air condition CHRYSLER VOYAGER 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 160 of 2399

DISASSEMBLY - CALIPER PISTON AND SEAL

WARNING: UNDER NO CONDITION SHOULD HIGH

PRESSURE AIR EVER BE USED TO REMOVE A PIS-

TON FROM A CALIPER BORE. PERSONAL INJURY

COULD RESULT FROM SUCH A PRACTICE.NOTE: Before disassembling the brake caliper,

clean and inspect it. Refer to CLEANING AND

INSPECTION in this section.

NOTE: The safest way to remove the piston from

the caliper bore is to use the hydraulic pressure of

the vehicle's brake system.

(1) Following the removal procedure in DISC

BRAKE SHOES found in this section, remove the

caliper from the brake rotor and hang the assembly

on a wire hook away from rotor and body of the vehi-

cle so brake fluid cannot get on these components.

Remove the brake shoes, and place a small piece of

wood between the piston and caliper fingers.

(2) Carefully depress the brake pedal to hydrauli-

cally push piston out of its bore. Once completed,

apply and hold down the brake pedal to any position

beyond the first inch of pedal travel using a brake

pedal holding tool. This will prevent the fluid in the

master cylinder reservoir from completely draining

out.

(3) Disconnect the brake fluid flex hose from the

caliper assembly and remove it from the vehicle.

CAUTION: Do not use excessive force when clamp-

ing caliper in vise. Excessive vise pressure will

cause bore distortion.

(4) Mount the caliper in a vise equipped with pro-

tective jaws.

(5) Remove the piston dust boot from the caliper

and discard.

NOTE: Do not use a screw driver or other metal tool

for seal removal. Using such tools can scratch the

bore or leave burrs on the seal groove edges.

(6) Using a soft tool such as a plastic trim stick,

work the piston seal out of its groove in caliper pis-

ton bore (Fig. 47). Discard the old seal.

(7) Clean the piston bore and drilled passage ways

using alcohol or a suitable solvent. Wipe it dry using

only a lint-free cloth.

(8) Inspect the piston bore for scoring or pitting.

Bores that show light scratches or corrosion can usu-

ally be cleared of the light scratches or corrosion

using crocus cloth.

Fig. 45 Caliper Guide Pin Bolts

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

Fig. 46 Removing/Installing Caliper

1 - LIFT THIS END OF CALIPER AWAY FROM ADAPTER FIRST

2 - DISC BRAKE CALIPER

3 - ADAPTER ABUTMENT

4 - OUTBOARD BRAKE SHOE HOLD DOWN CLIP

5 - OUTBOARD BRAKE SHOE

6 - ROTOR

7 - ADAPTER

RSBRAKES - BASE5-31

DISC BRAKE CALIPER - REAR (Continued)

ProCarManuals.com

Page 176 of 2399

(27) Install lower steering column cover/knee

blocker (Fig. 62).

(28) Install silencer panel below lower steering col-

umn cover/knee blocker.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery in following manor:

(a) Connect scan tool (DRBIIIt) to data link

diagnostic connector located below steering column.

(b) Turn ignition key to ON position. Exit vehi-

cle with scan tool leaving scan tool harness

plugged in.

(c) Ensuring that there are no occupants in vehi-

cle, connect ground (-) cable to the negative post of

the battery.

(d) Using scan tool, read and record any airbag

fault codes. Refer to Appropriate Diagnostic Infor-

mation if any faults are found.

(e) Through drivers open window, Reach around

back of steering wheel (between steering wheel and

instrument cluster) and turn ignition key to OFF,

then back ON while observing instrument cluster

airbag indicator lamp. It should go on for six to

eight seconds, then go out. This action indicates

that airbag system is functioning normally. If air-

bag indicator lamp fails to light, blinks on and off,

or goes on and stays on, there is an airbag system

malfunction. Refer to Appropriate Diagnostic Infor-

mation to diagnose the system malfunction.

(30) Using scan tool (DRBIIIt), check for and clear

any existing adjustable pedal fault codes. The adjust-

able pedal system is now activated.

(31) Turn key to OFF and remove scan tool from

vehicle.

(32) Test operation of adjustable pedals, memory

seats (if equipped), RKE (if equipped), and all func-

tions that are steering column operated. If applica-

ble, reset the radio and the clock.

(33) Road test the vehicle to ensure proper opera-

tion of the steering and brake systems.

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL)

(3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Removethe link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled.

