engine oil CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1492 of 2399

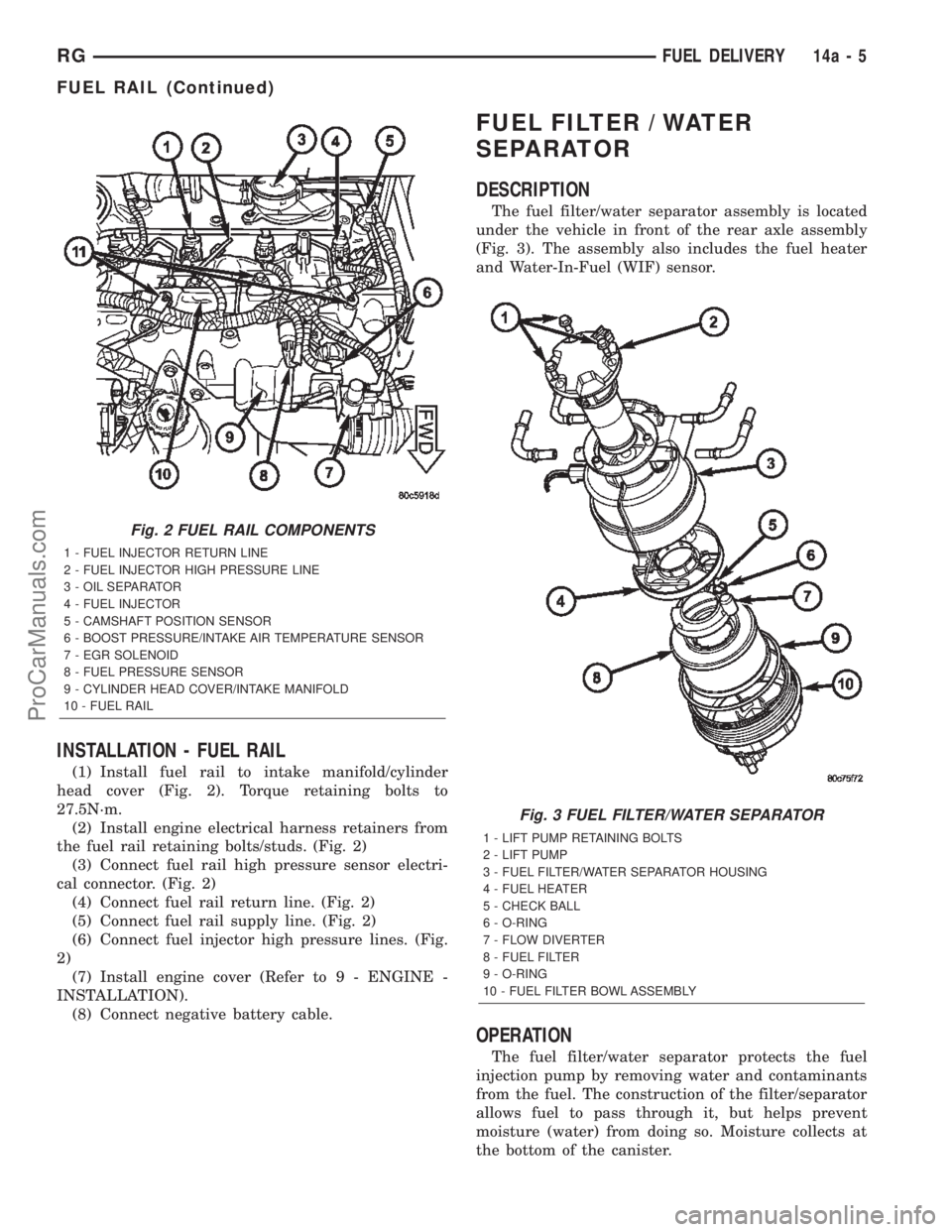

INSTALLATION - FUEL RAIL

(1) Install fuel rail to intake manifold/cylinder

head cover (Fig. 2). Torque retaining bolts to

27.5N´m.

(2) Install engine electrical harness retainers from

the fuel rail retaining bolts/studs. (Fig. 2)

(3) Connect fuel rail high pressure sensor electri-

cal connector. (Fig. 2)

(4) Connect fuel rail return line. (Fig. 2)

(5) Connect fuel rail supply line. (Fig. 2)

(6) Connect fuel injector high pressure lines. (Fig.

2)

(7) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(8) Connect negative battery cable.

