diagram CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 544 of 2399

The power liftgate control module communicates

on the J1850 Programmable Communication Inter-

face (PCI) Bus Circuit. Therefore, the power liftgate

control module can generate and store its own Diag-

nostic Trouble Codes (DTC). The vehicles Body Con-

trol Module (BCM) receives and supplies messages tothe power liftgate control module via the PCI bus cir-

cuit. A diagnostic scan tool, such as the DRB IIItis

used to read and troubleshoot these Diagnostic Trou-

ble Codes (DTC). Refer to the Body Diagnostic Man-

ual for a complete list of diagnostic routines.

For additional information refer to Power Liftgate

Operation. For a complete system wiring schematic

refer to Wiring Diagrams. For system operation

instructions refer to the vehicles owner manual.

Refer to the Body section of the service manual

for additional information on liftgate components

such as the prop rods, hinges, door alignment and

striker alignment.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS (NOTED BELOW) IN POWER LIFT-

GATE SYSTEM OPERATION BEFORE ATTEMPTING

ANY SERVICE OF THE POWER LIFTGATE SYSTEM

OR COMPONENTS.

OPERATION

With the push of a power liftgate open/close com-

mand switch (key fob or overhead console mounted) a

signal is sent out on the J1850 PCI Data Bus circuit.

This signal is detected at the body control module

(BCM). The BCM then sends a signal out on the

J1850 PCI Data Bus circuit to the power liftgate

module. The power liftgate module then signals the

power liftgate motor to start an open or close cycle,

depending on what position the liftgate is in open or

closed.

During a liftgate open or close cycle, if the power

liftgate module detects sufficient resistance to liftgate

travel, such as an obstruction in the liftgates path,

the power liftgate control module will immediately

stop the liftgate movement and reverse travel to the

full open or closed position. The ability for the power

liftgate module to detect resistance to liftgate travel

is accomplished by hall effect sensors, drive motor

speed and pinch sensors (tape switches).

