engine oil CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1875 of 2399

DIAGNOSIS AND TESTING - COMMON

PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

²Improper operation

HARD SHIFTING

Hard shifting may be caused by a misadjusted

crossover cable. If hard shifting is accompanied by

gear clash, synchronizer clutch and stop rings or gear

teeth may be worn or damaged.

Hard shifting may also be caused by a binding or

broken shift cover mechanism. Remove shift cover

and verify smooth operation. Replace as necessary.

Misassembled synchronizer components also cause

shifting problems. Incorrectly installed synchronizer

sleeves, keys, balls, or springs can cause shift prob-

lems.

NOISY OPERATION

Transaxle noise is most often a result of worn or

damaged components. Chipped, broken gear or syn-

chronizer teeth, and brinnelled, spalled bearings all

cause noise.

Abnormal wear and damage to the internal compo-

nents is frequently the end result of insufficient

lubricant.

SLIPS OUT OF GEAR

Transaxle disengagement may be caused by mis-

aligned or damaged shift components, or worn teeth

on the drive gears or synchronizer components. Incor-

rect assembly also causes gear disengagement. Check

for missing snap rings.

LOW LUBRICANT LEVEL

Insufficient transaxle lubricant is usually the

result of leaks, or inaccurate fluid level check or refill

method. Leakage is evident by the presence of oil

around the leak point. If leakage is not evident, the

condition is probably the result of an underfill.

If air±powered lubrication equipment is used to fill

a transaxle, be sure the equipment is properly cali-

brated. Equipment out of calibration can lead to an

underfill condition.

CLUTCH PROBLEMS

Worn, damaged, or misaligned clutch components

can cause difficult shifting, gear clash, and noise.

A worn or damaged clutch disc, pressure plate, or

release bearing can cause hard shifting and gear

clash.

REMOVAL

REMOVAL - 2.4L GAS

(1) Raise hood.

(2) Disconnect gearshift cables from shift levers/

cover assembly (Fig. 10).

(3) Remove gearshift cable retaining clips from

mounting bracket (Fig. 10). Remove cables and

secure out of way.

(4) Remove three (3) right engine mount bracket-

to-transaxle bolts (Fig. 11).

(5) Raise vehicle on hoist.

(6) Remove front wheel/tires and halfshafts.

(7) Drain transaxle fluid into suitable container.

(8) Remove front harness retainer and secure har-

ness out of way.

Fig. 10 Gearshift Cables at Transaxle

1 - SELECTOR CABLE

2 - CABLE RETAINER

3 - CABLE RETAINER

4 - CROSSOVER CABLE

5 - MOUNT BRACKET

21 - 318 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1876 of 2399

(9) Using Tool 6638A, disconnect clutch hydraulic

circuit quick connect (located on slave cylinder tube).

Remove clutch slave cylinder by depressing towards

case and rotating counter-clockwise 60É, while lifting

anti-rotation tab out of case slot with screwdriver

(Fig. 12).

(10) Remove engine left mount bracket.

(11) Remove starter motor (Fig. 13).

(12) Disconnect back-up lamp switch connector.

(13) Remove structural collar.

(14) Remove modular clutch assembly-to-drive

plate bolts.

(15) Position screw jack and wood block to engine

oil pan.

(16) Remove transmission upper mount through-

bolt from left frame rail.

(17) Lower engine/transaxle assembly on screw

jack.

Fig. 11 Transaxle Right Mount and Bracket

1 - MOUNT BRACKET

2 - BOLT (3)

3 - MOUNT

4 - BOLT (1)

Fig. 12 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 13 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

RST850 MANUAL TRANSAXLE21 - 319

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1879 of 2399

(11) Raise vehicle on hoist.

(12) Remove front wheel/tires and halfshafts.

(13) Remove underbody splash shield.

(14) Drain transaxle fluid into suitable container.

(15) Remove front harness retainer and secure

harness out of way.

