remote control CHRYSLER VOYAGER 2002 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1527 of 2399

If the steering wheel is equipped with remote radio

controls, disconnect the connector from the clock-

spring. Release the connector by depressing the tang

as shown (Fig. 38), then slide the connector apart.

(4) Remove the steering wheel retaining nut (Fig.

39) from the steering column shaft.

(5) Remove the steering wheel damper (Fig. 39)

from the steering wheel.

CAUTION: Do not bump or hammer on steering col-

umn or steering column shaft when removing steer-

ing wheel from steering column shaft.CAUTION: When installing steering wheel puller

bolts in steering wheel, (Fig. 40) do not thread bolt

into steering wheel more than a half inch. If bolts

are threaded into the steering wheel more than a

half inch they will contact and damage the clock-

spring.

(6) Remove the steering wheel from steering col-

umn shaft using a steering wheel puller (Fig. 40).

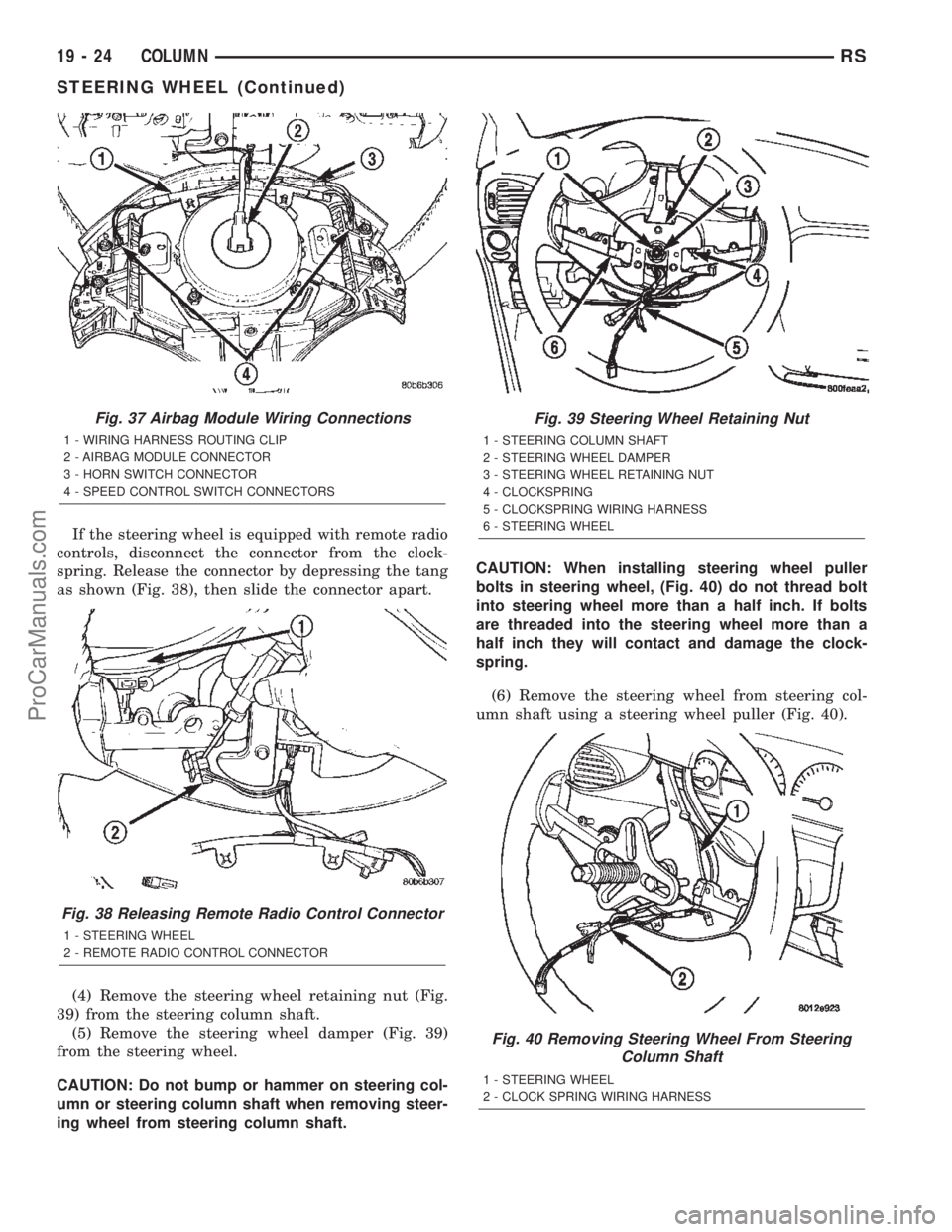

Fig. 37 Airbag Module Wiring Connections

1 - WIRING HARNESS ROUTING CLIP

2 - AIRBAG MODULE CONNECTOR

3 - HORN SWITCH CONNECTOR