The power liftgate control module has the ability to

learn. Anytime the liftgate is opened or closed using

the power liftgate system the module learns from its

cycle. If a replacement power liftgate component is

installed or a liftgate adjustment is made, the mod-

ule will relearn the effort and/or time required to

open or close the door. This learn cycle can be per-

formed with a Diagnostic Scan Tool, such as the DRB

IIItor with a complete cycle of the liftgate, using

any one of the command switches. Refer to Standard

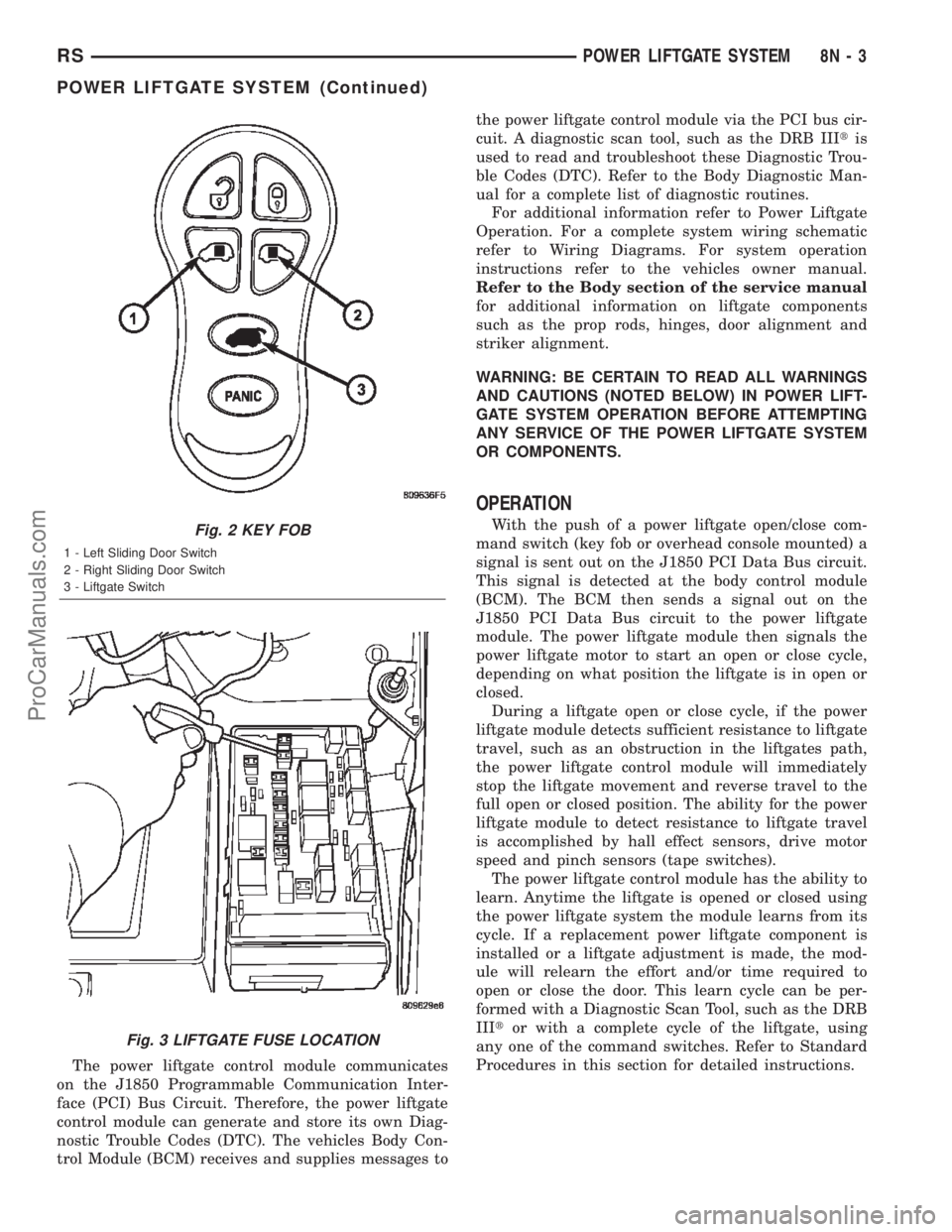

Procedures in this section for detailed instructions.Fig. 2 KEY FOB

1 - Left Sliding Door Switch

2 - Right Sliding Door Switch

3 - Liftgate Switch

Fig. 3 LIFTGATE FUSE LOCATION

RSPOWER LIFTGATE SYSTEM8N-3

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 547 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Binding or sticking of components Establish location of binding and replace

necessary components

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Power loss during Liftgate

operationWiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Low battery voltage Charge battery

Failure of Power Liftgate or Body

Control ModuleDisconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Failure of motor assembly Check for no drive condition

No power latching in

primary and/or secondary

positionsFailure of latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using Body Diagnostic

Manual. Replace latch assembly, if

necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Failure of Power Liftgate or Body

Control ModuleDisconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Door seal force too high Inspect seals for damage, mis-assembly,

foreign matter or other possible obstruction

Failure of motor assembly Check for no drive condition

Latch will not fully release

from primary positionFailure of latch assembly Check wire connections and for blown fuse

Check for foreign matter or damaged

components preventing the operation of

latch assembly

Troubleshoot using body electrical

troubleshooting manual Replace latch

assembly, if necessary

Failure of outside handle switch Troubleshoot using Body Diagnostic

Manual Replace switch, if necessary

Failure of Power Liftgate or Body

Control ModuleDisconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Binding or sticking of components Establish location of binding and replace

necessary components

8N - 6 POWER LIFTGATE SYSTEMRS

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 548 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Key fob, Outside Handle or

overhead console switches

do not power operate

liftgateBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery in key fob or

vehicle

Failure of latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Failure of Body Control Module

(BCM)Check electrical connections

Refer to the Body electrical troubleshooting

guide for additional checks

Replace BCM if necessary

Failure of key fob Reprogram key fob

Replace key fob if necessary

Failure of Power Liftgate Module Disconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Failure of liftgate motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Motor clutch does not engage, replace

assembly

Full open switch inoperative, replace

switch, if necessary

Troubleshoot using Body Diagnostic

Manual Replace motor, if necessary

Liftgate does not stay open Failure of liftgate prop rods Replace prop rods, if necessary

Check for broken attachments

High inside/outside opening

effortFailure of liftgate prop rods Replace prop rods, if necessary

Check for broken attachments

Gear motor did not disengage Troubleshoot using Body Diagnostic

Manual Replace components, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

RSPOWER LIFTGATE SYSTEM8N-7

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 549 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Liftgate continues to cinch

closed during power modeFailure of latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using Body Diagnostic