(16) Using Tool 6638A, disconnect clutch hydrau-

lic circuit quick connect (located on slave cylinder

tube). Remove clutch slave cylinder by depressing

towards case and rotating counter-clockwise 60É,

while lifting anti-rotation tab out of case slot with

screwdriver (Fig. 21).

(17) Remove engine left mount bracket (Fig. 22).

(18) Remove starter motor (Fig. 23).

(19) Disconnect back-up lamp switch connector.

(20) Position screw jack and wood block to engine

oil pan.

(21) Remove transmission upper mount through-

bolt from left frame rail.

(22) Lower engine/transaxle assembly on screw

jack.

Fig. 21 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

5 - QUICK CONNECT

Fig. 22 Left Mount Bracket Removal/Installation

1 - BOLT (2)

2 - MOUNT BRACKET

3 - BOLT (2)

Fig. 23 Starter Motor Removal/Installation

1 - STARTER MOTOR

2 - BOLT (3)

21 - 322 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1900 of 2399

(19) Install battery thermal shield and clutch cable

eyelet (Fig. 91).(20) Connect battery cables.

(21) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.46

2nd 2.07 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.53

Overall Top Gear 3.12 2.66

Fig. 91 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RST850 MANUAL TRANSAXLE21 - 343

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1995 of 2399

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lifgate stabalizer wedge striker to D-pillar bolts 3 Ð 30

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track quide to seat riser 3.5 Ð 31

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

23 - 12 BODYRS

BODY (Continued)

ProCarManuals.com

Page 2248 of 2399

control rear set temp button is pressed simulta-

neously with the rear control head, then the front

control head press events shall have priority, i.e. if

the front user presses Rear Set Temp down and the

rear user presses Set Temp up, then the rear set

temp will decrease.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C COOL DOWN

TEST

The heater-A/C control module can perform an A/C

cool down test, which is a test performed during the

manufacturing process to confirm that the air condi-

tioning system is performing satisfactorily. This test

can also provide a quick confirmation of air condi-

tioning system performance to the service technician.

If the test is completed satisfactorily, no further ser-

vice is required. If the test is failed, proceed to the

A/C Performance Test to confirm the a/c system is

operating properly, or use a DRBIIItscan tool to

diagnose the A/C system control and distribution sys-

tems. Refer to the appropriate diagnostic informa-

tion.

MANUAL TEMPERATURE CONTROL

The front blower speed and rear blower speed (if

equipped with rear HVAC) must be set to High and

the evaporator temperature sensor must be greater

than 55É F or the test will fail immediately. The test

is activated by depressing the A/C and PWR buttons

simultaneously and holding them depressed for no

less than five seconds. The PWR and A/C LEDs will

blink on and off until the test is complete. If the

LEDs stop blinking before two minutes, then the cool

down test has been completed successfully. If the two

minutes expire without the expansion valve temper-

ature reaching 20É F less than the outside air tem-

perature, then the cool down test has been failed and

further A/C system diagnosis is required. If the test

is failed, the LEDs will continue to blink until the

vehicle has been driven for greater than (8 miles).

AUTOMATIC TEMPERATURE CONTROL

The ambient air temperature in the room where

the vehicle will be tested must be a minimum of 21É

C (70ÉF) for this test. The test is activated by

depressing the A/C and PWR buttons simultaneously

and holding them depressed for no less than four sec-

onds. The snowflake icon and the DELAY text in the

ATC display will blink on and off alternately until

the test is complete. If the snowflake icon and the

DELAY text stop blinking before two minutes, then

the cool down test has been completed successfully. If

the two minutes expire without the evaporator tem-perature reaching 20É F less than the evaporator ini-

tial temperature, then the cool down test has been

failed and further A/C system diagnosis is required.

If the test is failed, the snowflake icon and the

DELAY text will continue to blink across ignition

cycles until the vehicle has been driven for greater

than (8 miles).

