steering CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 42 of 2399

(5) Hand-thread the nut on the end of each stabi-

lizer bar link stud. Hold the studs from turning by

placing an open-end wrench on the flat machined

into the link's mounting stud, then tighten each nut

while holding the wrench in place (Fig. 33). Tighten

each nut to a torque of 88 N´m (65 ft. lbs.).(6) Tighten the stabilizer bar bushing retainer to

cradle attaching bolts (Fig. 34) to 68 N´m (50 ft. lbs.)

torque.

(7) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 32). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(8) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten these

M-10 size bolts to a torque of 61 N´m (45 ft. lbs.).

(9) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 32). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(10) Install the power steering cooler (Fig. 31).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(11) Lower the vehicle.

STRUT

DESCRIPTION - STRUT ASSEMBLY

A Macpherson type strut assembly is used in place

of a conventional front suspension's upper control

arm and upper ball joint. The bottom of the strut

mounts directly to the steering knuckle using two

bolts and nuts going through the strut clevis bracket

and steering knuckle. The top of the strut mounts

directly to the strut tower of the vehicle using the

threaded studs on the strut assemblies upper mount.

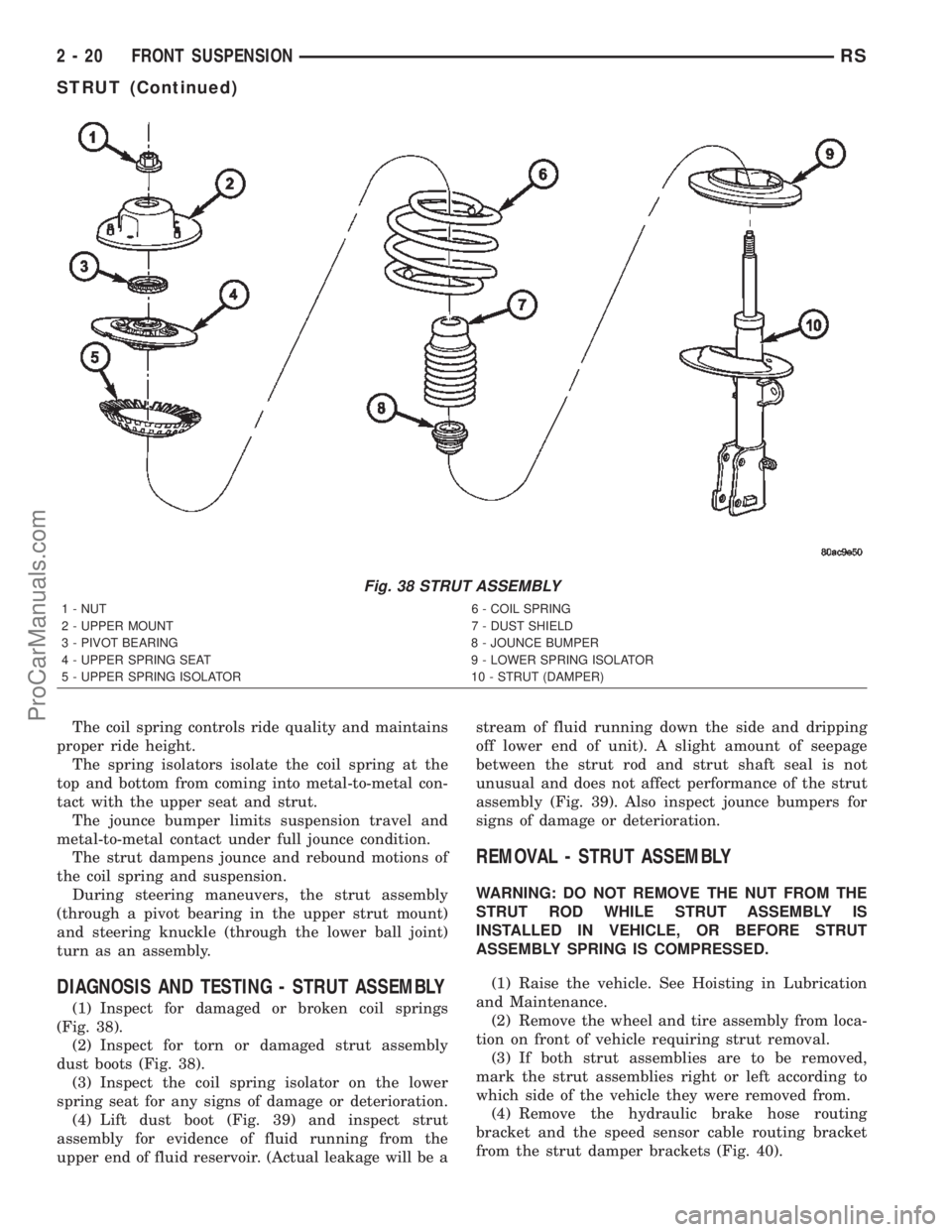

The strut assembly includes the components listed

in the figure (Fig. 38).

Each component is serviced by removing the strut

assembly from the vehicle and disassembling it.

