Interior CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1990 of 2399

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 5).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

damage part to its original strength and appearance

without exceeding the value of the replacement part.

²When plastic repairs are required, it is recom-

mended that the part be left on the vehicle when

every possible. That will save time, and the panel

will remain stationary during the repair. Misalign-

ment can cause stress in the repair areas and can

result in future failure.

VISUAL INSPECTION

Composite materials can mask the severity of an

accident. Adhesive bond lines, interior structure of

the doors, and steel structures need to be inspected

carefully to get a true damage assessment. Close

inspection may require partial removal of interior

trim or inner panels.

Identify the type of repair: Puncture or Crack -

Damage that has penetrated completely through the

panel. Damage is confined to one general area; a

panel section is not required. However, a backer

panel, open fiberglass tape, or matted material must

be bonded from behind (Fig. 7) (Fig. 6).

PANEL SURFACE PREPARATION

If a body panel has been punctured, cracked, or

crushed, the damaged area must be removed from

the panel to achieve a successful repair. All spider

web cracks leading away from a damaged area must

be stopped or removed. To stop a running crack in a

panel, drilla6mm(0.250 in.) hole at the end of the

crack farthest away from the damage. If spider web

cracks can not be stopped, the panel would require

replacement. The surfaces around the damaged area

should be stripped of paint and freed from wax and

oil. Scuff surfaces around repair area with 360 grit

wet/dry sandpaper, or equivalent, to assure adhesion

of repair materials.

PATCHING PANELS

An panel that has extensive puncture type damage

can be repaired by cutting out the damaged material

(Fig. 7). Use a suitable reciprocating saw or cut off

wheel to remove the section of the panel that is dam-

aged. The piece cut out can be used as a template to

shape the new patch. It is not necessary to have

access to the back of the panel to install a patch.

Bevel edges of cutout at 20 degrees to expose a larger

bonding area on the outer side. This will allow for an

increased reinforcement areas.

Fig. 4 BEVELING ANGLE - 20 DEGREE

Fig. 5 FIBERGLASS TAPE

Fig. 6 DAMAGE COMPONENT

1 - PUNCTURE

RSBODY23-7

BODY (Continued)

ProCarManuals.com

Page 2008 of 2399

(2) Roll center hinge forward in roller channel.

(3) Place center hinge in position on sliding door

and align marks.

(4) Install bolts attaching center hinge to sliding

door.

(5) Verify sliding door alignment and operation.

SLIDING DOOR STOP BUMPER

BEZEL

REMOVAL

(1) Using a trim stick (C-4755), disengage clips

attaching door stop bumper bezel to the door trim

panel.

(2) Remove bezel from vehicle (Fig. 1).

INSTALLATION

(1) Place door stop bumper bezel into position (Fig.

1).

(2) Engage clips attaching door stop bumper bezel

to the door trim panel.

STOP BUMPER

REMOVAL

(1) Remove door stop bumper bezel.

(2) Loosen screws attaching rear of stop bumper to

door inner panel (Fig. 1).

(3) Remove screw attaching front of door stop

bumper to door inner panel.

(4) Remove door stop bumper from vehicle.

INSTALLATION

(1) Place stop bumper in position on vehicle.

(2) Install screw attaching front of stop bumper to

door inner panel (Fig. 1).(3) Tighten screws attaching rear of stop bumper

to door inner panel.

(4) Install door stop bumper bezel.

HOLD OPEN LATCH

REMOVAL

(1) Open sliding door.

(2) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(3) Remove nuts attaching hold open latch to lower

roller arm (Fig. 2).

(4) Remove hold open latch from lower arm.

(5) Disconnect cable from hold open latch.

(6) Remove hold open latch from vehicle.

INSTALLATION

(1) Place hold open latch in position on vehicle.

(2) Connect cable to hold open latch.

(3) Place hold open latch in position on lower arm.

(4) Install nuts attaching the hold open latch to

lower roller arm. Tighten nuts to 5 N´m (45 in. lbs.)

torque.

(5) Install sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(6) Verify sliding door operation.

Fig. 1 SLIDING DOOR STOP BUMPER

1 - DOOR STOP BUMPER

2 - DOOR STOP BUMPER BEZEL

3 - SLIDING DOOR

Fig. 2 SLIDING DOOR HOLD OPEN LATCH

1 - SLIDING DOOR HOLD OPEN LATCH - MANUAL DOOR

2 - LOWER ROLLER ARM

RSDOORS - SLIDING23-25

CENTER HINGE (Continued)

ProCarManuals.com

Page 2009 of 2399

HOLD OPEN LATCH STRIKER

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Open sliding door, do not latch open.