DIAGNOSIS AND TESTING - A/C

PERFORMANCE TEST

An air conditioning performance test is the best

way to determine whether the system is performing

up to standard. This test also provides valuable clues

as to the possible cause of trouble with the air con-

ditioning system. The ambient air temperature in the

location where the vehicle will be tested must be a

minimum of 21É C (70ÉF) for this test.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer to monitor the engine

speed.

(2) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set to

monitor the refrigerant system pressures.

(3) Set the heater-air conditioner controls so that

the compressor is engaged, the air within the vehicle

is being recirculated, the output air is directed

through the panel outlets, the temperature control is

in the full cool position, and the blower motor is oper-

ating at its highest speed.

(4) Start the engine and allow the engine to oper-

ate for about five minutes or until it reaches normal

operating temperature. Then hold the engine speed

at 1000 rpm with the compressor clutch engaged. If

the compressor clutch does not engage, proceed with

diagnosis of the compressor clutch coil. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS -

FRONT/COMPRESSOR CLUTCH COIL - DIAGNO-

SIS AND TESTING).

(5) Close all the vehicle windows and doors.

(6) Insert a thermometer in the left center panel

outlet and operate the engine for five minutes.

RSHEATING & AIR CONDITIONING24-5

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2250 of 2399

If coolant flow is verified and the heater floor out-

let temperature is insufficient, a mechanical problem

may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT HEAT

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend-air door not functioning properly.TEMPERATURE CONTROL

If heater floor outlet temperature cannot be

adjusted with the heater-A/C control temperature

control lever, one of the following could require ser-

vice:

²Blend-air door binding.

²Faulty blend-air door motor.

²Improper engine coolant temperature.

²Faulty heater-A/C control.

