service CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1466 of 2399

(6) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(7) Insert quick-connect fitting to component being

serviced and into plastic retainer. When a connection

is made, a click will be heard.

(8) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(9) Connect negative cable to battery or auxiliary

jumper terminal.

(10) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

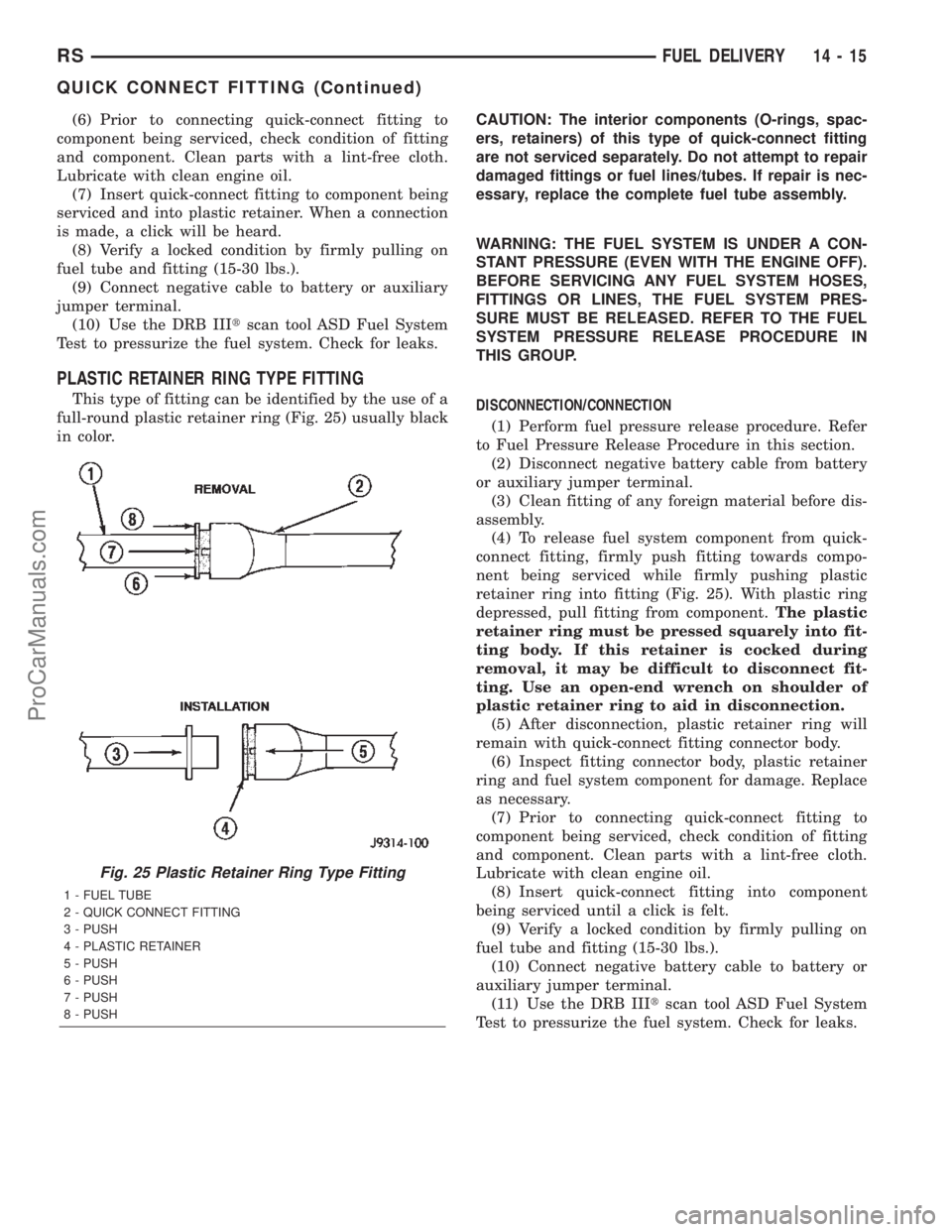

PLASTIC RETAINER RING TYPE FITTING

This type of fitting can be identified by the use of a

full-round plastic retainer ring (Fig. 25) usually black

in color.CAUTION: The interior components (O-rings, spac-

ers, retainers) of this type of quick-connect fitting

are not serviced separately. Do not attempt to repair

damaged fittings or fuel lines/tubes. If repair is nec-

essary, replace the complete fuel tube assembly.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this section.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To release fuel system component from quick-

connect fitting, firmly push fitting towards compo-

nent being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 25). With plastic ring

depressed, pull fitting from component.The plastic

retainer ring must be pressed squarely into fit-

ting body. If this retainer is cocked during

removal, it may be difficult to disconnect fit-

ting. Use an open-end wrench on shoulder of

plastic retainer ring to aid in disconnection.

(5) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(6) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage. Replace

as necessary.

(7) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(8) Insert quick-connect fitting into component

being serviced until a click is felt.

(9) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(10) Connect negative battery cable to battery or

auxiliary jumper terminal.

(11) Use the DRB IIItscan tool ASD Fuel System

Test to pressurize the fuel system. Check for leaks.

