air condition CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 321 of 2399

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

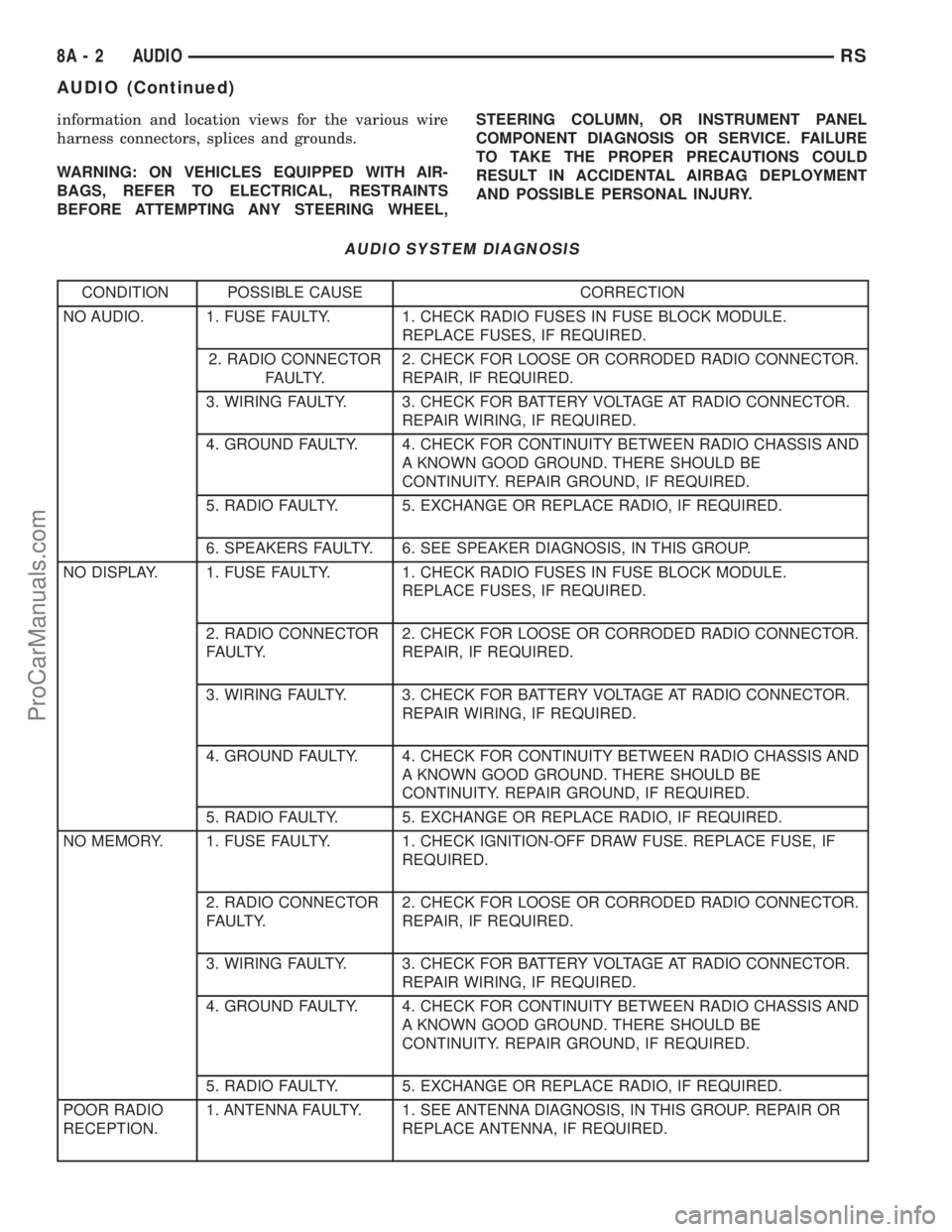

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO MEMORY. 1. FUSE FAULTY. 1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

POOR RADIO

RECEPTION.1. ANTENNA FAULTY. 1. SEE ANTENNA DIAGNOSIS, IN THIS GROUP. REPAIR OR

REPLACE ANTENNA, IF REQUIRED.

8A - 2 AUDIORS

AUDIO (Continued)

ProCarManuals.com

Page 322 of 2399

CONDITION POSSIBLE CAUSE CORRECTION

2. GROUND FAULTY. 2. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

3. RADIO FAULTY. 3. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

4. POOR ANTENNA

CONNECTION AT

RADIO OR IN LINE.4. SEAT CONNECTOR.

NO/POOR TAPE

OPERATION.1. FAULTY TAPE. 1. INSERT KNOWN GOOD TAPE AND TEST OPERATION.