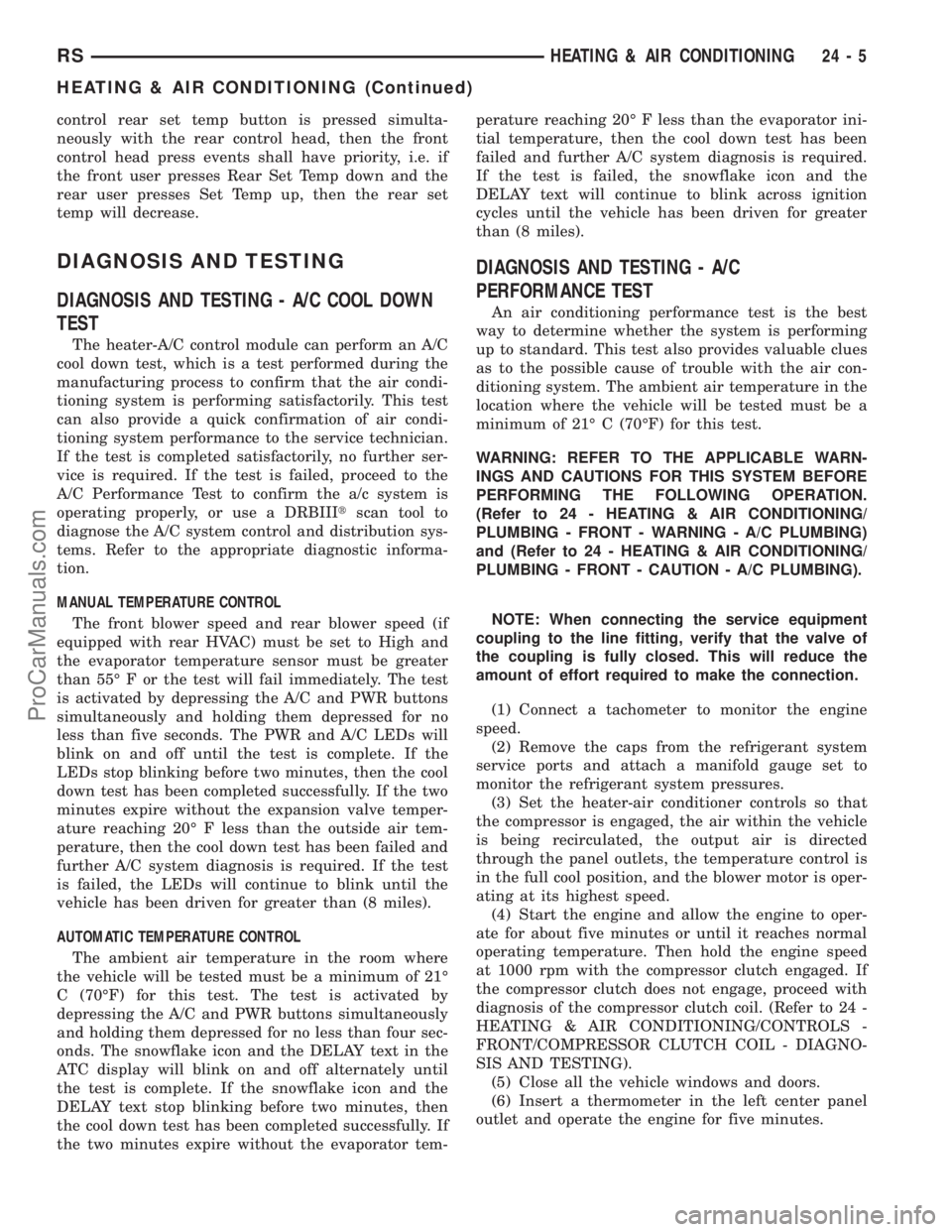

SPECIFICATIONS - HEATER-A/C SYSTEM

ITEM DESCRIPTION NOTES

Vehicle RS - Caravan, Town & Country, Voyager

System R134a with expansion valve(s)

Compressor Nippondenso - 10S20 ND-8 PAG Oil

Freeze±up Control evaporator temperature sensor expansion valve mounted - input

to heater-A/C control module

Low PSI Control liquid line mounted - input to

Powertrain Control Module (PCM)

- PCM opens compressor clutch

relay < 29.4 psi

High PSI Control pressure transducer liquid line mounted - input to

PCM - PCM opens compressor

clutch relay > 450 psi

pressure relief valve compressor mounted - opens >

495 psi

Control Head single zone, dual zone, and three zone

Manual Temperature Control (MTC) - or three

zone Automatic Temperature Control (ATC)PCI data bus messaging - ATC

uses three infrared temperature

sensors - two front/one rear

Mode Door electric actuator Control head driven

Blend Air Door electric actuator

Fresh/Recirc Door electric actuator

Blower Motor control head switch resistor and relay with MTC,

power module and relay with ATC

Cooling Fans pulse width modulated variable speed PCM control through solid state

fan relay

Clutch

Clutch Control PCM PCM control through compressor

clutch relay

Clutch Coil Draw 2.2 amps @ 12V 0.5amps@ 70É F

Compressor Clutch Air Gap 0.0209- 0.0359

Diagnostics DRBIIITscan tool

RSHEATING & AIR CONDITIONING24-7

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2256 of 2399

(5) Install and tighten the three screws that secure

the heater core shield to the left end of the heater/air

conditioner housing. Tighten the screws to 2 N´m (17

in. lbs.).

(6) Reinstall the silencer under the driver side end

of the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL

SILENCER - INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay (Fig. 6) is a International

Standards Organization (ISO) mini-relay. Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminal

patterns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Intelligent Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout mapmolded into the inner surface of the IPM cover for

blower motor relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (ATC control).

