dislodge clip from from

inside bellhousing using a suitable screwdriver (Fig.

10), pull outward on cable conduit, guiding cable core

wire through slot in bellhousing and disengaging

cable ªTº from clutch release lever (Fig. 11). If

retainer is not installed, disengage clutch cable from

transaxle by pulling outward on cable conduit, guid-

Disconnect Tool, 6638A

Remover/Installer, 6891

RGCLUTCH6a-7

CLUTCH (Continued)

Page 1733 of 4284

INSTALLATION

(1) Install modular clutch assembly to transaxle

input shaft (Fig. 31).

(2) Install transaxle to vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

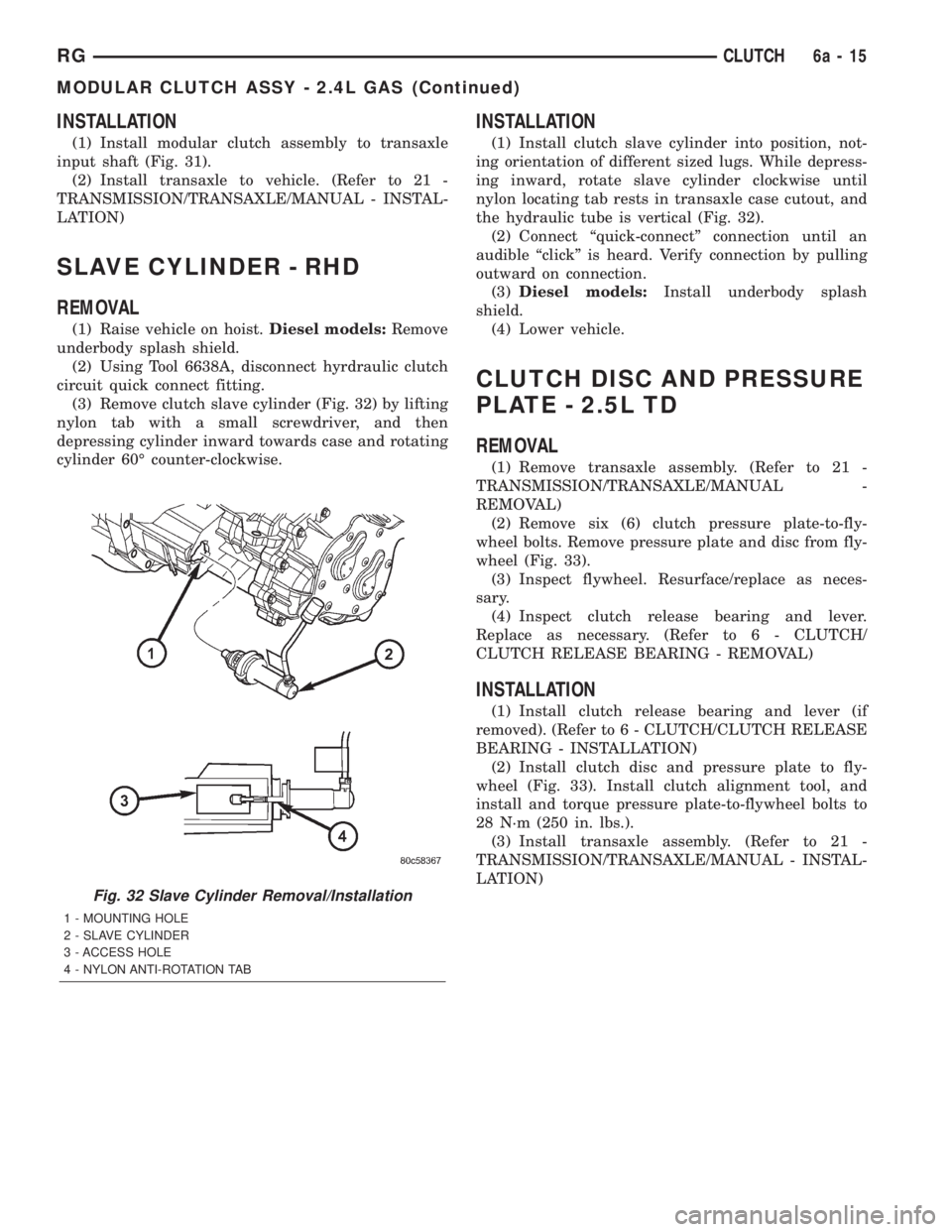

SLAVE CYLINDER - RHD

REMOVAL

(1) Raise vehicle on hoist.Diesel models:Remove

underbody splash shield.