Fig. 25 Plastic Retainer Ring Type Fitting

1 - FUEL TUBE

2 - QUICK CONNECT FITTING

3 - PUSH

4 - PLASTIC RETAINER

5 - PUSH

6 - PUSH

7 - PUSH

8 - PUSH

RSFUEL DELIVERY14-15

QUICK CONNECT FITTING (Continued)

ProCarManuals.com

Page 1472 of 2399

SYSTEM DIAGNOSIS

OPERATION

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.For DTC information see On-Board Diagnostics

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/POWERTRAIN CONTROL MOD-

ULE - DESCRIPTION) .

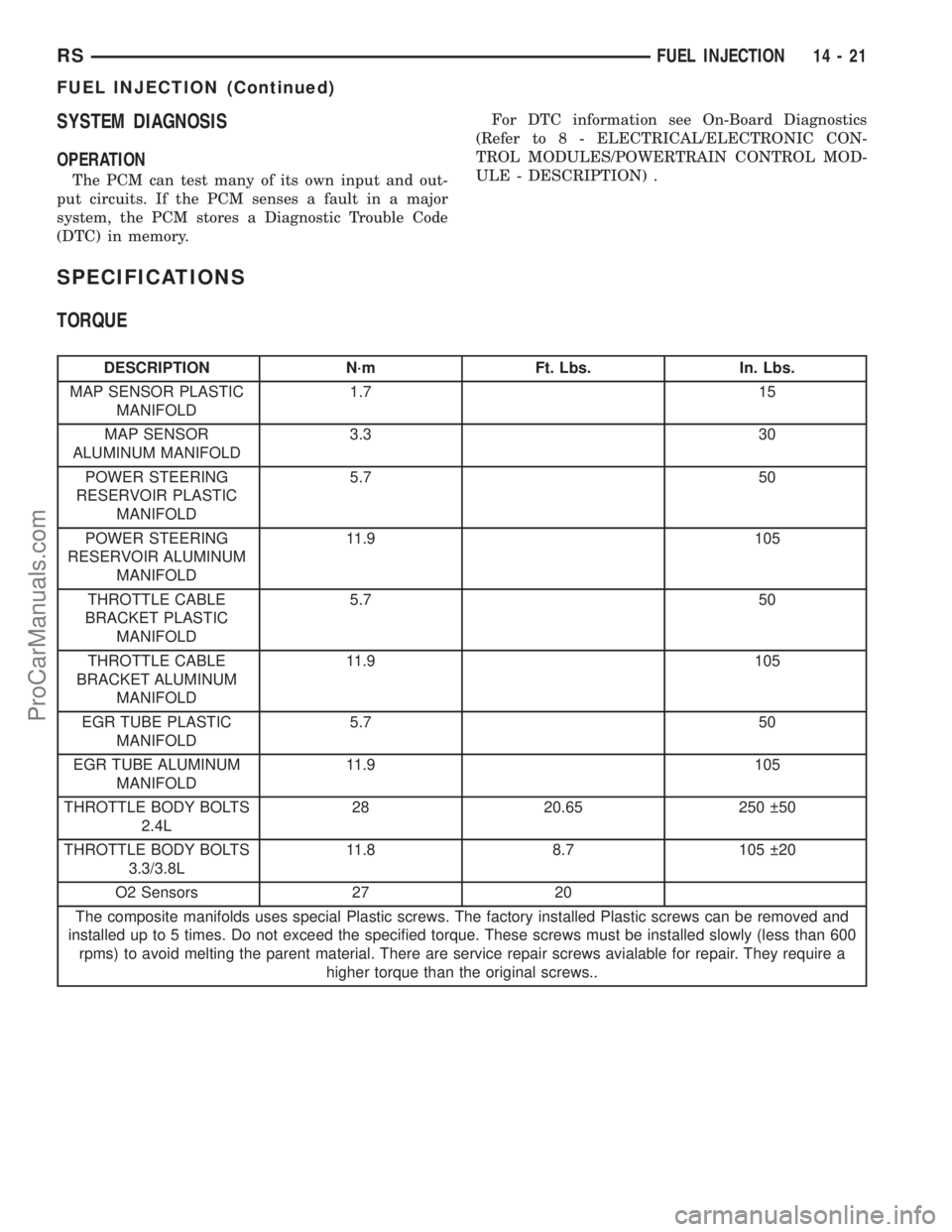

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

MAP SENSOR PLASTIC

MANIFOLD1.7 15

MAP SENSOR

ALUMINUM MANIFOLD3.3 30

POWER STEERING

RESERVOIR PLASTIC

MANIFOLD5.7 50

POWER STEERING

RESERVOIR ALUMINUM

MANIFOLD11.9 105

THROTTLE CABLE

BRACKET PLASTIC

MANIFOLD5.7 50

THROTTLE CABLE

BRACKET ALUMINUM

MANIFOLD11.9 105

EGR TUBE PLASTIC

MANIFOLD5.7 50

EGR TUBE ALUMINUM

MANIFOLD11.9 105

THROTTLE BODY BOLTS

2.4L28 20.65 250 50

THROTTLE BODY BOLTS

3.3/3.8L11.8 8.7 105 20

O2 Sensors 27 20

The composite manifolds uses special Plastic screws. The factory installed Plastic screws can be removed and

installed up to 5 times. Do not exceed the specified torque. These screws must be installed slowly (less than 600

rpms) to avoid melting the parent material. There are service repair screws avialable for repair. They require a

higher torque than the original screws..

