service CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1545 of 2399

(1) Remove the power steering pump from the

vehicle. Refer to Removal And Installation in this

section of the service manual.

(2) Remove the pulley from the shaft of the power

steering pump using Puller C-4333 (Fig. 14).

CAUTION: Do not hammer on power steering pump

pulley. This will damage the pulley and the power

steering pump.

(3) Replace pulley if it is found to be bent, cracked,

or loose.

ASSEMBLY - PUMP (PULLEY)

The only serviceable part of the power steering

pump is the pulley. The procedure following is for

removal and installation of the pulley from the pump

once the pump is removed from the vehicle.

(1) Install the pulley with Installer C-4063 (Fig.

15). Do not use the tool adapters.

(2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft.

(3) Install the pulley until it is flush with the end

of the power steering pump shaft (Fig. 16).

(4) Install the power steering pump on the vehicle.

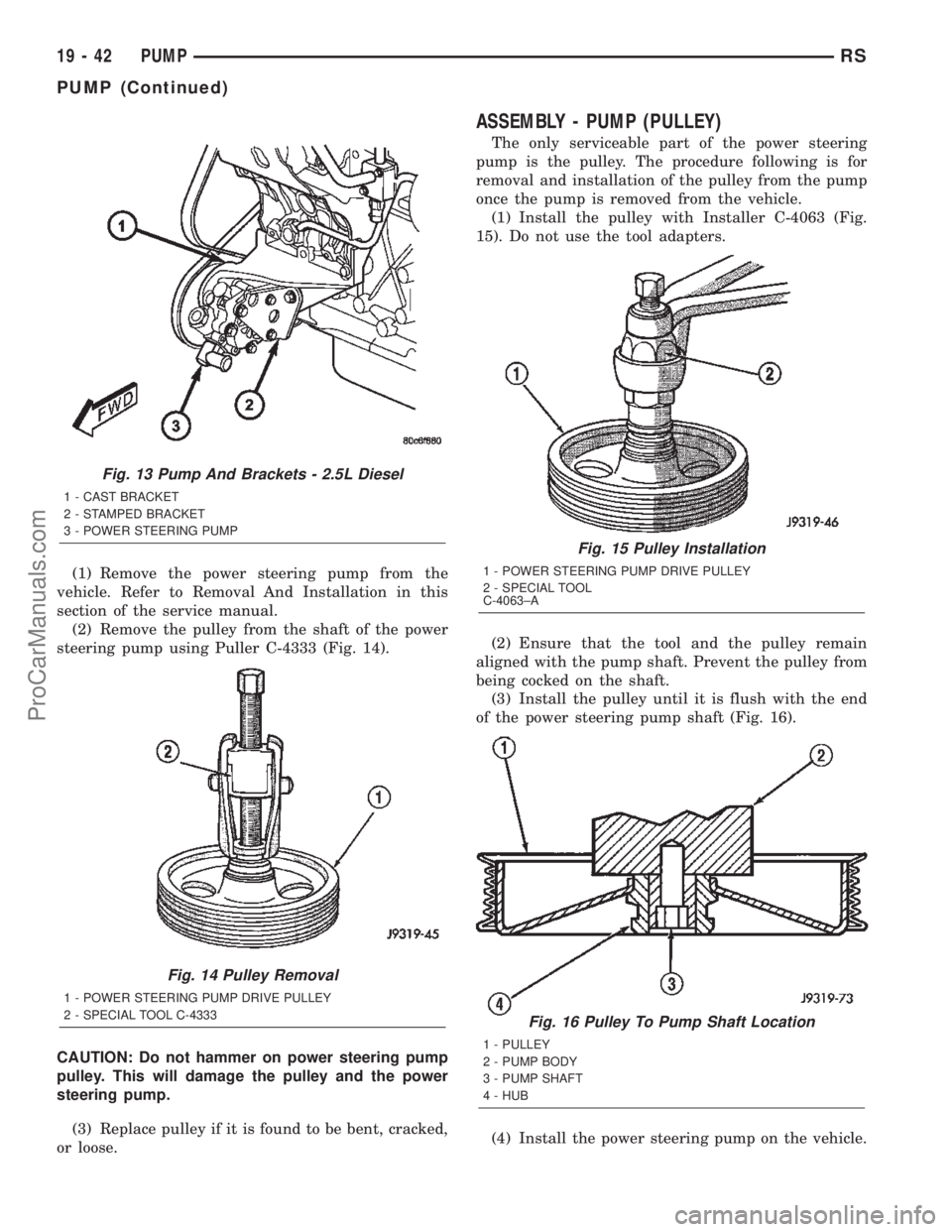

Fig. 13 Pump And Brackets - 2.5L Diesel

1 - CAST BRACKET

2 - STAMPED BRACKET

3 - POWER STEERING PUMP

Fig. 14 Pulley Removal

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4333

Fig. 15 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL

C-4063±A

Fig. 16 Pulley To Pump Shaft Location

1 - PULLEY

2 - PUMP BODY

3 - PUMP SHAFT

4 - HUB

19 - 42 PUMPRS

PUMP (Continued)