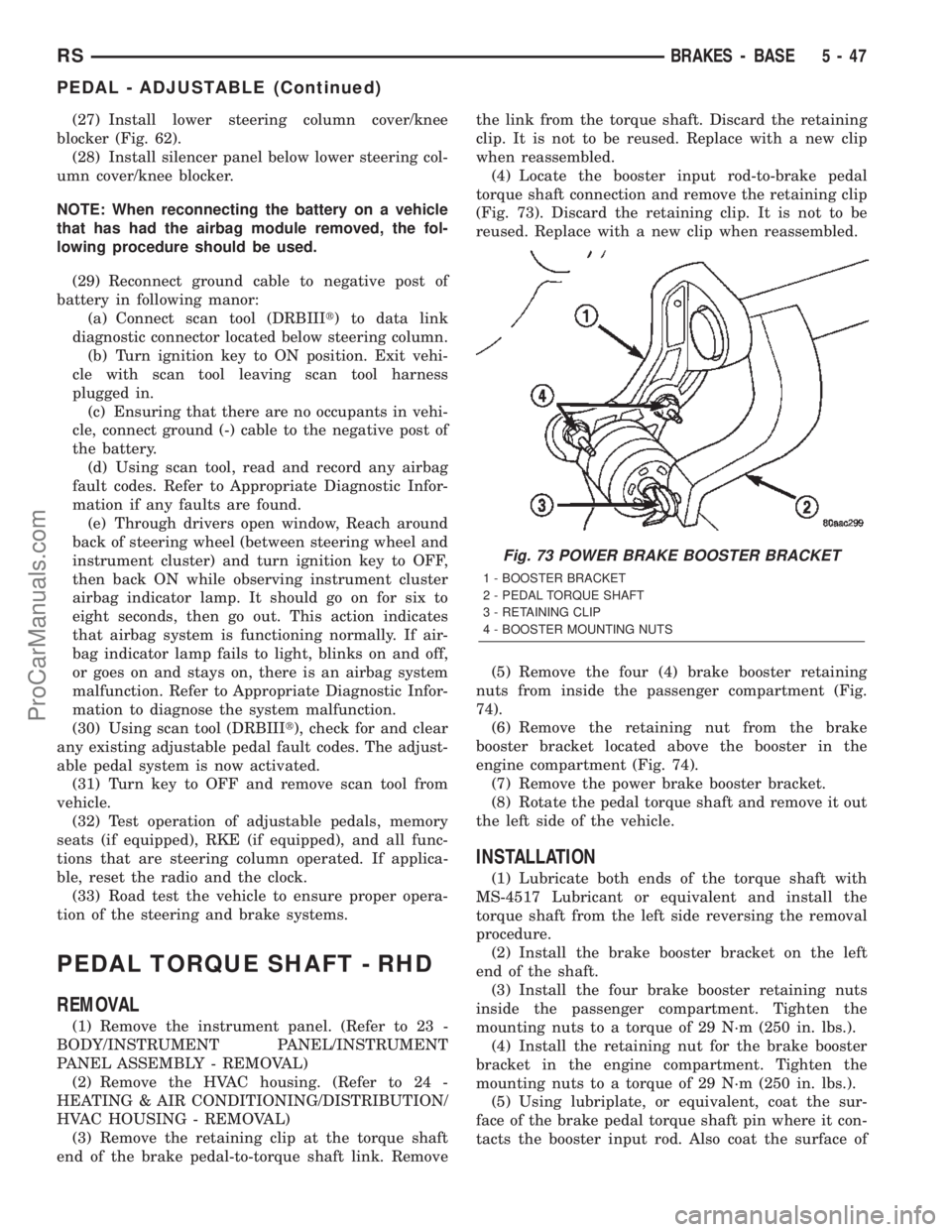

(4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 73). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled.

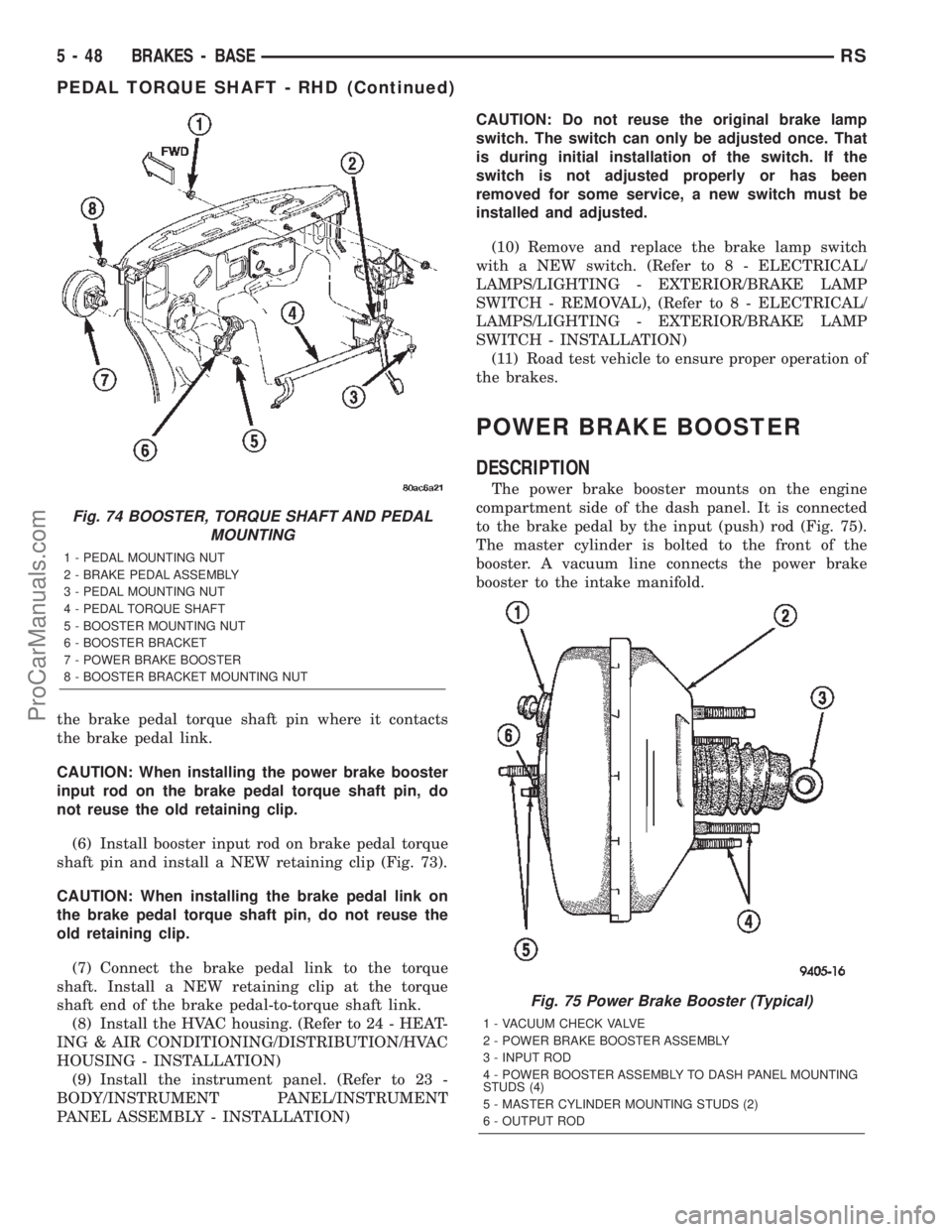

(5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

74).

(6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 74).

