brake light CHRYSLER VOYAGER 2001 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1694 of 4284

tem enters the ABS mode. During ABS braking,

hydraulic pressure in the four wheel circuits is mod-

ulated to prevent any wheel from locking. Each

wheel circuit is designed with a set of electric sole-

noids to allow modulation, although for vehicle sta-

bility, both rear wheel solenoids receive the same

electrical signal. Wheel lockup may be perceived at

the very end of an ABS stop and is considered nor-

mal.

During an ABS stop, the brakes hydraulic system

is still diagonally split. However, the brake system

pressure is further split into three control channels.

During antilock operation of the vehicle's brake sys-

tem, the front wheels are controlled independently

and are on two separate control channels, and the

rear wheels of the vehicle are controlled together.

The system can build and release pressure at each

wheel, depending on signals generated by the wheel

speed sensors (WSS) at each wheel and received at

the controller antilock brake (CAB).

NOISE AND BRAKE PEDAL FEEL

During ABS braking, some brake pedal movement

may be felt. In addition, ABS braking will create

ticking, popping, or groaning noises heard by the

driver. This is normal and is due to pressurized fluid

being transferred between the master cylinder and

the brakes. If ABS operation occurs during hard

braking, some pulsation may be felt in the vehicle

body due to fore and aft movement of the suspension

as brake pressures are modulated.

At the end of an ABS stop, ABS is turned off when

the vehicle is slowed to a speed of 3±4 mph. There

may be a slight brake pedal drop anytime that the

ABS is deactivated, such as at the end of the stop

when the vehicle speed is less than 3 mph or during

an ABS stop where ABS is no longer required. These

conditions exist when a vehicle is being stopped on a

road surface with patches of ice, loose gravel, or sand

on it. Also, stopping a vehicle on a bumpy road sur-

face activates ABS because of the wheel hop caused

by the bumps.

TIRE NOISE AND MARKS

Although the ABS system prevents complete wheel

lockup, some wheel slip is desired in order to achieve

optimum braking performance. Wheel slip is defined

as follows: 0 percent slip means the wheel is rolling

freely and 100 percent slip means the wheel is fully

locked. During brake pressure modulation, wheel slip

is allowed to reach up to 25±30 percent. This means

that the wheel rolling velocity is 25±30 percent less

than that of a free rolling wheel at a given vehicle

speed. This slip may result in some tire chirping,

depending on the road surface. This sound should not

be interpreted as total wheel lockup.Complete wheel lockup normally leaves black tire

marks on dry pavement. The ABS will not leave dark

black tire marks since the wheel never reaches a

fully locked condition. However, tire marks may be

noticeable as light patched marks.

START-UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

The ABS warning lamp will also be on for up to 5

seconds after the ignition is turned on. When the

vehicle is first driven off, a humming may be heard

or felt by the driver at approximately 20±40 kph

(12±25 mph). All of these conditions are a normal

function of ABS as the system is performing a diag-

nosis check.

PREMATURE ABS CYCLING

Symptoms of premature ABS cycling include: click-

ing sounds from the solenoid valves; pump/motor

running; and pulsations in the brake pedal. Prema-

ture ABS cycling can occur at any braking rate of the

vehicle and on any type of road surface. Neither the

red BRAKE warning lamp, nor the amber ABS warn-

ing lamp, illuminate and no fault codes are stored in

the CAB.

Premature ABS cycling is a condition that needs to

be correctly assessed when diagnosing problems with

the antilock brake system. It may be necessary to use

a DRB scan tool to detect and verify premature ABS

cycling.

Check the following common causes when diagnos-

ing premature ABS cycling: damaged tone wheels;

incorrect tone wheels; damaged steering knuckle

wheel speed sensor mounting bosses; loose wheel

speed sensor mounting bolts; excessive tone wheel

runout; or an excessively large tone wheel-to-wheel

speed sensor air gap. Give special attention to these

components when diagnosing a vehicle exhibiting

premature ABS cycling.

After diagnosing the defective component, repair or

replace it as required. When the component repair or

replacement is completed, test drive the vehicle to

verify that premature ABS cycling has been cor-

rected.