2. FOREIGN OBJECTS

BEHIND TAPE DOOR.2. REMOVE FOREIGN OBJECTS AND TEST OPERATION.

3. DIRTY CASSETTE

TAPE HEAD.3. CLEAN HEAD WITH MOPAR CASSETTE HEAD CLEANER.

4. FAULTY TAPE DECK. 4. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO COMPACT

DISC

OPERATION1. FAULTY CD. 1. INSERT KNOWN GOOD CD AND TEST OPERATION.

2. FOREIGN MATERIAL

ON CD.2. CLEAN CD AND TEST OPERATION.

3. CONDENSATION ON

CD OR OPTICS.3. ALLOW TEMPERATURE OF VEHICLE INTERIOR TO

STABILIZE AND TEST OPERATION.

4. FAULTY CD PLAYER. 4. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

HEADPHONES

WILL NOT HOLD

A CHANNEL OR

HAVE STATIC1. WEAK BATTERIES IN

THE HEADPHONES.1. REPLACE BATTERIES.

2. CLOSENESS TO

RADIO TRANSMITTER

SUCH AS A RADIO

TOWER, AIRPORT

TRANSMITTER OR

SOME MOBILE

RADIOS.2. MOVE TO AN AREA AWAY FREE FROM THESE

CONDITIONS.

REMOTE

CONTROL

INOPERATIVE1. WEAK BATTERIES IN

THE REMOTE

CONTROL.1. REPLACE BATTERIES.

2. OPERATION

CONSTRAINT OF

SYSTEM2. MAKE SURE THAT REAR AUDIO IS IN A DIFFERENT MODE

THAN FRONT SPEAKERS. REMOTE CONTROL WILL NOT

WORK WHEN BOTH ARE IN THE SAME MODE.

RSAUDIO8A-3

AUDIO (Continued)