Manual Replace components, if necessary

Failure of Power Liftgate or Body

Control ModuleDisconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Liftgate continues to open

during power mode

(runaway motor)Failure of Power Liftgate or Body

Control ModuleDisconnect then reconnect battery to reset

module, function liftgate, if no function

exists check for loose wire connections,

see Body Diagnostic Manual for detailed

procedures

Failure of full open switch Check wire connections

Replace switch, if necessary

Failure of motor assembly Check for continuous drive condition

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to Wiring Diagrams

Liftgate opens very slowly Failure of liftgate motor assembly Check wire connections

Replace motor assembly, if necessary

Failure of liftgate prop rods Replace prop rods, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Grade of vehicle too steep for power

operationOperate liftgate manually

Squeaks, Noises and rattles Foreign material in door

compartmentRemove foreign material

Loose components Check and tighten loose components

STANDARD PROCEDURE

STANDARD PROCEDURE - LIFTGATE

ADJUSTMENT

In order for the power liftgate system to function

properly the liftgate must move freely and smoothly.

The power liftgate system can acommodate for some

minor changes in the effort required to move the lift-

gate. However, in extreme conditions the liftgate may

need to be mechanicaly adjusted for proper fit and

finish. Refer to the Liftgate Adjustment procedure in

the Body section of the service manual for detailed

instructions.If a problem exists with the power liftgate and it is

suspected to be extreme effort check the liftgate prop

rods and hinges for free movement. Use a known

good vehicle for liftgate effort comparison.

NOTE: Routine application of Mopar MP-50Tor

equivalent on the chrome prop rod shafts and lift-

gate latch and hinges will help keep the liftgate in

good working order.

8N - 8 POWER LIFTGATE SYSTEMRS

POWER LIFTGATE SYSTEM (Continued)

ProCarManuals.com

Page 557 of 2399

(5) Grab the latch assembly and unhook the key

cylinder link rod from the key cylinder (Fig. 13).

(6) Place the latch assembly on a bench and locate

the three wires leading from the actuator portion of

the latch assembly.

(7) Disengage the main connector retaining push

pins from the latch actuator housing.

(8) Back the three wires out of the main latch elec-

trical connector. Refer to the wiring section of the

service manual for detailed instructions.

(9) Flip the latch assembly over and remove the

latch actuator retaining screw(s).

(10) Remove the latch actuator from the latch

assembly.

INSTALLATION

(1) Install the latch actuator on the latch assem-

bly.

(2) Install the three latch actuator retaining

screws. Torque the screws to 4 in. lbs.

(3) Install the three wires in the main latch elec-

trical connector. Refer to the wiring section of the

service manual for detailed instructions.

NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the latch actuator. Refer to Wiring Diagrams

if previous notes were not made.

(4) Secure the main connector retaining push pins

on the latch actuator housing.

(5) Grab the latch assembly and hook the key cyl-

inder link rod on the key cylinder.

(6) Position the latch and install the three latch

retaining bolts. Torque to 10 N´m (90 in. lbs.).

(7) Connect the power latch electrical connector.

(8) Install the lower liftgate trim panel. Refer to

Body for the procedure.

(9) Connect the negative battery cable.

EXTERIOR HANDLE SWITCH

DESCRIPTION

Vehicles equipped with a power liftgate or power

locks utilize a exterior handle switch. The exterior

handle switch is a electronic release switch mounted

to the rear license plate lamp housing assembly,

located just above the license plate. This switch con-

trols the power liftgate release function and is also

capable of reversing the power liftgate when it is in

motion. A full power open cycle cannot be performed

using this switch, only one of the power open com-

mand switches (key fob and overhead console

mounted) can be used to perform a full power open

cycle.The exterior handle switch is a serviceable compo-

nent. Consult your MoparŸ parts catalog for a spe-

cific part number.

OPERATION

When the exterior handle switch is depressed, with

the liftgate in the closed position. A message is sent

to the Body Control Module (BCM). The Body Con-

trol Module then sends a signal to the power liftgate

control module via the J1850 PCI data bus circuit.

The power liftgate control module then sends a sig-

nal to the power latch mounted actuator, which

moves the liftgate from the primary closed and

latched position to the open and movable position. If

the liftgate is not pulled open once the latch releases

within a few seconds, the latch will cinch closed

again.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Open the liftgate and remove the liftgate trim

panel. Refer to the Body section of the service man-

ual for the procedure.

(3) Remove the rear lamp bar assembly from the

vehicle. Refer to the Body section of the service man-

ual for the procedure.