(2) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(3) Remove two bolts attaching sliding door hold

open latch striker to door sill (Fig. 3).

(4) Remove hold open latch striker from vehicle.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Place hold open latch striker in position on

vehicle.

(2) Install two bolts attaching sliding door hold

open latch striker to door sill.

(3) Install sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(4) Verify sliding door operation.

LATCH / LOCK ASSEMBLY

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

CAUTION: Replace the latch/lock control if any of

the metal clips on the latch/lock control are bent or

broken. DO NOT attempt to repair the clips to retain

the links.

(4) Disengage external cable from latch/lock

assembly (Fig. 4).

(5) Remove foam block.

(6) Remove inside door handle assembly (Refer to

23 - BODY/DOORS - SLIDING/INSIDE LATCH

HANDLE - REMOVAL).

(7) Disengage inside cable from latch/lock assem-

bly.

(8) Disengage link from bellcrank.

(9) Disengage hold open latch cable from lower

hinge.

(10) Remove bolts attaching latch/lock control to

sliding door (Fig. 5).

(11) If equipped, lower latch and disconnect wire

connector from power door lock motor.

(12) Remove latch/lock from door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Position latch/lock locking lever in unlocked

position.

(2) Place latch/lock in position on door (Fig. 5).

(3) If equipped, engage wire connector into power

door lock motor (Fig. 4).

(4) Insert bolt into slots in sliding door inner

panel.

(5) Tighten bolts attaching latch/lock assembly to

sliding door.

(6) Engage inside cable into latch/lock assembly.

Fig. 3 SLIDING DOOR HOLD OPEN LATCH STRIKER

1 - POWER DOOR LOWER TRACK

2 - POWER DOOR HOLDING STRIKER

3 - MANUAL DOOR HOLDING STRIKER

4 - MANUAL DOOR LOWER TRACK

23 - 26 DOORS - SLIDINGRS

ProCarManuals.com

Page 2011 of 2399

(3) Install bolts attaching stop bumper.

(4) Install sliding door trim panel (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION).

LOWER HINGE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Open sliding door.

(2) Mark outline of roller arm on sliding door to

aid installation (Fig. 7).

(3) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(4) Remove screws attaching open latch to lower

roller arm.

(5) Remove open latch from lower arm.

(6) Support sliding door on a suitable lifting device

with a padded upper surface. The door must be

moveable with lifting device in place.

(7) Remove hold open latch striker.

(8) Remove bolts attaching lower roller arm to

sliding door.

(9) Remove roller arm from sliding door.

(10) Disengage roller arm from lower channel.

(11) Remove roller arm from vehicle.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Place roller arm into position (Fig. 7).

(2) Engage roller arm to lower channel.

(3) Install roller arm to sliding door.

(4) Install bolts attaching lower roller arm to slid-

ing door.

(5) Install hold open latch striker.

(6) Install screws attaching open latch to lower

roller arm.

(7) Install sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION)

(8) Check sliding door for proper operation.

REAR LATCH STRIKER

REMOVAL

(1) Open sliding door.

(2) Mark outline of striker on C-pillar door jamb

face to aid installation.

(3) Remove screws attaching striker to C-pillar

(Fig. 8).

(4) Remove striker from vehicle.

INSTALLATION

(1) Place striker in position on vehicle.

(2) Align striker to outline marks on C-pillar.

(3) Install screws attaching striker to C-pillar.

Tighten screws to 28 N´m (21 ft. lbs.) torque.

(4) Verify sliding door alignment and operation.

Fig. 7 SLIDING DOOR LOWER ROLLER ARM

1 - POWER LOWER ROLLER ARM

2 - MANUAL LOWER ROLLER ARM

Fig. 8 SLIDING DOOR LATCH STRIKER

1 - LATCH STRIKER

2 - SLIDING DOOR

23 - 28 DOORS - SLIDINGRS

CENTER STRIKER (Continued)

ProCarManuals.com

Page 2012 of 2399

SLIDING DOOR

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Apply masking tape to outside surface of quar-

ter panel below the center roller channel, rearward of

the door opening.

(2) Release sliding door latch and open door.

(3) Apply masking tape to door jamb area, rear-

ward of the upper roller channel.

(4) Remove screw attaching upper stop bumper to

upper roller arm (Fig. 9).

(5) Remove upper stop from upper roller arm.

