brake light CHRYSLER VOYAGER 2001 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3708 of 4284

(3) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(4) Remove the brake lamp switch from its mount-

ing bracket. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(5) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm.

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER - REMOV-

AL).

(6) Remove the three screws that secure the heater

core shield to the left end of the HVAC distribution

housing (Fig. 17).

(7) Pull the heater core shield rearward far enough

to disengage the two location tabs that position the

front of the shield to the receptacles in the two lower

finger formations of the evaporator housing near the

dash panel.

(8) Remove the heater core shield from the distri-

bution housing.

(9) Take the proper precautions to protect the car-

peting below the heater core from spilled engine cool-

ant and have absorbent toweling readily available to

mop up any spills.

(10) Remove the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports (Fig. 18).

(11) Push both heater core tubes simultaneously

toward the dash panel far enough to disengage their

fittings from the heater core supply and return ports.(12) Install plugs in, or tape over the opened

heater core tube fittings and both heater core ports.

(13) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation.

(14) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

(15) While pulling the accelerator pedal upward

(Fig. 19) and pushing the brake pedal downward

(Fig. 20) far enough for clearance, pull the heater

core out of the distribution housing.

Fig. 17 Heater Core Shield

1 - HEATER/ AIR CONDITIONER HOUSING

2 - HEATER CORE SHIELD

3 - DISTRIBUTION HOUSING

4 - SCREWS (3)

5 - LOCATION TABS (2)

Fig. 18 Heater Core

1 - SEALING PLATE

2 - SCREW

3 - SCREWS (2)

4 - HEATER CORE

5 - HEATER CORE TUBES

Fig. 19 Accelerator Pedal

1 - SLIDE HEATER CORE PAST ACCELERATOR PEDAL

24 - 78 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 3710 of 4284

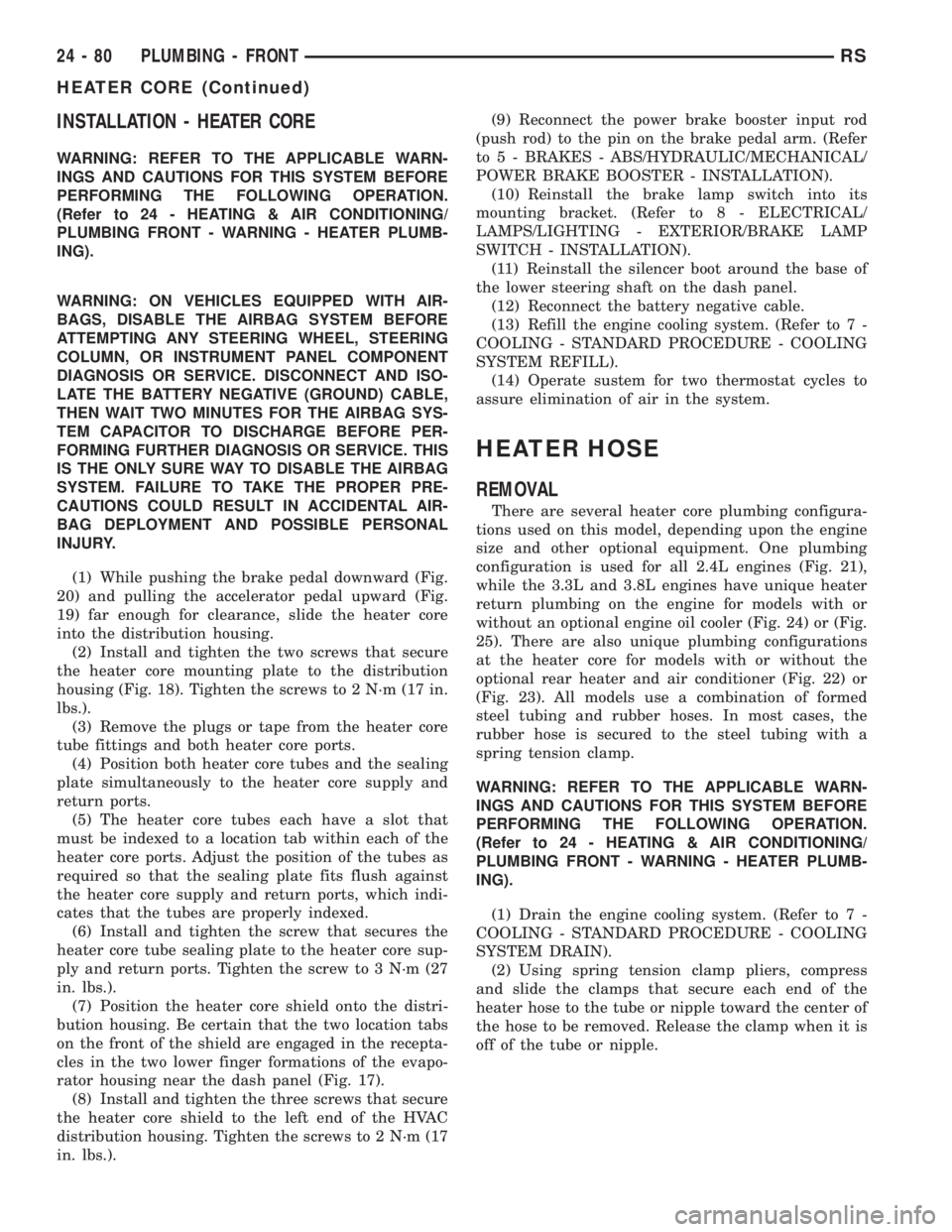

INSTALLATION - HEATER CORE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) While pushing the brake pedal downward (Fig.

