engine oil CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 2307 of 2399

(17) Remove the compressor from the engine com-

partment.

NOTE: If a replacement compressor is being

installed, be certain to drain and measure the refrig-

erant oil contained in the removed compressor.

This will determine how much oil the replacement

compressor must contain before it is installed.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT/REFRIGERANT OIL - STAN-

DARD PROCEDURE - REFRIGERANT OIL LEVEL).

REMOVAL - COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE

(1) Remove the compressor from the mounting

bracket. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/COMPRESSOR - REMOVAL).

(2) Remove the four screws that secure the com-

pressor mounting bracket to the engine (Fig. 3).

(3) Remove the compressor mounting bracket from

the engine.

INSTALLATION

INSTALLATION - COMPRESSOR

NOTE: If a replacement compressor is being

installed, be certain to check the refrigerant oil

level. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT/REFRIGERANT OIL - STAN-

DARD PROCEDURE - REFRIGERANT OIL LEVEL).

Use only refrigerant oil of the type recommended

for the compressor in the vehicle.(1) Position the compressor into the engine com-

partment.

(2) On models with the 2.4L engine, loosely install

the four screws that secure the compressor to the

mounting bracket on the engine. Tighten the screws

to 28 N´m (21 ft. lbs.).

(3) On models with the 3.3L and 3.8L engines,

loosely install the three screws and one nut that

secure the compressor to the engine. Tighten each of

the fasteners using the following sequence to 54 N´m

(40 ft. lbs.).

²The upper screw at the rear of the compressor.

²The lower screw at the rear of the compressor.

²The lower screw at the front of the compressor.

²The upper nut at the front of the compressor.

(4) On models with the 3.3L and 3.8L engines only,

engage the retainer on the engine wire harness com-

pressor clutch coil take out with the bracket on the

top of the compressor.

(5) Reconnect the engine wire harness connector

for the compressor clutch coil to the coil pigtail wire

connector on the top of the compressor.

(6) Reinstall the serpentine accessory drive belt

onto the front of the engine. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - 2.4L -

INSTALLATION) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3L/3.8L - INSTAL-

LATION).

(7) Lower the vehicle.

(8) Remove the tape or plugs from the compressor

discharge port and the discharge line fitting.

(9) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting.

(10) Reconnect the discharge line fitting to the

compressor discharge port.

(11) Install and tighten the nut that secures the

discharge line fitting to the compressor. Tighten the

nut to 23 N´m (17 ft. lbs.).

(12) Remove the tape or plugs from the compressor

suction port and the suction line fitting.

(13) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting.

(14) Reconnect the suction line fitting to the com-

pressor suction port.

(15) Install and tighten the nut that secures the

suction line fitting to the compressor. Tighten the nut

to 23 N´m (17 ft. lbs.).

(16) Reconnect the battery negative cable.

(17) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(18) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

Fig. 3 Compressor Mounting Bracket - 2.4L Engine

1 - MOUNTING BRACKET

2 - SCREWS (4)

3 - ENGINE

24 - 64 PLUMBING - FRONTRS

COMPRESSOR (Continued)

ProCarManuals.com

Page 2308 of 2399

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

INSTALLATION - COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE

(1) Position the compressor mounting bracket onto

the engine.

(2) Install and tighten the four screws that secure

the compressor mounting bracket to the engine.

Tighten the screws to 54 N´m (40 ft. lbs.).

(3) Reinstall the compressor onto the mounting

bracket. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/COMPRESSOR - INSTALLA-

TION).

CONDENSER

DESCRIPTION

The condenser is integral to a cooling module

which includes the radiator, the electric cooling fan,

the fan shroud, air seals and an automatic transmis-

sion oil cooler. The cooling module is located in the

air flow in the front of the engine compartment

behind the radiator grille. The condenser cannot be

repaired or adjusted and, if faulty or damaged, it

must be replaced. The condenser may be removed

from the cooling module for service without removing

the cooling module from the vehicle.