(7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.

(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(4) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

Fig. 73 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

RSBRAKES - BASE5-47

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 177 of 2399

the brake pedal torque shaft pin where it contacts

the brake pedal link.

CAUTION: When installing the power brake booster

input rod on the brake pedal torque shaft pin, do

not reuse the old retaining clip.

(6) Install booster input rod on brake pedal torque

shaft pin and install a NEW retaining clip (Fig. 73).

CAUTION: When installing the brake pedal link on

the brake pedal torque shaft pin, do not reuse the

old retaining clip.

(7) Connect the brake pedal link to the torque

shaft. Install a NEW retaining clip at the torque

shaft end of the brake pedal-to-torque shaft link.

(8) Install the HVAC housing. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

(9) Install the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - INSTALLATION)CAUTION: Do not reuse the original brake lamp

switch. The switch can only be adjusted once. That

is during initial installation of the switch. If the

switch is not adjusted properly or has been

removed for some service, a new switch must be

installed and adjusted.

(10) Remove and replace the brake lamp switch

with a NEW switch. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - REMOVAL), (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/BRAKE LAMP

SWITCH - INSTALLATION)

(11) Road test vehicle to ensure proper operation of

the brakes.

POWER BRAKE BOOSTER

DESCRIPTION

The power brake booster mounts on the engine

compartment side of the dash panel. It is connected

to the brake pedal by the input (push) rod (Fig. 75).

The master cylinder is bolted to the front of the

booster. A vacuum line connects the power brake

booster to the intake manifold.

Fig. 74 BOOSTER, TORQUE SHAFT AND PEDAL

MOUNTING

1 - PEDAL MOUNTING NUT

2 - BRAKE PEDAL ASSEMBLY

3 - PEDAL MOUNTING NUT

4 - PEDAL TORQUE SHAFT

5 - BOOSTER MOUNTING NUT

6 - BOOSTER BRACKET

7 - POWER BRAKE BOOSTER

8 - BOOSTER BRACKET MOUNTING NUT

Fig. 75 Power Brake Booster (Typical)

1 - VACUUM CHECK VALVE

2 - POWER BRAKE BOOSTER ASSEMBLY

3 - INPUT ROD

4 - POWER BOOSTER ASSEMBLY TO DASH PANEL MOUNTING

STUDS (4)

5 - MASTER CYLINDER MOUNTING STUDS (2)

6 - OUTPUT ROD

5 - 48 BRAKES - BASERS

PEDAL TORQUE SHAFT - RHD (Continued)

ProCarManuals.com

Page 186 of 2399

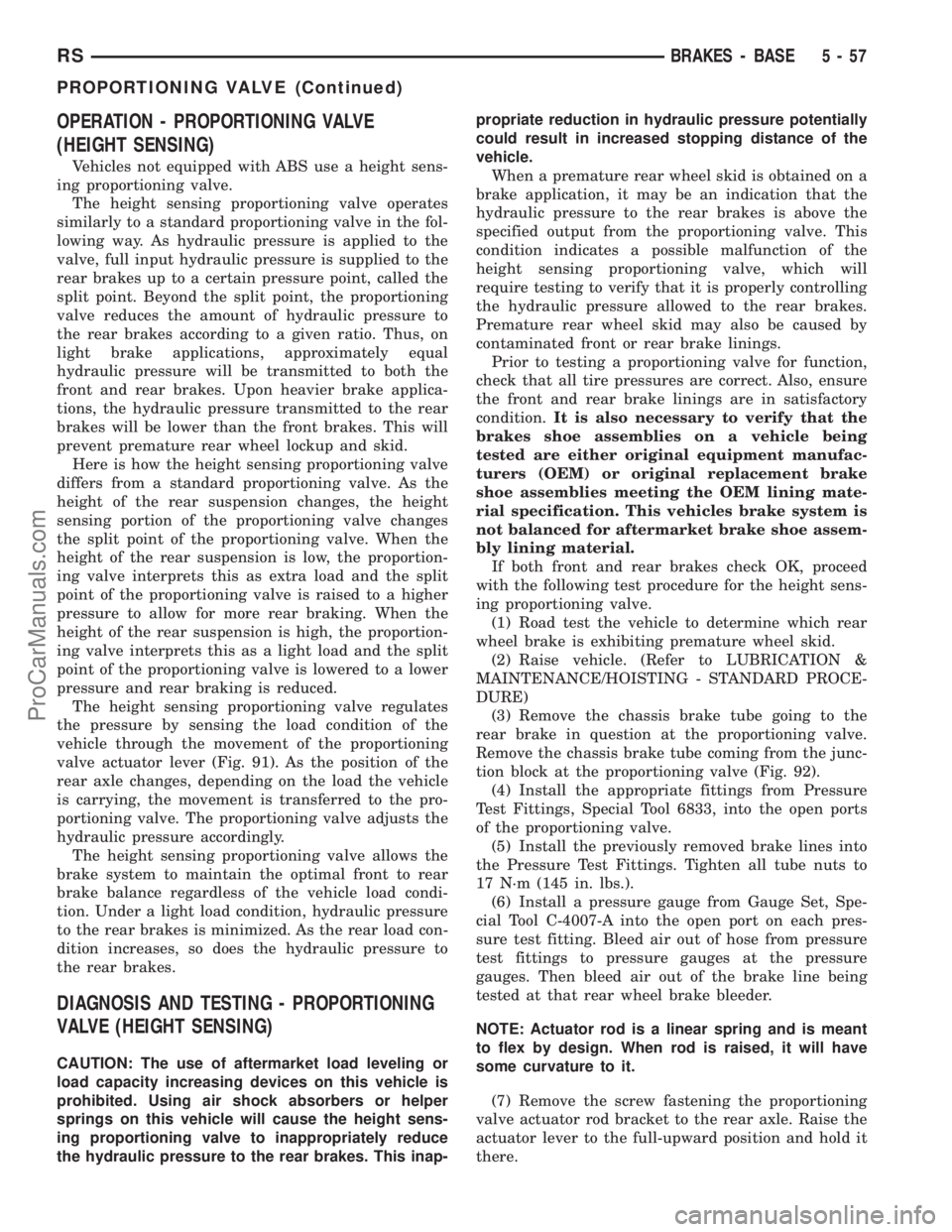

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)

Vehicles not equipped with ABS use a height sens-

ing proportioning valve.