OPERATION - ELECTRONIC BRAKE

DISTRIBUTION

Upon entry into EBD the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

5 - 68 BRAKES - ABSRS

BRAKES - ABS (Continued)

Page 1695 of 4284

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases the

pressure to the rear brakes. This back-and-forth pro-

cess will continue until the required slip difference is

obtained. At the end of EBD braking (brakes

released) the fluid in the LPA drains back to the

master cylinder by switching on the outlet valve and

draining through the inlet valve check valve. At the

same time the inlet valve is switched on in case of

another brake application.

The EBD will remain functional during many ABS

fault modes. If both the red BRAKE, and amber ABS

warning indicators are illuminated, the EBD may not

be functioning.

OPERATION - TRACTION CONTROL SYSTEM

The traction control module monitors wheel speed.

During acceleration, if the module detects front

(drive) wheel slip and the brakes are not applied, the

module enters traction control mode. Traction control

operation proceeds in the following order:

(1) Close the normally open isolation valves.

(2) Start the pump/motor and supply volume and

pressure to the front (drive) hydraulic circuit. (The

pump/motor runs continuously during traction con-

trol operation.)

(3) Open and close the build and decay valves to

maintain minimum wheel slip and maximum trac-

tion.

The cycling of the build and decay valves during

traction control is similar to that during antilock

braking, except the valves work to control wheel spin

by applying the brakes, whereas the ABS function is

to control wheel skid by releasing the brakes.

If the brakes are applied at anytime during a trac-

tion control cycle, the brake lamp switch triggers the

controller to switch off traction control.

HYDRAULIC SHUTTLE VALVES

Two pressure relief hydraulic shuttle valves allow

pressure and volume to return to the master cylinder

reservoir when not consumed by the build and decay

valves. These valves are necessary because the

pump/motor supplies more volume than the system

requires.

TRACTION CONTROL LAMP

The traction control system is enabled at each igni-

tion cycle. It may be turned off by depressing the

Traction Control Off switch button when the ignition

is in the ON position. The traction control function

lamp (TRAC OFF) illuminates immediately upon

depressing the button.

The traction control function lamp illuminates dur-

ing a traction control cycle, displaying TRAC.If the CAB calculates that the brake temperatures

are high, the traction control system becomes inoper-

ative until a time-out period has elapsed. During this

ªthermo-protection mode,º the traction control func-

tion lamp illuminates TRAC OFF; note that no trou-

ble code is registered.

CAUTION

The ABS uses an electronic control module, the

CAB. This module is designed to withstand normal

current draws associated with vehicle operation.

Care must be taken to avoid overloading the CAB

circuits.

CAUTION: In testing for open or short circuits, do

not ground or apply voltage to any of the circuits

unless instructed to do so for a diagnostic proce-

dure.

CAUTION: These circuits should only be tested

using a high impedance multi-meter or the DRBIIIT

scan tool as described in this section. Power

should never be removed or applied to any control

module with the ignition in the ON position. Before

removing or connecting battery cables, fuses, or

connectors, always turn the ignition to the OFF

position.

CAUTION: The CAB 24-way connector should never

be connected or disconnected with the ignition

switch in the ON position.

CAUTION: Use only factory wiring harnesses. Do

not cut or splice wiring to the brake circuits. The

addition of aftermarket electrical equipment (car

phone, radar detector, citizen band radio, trailer

lighting, trailer brakes, etc.) on a vehicle equipped

with antilock brakes may affect the function of the

antilock brake system.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS, do not apply a

12-volt power source to the ground circuit of the

pump motor in the HCU. Doing this will damage the

pump motor and will require replacement of the

entire HCU.

CAUTION: An attempt to remove or disconnect cer-

tain system components may result in improper

system operation. Only those components with

approved removal and installation procedures in

this manual should be serviced.

RSBRAKES - ABS5-69

BRAKES - ABS (Continued)

Page 1708 of 4284

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.

(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(4) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

the brake pedal torque shaft pin where it contacts

the brake pedal link.

CAUTION: When installing the power brake booster

input rod on the brake pedal torque shaft pin, do

not reuse the old retaining clip.(6) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 3).