ProCarManuals.com

Page 323 of 2399

ANTENNA BODY AND CABLE

DESCRIPTION

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

The factory-installed Electronically Tuned Radios

(ETRs) automatically compensate for radio antenna

trim. Therefore, no antenna trimmer adjustment is

required or possible when replacing the receiver or

the antenna.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

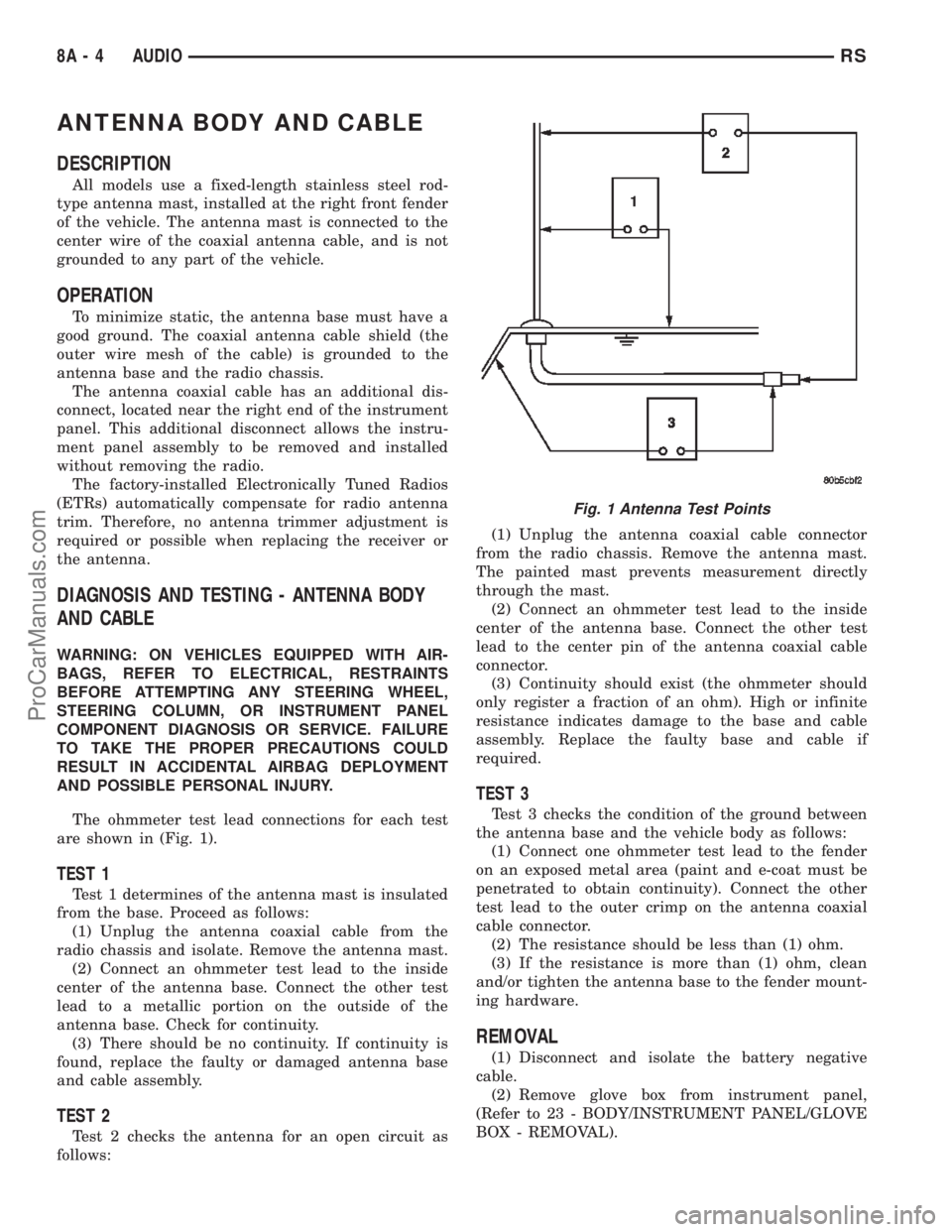

The ohmmeter test lead connections for each test

are shown in (Fig. 1).

TEST 1

Test 1 determines of the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable from the

radio chassis and isolate. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to a metallic portion on the outside of the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

TEST 2

Test 2 checks the antenna for an open circuit as

follows:(1) Unplug the antenna coaxial cable connector

from the radio chassis. Remove the antenna mast.

The painted mast prevents measurement directly

through the mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to the center pin of the antenna coaxial cable

connector.

(3) Continuity should exist (the ohmmeter should

only register a fraction of an ohm). High or infinite

resistance indicates damage to the base and cable

assembly. Replace the faulty base and cable if

required.

TEST 3

Test 3 checks the condition of the ground between

the antenna base and the vehicle body as follows:

(1) Connect one ohmmeter test lead to the fender

on an exposed metal area (paint and e-coat must be

penetrated to obtain continuity). Connect the other

test lead to the outer crimp on the antenna coaxial

cable connector.

(2) The resistance should be less than (1) ohm.

(3) If the resistance is more than (1) ohm, clean

and/or tighten the antenna base to the fender mount-

ing hardware.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box from instrument panel,

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - REMOVAL).