OPERATION

The condenser is a heat exchanger that allows the

high-pressure refrigerant gas being discharged by the

compressor to give up its heat to the air passing over

the condenser fins. When the refrigerant gas gives up

its heat, it condenses. When the refrigerant leaves

the condenser, it has become a high-pressure liquid

refrigerant. The volume of air flowing over the con-

denser fins is critical to the proper cooling perfor-

mance of the air conditioning system. Therefore, it is

important that there are no objects placed in front of

the radiator grille openings in the front of the vehicle

or foreign material on the condenser fins that might

obstruct air flow. Also, any factory-installed air seals

or shrouds must be properly reinstalled following

radiator or condenser service.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).NOTE: Before removing the condenser, note the

location of each of the radiator and condenser air

seals. These air seals are used to direct air through

the condenser and radiator. The air seals must be

reinstalled in their proper locations in order for the

air conditioning and engine cooling systems to per-

form as designed.

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/REFRIGERANT -

STANDARD PROCEDURE - REFRIGERANT

RECOVERY).

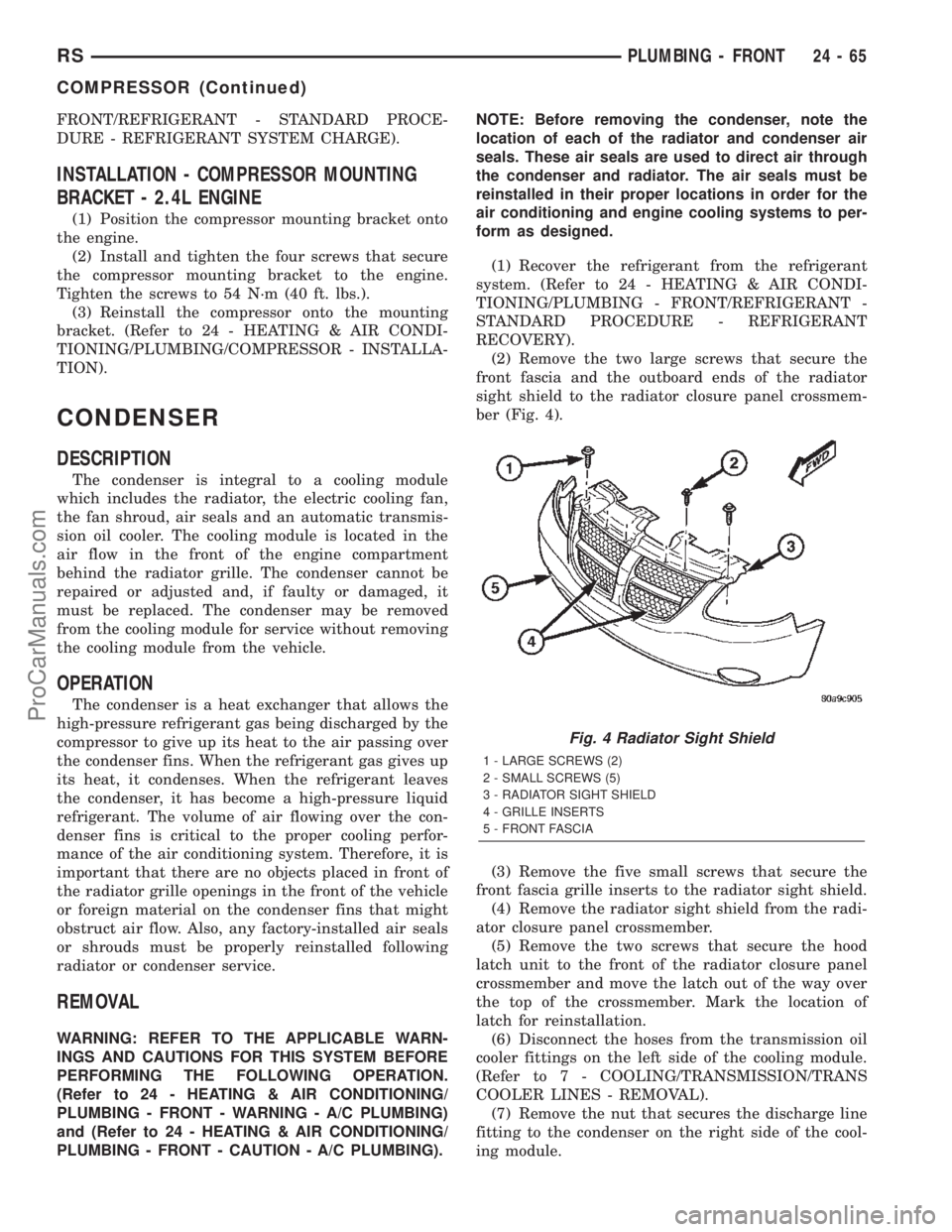

(2) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 4).