The coil springs are side-oriented. Springs on the

left side of the vehicle have a left-hand wind top-to-

bottom while springs on the right side have a right-

hand wind top-to-bottom. This helps provide better

vehicle stability during jounce and rebound maneu-

vers of the front suspension. Left and right springs

must not be interchanged. Coil springs are rated sep-

arately for each corner or side of the vehicle depend-

ing on optional equipment and type of vehicle

service. If the coil springs require replacement, be

sure that the springs are replaced with springs meet-

ing the correct load rating and spring rate for the

vehicle and its specific options.

OPERATION - STRUT ASSEMBLY

The strut assembly cushions the ride of the vehicle,

controlling vibration, along with jounce and rebound

of the suspension.

Fig. 36 Stabilizer Bar Bushing Retainer Installation

1-SWAYBAR

2 - SWAY BAR BUSHING

3 - BUSHING SPLIT

4 - FRONT SUSPENSION CRADLE

5 - BUSHING CUT-OUT

6 - BUSHING RETAINER

7 - RAISED BEAD

Fig. 37 Stabilizer Bar Correctly Positioned In Cradle

1 - RAISED BEAD

2-SWAYBAR

3 - WHEN INSTALLING SWAY BAR THE RAISED BEAD ON THE

SUSPENSION CRADLE MUST BE IN THE CENTER OF RADIUS

IN SWAY BAR

4 - FRONT SUSPENSION CRADLE

RSFRONT SUSPENSION2-19

STABILIZER BAR (Continued)

ProCarManuals.com

Page 43 of 2399

The coil spring controls ride quality and maintains

proper ride height.

The spring isolators isolate the coil spring at the

top and bottom from coming into metal-to-metal con-

tact with the upper seat and strut.

The jounce bumper limits suspension travel and

metal-to-metal contact under full jounce condition.

The strut dampens jounce and rebound motions of

the coil spring and suspension.

During steering maneuvers, the strut assembly

(through a pivot bearing in the upper strut mount)

and steering knuckle (through the lower ball joint)

turn as an assembly.

DIAGNOSIS AND TESTING - STRUT ASSEMBLY

(1) Inspect for damaged or broken coil springs

(Fig. 38).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 38).

(3) Inspect the coil spring isolator on the lower

spring seat for any signs of damage or deterioration.

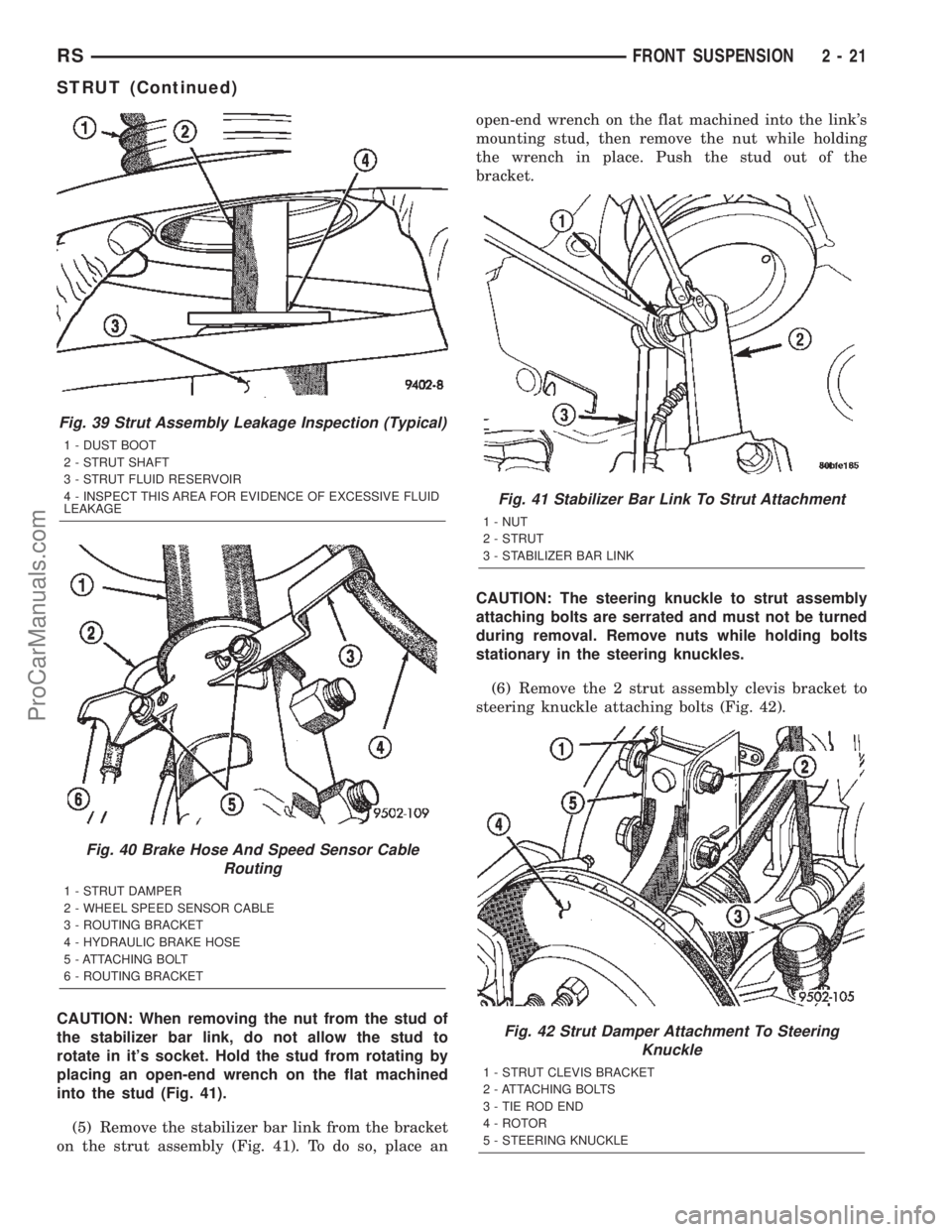

(4) Lift dust boot (Fig. 39) and inspect strut

assembly for evidence of fluid running from the

upper end of fluid reservoir. (Actual leakage will be astream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage

between the strut rod and strut shaft seal is not

unusual and does not affect performance of the strut

assembly (Fig. 39). Also inspect jounce bumpers for

signs of damage or deterioration.

REMOVAL - STRUT ASSEMBLY

WARNING: DO NOT REMOVE THE NUT FROM THE

STRUT ROD WHILE STRUT ASSEMBLY IS

INSTALLED IN VEHICLE, OR BEFORE STRUT

ASSEMBLY SPRING IS COMPRESSED.

(1) Raise the vehicle. See Hoisting in Lubrication

and Maintenance.

(2) Remove the wheel and tire assembly from loca-

tion on front of vehicle requiring strut removal.

(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

(4) Remove the hydraulic brake hose routing

bracket and the speed sensor cable routing bracket

from the strut damper brackets (Fig. 40).

Fig. 38 STRUT ASSEMBLY

1 - NUT 6 - COIL SPRING

2 - UPPER MOUNT 7 - DUST SHIELD

3 - PIVOT BEARING 8 - JOUNCE BUMPER

4 - UPPER SPRING SEAT 9 - LOWER SPRING ISOLATOR

5 - UPPER SPRING ISOLATOR 10 - STRUT (DAMPER)

2 - 20 FRONT SUSPENSIONRS

STRUT (Continued)

ProCarManuals.com

Page 44 of 2399

CAUTION: When removing the nut from the stud of

the stabilizer bar link, do not allow the stud to

rotate in it's socket. Hold the stud from rotating by

placing an open-end wrench on the flat machined

into the stud (Fig. 41).

(5) Remove the stabilizer bar link from the bracket

on the strut assembly (Fig. 41). To do so, place anopen-end wrench on the flat machined into the link's

mounting stud, then remove the nut while holding

the wrench in place. Push the stud out of the

bracket.

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during removal. Remove nuts while holding bolts

stationary in the steering knuckles.

(6) Remove the 2 strut assembly clevis bracket to

steering knuckle attaching bolts (Fig. 42).

Fig. 39 Strut Assembly Leakage Inspection (Typical)

1 - DUST BOOT

2 - STRUT SHAFT

3 - STRUT FLUID RESERVOIR

4 - INSPECT THIS AREA FOR EVIDENCE OF EXCESSIVE FLUID

LEAKAGE

Fig. 40 Brake Hose And Speed Sensor Cable

Routing

1 - STRUT DAMPER

2 - WHEEL SPEED SENSOR CABLE

3 - ROUTING BRACKET

4 - HYDRAULIC BRAKE HOSE

5 - ATTACHING BOLT

6 - ROUTING BRACKET

Fig. 41 Stabilizer Bar Link To Strut Attachment

1 - NUT

2 - STRUT

3 - STABILIZER BAR LINK

Fig. 42 Strut Damper Attachment To Steering

Knuckle

1 - STRUT CLEVIS BRACKET

2 - ATTACHING BOLTS

3 - TIE ROD END

4 - ROTOR

5 - STEERING KNUCKLE

RSFRONT SUSPENSION2-21

STRUT (Continued)

