air condition CHRYSLER VOYAGER 2002 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 255 of 2399

SPECIFICATIONS

COOLING SYSTEM CAPACITY

Engine Coolant Capacity*

2.4L 10.7 L (11.4 qts.)

3.3/3.8L (without

rear heater)12.6 L (13.4 qts.)

3.3/3.8L (with rear

heater)15.4 L (16.3 qts.)

*Includes Heater and Coolant Recovery System

ACCESSORY DRIVE BELT TENSION

ACCESSORY

DRIVE BELTTENSION

2.4L ENGINE

Air Conditioning

Compressor/

GeneratorDynamic Tensioner

Power

SteeringNew

Belt534 - 756 N

183 - 218 Hz

(120 - 170

lbs.)

Used

Belt*356 - 534 N

150 - 183 Hz

(80 - 120 lbs)

*Belt is considered used after 15 minutes of run-in

time

3.3/3.8L ENGINES

Air Conditioning

CompressorDynamic

Tensioner

Generator/Water

Pump/Power

Steering

TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Accessory Drive Belt Tensioner

Assembly (3.3/3.8L)ÐBolt28 Ð 250

Engine Coolant Temperature

Sensor

(2.4 & 3.3/3.8L) 7 Ð 60

Generator & A/C Compressor Drive

Belt Tensioner Assembly (2.4L)Ð

Bolt54 40 Ð

Coolant Outlet Connector/

Thermostat Housing

(2.4 & 3.3/3.8L)ÐBolts 28 Ð 250

Water Pump

(2.4 & 3.3/3.8L)ÐBolts 12 Ð 105

Water Pump Inlet Tube (2.4L)Ð

Bolts12 Ð 105

Water Pump Inlet Tube (3.3/3.8L)Ð

Bolts28 Ð 250

Water Pump Pulley (3.3/3.8L)Ð

Bolts28 Ð 250

Radiator to A/C CondenserÐ

Screws5Ð45

Radiator FanÐScrews 5 Ð 45

Radiator Mounting (Upper

Bracket)ÐNuts12 Ð 105

7 - 6 COOLINGRS

COOLING (Continued)

ProCarManuals.com

Page 259 of 2399

CONDITION POSSIBLE CAUSES CORRECTIONS

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt 1. Replace belt

2. Belt too loose, or too tight 2. (a) Replace belt (auto-tensioned

belts.)

(b) Adjust power steering belt

tension (4 cyl. engine)

3. Misaligned pulleys 3. Align accessories

4. Non-uniform groove or eccentric

pulley4. Replace pulley

DRIVE BELTS - 2.4L

STANDARD PROCEDURE - CHECKING POWER

STEERING BELT TENSION

WARNING: DO NOT CHECK BELT TENSION WITH

ENGINE RUNNING.

Accessory drive belt tension can be measured with

Special Tool 8371 ± Belt Tension Gauge Adapter, and

the DRBIIItusing the following procedures:

(1) Connect 8371 to the DRBIIItfollowing the

instructions provided with tool.

(2) Place end of microphone probe approximately

2.54 cm (1 in.) from belt at belt center span location

shown in (Fig. 3).

(3) Pluck the belt a minimum of 3 times. (Use your

finger or other suitable tool) The frequency of the

belt in hertz (Hz) will display on DRBIIItscreen.

(4) Adjust belt to obtain proper frequency (ten-

sion). Refer to ACCESSORY DRIVE BELT TENSION

CHART for belt tension specifications.

ACCESSORY DRIVE BELT TENSION CHART -

2.4L

Accessory Drive Belt Belt Tension

Air Conditioning

Compressor/GeneratorDynamic Tensioner

Power Steering PumpNew183 - 218

Hz

Used* 150 - 183

Hz

*A belt is considered used after 15 minutes of run-in

time.

REMOVAL

GENERATOR AND AIR CONDITIONING BELT

(1) Raise vehicle on hoist.

(2) Remove the drive belt shield (Fig. 8).WARNING: DO NOT ALLOW DRIVE BELT TEN-

SIONER TO SNAP BACK, AS DAMAGE TO TEN-

SIONER AND/OR PERSONAL INJURY COULD

RESULT.

(3) Position a wrench on the belt tensioner lug

(Fig. 4).

(4) Release belt tension by rotating the tensioner

clockwise (Fig. 4).

(5) Remove belt.

(1) Carefully return tensioner to its relaxed posi-

tion.

POWER STEERING PUMP

(1) From top of the vehicle, loosen locking nuts (D)

and (F) (Fig. 5).