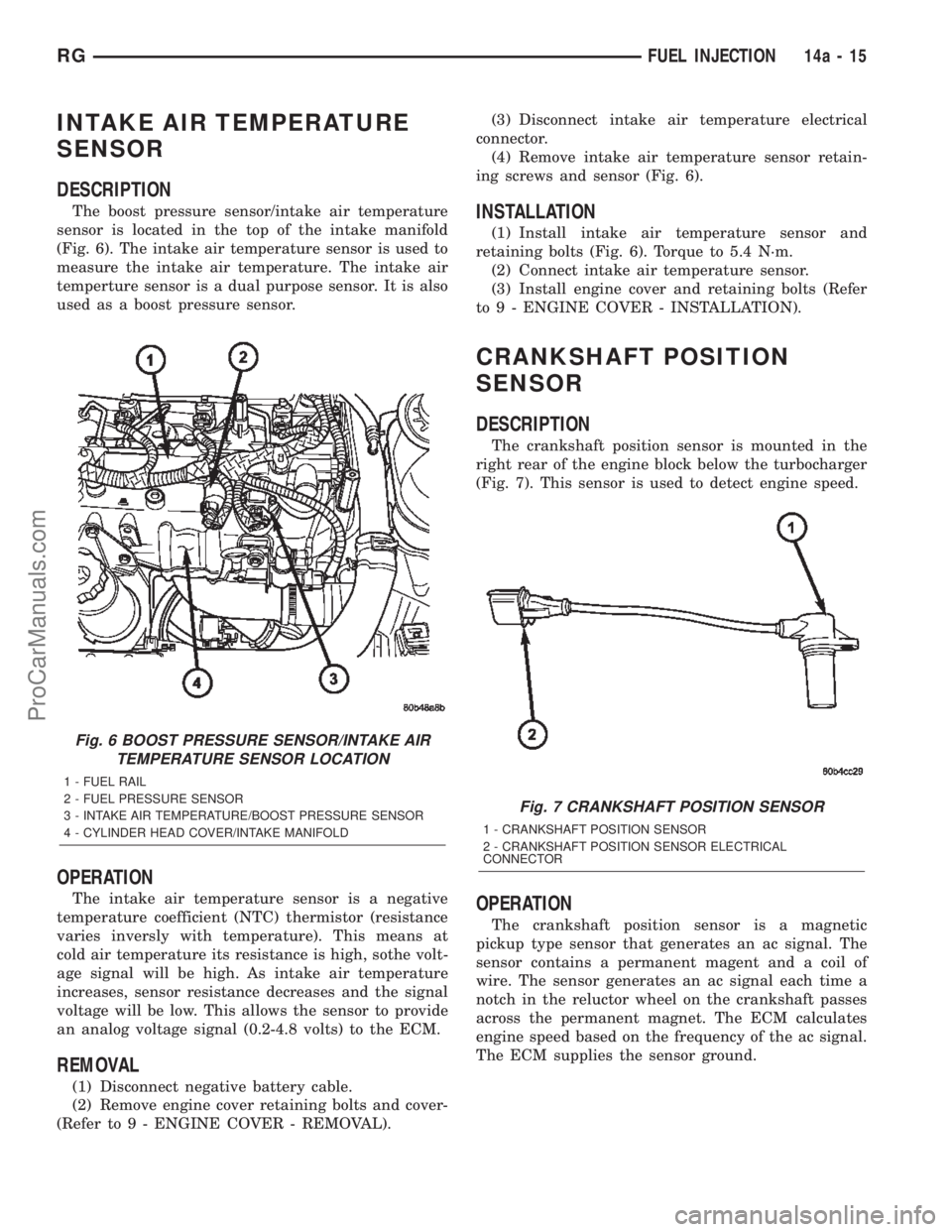

FUEL FILTER / WATER

SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located

under the vehicle in front of the rear axle assembly

(Fig. 3). The assembly also includes the fuel heater

and Water-In-Fuel (WIF) sensor.

OPERATION

The fuel filter/water separator protects the fuel

injection pump by removing water and contaminants

from the fuel. The construction of the filter/separator

allows fuel to pass through it, but helps prevent

moisture (water) from doing so. Moisture collects at

the bottom of the canister.

Fig. 2 FUEL RAIL COMPONENTS

1 - FUEL INJECTOR RETURN LINE

2 - FUEL INJECTOR HIGH PRESSURE LINE

3 - OIL SEPARATOR

4 - FUEL INJECTOR

5 - CAMSHAFT POSITION SENSOR

6 - BOOST PRESSURE/INTAKE AIR TEMPERATURE SENSOR

7 - EGR SOLENOID

8 - FUEL PRESSURE SENSOR

9 - CYLINDER HEAD COVER/INTAKE MANIFOLD

10 - FUEL RAIL

Fig. 3 FUEL FILTER/WATER SEPARATOR

1 - LIFT PUMP RETAINING BOLTS

2 - LIFT PUMP

3 - FUEL FILTER/WATER SEPARATOR HOUSING

4 - FUEL HEATER

5 - CHECK BALL

6 - O-RING

7 - FLOW DIVERTER

8 - FUEL FILTER

9 - O-RING

10 - FUEL FILTER BOWL ASSEMBLY

RGFUEL DELIVERY14a-5

FUEL RAIL (Continued)

