sensor CHRYSLER VOYAGER 2001 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 473 of 4284

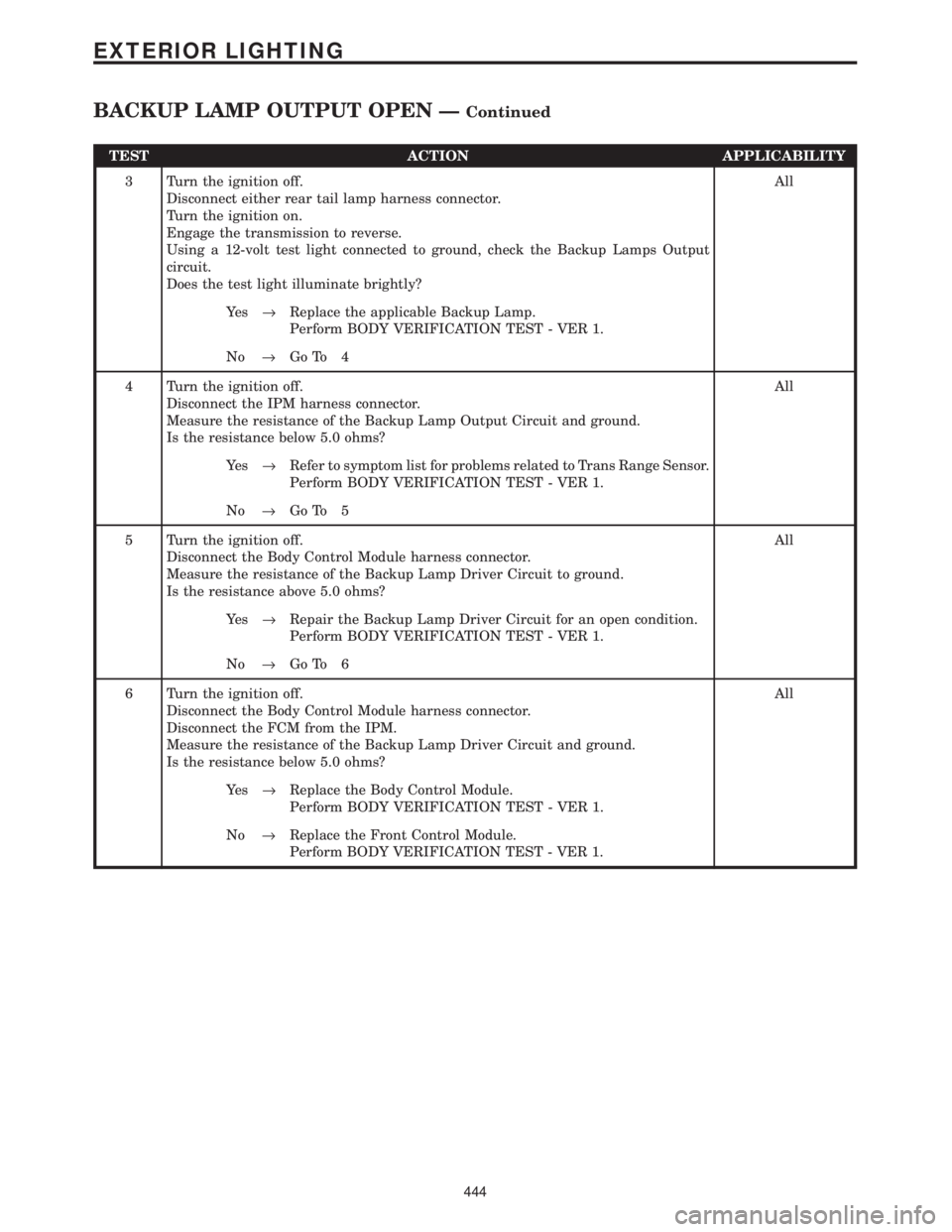

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect either rear tail lamp harness connector.

Turn the ignition on.

Engage the transmission to reverse.

Using a 12-volt test light connected to ground, check the Backup Lamps Output

circuit.

Does the test light illuminate brightly?All

Ye s®Replace the applicable Backup Lamp.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the IPM harness connector.

Measure the resistance of the Backup Lamp Output Circuit and ground.