(6) Remove center stop from sliding door. (Refer to

23 - BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(7) Remove sliding door sill plate. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(8) Remove hold open latch striker (Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - REMOVAL).

(9) Open quarter glass.

(10) Remove center roller channel end cover (Fig.

10).

(11) Support sliding door on a suitable lifting

device with a padded upper surface. The door must

be moveable with lifting device in place.

CAUTION: Do not allow the center hinge roller to

contact the quarter glass. Glass can break.

(12) Slide door rearward until the upper sliding

door hinge roller disengages from the upper channel

(Fig. 11).

(13) Continue moving the door rearward until the

lower rollers exit the lower track.

(14) Continue moving door rearward till center

hinge roller exits the channel (Fig. 12)

(15) Remove sliding door from vehicle.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.(1) Place sliding door in position on lifting device.

(2) Engage center hinge roller into channel and

move door forward (Fig. 12).

(3) Position door rearward of the sliding door open-

ing.

CAUTION: Do not allow the center hinge roller to

contact the quarter glass. Glass can break.

Fig. 9 SLIDING DOOR UPPER STOP

1 - UPPER STOP PLATE

2 - SLIDING DOOR

3 - UPPER SLIDING DOOR HINGE

Fig. 10 CENTER CHANNEL END COVER

1 - CENTER CHANNEL

2 - CENTER CHANNEL END COVER

3 - PLASTIC NUT

RSDOORS - SLIDING23-29

ProCarManuals.com

Page 2040 of 2399

INSTALLATION

NOTE: The crossbar assemblies are designed to be

installed in only one way. Check top and bottom

surfaces of the crossbar for the word FRONT and

directional arrows. The directional arrows must

point toward the front of the vehicle.

(1) Place crossbar in position on vehicle.

(2) Work from side to side sliding the crossbar

assembly back a little at a time to ensure it remains

perpendicular to the side rails.

(3) Position first crossbar assembly crossbar at the

second most rearward locator holes. Press the top of

the stanchion lever to lock it into position.

(4) Position the second crossbar assembly in the

second hole from the front. Lock into place.

(5) Place luggage rack riser into position.

(6) Install two fasteners into riser. Tighten fasten-

ers to 4 mm (35 in. lbs.) torque.

REAR QUARTER PANEL/

FENDER AIR EXHAUSTER

DESCRIPTION

Air exhausters, designed to conform to the body

structure, allow air entering at the front of the vehi-

cle to flow out the back. By reducing air pressure

within the vehicle, the exhausters also reduce blower

noise at any given air flow level compared to operat-

ing without them and help reduce door closing effort.

They are located in the lower rear comers of the

body.