CAUTION: When installing the brake pedal link on

the brake pedal torque shaft pin, do not reuse the

old retaining clip.

(7) Connect the brake pedal link to the torque

shaft. Install a NEW retaining clip at the torque

shaft end of the brake pedal-to-torque shaft link.

(8) Install the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

(9) Install the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(10) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(11) Road test vehicle to ensure proper operation of

the brakes.POWER BRAKE BOOSTER -

RHD

REMOVAL

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4 or 5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

Fig. 4 BOOSTER, TORQUE SHAFT AND PEDAL

MOUNTING

1 - PEDAL MOUNTING NUT

2 - BRAKE PEDAL ASSEMBLY

3 - PEDAL MOUNTING NUT

4 - PEDAL TORQUE SHAFT

5 - BOOSTER MOUNTING NUT

6 - BOOSTER BRACKET

7 - POWER BRAKE BOOSTER

8 - BOOSTER BRACKET MOUNTING NUT

5a - 4 BRAKES - BASERG

PEDAL TORQUE SHAFT (Continued)

Page 1711 of 4284

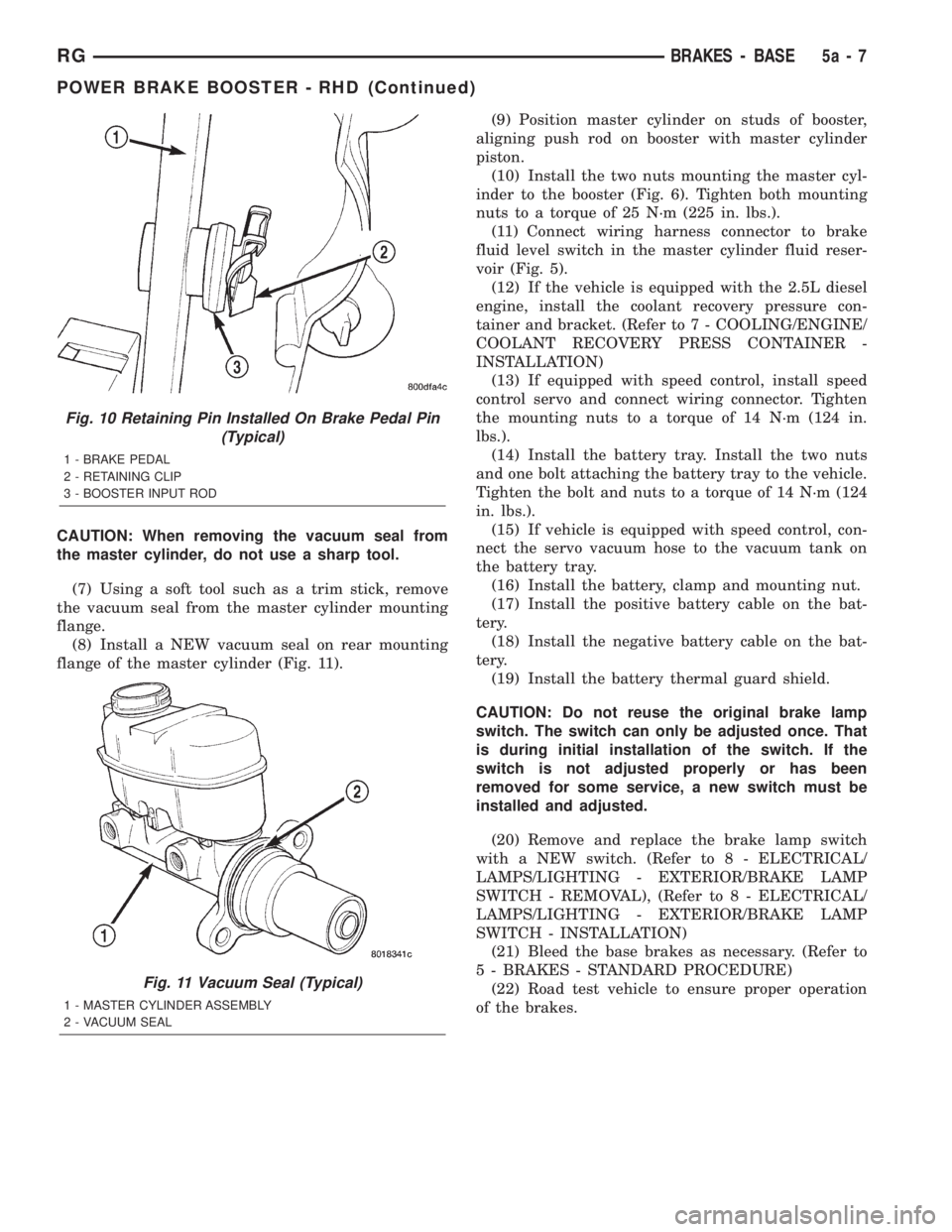

CAUTION: When removing the vacuum seal from

the master cylinder, do not use a sharp tool.

(7) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(8) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 11).(9) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(10) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 6). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(11) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 5).

(12) If the vehicle is equipped with the 2.5L diesel

engine, install the coolant recovery pressure con-

tainer and bracket. (Refer to 7 - COOLING/ENGINE/

COOLANT RECOVERY PRESS CONTAINER -

INSTALLATION)

(13) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).

(14) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(15) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(16) Install the battery, clamp and mounting nut.

(17) Install the positive battery cable on the bat-

tery.

(18) Install the negative battery cable on the bat-

tery.

(19) Install the battery thermal guard shield.

CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(20) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(21) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(22) Road test vehicle to ensure proper operation

of the brakes.

Fig. 10 Retaining Pin Installed On Brake Pedal Pin

(Typical)

1 - BRAKE PEDAL

2 - RETAINING CLIP

3 - BOOSTER INPUT ROD

Fig. 11 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

RGBRAKES - BASE5a-7

POWER BRAKE BOOSTER - RHD (Continued)

Page 1748 of 4284