(4) Locate the two wires going to the exterior han-

dle switch. Cut the tie strap and trace the wires to

the large electrical connector and back the wires out

of the large connector and through the grommet.

Refer to the Wiring section of the service manual for

detailed instructions.

(5) Depress the two exterior handle switch retain-

ing tabs and roll the switch out of the light bar

assembly (Fig. 14).

INSTALLATION

(1) Install the handle switch in the light bar

assembly.

(2) Locate the two wires going to the exterior han-

dle switch. Install the wires through the grommet

and in the large connector. Secure with a tie strap.

Refer to the Wiring section of the service manual for

detailed instructions.

NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the handle switch. Refer to Wiring Diagrams

if previous notes were not made.

(3) Install the rear light bar. Refer to the Body sec-

tion of the service manual for the procedure.

(4) Install the liftgate trim panel. Refer to the

Body section of the service manual for the procedure.

(5) Connect the negative battery cable.

8N - 16 POWER LIFTGATE SYSTEMRS

LATCH ACTUATOR (Continued)

ProCarManuals.com

Page 561 of 2399

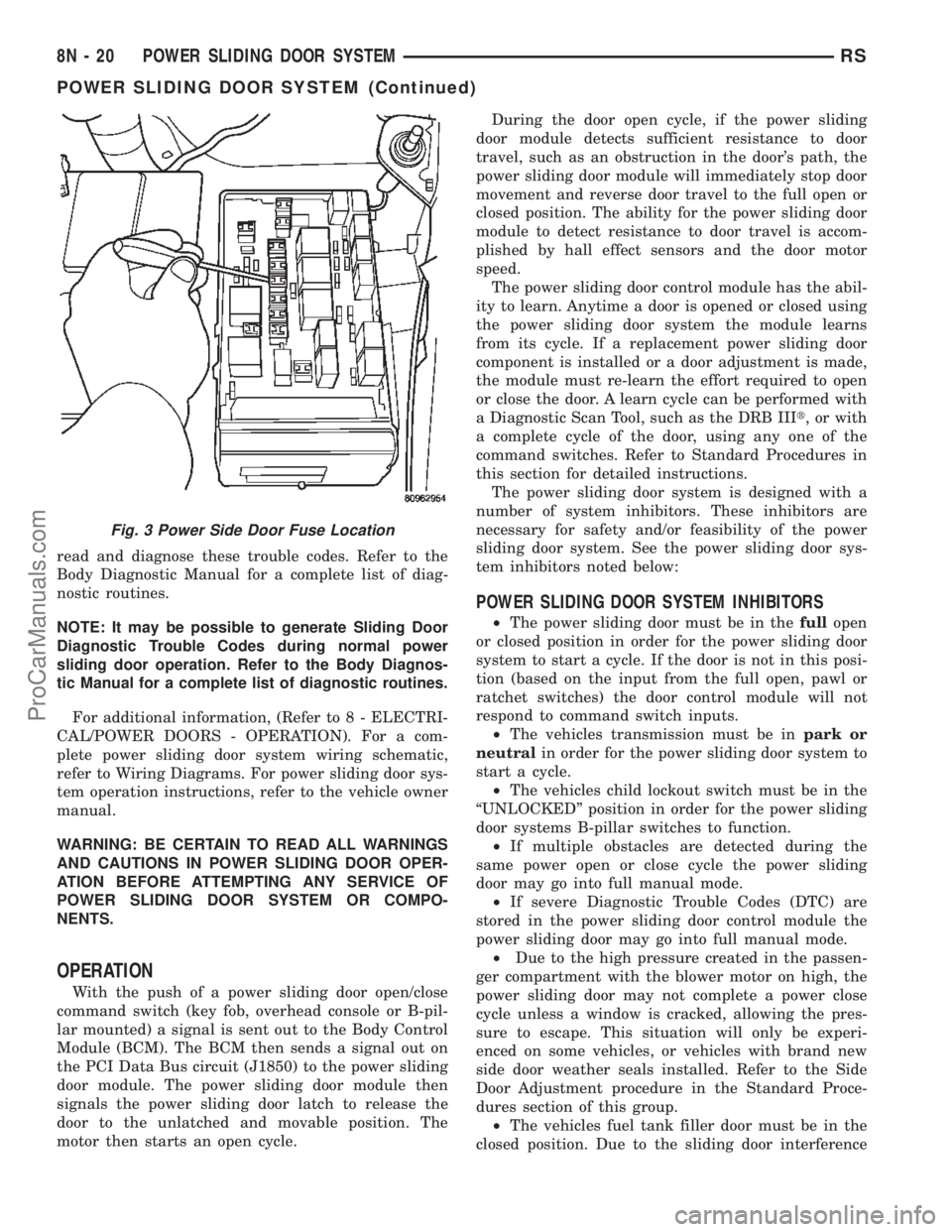

read and diagnose these trouble codes. Refer to the

Body Diagnostic Manual for a complete list of diag-

nostic routines.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). For a com-