ProCarManuals.com

Page 1502 of 2399

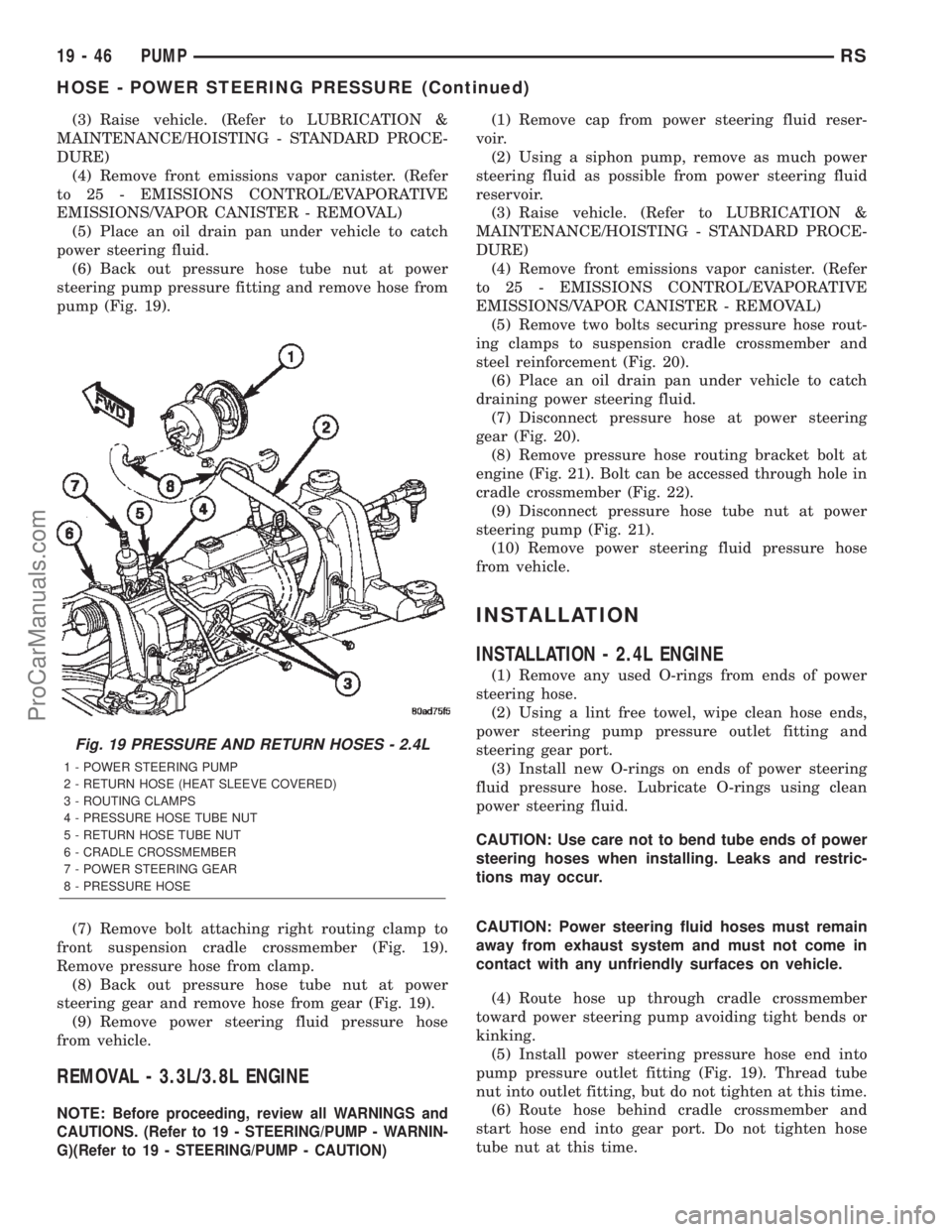

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

The boost pressure sensor/intake air temperature

sensor is located in the top of the intake manifold

(Fig. 6). The intake air temperature sensor is used to

measure the intake air temperature. The intake air

temperture sensor is a dual purpose sensor. It is also

used as a boost pressure sensor.

OPERATION

The intake air temperature sensor is a negative

temperature coefficient (NTC) thermistor (resistance

varies inversly with temperature). This means at

cold air temperature its resistance is high, sothe volt-

age signal will be high. As intake air temperature

increases, sensor resistance decreases and the signal

voltage will be low. This allows the sensor to provide

an analog voltage signal (0.2-4.8 volts) to the ECM.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover retaining bolts and cover-

(Refer to 9 - ENGINE COVER - REMOVAL).(3) Disconnect intake air temperature electrical

connector.