Fig. 3 Power Steering Belt - Center Span Location

1 - POWER STEERING BELT CENTER SPAN LOCATION

7 - 10 ACCESSORY DRIVERS

DRIVE BELTS (Continued)

ProCarManuals.com

Page 260 of 2399

(2) From under the vehicle, loosen the pivot bolt

(E). Loosen adjusting bolt (G) until belt can be

removed.

CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

INSPECTION

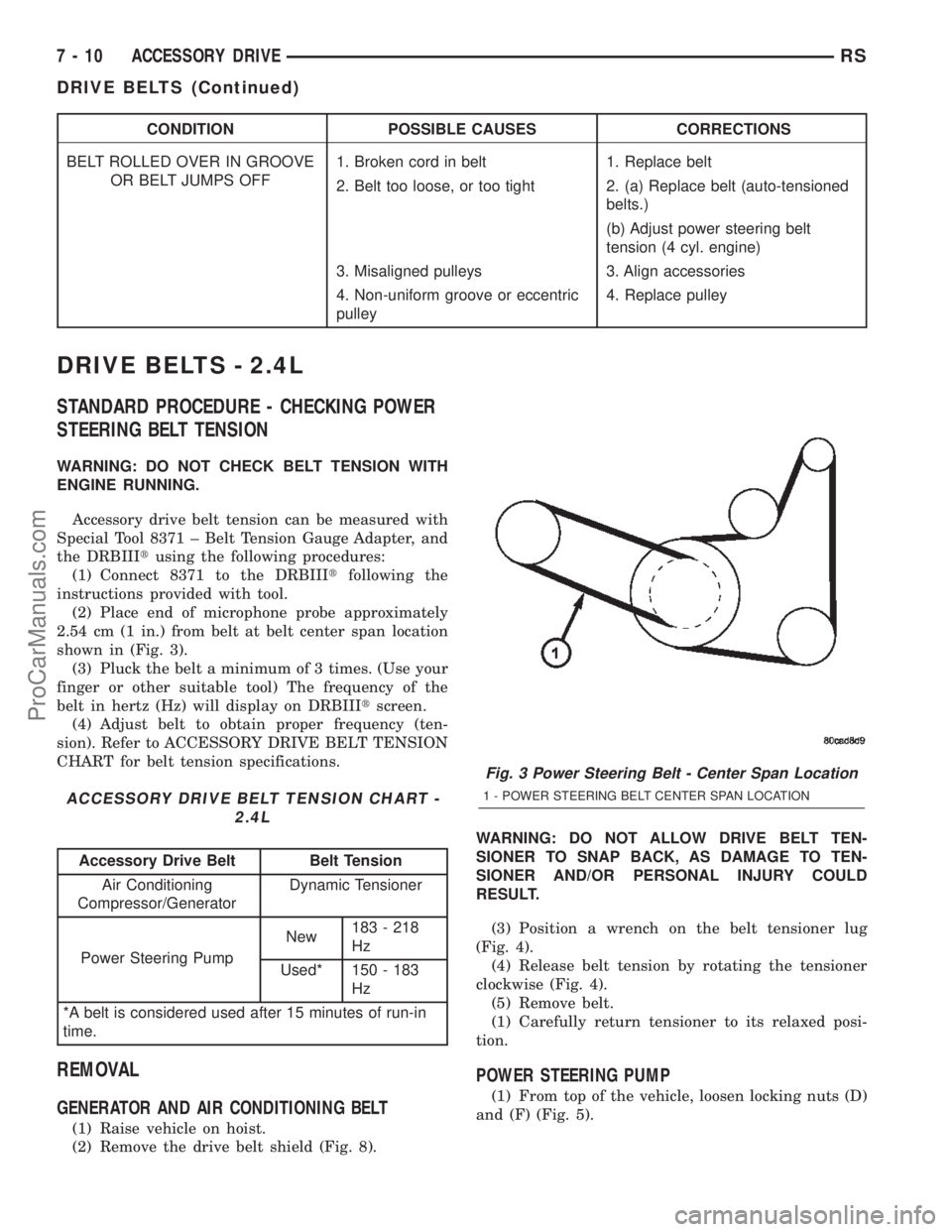

Belt replacement under any or all of the following

conditions is required:

²Excessive wear

²Frayed cords

²Severe glazing

Poly-V Belt system may develop minor cracks

across the ribbed side (due to reverse bending). These

minor cracks are considered normal and acceptable.