Is the resistance below 5.0 ohms?All

Ye s®Refer to symptom list for problems related to Trans Range Sensor.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

Disconnect the Body Control Module harness connector.

Measure the resistance of the Backup Lamp Driver Circuit to ground.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Backup Lamp Driver Circuit for an open condition.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6 Turn the ignition off.

Disconnect the Body Control Module harness connector.

Disconnect the FCM from the IPM.

Measure the resistance of the Backup Lamp Driver Circuit and ground.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

444

EXTERIOR LIGHTING

BACKUP LAMP OUTPUT OPEN ÐContinued

Page 479 of 4284

Symptom:

HEADLAMP SWITCH OPEN

When Monitored and Set Condition:

HEADLAMP SWITCH OPEN

When Monitored: Ignition ON

Set Condition: A Sensor voltage is over 4.8 volts for more than .0625 seconds.

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

HEADLAMP SWITCH MUX CIRCUIT OPEN

HEADLAMP SWITCH MUX RETURN CIRCUIT OPEN

HEADLAMP SWITCH OPEN

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase DTC's.

Turn the headlamps to the ON position.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay HEADLAMP SWITCH OPEN?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Disconnect the Headlamp Switch harness connector.

Connect a jumper wire between the Headlamp Switch MUX circuit and the

Headlamp Switch MUX Return circuit in the Headlamp Switch harness connector.

Turn the ignition on.

With the DRB, select Body, Body Controller and read the Headlamp Switch volts.

Does the DRB Headlamp Switch Sensor voltage read less than 0.5 Volts?All

Ye s®Replace the Headlamp Switch in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

450

EXTERIOR LIGHTING

Page 481 of 4284

Symptom:

HEADLAMP SWITCH SHORT TO GROUND

When Monitored and Set Condition:

HEADLAMP SWITCH SHORT TO GROUND

When Monitored: Ignition ON

Set Condition: A Sensor voltage is below 0.488 volts for more than 0.0625 seconds.

POSSIBLE CAUSES

HEADLAMP SWITCH SHORTED

INTERMITTENT WIRING AND CONNECTORS

HEADLAMP SWITCH MUX CIRCUIT SHORT TO GROUND

HEADLAMP SWITCH MUX RETURN CIRCUIT SHORT TO GROUND

HEADLAMP SWITCH MUX CIRCUIT SHORT TO MUX RETURN CIRCUIT

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase DTC's.

Turn the headlamps to the ON position.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay HEADLAMP SWITCH SHORT TO GROUND?All

Ye s®Go To 2

No®Go To 6

2 Turn the ignition off.

Disconnect the Headlamp Switch harness connector.

Turn the ignition on.

With the DRB, select Body, Body Control Module and read the Headlamp Switch

Sensor voltage..

Does the DRB display a Headlamp Switch Voltage of more than 4.8 volts?All

Ye s®Replace the Headlamp Switch in accordance with the Service

Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Headlamp Switch MUX circuit.

Is the resistance less than 5.0 ohms?All

Ye s®Repair the Headlamp Switch MUX Circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

452

EXTERIOR LIGHTING

Page 543 of 4284

Symptom List:

A/C FAULT (STORED) - MANUAL A/C

BACKLIGHT DIMMING RX FAILURE (STORED) - MANUAL A/C

BLEND OVERCURRENT (STORED) - MANUAL A/C

CHECKSUM FAILURE (STORED) - MANUAL A/C

EVAPORATOR TEMPERATURE SENSOR CIRCUIT OPEN

(STORED) - MANUAL A/C

EVAPORATOR TEMPERATURE SENSOR CIRCUIT SHORT

(STORED) - MANUAL A/C

LOOPBACK FAILURE (STORED) - MANUAL A/C

LOOPBACK TEST FAILURE (STORED) - MANUAL A/C

MODE OVERCURRENT (STORED) - MANUAL A/C

NO BCM MESSAGE RECEIVED (STORED) - MANUAL A/C

NO PCM MESSAGE RECEIVED (STORED) - MANUAL A/C

PCM COMMUNICATION FAILURE (STORED) - MANUAL A/C

POWER FAULT (STORED) - MANUAL A/C

REAR BLEND OVERCURRENT (STORED) - MANUAL A/C

REAR BLEND POT CIRCUIT OPEN (STORED) - MANUAL A/C

REAR BLEND POT CIRCUIT SHORT (STORED) - MANUAL A/C

REAR DEFOG FAILURE (STORED) - MANUAL A/C

REAR MODE OVERCURRENT (STORED) - MANUAL A/C

RECIRC OVERCURRENT (STORED) - MANUAL A/C

RECIRCULATION FAULT (STORED) - MANUAL A/C

TX FAILURE (STORED) - MANUAL A/C

UNKNOWN FAULT DETECTED (STORED) - MANUAL A/C

VEHICLE ODOMETER FAILURE (STORED) - MANUAL A/C

ZONE OVERCURRENT (STORED) - MANUAL A/C

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be A/C FAULT (STORED) - MANUAL

A/C.

When Monitored and Set Condition:

A/C FAULT (STORED) - MANUAL A/C

When Monitored: With the ignition on.

Set Condition: This DTC will set if the A/C switch stays closed for 10 minutes.

BACKLIGHT DIMMING RX FAILURE (STORED) - MANUAL A/C

When Monitored: With the ignition on.

Set Condition: If the A/C - Heater Control Module does not receive the dimming function

message from the BCM for more than 5 seconds, then the A/C - Heater Control Module

LEDs will default to full brightness and the DTC will set.