(3) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(4) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

(5) Remove the two screws that secure the hood

latch unit to the front of the radiator closure panel

crossmember and move the latch out of the way over

the top of the crossmember. Mark the location of

latch for reinstallation.

(6) Disconnect the hoses from the transmission oil

cooler fittings on the left side of the cooling module.

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER LINES - REMOVAL).

(7) Remove the nut that secures the discharge line

fitting to the condenser on the right side of the cool-

ing module.

Fig. 4 Radiator Sight Shield

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-65

COMPRESSOR (Continued)

ProCarManuals.com

Page 2309 of 2399

(8) Disconnect the discharge line fitting from the

condenser inlet port.

(9) Remove the seal from the discharge line fitting

and discard.

(10) Install plugs in, or tape over the opened dis-

charge line fitting and the condenser inlet port.

(11) Remove the nut that secures the liquid line

fitting to the condenser on the right side of the cool-

ing module.

(12) Disconnect the liquid line fitting from the con-

denser outlet port.

(13) Remove the seal from the liquid line fitting

and discard.

(14) Install plugs in, or tape over the opened liquid

line fitting and the condenser outlet port.

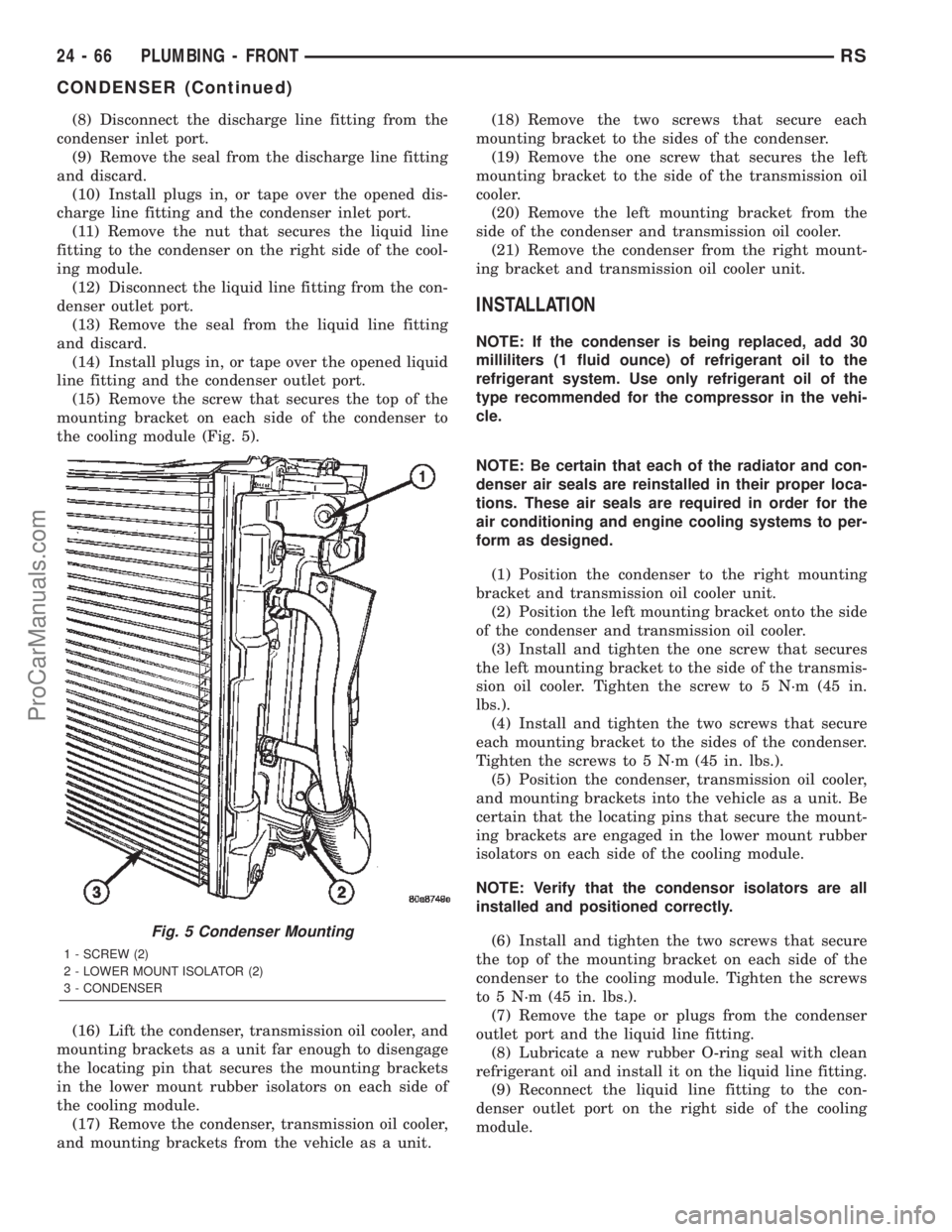

(15) Remove the screw that secures the top of the

mounting bracket on each side of the condenser to

the cooling module (Fig. 5).

(16) Lift the condenser, transmission oil cooler, and

mounting brackets as a unit far enough to disengage

the locating pin that secures the mounting brackets

in the lower mount rubber isolators on each side of

the cooling module.

(17) Remove the condenser, transmission oil cooler,

and mounting brackets from the vehicle as a unit.(18) Remove the two screws that secure each

mounting bracket to the sides of the condenser.

(19) Remove the one screw that secures the left

mounting bracket to the side of the transmission oil

cooler.

(20) Remove the left mounting bracket from the

side of the condenser and transmission oil cooler.

(21) Remove the condenser from the right mount-

ing bracket and transmission oil cooler unit.

INSTALLATION

NOTE: If the condenser is being replaced, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the compressor in the vehi-

cle.

NOTE: Be certain that each of the radiator and con-

denser air seals are reinstalled in their proper loca-

tions. These air seals are required in order for the