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Intelligent Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Fig. 6 Blower Motor Relay

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

RSCONTROLS - FRONT24-13

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2257 of 2399

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

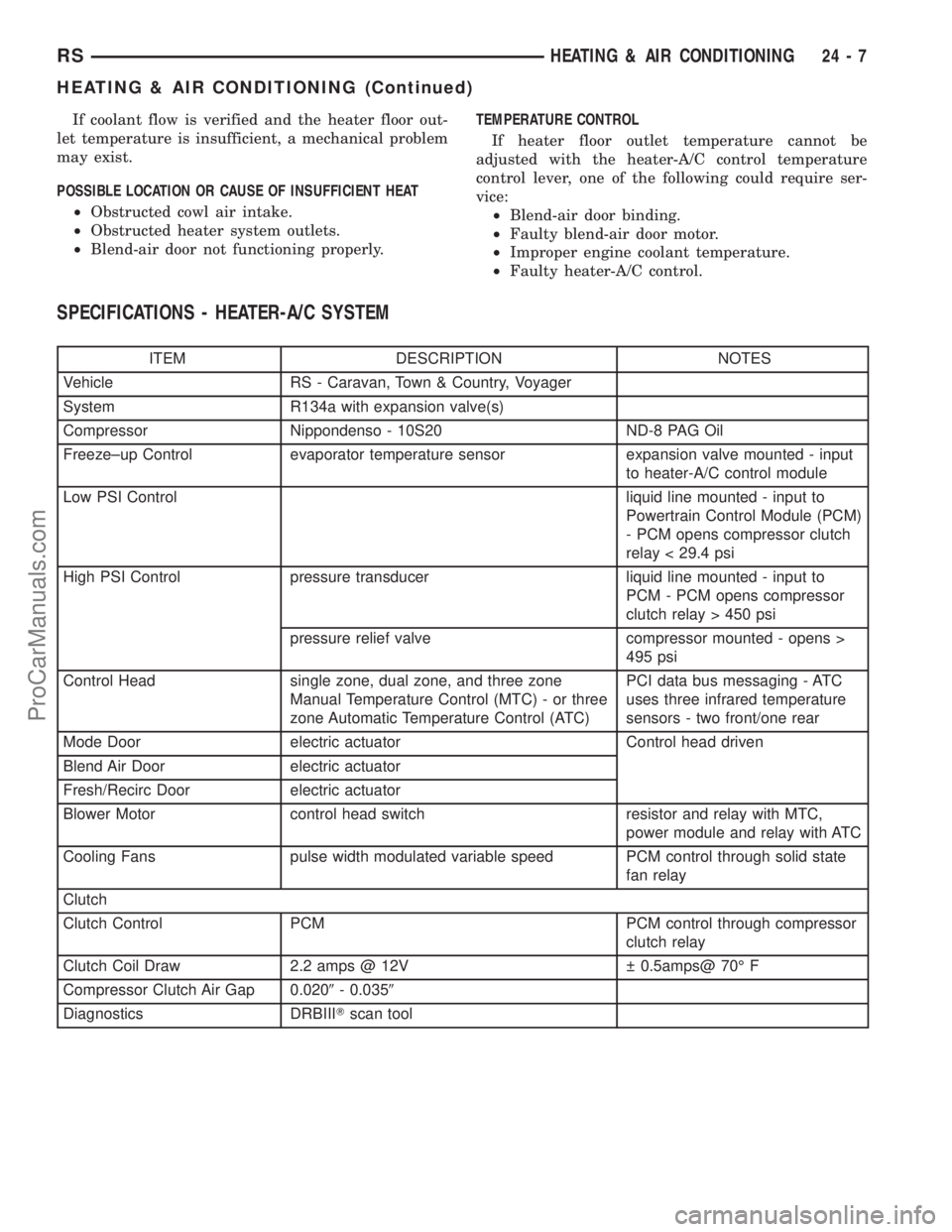

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

The front blower motor relay (Fig. 7) is located in

the Intelligent Power Module (IPM), which is in the

engine compartment near the battery. See the fuse

and relay layout map molded into the inner surface

of the IPM cover for front blower motor relay identi-

fication and location. Remove the relay from the IPM

to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, use a DRBIIItscan tool to perform

further diagnosis of the relay circuits. Refer to the

appropriate diagnostic information. If not OK,

replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Intelli-

gent Power Module (IPM) (Fig. 8).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for front blower

motor relay identification and location.