514

HEATING & A/C

Page 544 of 4284

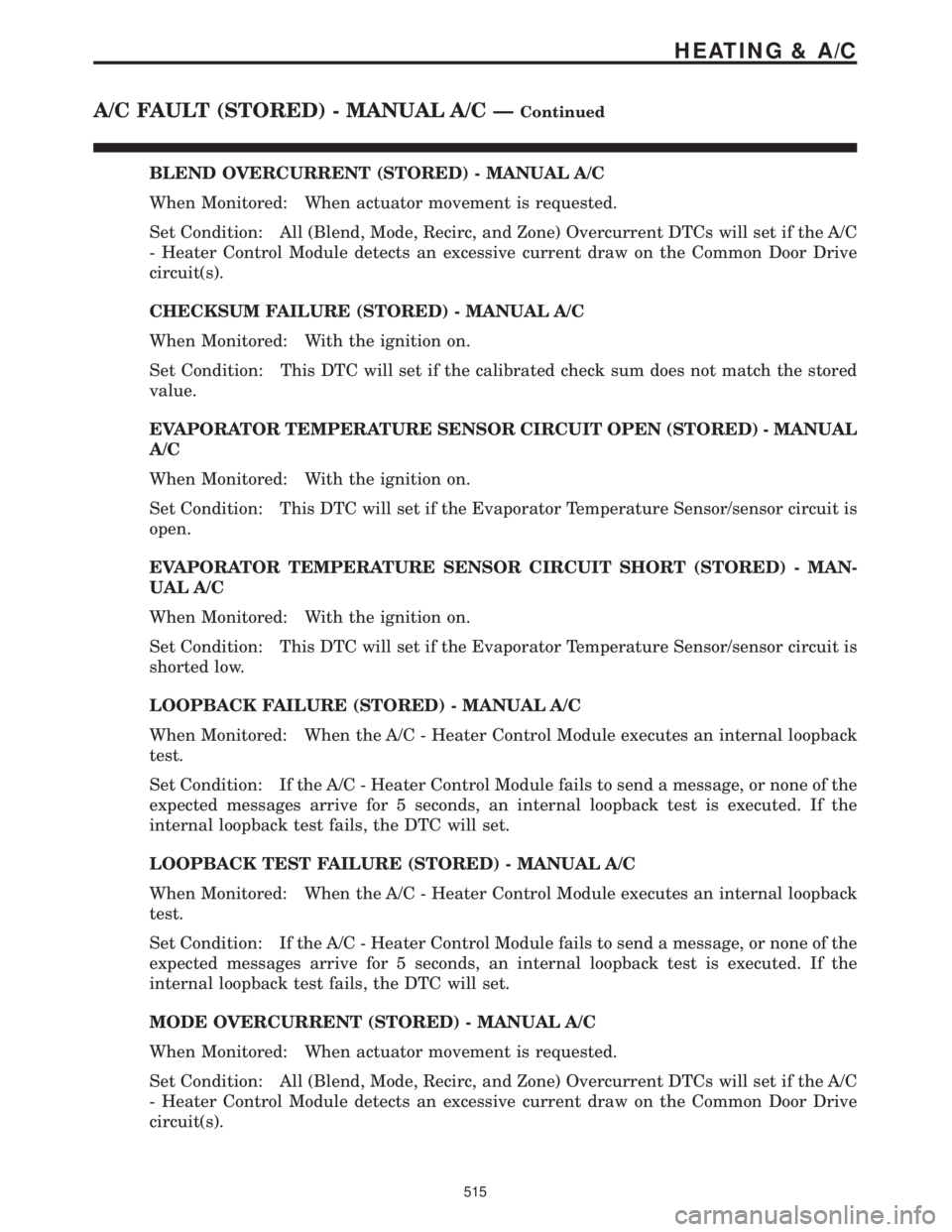

BLEND OVERCURRENT (STORED) - MANUAL A/C

When Monitored: When actuator movement is requested.

Set Condition: All (Blend, Mode, Recirc, and Zone) Overcurrent DTCs will set if the A/C

- Heater Control Module detects an excessive current draw on the Common Door Drive

circuit(s).

CHECKSUM FAILURE (STORED) - MANUAL A/C

When Monitored: With the ignition on.

Set Condition: This DTC will set if the calibrated check sum does not match the stored

value.

EVAPORATOR TEMPERATURE SENSOR CIRCUIT OPEN (STORED) - MANUAL

A/C

When Monitored: With the ignition on.

Set Condition: This DTC will set if the Evaporator Temperature Sensor/sensor circuit is

open.

EVAPORATOR TEMPERATURE SENSOR CIRCUIT SHORT (STORED) - MAN-

UAL A/C

When Monitored: With the ignition on.

Set Condition: This DTC will set if the Evaporator Temperature Sensor/sensor circuit is

shorted low.

LOOPBACK FAILURE (STORED) - MANUAL A/C

When Monitored: When the A/C - Heater Control Module executes an internal loopback

test.

Set Condition: If the A/C - Heater Control Module fails to send a message, or none of the

expected messages arrive for 5 seconds, an internal loopback test is executed. If the

internal loopback test fails, the DTC will set.

LOOPBACK TEST FAILURE (STORED) - MANUAL A/C

When Monitored: When the A/C - Heater Control Module executes an internal loopback

test.

Set Condition: If the A/C - Heater Control Module fails to send a message, or none of the

expected messages arrive for 5 seconds, an internal loopback test is executed. If the

internal loopback test fails, the DTC will set.

MODE OVERCURRENT (STORED) - MANUAL A/C

When Monitored: When actuator movement is requested.

Set Condition: All (Blend, Mode, Recirc, and Zone) Overcurrent DTCs will set if the A/C

- Heater Control Module detects an excessive current draw on the Common Door Drive

circuit(s).