The height sensing proportioning valve operates

similarly to a standard proportioning valve in the fol-

lowing way. As hydraulic pressure is applied to the

valve, full input hydraulic pressure is supplied to the

rear brakes up to a certain pressure point, called the

split point. Beyond the split point, the proportioning

valve reduces the amount of hydraulic pressure to

the rear brakes according to a given ratio. Thus, on

light brake applications, approximately equal

hydraulic pressure will be transmitted to both the

front and rear brakes. Upon heavier brake applica-

tions, the hydraulic pressure transmitted to the rear

brakes will be lower than the front brakes. This will

prevent premature rear wheel lockup and skid.

Here is how the height sensing proportioning valve

differs from a standard proportioning valve. As the

height of the rear suspension changes, the height

sensing portion of the proportioning valve changes

the split point of the proportioning valve. When the

height of the rear suspension is low, the proportion-

ing valve interprets this as extra load and the split

point of the proportioning valve is raised to a higher

pressure to allow for more rear braking. When the

height of the rear suspension is high, the proportion-

ing valve interprets this as a light load and the split

point of the proportioning valve is lowered to a lower

pressure and rear braking is reduced.

The height sensing proportioning valve regulates

the pressure by sensing the load condition of the

vehicle through the movement of the proportioning

valve actuator lever (Fig. 91). As the position of the

rear axle changes, depending on the load the vehicle

is carrying, the movement is transferred to the pro-

portioning valve. The proportioning valve adjusts the

hydraulic pressure accordingly.

The height sensing proportioning valve allows the

brake system to maintain the optimal front to rear

brake balance regardless of the vehicle load condi-

tion. Under a light load condition, hydraulic pressure

to the rear brakes is minimized. As the rear load con-

dition increases, so does the hydraulic pressure to

the rear brakes.

DIAGNOSIS AND TESTING - PROPORTIONING

VALVE (HEIGHT SENSING)

CAUTION: The use of aftermarket load leveling or

load capacity increasing devices on this vehicle is

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

When a premature rear wheel skid is obtained on a

brake application, it may be an indication that the

hydraulic pressure to the rear brakes is above the

specified output from the proportioning valve. This

condition indicates a possible malfunction of the

height sensing proportioning valve, which will

require testing to verify that it is properly controlling

the hydraulic pressure allowed to the rear brakes.

Premature rear wheel skid may also be caused by

contaminated front or rear brake linings.

Prior to testing a proportioning valve for function,

check that all tire pressures are correct. Also, ensure

the front and rear brake linings are in satisfactory

condition.It is also necessary to verify that the

brakes shoe assemblies on a vehicle being

tested are either original equipment manufac-

turers (OEM) or original replacement brake

shoe assemblies meeting the OEM lining mate-

rial specification. This vehicles brake system is

not balanced for aftermarket brake shoe assem-

bly lining material.

If both front and rear brakes check OK, proceed

with the following test procedure for the height sens-

ing proportioning valve.

(1) Road test the vehicle to determine which rear

wheel brake is exhibiting premature wheel skid.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove the chassis brake tube going to the

rear brake in question at the proportioning valve.

Remove the chassis brake tube coming from the junc-

tion block at the proportioning valve (Fig. 92).

(4) Install the appropriate fittings from Pressure

Test Fittings, Special Tool 6833, into the open ports

of the proportioning valve.

(5) Install the previously removed brake lines into

the Pressure Test Fittings. Tighten all tube nuts to

17 N´m (145 in. lbs.).

(6) Install a pressure gauge from Gauge Set, Spe-

cial Tool C-4007-A into the open port on each pres-

sure test fitting. Bleed air out of hose from pressure

test fittings to pressure gauges at the pressure

gauges. Then bleed air out of the brake line being

tested at that rear wheel brake bleeder.

NOTE: Actuator rod is a linear spring and is meant

to flex by design. When rod is raised, it will have

some curvature to it.

(7) Remove the screw fastening the proportioning

valve actuator rod bracket to the rear axle. Raise the

actuator lever to the full-upward position and hold it

there.

RSBRAKES - BASE5-57

PROPORTIONING VALVE (Continued)

ProCarManuals.com

Page 214 of 2399

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE

SYSTEM............................85

DESCRIPTION - ANTILOCK BRAKE

SYSTEM (EXPORT)....................85

DESCRIPTION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............86

DESCRIPTION - TRACTION CONTROL

SYSTEM............................86

OPERATION

OPERATION - ANTILOCK BRAKE SYSTEM . . 86

OPERATION - ELECTRONIC VARIABLE

BRAKE PROPORTIONING...............87

OPERATION - TRACTION CONTROL

SYSTEM............................87

CAUTION

CAUTIONS..........................88

STANDARD PROCEDURE - ANTILOCK BRAKE

SYSTEM BLEEDING...................88

SPECIFICATIONS

ABS FASTENER TORQUE...............89

TONE WHEEL RUNOUT................89

WHEEL SPEED SENSOR AIR GAP........89

FRONT WHEEL SPEED SENSOR

REMOVAL.............................89

INSTALLATION.........................89

REAR WHEEL SPEED SENSOR - AWD

REMOVAL.............................90INSTALLATION.........................90

REAR WHEEL SPEED SENSOR - FWD

REMOVAL.............................91

INSTALLATION.........................91

TONE WHEEL

INSPECTION - TONE WHEEL..............92

TRACTION CONTROL SWITCH

DIAGNOSIS AND TESTING - TRACTION

CONTROL SWITCH....................92

HYDRAULIC/MECHANICAL

OPERATION - HYDRAULIC CIRCUITS AND

VALVES .............................93

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................99

OPERATION...........................99

ICU (INTEGRATED CONTROL UNIT)

DESCRIPTION........................100

OPERATION..........................100

REMOVAL

REMOVAL - LHD.....................100

REMOVAL - RHD.....................101

DISASSEMBLY - ICU...................103

ASSEMBLY - ICU......................103

INSTALLATION

INSTALLATION - LHD.................104

INSTALLATION - RHD.................105

BRAKES - ABS

DESCRIPTION

DESCRIPTION - ANTILOCK BRAKE SYSTEM

This section covers the physical and operational

descriptions and the on-car service procedures for the

Mark 20e Antilock Brake System and the Mark 20e

Antilock Brake System with traction control.