ProCarManuals.com

Page 48 of 2399

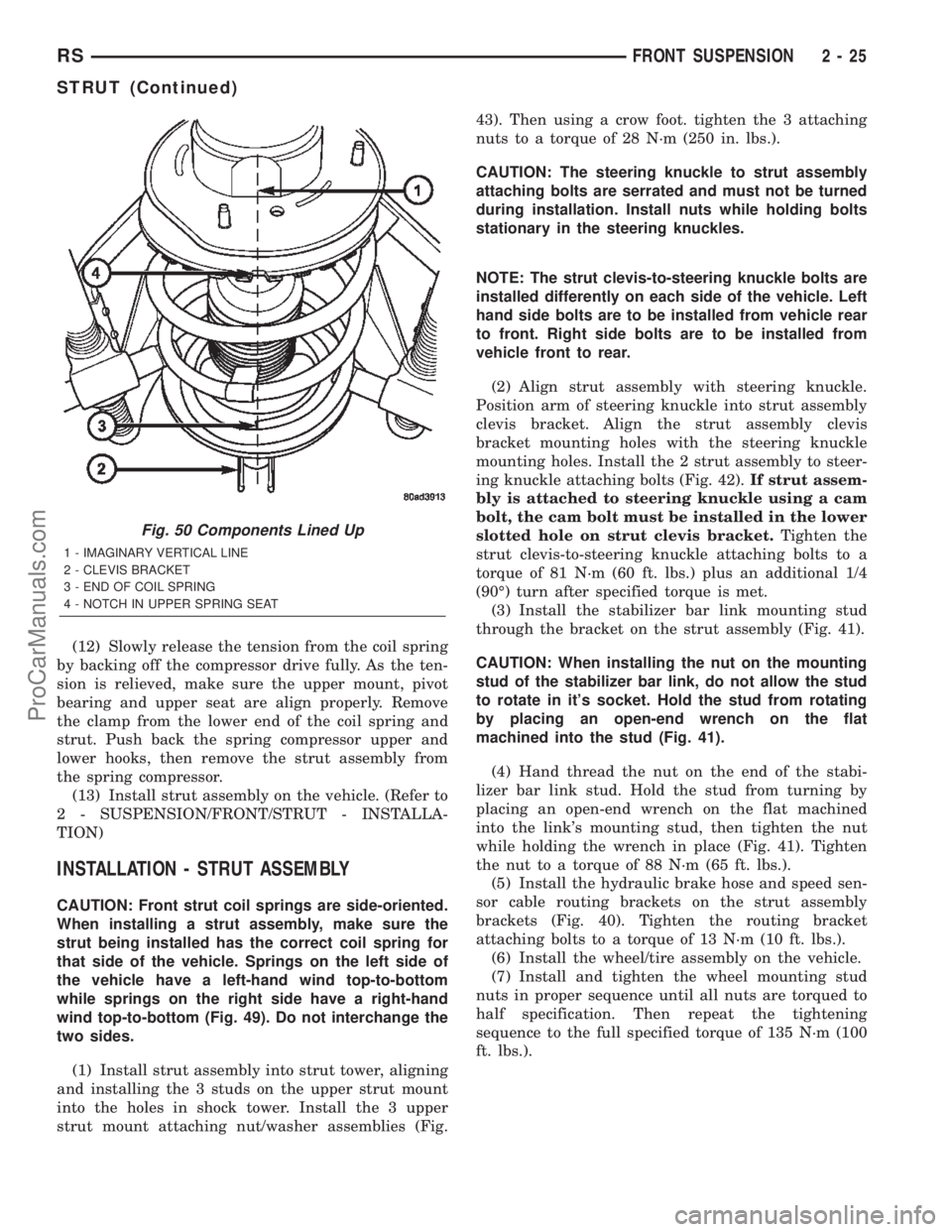

(12) Slowly release the tension from the coil spring

by backing off the compressor drive fully. As the ten-

sion is relieved, make sure the upper mount, pivot

bearing and upper seat are align properly. Remove

the clamp from the lower end of the coil spring and

strut. Push back the spring compressor upper and

lower hooks, then remove the strut assembly from

the spring compressor.

(13) Install strut assembly on the vehicle. (Refer to

2 - SUSPENSION/FRONT/STRUT - INSTALLA-

TION)

INSTALLATION - STRUT ASSEMBLY

CAUTION: Front strut coil springs are side-oriented.

When installing a strut assembly, make sure the

strut being installed has the correct coil spring for

that side of the vehicle. Springs on the left side of

the vehicle have a left-hand wind top-to-bottom

while springs on the right side have a right-hand

wind top-to-bottom (Fig. 49). Do not interchange the

two sides.

(1) Install strut assembly into strut tower, aligning

and installing the 3 studs on the upper strut mount

into the holes in shock tower. Install the 3 upper

strut mount attaching nut/washer assemblies (Fig.43). Then using a crow foot. tighten the 3 attaching

nuts to a torque of 28 N´m (250 in. lbs.).

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckles.

NOTE: The strut clevis-to-steering knuckle bolts are

installed differently on each side of the vehicle. Left

hand side bolts are to be installed from vehicle rear

to front. Right side bolts are to be installed from

vehicle front to rear.

(2) Align strut assembly with steering knuckle.

Position arm of steering knuckle into strut assembly

clevis bracket. Align the strut assembly clevis

bracket mounting holes with the steering knuckle

mounting holes. Install the 2 strut assembly to steer-

ing knuckle attaching bolts (Fig. 42).If strut assem-

bly is attached to steering knuckle using a cam

bolt, the cam bolt must be installed in the lower

slotted hole on strut clevis bracket.Tighten the

strut clevis-to-steering knuckle attaching bolts to a

torque of 81 N´m (60 ft. lbs.) plus an additional 1/4

(90É) turn after specified torque is met.

(3) Install the stabilizer bar link mounting stud

through the bracket on the strut assembly (Fig. 41).

CAUTION: When installing the nut on the mounting

stud of the stabilizer bar link, do not allow the stud

to rotate in it's socket. Hold the stud from rotating

by placing an open-end wrench on the flat

machined into the stud (Fig. 41).

(4) Hand thread the nut on the end of the stabi-

lizer bar link stud. Hold the stud from turning by

placing an open-end wrench on the flat machined

into the link's mounting stud, then tighten the nut

while holding the wrench in place (Fig. 41). Tighten

the nut to a torque of 88 N´m (65 ft. lbs.).

(5) Install the hydraulic brake hose and speed sen-

sor cable routing brackets on the strut assembly

brackets (Fig. 40). Tighten the routing bracket

attaching bolts to a torque of 13 N´m (10 ft. lbs.).

