clock CHRYSLER VOYAGER 2001 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1756 of 4284

DIAGNOSIS AND TESTING - ENGINE COOLANT

THERMOSTAT

The thermostat is operated by a wax filled cham-

ber (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

Thermostat diagnostics is included in powertrain

control module's (PCM) programing for on-board

diagnosis. The malfunction indicator light (MIL) will

illuminate and a diagnostic trouble code (DTC) will

be set when an ªopen too soonº condition occurs. Do

not change a thermostat for lack of heater perfor-

mance or temperature gauge position, unless a DTC

is present. For other probable causes, (Refer to 7 -

COOLING/ENGINE - DIAGNOSIS AND TESTING) .

Thermostat failing shut is the normal long term

mode of failure, and normally, only on high mileage

vehicles. The temperature gauge will indicate this

(Refer to 7 - COOLING/ENGINE - DIAGNOSIS AND

TESTING) .

ENGINE COOLANT

THERMOSTAT - 2.4L

REMOVAL

(1) Drain cooling system below the thermostat

level. (Refer to 7 - COOLING - STANDARD PROCE-

DURE)

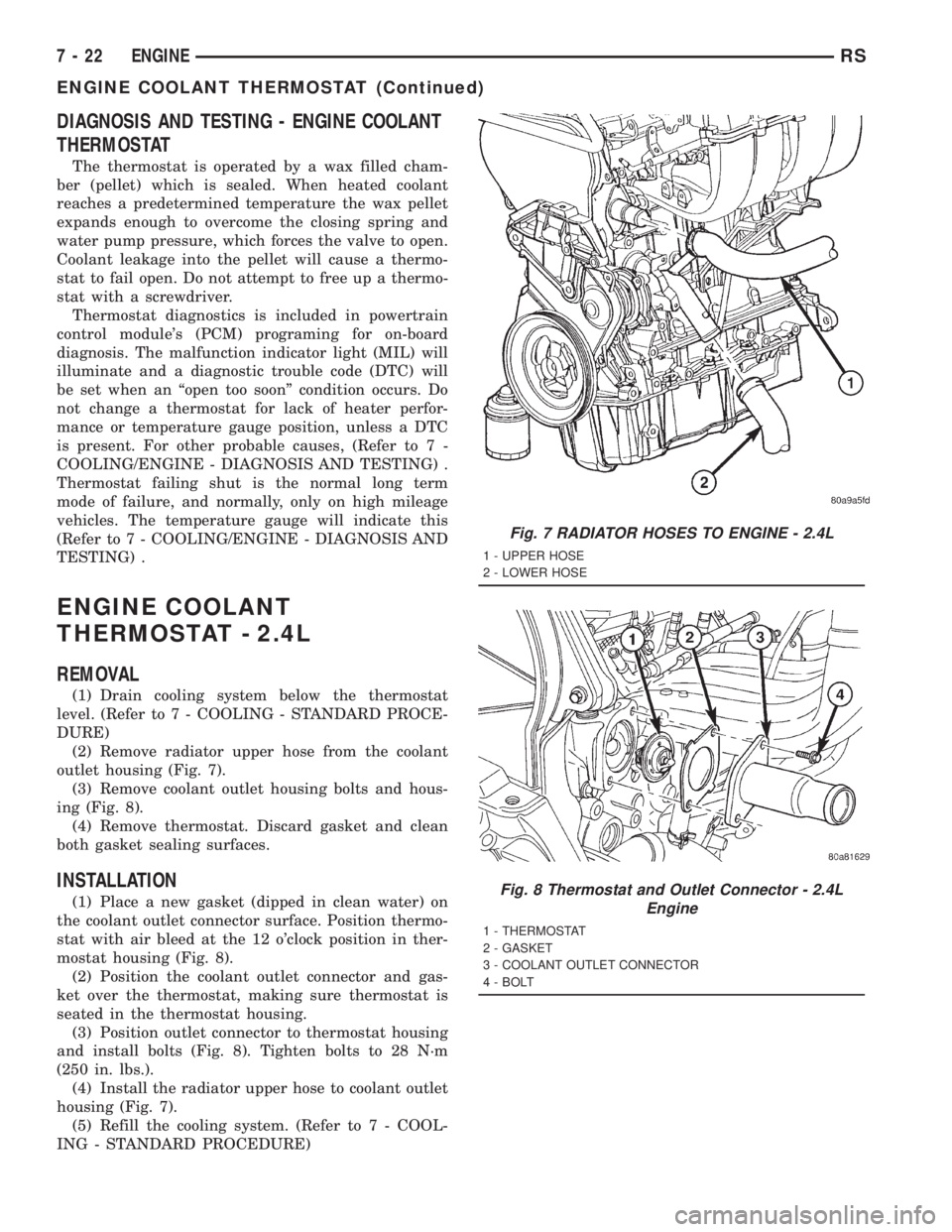

(2) Remove radiator upper hose from the coolant

outlet housing (Fig. 7).

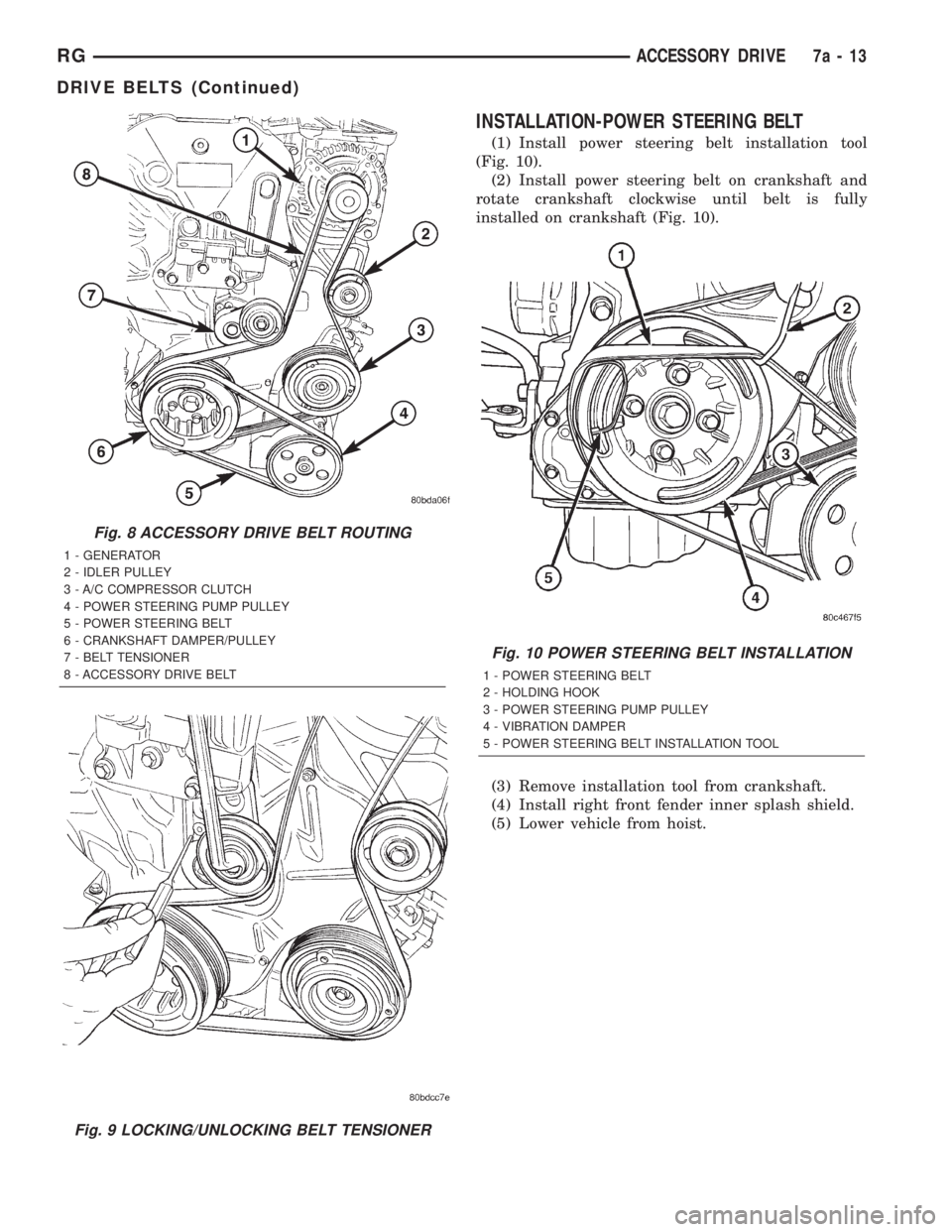

(3) Remove coolant outlet housing bolts and hous-

ing (Fig. 8).