ENGINE

DIAGNOSIS AND TESTING - ENGINE COOLING

SYSTEM

Establish what driving condition caused the cooling

system complaint. The problem may be caused by an

abnormal load on the system such as the following:

prolonged idle, very high ambient temperature, slight

tail wind at idle, slow traffic speed, traffic jam, high

speed, steep grade.

DRIVING TECHNIQUES

To avoid overheating the cooling system:

(1) Idle with A/C off when temperature gauge is at

end of normal range.

(2) Do not increase engine speed for more air flow

and coolant flow because the electric motor fan sys-

tems are not responsive to engine RPM. The added

cooling from higher coolant flow rate is more than

offset by increased heat rejection (engine heat added

to coolant).

TRAILER TOWING

Consult the owner's manual under Trailer Towing

and do not exceed specified limits.

VISUAL INSPECTION

If the cooling system problem is not caused by a

driving condition, perform a visual inspection to

determine if there was a recent service or accident

repair, including the following:

²Loose/damaged water pump drive belt

²Incorrect cooling system refilling (trapped air or

low level)

²Brakes possibly dragging

²Damaged hoses

²Loose/damaged hose clamps

²Damaged/incorrect engine thermostat

²Damaged cooling fan motor, fan blade and fan

shroud

²Damaged head gasket

²Damaged water pump

²Damaged radiator

²Damaged coolant recovery system

²Damaged heater core

²Open/shorted electrical circuits

If the visual inspection reveals none of the above

as cause for a cooling system complaint, refer to the

following diagnostic charts.

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.1. Check condition of radiator cap

and cap seal. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING) Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING)

7 - 14 ENGINERS

Page 1775 of 4284

COOLING 2.5L TURBO DIESEL

TABLE OF CONTENTS

page page

COOLING 2.5L TURBO DIESEL

DESCRIPTION............................1

DIAGNOSIS AND TESTING..................1

COOLING SYSTEM......................1

COOLING SYSTEM LEAK TEST.............6

COOLING SYSTEM FLOW CHECK..........7COOLING SYSTEM AERATION.............7

CLEANING...............................7

INSPECTION.............................7

SPECIFICATIONS.........................8

ACCESSORY DRIVE.......................9

ENGINE................................14

COOLING 2.5L TURBO DIESEL

DESCRIPTION - COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible, maintains

normal operating temperature and prevents over-

heating.