(4) Remove intake air temperature sensor retain-

ing screws and sensor (Fig. 6).

INSTALLATION

(1) Install intake air temperature sensor and

retaining bolts (Fig. 6). Torque to 5.4 N´m.

(2) Connect intake air temperature sensor.

(3) Install engine cover and retaining bolts (Refer

to 9 - ENGINE COVER - INSTALLATION).

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

The crankshaft position sensor is mounted in the

right rear of the engine block below the turbocharger

(Fig. 7). This sensor is used to detect engine speed.

OPERATION

The crankshaft position sensor is a magnetic

pickup type sensor that generates an ac signal. The

sensor contains a permanent magent and a coil of

wire. The sensor generates an ac signal each time a

notch in the reluctor wheel on the crankshaft passes

across the permanent magnet. The ECM calculates

engine speed based on the frequency of the ac signal.

The ECM supplies the sensor ground.

Fig. 6 BOOST PRESSURE SENSOR/INTAKE AIR

TEMPERATURE SENSOR LOCATION

1 - FUEL RAIL

2 - FUEL PRESSURE SENSOR

3 - INTAKE AIR TEMPERATURE/BOOST PRESSURE SENSOR

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD

Fig. 7 CRANKSHAFT POSITION SENSOR

1 - CRANKSHAFT POSITION SENSOR

2 - CRANKSHAFT POSITION SENSOR ELECTRICAL

CONNECTOR

RGFUEL INJECTION14a-15

ProCarManuals.com

Page 1529 of 2399

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION.........................26

OPERATION...........................26

WARNING

WARNINGS AND CAUTIONS.............26

REMOVAL

REMOVAL - LHD GEAR.................26

REMOVAL - RHD GEAR................29INSTALLATION

INSTALLATION - LHD GEAR.............32

INSTALLATION - RHD GEAR.............33

SPECIAL TOOLS

POWER STEERING GEAR..............34

OUTER TIE ROD

REMOVAL.............................34

INSTALLATION.........................34

GEAR

DESCRIPTION

This vehicle is equipped with a rack and pinion

power steering gear (Fig. 1). It is mounted to the

underside of the front suspension cradle/crossmem-

ber.

The steering column is attached to the gear

through the use of an intermediate shaft and cou-

plers. The outer ends of the power steering gear's

outer tie rods connect to the steering knuckles.

NOTE: The power steering gear should NOT be ser-

viced or adjusted unless DaimlerChrysler Corpora-

tion authorizes. If a malfunction or oil leak occurs,

the complete steering gear should be replaced.

Only the outer tie rods may be replaced separately

from the rest of the gear.

OPERATION

Turning of the steering wheel is converted into lin-

ear (side-to-side) travel through the meshing of the

helical pinion teeth with the rack teeth in the steer-

ing gear. This travel pushes and pulls the tie rods to

change the direction of the vehicle's front wheels.

Power assist steering provided by the power steer-

ing pump is controlled by an open center, rotary type

control valve which directs oil from the pump to

either side of the integral rack piston upon demand.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As required

steering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston

which, in turn, builds hydraulic pressure and assists

in the turning effort.Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However,

under this condition, steering effort is significantly

increased.

WARNING

WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

REMOVAL

REMOVAL - LHD GEAR

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.Use

care not to damage the filter mesh below the

fluid surface.