(4) Remove thermostat. Discard gasket and clean

both gasket sealing surfaces.

INSTALLATION

(1) Place a new gasket (dipped in clean water) on

the coolant outlet connector surface. Position thermo-

stat with air bleed at the 12 o'clock position in ther-

mostat housing (Fig. 8).

(2) Position the coolant outlet connector and gas-

ket over the thermostat, making sure thermostat is

seated in the thermostat housing.

(3) Position outlet connector to thermostat housing

and install bolts (Fig. 8). Tighten bolts to 28 N´m

(250 in. lbs.).

(4) Install the radiator upper hose to coolant outlet

housing (Fig. 7).

(5) Refill the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

Fig. 7 RADIATOR HOSES TO ENGINE - 2.4L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 8 Thermostat and Outlet Connector - 2.4L

Engine

1 - THERMOSTAT

2 - GASKET

3 - COOLANT OUTLET CONNECTOR

4 - BOLT

7 - 22 ENGINERS

ENGINE COOLANT THERMOSTAT (Continued)

Page 1759 of 4284

INSTALLATION

(1)Be sure the air seal is in position before

radiator is installed.Slide radiator down into posi-

tion. Seat the radiator with the rubber isolators into

the mounting holes provided, with a 10 lbs. force.

(2) Position air conditioning condenser onto the

radiator lower mounts and install upper screws (Fig.

15). Tighten fasteners to 5 N´m (45 in. lbs.).

(3) Install the radiator upper and lower hoses (Fig.

13) or (Fig. 14).

(4) Connect the coolant reserve/recovery hose.

(5) Connect the vapor purge solenoid to the mount-

ing bracket.

(6) Install the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION)

(7) Install the radiator upper crossmember sup-

port. (Refer to 23 - BODY/EXTERIOR/GRILLE

OPENING REINFORCEMENT - INSTALLATION)

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

(9) Connect negative cable to battery.

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not recom-

mended. Damage may occur to radiator or drain-

cock.

NOTE: It is not necessary to remove draincock dur-

ing a routine coolant drain.

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Open the draincock by turning it counterclock-

wise until it stops.

(3) Turn the draincock back (clockwise) 1/8 turn.

(4) Pull the draincock (Fig. 16) from the radiator

tank.

INSTALLATION

(1) Align draincock stem to radiator tank opening.

(2) Push draincock into the radiator tank opening.

(3) Tighten the draincock by turning clockwise

until it stops.

(4) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

Fig. 15 Radiator to A/C Condenser Mounting (left

mount shown, right similar)

1 - SCREW - A/C CONDENSER SIDE BRACKET TO RADIATOR

2 - LOWER MOUNT

3 - A/C CONDENSER

Fig. 16 Draincock

1 - RADIATOR TANK

2 - DRAINCOCK

RSENGINE7-25

RADIATOR (Continued)

Page 1761 of 4284

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

INSPECTION

Hold the cap in your hand,top side up(Fig. 20).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.

Hold the cleaned cap in your hand,upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap.Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 21). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

Fig. 19 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - PRESSURE BOTTLE

8 - FILLER NECK

Fig. 20 Cooling System Pressure Cap

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - THERMOSTAT HOUSING/ENGINE OUTLET CONNECTOR

8 - FILLER NECK

RSENGINE7-27

RADIATOR PRESSURE CAP (Continued)

Page 1785 of 4284

DIAGNOSIS AND TESTING - ACCESSORY DRIVE BELT

CONDITION POSSIBLE CAUSES CORRECTIONS

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT

SLIPPAGE1. Belt too loose 1. (a) Replace belt (auto-tensioned

belts)