Parallel cracks are not (Fig. 6).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

INSTALLATION

GENERATOR AND AIR CONDITIONING BELT

(1) Install belt onto all pulleys except for the

crankshaft (Fig. 7).

(2) Rotate belt tensioner clockwise until belt can

be installed onto the crankshaft pulley (Fig. 4).

Slowly release belt tensioner.

(3) Verify belt is properly routed and engaged on

all pulleys (Fig. 7).

(4) Install drive belt shield (Fig. 8) and lower vehi-

cle.

Fig. 4 A/C & GENERATOR BELT TENSION RELEASE

1 - BELT TENSIONER

2 - WRENCH

Fig. 5 Power Steering Pump

1 - REAR LOCKING NUT

2 - ADJUSTING BOLT

3 - PIVOT BOLT

4 - FRONT LOCKING NUT

Fig. 6 Drive Belt Wear Pattern

1 - NORMAL CRACKS - BELT OK

2 - NOT NORMAL CRACKS - REPLACE BELT

RSACCESSORY DRIVE7-11

DRIVE BELTS - 2.4L (Continued)

ProCarManuals.com

Page 262 of 2399

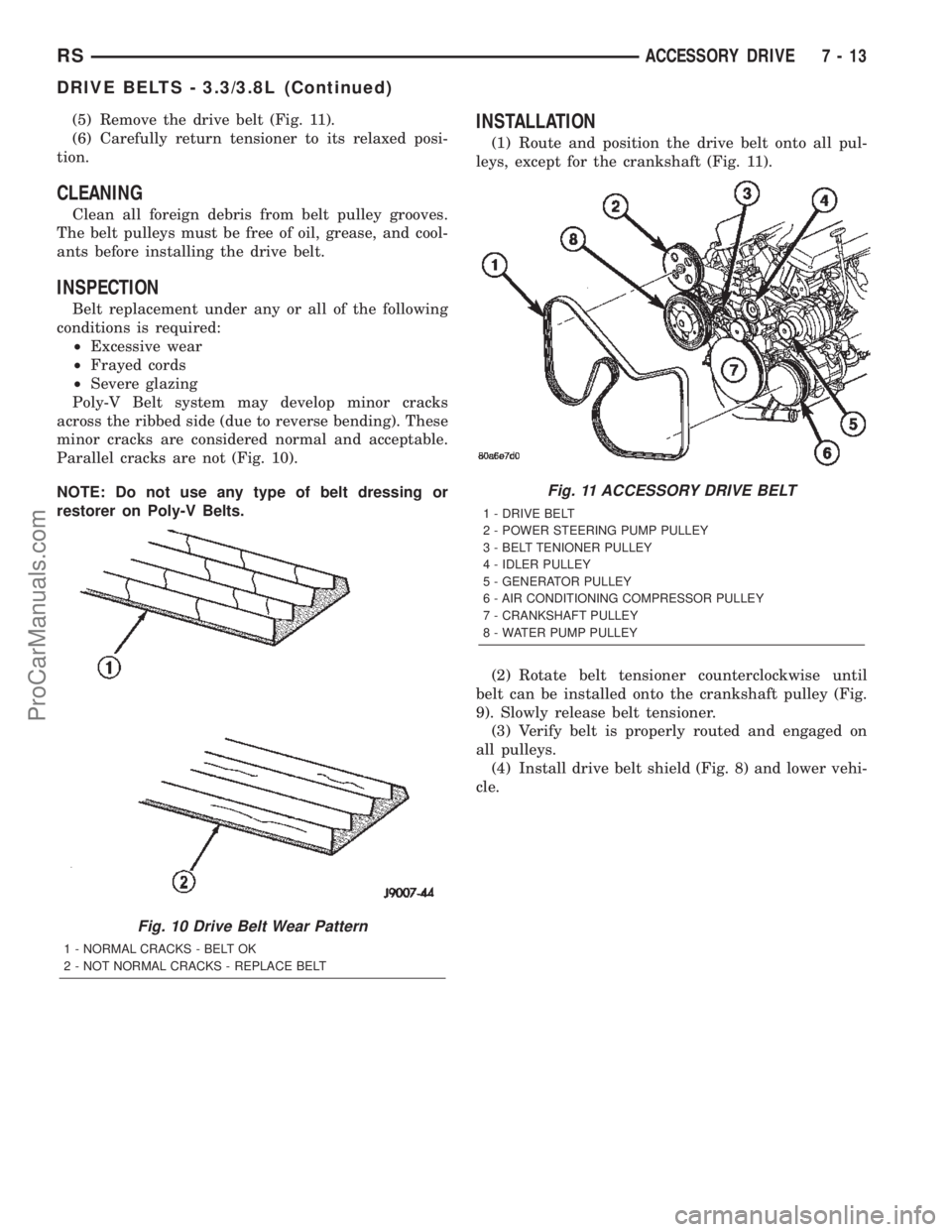

(5) Remove the drive belt (Fig. 11).