4 - SPEED CONTROL SWITCH CONNECTORS

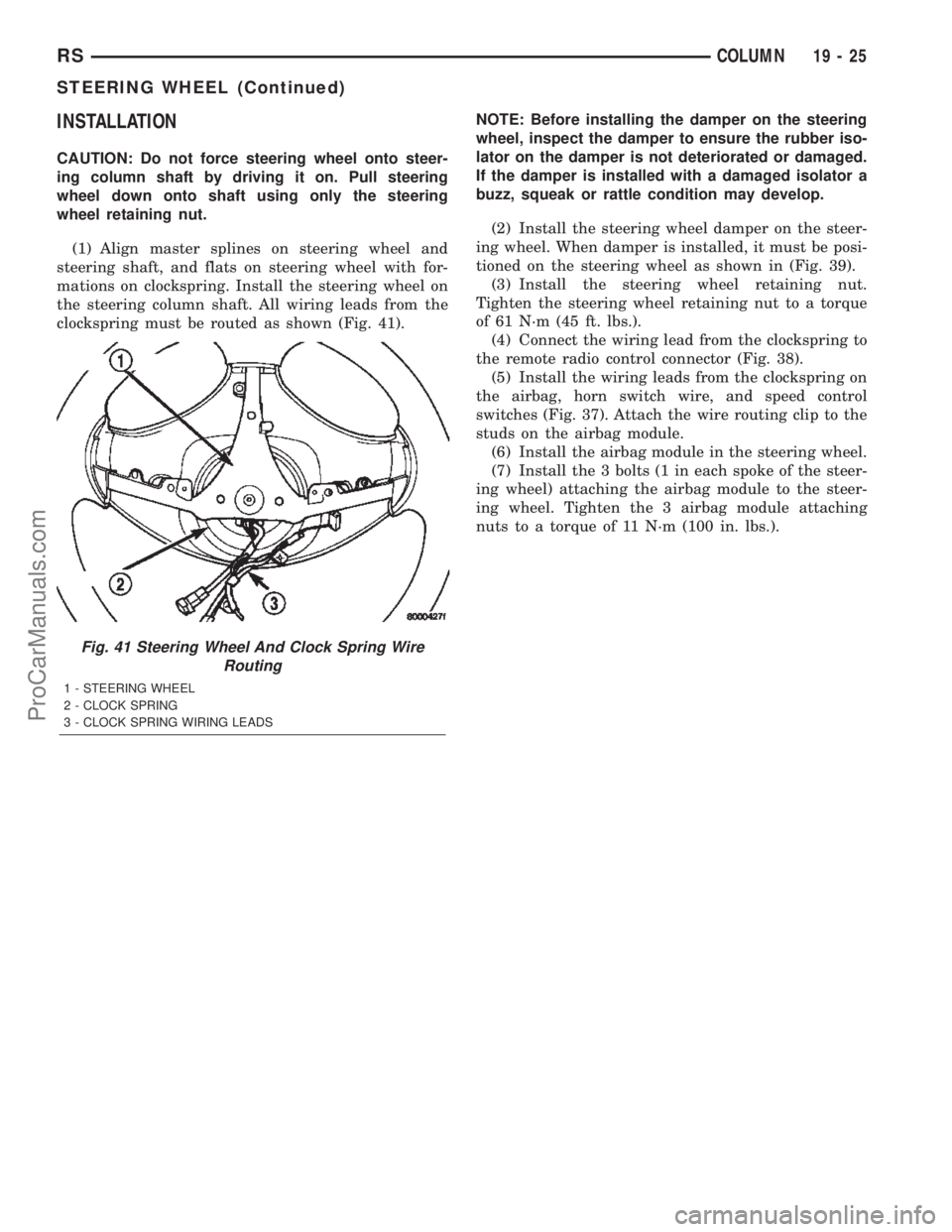

Fig. 38 Releasing Remote Radio Control Connector

1 - STEERING WHEEL

2 - REMOTE RADIO CONTROL CONNECTOR

Fig. 39 Steering Wheel Retaining Nut

1 - STEERING COLUMN SHAFT

2 - STEERING WHEEL DAMPER

3 - STEERING WHEEL RETAINING NUT

4 - CLOCKSPRING

5 - CLOCKSPRING WIRING HARNESS

6 - STEERING WHEEL

Fig. 40 Removing Steering Wheel From Steering

Column Shaft

1 - STEERING WHEEL

2 - CLOCK SPRING WIRING HARNESS

19 - 24 COLUMNRS

STEERING WHEEL (Continued)

ProCarManuals.com

Page 1528 of 2399

INSTALLATION

CAUTION: Do not force steering wheel onto steer-

ing column shaft by driving it on. Pull steering

wheel down onto shaft using only the steering

wheel retaining nut.

(1) Align master splines on steering wheel and

steering shaft, and flats on steering wheel with for-

mations on clockspring. Install the steering wheel on

the steering column shaft. All wiring leads from the

clockspring must be routed as shown (Fig. 41).NOTE: Before installing the damper on the steering

wheel, inspect the damper to ensure the rubber iso-

lator on the damper is not deteriorated or damaged.

If the damper is installed with a damaged isolator a

buzz, squeak or rattle condition may develop.

(2) Install the steering wheel damper on the steer-

ing wheel. When damper is installed, it must be posi-

tioned on the steering wheel as shown in (Fig. 39).

(3) Install the steering wheel retaining nut.

Tighten the steering wheel retaining nut to a torque

of 61 N´m (45 ft. lbs.).

(4) Connect the wiring lead from the clockspring to

the remote radio control connector (Fig. 38).

(5) Install the wiring leads from the clockspring on

the airbag, horn switch wire, and speed control

switches (Fig. 37). Attach the wire routing clip to the

studs on the airbag module.

(6) Install the airbag module in the steering wheel.

(7) Install the 3 bolts (1 in each spoke of the steer-

ing wheel) attaching the airbag module to the steer-

ing wheel. Tighten the 3 airbag module attaching

nuts to a torque of 11 N´m (100 in. lbs.).

Fig. 41 Steering Wheel And Clock Spring Wire

Routing

1 - STEERING WHEEL

2 - CLOCK SPRING

3 - CLOCK SPRING WIRING LEADS

RSCOLUMN19-25

STEERING WHEEL (Continued)