20) and pulling the accelerator pedal upward (Fig.

19) far enough for clearance, slide the heater core

into the distribution housing.

(2) Install and tighten the two screws that secure

the heater core mounting plate to the distribution

housing (Fig. 18). Tighten the screws to 2 N´m (17 in.

lbs.).

(3) Remove the plugs or tape from the heater core

tube fittings and both heater core ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

(5) The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes as

required so that the sealing plate fits flush against

the heater core supply and return ports, which indi-

cates that the tubes are properly indexed.

(6) Install and tighten the screw that secures the

heater core tube sealing plate to the heater core sup-

ply and return ports. Tighten the screw to 3 N´m (27

in. lbs.).

(7) Position the heater core shield onto the distri-

bution housing. Be certain that the two location tabs

on the front of the shield are engaged in the recepta-

cles in the two lower finger formations of the evapo-

rator housing near the dash panel (Fig. 17).

(8) Install and tighten the three screws that secure

the heater core shield to the left end of the HVAC

distribution housing. Tighten the screws to 2 N´m (17

in. lbs.).(9) Reconnect the power brake booster input rod

(push rod) to the pin on the brake pedal arm. (Refer

to 5 - BRAKES - ABS/HYDRAULIC/MECHANICAL/

POWER BRAKE BOOSTER - INSTALLATION).

(10) Reinstall the brake lamp switch into its

mounting bracket. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION).

(11) Reinstall the silencer boot around the base of

the lower steering shaft on the dash panel.

(12) Reconnect the battery negative cable.

(13) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(14) Operate sustem for two thermostat cycles to

assure elimination of air in the system.

HEATER HOSE

REMOVAL

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines (Fig. 21),

while the 3.3L and 3.8L engines have unique heater

return plumbing on the engine for models with or

without an optional engine oil cooler (Fig. 24) or (Fig.

25). There are also unique plumbing configurations

at the heater core for models with or without the

optional rear heater and air conditioner (Fig. 22) or

(Fig. 23). All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

(1) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose to the tube or nipple toward the center of

the hose to be removed. Release the clamp when it is

off of the tube or nipple.

24 - 80 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 3767 of 4284

PCV VALVE

DESCRIPTION

The PCV valve contains a spring loaded plunger.

The plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

OPERATION

When the engine is not operating or during an

engine backfire, the spring forces the plunger back

against the seat. This prevents vapors from flowing

through the valve (Fig. 8).

When the engine is at idle or cruising, high mani-

fold vacuum is present. At these times manifold vac-

uum is able to completely compress the spring and

pull the plunger to the top of the valve (Fig. 9). In

this position there is minimal vapor flow through the

valve.During periods of moderate intake manifold vac-

uum the plunger is only pulled part way back from

the inlet. This results in maximum vapor flow

through the valve (Fig. 10).

DIAGNOSIS AND TESTING - PCV SYSTEM

INSPECTION

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE PERFORMING ANY TEST

OR ADJUSTMENT WITH THE ENGINE OPERATING.

(1) With engine idling, remove the hose from the

PCV valve. If the valve is not plugged, a hissing

noise will be heard as air passes through the valve. A

strong vacuum should also be felt when a finger is

placed over the valve inlet.

(2) Install hose on PCV valve. Remove the

make-up air hose from the air plenum at the rear of

the engine. Hold a piece of stiff paper (parts tag)

loosely over the end of the make-up air hose.

(3)

After allowing approximately one minute for

crankcase pressure to reduce, the paper should draw up

against the hose with noticeable force. If the engine

does not draw the paper against the grommet after

installing a new valve, replace the PCV valve hose.

(4)Turn the engine off. Remove the PCV valve from

intake manifold. The valve should rattle when shaken.

(5) Replace the PCV valve and retest the system if

it does not operate as described in the preceding

tests.Do not attempt to clean the old PCV valve.

If the valve rattles, apply a light coating of Loctitet

Pipe Sealant With Teflon to the threads. Thread the

PCV valve into the manifold plenum and tighten to 7

N´m (60 in. lbs.) torque.