(4) Remove the front blower motor relay from the

IPM by pulling the relay straight up.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Intelligent Power Module

(IPM) cover for front blower motor relay identifica-

tion and location.

(2) Position the front blower motor relay to the

proper receptacle in the IPM.

(3) Align the front blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the front blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install and latch the cover onto the IPM.

(6) Reconnect the battery negative cable.

Fig. 7 Blower Motor Relay - Terminal Legend

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 8 Intelligent Power Module

1 - BATTERY THERMAL GUARD

2 - INTELLIGENT POWER MODULE

3 - FRONT CONTROL MODULE

24 - 14 CONTROLS - FRONTRS

BLOWER MOTOR RELAY (Continued)

ProCarManuals.com

Page 2260 of 2399

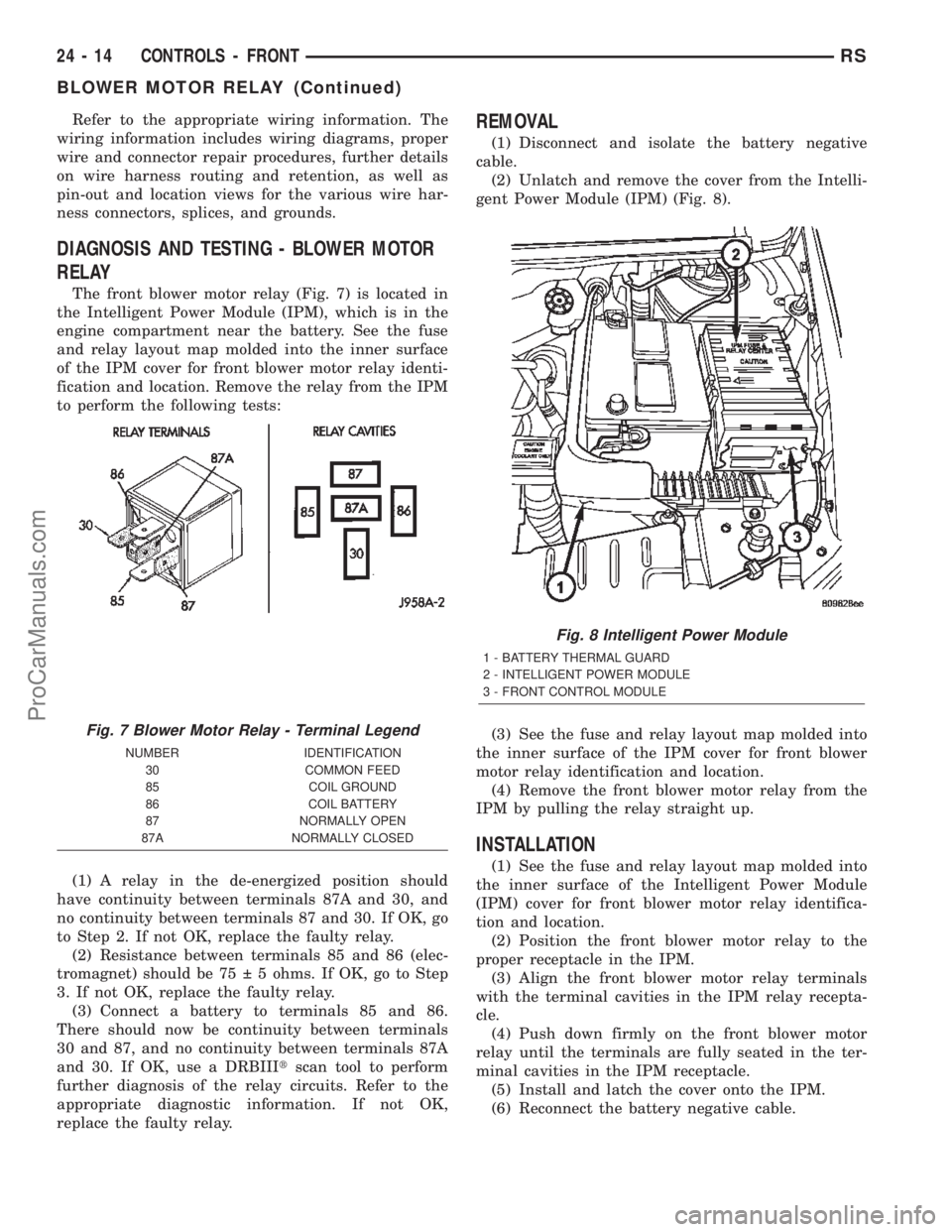

The compressor clutch plate and pulley unit, or the

clutch coil are available for separate service replace-

ment. The clutch coil zener diode is integral to the

clutch coil pigtail wire and connector and, if faulty or

damaged, the clutch electromagnetic coil unit must

be replaced.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch plate into contact with the clutch pulley and

drives the compressor shaft. When the coil is not

energized, the pulley freewheels on the clutch hub

bearing, which is part of the pulley.

A zener diode is connected in parallel with the

clutch electromagnetic coil. This diode controls the

dissipation of voltage induced into the coil windings

by the collapsing of the electromagnetic fields that

occurs when the compressor clutch is disengaged.

The zener diode dissipates this induced voltage by

regulating a current path to ground. This arrange-

ment serves to protect other circuits and components

from potentially damaging voltage spikes in the vehi-

cle electrical system that might occur if the voltage

induced in the clutch coil windings could not be dis-

sipated.

The compressor clutch engagement is controlled by

several components: the heater-A/C controls in the

passenger compartment, the A/C pressure transducer

on the liquid line, the evaporator temperature sensor