19 - 26 GEARRS

ProCarManuals.com

Page 1549 of 2399

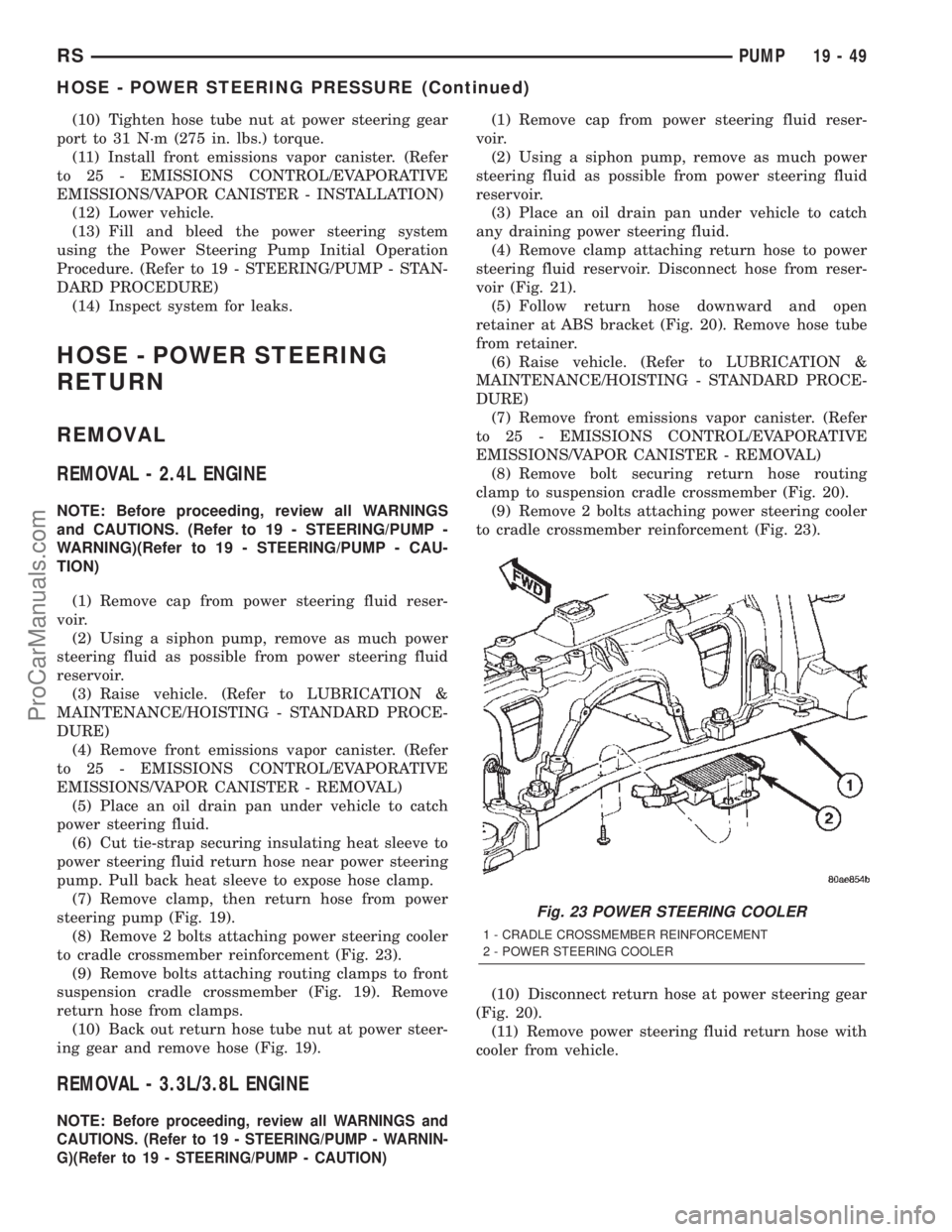

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Place an oil drain pan under vehicle to catch

power steering fluid.

(6) Back out pressure hose tube nut at power

steering pump pressure fitting and remove hose from

pump (Fig. 19).

(7) Remove bolt attaching right routing clamp to

front suspension cradle crossmember (Fig. 19).

Remove pressure hose from clamp.

(8) Back out pressure hose tube nut at power

steering gear and remove hose from gear (Fig. 19).

(9) Remove power steering fluid pressure hose

from vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE:Before proceeding, review all WARNINGS and

CAUTIONS. (Refer to 19 - STEERING/PUMP - WARNIN-

G)(Refer to 19 - STEERING/PUMP - CAUTION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Remove two bolts securing pressure hose rout-

ing clamps to suspension cradle crossmember and

steel reinforcement (Fig. 20).

(6) Place an oil drain pan under vehicle to catch

draining power steering fluid.

(7) Disconnect pressure hose at power steering

gear (Fig. 20).

(8) Remove pressure hose routing bracket bolt at

engine (Fig. 21). Bolt can be accessed through hole in

cradle crossmember (Fig. 22).

(9) Disconnect pressure hose tube nut at power

steering pump (Fig. 21).

(10) Remove power steering fluid pressure hose

from vehicle.

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Remove any used O-rings from ends of power

steering hose.

(2) Using a lint free towel, wipe clean hose ends,

power steering pump pressure outlet fitting and

steering gear port.

(3) Install new O-rings on ends of power steering

fluid pressure hose. Lubricate O-rings using clean

power steering fluid.

CAUTION: Use care not to bend tube ends of power

steering hoses when installing. Leaks and restric-

tions may occur.

CAUTION: Power steering fluid hoses must remain

away from exhaust system and must not come in

contact with any unfriendly surfaces on vehicle.

(4) Route hose up through cradle crossmember

toward power steering pump avoiding tight bends or

kinking.

(5) Install power steering pressure hose end into

pump pressure outlet fitting (Fig. 19). Thread tube

nut into outlet fitting, but do not tighten at this time.

(6) Route hose behind cradle crossmember and

start hose end into gear port. Do not tighten hose

tube nut at this time.