(6) Install the wheel/tire assembly on the vehicle.

(7) Install and tighten the wheel mounting stud

nuts in proper sequence until all nuts are torqued to

half specification. Then repeat the tightening

sequence to the full specified torque of 135 N´m (100

ft. lbs.).

Fig. 50 Components Lined Up

1 - IMAGINARY VERTICAL LINE

2 - CLEVIS BRACKET

3 - END OF COIL SPRING

4 - NOTCH IN UPPER SPRING SEAT

RSFRONT SUSPENSION2-25

STRUT (Continued)

ProCarManuals.com

Page 69 of 2399

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

DESCRIPTION - WHEEL ALIGNMENT.......46

DIAGNOSIS AND TESTING - SUSPENSION

AND STEERING......................49

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

ALIGNMENT.........................51STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT......................54

STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT (EXPORT)..............55

SPECIFICATIONS

WHEEL ALIGNMENT...................56

WHEEL ALIGNMENT

DESCRIPTION - WHEEL ALIGNMENT

Vehicle wheel alignment is the positioning of all

interrelated front and rear suspension angles. These

angles affect the handling and steering of the vehicle

when it is in motion. Proper wheel alignment is

essential for efficient steering, good directional stabil-

ity, and proper tire wear.

The method of checking a vehicle's front and rear

wheel alignment varies depending on the manufac-

turer and type of equipment used. The manufactur-

er's instructions should always be followed to ensure

accuracy of the alignment, except when

DaimlerChrysler Corporation's wheel alignment spec-

ifications differ.

On this vehicle, the suspension angles that can be

adjusted are as follows:

²Front Camber (with camber bolt package and

standard procedure)

²Front Toe

Check the wheel alignment and make all wheel

alignment adjustments with the vehicle standing at

its proper curb height specification. Curb height is

the normal riding height of the vehicle. It is mea-

sured from a certain point on the vehicle to the

ground or a designated area while the vehicle is sit-

ting on a flat, level surface. Refer to Curb Height

Measurement in this section for additional informa-

tion.

Typical wheel alignment angles and measurements

are described in the following paragraphs.