ProCarManuals.com

Page 1579 of 2399

ASSEMBLY...........................115

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................115

OPERATION..........................115

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................117

REMOVAL............................117

INSTALLATION........................118

SOLENOID - TCC

DESCRIPTION........................119

OPERATION..........................119

REMOVAL............................119

INSTALLATION........................120

THROTTLE VALVE CABLE

REMOVAL............................120

INSTALLATION........................121

ADJUSTMENTS

THROTTLE VALVE LINKAGE

ADJUSTMENT.......................122

TORQUE CONVERTER

DESCRIPTION........................122

OPERATION..........................126

REMOVAL............................127

INSTALLATION........................127

TRANSFER SYSTEM - OUTPUT SHAFT/GEAR/

BEARING

REMOVAL............................128INSTALLATION........................131

ADJUSTMENTS

ADJUSTMENT - OUTPUT SHAFT BEARING . 135

TRANSFER SYSTEM - TRANSFER SHAFT/

GEAR/BEARING

REMOVAL............................137

INSTALLATION........................141

ADJUSTMENTS

ADJUSTMENT - TRANSFER SHAFT

BEARING...........................145

VALVE BODY

REMOVAL............................146

DISASSEMBLY........................148

CLEANING...........................154

INSPECTION.........................155

ASSEMBLY...........................155

INSTALLATION........................158

ADJUSTMENTS

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS......................160

VEHICLE SPEED SENSOR/PINION GEAR

REMOVAL............................160

INSTALLATION........................160

31TH AUTOMATIC

TRANSAXLE

DESCRIPTION

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heatexchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

21 - 22 31TH AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1996 of 2399

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Liftgate Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Liftgate Lock Cylinder