Fig. 19 PRESSURE AND RETURN HOSES - 2.4L

1 - POWER STEERING PUMP

2 - RETURN HOSE (HEAT SLEEVE COVERED)

3 - ROUTING CLAMPS

4 - PRESSURE HOSE TUBE NUT

5 - RETURN HOSE TUBE NUT

6 - CRADLE CROSSMEMBER

7 - POWER STEERING GEAR

8 - PRESSURE HOSE

19 - 46 PUMPRS

HOSE - POWER STEERING PRESSURE (Continued)

ProCarManuals.com

Page 1552 of 2399

(10) Tighten hose tube nut at power steering gear

port to 31 N´m (275 in. lbs.) torque.

(11) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(12) Lower vehicle.

(13) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(14) Inspect system for leaks.

HOSE - POWER STEERING

RETURN

REMOVAL

REMOVAL - 2.4L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Place an oil drain pan under vehicle to catch

power steering fluid.

(6) Cut tie-strap securing insulating heat sleeve to

power steering fluid return hose near power steering

pump. Pull back heat sleeve to expose hose clamp.

(7) Remove clamp, then return hose from power

steering pump (Fig. 19).

(8) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 23).

(9) Remove bolts attaching routing clamps to front

suspension cradle crossmember (Fig. 19). Remove

return hose from clamps.

(10) Back out return hose tube nut at power steer-

ing gear and remove hose (Fig. 19).

REMOVAL - 3.3L/3.8L ENGINE

NOTE:Before proceeding, review all WARNINGS and

CAUTIONS. (Refer to 19 - STEERING/PUMP - WARNIN-

G)(Refer to 19 - STEERING/PUMP - CAUTION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching return hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Follow return hose downward and open

retainer at ABS bracket (Fig. 20). Remove hose tube

from retainer.

(6) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(7) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(8) Remove bolt securing return hose routing

clamp to suspension cradle crossmember (Fig. 20).

(9) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 23).

(10) Disconnect return hose at power steering gear

(Fig. 20).

(11) Remove power steering fluid return hose with

cooler from vehicle.

Fig. 23 POWER STEERING COOLER

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

RSPUMP19-49

HOSE - POWER STEERING PRESSURE (Continued)

ProCarManuals.com

Page 1554 of 2399

HOSE - POWER STEERING

SUPPLY

REMOVAL

REMOVAL - 2.4L ENGINE

(1) Remove filler cap from power steering fluid res-

ervoir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove hose clamp securing supply hose to

power steering pump, then remove supply hose from

pump fitting.

(5) Lower vehicle.

(6) Remove hose clamp attaching power steering

fluid supply hose to power steering fluid reservoir,

then remove supply hose.

(7) Remove the power steering fluid supply hose

from the vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching supply hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Pull upward on hose routing clip releasing it

from bracket on cylinder head cover (Fig. 21).

NOTE: It may be necessary to remove air cleaner

housing to gain greater access to supply hose at

power steering pump. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL)

(6) Remove clamp attaching supply hose to power

steering pump. Disconnect hose from pump and

remove from vehicle (Fig. 21).

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Install and correctly route power steering fluid

supply hose from remote fluid reservoir to power

steering pump.

(2) Install fluid supply hose onto power steering

fluid reservoir. Install hose clamp.Be sure hose

clamp is installed past bead on fluid reservoir

fitting.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Install power steering fluid supply hose on

power steering pump supply fitting. Install hose

clamp.Be sure hose clamp is installed past bead

on pump fitting.

(5) Lower vehicle.

(6) Fill and bleed power steering system using

Power Steering Pump Initial Operation Procedure.

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE)

(7) Inspect system for leaks.

INSTALLATION - 3.3L/3.8L ENGINE

(1) Install supply hose onto supply fitting on power

steering pump (Fig. 21). Slide the hose clamp into

position on fluid reservoir and attach it.Be sure

hose clamp in installed past bead on fluid res-

ervoir fitting.

(2) Align routing clip located toward center of sup-

ply hose with hole in bracket on cylinder head cover

and push into place (Fig. 21).

(3) Install supply hose onto reservoir (Fig. 21).

Slide the hose clamp into position on fluid reservoir

and attach it.Be sure hose clamp in installed

past bead on fluid reservoir fitting.

(4) Fill and bleed power steering system using

Power Steering Pump Initial Operation Procedure.

(Refer to 19 - STEERING/PUMP - STANDARD PRO-

CEDURE)

(5) Inspect system for leaks.

RESERVOIR - POWER

STEERING FLUID

DESCRIPTION

DESCRIPTION - 2.4L/3.3L/3.8L ENGINE

All vehicles use a remote mounted power steering

fluid reservoir. The power steering fluid reservoir is

mounted to the engine near the battery (Fig. 24).