(6) Carefully return tensioner to its relaxed posi-

tion.

CLEANING

Clean all foreign debris from belt pulley grooves.

The belt pulleys must be free of oil, grease, and cool-

ants before installing the drive belt.

INSPECTION

Belt replacement under any or all of the following

conditions is required:

²Excessive wear

²Frayed cords

²Severe glazing

Poly-V Belt system may develop minor cracks

across the ribbed side (due to reverse bending). These

minor cracks are considered normal and acceptable.

Parallel cracks are not (Fig. 10).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V Belts.

INSTALLATION

(1) Route and position the drive belt onto all pul-

leys, except for the crankshaft (Fig. 11).

(2) Rotate belt tensioner counterclockwise until

belt can be installed onto the crankshaft pulley (Fig.

9). Slowly release belt tensioner.

(3) Verify belt is properly routed and engaged on

all pulleys.

(4) Install drive belt shield (Fig. 8) and lower vehi-

cle.

Fig. 10 Drive Belt Wear Pattern

1 - NORMAL CRACKS - BELT OK

2 - NOT NORMAL CRACKS - REPLACE BELT

Fig. 11 ACCESSORY DRIVE BELT

1 - DRIVE BELT

2 - POWER STEERING PUMP PULLEY

3 - BELT TENIONER PULLEY

4 - IDLER PULLEY

5 - GENERATOR PULLEY

6 - AIR CONDITIONING COMPRESSOR PULLEY

7 - CRANKSHAFT PULLEY

8 - WATER PUMP PULLEY

RSACCESSORY DRIVE7-13

DRIVE BELTS - 3.3/3.8L (Continued)

ProCarManuals.com

Page 264 of 2399

ENGINE

DIAGNOSIS AND TESTING - ENGINE COOLING

SYSTEM

Establish what driving condition caused the cooling

system complaint. The problem may be caused by an

abnormal load on the system such as the following:

prolonged idle, very high ambient temperature, slight

tail wind at idle, slow traffic speed, traffic jam, high

speed, steep grade.

DRIVING TECHNIQUES

To avoid overheating the cooling system:

(1) Idle with A/C off when temperature gauge is at

end of normal range.

(2) Do not increase engine speed for more air flow

and coolant flow because the electric motor fan sys-

tems are not responsive to engine RPM. The added

cooling from higher coolant flow rate is more than

offset by increased heat rejection (engine heat added

to coolant).

TRAILER TOWING

Consult the owner's manual under Trailer Towing

and do not exceed specified limits.

VISUAL INSPECTION

If the cooling system problem is not caused by a

driving condition, perform a visual inspection to

determine if there was a recent service or accident

repair, including the following:

²Loose/damaged water pump drive belt

²Incorrect cooling system refilling (trapped air or

low level)

²Brakes possibly dragging

²Damaged hoses

²Loose/damaged hose clamps

²Damaged/incorrect engine thermostat

²Damaged cooling fan motor, fan blade and fan

shroud

²Damaged head gasket

²Damaged water pump

²Damaged radiator

²Damaged coolant recovery system

²Damaged heater core

²Open/shorted electrical circuits

If the visual inspection reveals none of the above

as cause for a cooling system complaint, refer to the

following diagnostic charts.

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.1. Check condition of radiator cap

and cap seal. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING) Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING)