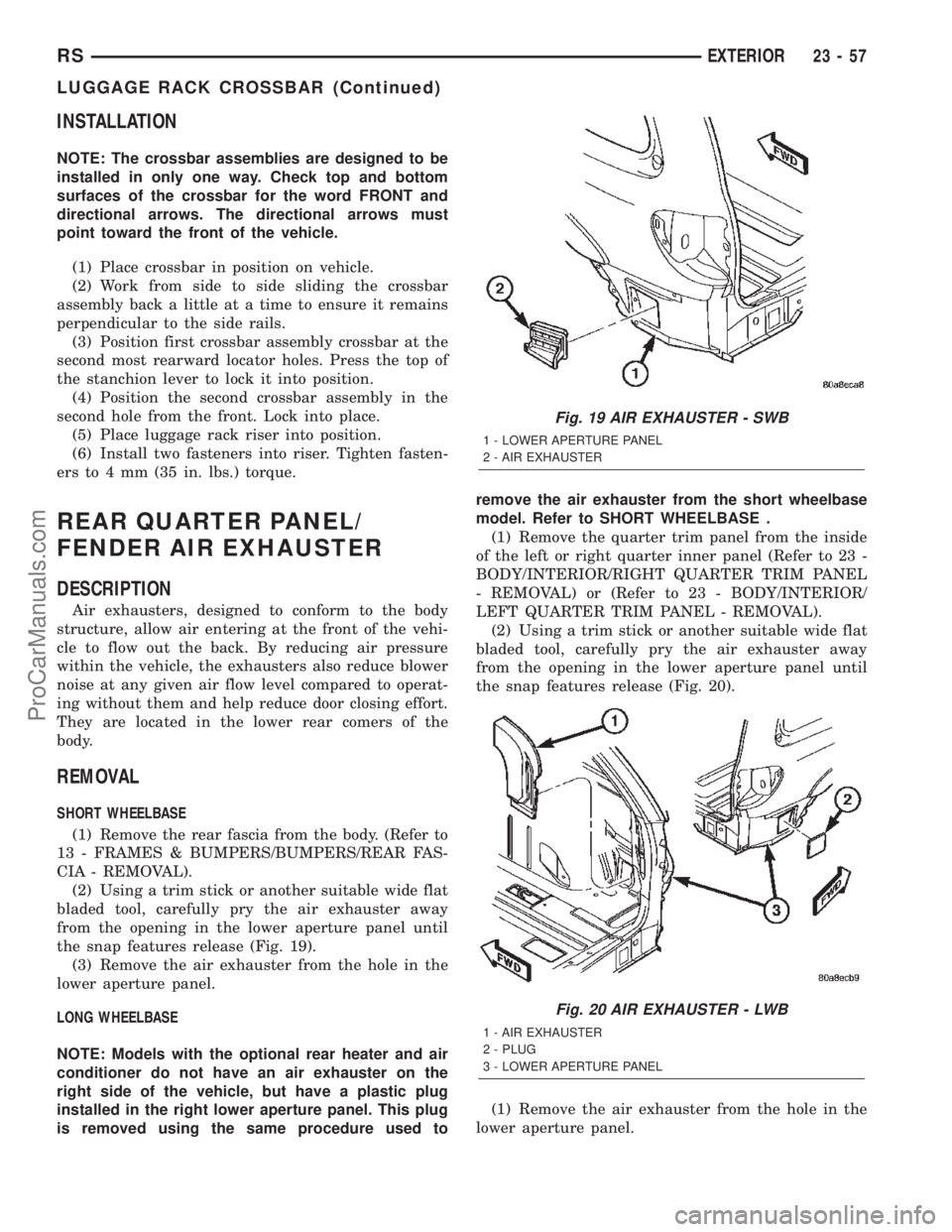

REMOVAL

SHORT WHEELBASE

(1) Remove the rear fascia from the body. (Refer to

13 - FRAMES & BUMPERS/BUMPERS/REAR FAS-

CIA - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 19).

(3) Remove the air exhauster from the hole in the

lower aperture panel.

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is removed using the same procedure used toremove the air exhauster from the short wheelbase

model. Refer to SHORT WHEELBASE .

(1) Remove the quarter trim panel from the inside

of the left or right quarter inner panel (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- REMOVAL) or (Refer to 23 - BODY/INTERIOR/

LEFT QUARTER TRIM PANEL - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 20).

(1) Remove the air exhauster from the hole in the

lower aperture panel.

Fig. 19 AIR EXHAUSTER - SWB

1 - LOWER APERTURE PANEL

2 - AIR EXHAUSTER

Fig. 20 AIR EXHAUSTER - LWB

1 - AIR EXHAUSTER

2 - PLUG

3 - LOWER APERTURE PANEL

RSEXTERIOR23-57

LUGGAGE RACK CROSSBAR (Continued)

ProCarManuals.com

Page 2041 of 2399

INSTALLATION

SHORT WHEELBASE

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 19).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the rear fascia onto the body. (Refer

to 13 - FRAMES & BUMPERS/BUMPERS/REAR

FASCIA - INSTALLATION).

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is installed using the same procedure used to

install the air exhauster onto the short wheelbase

model. Refer to SHORT WHEELBASE .

(1) Position the air exhauster to the hole in the

lower aperture panel (Fig. 20).

(2) Using hand pressure, press the air exhauster

into the opening in the lower aperture panel until

the snap features are fully engaged.

(3) Reinstall the quarter trim panel onto the inside

of the left or right quarter inner panel. (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- INSTALLATION) or (Refer to 23 - BODY/INTERI-

OR/LEFT QUARTER TRIM PANEL - INSTALLA-

TION).

ROOF JOINT MOLDING

REMOVAL

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) Warm the affected stick-on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.

(2) Pull stick-on molding from painted surface.(3) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Discs, or equivalent, to

clean adhesive residue from painted surfaces. The

adhesive removal discs are available from automotive

paint suppliers. Refer to instructions supplied with

the discs for proper usage.

INSTALLATION

The RAP molding is set with body side molding

tape. The temperature in the work area and the vehi-

cle should be at least 21É C (70É F) to avoid damag-

ing the RAP moldings.

(1) If molding is to be reused;

(a) Remove tape residue from molding.

(b) Clean back of molding with MopartSuper

Kleen solvent, or equivalent.

(c) Wipe molding dry with lint free cloth.