515

HEATING & A/C

A/C FAULT (STORED) - MANUAL A/C ÐContinued

Page 561 of 4284

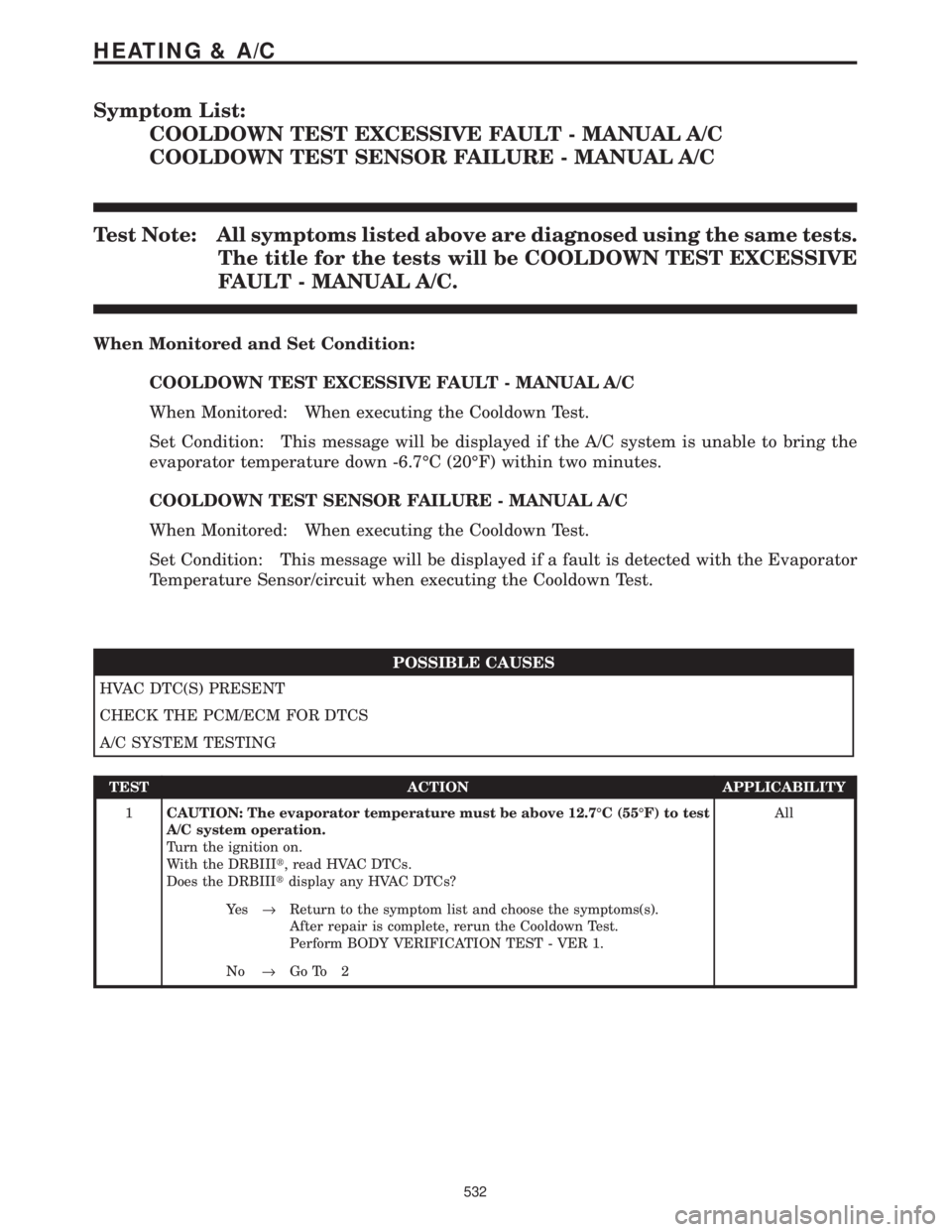

Symptom List:

COOLDOWN TEST EXCESSIVE FAULT - MANUAL A/C

COOLDOWN TEST SENSOR FAILURE - MANUAL A/C

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be COOLDOWN TEST EXCESSIVE

FAULT - MANUAL A/C.

When Monitored and Set Condition:

COOLDOWN TEST EXCESSIVE FAULT - MANUAL A/C

When Monitored: When executing the Cooldown Test.

Set Condition: This message will be displayed if the A/C system is unable to bring the

evaporator temperature down -6.7ÉC (20ÉF) within two minutes.

COOLDOWN TEST SENSOR FAILURE - MANUAL A/C

When Monitored: When executing the Cooldown Test.

Set Condition: This message will be displayed if a fault is detected with the Evaporator

Temperature Sensor/circuit when executing the Cooldown Test.

POSSIBLE CAUSES

HVAC DTC(S) PRESENT

CHECK THE PCM/ECM FOR DTCS

A/C SYSTEM TESTING

TEST ACTION APPLICABILITY

1CAUTION: The evaporator temperature must be above 12.7ÉC (55ÉF) to test

A/C system operation.

Turn the ignition on.

With the DRBIIIt, read HVAC DTCs.

Does the DRBIIItdisplay any HVAC DTCs?All

Ye s®Return to the symptom list and choose the symptoms(s).

After repair is complete, rerun the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

532

HEATING & A/C

Page 564 of 4284

Symptom:

COOLDOWN TEST TOO COLD TO START - MANUAL A/C

When Monitored and Set Condition:

COOLDOWN TEST TOO COLD TO START - MANUAL A/C

When Monitored: When executing the Cooldown Test.

Set Condition: This message will be displayed if the A/C - Heater Control Module sees

evaporator temperature below 12.7ÉC (55ÉF) when executing the Cooldown Test.