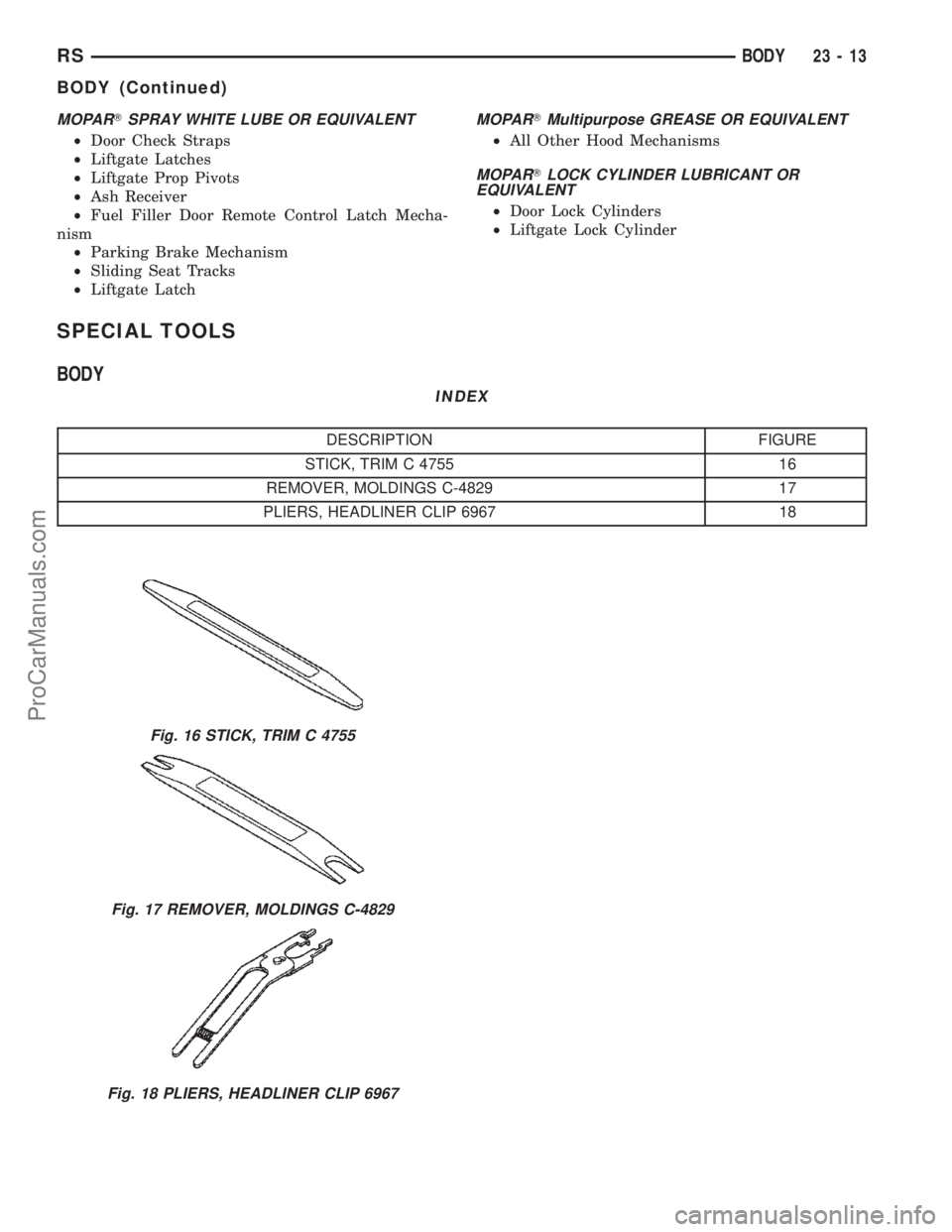

SPECIAL TOOLS

BODY

INDEX

DESCRIPTION FIGURE

STICK, TRIM C 4755 16

REMOVER, MOLDINGS C-4829 17

PLIERS, HEADLINER CLIP 6967 18

Fig. 16 STICK, TRIM C 4755

Fig. 17 REMOVER, MOLDINGS C-4829

Fig. 18 PLIERS, HEADLINER CLIP 6967

RSBODY23-13

BODY (Continued)

ProCarManuals.com

Page 2284 of 2399

or damaged, the instrument panel top cover must be

replaced.

²Demister Outlets- There are two side window

demisters that aid in defogging and defrosting the

front door windows. One demister outlet is located at

each outboard end of the instrument panel top pad,

near the belt line at the A-pillars. The demister out-

lets can be removed from the top pad individually for

service replacement.

²Instrument Panel Outlets- There are five

panel outlets in the instrument panel, one located

near each outboard end of the instrument panel fac-

ing the rear of the vehicle, and three located near the

top of the instrument panel center bezel. On models

with manual temperature control, all five of these

outlets are fully adjustable. On models with Auto-

matic Temperature Control (ATC), the center outlet

in the center bezel has fixed vanes because it also

houses the remote infrared temperature sensors for

the front seat positions. The outboard outlets can be

removed individually for service replacement. The

center bezel outlets are serviced as a gang of three

outlets and, on models with ATC, also includes the

infrared sensors.

²Front Door Rear Outlets- A fully adjustable

outlet located at the rear of each front door trim

panel supplies only cooled air to the intermediate

seat passengers. Air is supplied to these outlets from

the instrument panel through ducts in the doors that

use molded seals at the instrument panel to prevent

air leakage. The door ducts are integral to the front

door trim panels. These outlets also incorporate a red

reflector to improve the safety and visibility of an

opened front door to traffic approaching the vehicle

from the rear at night. These outlets can be removed

from the door trim panels for service replacement.

²Front Floor Outlets- There are two front floor

outlets, one located above each side of the floor panel

center tunnel below the instrument panel. These out-

lets are integral to the front heater-A/C unit distri-

bution housing.

²Rear Floor Outlets- Wide rear floor outlets

located under each front seat have integral, fixed

directional dividers to distribute heated air across

the floor for intermediate seat passengers. These out-

lets are integral to the floor distribution ducts routed

under the front floor carpet from an outlet nozzle on

the bottom of the front heater-A/C unit distribution

housing.

REMOVAL

REMOVAL - CENTER BEZEL OUTLETS

The three outlets located near the top of the

instrument panel center bezel are serviced only as a

set of all three outlets. If the vehicle is equipped withthe optional Automatic Temperature Control (ATC)

system, the center outlet of the three has fixed vanes

and also houses the remote front infrared tempera-

ture sensors.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - REMOV-

AL).

(3) Place the center bezel face down on a suitable

work surface. Be certain to take the proper precau-

tions to protect the face of the center bezel from cos-

metic damage.

(4) If the vehicle is equipped with the optional

ATC system, disconnect the ATC remote infrared

temperature sensor jumper harness from the sensor

connector receptacle located on the bottom of the cen-

ter outlet housing (Fig. 3).