ProCarManuals.com

Page 1558 of 2399

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT..................1

31TH AUTOMATIC TRANSAXLE.............2141TE AUTOMATIC TRANSAXLE............161

T850 MANUAL TRANSAXLE...............308

POWER TRANSFER UNIT

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING

SEAL IDENTIFICATION..................3

FLUID LEAK DIAGNOSIS................4

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

INSPECTION..........................5

STANDARD PROCEDURE - PTU FLUID

CHANGE.............................5

REMOVAL.............................6

INSTALLATION..........................7

ADJUSTMENTS

OUTPUT FLANGE SHIM SELECTION.......7

SPECIFICATIONS

TORQUE.............................8

SPECIAL TOOLS

SDP POWER TRANSFER UNIT............8

DIFFERENTIAL CARRIER SEAL

REMOVAL.............................9

INSTALLATION..........................9

END COVER BALL BEARING

REMOVAL.............................9INSTALLATION.........................10

END COVER SEAL

REMOVAL.............................11

INSTALLATION.........................11

HALF SHAFT INNER SEAL

REMOVAL.............................12

INSTALLATION.........................13

INPUT SHAFT COVER SEAL

REMOVAL.............................13

INSTALLATION.........................14

INPUT SHAFT END SEAL

REMOVAL.............................16

INSTALLATION.........................16

INPUT SHAFT SEAL

REMOVAL.............................17

INSTALLATION.........................18

OUTER HALF SHAFT SEAL

REMOVAL.............................19

INSTALLATION.........................19

REAR COVER O-RING

REMOVAL.............................19

INSTALLATION.........................20

POWER TRANSFER UNIT

DESCRIPTION

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located.

The Power Transfer Unit is sealed from the trans-

axle and has its own oil sump. The Unit uses MopartSAE 80W-90 Gear and Axle Lubricant (MS-9020) and

holds 1.15 liters (1.22 quarts).

Service of the Power Transfer Unit is limited to:

²Fluid Change

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

RSTRANSMISSION/TRANSAXLE21-1

ProCarManuals.com

Page 1561 of 2399

FLUID LEAK DIAGNOSIS

When diagnosing fluid leaks on the Power Transfer

Unit two weep holes are provided to diagnose certain

seal leaks. These holes are located on the bottom side

of the assembly (Fig. 5).

If fluid leak is detected from either weep hole, seal

replacement is necessary.Do not attempt to repair

the leak by sealing weep holes,they must be kept

clear of sealants for proper seal operation.

If fluid is leaking from weep hole A (Fig. 5) the

type of fluid leaking will determine which seal needs

to be replaced. If the fluid leaking is red in color(transmission fluid) this indicates that the Transmis-

sion differential carrier seal should be replaced. If

the fluid leaking is light brown (gear lube) this indi-

cates that the Power Transfer Unit input seal should

be replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

If fluid is leaking from weep hole B (Fig. 5) the

type of fluid leaking will determine which seal is

leaking. If the fluid leaking is red in color (transmis-

sion fluid) this indicates that the input shaft end seal

should be replaced. If the fluid leaking is light brown

(gear lube) this indicates that the half shaft inner

seal and P.T.U. input shaft cover seal should be

replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

Before condemning any seal or gasket be sure that

the rear rocker arm cover on the engine is not the

cause of the oil leak. Oil leaking from the rocker arm

cover is easily mistaken for a leaking Power Transfer

Unit.

Fig. 3 Seal Location

1 - INPUT SHAFT

2 - OUTPUT SHAFT

3 - REAR COVER

4 - P.T.U. CASE

5 - INPUT SHAFT SEAL

Fig. 4 Seal Location

1 - P.T.U. INPUT SHAFT COVER SEAL

2 - HALF SHAFT INNER SEAL

3 - INSIDE VIEW OF P.T.U. END COVER

Fig. 5 Weep Hole Locations

1 - ENGINE OIL PAN

2 - WEEP HOLE ªAº

3 - TRANSAXLE CASE

4 - P.T.U.