The purpose of the antilock brake system (ABS) is

to prevent wheel lockup under braking conditions on

virtually any type of road surface. Antilock braking is

desirable because a vehicle that is stopped without

locking the wheels retains directional stability and

some steering capability. This allows the driver to

retain greater control of the vehicle during braking.

DESCRIPTION - ANTILOCK BRAKE SYSTEM

(EXPORT)

Four-wheel disc antilock brakes are standard on all

models. The Mark 20e antilock brake system is used

on all models. Depending on whether the vehicle is a

left-hand drive (LHD) or right-hand drive (RHD)

model, the integrated control unit (ICU) is located in

one of two locations. On LHD models, the ICU is

mounted above the front suspension cradle/cross-

member below the master cylinder. On RHD models,

the ICU is located behind the front suspension cra-

dle/crossmember on the left side of the vehicle.

RSBRAKES - ABS5-85

ProCarManuals.com

Page 216 of 2399

black tire marks since the wheel never reaches a

fully locked condition. However, tire marks may be

noticeable as light patched marks.

START-UP CYCLE

When the ignition is turned on, a popping sound

and a slight brake pedal movement may be noticed.

The ABS warning lamp will also be on for up to 5

seconds after the ignition is turned on. When the

vehicle is first driven off, a humming may be heard

or felt by the driver at approximately 20±40 kph

(12±25 mph). All of these conditions are a normal

function of ABS as the system is performing a diag-

nosis check.

PREMATURE ABS CYCLING

Symptoms of premature ABS cycling include: click-

ing sounds from the solenoid valves; pump/motor

running; and pulsations in the brake pedal. Prema-

ture ABS cycling can occur at any braking rate of the

vehicle and on any type of road surface. Neither the

red BRAKE warning lamp, nor the amber ABS warn-

ing lamp, illuminate and no fault codes are stored in

the CAB.

Premature ABS cycling is a condition that needs to

be correctly assessed when diagnosing problems with

the antilock brake system. It may be necessary to use

a DRB scan tool to detect and verify premature ABS

cycling.

Check the following common causes when diagnos-

ing premature ABS cycling: damaged tone wheels;

incorrect tone wheels; damaged steering knuckle

wheel speed sensor mounting bosses; loose wheel

speed sensor mounting bolts; excessive tone wheel

runout; or an excessively large tone wheel-to-wheel

speed sensor air gap. Give special attention to these

components when diagnosing a vehicle exhibiting

premature ABS cycling.

After diagnosing the defective component, repair or

replace it as required. When the component repair or

replacement is completed, test drive the vehicle to

verify that premature ABS cycling has been cor-

rected.

OPERATION - ELECTRONIC VARIABLE BRAKE

PROPORTIONING

Upon entry into EVBP the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure, the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

hydraulic control unit (HCU) resulting in a drop in

fluid pressure to the rear brakes. In order to increase

the rear brake pressure, the outlet valve is switched

off and the inlet valve is pulsed. This increases thepressure to the rear brakes. This back-and-forth pro-

cess will continue until the required slip difference is

obtained. At the end of EVBP braking (brakes

released) the fluid in the LPA drains back to the

master cylinder by switching on the outlet valve and

draining through the inlet valve check valve. At the

same time the inlet valve is switched on in case of

another brake application.

The EVBP will remain functional during many

ABS fault modes. If both the red BRAKE and amber

ABS warning indicators are illuminated, the EVBP

may not be functioning.

OPERATION - TRACTION CONTROL SYSTEM

The traction control module monitors wheel speed.

During acceleration, if the module detects front

(drive) wheel slip and the brakes are not applied, the

module enters traction control mode. Traction control

operation proceeds in the following order:

(1) Close the normally open isolation valves.

(2) Start the pump/motor and supply volume and

pressure to the front (drive) hydraulic circuit. (The

pump/motor runs continuously during traction con-

trol operation.)

(3) Open and close the build and decay valves to

maintain minimum wheel slip and maximum trac-

tion.

The cycling of the build and decay valves during

traction control is similar to that during antilock

braking, except the valves work to control wheel spin

by applying the brakes, whereas the ABS function is

to control wheel skid by releasing the brakes.

If the brakes are applied at anytime during a trac-

tion control cycle, the brake lamp switch triggers the

controller to switch off traction control.

HYDRAULIC SHUTTLE VALVES

Two pressure relief hydraulic shuttle valves allow

pressure and volume to return to the master cylinder

reservoir when not consumed by the build and decay

valves. These valves are necessary because the

pump/motor supplies more volume than the system

requires.

TRACTION CONTROL LAMP

The traction control system is enabled at each igni-

tion cycle. It may be turned off by depressing the

Traction Control Off switch button when the ignition

is in the ON position. The traction control function

lamp (TRAC OFF) illuminates immediately upon

depressing the button.

The traction control function lamp illuminates dur-

ing a traction control cycle, displaying TRAC.