RSFUEL INJECTION14-21

FUEL INJECTION (Continued)

ProCarManuals.com

Page 1488 of 2399

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL SYSTEM 2.5L TURBO DIESEL

DESCRIPTION - DIESEL FUEL DELIVERY

SYSTEM.............................1

WARNING - HIGH FUEL SYSTEM PRESSURE . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AIR IN FUEL

SYSTEM.............................1

DIAGNOSIS AND TESTING - FUEL SUPPLY

RESTRICTIONS........................1

STANDARD PROCEDURE

STANDARD PROCEDURES - DRAINING

WATER FROM FUEL FILTER..............2STANDARD PROCEDURE - FUEL SYSTEM

AIR PURGE...........................2

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM COMPONENTS............2

SPECIFICATIONS - TORQUE...............3

FUEL DELIVERY..........................4

FUEL INJECTION........................11

FUEL SYSTEM 2.5L TURBO

DIESEL

DESCRIPTION - DIESEL FUEL DELIVERY

SYSTEM

The fuel system on the 2.5L Common Rail Diesel

Engine uses a fuel injection pump and an Electronic

Control Module (ECM).

The fuel delivery system consists of the:

²Accelerator pedal

²Air cleaner housing/element

²Fuel filter/water separator

²Fuel heater

²Fuel heater relay

²Fuel transfer (lift) pump

²Fuel injection pump

²Fuel injectors

²Fuel tank

²Fuel tank filler/vent tube assembly

²Fuel tank filler tube cap

²Fuel tank module containing the rollover valve

and a fuel gauge sending unit (fuel level sensor).

²Fuel tubes/lines/hoses

²High-pressure fuel injector lines

²Low-pressure fuel supply lines

²Low-pressure fuel return line

²Overflow valve

²Quick-connect fittings

²Water draining

WARNING - HIGH FUEL SYSTEM PRESSURE

WARNING:: THE INJECTION PUMP SUPPLIES HIGH-

PRESSURE FUEL TO EACH INDIVIDUAL INJECTOR

THROUGH HIGH-PRESSURE LINES. FUEL UNDERTHIS AMOUNT OF PRESSURE CAN PENETRATE

SKIN AND CAUSE PERSONAL INJURY. WEAR

SAFETY GOGGLES AND ADEQUATE PROTECTIVE

CLOTHING. AVOID CONTACT WITH FUEL SPRAY

WHEN BLEEDING HIGH-PRESSURE FUEL LINES.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AIR IN FUEL

SYSTEM

Air will enter the fuel system whenever fuel supply

lines, separator filters, injection pump, high-pressure

lines or injectors are removed or disconnected. Air

trapped in the fuel system can result in hard start-

ing, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

is performed, air must be bled from the system

before starting the engine.

Inspect the fuel system from the fuel tank to the

injectors for loose connections. Leaking fuel is an

indicator of loose connections or defective seals. Air

can also enter the fuel system between the fuel tank

and the transfer pump. Inspect the fuel tank and fuel

lines for damage that might allow air into the sys-

tem.

DIAGNOSIS AND TESTING - FUEL SUPPLY

RESTRICTIONS

LOW-PRESSURE LINES

Fuel supply line restrictions or a defective fuel

transfer pump can cause starting problems and pre-

vent engine from accelerating. The starting problems

include; low power and/or white fog like exhaust.

RGFUEL SYSTEM14a-1

ProCarManuals.com

Page 1504 of 2399

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION - POWER STEERING SYSTEM . . 1

OPERATION - POWER STEERING SYSTEM . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER

STEERING SYSTEM FLOW AND

PRESSURE TEST......................1

DIAGNOSIS AND TESTING - STEERING

SYSTEM DIAGNOSIS CHARTS............3SPECIFICATIONS

POWER STEERING FASTENER TORQUE . . . 9

SPECIAL TOOLS

POWER STEERING....................9

COLUMN..............................10

GEAR.................................26

PUMP.................................36

STEERING

DESCRIPTION - POWER STEERING SYSTEM

This vehicle comes with power steering as stan-

dard equipment. The power steering system consists

of these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID

²POWER STEERING FLUID COOLER

²POWER STEERING FLUID RESERVOIR

²POWER STEERING FLUID SUPPLY HOSE

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on all other components can

be found in POWER STEERING PUMP.

OPERATION - POWER STEERING SYSTEM

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth within the

steering gear. The lateral travel pushes and pulls the

tie rods to change the direction of the vehicle's front

wheels.

Power assist steering is provided by a belt driven

rotary type pump. It directs fluid through power

steering fluid hoses to the power steering gear where

it is used to assist the driver's turning effort.

Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM FLOW AND PRESSURE TEST

ALL ENGINES

The following procedure is to be used to test the

operation of the power steering system on this vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed to determine if the

power steering pump or power steering gear is not

functioning properly. The following flow and pressure

test is performed using the Power Steering Analyzer

Kit, Special Tool 6815 (Fig. 1), hoses, Special Tools

6905 and 6959, and fittings from adapter kit, Special

Tool 6893.

Fig. 1 Power Steering Analyzer With Hoses Installed

1 - OUTLET

2 - SPECIAL TOOL 6815

3 - INLET

RSSTEERING19-1

ProCarManuals.com

Page 1509 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

3. Loose steering column to

instrument panel fasteners.3. Tighten fasteners to specified torque.