(d) Apply new body side molding (two sided

adhesive) tape to back of molding.

(2) Clean body surface with MopartSuper Kleen

solvent, or equivalent. Wipe surface dry with lint free

cloth.

(3) Remove protective cover from tape on back of

molding.

(4) Apply molding to body from front of vehicle to

rear.

(5) Using a roller tool, roll molding onto body

panel with enough force to assure adhesion and not

bend roof panels.

SIDE VIEW MIRROR

REMOVAL

(1) Using a trim stick or equivalent, remove the

trim cover (Fig. 21).

(2) Remove the bolts.

(3) Remove the mirror from the pillar.

(4) Disconnect the electrical connector, if equipped.

INSTALLATION

(1) Connect the electrical connector, if equipped.

(2) Place side view mirror in position on vehicle

(Fig. 21).

(3) Install the bolts.

(4) Install the trim cover.

23 - 58 EXTERIORRS

REAR QUARTER PANEL/FENDER AIR EXHAUSTER (Continued)

ProCarManuals.com

Page 2055 of 2399

INTERIOR

TABLE OF CONTENTS

page page

A-PILLAR LOWER EXTENSION TRIM

REMOVAL.............................73

INSTALLATION.........................73

A-PILLAR TRIM

REMOVAL.............................73

INSTALLATION.........................73

ASSIST HANDLE

REMOVAL.............................73

INSTALLATION.........................73

B-PILLAR LOWER TRIM

REMOVAL.............................73

INSTALLATION.........................74

B-PILLAR UPPER TRIM

REMOVAL.............................74

INSTALLATION.........................74

CARPETS AND FLOOR MATS

REMOVAL.............................74

INSTALLATION.........................75

COWL TRIM

REMOVAL.............................75

INSTALLATION.........................75

C-PILLAR TRIM

REMOVAL.............................75

INSTALLATION.........................76

DOOR SILL TRIM PLATE

REMOVAL.............................76

INSTALLATION.........................76

HEADLINER

REMOVAL.............................76

INSTALLATION.........................76

LEFT D-PILLAR TRIM PANEL

REMOVAL.............................77

INSTALLATION.........................77

LIFTGATE SILL PLATE

REMOVAL.............................77

INSTALLATION.........................77

QUARTER TRIM BOLSTER

REMOVAL.............................77INSTALLATION.........................77

RIGHT QUARTER TRIM PANEL

REMOVAL.............................78

INSTALLATION.........................78

LEFT QUARTER TRIM PANEL

REMOVAL.............................78

INSTALLATION.........................78

REAR HEADER TRIM

REMOVAL.............................79

INSTALLATION.........................79

REAR HVAC LOUVER

REMOVAL.............................79

INSTALLATION.........................79

REAR VIEW MIRROR

REMOVAL.............................80

INSTALLATION.........................80

RIGHT D-PILLAR TRIM PANEL

REMOVAL.............................80

INSTALLATION.........................80

SLIDING DOOR SILL PLATE

REMOVAL.............................80

INSTALLATION.........................80

SUN VISOR

REMOVAL.............................81

INSTALLATION.........................81

SUN VISOR SUPPORT

REMOVAL.............................81

INSTALLATION.........................81

FLOOR CONSOLE TRAY

REMOVAL.............................82

INSTALLATION.........................82

FLOOR CONSOLE TRAY - BRACKET

ASSEMBLY

REMOVAL.............................82

INSTALLATION.........................82

23 - 72 INTERIORRS

ProCarManuals.com

Page 2056 of 2399

A-PILLAR LOWER EXTENSION

TRIM

REMOVAL

(1) Remove instrument panel side cover.

(2) Remove A-pillar extension trim from vehicle by

disengaging hidden clips (Fig. 1).

INSTALLATION

(1) Place A-pillar extension trim in position on

vehicle (Fig. 1).

(2) Install instrument panel side cover.

A-PILLAR TRIM

REMOVAL

(1) Remove the assist handle if equipped. (Refer to

23 - BODY/INTERIOR/ASSIST HANDLE -

REMOVAL)

(2) Disengage hidden clips holding A-pillar trim

panel to A-pillar (Fig. 2).

(3) Remove A-pillar trim from vehicle.

INSTALLATION

(1) Position foot on A-pillar trim panel into instru-

ment panel top cover channel.

(2) Position A-pillar trim in vehicle.

(3) Align locator pins.