air conditioning and engine cooling systems to per-

form as designed.

(1) Position the condenser to the right mounting

bracket and transmission oil cooler unit.

(2) Position the left mounting bracket onto the side

of the condenser and transmission oil cooler.

(3) Install and tighten the one screw that secures

the left mounting bracket to the side of the transmis-

sion oil cooler. Tighten the screw to 5 N´m (45 in.

lbs.).

(4) Install and tighten the two screws that secure

each mounting bracket to the sides of the condenser.

Tighten the screws to 5 N´m (45 in. lbs.).

(5) Position the condenser, transmission oil cooler,

and mounting brackets into the vehicle as a unit. Be

certain that the locating pins that secure the mount-

ing brackets are engaged in the lower mount rubber

isolators on each side of the cooling module.

NOTE: Verify that the condensor isolators are all

installed and positioned correctly.

(6) Install and tighten the two screws that secure

the top of the mounting bracket on each side of the

condenser to the cooling module. Tighten the screws

to 5 N´m (45 in. lbs.).

(7) Remove the tape or plugs from the condenser

outlet port and the liquid line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Reconnect the liquid line fitting to the con-

denser outlet port on the right side of the cooling

module.

Fig. 5 Condenser Mounting

1 - SCREW (2)

2 - LOWER MOUNT ISOLATOR (2)

3 - CONDENSER

24 - 66 PLUMBING - FRONTRS

CONDENSER (Continued)

ProCarManuals.com

Page 2310 of 2399

(10) Install and tighten the nut that secures the

liquid line fitting to the condenser. Tighten the nut to

23 N´m (17 ft. lbs.).

(11) Remove the tape or plugs from the condenser

inlet port and the discharge line fitting.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting.

(13) Reconnect the discharge line fitting to the

condenser inlet port on the right side of the cooling

module.

(14) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 23 N´m (17 ft. lbs.).

(15) Reconnect the hoses to the transmission oil

cooler fittings on the left side of the cooling module.

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER LINES - INSTALLATION).

(16) Reposition the hood latch unit to the front of

the radiator closure panel crossmember.

(17) Install and tighten the two screws that secure

the hood latch unit to the front of the radiator clo-

sure panel crossmember. Check and adjust the hood

latch as needed. Tighten the screws to 14 N´m (123

in. lbs.).

(18) Position the radiator sight shield onto the

radiator closure panel crossmember.