Fig. 7 PCV VALVE 2.4L

1 - PCV Valve

Fig. 8 Engine Off or Engine Backfire No Vapor Flow

Fig. 9 High Intake Manifold Vacuum Minimal Vapor

Flow

Fig. 10 Moderate Intake Manifold Vacuum Maximum

Vapor Flow

RSEVAPORATIVE EMISSIONS25-17

Page 3804 of 4284

SYMPTOM DIAGNOSTIC TEST

POOR FUEL ECONOMY CHECKING PCM POWER AND GND CKT

CHECKING THE FUEL PRESSURE

CHECKING ECT SENSOR

CHECKING THROTTLE POSITION SENSOR

CHECKING MAP SENSOR

CHECKING IDLE AIR CONTROL MOTOR OPERATION

CHECKING IAT SENSOR

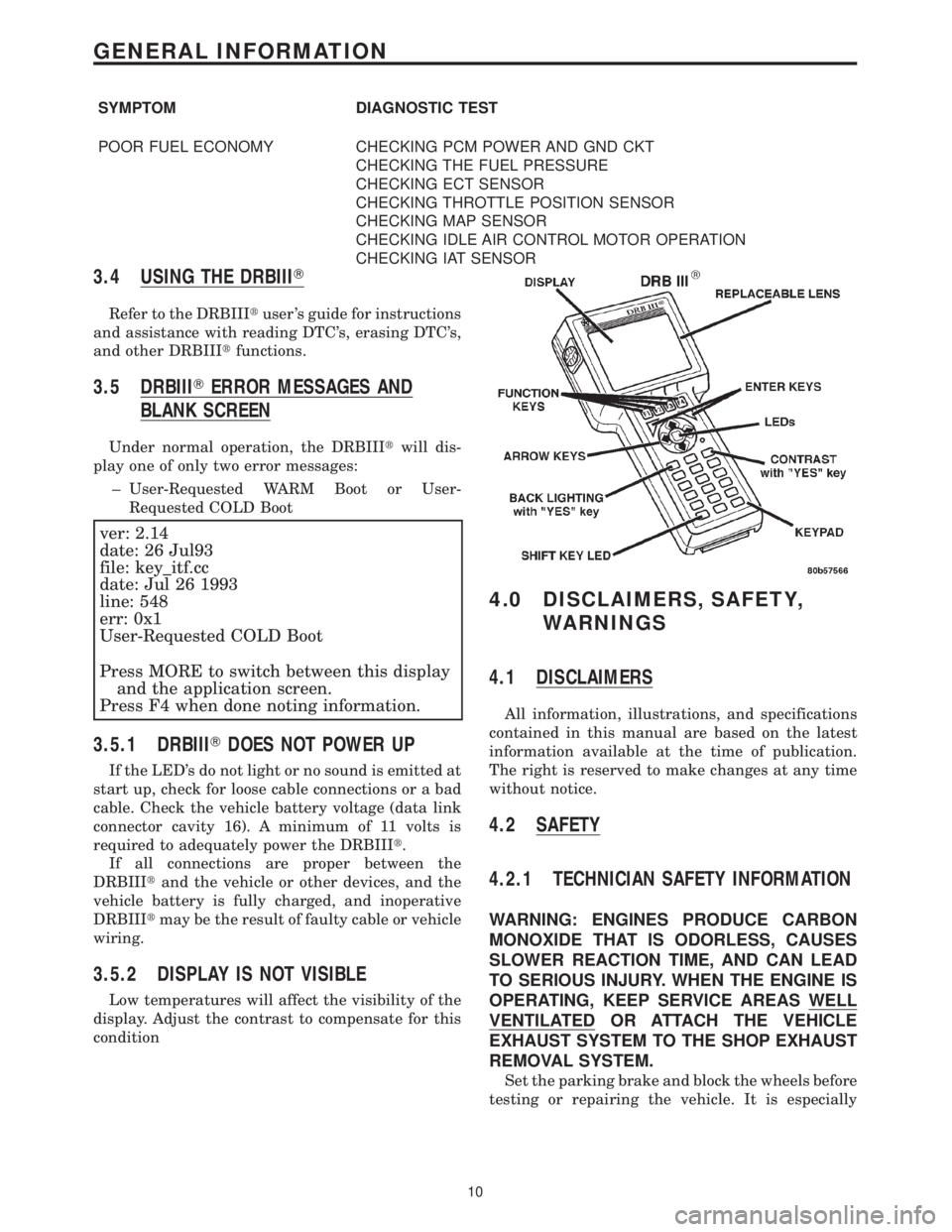

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading DTC's, erasing DTC's,

and other DRBIIItfunctions.

3.5 DRBIIITERROR MESSAGES AND

BLANK SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRBIIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand the vehicle or other devices, and the

vehicle battery is fully charged, and inoperative

DRBIIItmay be the result of faulty cable or vehicle

wiring.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially

10

GENERAL INFORMATION

Page 3806 of 4284

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second DTC could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

Evaporative System Diagnostic Kit #6917

fuel filler adapter #8382

fuel pressure adapter (C-6631) or #6539

fuel pressure kit (C-4799-B) or #5069

fuel release hose (C-4799-1)

Min Air flow fitting #6714

jumper wires

ohmmeter

oscilloscope

vacuum gauge

voltmeter

12 volt test light minimum 25 ohms resistance

with probe #6801

CAUTION: A 12 VOLT TEST LIGHT SHOULD

NOT BE USED FOR THE FOLLOWING

CIRCUITS, DAMAGE TO THE POWERTRAIN

CONTROLLER WILL OCCUR.