STEERING WHEEL, DASH

OR VEHICLE VIBRATES

DURING LOW SPEED OR

STANDSTILL STEERING

MANEUVERS.1. Air in the fluid of the power

steering system.1. Bleed air from system following the

power steering pump initial operation

service procedure.*

2. Tires not properly inflated. 2. Inflate tires to the specified pressure.

3. Excessive engine vibration. 3. Ensure that the engine is tuned properly.

4. Loose tie rod end jam nut. 4. Tighten the inner to outer tie rod jam nut

to the specified torque.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure and correct as necessary.

6. Grounded engine mount. 6. Repair as necessary.

7. Loose outer tie rod. 7. Replace outer tie rod.

STEERING CATCHES,

SURGES OR STICKS IN

CERTAIN POSITIONS OR

IS DIFFICULT TO TURN.

***1. Low power steering fluid level. 1. Fill power steering fluid reservoir to

specified level and check for leaks.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified pressure.

3. Lack of lubrication in front lower

control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated-for-life type ball joint. If ball joint

is a lubricated-for-life ball joint, replace ball

joint.

4. Worn or binding lower control arm

ball joint.4. Replace lower control arm ball joint.

5. Lack of lubrication in steering gear

outer tie rod ends.5. Lubricate tie rod ends if they are not a

lubricated-for-life type. If tie rod end is a

lubricated-for-life type, replace tie rod end.

6. Loose power steering pump drive

belt.6. Tighten the power steering pump drive

belt to specifications or replace automatic

tensioner where applicable. If drive belt is

worn or glazed, replace belt.

7. Faulty power steering pump

(Perform Power Steering Flow and

Pressure Test).7. Replace power steering pump.

8. Faulty power steering gear

(Perform Power Steering Flow and

Pressure Test).8. Replace power steering gear.

9. Excessive friction in steering

column or intermediate shaft/coupler.9. Isolate and correct condition.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

19 - 6 STEERINGRS

STEERING (Continued)

ProCarManuals.com

Page 1510 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

11. Worn or binding seat and bearing

in front strut assembly.11. Replace seat and bearing in front strut

assembly.

STEERING WHEEL DOES

NOT RETURN TO

CENTER POSITION.1. Tires not inflated properly. 1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust wheel alignment as

necessary.

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mispositioned or

unlubricated steering column coupler

to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding mount bearing in front

strut assembly.7. Replace mount bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on

cradle/crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling or

intermediate shaft worn, broken or

loose.3. Replace steering column coupling or

intermediate shaft.

4. Free play in steering column. 4. Check all components of the steering

column and repair or replace as required.

5. Worn lower control arm ball joints. 5. Replace lower control arm ball joints as

required.

6. Loose steering knuckle-to-ball joint

stud pinch bolt.6. Inspect pinch bolt, replace as necessary,

and tighten to specified torque.

7. Front wheel bearing loose or

worn.7. Replace hub and bearing as necessary.

8. Loose outer tie rod end. 8. Replace outer tie rod end that has

excessive free play.

RSSTEERING19-7

STEERING (Continued)

ProCarManuals.com

Page 1513 of 2399

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION - STEERING COLUMN.......10