(5) Remove the three screws that secure the bot-

tom of the outlet housing to the center bezel.

(6) Roll the bottom of the outlet housing upwards

towards the top of the center bezel far enough to dis-

engage the retainer features on the top of the outlet

housing from their receptacles at the top of the cen-

ter bezel.

(7) Remove the center bezel outlets and housing

from the center bezel as a unit.

REMOVAL - DEMISTER OUTLET

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the outer perimeter of the

demister outlet away from the instrument panel top

pad until the snap features on the outlet are released

(Fig. 4).

(2) Remove the demister outlet from the demister

duct opening in the instrument panel top pad.

REMOVAL - FRONT DOOR REAR OUTLET

(1) Disconnect and isolate the battery negative

cable.

RSDISTRIBUTION - FRONT24-41

AIR OUTLETS (Continued)

ProCarManuals.com

Page 2286 of 2399

INSTALLATION

INSTALLATION - CENTER BEZEL OUTLETS

(1) Position the center bezel outlets and housing

onto the center bezel as a unit.

(2) Engage the retainer features on the top of the

outlet housing with their receptacles at the top of the

center bezel, then roll the bottom of the outlet hous-

ing downwards towards the center bezel.

(3) Install and tighten the three screws that secure

the bottom of the outlet housing to the center bezel.

Tighten the screws to 2 N´m (17 in. lbs.).

(4) If the vehicle is equipped with the optional

ATC system, reconnect the ATC remote infrared tem-

perature sensor jumper harness to the sensor connec-

tor receptacle located on the bottom of the center

outlet housing.

(5) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(6) Reconnect the battery negative cable.

INSTALLATION - DEMISTER OUTLET

(1) Position the demister outlet over the demister

duct opening in the instrument panel top pad.

(2) Using hand pressure, press the demister outlet

firmly and evenly into the instrument panel top pad

opening until the snap features on the outlet are

fully engaged.

INSTALLATION - FRONT DOOR REAR OUTLET

(1) Position the front door rear outlet through the

outside of the front door trim panel outlet opening.

(2) While keeping the outlet aligned with the door

duct opening behind the trim panel, use hand pres-

sure to press the outlet firmly and evenly through

the outside of the front door trim panel outlet open-

ing until the four latch features (two top and two bot-

tom) that secure the outlet to the inside of the

opening are fully engaged.

(3) Reinstall the trim panel onto the front door

inner panel. (Refer to 23 - BODY/DOOR - FRONT/

TRIM PANEL - INSTALLATION).

(4) Reconnect the battery negative cable.

INSTALLATION - INSTRUMENT PANEL OUTLET

(1) Position the instrument panel outlet into the

panel duct opening in the instrument panel top pad.

(2) Using hand pressure, press the instrument

panel outlet firmly and evenly into the instrument

panel top pad opening until the snap features on the

outlet are fully engaged.

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 7). The

blower motor and wheel are located near the passen-

ger side end of the heater-A/C unit within the two

halves of the intake air housing in the passenger

compartment below the instrument panel. The

blower motor and blower motor wheel are a factory

balanced unit and cannot be adjusted or repaired. If

faulty or damaged, the blower motor and blower

wheel must be replaced as a unit.

OPERATION

The blower motor will operate whenever the igni-

tion switch is in the On position and the heater-A/C

control power is turned on. The blower motor can

only be turned off by turning off the power at the

heater-A/C control. The blower motor receives battery

current whenever the front blower motor relay is

energized. The front blower motor relay output cir-

cuit is protected by a fuse in the Intelligent Power

Module (IPM) located in the engine compartment

near the battery. In the Manual system, the blower

motor speed is controlled by regulating the path to

ground through the blower control switch and the

blower motor resistor. In the ATC system, the blower

motor speed is controlled by an electronic blower

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

Fig. 7 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

RSDISTRIBUTION - FRONT24-43

AIR OUTLETS (Continued)

ProCarManuals.com