(2) Using Tool 6638A, disconnect hyrdraulic clutch

circuit quick connect fitting.

(3) Remove clutch slave cylinder (Fig. 32) by lifting

nylon tab with a small screwdriver, and then

depressing cylinder inward towards case and rotating

cylinder 60É counter-clockwise.

INSTALLATION

(1) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs. While depress-

ing inward, rotate slave cylinder clockwise until

nylon locating tab rests in transaxle case cutout, and

the hydraulic tube is vertical (Fig. 32).

(2) Connect ªquick-connectº connection until an

audible ªclickº is heard. Verify connection by pulling

outward on connection.

(3)Diesel models:Install underbody splash

shield.

(4) Lower vehicle.

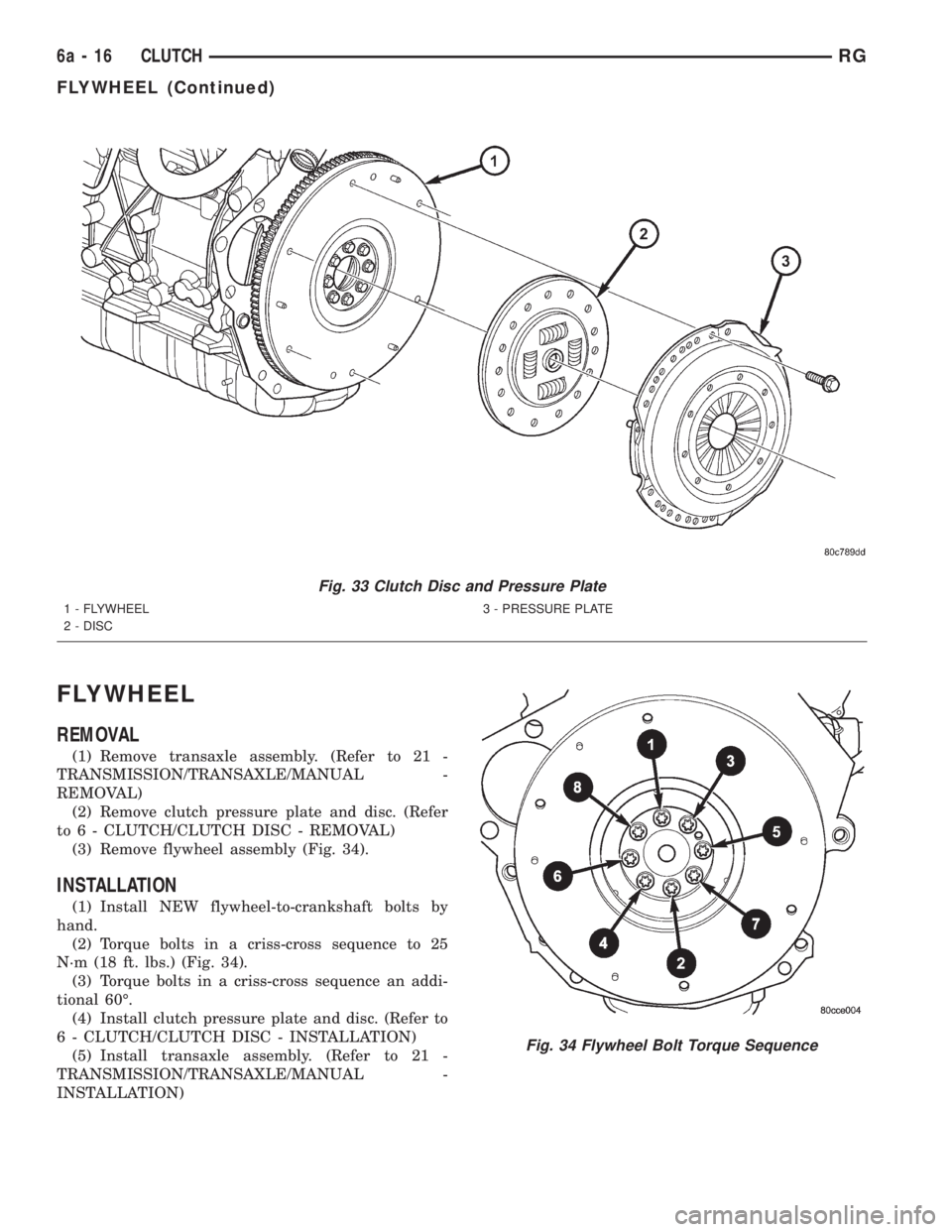

CLUTCH DISC AND PRESSURE

PLATE - 2.5L TD

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove six (6) clutch pressure plate-to-fly-

wheel bolts. Remove pressure plate and disc from fly-

wheel (Fig. 33).