(4) Engage hidden clips.(5) Install the assist handle, if equipped. (Refer to

23 - BODY/INTERIOR/ASSIST HANDLE - INSTAL-

LATION)

ASSIST HANDLE

REMOVAL

(1) Using a trim stick (C-4755), remove screw

access covers from grab-handle.

(2) Remove screws holding grab-handle to roof rail.

(3) Remove grab-handle from vehicle.

INSTALLATION

(1) Place grab-handle in position on vehicle.

(2) Install screws to hold grab-handle to roof rail.

(3) Install screw access covers into grab-handle.

B-PILLAR LOWER TRIM

REMOVAL

(1) Slide lower seat belt cover rearward to expose

anchor bolt.

(2) Remove bolt attaching lower seat belt anchor to

floor.

(3) Remove upper B-pillar trim cover.

(4) Remove access panel from B-pillar trim (Fig.

3).

Fig. 1 A-PILLAR LOWER EXTENSION TRIM

1 - FRONT LOWER EXTENSION TRIM

2 - FRONT EXTENSION TRIM TO INSTRUMENT PANEL

RETAINER

3 - CLIP

4 - COWL TRIM PANEL

Fig. 2 A-PILLAR TRIM

1 - A-PILLAR

2 - CLIPS

RSINTERIOR23-73

ProCarManuals.com

Page 2057 of 2399

(5) Disengage hidden clips attaching lower trim

cover to B-pillar.

(6) Remove lower B-pillar trim cover from vehicle.

INSTALLATION

(1) Place lower B-pillar trim cover in position on

vehicle (Fig. 3).

(2) Insert seat belt through hole in lower B-pillar

trim.

(3) Engage hidden clips attaching lower trim cover

to B-pillar.

(4) Install access cover.

(5) Install upper B-pillar trim cover.

(6) Place seat belt anchor in position on floor so

webbing is pointed rearward and slightly outboard.

(7) Install bolt attaching lower seat belt anchor to

floor. Tighten all seat belt bolts to 39 N´m (29 ft. lbs.)

torque.

(8) Verify that seat belt anchor does not interfere

with seat track travel.

B-PILLAR UPPER TRIM

REMOVAL

(1) Remove bolt attaching lower seat belt anchor to

floor.(2) Lower shoulder belt height adjuster to the bot-

tom of travel.

(3) Remove shoulder belt turning loop from height

adjuster.

(4) Use a Snap-ontTrim Pad Remover tool

(A179A), or equivalent, and remove shoulder belt

height adjuster knob.

(5) Remove shoulder belt bezel from trim cover

(Fig. 3).

(6) Remove screw attaching trim cover to B-pillar

from inside bezel cavity.

(7) Disengage hidden clips attaching trim cover to

B-pillar.

(8) Remove B-pillar trim cover from vehicle.

INSTALLATION

(1) Insert seat belt through B-pillar trim and web

guide (Fig. 3).

(2) Place B-pillar trim cover in position on vehicle.

(3) Engage hidden clips attaching trim cover to

B-pillar.

(4) Install shoulder belt bezel into trim cover.

(5) Install height adjuster knob.

(6) Install shoulder belt turning loop onto height

adjuster. Tighten bolt to 39 N´m (29 ft. lbs.) torque.

(7) Place seat anchor in position on floor so web-

bing is pointed rearward and slightly outboard.

(8) Install bolt attaching lower seat belt anchor to

floor. Tighten seat belt bolt to 39 N´m (29 ft. lbs.)

torque.

CARPETS AND FLOOR MATS

REMOVAL

(1) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(2) Remove front center console.

(3) Remove the remaining seats. Refer to the Own-

er's Manual for the proper procedures.

(4) Remove front cowl panels and sill plates.

(5) Remove sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

REMOVAL)

(6) Remove the cargo organizer, if equipped.

(7) Remove liftgate scuff plate. (Refer to 23 -

BODY/INTERIOR/LIFTGATE SCUFF PLATE -

REMOVAL)

(8) Remove lower B-pillar trim covers.

(9) Remove D-pillar trim covers.

(10) Remove Quarter trim panels.

(11) Remove floor escutcheons (Fig. 4).

(12) Remove the floor console trays. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE TRAY -

REMOVAL)

Fig. 3 LOWER B-PILLAR TRIM COVER

1 - B-PILLAR UPPER TRIM

2 - B-PILLAR UPPER PLUG

3 - POWER SLIDING DOOR SWITCH AND BEZEL

4 - BELT ASSEMBLY

5 - B-PILLAR LOWER TRIM

23 - 74 INTERIORRS

B-PILLAR LOWER TRIM (Continued)

ProCarManuals.com