(19) Install and tighten the five small screws that

secure the front fascia grille inserts to the radiator

sight shield. Tighten the screws to 2 N´m (18 in. lbs.).

(20) Install and tighten the two large screws that

secure the front fascia and the outboard ends of the

radiator sight shield to the radiator closure panel

crossmember. Tighten the screws to 6 N´m (53 in.

lbs.).

(21) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(22) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

DISCHARGE LINE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/REFRIGERANT -

STANDARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Remove the two large screws that secure the

front fascia and the outboard ends of the radiator

sight shield to the radiator closure panel crossmem-

ber (Fig. 6).

(3) Remove the five small screws that secure the

front fascia grille inserts to the radiator sight shield.

(4) Remove the radiator sight shield from the radi-

ator closure panel crossmember.

(5) Remove the nut that secures the discharge line

fitting to the condenser on the right side of the cool-

ing module (Fig. 7).

(6) Disconnect the discharge line fitting from the

condenser inlet port.

(7) Remove the seal from the discharge line fitting

and discard.

(8) Install plugs in, or tape over the opened dis-

charge line fitting and the condenser inlet port.

(9) Remove the nut that secures the discharge line

fitting to the top of the compressor (Fig. 8).

(10) Disconnect the discharge line fitting from the

compressor discharge port.

(11) Remove the seal from the discharge line fit-

ting and discard.

(12) Install plugs in, or tape over the opened dis-

charge line fitting and the compressor discharge port.

(13) Remove the discharge line from the engine

compartment.

Fig. 6 Radiator Sight Shield

1 - LARGE SCREWS (2)

2 - SMALL SCREWS (5)

3 - RADIATOR SIGHT SHIELD

4 - GRILLE INSERTS

5 - FRONT FASCIA

RSPLUMBING - FRONT24-67

CONDENSER (Continued)

ProCarManuals.com

Page 2311 of 2399

INSTALLATION

(1) Position the discharge line into the engine com-

partment.

(2) Remove the tape or plugs from the compressor

discharge port and the discharge line fitting.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting.

(4) Reconnect the discharge line fitting to the com-

pressor discharge port on the top of the compressor.(5) Install and tighten the nut that secures the

discharge line fitting to the compressor. Tighten the

nut to 23 N´m (17 ft. lbs.).

(6) Remove the tape or plugs from the condenser

inlet port and the discharge line fitting.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting.

(8) Reconnect the discharge line fitting to the con-

denser inlet port on the right side of the cooling mod-

ule.

(9) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 23 N´m (17 ft. lbs.).

(10) Position the radiator sight shield onto the

radiator closure panel crossmember.

(11) Install and tighten the five small screws that

secure the front fascia grille inserts to the radiator

sight shield. Tighten the screws to 2 N´m (18 in. lbs.).

(12) Install and tighten the two large screws that

secure the front fascia and the outboard ends of the

radiator sight shield to the radiator closure panel

crossmember. Tighten the screws to 6 N´m (53 in.

lbs.).

(13) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(14) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

EVAPORATOR

DESCRIPTION

The evaporator is located in the heater-A/C unit

housing, behind the instrument panel. The evapora-

tor is positioned in the heater-A/C housing so that all

air that enters the housing must pass over the fins of

the evaporator before it is distributed through the

system ducts and outlets. However, air passing over

the evaporator fins will only be conditioned when the

compressor is engaged and circulating refrigerant

through the evaporator tubes. The heater-A/C unit

housing must be removed from the vehicle to access

the evaporator for service. The evaporator cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

OPERATION

Refrigerant enters the evaporator from the expan-

sion valve as a low-temperature, low-pressure liquid/

vapor mixture. As air flows over the fins of the evap-

orator, the humidity in the air condenses on the fins,

Fig. 7 Condenser Connections

1 - CONDENSER

2 - DISCHARGE LINE FITTING

3 - LIQUID LINE FITTING

4 - NUT

Fig. 8 Discharge Line

1 - DISCHARGE LINE

2 - NUT

3 - DISCHARGE LINE FITTING

4 - STUD

5 - DISCHARGE PORT

24 - 68 PLUMBING - FRONTRS

DISCHARGE LINE (Continued)

ProCarManuals.com

Page 2316 of 2399

(14) Remove the two screws that secure the expan-

sion valve to the evaporator tube tapping plate.