²5 Volt Supply

²8 Volt Supply

²J1850 PCI Bus

²CCD Bus

²CKP Sensor Signal

²CMP Sensor Signal

²Vehicle Speed Sensor Signal

²O2 Sensor Signal

6.0 GLOSSARY OF TERMS

ABSanti-lock brake system

backfire,

popbackfuel ignites in either the intake or

the exhaust system

CKPcrank position sensor

CMPcamshaft position sensorcuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector (previously

called engine diagnostic connector)

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECTengine coolant temperature sensor

EGRexhaust gas recirculation valve

genera-

torpreviously called alternator

hard

startThe engine takes longer than usual

to start, even though it is able to

crank normally.

hesita-

tion, sag,

stumbleThere is a momentary lack of re-

sponse when the throttle is opened.

This can occur at all vehicle speeds.

If it is severe enough, the engine

may stall.

IATintake air temperature sensor

IACidle air control motor

JTECCombined engine and transmission

control module

lack of

power,

sluggishThe engine has less than expected

power, with little or no increase in

vehicle speed when the throttle is

opened.

LDPleak detection pump

MAPmanifold absolute pressure sensor

MILmalfunction indicator lamp

MTVmanifold tuning valve

O2Soxygen sensor

PCIprogrammable communication inter-

face

PCMpowertrain control module

PCVpositive crankcase ventilation

PEPperipheral expansion port

poor fuel

economyThere is significantly less fuel mile-

age than other vehicles of the same

design ad configuration

12

GENERAL INFORMATION

Page 3956 of 4284

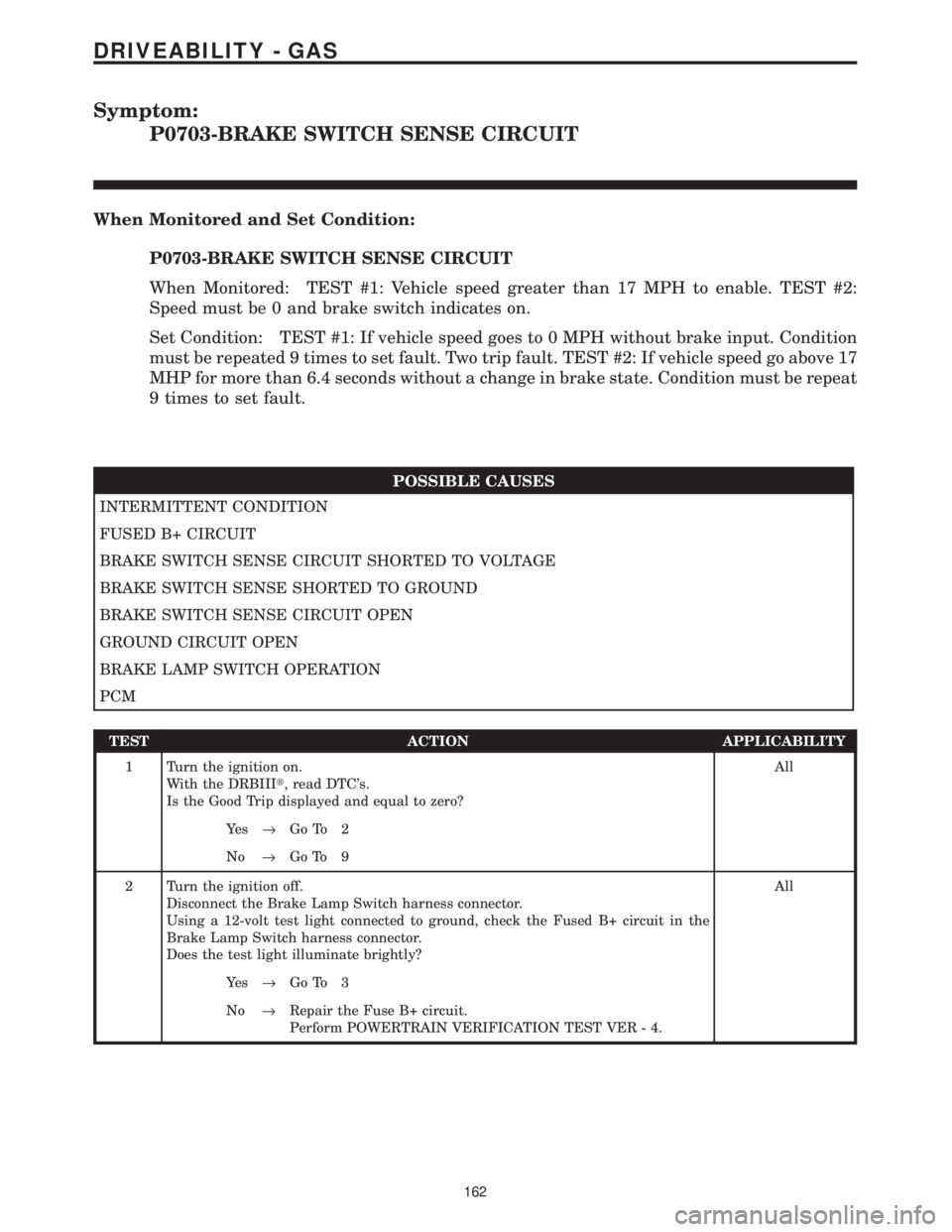

Symptom:

P0703-BRAKE SWITCH SENSE CIRCUIT

When Monitored and Set Condition:

P0703-BRAKE SWITCH SENSE CIRCUIT

When Monitored: TEST #1: Vehicle speed greater than 17 MPH to enable. TEST #2:

Speed must be 0 and brake switch indicates on.

Set Condition: TEST #1: If vehicle speed goes to 0 MPH without brake input. Condition

must be repeated 9 times to set fault. Two trip fault. TEST #2: If vehicle speed go above 17

MHP for more than 6.4 seconds without a change in brake state. Condition must be repeat

9 times to set fault.

POSSIBLE CAUSES

INTERMITTENT CONDITION

FUSED B+ CIRCUIT

BRAKE SWITCH SENSE CIRCUIT SHORTED TO VOLTAGE

BRAKE SWITCH SENSE SHORTED TO GROUND

BRAKE SWITCH SENSE CIRCUIT OPEN

GROUND CIRCUIT OPEN

BRAKE LAMP SWITCH OPERATION

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 9

2 Turn the ignition off.

Disconnect the Brake Lamp Switch harness connector.

Using a 12-volt test light connected to ground, check the Fused B+ circuit in the

Brake Lamp Switch harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Fuse B+ circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

162

DRIVEABILITY - GAS

Page 4045 of 4284

TEST ACTION APPLICABILITY

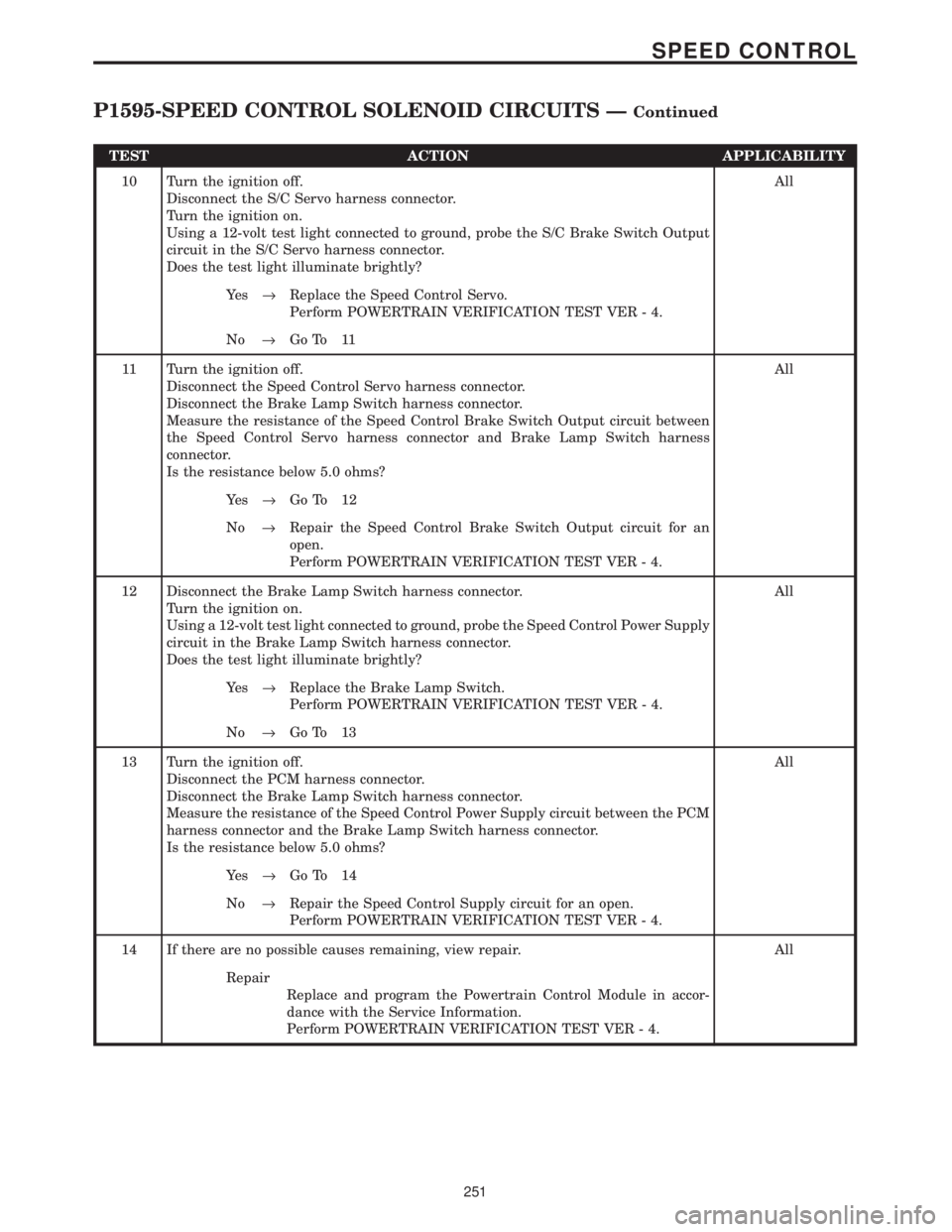

10 Turn the ignition off.

Disconnect the S/C Servo harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the S/C Brake Switch Output

circuit in the S/C Servo harness connector.

Does the test light illuminate brightly?All

Ye s®Replace the Speed Control Servo.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

No®Go To 11

11 Turn the ignition off.

Disconnect the Speed Control Servo harness connector.

Disconnect the Brake Lamp Switch harness connector.

Measure the resistance of the Speed Control Brake Switch Output circuit between

the Speed Control Servo harness connector and Brake Lamp Switch harness

connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 12

No®Repair the Speed Control Brake Switch Output circuit for an

open.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

12 Disconnect the Brake Lamp Switch harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Speed Control Power Supply

circuit in the Brake Lamp Switch harness connector.

Does the test light illuminate brightly?All

Ye s®Replace the Brake Lamp Switch.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

No®Go To 13

13 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Brake Lamp Switch harness connector.

Measure the resistance of the Speed Control Power Supply circuit between the PCM

harness connector and the Brake Lamp Switch harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 14

No®Repair the Speed Control Supply circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

14 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 4.