RSPUMP19-51

ProCarManuals.com

Page 1561 of 2399

FLUID LEAK DIAGNOSIS

When diagnosing fluid leaks on the Power Transfer

Unit two weep holes are provided to diagnose certain

seal leaks. These holes are located on the bottom side

of the assembly (Fig. 5).

If fluid leak is detected from either weep hole, seal

replacement is necessary.Do not attempt to repair

the leak by sealing weep holes,they must be kept

clear of sealants for proper seal operation.

If fluid is leaking from weep hole A (Fig. 5) the

type of fluid leaking will determine which seal needs

to be replaced. If the fluid leaking is red in color(transmission fluid) this indicates that the Transmis-

sion differential carrier seal should be replaced. If

the fluid leaking is light brown (gear lube) this indi-

cates that the Power Transfer Unit input seal should

be replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

If fluid is leaking from weep hole B (Fig. 5) the

type of fluid leaking will determine which seal is

leaking. If the fluid leaking is red in color (transmis-

sion fluid) this indicates that the input shaft end seal

should be replaced. If the fluid leaking is light brown

(gear lube) this indicates that the half shaft inner

seal and P.T.U. input shaft cover seal should be

replaced. For replacement of these seals refer to

Power Transfer Unit Service Procedures.

Before condemning any seal or gasket be sure that

the rear rocker arm cover on the engine is not the

cause of the oil leak. Oil leaking from the rocker arm

cover is easily mistaken for a leaking Power Transfer

Unit.

Fig. 3 Seal Location

1 - INPUT SHAFT

2 - OUTPUT SHAFT

3 - REAR COVER

4 - P.T.U. CASE

5 - INPUT SHAFT SEAL

Fig. 4 Seal Location

1 - P.T.U. INPUT SHAFT COVER SEAL

2 - HALF SHAFT INNER SEAL

3 - INSIDE VIEW OF P.T.U. END COVER

Fig. 5 Weep Hole Locations

1 - ENGINE OIL PAN

2 - WEEP HOLE ªAº

3 - TRANSAXLE CASE

4 - P.T.U.

5 - WEEP HOLE ªBº

21 - 4 POWER TRANSFER UNITRS

POWER TRANSFER UNIT (Continued)

ProCarManuals.com

Page 1579 of 2399

ASSEMBLY...........................115

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................115

OPERATION..........................115

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................117

REMOVAL............................117

INSTALLATION........................118

SOLENOID - TCC

DESCRIPTION........................119

OPERATION..........................119

REMOVAL............................119

INSTALLATION........................120

THROTTLE VALVE CABLE

REMOVAL............................120

INSTALLATION........................121

ADJUSTMENTS

THROTTLE VALVE LINKAGE

ADJUSTMENT.......................122

TORQUE CONVERTER

DESCRIPTION........................122

OPERATION..........................126

REMOVAL............................127

INSTALLATION........................127

TRANSFER SYSTEM - OUTPUT SHAFT/GEAR/

BEARING

REMOVAL............................128INSTALLATION........................131

ADJUSTMENTS

ADJUSTMENT - OUTPUT SHAFT BEARING . 135

TRANSFER SYSTEM - TRANSFER SHAFT/

GEAR/BEARING

REMOVAL............................137

INSTALLATION........................141

ADJUSTMENTS

ADJUSTMENT - TRANSFER SHAFT

BEARING...........................145

VALVE BODY

REMOVAL............................146

DISASSEMBLY........................148

CLEANING...........................154

INSPECTION.........................155

ASSEMBLY...........................155

INSTALLATION........................158

ADJUSTMENTS

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS......................160

VEHICLE SPEED SENSOR/PINION GEAR

REMOVAL............................160

INSTALLATION........................160

31TH AUTOMATIC

TRANSAXLE

DESCRIPTION

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heatexchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