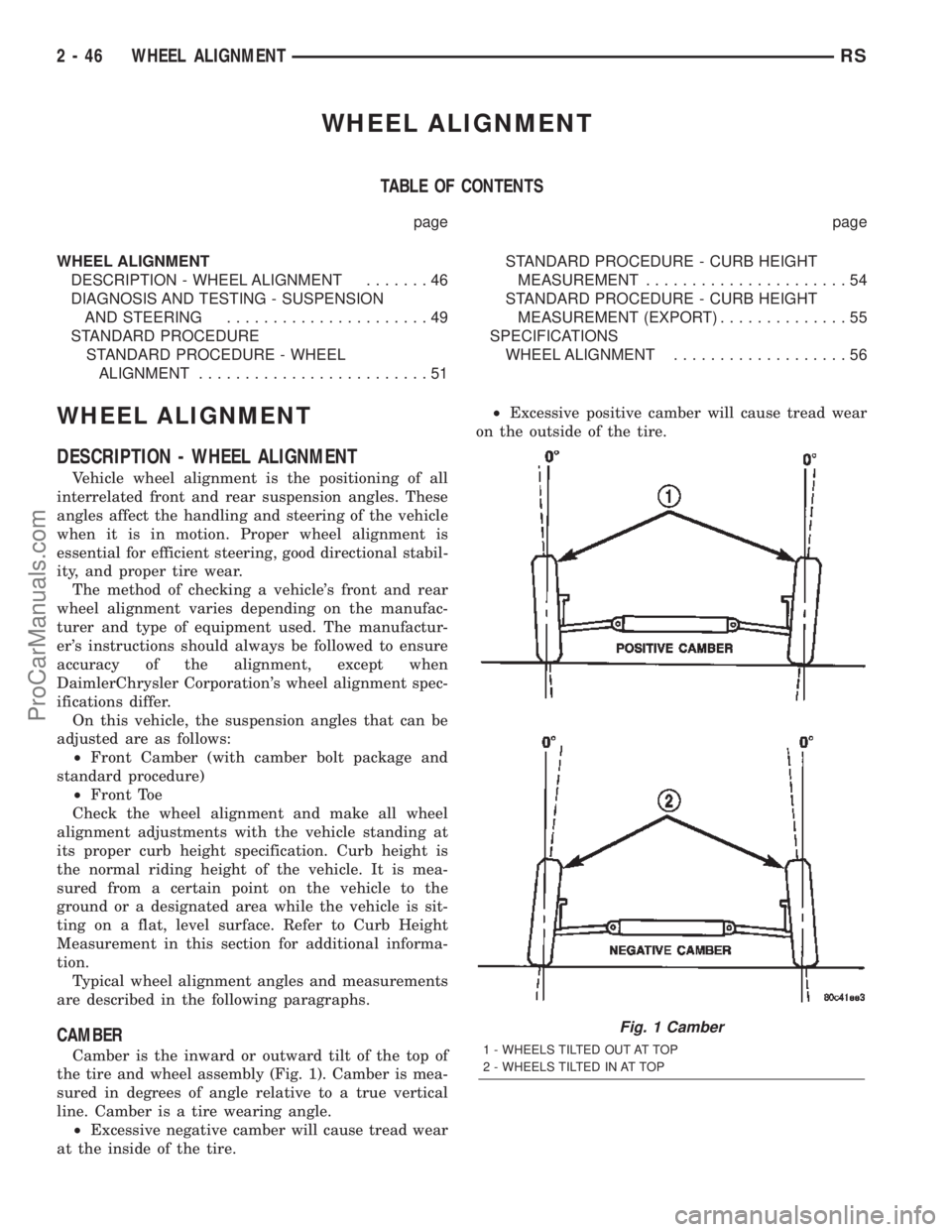

CAMBER

Camber is the inward or outward tilt of the top of

the tire and wheel assembly (Fig. 1). Camber is mea-

sured in degrees of angle relative to a true vertical

line. Camber is a tire wearing angle.

²Excessive negative camber will cause tread wear

at the inside of the tire.²Excessive positive camber will cause tread wear

on the outside of the tire.

Fig. 1 Camber

1 - WHEELS TILTED OUT AT TOP

2 - WHEELS TILTED IN AT TOP

2 - 46 WHEEL ALIGNMENTRS

ProCarManuals.com

Page 71 of 2399

TOE-OUT ON TURNS

Toe-out on turns is the relative positioning of the

front wheels while steering through a turn (Fig. 4).

This compensates for each front wheel's turning

radius. As the vehicle encounters a turn, the out-

board wheel must travel in a larger radius circle

than the inboard wheel. The steering system is

designed to make each wheel follow its particular

radius circle. To accomplish this, the front wheels

must progressively toe outward as the steering is

turned from center. This eliminates tire scrubbing

and undue tire wear when steering a vehicle through

a turn.

DYNAMIC TOE PATTERN

Dynamic toe pattern is the inward and outward toe

movement of the front and rear tires through the

suspension's jounce and rebound travel. As the vehi-

cle's suspension moves up and down, the toe pattern

varies. Toe pattern is critical in controlling the direc-

tional stability of the vehicle while in motion. Front

and rear dynamic toe pattern is preset by the factory

at the time the vehicle is assembled.

It is not necessary to check or adjust front or rear

dynamic toe pattern when doing a normal wheel

alignment. The only time dynamic toe pattern needs

to be checked or adjusted is if the frame of the vehi-

cle has been damaged.

STEERING AXIS INCLINATION (S. A. I.)

Steering axis inclination is the angle between a

true vertical line starting at the center of the tire at

the road contact point and a line drawn through the

center of the upper ball joint (or strut) and the lower

ball joint (Fig. 5). S.A.I. is built into the vehicle and

is not an adjustable angle. If S.A.I. is not within

specifications, a bent or damaged suspension compo-

nent may be the cause.

INCLUDED ANGLE (I. A.)

Included angle is the sum of the S.A.I. angle plus

or minus the camber angle, depending on whether or

not the wheel has positive or negative camber (Fig.

5). If camber is positive, add the camber angle to the

S.A.I. angle. If camber is negative, subtract the cam-

ber angle from the S.A.I. angle. Included angle is not

adjustable, but can be used to diagnose a frame mis-

alignment or bent suspension component (spindle,

strut).

Fig. 4 Toe-Out On Turns

1 - TOE-OUT ON TURNS

Fig. 5 S.A.I. and I.A.

1 - S.A.I.

2 - CAMBER

3 - I.A.

2 - 48 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

ProCarManuals.com

Page 72 of 2399

THRUST ANGLE

Thrust angle is the averaged direction the rear

wheels are pointing in relation to the vehicle's center

line (Fig. 6). The presence of negative or positive

thrust angle causes the rear tires to track improperly

to the left or right of the front tires (dog tracking).

²Negative thrust angle means the rear tires are

tracking to the left of the front tires.

²Positive thrust angle means the rear tires are

tracking to the right of the front tires.

Improper tracking can cause undue tire wear, a

lead or pull and a crooked steering wheel. Excessive

thrust angle can usually be corrected by adjusting

the rear wheel toe so that each wheel has one-half of

the total toe measurement.