251

SPEED CONTROL

P1595-SPEED CONTROL SOLENOID CIRCUITS ÐContinued

Page 4053 of 4284

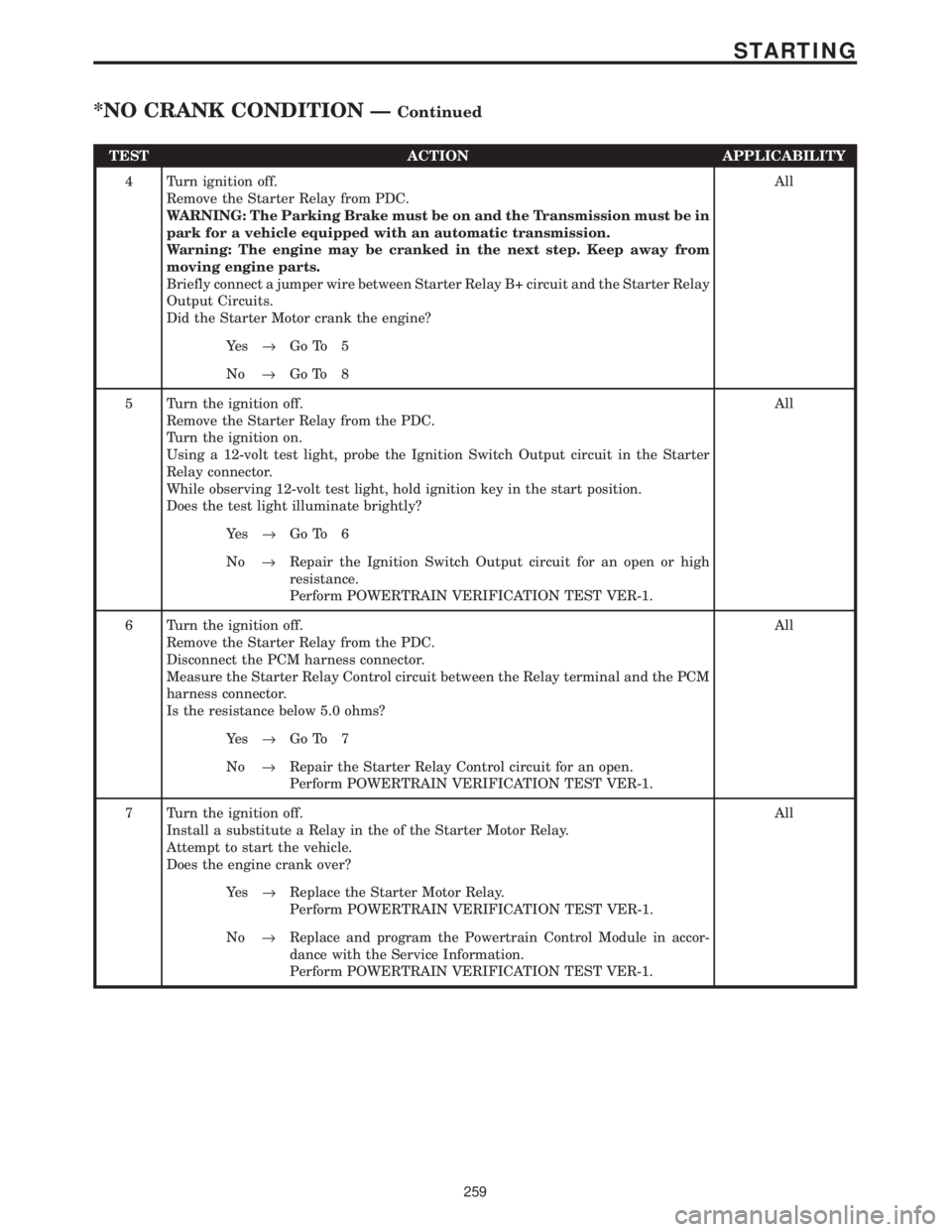

TEST ACTION APPLICABILITY

4 Turn ignition off.

Remove the Starter Relay from PDC.

WARNING: The Parking Brake must be on and the Transmission must be in

park for a vehicle equipped with an automatic transmission.

Warning: The engine may be cranked in the next step. Keep away from

moving engine parts.

Briefly connect a jumper wire between Starter Relay B+ circuit and the Starter Relay

Output Circuits.

Did the Starter Motor crank the engine?All

Ye s®Go To 5

No®Go To 8

5 Turn the ignition off.

Remove the Starter Relay from the PDC.

Turn the ignition on.

Using a 12-volt test light, probe the Ignition Switch Output circuit in the Starter

Relay connector.

While observing 12-volt test light, hold ignition key in the start position.

Does the test light illuminate brightly?All

Ye s®Go To 6

No®Repair the Ignition Switch Output circuit for an open or high

resistance.

Perform POWERTRAIN VERIFICATION TEST VER-1.

6 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the PCM harness connector.

Measure the Starter Relay Control circuit between the Relay terminal and the PCM

harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 7

No®Repair the Starter Relay Control circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

7 Turn the ignition off.

Install a substitute a Relay in the of the Starter Motor Relay.

Attempt to start the vehicle.

Does the engine crank over?All

Ye s®Replace the Starter Motor Relay.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER-1.