RSENGINE7-15

ProCarManuals.com

Page 265 of 2399

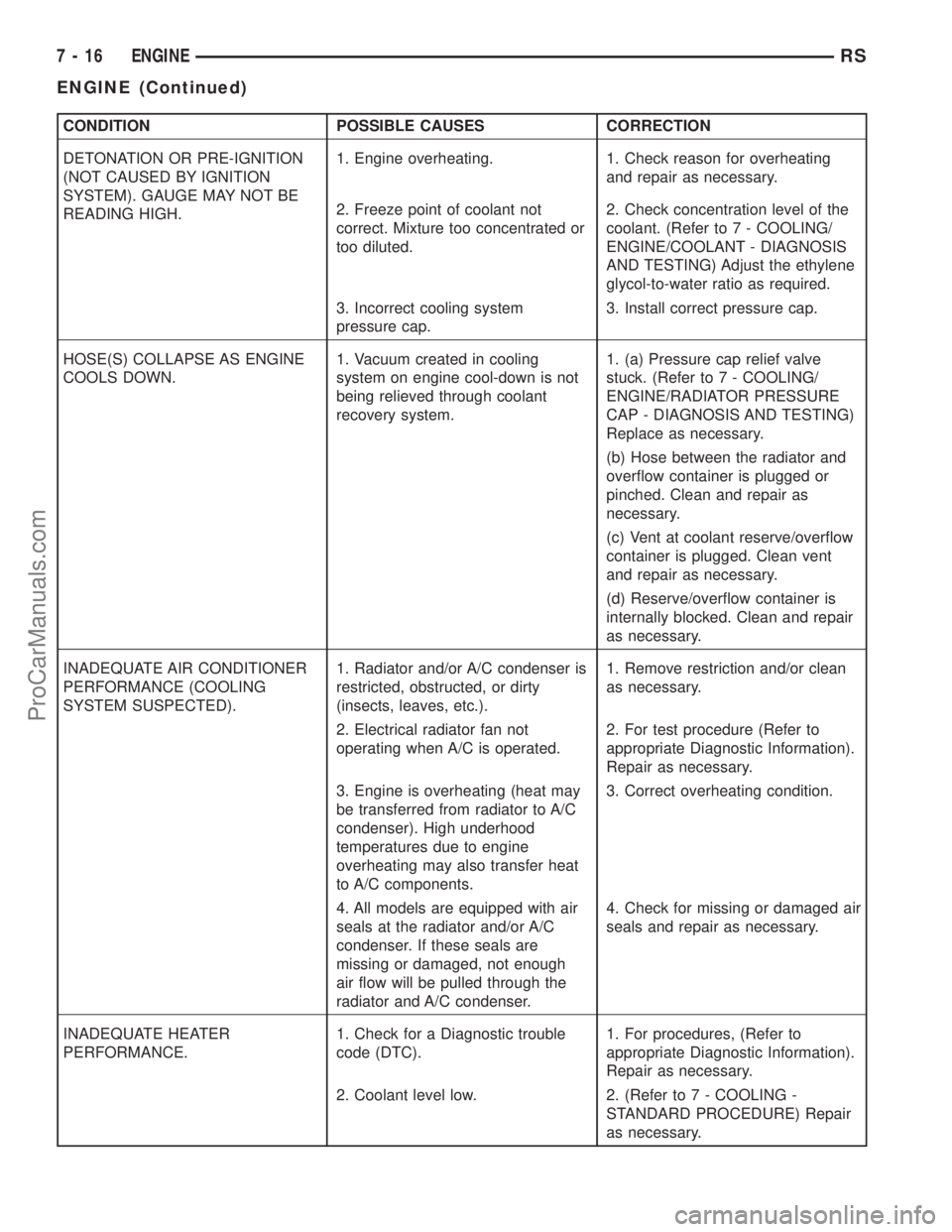

CONDITION POSSIBLE CAUSES CORRECTION

DETONATION OR PRE-IGNITION

(NOT CAUSED BY IGNITION

SYSTEM). GAUGE MAY NOT BE

READING HIGH.1. Engine overheating. 1. Check reason for overheating

and repair as necessary.

2. Freeze point of coolant not

correct. Mixture too concentrated or

too diluted.2. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

3. Incorrect cooling system

pressure cap.3. Install correct pressure cap.

HOSE(S) COLLAPSE AS ENGINE

COOLS DOWN.1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

recovery system.1. (a) Pressure cap relief valve

stuck. (Refer to 7 - COOLING/

ENGINE/RADIATOR PRESSURE

CAP - DIAGNOSIS AND TESTING)

Replace as necessary.

(b) Hose between the radiator and

overflow container is plugged or

pinched. Clean and repair as

necessary.

(c) Vent at coolant reserve/overflow

container is plugged. Clean vent

and repair as necessary.

(d) Reserve/overflow container is

internally blocked. Clean and repair

as necessary.

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED).1. Radiator and/or A/C condenser is

restricted, obstructed, or dirty

(insects, leaves, etc.).1. Remove restriction and/or clean

as necessary.

2. Electrical radiator fan not

operating when A/C is operated.2. For test procedure (Refer to

appropriate Diagnostic Information).

Repair as necessary.