plete power sliding door system wiring schematic,

refer to Wiring Diagrams. For power sliding door sys-

tem operation instructions, refer to the vehicle owner

manual.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the PCI Data Bus circuit (J1850) to the power sliding

door module. The power sliding door module then

signals the power sliding door latch to release the

door to the unlatched and movable position. The

motor then starts an open cycle.During the door open cycle, if the power sliding

door module detects sufficient resistance to door

travel, such as an obstruction in the door's path, the

power sliding door module will immediately stop door

movement and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors and the door motor

speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a Diagnostic Scan Tool, such as the DRB IIIt, or with

a complete cycle of the door, using any one of the

command switches. Refer to Standard Procedures in

this section for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. See the power sliding door sys-

tem inhibitors noted below:

POWER SLIDING DOOR SYSTEM INHIBITORS

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The vehicles transmission must be inpark or

neutralin order for the power sliding door system to

start a cycle.

²The vehicles child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

²If multiple obstacles are detected during the

same power open or close cycle the power sliding

door may go into full manual mode.

²If severe Diagnostic Trouble Codes (DTC) are

stored in the power sliding door control module the

power sliding door may go into full manual mode.

²Due to the high pressure created in the passen-

ger compartment with the blower motor on high, the

power sliding door may not complete a power close

cycle unless a window is cracked, allowing the pres-

sure to escape. This situation will only be experi-

enced on some vehicles, or vehicles with brand new

side door weather seals installed. Refer to the Side

Door Adjustment procedure in the Standard Proce-

dures section of this group.

²The vehicles fuel tank filler door must be in the

closed position. Due to the sliding door interference

Fig. 3 Power Side Door Fuse Location

8N - 20 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 564 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Replace the handle if necessary

Failure of latch assembly Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Replace latch assembly, if necessary

Failure of outside handle cable

assemblyCheck cable for binding

Check cable for broken condition

Replace the cable, if necessary

Binding or sticking of components Check for foreign matter preventing the

operation of door

Establish location of binding

Replace necessary components

Sliding door will not

open/close manuallyBinding or sticking of components Establish location of binding. Disconnect

flex drive and recheck. Replace necessary

components

Failure of latch assembly Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Replace latch assembly, if necessary

Sliding door will not

open/close under powerFailure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of latch assembly Check wire connections and for blown fuse

Check cable connections

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of motor assembly Troubleshoot using body diagnostic manual

Failure of full open switch assembly Troubleshoot using body diagnostic manual

Failure of flex drive assembly Disconnect flex drive and check for broken

condition

Failure of lower drive unit assembly Remove lower drive unit and check for

broken condition

Binding or sticking of components Establish location of binding and replace

necessary components

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Power loss during power

door operationWiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

RSPOWER SLIDING DOOR SYSTEM8N-23

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 566 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Striker damaged

Replace striker if necessary

Cables worn and stretched Replace cables as necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Key fob, B-pillar or

overhead console switch

does not power operate

doorBlown Fuse Check fuse and replace

Battery voltage low Charge or replace battery

Failure of latch assembly Check for foreign matter preventing the

operation of latch assembly

Check wire connection

Pawl and/or ratchet switch inoperative

Replace latch if necessary

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Failure of body control module Check electrical connections

Refer to the body diagnostic manual for

additional checks

Replace BCM if necessary

Failure of key fob Replace key fob battery

Replace key fob if necessary

Failure of sliding door control module Disconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of door motor assembly Check for foreign matter preventing the

operation of gear motor assembly

Check wire connections

Gear motor clutch does not engage,

replace assembly

Full open switch inoperative, replace hold

open latch assembly

Replace motor assembly. if necessary

Door does not stay open Failure of hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Failure of hold open latch striker Replace hold open latch striker, if

necessary

High inside/outside opening

effortFailure of latch assembly Check wire connections and for blown fuse

Check cable connections

RSPOWER SLIDING DOOR SYSTEM8N-25

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 567 of 2399

CONDITION POSSIBLE CAUSES CORRECTION

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of inside/outside handle

assemblyGo to that9POSSIBLE CAUSE9and review

9CORRECTIONS9

Binding or sticking of components Establish location of binding and replace

necessary components

Door continues to cinch

closed during power modeFailure of latch assembly Check wire connections and for blown fuse