WARNING

WARNINGS AND CAUTIONS.............10

DIAGNOSIS AND TESTING - STEERING

COLUMN............................12

REMOVAL.............................12

INSTALLATION.........................13

SPECIFICATIONS

COLUMN TORQUE....................14

IGNITION SWITCH

REMOVAL.............................15

INSTALLATION.........................16

LOCK CYLINDER HOUSING

DESCRIPTION - IGNITION INTERLOCK......17

REMOVAL.............................17INSTALLATION.........................20

KEY/LOCK CYLINDER

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................22

INSTALLATION.........................22

GEAR SHIFT LEVER

REMOVAL.............................22

INSTALLATION.........................22

SHROUD

REMOVAL.............................23

INSTALLATION.........................23

STEERING WHEEL

REMOVAL.............................23

INSTALLATION.........................25

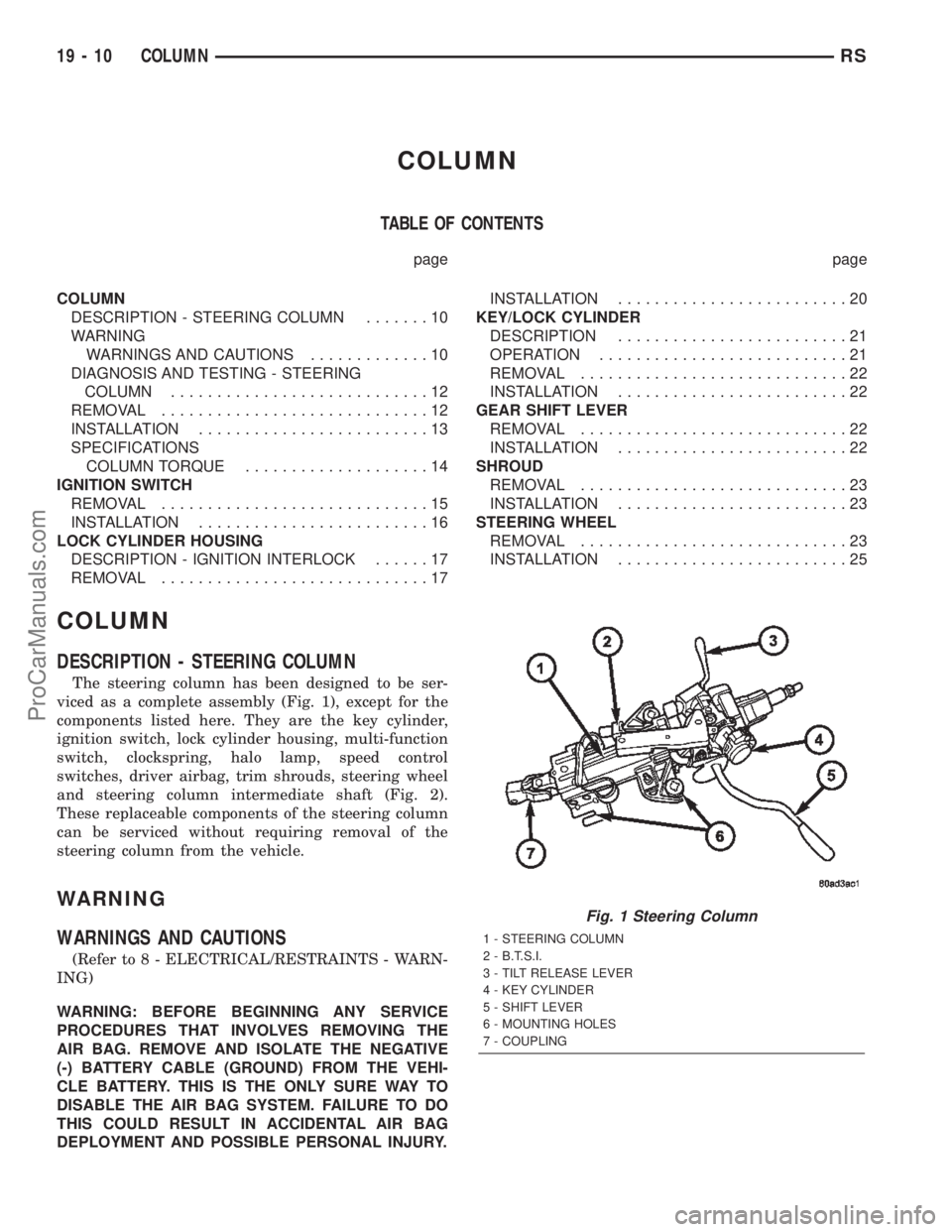

COLUMN

DESCRIPTION - STEERING COLUMN

The steering column has been designed to be ser-

viced as a complete assembly (Fig. 1), except for the

components listed here. They are the key cylinder,

ignition switch, lock cylinder housing, multi-function

switch, clockspring, halo lamp, speed control

switches, driver airbag, trim shrouds, steering wheel

and steering column intermediate shaft (Fig. 2).

These replaceable components of the steering column

can be serviced without requiring removal of the

steering column from the vehicle.

WARNING

WARNINGS AND CAUTIONS

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

Fig. 1 Steering Column

1 - STEERING COLUMN

2 - B.T.S.I.

3 - TILT RELEASE LEVER

4 - KEY CYLINDER

5 - SHIFT LEVER

6 - MOUNTING HOLES

7 - COUPLING

19 - 10 COLUMNRS

ProCarManuals.com

Page 1515 of 2399

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIR BAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIR BAG COMPONENTS, HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY DESIGNED

FOR THE AIR BAG SYSTEM. THEY MUST NEVER

BE REPLACED WITH ANY SUBSTITUTES. ANYTIME

A NEW FASTENER IS NEEDED, REPLACE WITH

THE CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR FASTENERS LISTED IN

THE PARTS BOOKS.

WARNING: SAFETY GOGGLES SHOULD BE WORN

AT ALL TIMES WHEN WORKING ON STEERING

COLUMNS.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any column compo-

nent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

DIAGNOSIS AND TESTING - STEERING

COLUMN

For diagnosis of conditions relating to the steering

column (Refer to 19 - STEERING - DIAGNOSIS ANDTESTING) and (Refer to 19 - STEERING - DIAGNO-

SIS AND TESTING).

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING).

(1) Make sure the front wheels of the vehicle are

in the STRAIGHT AHEAD position before beginning

the column removal procedure.

(2) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(3) Remove the lower shroud (Refer to 19 -

STEERING/COLUMN/LOWER SHROUD - REMOV-

AL).

(4) Remove the traction off switch.

(5) Remove the upper shroud.

(6) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(7) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(8) Remove the parking brake handle link.

(9) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(10) Remove the airbag (Refer to 8 - ELECTRI-

CAL/RESTRAINTS/DRIVER AIRBAG - REMOVAL).

(11) Remove the steering wheel retaining nut.

(12) Remove the vibration damper weight.