The cooling system also provides a means of heat-

ing the passenger compartment. The cooling system

is pressurized and uses a centrifugal water pump to

circulate coolant throughout the system. A separate

and remotely mounted, pressurized coolant tank

using a pressure/vent cap is used.

COOLING SYSTEM COMPONENTS

The cooling system consists of:

²Charge Air Cooler

²Electric Cooling Fans

²A aluminum-core radiator with plastic side

tanks

²A separate pressurized coolant tank

²A pressure/vent cap on the coolant tank

²Fan shroud

²Thermostat

²Coolant

²Low coolant warning lamp

²Coolant temperature gauge

²Water pump

²Hoses and hose clamps

DIAGNOSIS AND TESTING - COOLING SYSTEM

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

(1) PROLONGED IDLE, VERY HIGH AMBIENT

TEMPERATURE, SLIGHT TAIL WIND AT IDLE,

SLOW TRAFFIC, TRAFFIC JAMS, HIGH SPEED

OR STEEP GRADES.

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is rec-

ommended.

(2) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(3) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt

²Brakes (possibly dragging)

²Changed parts (incorrect water pump)

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only.

RGCOOLING 2.5L TURBO DIESEL7a-1

Page 1777 of 4284

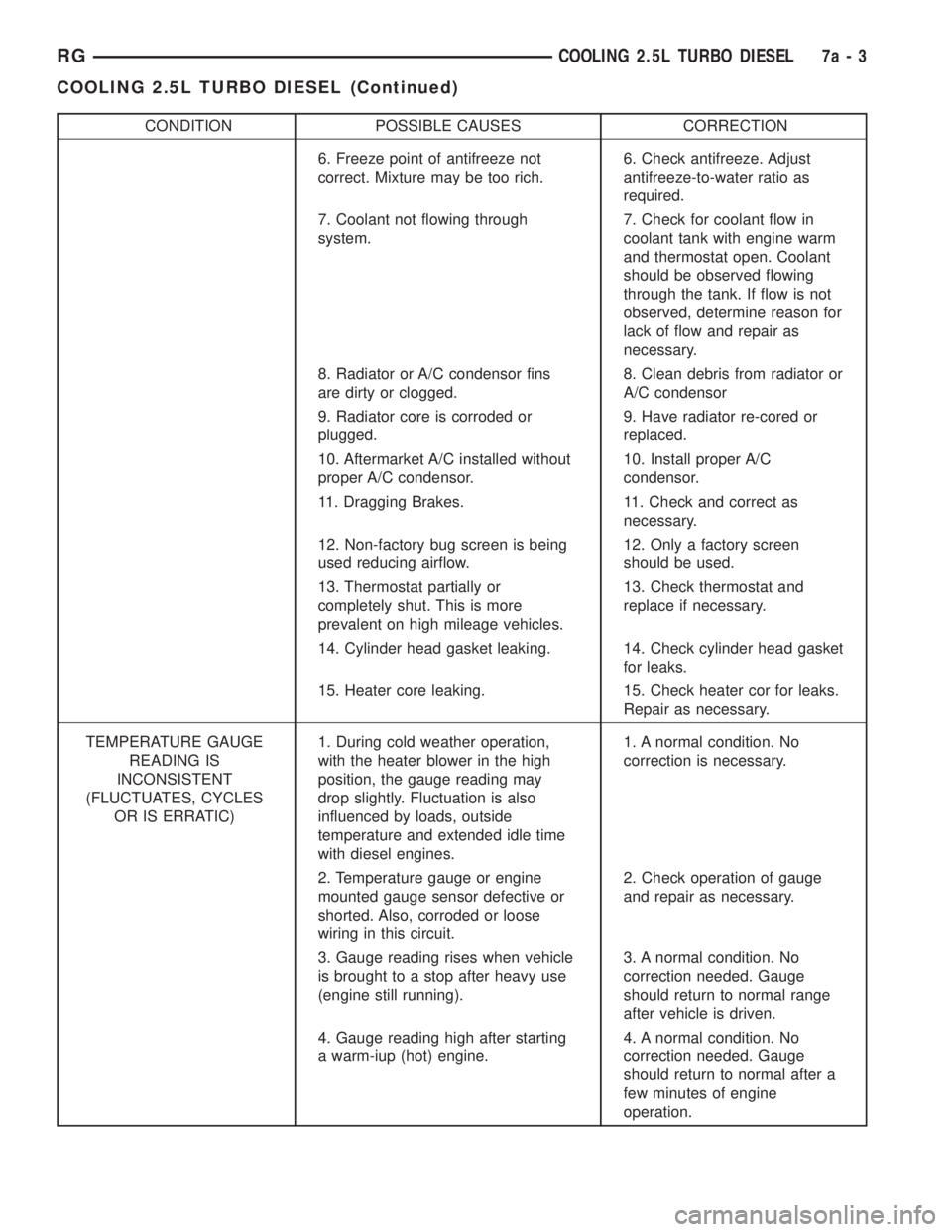

CONDITION POSSIBLE CAUSES CORRECTION

6. Freeze point of antifreeze not

correct. Mixture may be too rich.6. Check antifreeze. Adjust

antifreeze-to-water ratio as

required.

7. Coolant not flowing through

system.7. Check for coolant flow in

coolant tank with engine warm

and thermostat open. Coolant

should be observed flowing

through the tank. If flow is not

observed, determine reason for

lack of flow and repair as

necessary.

8. Radiator or A/C condensor fins

are dirty or clogged.8. Clean debris from radiator or

A/C condensor

9. Radiator core is corroded or

plugged.9. Have radiator re-cored or

replaced.

10. Aftermarket A/C installed without

proper A/C condensor.10. Install proper A/C

condensor.

11. Dragging Brakes. 11. Check and correct as

necessary.

12. Non-factory bug screen is being

used reducing airflow.12. Only a factory screen

should be used.

13. Thermostat partially or

completely shut. This is more