Fig. 1 Antenna Test Points

8A - 4 AUDIORS

ProCarManuals.com

Page 325 of 2399

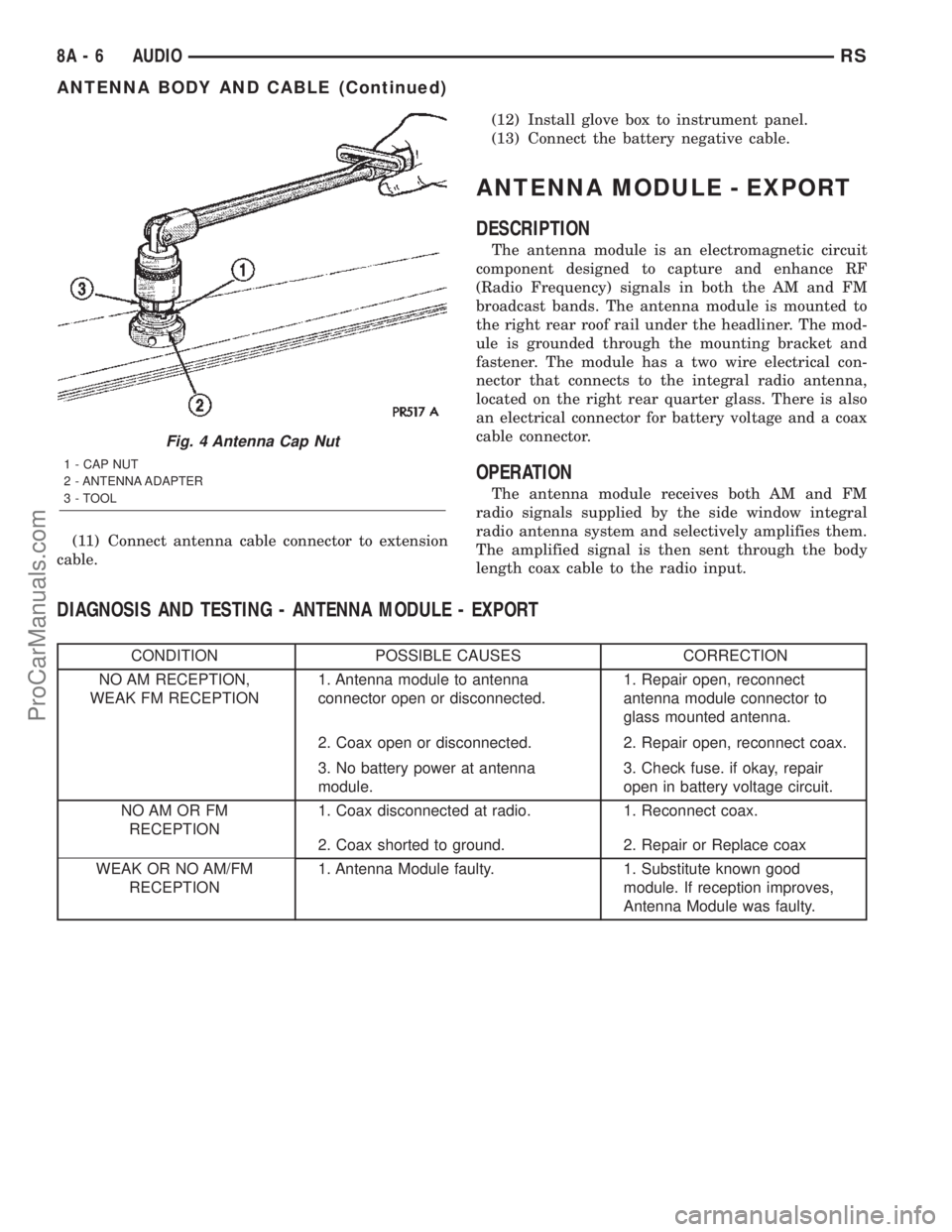

(11) Connect antenna cable connector to extension

cable.(12) Install glove box to instrument panel.

(13) Connect the battery negative cable.

ANTENNA MODULE - EXPORT

DESCRIPTION

The antenna module is an electromagnetic circuit

component designed to capture and enhance RF

(Radio Frequency) signals in both the AM and FM

broadcast bands. The antenna module is mounted to

the right rear roof rail under the headliner. The mod-

ule is grounded through the mounting bracket and

fastener. The module has a two wire electrical con-

nector that connects to the integral radio antenna,

located on the right rear quarter glass. There is also

an electrical connector for battery voltage and a coax

cable connector.

OPERATION

The antenna module receives both AM and FM

radio signals supplied by the side window integral

radio antenna system and selectively amplifies them.

The amplified signal is then sent through the body

length coax cable to the radio input.

DIAGNOSIS AND TESTING - ANTENNA MODULE - EXPORT

CONDITION POSSIBLE CAUSES CORRECTION

NO AM RECEPTION,

WEAK FM RECEPTION1. Antenna module to antenna

connector open or disconnected.1. Repair open, reconnect

antenna module connector to

glass mounted antenna.

2. Coax open or disconnected. 2. Repair open, reconnect coax.

3. No battery power at antenna

module.3. Check fuse. if okay, repair

open in battery voltage circuit.

NO AM OR FM

RECEPTION1. Coax disconnected at radio. 1. Reconnect coax.

2. Coax shorted to ground. 2. Repair or Replace coax

WEAK OR NO AM/FM

RECEPTION1. Antenna Module faulty. 1. Substitute known good

module. If reception improves,

Antenna Module was faulty.

Fig. 4 Antenna Cap Nut

1 - CAP NUT

2 - ANTENNA ADAPTER

3 - TOOL

8A - 6 AUDIORS

ANTENNA BODY AND CABLE (Continued)