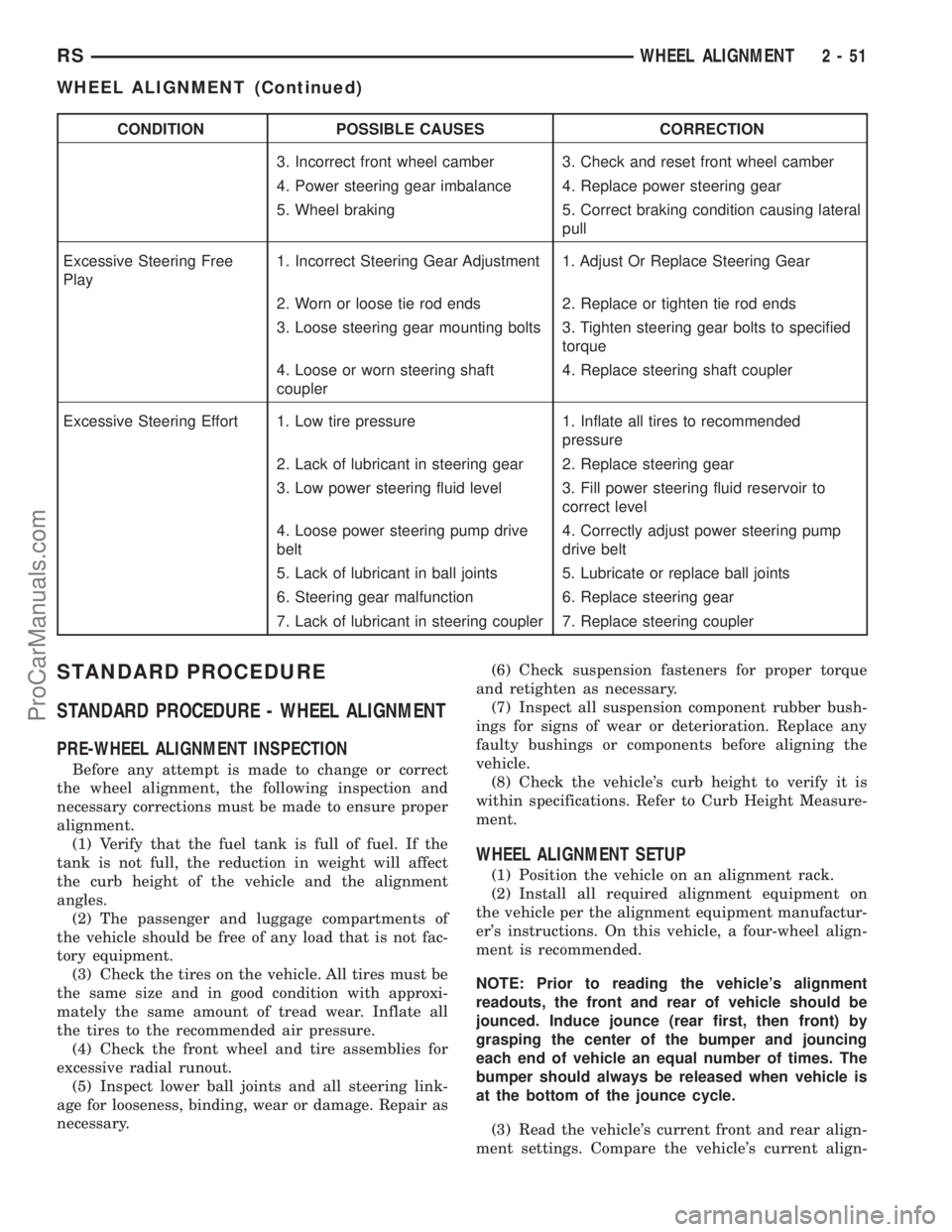

DIAGNOSIS AND TESTING - SUSPENSION AND STEERING

CONDITION POSSIBLE CAUSES CORRECTION

Front End Whine On Turns 1. Defective wheel bearing 1. Replace wheel bearing

2. Incorrect wheel alignment 2. Check and reset wheel alignment

3. Worn tires 3. Replace tires

Front End Growl Or

Grinding On Turns1. Defective wheel bearing 1. Replace wheel bearing

2. Engine mount grounding 2. Check for motor mount hitting frame rail

and reposition engine as required

3. Worn or broken C/V joint 3. Replace C/V joint

4. Loose wheel lug nuts 4. Verify wheel lug nut torque

5. Incorrect wheel alignment 5. Check and reset wheel alignment

6. Worn tires 6. Replace tires

7. Front strut pin in upper strut mount 7. Replace the front strut upper mount and

bearing

Front End Clunk Or Snap

On Turns1. Loose lug nuts 1. Verify wheel lug nut torque

2. Worn or broken C/V joint 2. Replace C/V joint

3. Worn or loose tie rod 3. Tighten or replace tie rod end

4. Worn or loose ball joint 4. Tighten or replace ball joint

5. Worn/loose control arm bushing 5. Replace control arm bushing

6. Loose stabilizer bar. 6. Tighten stabilizer bar to specified torque

Fig. 6 Thrust Angle

RSWHEEL ALIGNMENT2-49

WHEEL ALIGNMENT (Continued)

ProCarManuals.com

Page 73 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

7. Loose strut mount to body

attachment7. Tighten strut attachment to specified

torque

8. Loose crossmember bolts 8. Tighten crossmember bolts to specified

torque

Front End Whine With

Vehicle Going Straight At A

Constant Speed1. Defective wheel bearing 1. Replace wheel bearing

2. Incorrect wheel alignment 2. Check and reset wheel alignment

3. Worn tires 3. Replace tires

4. Worn or defective transaxle gears

or bearings4. Replace transaxle gears or bearings

Front End Growl Or

Grinding With Vehicle

Going Straight At A

Constant Speed1. Engine mount grounding 1. Reposition engine as required

2. Worn or broken C/V joint 2. Replace C/V joint

Front End Whine When

Accelerating Or

Decelerating1. Worn or defective transaxle gears

or bearings1. Replace transaxle gears or bearings

Front End Clunk When

Accelerating Or

Decelerating1. Worn or broken engine mount 1. Replace engine mount

2. Worn or defective transaxle gears

or bearings2. Replace transaxle gears or bearings

3. Loose lug nuts 3. Verify wheel lug nut torque

4. Worn or broken C/V joint 4. Replace C/V joint

5. Worn or loose ball joint 5. Tighten or replace ball joint

6. Worn or loose control arm bushing 6. Replace control arm bushing

7. Loose crossmember bolts 7. Tighten crossmember bolts to specified

torque

8. Worn tie rod end 8. Replace tie rod end

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

2 - 50 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

ProCarManuals.com

Page 74 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

3. Incorrect front wheel camber 3. Check and reset front wheel camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing lateral

pull

Excessive Steering Free

Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to specified

torque

4. Loose or worn steering shaft

coupler4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering pump

drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering coupler 7. Replace steering coupler

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to ensure proper

alignment.