2. Faulty belt tensioner 2. Replace tensioner as necessary

3. Belt excessively glazed or worn 3. Replace belt

BELT SQUEAL WHEN

ACCELERATING ENGINE1. Belts too loose 1. Check and replace belt tensioner if

necessary

2. Belt glazed 2. Replace belt

BELT SQUEAK AT IDLE 1. Belts too loose 1. (a) Replace belt

2. Dirt or paint imbedded in belt 2. Replace belt

3. Non-uniform belt 3. Replace belt

4. Misaligned pulleys 4. Align accessories

5. Non-uniform groove or eccentric

pulley5. Replace pulley

BELT ROLLED OVER IN

GROOVE OR BELT JUMPS

OFF1. Broken cord in belt 1. Replace belt

2. Belt too loose, or too tight 2. Replace belt

3. Misaligned pulleys 3. Align accessories

4. Non-uniform groove or eccentric

pulley4. Replace pulley

REMOVAL-ACCESSORY DRIVE BELT

(1) Remove the power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Relieve tension on belt tensioner using a suit-

able wrench (Fig. 4) and lock tensioner with a drift

punch (Fig. 5).

(3) Remove the accessory drive belt.

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove right front fender inner splash shield.

(3) Install power steering belt remover tool on

crankshaft damper (Fig. 6).

(4) Rotate engine clockwise to remove belt (Fig. 7).