ProCarManuals.com

Page 348 of 2399

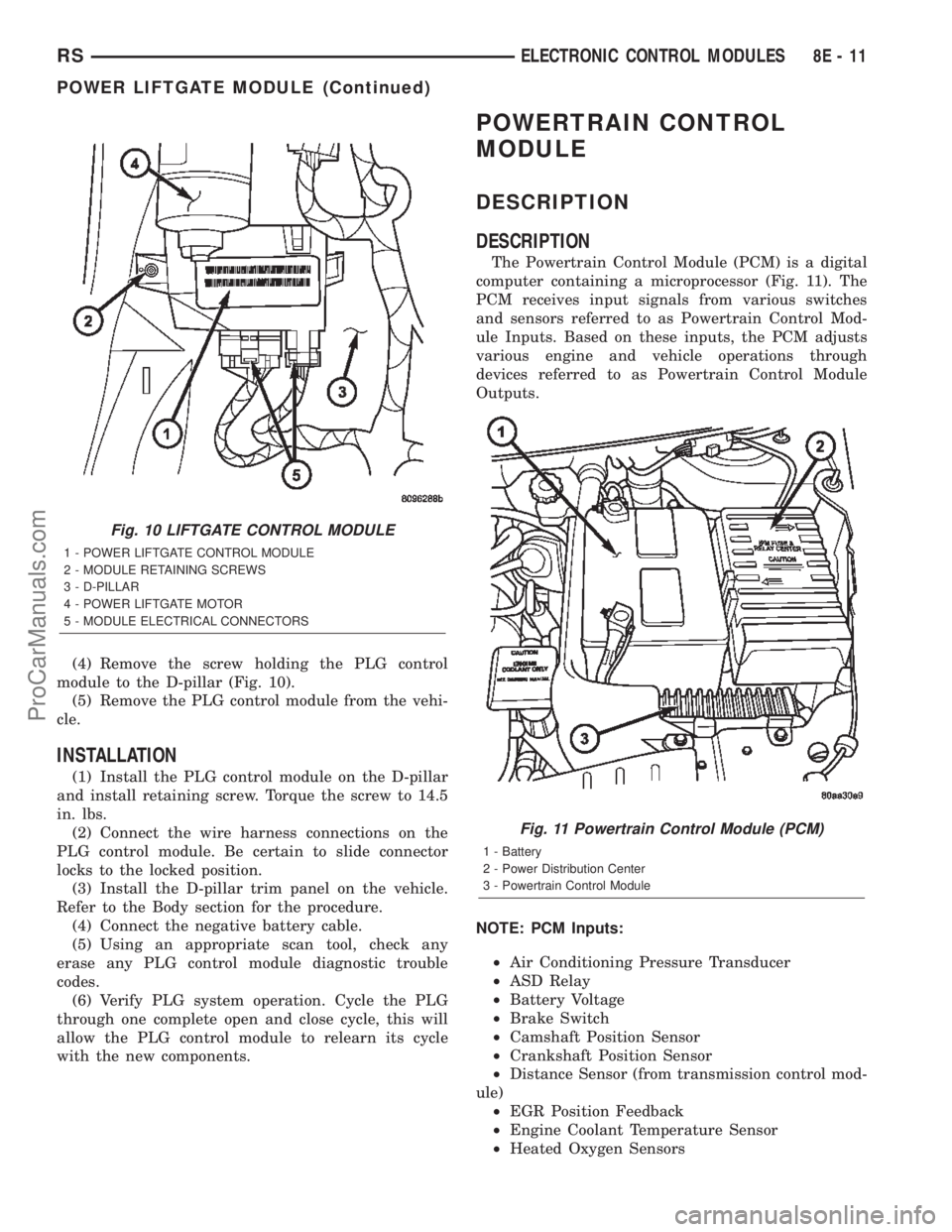

(4) Remove the screw holding the PLG control

module to the D-pillar (Fig. 10).

(5) Remove the PLG control module from the vehi-

cle.

INSTALLATION

(1) Install the PLG control module on the D-pillar

and install retaining screw. Torque the screw to 14.5

in. lbs.

(2) Connect the wire harness connections on the

PLG control module. Be certain to slide connector

locks to the locked position.

(3) Install the D-pillar trim panel on the vehicle.

Refer to the Body section for the procedure.

(4) Connect the negative battery cable.

(5) Using an appropriate scan tool, check any

erase any PLG control module diagnostic trouble

codes.

(6) Verify PLG system operation. Cycle the PLG

through one complete open and close cycle, this will

allow the PLG control module to relearn its cycle

with the new components.

POWERTRAIN CONTROL

MODULE

DESCRIPTION

DESCRIPTION

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 11). The

PCM receives input signals from various switches

and sensors referred to as Powertrain Control Mod-

ule Inputs. Based on these inputs, the PCM adjusts

various engine and vehicle operations through

devices referred to as Powertrain Control Module

Outputs.

NOTE: PCM Inputs:

²Air Conditioning Pressure Transducer

²ASD Relay

²Battery Voltage

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Distance Sensor (from transmission control mod-

ule)

²EGR Position Feedback

²Engine Coolant Temperature Sensor

²Heated Oxygen Sensors

Fig. 10 LIFTGATE CONTROL MODULE

1 - POWER LIFTGATE CONTROL MODULE

2 - MODULE RETAINING SCREWS

3 - D-PILLAR

4 - POWER LIFTGATE MOTOR

5 - MODULE ELECTRICAL CONNECTORS

Fig. 11 Powertrain Control Module (PCM)

1 - Battery

2 - Power Distribution Center

3 - Powertrain Control Module

RSELECTRONIC CONTROL MODULES8E-11

POWER LIFTGATE MODULE (Continued)