259

STARTING

*NO CRANK CONDITION ÐContinued

Page 4072 of 4284

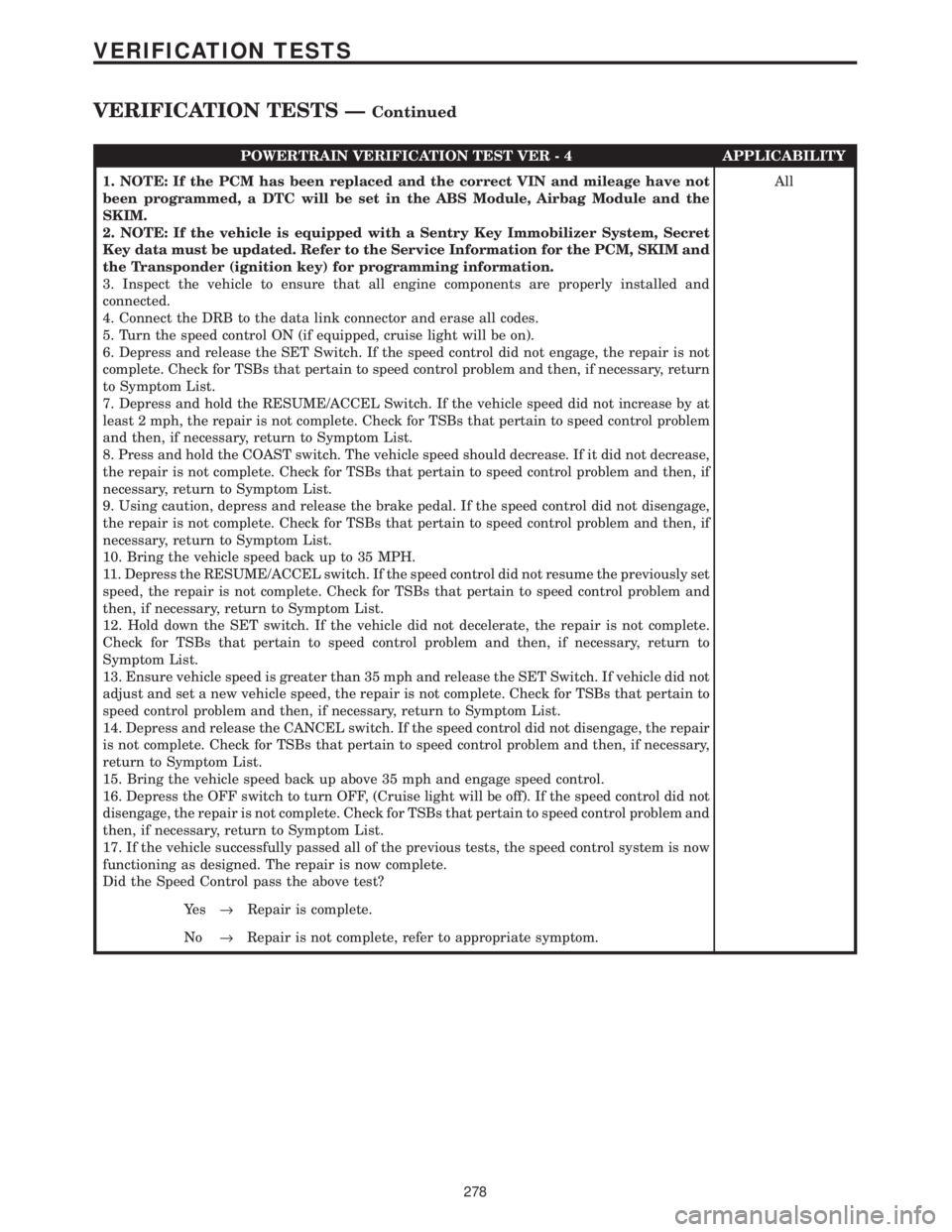

POWERTRAIN VERIFICATION TEST VER - 4 APPLICABILITY

1. NOTE: If the PCM has been replaced and the correct VIN and mileage have not

been programmed, a DTC will be set in the ABS Module, Airbag Module and the

SKIM.

2. NOTE: If the vehicle is equipped with a Sentry Key Immobilizer System, Secret

Key data must be updated. Refer to the Service Information for the PCM, SKIM and

the Transponder (ignition key) for programming information.

3. Inspect the vehicle to ensure that all engine components are properly installed and

connected.

4. Connect the DRB to the data link connector and erase all codes.

5. Turn the speed control ON (if equipped, cruise light will be on).

6. Depress and release the SET Switch. If the speed control did not engage, the repair is not

complete. Check for TSBs that pertain to speed control problem and then, if necessary, return

to Symptom List.

7. Depress and hold the RESUME/ACCEL Switch. If the vehicle speed did not increase by at

least 2 mph, the repair is not complete. Check for TSBs that pertain to speed control problem

and then, if necessary, return to Symptom List.

8. Press and hold the COAST switch. The vehicle speed should decrease. If it did not decrease,

the repair is not complete. Check for TSBs that pertain to speed control problem and then, if

necessary, return to Symptom List.

9. Using caution, depress and release the brake pedal. If the speed control did not disengage,

the repair is not complete. Check for TSBs that pertain to speed control problem and then, if

necessary, return to Symptom List.

10. Bring the vehicle speed back up to 35 MPH.

11. Depress the RESUME/ACCEL switch. If the speed control did not resume the previously set

speed, the repair is not complete. Check for TSBs that pertain to speed control problem and

then, if necessary, return to Symptom List.

12. Hold down the SET switch. If the vehicle did not decelerate, the repair is not complete.

Check for TSBs that pertain to speed control problem and then, if necessary, return to

Symptom List.

13. Ensure vehicle speed is greater than 35 mph and release the SET Switch. If vehicle did not

adjust and set a new vehicle speed, the repair is not complete. Check for TSBs that pertain to