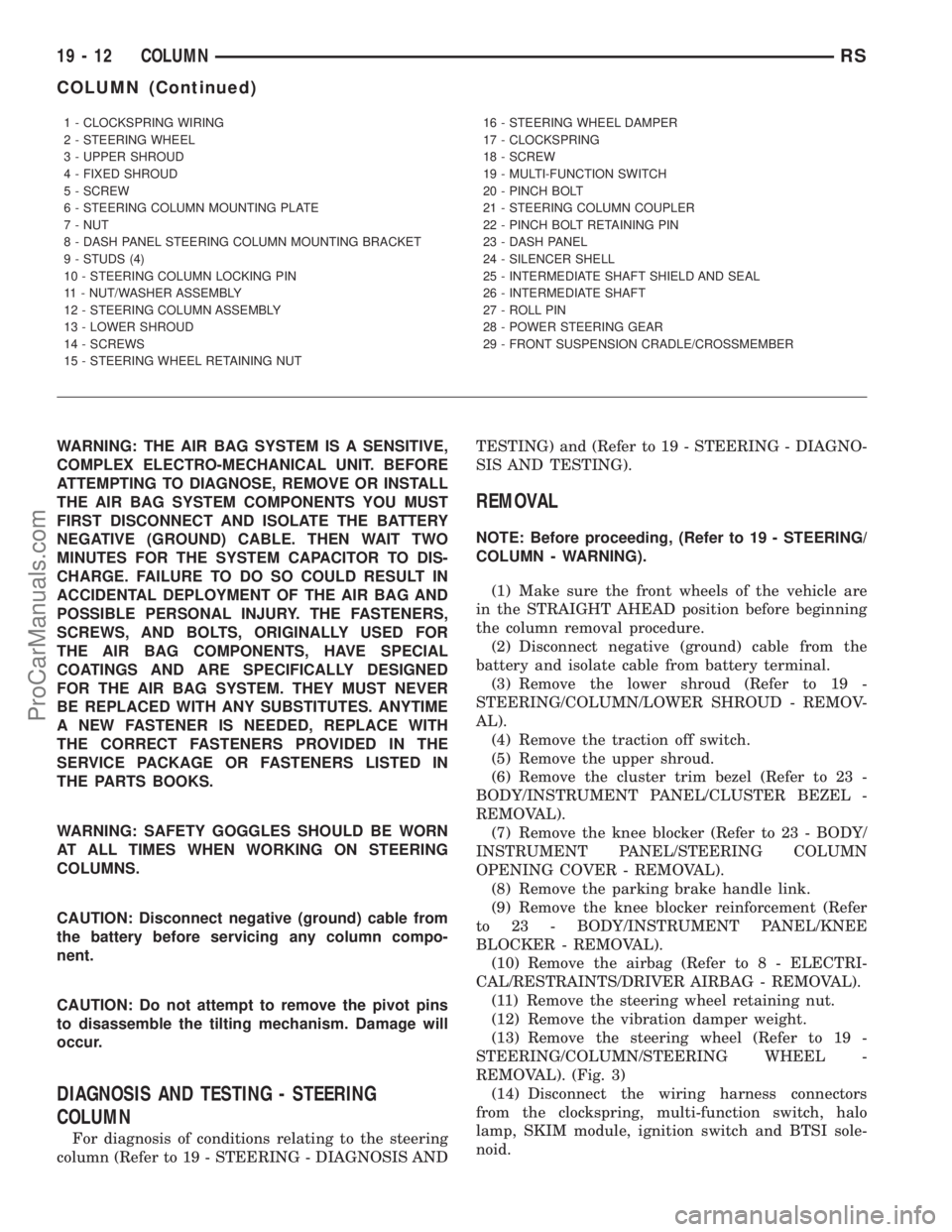

(13) Remove the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

REMOVAL). (Fig. 3)

(14) Disconnect the wiring harness connectors

from the clockspring, multi-function switch, halo

lamp, SKIM module, ignition switch and BTSI sole-

noid.

1 - CLOCKSPRING WIRING

2 - STEERING WHEEL

3 - UPPER SHROUD

4 - FIXED SHROUD

5 - SCREW

6 - STEERING COLUMN MOUNTING PLATE

7 - NUT

8 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

9 - STUDS (4)

10 - STEERING COLUMN LOCKING PIN

11 - NUT/WASHER ASSEMBLY

12 - STEERING COLUMN ASSEMBLY

13 - LOWER SHROUD

14 - SCREWS

15 - STEERING WHEEL RETAINING NUT16 - STEERING WHEEL DAMPER

17 - CLOCKSPRING

18 - SCREW

19 - MULTI-FUNCTION SWITCH

20 - PINCH BOLT

21 - STEERING COLUMN COUPLER

22 - PINCH BOLT RETAINING PIN

23 - DASH PANEL

24 - SILENCER SHELL

25 - INTERMEDIATE SHAFT SHIELD AND SEAL

26 - INTERMEDIATE SHAFT

27 - ROLL PIN

28 - POWER STEERING GEAR

29 - FRONT SUSPENSION CRADLE/CROSSMEMBER

19 - 12 COLUMNRS

COLUMN (Continued)