prevalent on high mileage vehicles.13. Check thermostat and

replace if necessary.

14. Cylinder head gasket leaking. 14. Check cylinder head gasket

for leaks.

15. Heater core leaking. 15. Check heater cor for leaks.

Repair as necessary.

TEMPERATURE GAUGE

READING IS

INCONSISTENT

(FLUCTUATES, CYCLES

OR IS ERRATIC)1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly. Fluctuation is also

influenced by loads, outside

temperature and extended idle time

with diesel engines.1. A normal condition. No

correction is necessary.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.2. Check operation of gauge

and repair as necessary.

3. Gauge reading rises when vehicle

is brought to a stop after heavy use

(engine still running).3. A normal condition. No

correction needed. Gauge

should return to normal range

after vehicle is driven.

4. Gauge reading high after starting

a warm-iup (hot) engine.4. A normal condition. No

correction needed. Gauge

should return to normal after a

few minutes of engine

operation.

RGCOOLING 2.5L TURBO DIESEL7a-3

COOLING 2.5L TURBO DIESEL (Continued)

Page 1830 of 4284

²Front Fog Lamp Relay Actuation

²Front and Rear Blower Motor Relay Actuation

²Accessory Relay Actuation

²Electronic Back Light (EBL) Rear Defogger

²Horn Relay Actuation

²Park Lamp Relay Actuation

²Name Brand Speaker (NBS) Relay Actuation

²Headlamp Washer Relay Actuation

²Diesel Cabin Heater (Diesel Engine Vehicles)

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Ambient Temperature Sensing

²Right/Left Park Lamp Outage

²Ignition Switch Start Only

²Ignition Switch Run and Start Only

²Washer Fluid Level

²Windshield Wiper Park

²Brake Fluid Level

²Back-Up switch

²Stop Lamp Sense

²Engine Crank Signal (Diesel Engine Vehicles)

²Horn Input

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Remove the battery from the vehicle. Refer to

the procedure in Battery Systems.(3) Using a long flat-pladed screwdriver, gently

twist the Intelligent Power Module (IPM) retaining

clip outboard to free the intelligent power module

from its mounting bracket (Fig. 6). Rotate intelligent

power module upward to access the Front Control

Module (FCM) retaining screws.

(4) Remove the front control module retaining

screws.