on the expansion valve, the Powertrain Control Mod-ule (PCM) in the engine compartment, and the com-

pressor clutch relay in the Intelligent Power Module

(IPM). The PCM may delay compressor clutch

engagement for up to thirty seconds. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION - PCM OPERATION).

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSOR

CLUTCH AIR GAP

If a new clutch plate and/or clutch pulley are being

used, the air gap between the clutch plate and clutch

pulley must be checked using the following proce-

dure:

(1) Using feeler gauges, measure the air gap

between the clutch plate and the clutch pulley fric-

tion surfaces.

(2) If the air gap is not between 0.5 and 0.9 mm

(0.020 and 0.035 in.), add or subtract shims until the

desired air gap is obtained.

NOTE: The shims may compress after tightening

the compressor shaft bolt. Check the air gap in four

or more places on the clutch plate to verify that the

air gap is still correct. Spin the clutch pulley before

making the final air gap check.

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

check that the compressor clutch coil is performing to

specifications. (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS - FRONT/COMPRESSOR

CLUTCH COIL - DIAGNOSIS AND TESTING). If

the clutch coil is performing to specifications, per-

form the compressor clutch break-in procedure. This

procedure (burnishing) will seat the opposing friction

surfaces and provide a higher compressor clutch

torque capability.

(1) Set the heater-A/C controls to the A/C mode,

with the blower switch in the highest speed position.

(2) Start the engine and hold the engine speed at

1500 to 2000 rpm.

(3) Cycle the compressor clutch On and Off about

twenty times (five seconds On, then five seconds Off).

REMOVAL

The refrigerant system can remain fully charged

during compressor clutch, pulley, or coil replacement.

Although the compressor assembly must be removed

from its mounting, the compressor clutch can be ser-

vice with the compressor in the vehicle.

Fig. 11 Compressor Clutch - Typical

1 - CLUTCH PLATE

2 - SHAFT KEY (SOME MODELS)

3 - PULLEY AND BEARING

4 - CLUTCH COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

RSCONTROLS - FRONT24-17

COMPRESSOR CLUTCH (Continued)

ProCarManuals.com