ProCarManuals.com

Page 349 of 2399

²Ignition sense

²Intake Air Temperature Sensor

²Knock Sensor

²Leak Detection Pump Feedback

²Manifold Absolute Pressure (MAP) Sensor

²Park/Neutral (from transmission control module)

²PCI Bus

²Power Steering Pressure Switch

²Proportional Purge Sense

²SCI Receive

²Speed Control

²Throttle Position Sensor

²Torque Management Input (From TCM)

²Transaxle Control Module (TCM)

²Transaxle Gear Engagement (From TCM)

²Vehicle Speed (from transmission control mod-

ule)

NOTE: PCM Outputs:

²Air Conditioning Clutch Relay

²Automatic Shut Down (ASD) and Fuel Pump

Relays

²Data Link Connector (PCI and SCI Transmit)

²Double Start Override

²EGR Solenoid

²Fuel Injectors

²Generator Field

²High Speed Fan Relay

²Idle Air Control Motor

²Ignition Coils

²Leak Detection Pump

²Low Speed Fan Relay

²MTV Actuator

²Proportional Purge Solenoid

²SRV Valve

²Speed Control Relay

²Speed Control Vent Relay

²Speed Control Vacuum Relay

²8 Volt Output

²5 Volt Output

Based on inputs it receives, the powertrain control

module (PCM) adjusts fuel injector pulse width, idle

speed, ignition timing, and canister purge operation.

The PCM regulates the cooling fans, air conditioning

and speed control systems. The PCM changes gener-

ator charge rate by adjusting the generator field.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery Voltage

²Intake Air Temperature Sensor

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)²Exhaust Gas Oxygen Content (heated oxygen

sensors)

²Manifold Absolute Pressure

²Throttle Position

The PCM adjusts engine idle speed through the

idle air control motor based on the following inputs.

²Brake Switch

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Park/Neutral (transmission gear selection)

²Transaxle Gear Engagement

²Throttle Position

²Vehicle Speed (from Transmission Control Mod-

ule)

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Intake Air Temperature

²Engine Coolant Temperature

²Engine Speed (crankshaft position sensor)

²Knock Sensor

²Manifold Absolute Pressure

²Park/Neutral (transmission gear selection)

²Transaxle Gear Engagement

²Throttle Position

The automatic shut down (ASD) and fuel pump

relays are mounted externally, but turned on and off

by the powertrain control module through the same

circuit.

The camshaft and crankshaft signals are sent to

the powertrain control module. If the PCM does not

receive both signals within approximately one second

of engine cranking, it deactivates the ASD and fuel

pump relays. When these relays are deactivated,

power is shut off to the fuel injectors, ignition coils,

fuel pump and the heating element in each oxygen

sensor.

The PCM contains a voltage converter that

changes battery voltage to a regulated 8.0 volts. The

8.0 volts power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5.0 volts supply for the engine

coolant temperature sensor, intake air temperature

sensor, manifold absolute pressure sensor and throt-

tle position sensor.

The PCM engine control strategy prevents reduced

idle speeds until after the engine operates for 320 km

(200 miles). If the PCM is replaced after 320 km (200

miles) of usage, update the mileage in new PCM. Use

the DRB scan tool to change the mileage in the PCM.

Refer to the appropriate Powertrain Diagnostic Man-

ual and the DRB scan tool.