speed control problem and then, if necessary, return to Symptom List.

14. Depress and release the CANCEL switch. If the speed control did not disengage, the repair

is not complete. Check for TSBs that pertain to speed control problem and then, if necessary,

return to Symptom List.

15. Bring the vehicle speed back up above 35 mph and engage speed control.

16. Depress the OFF switch to turn OFF, (Cruise light will be off). If the speed control did not

disengage, the repair is not complete. Check for TSBs that pertain to speed control problem and

then, if necessary, return to Symptom List.

17. If the vehicle successfully passed all of the previous tests, the speed control system is now

functioning as designed. The repair is now complete.

Did the Speed Control pass the above test?All

Ye s®Repair is complete.

No®Repair is not complete, refer to appropriate symptom.

278

VERIFICATION TESTS

VERIFICATION TESTS ÐContinued

Page 4250 of 4284

Symptom:

*BRAKE SHIFT INTERLOCK OUTPUT OPEN

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

BRAKE SHIFT INTERLOCK CONTROL CIRCUIT OPEN

BRAKE SHIFT INTERLOCK FEED CIRCUIT OPEN

BRAKE SHIFT INTERLOCK SOLENOID

FRONT CONTROL MODULE

TEST ACTION APPLICABILITY

1 Ignition on, engine not running.

With the DRBIIIt, record and erase DTC's.

Turn the ignition off to the lock position.

Turn the ignition on.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay BRAKE SHIFT INTERLOCK OUTPUT OPEN?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off to the lock position.

Disconnect the Brake Shift Interlock harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to B+, check the Brake Shift Interlock Control

circuit in the Brake Shift Interlock harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 6

3 Turn the ignition off to the lock position.

Disconnect the Brake Shift Interlock harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Using a 12-volt test light connected to ground, check the Brake Shift Interlock Feed

circuit in the Brake Shift Interlock harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 4

No®Go To 5

4 If there are no possible causes remaining, view repair. All

Repair

Replace the Brake Shift Interlock Solenoid in accordance with the

Service Information.

146

TRANSMISSION