If the CAB calculates that the brake temperatures

are high, the traction control system becomes inoper-

ative until a time-out period has elapsed. During this

RSBRAKES - ABS5-87

BRAKES - ABS (Continued)

ProCarManuals.com

Page 240 of 2399

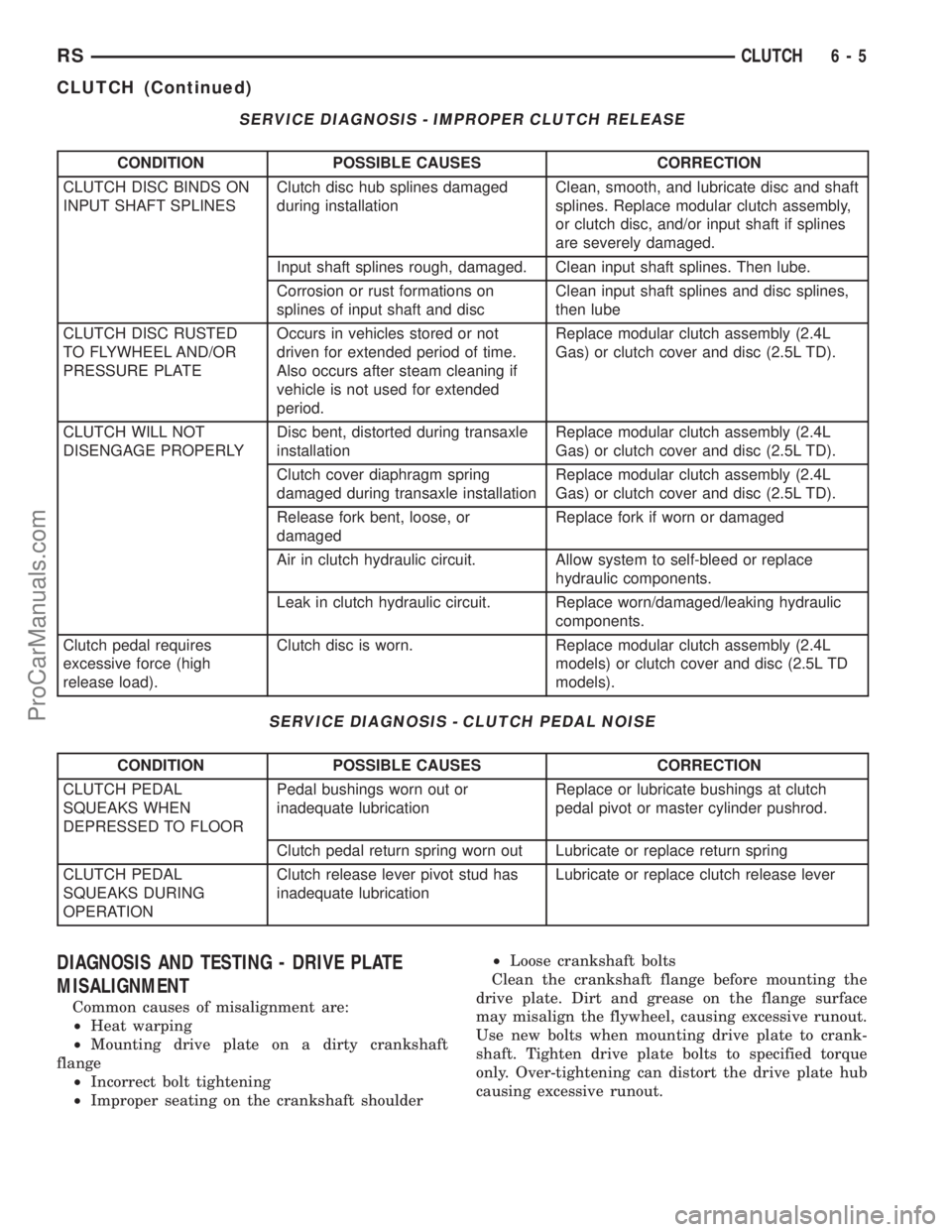

SERVICE DIAGNOSIS - IMPROPER CLUTCH RELEASE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC BINDS ON

INPUT SHAFT SPLINESClutch disc hub splines damaged

during installationClean, smooth, and lubricate disc and shaft

splines. Replace modular clutch assembly,

or clutch disc, and/or input shaft if splines

are severely damaged.

Input shaft splines rough, damaged. Clean input shaft splines. Then lube.

Corrosion or rust formations on

splines of input shaft and discClean input shaft splines and disc splines,

then lube

CLUTCH DISC RUSTED

TO FLYWHEEL AND/OR

PRESSURE PLATEOccurs in vehicles stored or not

driven for extended period of time.

Also occurs after steam cleaning if

vehicle is not used for extended

period.Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

CLUTCH WILL NOT

DISENGAGE PROPERLYDisc bent, distorted during transaxle

installationReplace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch cover diaphragm spring

damaged during transaxle installationReplace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Release fork bent, loose, or

damagedReplace fork if worn or damaged

Air in clutch hydraulic circuit. Allow system to self-bleed or replace

hydraulic components.

Leak in clutch hydraulic circuit. Replace worn/damaged/leaking hydraulic

components.

Clutch pedal requires

excessive force (high

release load).Clutch disc is worn. Replace modular clutch assembly (2.4L

models) or clutch cover and disc (2.5L TD

models).

SERVICE DIAGNOSIS - CLUTCH PEDAL NOISE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH PEDAL

SQUEAKS WHEN

DEPRESSED TO FLOORPedal bushings worn out or

inadequate lubricationReplace or lubricate bushings at clutch

pedal pivot or master cylinder pushrod.