ProCarManuals.com

Page 1516 of 2399

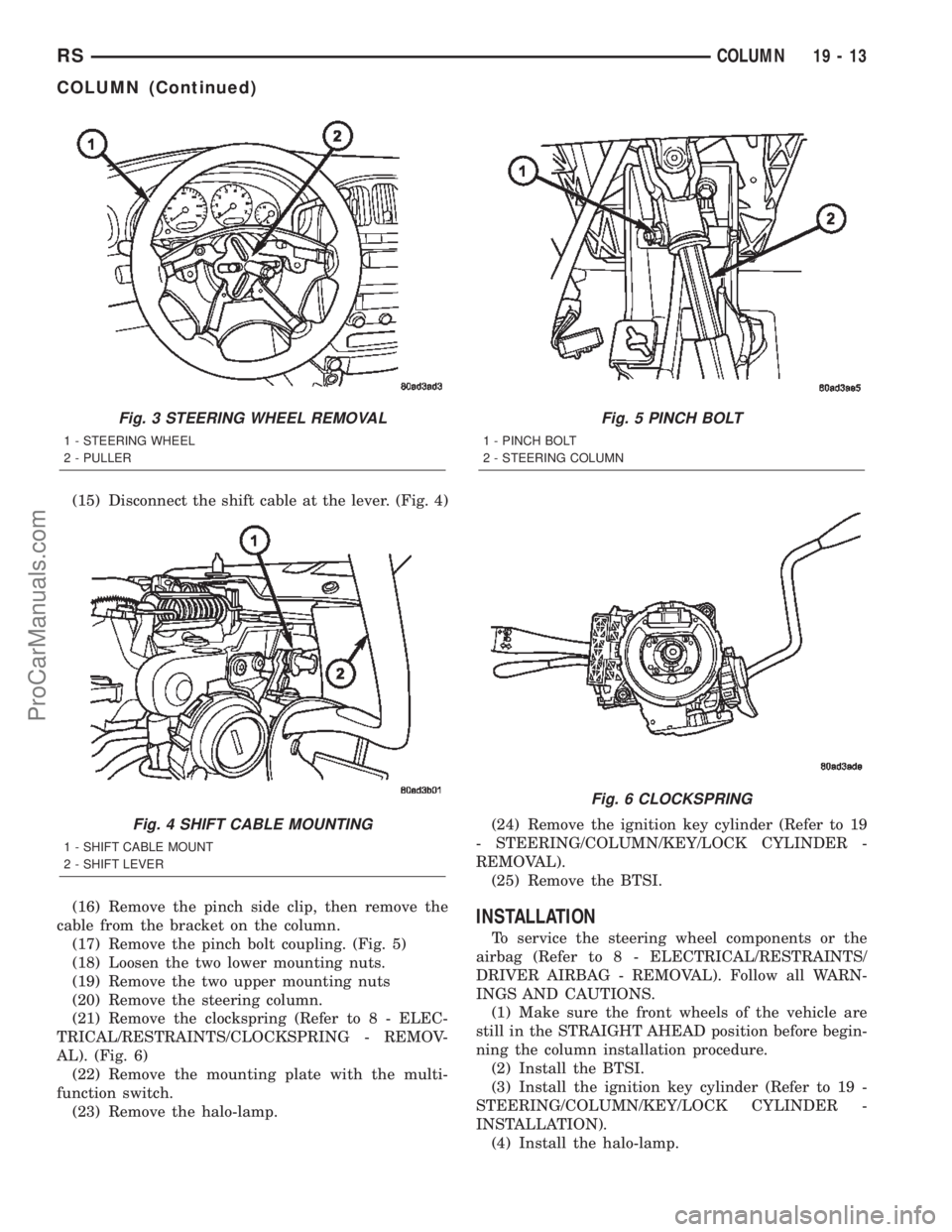

(15) Disconnect the shift cable at the lever. (Fig. 4)

(16) Remove the pinch side clip, then remove the

cable from the bracket on the column.

(17) Remove the pinch bolt coupling. (Fig. 5)

(18) Loosen the two lower mounting nuts.

(19) Remove the two upper mounting nuts

(20) Remove the steering column.

(21) Remove the clockspring (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/CLOCKSPRING - REMOV-

AL). (Fig. 6)

(22) Remove the mounting plate with the multi-

function switch.

(23) Remove the halo-lamp.(24) Remove the ignition key cylinder (Refer to 19

- STEERING/COLUMN/KEY/LOCK CYLINDER -

REMOVAL).

(25) Remove the BTSI.

INSTALLATION

To service the steering wheel components or the

airbag (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL). Follow all WARN-

INGS AND CAUTIONS.

(1) Make sure the front wheels of the vehicle are

still in the STRAIGHT AHEAD position before begin-

ning the column installation procedure.

(2) Install the BTSI.

(3) Install the ignition key cylinder (Refer to 19 -

STEERING/COLUMN/KEY/LOCK CYLINDER -

INSTALLATION).

(4) Install the halo-lamp.

Fig. 3 STEERING WHEEL REMOVAL

1 - STEERING WHEEL

2 - PULLER

Fig. 4 SHIFT CABLE MOUNTING

1 - SHIFT CABLE MOUNT

2 - SHIFT LEVER

Fig. 5 PINCH BOLT

1 - PINCH BOLT

2 - STEERING COLUMN

Fig. 6 CLOCKSPRING

RSCOLUMN19-13

COLUMN (Continued)