3. Engine is overheating (heat may

be transferred from radiator to A/C

condenser). High underhood

temperatures due to engine

overheating may also transfer heat

to A/C components.3. Correct overheating condition.

4. All models are equipped with air

seals at the radiator and/or A/C

condenser. If these seals are

missing or damaged, not enough

air flow will be pulled through the

radiator and A/C condenser.4. Check for missing or damaged air

seals and repair as necessary.

INADEQUATE HEATER

PERFORMANCE.1. Check for a Diagnostic trouble

code (DTC).1. For procedures, (Refer to

appropriate Diagnostic Information).

Repair as necessary.

2. Coolant level low. 2. (Refer to 7 - COOLING -

STANDARD PROCEDURE) Repair

as necessary.

7 - 16 ENGINERS

ENGINE (Continued)

ProCarManuals.com

Page 266 of 2399

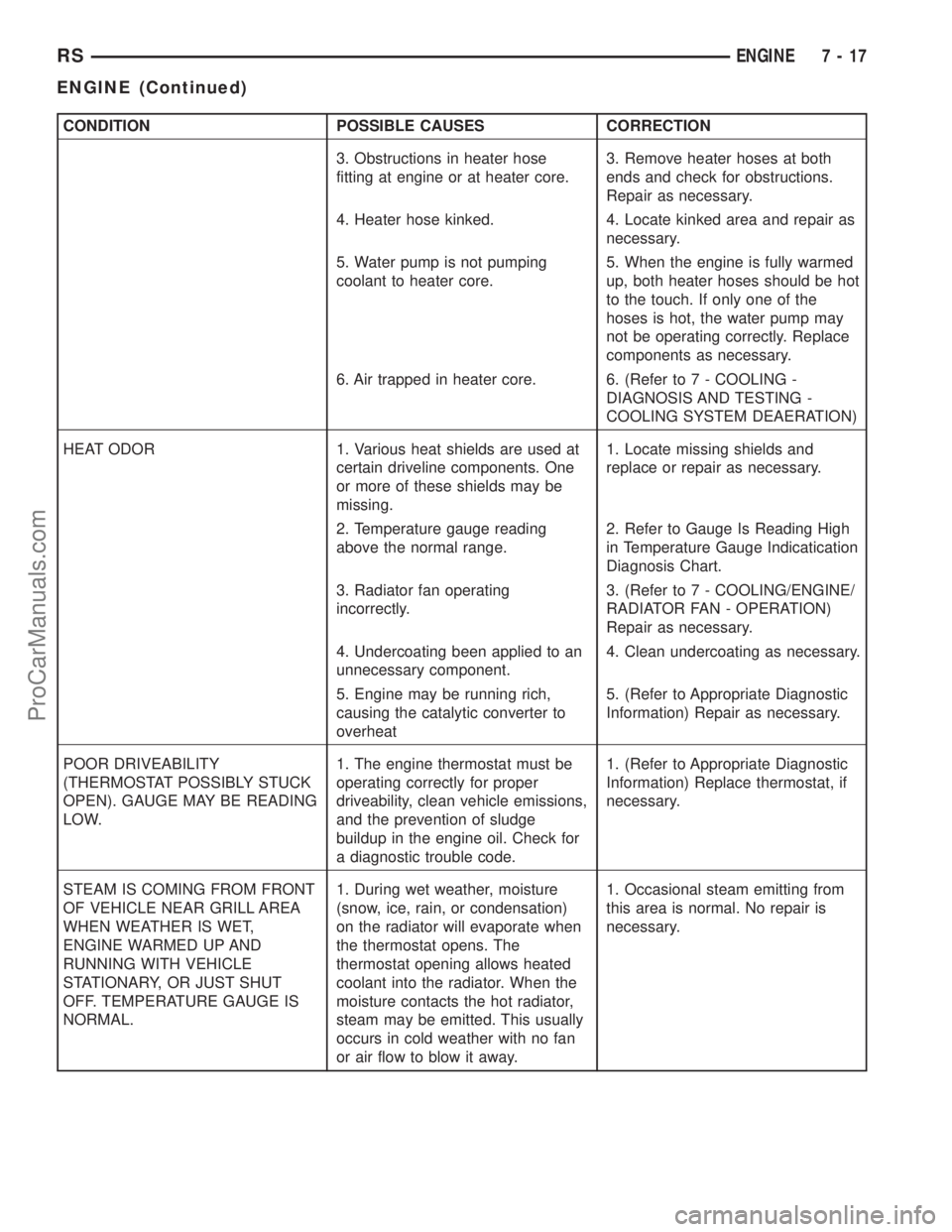

CONDITION POSSIBLE CAUSES CORRECTION

3. Obstructions in heater hose

fitting at engine or at heater core.3. Remove heater hoses at both

ends and check for obstructions.