8E - 12 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 351 of 2399

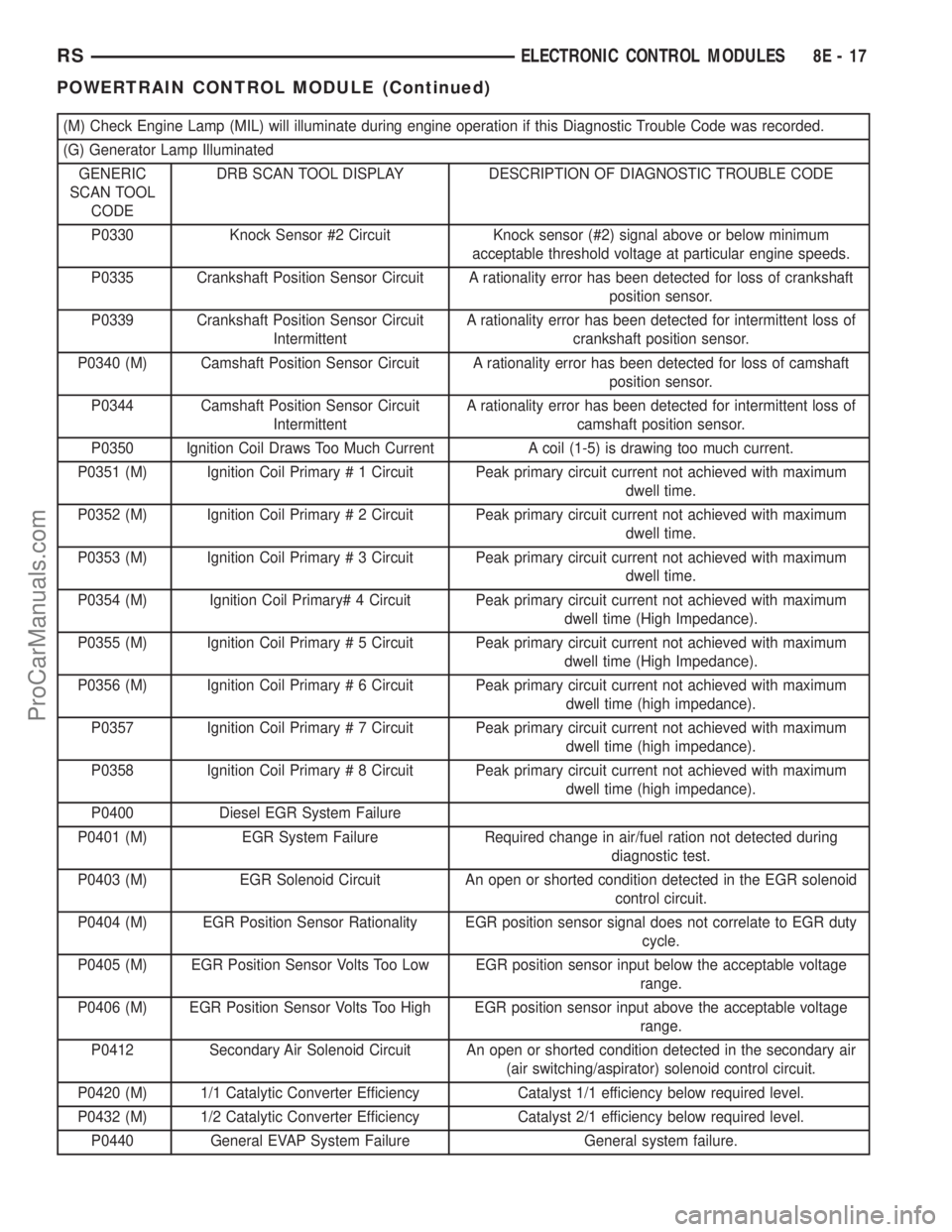

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0106 (M) Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

P0110 Intake Air Temp Sensor Stuck A rationality error has been detected for the intake air temp.

sensor.

P0111 (M) Intake Air Temp Sensor Performance Intake Air change less than 3É C in 200 Miles

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage High Intake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 Engine Coolant Temp Performance A rationality error has been detected in the coolant temp

sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the minimum

acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0122 (M) Throttle Position Sensor Voltage Low Throttle position sensor input below the acceptable voltage

range.

P0123 (M) Throttle Position Sensor Voltage High Throttle position sensor input above the maximum

acceptable voltage.

P0125 (M) Engine Coolant Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0128 Thermostat Rationality A rationality error has been detected for the thermostat

P0129 Barometic Pressure Out-of-Range low MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure.

P0130 1/1 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0134 (M) 1/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor input.

P0135 (M) 1/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0136 1/2 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or CNG

shutoff relay control ckt.

P0137 (M) 1/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

8E - 14 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 352 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0138 (M) 1/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0139 (M) 1/2 O2 Sensor Slow Response Oxygen sensor response not as expected.

P0140 (M) 1/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0141 (M) 1/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0143 1/3 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0144 1/3 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0145 1/3 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0146 1/3 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0147 1/3 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0151 (M) 2/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0152 (M) 2/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage sustained above normal

operating range.

P0153 (M) 2/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0154 (M) 2/1 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0155 (M) 2/1 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0157 (M) 2/2 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0158 (M) 2/2 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0159 2/2 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

P0160 (M) 2/2 O2 Sensor Stays at Center Neither rich or lean condition is detected from the oxygen

sensor.

P0161 (M) 2/2 O2 Sensor Heater Failure Oxygen sensor heater element malfunction.

P0165 Starter Relay Circuit

P0171 (M) 1/1 Fuel System Lean A lean air/fuel mixture has been indicated by an abnormally

rich correction factor.

P0172 (M) 1/1 Fuel System Rich A rich air/fuel mixture has been indicated by an abnormally

lean correction factor.

P0174 (M) 2/1 Fuel System Lean A lean air/fuel mixture has been indicated by an abnormally

rich correction factor.