ProCarManuals.com

Page 1544 of 2399

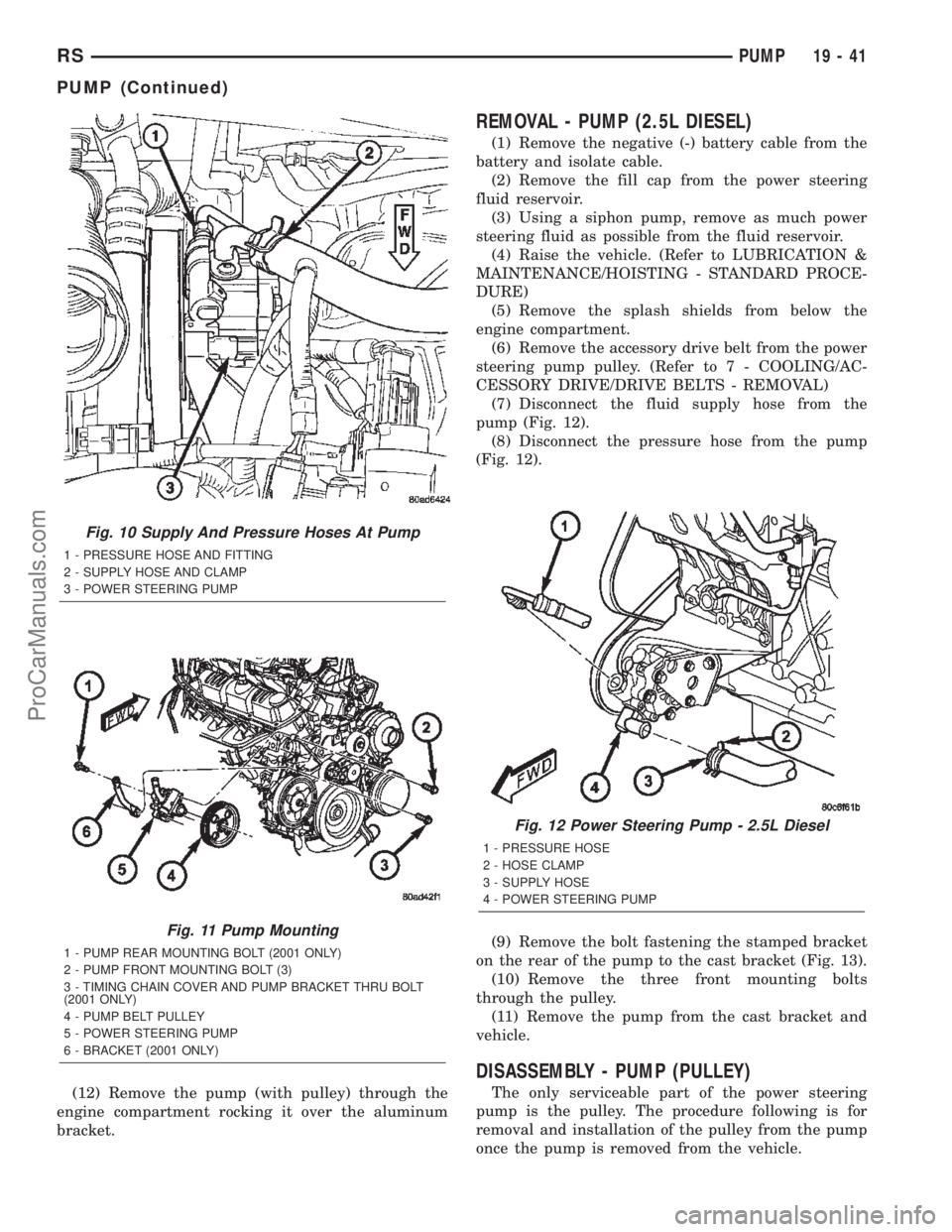

(12) Remove the pump (with pulley) through the

engine compartment rocking it over the aluminum

bracket.

REMOVAL - PUMP (2.5L DIESEL)

(1) Remove the negative (-) battery cable from the

battery and isolate cable.

(2) Remove the fill cap from the power steering

fluid reservoir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the fluid reservoir.

(4) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(5) Remove the splash shields from below the

engine compartment.

(6) Remove the accessory drive belt from the power

steering pump pulley. (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - REMOVAL)

(7) Disconnect the fluid supply hose from the

pump (Fig. 12).

(8) Disconnect the pressure hose from the pump

(Fig. 12).

(9) Remove the bolt fastening the stamped bracket

on the rear of the pump to the cast bracket (Fig. 13).

(10) Remove the three front mounting bolts

through the pulley.

(11) Remove the pump from the cast bracket and

vehicle.

DISASSEMBLY - PUMP (PULLEY)

The only serviceable part of the power steering

pump is the pulley. The procedure following is for

removal and installation of the pulley from the pump

once the pump is removed from the vehicle.

Fig. 10 Supply And Pressure Hoses At Pump

1 - PRESSURE HOSE AND FITTING

2 - SUPPLY HOSE AND CLAMP

3 - POWER STEERING PUMP

Fig. 11 Pump Mounting

1 - PUMP REAR MOUNTING BOLT (2001 ONLY)

2 - PUMP FRONT MOUNTING BOLT (3)

3 - TIMING CHAIN COVER AND PUMP BRACKET THRU BOLT

(2001 ONLY)

4 - PUMP BELT PULLEY

5 - POWER STEERING PUMP

6 - BRACKET (2001 ONLY)

Fig. 12 Power Steering Pump - 2.5L Diesel

1 - PRESSURE HOSE

2 - HOSE CLAMP

3 - SUPPLY HOSE

4 - POWER STEERING PUMP

RSPUMP19-41

PUMP (Continued)

ProCarManuals.com