(15) Disconnect the HVAC wire harness connector

for the evaporator temperature sensor from the sen-

sor on the top of the expansion valve.

(16) Remove the expansion valve from the evapo-

rator inlet and outlet tube fittings.

(17) Remove the seals from the evaporator inlet

and outlet tube fittings and discard.

(18) Install plugs in, or tape over the opened evap-

orator inlet and outlet tube fittings and both expan-

sion valve ports.

INSTALLATION

(1) Remove the tape or plugs from the evaporator

inlet and outlet tube fittings and both ports on the

back of the expansion valve.

(2) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the evaporator

inlet and outlet tube fittings.

(3) Position the expansion valve onto the evapora-

tor inlet and outlet tube fittings.

(4) Install and tighten the two screws that secure

the expansion valve to the evaporator tube tapping

plate plate. Tighten the screws to 11 N´m (97 in.

lbs.).

(5) Reconnect the HVAC wire harness connector

for the evaporator temperature sensor to the sensor

connector receptacle on the top of the expansion

valve.

(6) Remove the tape or plugs from the front liquid

line rear section and suction line fittings for the

expansion valve and both ports on the front of the

expansion valve.

(7) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the front liquid

line rear section and suction line fittings for the

expansion valve.

(8) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(9) Install and tighten the nut that secures the

suction line and liquid line fittings to the stud on the

expansion valve. Tighten the nut to 23 N´m (17 ft.

lbs.).

(10) Remove the tape or plugs from the liquid line

rear section fitting for the filter-drier and the filter-

drier outlet port.

(11) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(12) Reconnect the liquid line fitting to the filter-

drier outlet port on the top of the filter-drier.

(13) Install and tighten the screw that secures the

liquid line fitting to the filter-drier. Tighten the screw

to 2 N´m (18 in. lbs.).(14) Reconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer to the

transducer on the front liquid line rear section.

(15) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(16) Reinstall the air cleaner housing into the

right side of the engine compartment.

(17) Reconnect the battery negative cable.

(18) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(19) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

HEATER CORE

DESCRIPTION

The heater core is located in the distribution hous-

ing of the heater-A/C unit, under the instrument

panel. It is a heat exchanger made of rows of tubes

and fins. One end of the core is fitted with a molded

plastic tank that includes integral heater core inlet

and outlet ports. The removable heater core tubes

are held in place these ports by a sealing plate

secured with a screw to the heater core tank. This

removable heater core tube arrangement allows the

heater core to be serviced without removing the heat-

er-A/C unit housing from the vehicle. The heater core

cannot be repaired and, if faulty or damaged, it must

be replaced.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend air door

allows control of the heater output air temperature

by controlling how much of the air flowing through

the heater-A/C unit housing is directed through the

heater core.

RSPLUMBING - FRONT24-73

EXPANSION VALVE (Continued)

ProCarManuals.com

Page 2321 of 2399

HEATER HOSE

REMOVAL

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines (Fig. 21),

while the 3.3L and 3.8L engines have unique heater

return plumbing on the engine for models with or

without an optional engine oil cooler (Fig. 24) or (Fig.

25). There are also unique plumbing configurations

at the heater core for models with or without the

optional rear heater and air conditioner (Fig. 22) or

(Fig. 23). All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).(1) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose to the tube or nipple toward the center of

the hose to be removed. Release the clamp when it is

off of the tube or nipple.

Fig. 22 Heater Plumbing - 3.3/3.8L Engine w/o Rear

Heater

1 - ENGINE OUTLET NIPPLE

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - HEATER RETURN TUBE & HOSE (TYPICAL)

Fig. 23 Heater Plumbing - 3.3/3.8L Engine w/Rear

Heater

1 - STUD

2 - HEATER CORE OUTLET

3 - HEATER CORE INLET

4 - TO ENGINE OUTLET NIPPLE

5 - TO UNDERBODY PLUMBING

6 - TO HEATER RETURN TUBE & HOSE

Fig. 21 Heater Plumbing - 2.4L Engine

1 - ENGINE OUTLET NIPPLE

2 - HEATER SUPPLY

3 - HEATER CORE OUTLET

4 - HEATER CORE INLET

5 - SCREW

6 - HEATER TUBE & HOSE UNIT

7 - HEATER RETURN

8 - ENGINE INLET NIPPLE

24 - 78 PLUMBING - FRONTRS

ProCarManuals.com

Page 2322 of 2399

CAUTION:

When removing the heater hose from the heater

core or supply and return tube nipples, DO NOT

apply excessive pressure. Excessive pressure may

damage or deform the nipples and/or the heater

core causing an engine coolant leak.(3) After the clamp has been moved, grasp the end

of the hose firmly and carefully twist the hose back

and forth while pulling it away from the barbed end

of the nipple. Repeat this procedure at the opposite

end of the hose being removed. If this procedure is

not successful in removing the hose from the nipple,

carefully make a parallel cut through the hose where

it is engaged on the nipple and peel the hose off of

the nipple. This method of removal will require

heater hose replacement.

INSTALLATION

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines, while the

3.3L and 3.8L engines have unique heater return

plumbing on the engine for models with or without

an optional engine oil cooler. There are also unique

plumbing configurations at the heater core for mod-

els with or without the optional rear heater and air

conditioner. All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

(1) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose toward the center of the hose being

installed. Release the clamp when it is near the cen-

ter of the hose.

(2) Grasp one end of the heater hose being

installed firmly and carefully twist the hose back and

forth while pushing it over from the barbed end of

the nipple. Repeat this procedure at the opposite end

of the hose being installed.

(3) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose over the tube or nipple. Release the

clamp when it is over the tube or nipple.

(4) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

Fig. 24 Heater Return - 3.3/3.8L Engine w/o Oil

Cooler

1 - WATER PUMP RETURN NIPPLE

2 - HEATER RETURN TUBE & HOSE

3 - SCREW

4 - SCREW

Fig. 25 Heater Return - 3.3/3.8L Engine w/Oil Cooler

1 - ENGINE INLET NIPPLE

2 - HEATER RETURN TUBE & HOSE

3 - SCREW

4 - SCREW

5 - OIL COOLER

6 - HEATER RETURN HOSE

RSPLUMBING - FRONT24-79

HEATER HOSE (Continued)

ProCarManuals.com

Page 2327 of 2399

(10) Remove the seal from the liquid line fitting

and discard.

(11) Install plugs in, or tape over the opened liquid

line fitting and the filter-drier outlet port.

(12) Remove the nut that secures the suction line

and liquid line fittings to the expansion valve.

(13) Disconnect the suction line and liquid line fit-

tings from the expansion valve.

(14) Remove the seals from the suction line and

liquid line fittings and discard.

(15) Install plugs in, or tape over the opened suc-

tion line and liquid line fittings and both expansion

valve ports.

(16) If the vehicle is equipped with the optional

rear air conditioner, go to Step 17. If the vehicle does

not have the optional rear air conditioner, go to Step

23.

(17) Raise and support the vehicle.

(18) Cut the tie strap located just forward of the

connections between the underbody plumbing and

the engine compartment plumbing for the rear

heater and air conditioner (Fig. 31).

(19) Disconnect the front liquid line extension fit-

ting from the underbody liquid line fitting for the

rear air conditioner.

(20) Remove the seal from the underbody liquid

line fitting and discard.

(21) Install plugs in, or tape over the opened liquid

line fittings.

(22) Lower the vehicle.

(23) Remove the front liquid line rear section from

the engine compartment.INSTALLATION

The front air conditioner liquid line is serviced in

two sections. The front section connects between the

condenser and the filter/drier and includes the high

side service port on the fitting for the filter/drier. The

rear section connects between the filter/drier and the

expansion valve and includes the fitting for the A/C

pressure transducer. On models equipped with the

optional rear air conditioner, the rear section of the

front air conditioner liquid line also includes a liquid

line hose and tube extension that connects the front

liquid line to the liquid line for the rear air condi-

tioner.

FRONT SECTION

(1) Position the front section of the front liquid

line into the engine compartment.

(2) Remove the tape or plugs from the liquid line

front section fitting for the filter-drier and the filter-

drier inlet port.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(4) Reconnect the liquid line fitting to the filter-

drier inlet port on the top of the filter-drier.

(5) Install and tighten the screw that secures the

liquid line fitting to the filter-drier. Tighten the screw

to 2 N´m (16 in. lbs.).

(6) Engage the retainer that secures the liquid line

routing clip to the top of the right frame rail ahead of

the front strut tower in the engine compartment.