(1) Verify that the fuel tank is full of fuel. If the

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

angles.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. All tires must be

the same size and in good condition with approxi-

mately the same amount of tread wear. Inflate all

the tires to the recommended air pressure.

(4) Check the front wheel and tire assemblies for

excessive radial runout.

(5) Inspect lower ball joints and all steering link-

age for looseness, binding, wear or damage. Repair as

necessary.(6) Check suspension fasteners for proper torque

and retighten as necessary.

(7) Inspect all suspension component rubber bush-

ings for signs of wear or deterioration. Replace any

faulty bushings or components before aligning the

vehicle.

(8) Check the vehicle's curb height to verify it is

within specifications. Refer to Curb Height Measure-

ment.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle per the alignment equipment manufactur-

er's instructions. On this vehicle, a four-wheel align-

ment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

RSWHEEL ALIGNMENT2-51

WHEEL ALIGNMENT (Continued)

ProCarManuals.com

Page 75 of 2399

ment settings to the vehicle specifications for camber,

caster and toe-in. (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - SPECIFICATIONS)

(4) If front camber and caster are not within spec-

ifications, proceed to CAMBER AND CASTER below.

If caster and camber are within specifications, pro-

ceed to TOE which can be found following CAMBER

AND CASTER. Rear camber, caster and toe are not

adjustable. If found not to be within specifications,

reinspect for damaged suspension or body compo-

nents and replace as necessary.

CAMBER AND CASTER

Camber and caster settings on this vehicle are

determined at the time the vehicle is designed, by

the location of the vehicle's suspension components.

This is referred to as NET BUILD. The result is no

required adjustment of camber and caster after the

vehicle is built or when servicing the suspension

components. Thus, when performing a wheel align-

ment, caster and camber are not normally considered

adjustable angles. Camber and caster should be

checked to ensure they meet vehicle specifications.

If front camber is found not to meet alignment

specifications, it can be adjusted using an available

camber adjustment bolt package. Before installing a

camber adjustment bolt package on a vehicle found

to be outside the specifications, inspect the suspen-

sion components for any signs of damage or bending.

CAUTION: Do not attempt to adjust the vehicles

wheel alignment by heating, bending or by perform-

ing any other modification to the vehicle's front

suspension components or body.

If camber readings are not within specifications,

use the following procedure to install the front cam-

ber adjustment bolt package and then adjust front

camber.

CAMBER ADJUSTMENT BOLT PACKAGE INSTALLATION

The camber adjustment bolt package contains 2

flange bolts, 2 cam bolts, 2 dog bone washers, and 4

nuts. This package services both sides of the vehicle.

Use the package to attach the strut clevis bracket to

the steering knuckle after the strut clevis bracket

has been modified. To install and adjust the camber

adjustment bolt package, follow the procedure below.

(1) Raise the vehicle until its tires are not support-

ing the weight of the vehicle.

(2) Remove the front tire and wheel assemblies.

CAUTION: When removing the steering knuckle

from the strut clevis bracket, do not put a strain on

the brake flex hose. Also, do not let the weight of

the steering knuckle assembly be supported by the

brake flex hose when removed from the strutassembly. If necessary use a wire hanger to sup-

port the steering knuckle assembly or if required

remove the brake flex hose from the caliper assem-

bly.

CAUTION: The knuckle to strut assembly attaching

bolt shanks are serrated and must not be turned

during removal. Remove the nuts while holding the

bolts stationary.

(3) Remove the top and bottom, strut clevis

bracket to steering knuckle attaching bolts (Fig.

7)and discard. Separate the steering knuckle from

the strut clevis bracket and position steering knuckle

so it is out of the way of the strut.

CAUTION: When slotting the bottom mounting hole

on the strut clevis bracket, do not enlarge the hole

beyond the indentations on the sides of the strut

clevis bracket (Fig. 8).

(4) Using an appropriate grinder and grinding

wheel, slot the bottom hole in both sides of the strut

clevis bracket (Fig. 8).

CAUTION: After slotting the strut clevis bracket

hole, do not install the original attaching bolts when

assembling the steering knuckle to the strut assem-

bly. Only the flange bolts, cam bolts, and dog bone

washers from the service package must be used to

attach the steering knuckle to the strut after the

mounting hole is slotted.

Fig. 7 Clevis Bracket To Steering Knuckle Attaching

Bolts

1 - STRUT CLEVIS BRACKET

2 - ATTACHING BOLTS

3 - TIE ROD END

4 - ROTOR

5 - STEERING KNUCKLE

2 - 52 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

ProCarManuals.com