P0175 (M) 2/1 Fuel System Rich A rich air/fuel mixture has been indicated by an abnormally

lean correction factor.

P0176 Flex Fuel Calibration Signal No calibration voltage present from flex fuel sensor.

RSELECTRONIC CONTROL MODULES8E-15

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 354 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0330 Knock Sensor #2 Circuit Knock sensor (#2) signal above or below minimum

acceptable threshold voltage at particular engine speeds.

P0335 Crankshaft Position Sensor Circuit A rationality error has been detected for loss of crankshaft

position sensor.

P0339 Crankshaft Position Sensor Circuit

IntermittentA rationality error has been detected for intermittent loss of

crankshaft position sensor.

P0340 (M) Camshaft Position Sensor Circuit A rationality error has been detected for loss of camshaft

position sensor.

P0344 Camshaft Position Sensor Circuit

IntermittentA rationality error has been detected for intermittent loss of

camshaft position sensor.

P0350 Ignition Coil Draws Too Much Current A coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil Primary # 1 Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil Primary # 2 Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil Primary # 3 Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil Primary# 4 Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil Primary # 5 Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil Primary # 6 Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 Ignition Coil Primary # 7 Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 Ignition Coil Primary # 8 Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0400 Diesel EGR System Failure

P0401 (M) EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 (M) EGR Solenoid Circuit An open or shorted condition detected in the EGR solenoid

control circuit.

P0404 (M) EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR duty

cycle.

P0405 (M) EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

P0406 (M) EGR Position Sensor Volts Too High EGR position sensor input above the acceptable voltage

range.

P0412 Secondary Air Solenoid Circuit An open or shorted condition detected in the secondary air

(air switching/aspirator) solenoid control circuit.

P0420 (M) 1/1 Catalytic Converter Efficiency Catalyst 1/1 efficiency below required level.

P0432 (M) 1/2 Catalytic Converter Efficiency Catalyst 2/1 efficiency below required level.

P0440 General EVAP System Failure General system failure.

RSELECTRONIC CONTROL MODULES8E-17

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com

Page 355 of 2399

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC

SCAN TOOL

CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0441 (M) Evap Purge Flow Monitor Insufficient or excessive vapor flow detected during

evaporative emission system operation.

P0442 (M) Evap Leak Monitor 0.040 Leak

DetectedA 0.040 leak has been detected in the evaporative system.

P0443 (M) Evap Purge Solenoid Circuit An open or shorted condition detected in the EVAP purge

solenoid control circuit.

P0452 NVLD Pressure Switch Stuck Closed NVLD pressure switch stuck closed.

P0453 NVLD Pressure Switch Stuck Open NVLD pressure switch stuck open.

P0455 (M) Evap Leak Monitor Large Leak

DetectedA large leak has been detected in the evaporative system.

P0456 (M) Evap Leak Monitor 0.020 Leak

DetectedA 0.020 leak has been detected in the evaporative system.

P0460 Fuel Level Unit No Change Over Miles No movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover Time No level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too Low Fuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0480 Low Speed Fan Relay Control Circuit An open or shorted condition detected in the low speed rad.

fan relay control circuit.

P0481 High Speed Fan Relay Control Circuit An open or shorted condition detected in the high speed rad.

fan relay control circuit.

P0498 NVLD Canister Vent Valve Solenoid

Circuit LowA shorted low condition detected in NVLD solenoid circuit.

P0499 NVLD Canister Vent Valve Solenoid

Circuit HighA shorted high condition detected in NVLD solenoid circuit.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road load

conditions.

P0501 Vehicle Speed Sensor #1 Performance A rationality error has been detected for no vehicle speed

sensor signal detected during road load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace idle air control motor.

P0508 (M) Idle Air Control Motor Circuit Low Idle Air Control Motor Circuit input below acceptable current

P0509 (M) Idle Air Control Motor Circuit High Idle Air Control Motor Circuit input above acceptable current

P0511 Idle Air Control Valve Solenoid Circuit An open or shorted condition detected in the IAC control

circuit.

P0513 Invalid SKIM Key The engine controller has received an invalid key from the

Smart Key Immobilizer Module.

P0516 Battery Temperature Sensor Low Battery Temp. sensor input below minimum acceptable

voltage.

P0517 Battery Temperature Sensor High Battery Temp. sensor input above maximum acceptable

voltage.

P0519 Idle Speed Performance A rationality error has been detected for target RPM not met

during drive idle condition. Possible Vacuum leak or IAC lost

steps.

8E - 18 ELECTRONIC CONTROL MODULESRS

POWERTRAIN CONTROL MODULE (Continued)

ProCarManuals.com