Repair as necessary.

4. Heater hose kinked. 4. Locate kinked area and repair as

necessary.

5. Water pump is not pumping

coolant to heater core.5. When the engine is fully warmed

up, both heater hoses should be hot

to the touch. If only one of the

hoses is hot, the water pump may

not be operating correctly. Replace

components as necessary.

6. Air trapped in heater core. 6. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING -

COOLING SYSTEM DEAERATION)

HEAT ODOR 1. Various heat shields are used at

certain driveline components. One

or more of these shields may be

missing.1. Locate missing shields and

replace or repair as necessary.

2. Temperature gauge reading

above the normal range.2. Refer to Gauge Is Reading High

in Temperature Gauge Indicatication

Diagnosis Chart.

3. Radiator fan operating

incorrectly.3. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - OPERATION)

Repair as necessary.

4. Undercoating been applied to an

unnecessary component.4. Clean undercoating as necessary.

5. Engine may be running rich,

causing the catalytic converter to

overheat5. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

POOR DRIVEABILITY

(THERMOSTAT POSSIBLY STUCK

OPEN). GAUGE MAY BE READING

LOW.1. The engine thermostat must be

operating correctly for proper

driveability, clean vehicle emissions,

and the prevention of sludge

buildup in the engine oil. Check for

a diagnostic trouble code.1. (Refer to Appropriate Diagnostic

Information) Replace thermostat, if

necessary.

STEAM IS COMING FROM FRONT

OF VEHICLE NEAR GRILL AREA

WHEN WEATHER IS WET,

ENGINE WARMED UP AND

RUNNING WITH VEHICLE

STATIONARY, OR JUST SHUT

OFF. TEMPERATURE GAUGE IS

NORMAL.1. During wet weather, moisture

(snow, ice, rain, or condensation)

on the radiator will evaporate when

the thermostat opens. The

thermostat opening allows heated

coolant into the radiator. When the

moisture contacts the hot radiator,

steam may be emitted. This usually

occurs in cold weather with no fan

or air flow to blow it away.1. Occasional steam emitting from

this area is normal. No repair is

necessary.

RSENGINE7-17

ENGINE (Continued)

ProCarManuals.com

Page 267 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

COOLANT COLOR 1. Coolant color is not necessarily

an indication of adequate corrosion

or temperature protection. Do not

rely on coolant color for determining

condition of coolant.1. Check the freeze point of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as necessary.

COOLANT LEVEL CHANGES IN

COOLANT BOTTLE.

TEMPERATURE GAUGE IS IN

NORMAL RANGE.1. Level changes are to be

expected as coolant volume

fluctuates with engine temperature.

The coolant level will also drop as

the system removes air from a

recent filling.1. A normal condition. No repair is

necessary.

Refer to (Fig. 1) when using the TEMPERATURE

GAUGE INDICATION DIAGNOSIS CHART.

TEMPERATURE GAUGE INDICATION DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READING

IS INCONSISTENT (FLUCTUATES,

CYCLES OR IS ERRATIC).1. Normal reaction to fan and/or

thermostat cycle (Fig. 1 ),

Examples B and C. During cold

weather operation with the heater

blower in the high position, the

gauge reading may drop slightly

(Fig. 1 ), Example D. Fluctuation is

also influenced by outside

temperature and heavy loads (Fig.

1 ), Example E.1. A normal condition. No correction

is necessary.

2. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running)

(Fig. 1 ), Example F.2. A normal condition. No correction

is necessary. Gauge reading should

return to normal range (Fig. 1 ),

Example A, after vehicle is driven.

3. Gauge reading high after

restarting a warmed-up (hot)

engine.3. A normal condition. No correction

is necessary. The gauge should

return to normal range (Fig. 1 ),

Example A, after a few minutes of

engine operation.

4. Temperature gauge or engine

coolant temperature sensor

defective or shorted. Also, corroded

or loose wiring in the electrical

circuit.4. Check operation of gauge or

engine coolant temperature sensor

and repair, if necessary.

7 - 18 ENGINERS

ENGINE (Continued)

ProCarManuals.com

Page 272 of 2399

(6) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

ENGINE COOLANT

THERMOSTAT

DESCRIPTION

The engine cooling thermostats are a wax pellet

driven, reverse poppet choke type. The thermostat is

mounted in a housing on the coolant outlet of the

engine (Fig. 8) or (Fig. 10).