POSSIBLE CAUSES

EVAPORATOR TEMPERATURE TOO LOW

HVAC DTC(S) PRESENT

CHECK THE PCM/ECM FOR DTCS

EVAPORATOR TEMPERATURE SENSOR

SENSOR GROUND CIRCUIT HIGH RESISTANCE

EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT HIGH RESISTANCE

A/C - HEATER CONTROL MODULE

TEST ACTION APPLICABILITY

1CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Start the engine.

Turn the A/C off.

Turn the Blower on high. Allow the blower to run for 5 minutes to ensure that the

Evaporator Temperature Sensor temperature is above 12.7ÉC (55ÉF).

With the DRBIIIt, actuate the Cooldown Test.

Does the DRBIIItdisplay: Cooldown Test Too Cold To Start?All

Ye s®Go To 2

No®Perform additional testing as necessary.

Perform BODY VERIFICATION TEST - VER 1.

2CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Turn the ignition on.

With the DRBIIIt, read HVAC DTCs.

Does the DRBIIItdisplay any HVAC DTCs?All

Ye s®Return to the symptom list and choose the symptom(s). After the

repair is complete, with the DRBIIIt, erase the DTC(s). Cycle the

ignition switch. With the DRBIIIt, actuate the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

535

HEATING & A/C

Page 565 of 4284

TEST ACTION APPLICABILITY

3CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Turn the ignition on.

With the DRBIIIt, check the PCM/ECM for DTCs.

Are any DTCs present?All

Ye s®Refer to Powertrain Diagnostic information for the related symp-

tom(s). After the repair is complete, with the DRBIIIt, erase the

DTC(s). Cycle the ignition switch. With the DRBIIIt, actuate the

Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Is the voltage above 4.9 volts?All

Ye s®Go To 5

No®Go To 6

5 Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Connect a jumper wire between the Evaporator Temperature Sensor Signal circuit

and the Sensor Ground circuit at the Evaporator Temperature Sensor harness

connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Is the voltage 0.0 volts?All

Ye s®Replace the Evaporator Temperature Sensor in accordance with

the Service Information. After repair is complete, rerun the

Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6NOTE: Ensure that the voltmeter leads meet the terminals in the connector

and that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity.

Back probe the Sensor Ground circuit between the Evaporator Temperature Sensor

harness connector and the A/C - Heater Control Module C1 harness connector.

Turn the ignition on.

Is the voltage below 0.10 volt?All

Ye s®Go To 7

No®Repair the high resistance in the Sensor Ground circuit. After

repair is complete, rerun the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