(7) Remove the tape or plugs from the condenser

outlet port and the liquid line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Reconnect the liquid line fitting to the con-

denser outlet port on the right side of the cooling

module.

(10) Install and tighten the nut that secures the

liquid line fitting to the condenser. Tighten the nut to

23 N´m (17 ft. lbs.).

(11) Position the radiator sight shield onto the

radiator closure panel crossmember.

(12) Install and tighten the five small screws that

secure the front fascia grille inserts to the radiator

sight shield. Tighten the screws to 2 N´m (16 in. lbs.).

(13) Install and tighten the two large screws that

secure the front fascia and the outboard ends of the

radiator sight shield to the radiator closure panel

crossmember. Tighten the screws to 6 N´m (53 in.

lbs.).

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Reconnect the battery negative cable.

(16) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

Fig. 31 Underbody Connections

1 - SUCTION LINE EXTENSION

2 - LIQUID LINE EXTENSION

3 - TIE STRAP

4- HEATER LINE EXTENSIONS

5 - UNDERBODY LINES

24 - 84 PLUMBING - FRONTRS

LIQUID LINE (Continued)

ProCarManuals.com

Page 2328 of 2399

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(17) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

REAR SECTION

(1) Position the rear section of the front liquid line

into the engine compartment.

(2) Remove the tape or plugs from the suction line

and liquid line fittings and both expansion valve

ports.

(3) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction line

and liquid line fittings.

(4) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(5) Install and tighten the nut that secures the

suction line and liquid line fittings to the expansion

valve. Tighten the nut to 23 N´m (17 ft. lbs.).

(6) Remove the tape or plugs from the liquid line

rear section fitting for the filter-drier and the filter-

drier outlet port.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(8) Reconnect the liquid line fitting to the filter-

drier outlet port on the top of the filter-drier.

(9) Install and tighten the screw that secures the

liquid line fitting to the filter-drier. Tighten the screw

to 2 N´m (16 in. lbs.).

(10) Reinstall the A/C ground strap eyelet terminal

connector onto the weld stud on the top of the right

front strut tower.

(11) Install and tighten the nut that secures the

A/C ground strap to the weld stud. Tighten the nut

to 12 N´m (106 in. lbs.).

(12) Reinstall the A/C pressure transducer onto

the fitting on the front liquid line rear section. (Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS - FRONT/A/C PRESSURE TRANSDUCER -

INSTALLATION).

(13) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(14) Reinstall the air cleaner housing into the

right side of the engine compartment.

(15) Reconnect the battery negative cable.

(16) If the vehicle is equipped with the optional

rear air conditioner, go to Step 17. If the vehicle does

not have the optional rear air conditioner, go to Step

23.

(17) Raise and support the vehicle.

(18) Remove the tape or plugs from the liquid line

rear section extension fitting and the underbody liq-

uid line fitting.(19) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the underbody liquid

line fitting.

(20) Reconnect the liquid line rear section exten-

sion fitting to the underbody liquid line fitting.

Tighten the fittings to 23 N´m (17 ft. lbs.).

(21) Install a new tie strap just forward of the con-

nections between the underbody plumbing and the

engine compartment plumbing for the rear heater

and air conditioner.

(22) Lower the vehicle.

(23) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(24) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

RECEIVER/DRIER

DESCRIPTION

The filter-drier is mounted in a bracket secured to

the right front strut tower in the engine compart-

ment. The filter-drier is connected between the front

and rear sections of the liquid line between the con-

denser outlet and the evaporator inlet. The filter-

drier cannot be repaired. If the filter-drier is faulty

or damaged, or if the refrigerant system has been

contaminated or left open to the atmosphere for an

indeterminable period, it must be replaced.

OPERATION

The filter-drier performs a filtering action to pre-

vent foreign material in the refrigerant from contam-

inating the expansion valve. A desiccant bag is

mounted inside the filter-drier canister to absorb any

moisture which may have entered and become

trapped within the refrigerant system. In addition,

during periods of high demand air conditioner opera-

tion, the filter-drier acts as a reservoir to store sur-

plus refrigerant. Refrigerant enters the filter-drier as

a high-pressure, low temperature liquid.

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

RSPLUMBING - FRONT24-85

LIQUID LINE (Continued)

ProCarManuals.com