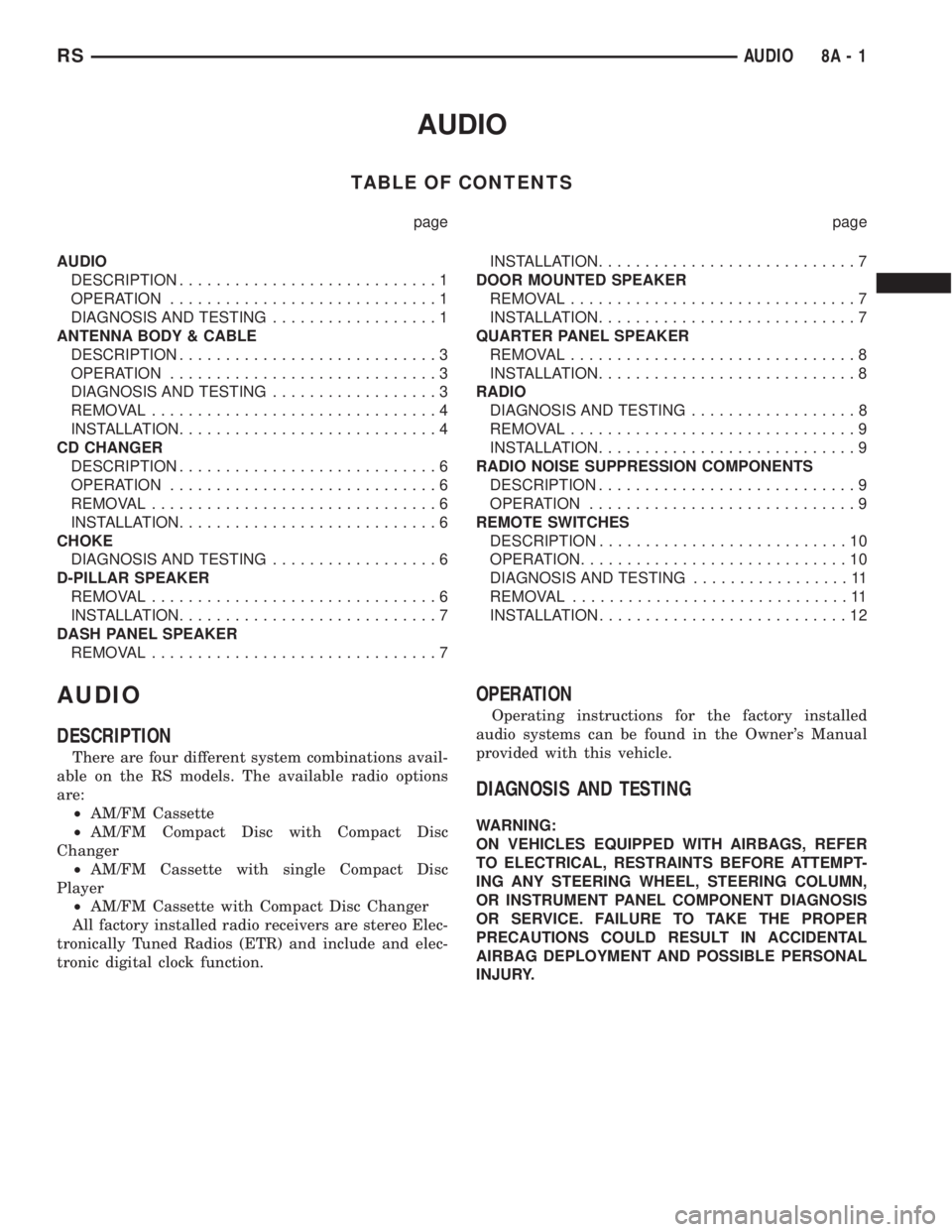

INSTALLATION-ACCESSORY DRIVE BELT

(1) Install the accessory drive belt in proper posi-

tion (Fig. 8).

(2) Unlock belt tensioner by removing punch and

apply tension to accessory drive belt (Fig. 9).

(3) Install the power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

RGACCESSORY DRIVE7a-11

DRIVE BELTS (Continued)

Page 1787 of 4284

INSTALLATION-POWER STEERING BELT

(1) Install power steering belt installation tool

(Fig. 10).

(2) Install power steering belt on crankshaft and

rotate crankshaft clockwise until belt is fully

installed on crankshaft (Fig. 10).

(3) Remove installation tool from crankshaft.

(4) Install right front fender inner splash shield.

(5) Lower vehicle from hoist.

Fig. 8 ACCESSORY DRIVE BELT ROUTING

1 - GENERATOR

2 - IDLER PULLEY

3 - A/C COMPRESSOR CLUTCH

4 - POWER STEERING PUMP PULLEY

5 - POWER STEERING BELT

6 - CRANKSHAFT DAMPER/PULLEY

7 - BELT TENSIONER

8 - ACCESSORY DRIVE BELT

Fig. 9 LOCKING/UNLOCKING BELT TENSIONER

Fig. 10 POWER STEERING BELT INSTALLATION

1 - POWER STEERING BELT

2 - HOLDING HOOK

3 - POWER STEERING PUMP PULLEY

4 - VIBRATION DAMPER

5 - POWER STEERING BELT INSTALLATION TOOL

RGACCESSORY DRIVE7a-13

DRIVE BELTS (Continued)

Page 1796 of 4284

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not recom-

mended. Damage may occur to radiator or drain-

cock.

NOTE: It is not necessary to remove draincock dur-

ing a routine coolant drain.

(1) Drain the cooling system (Refer to 7 - COOL-

ING/ENGINE/COOLANT - STANDARD PROCE-

DURE).

(2) Open the draincock by turning it counterclock-

wise until it stops.

(3) Turn the draincock back (clockwise) 1/8 turn.

(4) Pull the draincock (Fig. 13) from the radiator

tank.

INSTALLATION

(1) Align draincock stem to radiator tank opening.

(2) Push draincock into the radiator tank opening.

(3) Tighten the draincock by turning clockwise

until it stops.

(4) Fill the cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

WATER PUMP

DESCRIPTION

The water pump on the 2.5L CRD diesel has a die

cast aluminum housing. It bolts to a aluminum hous-

ing which attaches to the engine block (Fig. 14).

OPERATION

The water pump is used to circulate coolant

through the cooling system. The coolant is pumped

through the engine block, cylinder head, heater core,

EGR cooler, cabin heater, and radiator.

REMOVAL - WATER PUMP

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove timing belt inner and outer covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Remove water pump retaining bolts and pump

(Fig. 15).

Fig. 13 Draincock

1 - RADIATOR TANK

2 - DRAINCOCK

Fig. 14 WATER PUMP

1 - WATER PUMP HOUSING STUDS

2 - WATER PUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

7a - 22 ENGINERG

Page 1799 of 4284

DIAGNOSIS AND TESTING - COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water. Clean any deposits

off the vent valve or its seat and apply cap to end of

the Pressure Cap Test Adaptor that is included with

the Cooling System Tester 7700. Working the

plunger, bring the pressure to 104 kPa (15 psi) on the

gauge. If the pressure cap fails to hold pressure of at

least 97 kPa (14 psi), replace the pressure cap.