(3) Inspect flywheel. Resurface/replace as neces-

sary.

(4) Inspect clutch release bearing and lever.

Replace as necessary. (Refer to 6 - CLUTCH/

CLUTCH RELEASE BEARING - REMOVAL)

INSTALLATION

(1) Install clutch release bearing and lever (if

removed). (Refer to 6 - CLUTCH/CLUTCH RELEASE

BEARING - INSTALLATION)

(2) Install clutch disc and pressure plate to fly-

wheel (Fig. 33). Install clutch alignment tool, and

install and torque pressure plate-to-flywheel bolts to

28 N´m (250 in. lbs.).

(3) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

Fig. 32 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

RGCLUTCH6a-15

MODULAR CLUTCH ASSY - 2.4L GAS (Continued)

Page 1734 of 4284

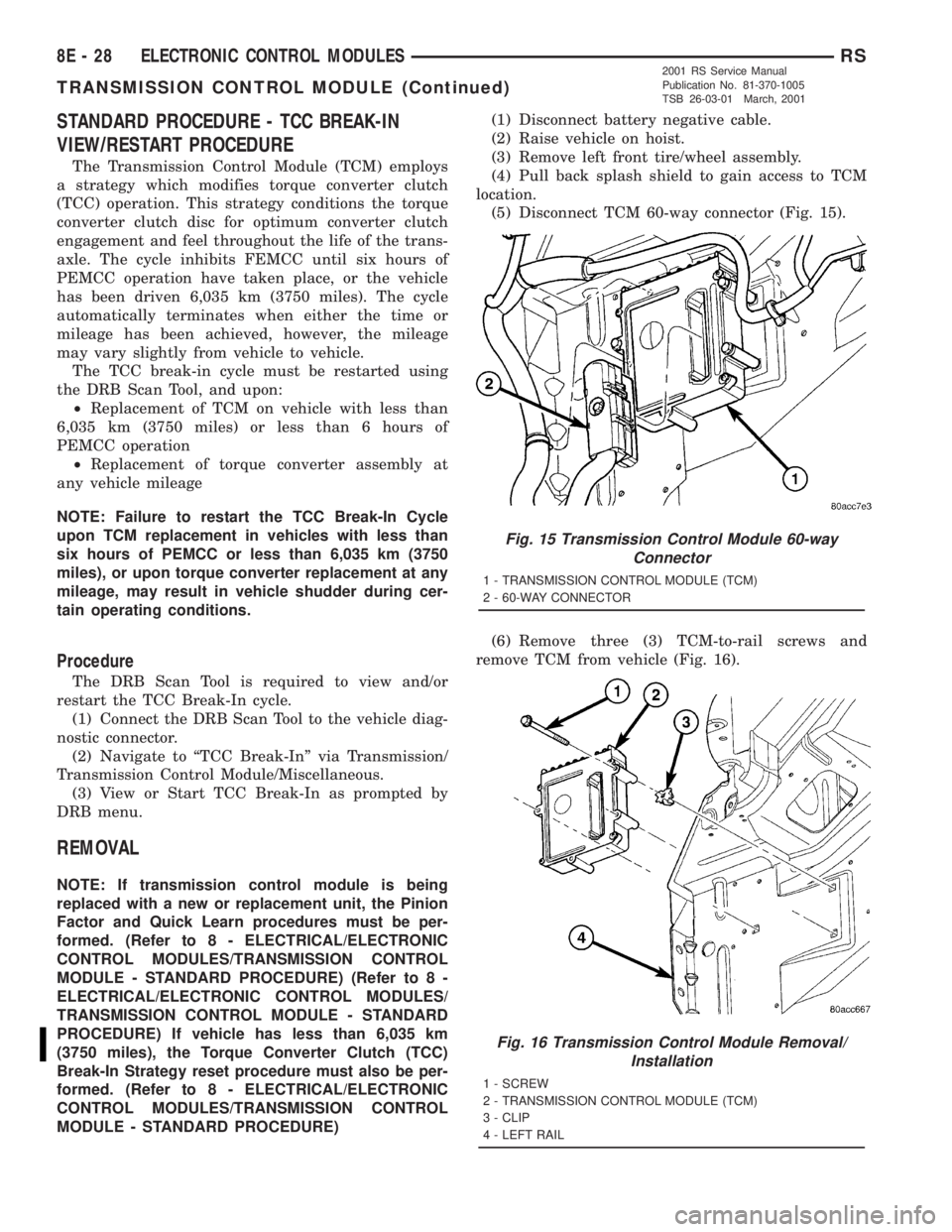

FLYWHEEL

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove clutch pressure plate and disc. (Refer

to 6 - CLUTCH/CLUTCH DISC - REMOVAL)

(3) Remove flywheel assembly (Fig. 34).

INSTALLATION

(1) Install NEW flywheel-to-crankshaft bolts by

hand.

(2) Torque bolts in a criss-cross sequence to 25

N´m (18 ft. lbs.) (Fig. 34).

(3) Torque bolts in a criss-cross sequence an addi-

tional 60É.

(4) Install clutch pressure plate and disc. (Refer to

6 - CLUTCH/CLUTCH DISC - INSTALLATION)

(5) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

INSTALLATION)

Fig. 33 Clutch Disc and Pressure Plate

1 - FLYWHEEL

2 - DISC3 - PRESSURE PLATE

Fig. 34 Flywheel Bolt Torque Sequence

6a - 16 CLUTCHRG

FLYWHEEL (Continued)

Page 1852 of 4284

STANDARD PROCEDURE - TCC BREAK-IN

VIEW/RESTART PROCEDURE

The Transmission Control Module (TCM) employs

a strategy which modifies torque converter clutch

(TCC) operation. This strategy conditions the torque

converter clutch disc for optimum converter clutch

engagement and feel throughout the life of the trans-

axle. The cycle inhibits FEMCC until six hours of

PEMCC operation have taken place, or the vehicle

has been driven 6,035 km (3750 miles). The cycle

automatically terminates when either the time or