Clutch pedal return spring worn out Lubricate or replace return spring

CLUTCH PEDAL

SQUEAKS DURING

OPERATIONClutch release lever pivot stud has

inadequate lubricationLubricate or replace clutch release lever

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

RSCLUTCH6-5

CLUTCH (Continued)

ProCarManuals.com

Page 243 of 2399

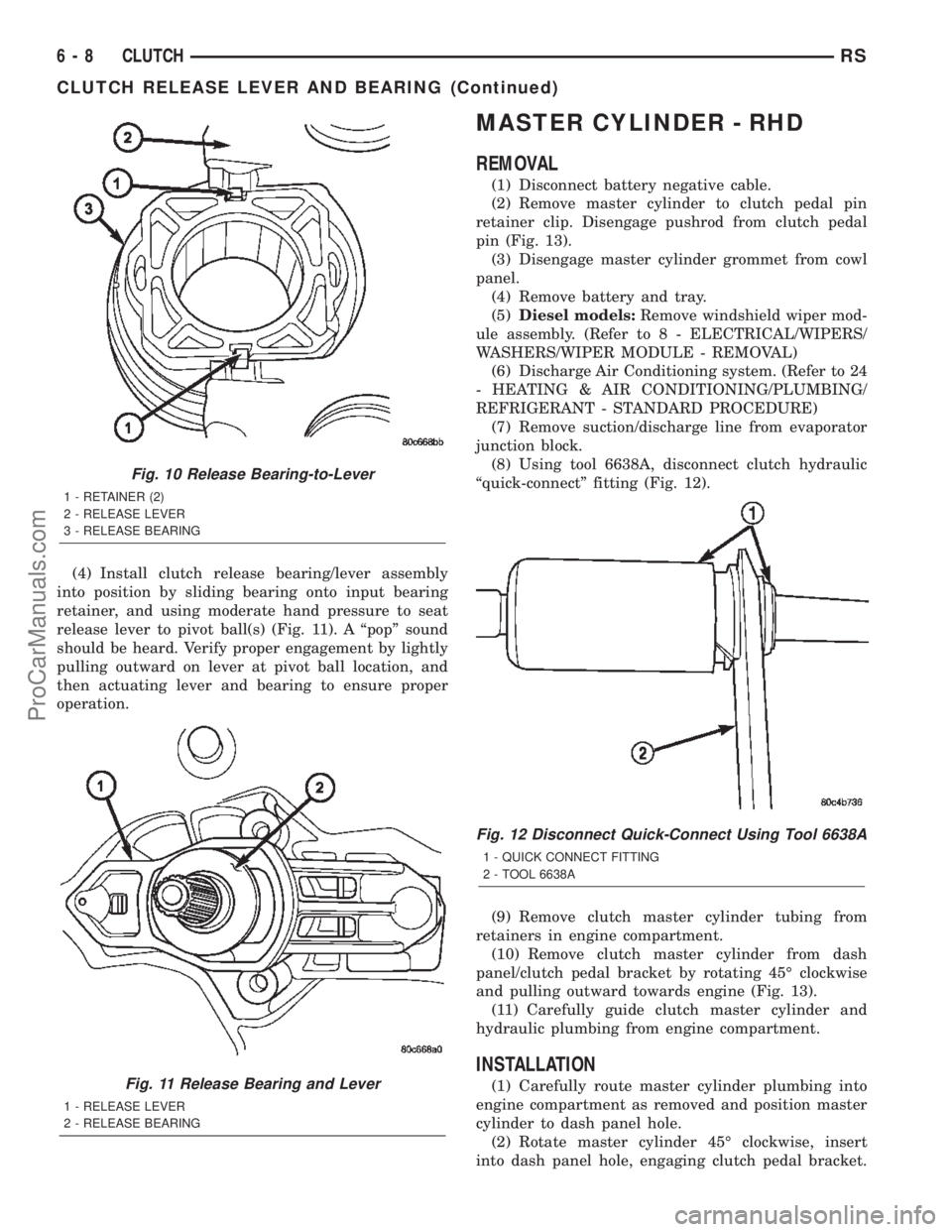

(4) Install clutch release bearing/lever assembly

into position by sliding bearing onto input bearing

retainer, and using moderate hand pressure to seat

release lever to pivot ball(s) (Fig. 11). A ªpopº sound

should be heard. Verify proper engagement by lightly

pulling outward on lever at pivot ball location, and

then actuating lever and bearing to ensure proper

operation.

MASTER CYLINDER - RHD

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove master cylinder to clutch pedal pin

retainer clip. Disengage pushrod from clutch pedal

pin (Fig. 13).

(3) Disengage master cylinder grommet from cowl

panel.

(4) Remove battery and tray.

(5)Diesel models:Remove windshield wiper mod-

ule assembly. (Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL)

(6) Discharge Air Conditioning system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING/

REFRIGERANT - STANDARD PROCEDURE)

(7) Remove suction/discharge line from evaporator

junction block.

(8) Using tool 6638A, disconnect clutch hydraulic

ªquick-connectº fitting (Fig. 12).

(9) Remove clutch master cylinder tubing from

retainers in engine compartment.

(10) Remove clutch master cylinder from dash

panel/clutch pedal bracket by rotating 45É clockwise

and pulling outward towards engine (Fig. 13).

(11) Carefully guide clutch master cylinder and

hydraulic plumbing from engine compartment.

INSTALLATION

(1) Carefully route master cylinder plumbing into

engine compartment as removed and position master

cylinder to dash panel hole.

(2) Rotate master cylinder 45É clockwise, insert

into dash panel hole, engaging clutch pedal bracket.

Fig. 10 Release Bearing-to-Lever

1 - RETAINER (2)

2 - RELEASE LEVER

3 - RELEASE BEARING

Fig. 11 Release Bearing and Lever

1 - RELEASE LEVER

2 - RELEASE BEARING

Fig. 12 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

6 - 8 CLUTCHRS

CLUTCH RELEASE LEVER AND BEARING (Continued)

ProCarManuals.com

Page 244 of 2399

Rotate master cylinder 45É counter-clockwise, secur-

ing it to pedal bracket (Fig. 13).

(3) Install and secure grommet to dash panel.

(4) Connect pushrod to clutch pedal pin. Install

retainer clip (Fig. 13).

(5) Secure master cylinder plumbing to retainers

in engine compartment.

(6) Connect clutch master cylinder plumbing to

slave cylinder ªquick connectº fitting. An audible

ªclickº should be heard. Verify connection by pulling

outward.

(7) Connect A/C suction/discharge line to evapora-

tor junction block.

(8)Diesel models:Install wiper module assembly.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION)

(9) Install battery and tray.