OPERATION

The engine cooling thermostat is a wax pellet

driven, reverse poppet choke type. The thermostat is

designed to provide the fastest warm up possible by

preventing leakage through it and to guarantee a

minimum engine operating temperature of 88 to

93ÉC (192 to 199ÉF). The thermostat also will auto-

matically reach wide open so it will not restrict flow

to the radiator as temperature of the coolant rises in

hot weather to around 104ÉC (220ÉF). Above this

temperature the coolant temperature is controlled by

the radiator, fan, and ambient temperature, not the

thermostat.

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolantreaches a predetermined temperature, the wax

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

DIAGNOSIS AND TESTING - ENGINE COOLANT

THERMOSTAT

The thermostat is operated by a wax filled cham-

ber (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

Thermostat diagnostics is included in powertrain

control module's (PCM) programing for on-board

diagnosis. The malfunction indicator light (MIL) will

illuminate and a diagnostic trouble code (DTC) will

be set when an ªopen too soonº condition occurs. Do

not change a thermostat for lack of heater perfor-

mance or temperature gauge position, unless a DTC

is present. For other probable causes, (Refer to 7 -

COOLING/ENGINE - DIAGNOSIS AND TESTING).

Thermostat failing shut is the normal long term

mode of failure, and normally, only on high mileage

vehicles. The temperature gauge will indicate this

(Refer to 7 - COOLING/ENGINE - DIAGNOSIS AND

TESTING).

ENGINE COOLANT

THERMOSTAT - 2.4L

REMOVAL

(1) Drain cooling system below the thermostat

level. (Refer to 7 - COOLING - STANDARD PROCE-

DURE)

(2) Remove radiator upper hose from the coolant

outlet housing (Fig. 7).

(3) Remove coolant outlet housing bolts and hous-

ing (Fig. 8).

(4) Remove thermostat. Discard gasket and clean

both gasket sealing surfaces.

INSTALLATION

(1) Place a new gasket (dipped in clean water) on

the coolant outlet connector surface. Position thermo-

stat with air bleed at the 12 o'clock position in ther-

mostat housing (Fig. 8).

(2) Position the coolant outlet connector and gas-

ket over the thermostat, making sure thermostat is

seated in the thermostat housing.

(3) Position outlet connector to thermostat housing

and install bolts (Fig. 8). Tighten bolts to 28 N´m

(250 in. lbs.).

Fig. 6 Engine Coolant Temperature Sensor

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

RSENGINE7-23

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L (Continued)

ProCarManuals.com

Page 275 of 2399

(6) Remove vapor purge solenoid from mounting

bracket.

(7) Disconnect upper and lower hoses from the

radiator (Fig. 13) or (Fig. 14).

(8) Remove the A/C condenser side brackets to

radiator attaching screws (Fig. 15). Separate the con-

denser from the radiator by lifting upward to disen-

gage from lower mounts (Fig. 15). Allow the

condenser to rest in front of radiator.

(9) Radiator can now be lifted free from engine

compartment.Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

INSTALLATION

(1)Be sure the air seal is in position before

radiator is installed.Slide radiator down into posi-

tion. Seat the radiator with the rubber isolators into

the mounting holes provided, with a 10 lbs. force.

(2) Position air conditioning condenser onto the

radiator lower mounts and install upper screws (Fig.

15). Tighten fasteners to 5 N´m (45 in. lbs.).

(3) Install the radiator upper and lower hoses (Fig.

13) or (Fig. 14).

(4) Connect the coolant reserve/recovery hose.

(5) Connect the vapor purge solenoid to the mount-

ing bracket.

(6) Install the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION)

(7) Install the radiator upper crossmember sup-

port. (Refer to 23 - BODY/EXTERIOR/GRILLE

OPENING REINFORCEMENT - INSTALLATION)

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

(9) Connect negative cable to battery.

Fig. 13 Radiator Hoses to Radiator - 2.4L

1 - UPPER HOSE

2 - LOWER HOSE

3 - HOSE SUPPORT CLIP

Fig. 14 Radiator Hoses to Radiator - 3.3/3.8L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 15 Radiator to A/C Condenser Mounting (left

mount shown, right similar)

1 - SCREW - A/C CONDENSER SIDE BRACKET TO RADIATOR

2 - LOWER MOUNT

3 - A/C CONDENSER

7 - 26 ENGINERS

RADIATOR (Continued)

ProCarManuals.com