mileage has been achieved, however, the mileage

may vary slightly from vehicle to vehicle.

The TCC break-in cycle must be restarted using

the DRB Scan Tool, and upon:

²Replacement of TCM on vehicle with less than

6,035 km (3750 miles) or less than 6 hours of

PEMCC operation

²Replacement of torque converter assembly at

any vehicle mileage

NOTE: Failure to restart the TCC Break-In Cycle

upon TCM replacement in vehicles with less than

six hours of PEMCC or less than 6,035 km (3750

miles), or upon torque converter replacement at any

mileage, may result in vehicle shudder during cer-

tain operating conditions.

Procedure

The DRB Scan Tool is required to view and/or

restart the TCC Break-In cycle.

(1) Connect the DRB Scan Tool to the vehicle diag-

nostic connector.

(2) Navigate to ªTCC Break-Inº via Transmission/

Transmission Control Module/Miscellaneous.

(3) View or Start TCC Break-In as prompted by

DRB menu.

REMOVAL

NOTE: If transmission control module is being

replaced with a new or replacement unit, the Pinion

Factor and Quick Learn procedures must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE) (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE) If vehicle has less than 6,035 km

(3750 miles), the Torque Converter Clutch (TCC)

Break-In Strategy reset procedure must also be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3) Remove left front tire/wheel assembly.

(4) Pull back splash shield to gain access to TCM

location.

(5) Disconnect TCM 60-way connector (Fig. 15).

(6) Remove three (3) TCM-to-rail screws and

remove TCM from vehicle (Fig. 16).

Fig. 15 Transmission Control Module 60-way

Connector

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60-WAY CONNECTOR

Fig. 16 Transmission Control Module Removal/

Installation

1 - SCREW

2 - TRANSMISSION CONTROL MODULE (TCM)

3 - CLIP

4 - LEFT RAIL

8E - 28 ELECTRONIC CONTROL MODULESRS

TRANSMISSION CONTROL MODULE (Continued)

2001 RS Service Manual

Publication No. 81-370-1005

TSB 26-03-01 March, 2001