(5) Using both hands, pull the front control module

straight from the intelligent power module assembly

to disconnect the 49-way electrical connector (Fig. 7)

and remove the front control module from the vehi-

cle.

INSTALLATION

(1) Install the front control module in the intelli-

gent power module assembly by pushing the 49-way

electrical connector straight in (Fig. 7).

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Rotate the intelligent power module assembly

downward to secure in mounting bracket.

(4) Install the battery in the vehicle. Refer to the

procedure in Battery Systems.

(5) Connect the positive and negative battery

cables.

NOTE: If the vehicle is not equipped with Name

Brand Speakers (NBS, Infinity) or Headlamp Wash-

ers the DRB IIITmust be used to Disable the appro-

priate relays in the Intelligent Power Module

Assembly.

Fig. 6 REMOVING INTELLIGENT POWER MODULE

8E - 6 ELECTRONIC CONTROL MODULESRS

FRONT CONTROL MODULE (Continued)

Page 1886 of 4284

(1) Check battery before performing this test. Bat-

tery must be fully charged.

(2) Connect a volt-ampere tester to the battery ter-

minals. Refer to the operating instructions provided

with the tester being used.

(3) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(4) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

and SET parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(5) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

2).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps, the problem is the starter. Replace

the starter refer to starter removal.

(6) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testingequipment and connect ASD relay. Start the vehicle

several times to assure the problem has been cor-

rected.

SPECIFICATIONS

STARTER

MANUFACTURER NIPPONDENSO

Engine Application 2.4L /3.3/3.8L

Power rating 1.2 Kw

Voltage 12 VOLTS

No. of Fields 4

No. of Poles 4

Brushes 4

Drive Conventional Gear Train

Free running Test

Voltage 11

Amperage Draw 73 Amp

Minimum Speed 3401 RPM

SolenoidClosing Voltage 7.5 Volts

Cranking Amperage Draw

test150 - 200 Amps.

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

Torques

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Starter Mounting Bolts 47.4 35

Starter Solenoid Battery

Nut11.3 8.3 100

8F - 32 STARTINGRS

STARTING (Continued)

Page 1941 of 4284

LAMPS

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR............... 1LAMPS/LIGHTING - INTERIOR............... 17

LAMPS/LIGHTING - EXTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION............................2

OPERATION.............................2

DIAGNOSIS AND TESTING..................3

LAMPS/LIGHTING - EXTERIOR.............3

SPECIFICATIONS.........................7

BRAKE LAMP SWITCH

DESCRIPTION............................7

OPERATION.............................7

DIAGNOSIS AND TESTING..................7

BRAKE LAMP SWITCH...................7

REMOVAL...............................8

INSTALLATION............................8

CENTER HIGH MOUNTED STOP LAMP

REMOVAL...............................9

INSTALLATION............................9

CENTER HIGH MOUNTED STOP LAMP UNIT

REMOVAL...............................9

INSTALLATION............................9

FOG LAMP

REMOVAL...............................9

INSTALLATION............................9

FOG LAMP UNIT

REMOVAL..............................10

INSTALLATION...........................10

ADJUSTMENTS..........................10

HEADLAMP

REMOVAL..............................11

INSTALLATION...........................11HEADLAMP SWITCH

DIAGNOSIS AND TESTING.................11

HEADLAMP SWITCH....................11

REMOVAL..............................11

INSTALLATION...........................11

HEADLAMP UNIT

REMOVAL..............................12

INSTALLATION...........................12

ADJUSTMENTS..........................12

LICENSE PLATE LAMP

REMOVAL..............................14

INSTALLATION...........................14

MULTI-FUNCTION SWITCH

DESCRIPTION...........................14

OPERATION.............................15

DIAGNOSIS AND TESTING.................15

MULTI-FUNCTION SWITCH...............15

REMOVAL..............................15

INSTALLATION...........................15

PARK/TURN SIGNAL LAMP

REMOVAL..............................15

INSTALLATION...........................15

TAIL LAMP

REMOVAL..............................16

INSTALLATION...........................16

TAIL LAMP UNIT

REMOVAL..............................16

INSTALLATION...........................16

RSLAMPS8L-1