(10) Connect battery negative cable

(11) Charge Air Conditioning system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/RE-

FRIGERANT - STANDARD PROCEDURE)

MASTER CYLINDER - LHD

REMOVAL

(1) Disconnect battery cables.

(2) Remove instrument panel lower silencer (Fig.

14).

(3) Remove knee bolster (Fig. 15).

Fig. 13 Clutch Master Cylinder at Pedal Bracket

1 - CLUTCH MASTER CYLINDER

2 - RETAINER CLIP

3 - CLUTCH PEDAL PIN

4 - PUSH RODFig. 14 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 15 Knee Bolster

1 - KNEE BOLSTER

RSCLUTCH6-9

MASTER CYLINDER - RHD (Continued)

ProCarManuals.com

Page 251 of 2399

OPERATION

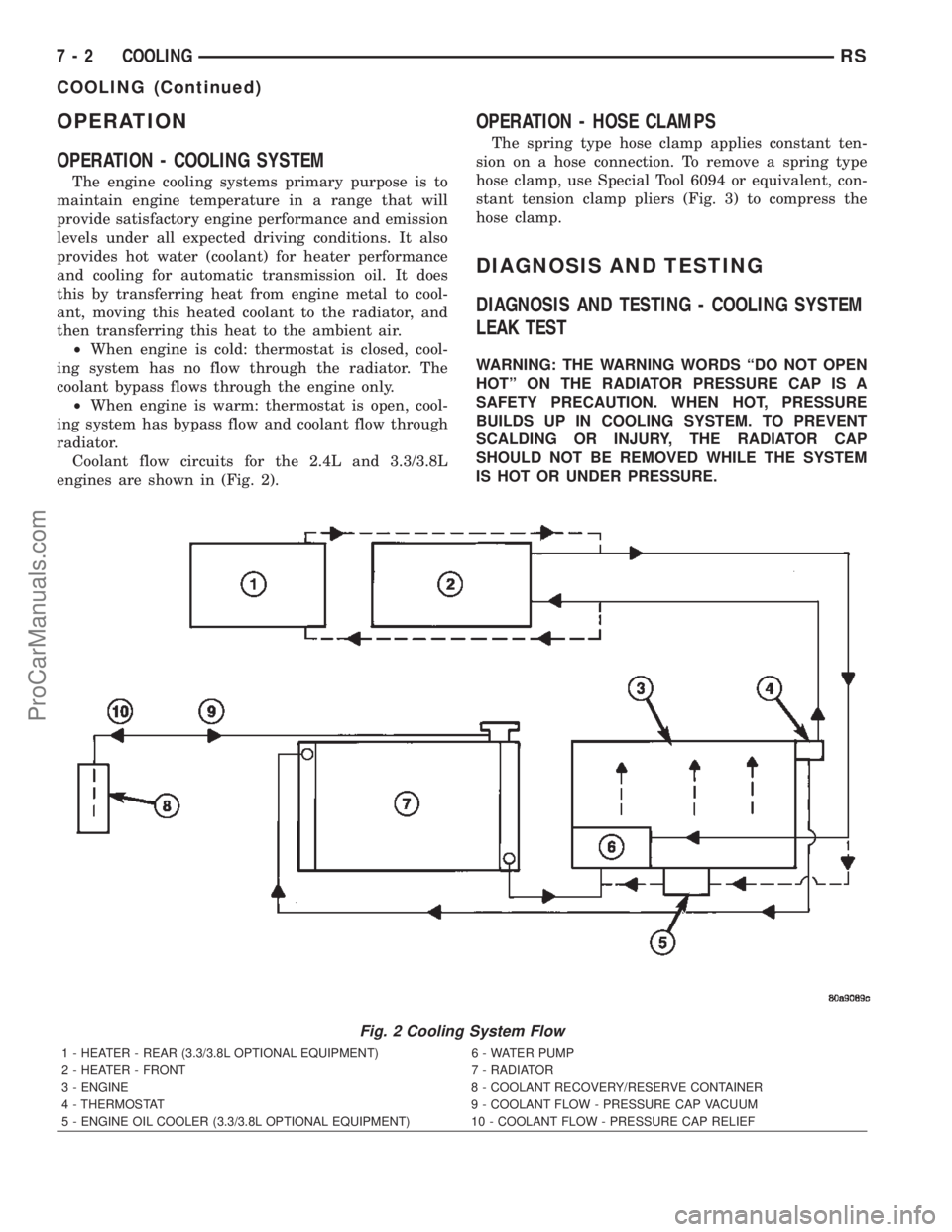

OPERATION - COOLING SYSTEM

The engine cooling systems primary purpose is to

maintain engine temperature in a range that will

provide satisfactory engine performance and emission

levels under all expected driving conditions. It also

provides hot water (coolant) for heater performance

and cooling for automatic transmission oil. It does

this by transferring heat from engine metal to cool-

ant, moving this heated coolant to the radiator, and

then transferring this heat to the ambient air.

²When engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²When engine is warm: thermostat is open, cool-

ing system has bypass flow and coolant flow through

radiator.

Coolant flow circuits for the 2.4L and 3.3/3.8L

engines are shown in (Fig. 2).

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, use Special Tool 6094 or equivalent, con-

stant tension clamp pliers (Fig. 3) to compress the

hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAK TEST

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

Fig. 2 Cooling System Flow

1 - HEATER - REAR (3.3/3.8L OPTIONAL EQUIPMENT) 6 - WATER PUMP

2 - HEATER - FRONT 7 - RADIATOR

3 - ENGINE 8 - COOLANT RECOVERY/RESERVE CONTAINER

4 - THERMOSTAT 9 - COOLANT FLOW - PRESSURE CAP VACUUM

5 - ENGINE OIL COOLER (3.3/3.8L OPTIONAL EQUIPMENT) 10 - COOLANT FLOW - PRESSURE CAP RELIEF

7 - 2 COOLINGRS

COOLING (Continued)

ProCarManuals.com