5 - WEEP HOLE ªBº

21 - 4 POWER TRANSFER UNITRS

POWER TRANSFER UNIT (Continued)

ProCarManuals.com

Page 1570 of 2399

INSTALLATION

The power transfer unit half shaft inner seal is the

smaller of the two seals located on the inside of the

end cover.

(1) Clean and inspect seal area.

(2) Install seal with a 1 1/16 inch socket (Fig. 28).

The seal must be installed with the spring side of the

seal facing end cover ball bearing. The seal will bot-

tom against a machined shoulder in the cover.

(3) Clean sealing surfaces of the end cover and

P.T.U. case. Apply a bead of MopartGasket Maker,

Loctite Gasket Eliminator No. 518 or equivalent.

(4) Place end cover onto P.T.U. case and install

bolts. Tighten bolts to 28 N´m (250 in. lbs.) in the

sequence shown in (Fig. 29). Retighten first bolt after

all other bolts are tight.

(5) Reinstall P.T.U. assembly.

(6) Check and fill fluids as required.

INPUT SHAFT COVER SEAL

REMOVAL

The power transfer unit input shaft cover seal is

the larger of the two seals located on the inside of

the end cover. The differential bearing cup must be

removed to service this seal.

(1) Remove P.T.U. end cover bolts (Fig. 30).

Fig. 28 Seal Installation

1 - END COVER

2 - SOCKET

3 - HAMMER

Fig. 29 Bolt Tightening Sequence

Fig. 30 P.T.U. End Cover Bolts

1 - POWER TRANSFER UNIT

2 - FILL PLUG

3 - END COVER

4 - OUTPUT SHAFT

RSPOWER TRANSFER UNIT21-13

HALF SHAFT INNER SEAL (Continued)

ProCarManuals.com

Page 1571 of 2399

(2) Gently tap on end cover ears to separate cover

from case (Fig. 31).

(3) Use special tool No. 6514 and remove the dif-

ferential bearing race located in the end cover (Fig.

32). The race must be removed to gain access to the

seal.(4) Use special tool No. 7794-A to remove seal (Fig.

33).

INSTALLATION

The power transfer unit input shaft cover seal is

the larger of the two seals located on the inside of

the end cover. The differential bearing cup must be

removed to service this seal.

(1) Clean and inspect seal area.

(2) Use special tool No. MD998803 and install seal

(Fig. 34). When installing seal the spring side of the

seal must face toward the special tool.

Fig. 31 End Cover Removal

1 - END COVER EARS

2 - HAMMER

3 - POWER TRANSFER UNIT

Fig. 32 Bearing Race Removal

1 - END COVER

2 - SPECIAL TOOL

No. 6514

Fig. 33 Seal Removal

1 - END COVER

2 - SPECIAL TOOL 7794±A

3 - SLIDE HAMMER

4 - SOFT JAW VICE

Fig. 34 Seal Installation

1 - SPECIAL TOOL No. MD998803

2 - HAMMER

3 - END COVER

21 - 14 POWER TRANSFER UNITRS

INPUT SHAFT COVER SEAL (Continued)

ProCarManuals.com

Page 1574 of 2399

(5) Place end cover onto P.T.U. case and install

bolts. Tighten bolts to 28 N´m (250 in. lbs.) in the

sequence shown in (Fig. 41). Retighten first bolt after

all others are tight.

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. assembly.

(7) Check and fill fluids as required.

INPUT SHAFT SEAL

REMOVAL

The Power Transfer Unit must be removed from

the vehicle to service this seal. Refer to Power Trans-

fer Unit Removal in this section for procedures.

(1) Remove P.T.U. end cover bolts (Fig. 42).

(2) Gently tap on end cover ears to separate cover

from case (Fig. 43).

(3) Remove ring gear oil trough (Fig. 44).

(4) Remove input shaft and ring gear from case

(Fig. 45).

(5) Use Special Tool No. 7794-A (seal puller) to

remove seal (Fig. 46).

Fig. 41 Bolt Tightening Sequence

Fig. 42 P.T.U. End Cover Bolts

1 - POWER TRANSFER UNIT

2 - FILL PLUG

3 - END COVER

4 - OUTPUT SHAFT

Fig. 43 End Cover Removal

1 - END COVER EARS

2 - HAMMER

3 - POWER TRANSFER UNIT

RSPOWER TRANSFER UNIT21-17

INPUT SHAFT END SEAL (Continued)

ProCarManuals.com

Page 1575 of 2399

INSTALLATION

The Power Transfer Unit must be removed from

the vehicle to service this seal. Refer to Power Trans-

fer Unit Removal in this section for procedures.