Check for foreign matter preventing the

operation of latch assembly

Troubleshoot using body diagnostic manual

Replace latch assembly, if necessary

Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door continues to open

during power mode

(runaway motor)Failure of sliding door control or

body control moduleDisconnect then reconnect battery to reset

module, function door, if no function exists

check for loose wire connections, see Body

Diagnostic Manual for detailed procedures

Failure of hold open latch assembly Check wire/cable connections

Replace hold open latch, if necessary

Failure of drive assembly Remove lower drive unit and check for no

drive condition

Wiring problems (system or vehicle) Troubleshoot using electrical schematics.

Refer to wiring diagrams

Door opens very slowly Failure of door motor assembly Check wire/cable connections

Replace motor assembly, if necessary

Binding or sticking of components Establish location of binding and replace

necessary components

Squeaks, Noises and rattles Foreign material in door

compartmentRemove foreign material

Loose components Check and tighten loose components

Poor door track lubrication Lubricate the front portions of the side door

tracks with9Door EaseT9or equivalent

8N - 26 POWER SLIDING DOOR SYSTEMRS

POWER SLIDING DOOR SYSTEM (Continued)

ProCarManuals.com

Page 583 of 2399

CAUTION: Do not disconnect the switch from the

rear of the door key cylinder. This switch is a one

time use switch. Once it is removed from the rear of

the switch, it is not reusable and must be replaced.

Test the switch at the harness connector.

DOOR CYLINDER LOCK SWITCH RESISTANCE

SWITCH POSITION RESISTANCE VALUE

COUNTERCLOCKWISE 5.4K OHMS

NEUTRAL 18.4K OHMS

CLOCKWISE 2K OHMS

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel of the effected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - REMOVAL).

(3) Close the door window.

(4) Disconnect the door cylinder lock switch wire

connector from the door harness, and wiring clip

from the impact beam.

(5) Remove the outer door handle from the door.

(6) Remove the switch from the key cylinder in the

door handle and remove from vehicle.

INSTALLATION

(1) Install the switch on the key cylinder in the

door handle.

(2) Install the door handle.

(3) Connect the door cylinder lock switch wire con-

nector to the door harness, and the wiring clip to the

impact beam.

(4) Install the door trim panel of the affected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Verify system operation.

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING - DOOR LOCK

MOTOR

Verify battery condition before testing door lock

motor(s) (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - DIAGNOSIS AND TESTING).

To determine which motor is faulty, check each

individual door for electrical lock and unlock or dis-

connect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem may be caused

by a shorted motor or a bad switch. Disconnecting

the defective motor will allow the others to work.To test an individual door lock motor, disconnect

the electrical connector from the motor. To lock the

door, connect a 12 volt power source to the positive

pin of the lock motor and a ground wire to the other

pin. Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. To unlock the

door reverse the wire connections at the motor pin

terminals. If these results are NOT obtained, replace

the motor.

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK

SWITCH

(1) Remove door trim panel. Refer to Body, Door -

Front, Trim Panel, Removal and Installation.

(2) Disconnect wire connector from back of door

lock switch.

(3) Depress switch to LOCK position.

(4) Using an ohmmeter, test switch resistance

between Pins 2 and 3. Refer to the DOOR LOCK

SWITCH CONTINUITY test and (Fig. 2).

(5) Depress switch to UNLOCK position.

(6) Test resistance between Pins 2 and 3.

(7) Test resistance between pins 2 and 3 while

switch is in its normal unactuated mode.

(8) If resistance values are not within the param-

eters shown replace the door lock switch.

DOOR LOCK SWITCH CONTINUITY

SWITCH

POSITIONCONTINUITY

BETWEENRESISTANCE

VALUE

LOCK 2 and 3 5.3K Ohm 5%

UNLOCK 2 and 3 2.0K Ohm 5%

UNACTUATED 2 and 3 18.3K Ohms

5%

Fig. 2 DOOR LOCK SWITCH

8N - 42 POWER LOCKSRS

DOOR CYLINDER LOCK SWITCH (Continued)

ProCarManuals.com