21 - 22 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1586 of 2399

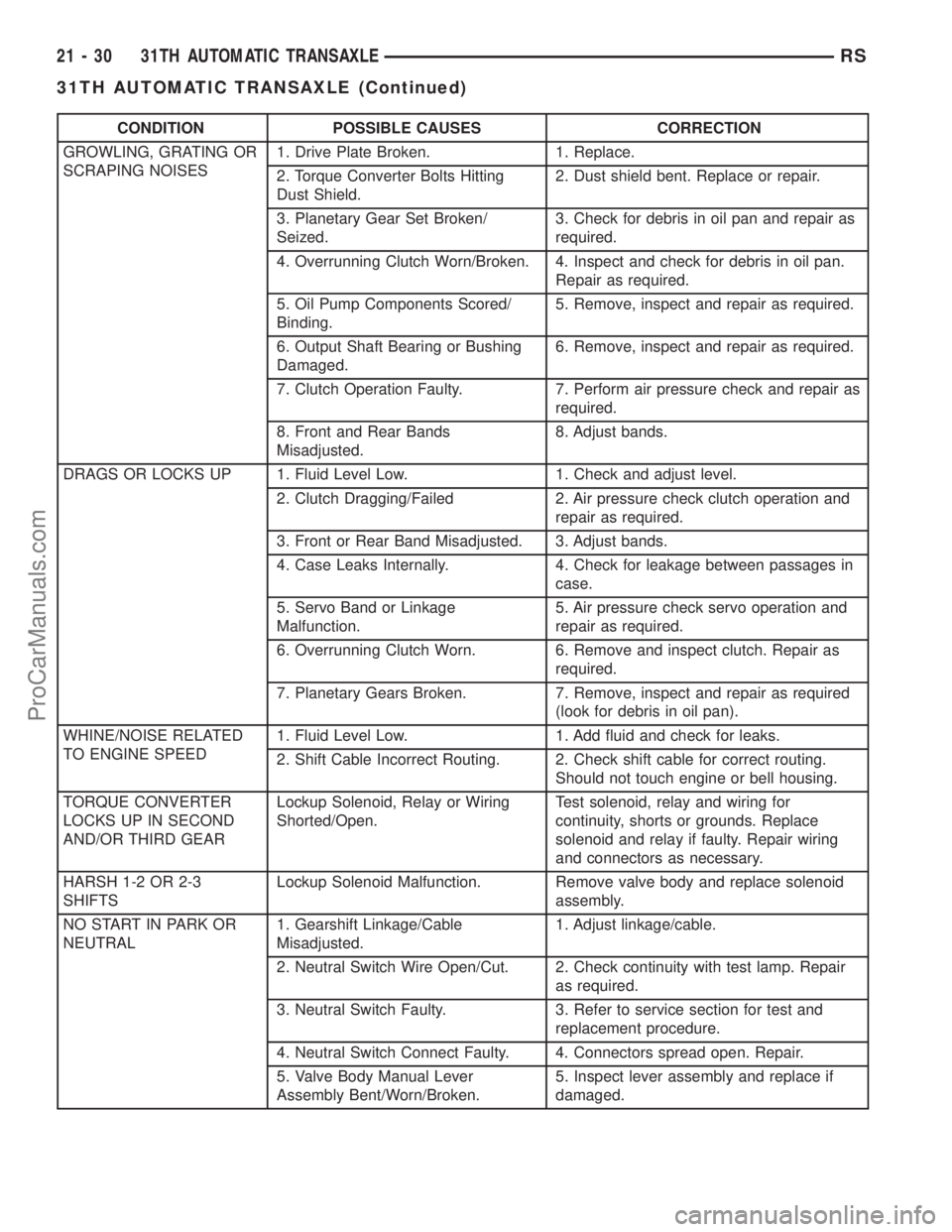

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Misassembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Misassembled. 3. Remove, disassemble, inspect valve

body. Reassemble correctly if necessary.

Replace assembly if valves or springs are

damaged. Check for loose bolts or screws.

4. Pump Passages Leaking 4. Check pump for porous casting, scores

on mating surfaces and excess rotor

clearance. Repair as required. Loose pump

bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as

needed.

6.Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE ONLY 1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Misadjusted. 2. Adjust linkage.

3. Rear Band Misadjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Hydraulic Pressure Too Low. 5. Perform hydraulic pressure tests to

determine cause.

6. Rear Servo Leaking. 6. Air pressure check clutch-servo operation

and repair as required.

7. Band Linkage Binding. 7. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump

gasket or seals, dirt between pump halves

and loose pump bolts. Replace pump if

necessary.

3. Throttle Linkage Misadjusted. 3. Adjust linkage.

4. Gearshift Linkage Misadjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking

Governor, Leaking Seal Rings,

Clutch Seals Leaking, Servo Leaks,

Clogged Filter or Cooler Lines6. Perform hydraulic and air pressure tests

to determine cause.

7. Rear Clutch Malfunction, Leaking

Seals or Worn Plates.7. Air pressure check clutch-servo operation

and repair as required.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).8. Replace Clutch.

SLIPS IN LOW GEAR9D9

ONLY, BUT NOT IN 1

POSITIONOverrunning Clutch Faulty. Replace overrunning clutch.

RS31TH AUTOMATIC TRANSAXLE21-29

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1587 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

Repair as required.

5. Oil Pump Components Scored/

Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Misadjusted.8. Adjust bands.

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

repair as required.

3. Front or Rear Band Misadjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and

repair as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

(look for debris in oil pan).

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK OR

NEUTRAL1. Gearshift Linkage/Cable

Misadjusted.1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

21 - 30 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com