(1) Clean and inspect seal area.

(2) Lay housing on bench and install new seal with

seal driver C-4657 and handle C-4171 (Fig. 47). The

seal must be installed with the spring side facing

towards the ring gear. Drive the seal in until it bot-

toms against the case shoulder.

(3) Install input shaft.(4) Install oil trough.

Fig. 44 Oil Trough

1 - OIL TROUGH

2 - POWER TRANSFER UNIT

Fig. 45 Input Shaft and Ring Gear Removal

1 - POWER TRANSFER UNIT

2 - RING GEAR

Fig. 46 Seal Removal

1 - POWER TRANSFER UNIT

2 - SPECIAL TOOL 7794±A

Fig. 47 Seal Installation

1 - HAMMER

2 - SPECIAL TOOL C-4171

3 - SPECIAL TOOL C-4657

4 - POWER TRANSFER UNIT

21 - 18 POWER TRANSFER UNITRS

INPUT SHAFT SEAL (Continued)

ProCarManuals.com

Page 1582 of 2399

TRANSAXLE DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low 1. Add Fluid

2. Throttle Linkage Misadjusted 2. Adjust linkage - setting may be too long.

3. Excessive Pinion Backlash 3. Check per Service Manual. Correct as

needed.

4. Hydraulic Pressure Incorrect 4. Check pressure. Remove, overhaul or

adjust valve body as needed.

5. Band Misadjusted. 5. Adjust rear band.

6. Valve Body Check Balls Missing. 6. Inspect valve body for proper check ball

installation.

7. Clutch, band or planetary

component Damaged.7. Remove, disassemble and repair

transmission as necessary.

8. Converter Clutch (if equipped)

Faulty.8. Replace converter and flush cooler and

line before installing new converter.

DELAYED ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Misadjusted. 3. Adjust linkage and repair linkage if worn

or damaged.

4. Rear Band Misadjusted. 4. Adjust band.

5. Valve Body Filter Plugged. 5. Replace fluid and filter. If oil pan and old

fluid were full of clutch disc material and/or

metal particles, overhaul will be necessary.

6. Oil Pump Gears Worn/Damaged. 6. Remove transmission and replace oil

pump.

7. Hydraulic Pressure Incorrect. 7. Perform pressure test, remove

transmission and repair as needed.

8. Reaction Shaft Seal Rings

Worn/Broken.8. Remove transmission, remove oil pump

and replace seal rings.

9. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.9. Remove and disassemble transmission

and repair as necessary.

10. Governor Valve Stuck. 10. Remove and inspect governor

components. Replace worn or damaged

parts.

11. Regulator Valve Stuck. 11. Clean.

RS31TH AUTOMATIC TRANSAXLE21-25

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1584 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

SHIFTS DELAYED OR

ERRATIC (ALSO SHIFTS

HARSH AT TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

clutch material or metal particles, an

overhaul may be necessary. Perform lube

flow test.

3. Throttle Linkage Misadjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

to closed throttle at transmission.

5. Gearshift Linkage/Cable

Misadjusted.5. Adjust linkage/cable as described in

service section.

6. Governor Valve Sticking. 6. Inspect, clean or repair.

7. Governor Seal Rings Worn/

Damaged.7. Inspect/replace.

8. Clutch or Servo Failure. 8. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

9. Front Band Misadjusted. 9. Adjust band.

10. Pump Suction Passage Leak. 10. Check for excessive foam on dipstick

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

NO REVERSE (D RANGES

OK)1. Gearshift Linkage/Cable

Misadjusted/Damaged.1. Repair or replace linkage parts as

needed.

2. Rear Band Misadjusted/Worn. 2. Adjust band; replace.

3. Valve Body Malfunction. 3. Remove and service valve body. Replace

valve body if any valves or valve bores are

worn or damaged.

4. Rear Servo Malfunction. 4. Remove and disassemble transmission.

Replace worn/damaged servo parts as

necessary.

5. Direct Clutch in Overdrive Worn 5. Disassemble overdrive. Replace worn or

damaged parts.

6. Front Clutch Burnt. 6. Remove and disassemble transmission.

Replace worn, damaged clutch parts as

required.

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)1. Governor Valve, Shaft, Weights or

Body Damaged/Stuck.1. Remove governor assembly and clean or

repair as necessary.