CAUTION: The Cooling System Tester Tool is very

sensitive to small air leaks that will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn tool

upside down and recheck pressure cap to confirm

that cap is bad.

If the pressure cap tests properly while positioned

on Cooling System Tester (Fig. 20), but will not hold

pressure or vacuum when positioned on the filler

neck. Inspect the filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

DIAGNOSIS AND TESTING - PRESSURE

RELIEF TEST

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 21). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

Fig. 20 Testing Cooling System Pressure Cap

1 - PRESSURE CAP

2 - PRESSURE TESTER

Fig. 21 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - PRESSURE BOTTLE

8 - FILLER NECK

RGENGINE7a-25

RADIATOR PRESSURE CAP (Continued)

Page 1805 of 4284

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

ANTENNA BODY & CABLE

DESCRIPTION............................3

OPERATION.............................3

DIAGNOSIS AND TESTING..................3

REMOVAL...............................4

INSTALLATION............................4

CD CHANGER

DESCRIPTION............................6

OPERATION.............................6

REMOVAL...............................6

INSTALLATION............................6

CHOKE

DIAGNOSIS AND TESTING..................6

D-PILLAR SPEAKER

REMOVAL...............................6

INSTALLATION............................7

DASH PANEL SPEAKER

REMOVAL...............................7INSTALLATION............................7

DOOR MOUNTED SPEAKER

REMOVAL...............................7

INSTALLATION............................7

QUARTER PANEL SPEAKER

REMOVAL...............................8

INSTALLATION............................8

RADIO

DIAGNOSIS AND TESTING..................8

REMOVAL...............................9

INSTALLATION............................9

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION............................9

OPERATION.............................9

REMOTE SWITCHES

DESCRIPTION...........................10

OPERATION.............................10

DIAGNOSIS AND TESTING.................11

REMOVAL..............................11

INSTALLATION...........................12

AUDIO

DESCRIPTION

There are four different system combinations avail-

able on the RS models. The available radio options

are:

²AM/FM Cassette

²AM/FM Compact Disc with Compact Disc

Changer

²AM/FM Cassette with single Compact Disc

Player

²AM/FM Cassette with Compact Disc Changer

All factory installed radio receivers are stereo Elec-

tronically Tuned Radios (ETR) and include and elec-

tronic digital clock function.

OPERATION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with this vehicle.

DIAGNOSIS AND TESTING

WARNING:

ON VEHICLES EQUIPPED WITH AIRBAGS, REFER

TO ELECTRICAL, RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

RSAUDIO8A-1

Page 1814 of 4284

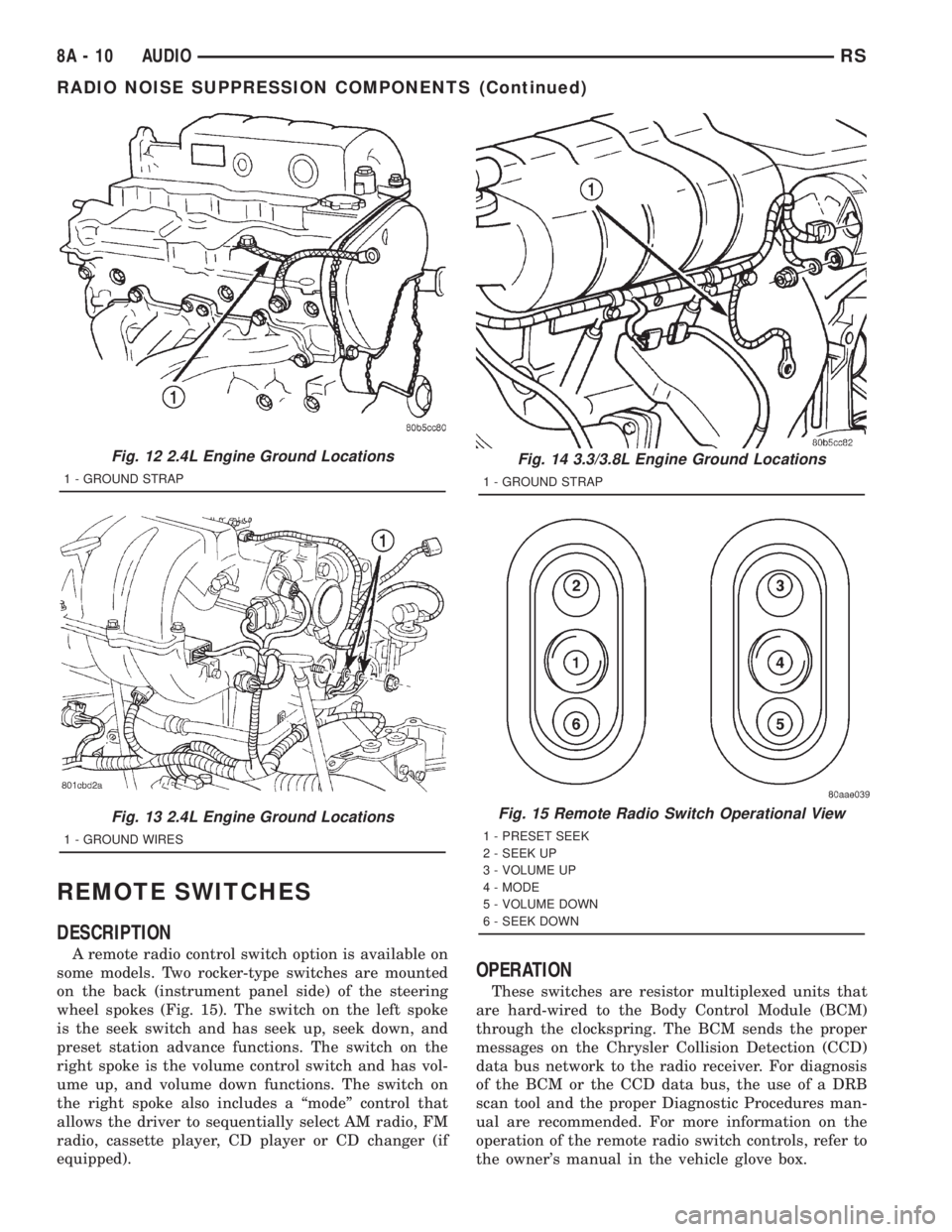

REMOTE SWITCHES

DESCRIPTION

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 15). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Chrysler Collision Detection (CCD)

data bus network to the radio receiver. For diagnosis

of the BCM or the CCD data bus, the use of a DRB

scan tool and the proper Diagnostic Procedures man-

ual are recommended. For more information on the

operation of the remote radio switch controls, refer to

the owner's manual in the vehicle glove box.