536

HEATING & A/C

COOLDOWN TEST TOO COLD TO START - MANUAL A/C ÐContinued

Page 566 of 4284

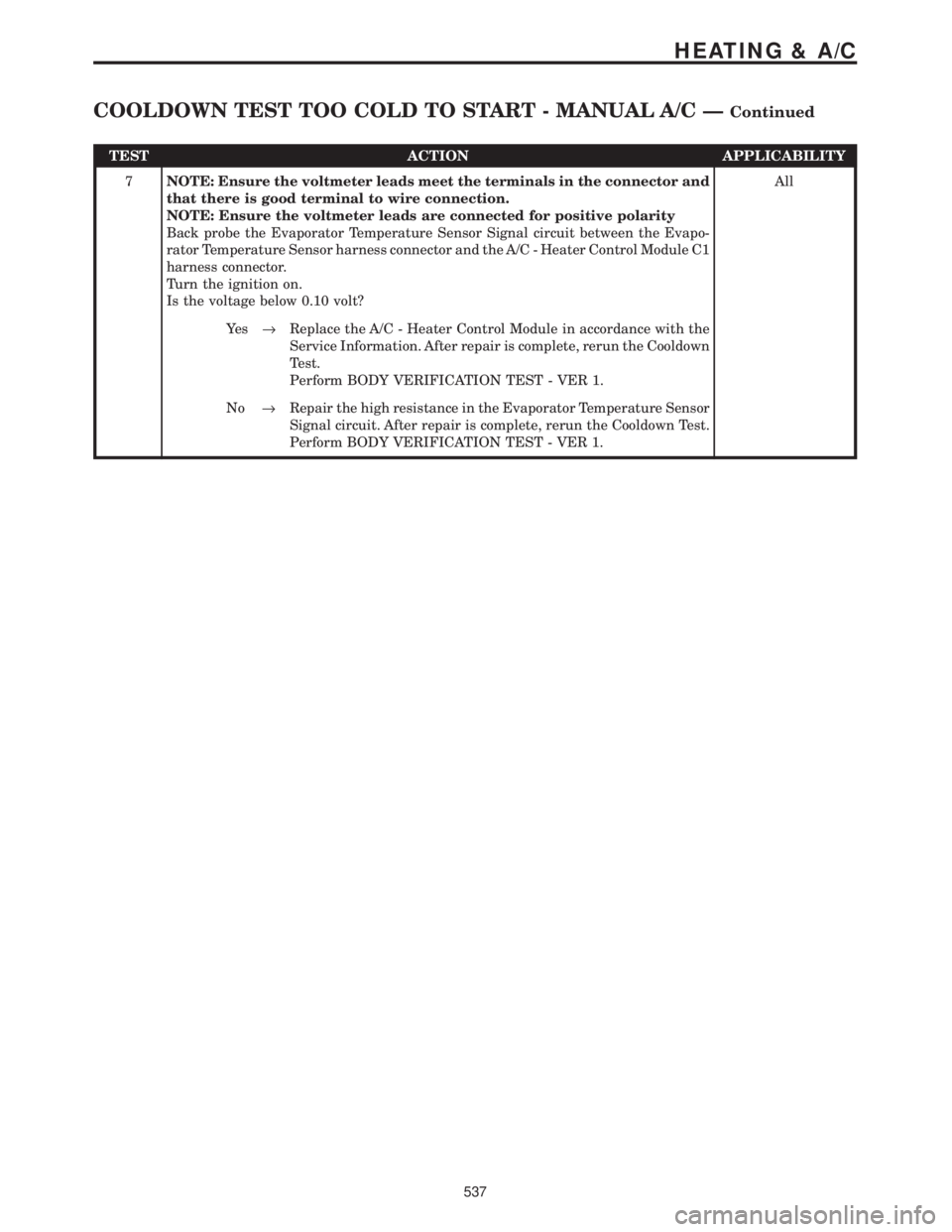

TEST ACTION APPLICABILITY

7NOTE: Ensure the voltmeter leads meet the terminals in the connector and

that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity

Back probe the Evaporator Temperature Sensor Signal circuit between the Evapo-

rator Temperature Sensor harness connector and the A/C - Heater Control Module C1

harness connector.

Turn the ignition on.

Is the voltage below 0.10 volt?All

Ye s®Replace the A/C - Heater Control Module in accordance with the

Service Information. After repair is complete, rerun the Cooldown

Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Repair the high resistance in the Evaporator Temperature Sensor

Signal circuit. After repair is complete, rerun the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

537

HEATING & A/C

COOLDOWN TEST TOO COLD TO START - MANUAL A/C ÐContinued

Page 567 of 4284

Symptom:

EVAPORATOR TEMPERATURE SENSOR CIRCUIT OPEN (ACTIVE)

- MANUAL A/C

When Monitored and Set Condition:

EVAPORATOR TEMPERATURE SENSOR CIRCUIT OPEN (ACTIVE) - MANUAL

A/C

When Monitored: With the ignition on.

Set Condition: This DTC will set if the Evaporator Temperature Sensor/sensor circuit is

open.

POSSIBLE CAUSES

EVAPORATOR TEMPERATURE SENSOR

EVAPORATOR TEMPERATURE SENSOR SIGNAL CIRCUIT OPEN

SENSOR GROUND CIRCUIT OPEN

A/C - HEATER CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Open the glove box door. Disconnect the glove box door roller latch from each side of

the glove box. Roll the glove box downward toward the floor.

Disconnect the in-line C202 harness connector.

Connect a jumper wire between the Evaporator Temperature Sensor Signal circuit

and the Sensor Ground circuit at the in-line C202 harness connector (HVAC side).

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Does the DRBIIItdisplay: 0.0 volts?All

Ye s®Check the wiring harness between the in-line C202 harness

connector (plenum side) and the Evap Temp Sensor for an open.

Repair as necessary. If Ok, replace the Evaporator Temperature

Sensor in accordance with the Service Information.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 2

538

HEATING & A/C