2. Valve Body Malfunction. 2. Stuck 1-2 shift valve or governor plug.

3. Front Servo/Kickdown Band

Damaged/Burned.3. Repair/replace.

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

stuck 1-2 valve or governor plug.

2. Governor Valve Sticking. 2. Remove, clean and inspect. Replace

faulty parts.

RS31TH AUTOMATIC TRANSAXLE21-27

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1587 of 2399

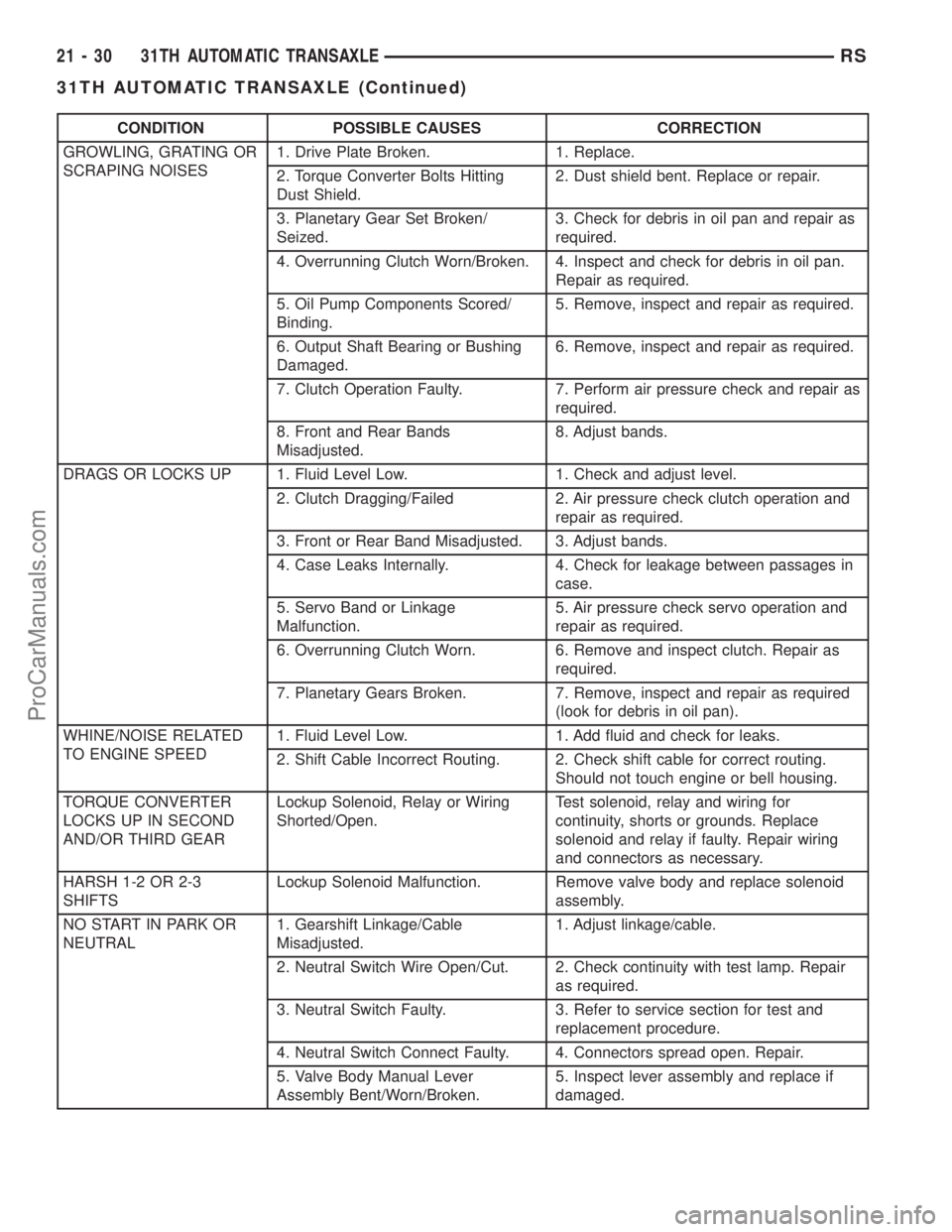

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

Repair as required.

5. Oil Pump Components Scored/

Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Misadjusted.8. Adjust bands.

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

repair as required.

3. Front or Rear Band Misadjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and

repair as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

(look for debris in oil pan).

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK OR

NEUTRAL1. Gearshift Linkage/Cable

Misadjusted.1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

21 - 30 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com