Fig. 12 2.4L Engine Ground Locations

1 - GROUND STRAP

Fig. 13 2.4L Engine Ground Locations

1 - GROUND WIRES

Fig. 14 3.3/3.8L Engine Ground Locations

1 - GROUND STRAP

Fig. 15 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

8A - 10 AUDIORS

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

Page 1868 of 4284

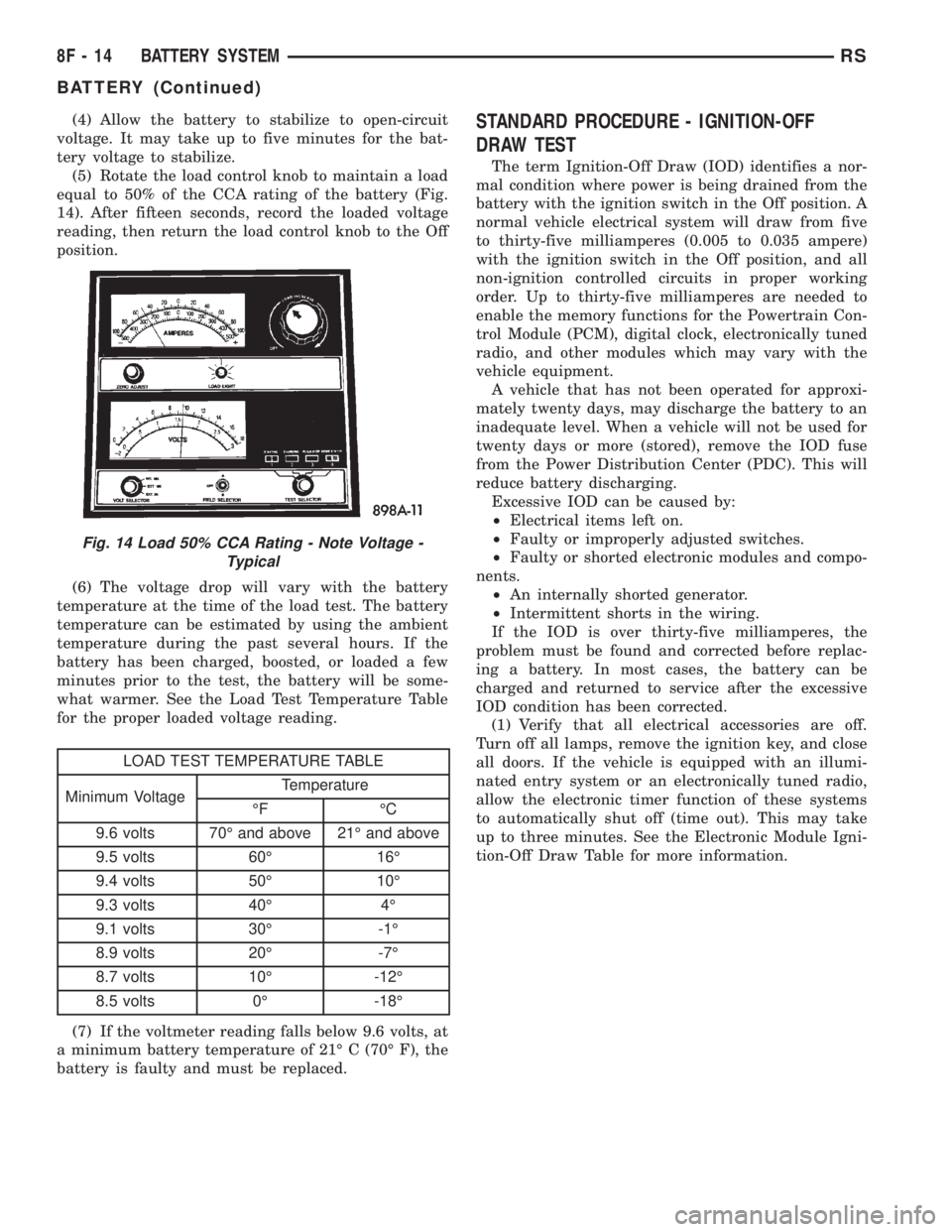

(4) Allow the battery to stabilize to open-circuit

voltage. It may take up to five minutes for the bat-

tery voltage to stabilize.

(5) Rotate the load control knob to maintain a load

equal to 50% of the CCA rating of the battery (Fig.

14). After fifteen seconds, record the loaded voltage

reading, then return the load control knob to the Off

position.

(6) The voltage drop will vary with the battery

temperature at the time of the load test. The battery

temperature can be estimated by using the ambient

temperature during the past several hours. If the

battery has been charged, boosted, or loaded a few

minutes prior to the test, the battery will be some-

what warmer. See the Load Test Temperature Table

for the proper loaded voltage reading.

LOAD TEST TEMPERATURE TABLE

Minimum VoltageTemperature

ÉF ÉC

9.6 volts 70É and above 21É and above

9.5 volts 60É 16É

9.4 volts 50É 10É

9.3 volts 40É 4É

9.1 volts 30É -1É

8.9 volts 20É -7É

8.7 volts 10É -12É

8.5 volts 0É -18É

(7) If the voltmeter reading falls below 9.6 volts, at

a minimum battery temperature of 21É C (70É F), the

battery is faulty and must be replaced.

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.005 to 0.035 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to thirty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty days, may discharge the battery to an

inadequate level. When a vehicle will not be used for

twenty days or more (stored), remove the IOD fuse

from the Power Distribution Center (PDC). This will

reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over thirty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes. See the Electronic Module Igni-

tion-Off Draw Table for more information.

Fig. 14 Load 50% CCA Rating - Note Voltage -

Typical

8F - 14 BATTERY SYSTEMRS

BATTERY (Continued)