heater CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2409 of 2585

CONTROLS - FRONT

TABLE OF CONTENTS

page page

A/C COMPRESSOR CLUTCH/COIL

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - A/C

COMPRESSOR CLUTCH COIL...........15

REMOVAL.............................16

INSPECTION..........................17

INSTALLATION.........................17

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................19

OPERATION...........................19

REMOVAL.............................20

INSTALLATION.........................20

A/C HEATER CONTROL

DESCRIPTION.........................20

STANDARD PROCEDURE - A/C-HEATER

CONTROL CALIBRATION...............20

REMOVAL.............................21

INSTALLATION.........................21

A/C PRESSURE TRANSDUCER

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................22

REMOVAL.............................22

INSTALLATION.........................22

BLEND DOOR ACTUATOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................23

BLOWER MOTOR RELAY

DESCRIPTION.........................24

OPERATION...........................24

REMOVAL.............................25

INSTALLATION.........................25

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................26OPERATION...........................26

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR BLOCK..............26

REMOVAL.............................26

INSTALLATION.........................27

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................27

OPERATION...........................28

REMOVAL

REMOVAL - AUTOMATIC TEMPERATURE

CONTROL (ATC)......................28

REMOVAL - MANUAL TEMPERATURE

CONTROL (MTC)......................29

INSTALLATION

INSTALLATION - AUTOMATIC

TEMPERATURE CONTROL (ATC).........29

INSTALLATION - MANUAL TEMPERATURE

CONTROL (MTC)......................29

INFRARED TEMPERATURE SENSOR

DESCRIPTION.........................29

OPERATION...........................29

MODE DOOR ACTUATOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

POWER MODULE - BLOWER MOTOR

DESCRIPTION.........................31

OPERATION...........................31

REMOVAL.............................31

INSTALLATION.........................32

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................33

INSTALLATION.........................33

24 - 14 CONTROLS - FRONTRS

Page 2410 of 2585

A/C COMPRESSOR CLUTCH/

COIL

DESCRIPTION

The A/C compressor clutch assembly consists of a

stationary electromagnetic A/C clutch field coil with a

zener diode, a pulley bearing and pulley assembly,

and a clutch plate (Fig. 1). A/C clutch field coil and

the pulley bearing and pulley assembly are each

retained on the nose of the compressor front housing

with snap rings. The clutch plate is keyed or splined

to the compressor shaft, and secured with a nut or

bolt (depending on application). These components

provide the means to engage and disengage the com-

pressor from the engine serpentine accessory drive

belt.

The A/C compressor clutch and coil are available

for separate service replacement. The clutch coil

zener diode is integral to the clutch coil pigtail wire

and connector and, if faulty or damaged, the clutch

electromagnetic coil must be replaced.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch plate into contact with the clutch pulley and

drives the compressor shaft. When the coil is not

energized, the pulley freewheels on the clutch hub

bearing, which is part of the pulley.

A zener diode is connected in parallel with the

clutch electromagnetic coil. This diode controls the

dissipation of voltage induced into the coil windingsby the collapsing of the electromagnetic fields that

occurs when the compressor clutch is disengaged.

The zener diode dissipates this induced voltage by

regulating a current path to ground. This arrange-

ment serves to protect other circuits and components

from potentially damaging voltage spikes in the vehi-

cle electrical system that might occur if the voltage

induced in the clutch coil windings could not be dis-

sipated.

The compressor clutch engagement is controlled by

several components: the heater-A/C controls in the

passenger compartment, the A/C pressure transducer

on the liquid line, the evaporator temperature sensor

on the expansion valve for automatic temperature

control (ATC) system or on the HVAC housing for

manual temperature control (MTC) system, the Pow-

ertrain Control Module (PCM) in the engine compart-

ment, and the compressor clutch relay in the

Integrated Power Module (IPM). The PCM may delay

compressor clutch engagement for up to thirty sec-

onds (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/POWERTRAIN CONTROL

MODULE - DESCRIPTION - PCM OPERATION).

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

The air conditioning compressor clutch coil electri-

cal circuit is controlled by the powertrain control

module (PCM) through the A/C compressor clutch

relay, which is located in the integrated power mod-

ule (IPM) in the engine compartment. Begin testing

of a suspected compressor clutch coil problem by per-

forming the preliminary checks.

PRELIMINARY CHECKS

(1) If the compressor clutch will not engage, verify

the refrigerant charge level (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - FRONT/RE-

FRIGERANT - DIAGNOSIS AND TESTING -

REFRIGERANT CHARGE LEVEL). If the refriger-

ant charge level is OK, go to Step 2. If the refriger-

ant charge level is not OK, adjust the refrigerant

charge as required.

(2) If the A/C compressor clutch still will not

engage, disconnect the wire harness connector for the

A/C pressure transducer and check for battery cur-

rent at the connector with the engine running and

the A/C-heater control set to the A/C mode. If OK, go

to TESTS. If not OK, refer to Body Diagnostic Proce-

dures to perform further diagnosis.

TESTS

(1) Verify the battery state of charge (Refer to 8 -

ELECTRICAL/BATTERY SYSTEM/BATTERY -

DIAGNOSIS AND TESTING).

Fig. 1 Compressor Clutch - Typical

1 - CLUTCH PLATE

2 - SHAFT KEY (SOME MODELS)

3 - PULLEY AND BEARING

4 - CLUTCH COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

RSCONTROLS - FRONT24-15

Page 2411 of 2585

(2) Connect an ammeter (0 to 10 ampere scale

selected) in series with the clutch coil feed terminal.

Connect a voltmeter (0 to 20 volt scale selected) to

measure voltage across the battery and the clutch

coil.

(3) With the heater-A/C control in the A/C mode

and the blower at low speed, start the engine and

allow it to run at a normal idle speed.

(4) The compressor clutch should engage immedi-

ately, and the clutch coil voltage should be within

two volts of the battery voltage. If the coil voltage is

not within two volts of battery voltage, test the

clutch coil feed circuit for excessive voltage drop. If

the compressor clutch does not engage, refer to Body

Diagnostic Procedures to perform further diagnosis.

(5) Refer to the A/C Clutch Coil Current Draw

chart for the acceptable A/C clutch coil current draw

specifications. Specifications apply for a work area

temperature of 21É C (70É F). If voltage is more than

12.5 volts, add electrical loads by turning on electri-

cal accessories until voltage reads below 12.5 volts.

(a) If the compressor clutch coil current reading

is zero, the coil is open and must be replaced.

(b) If the compressor clutch coil current reading

is four amperes or more, the coil is shorted and

must be replaced.

A/C CLUTCH COIL CURRENT DRAW

Compressor Current Draw

Nippondenso - 10S20

(2.5L/3.3L/3.8L engines)

Nippondenso - 10S17

(2.4L engine)2.2 amps @ 11.5 - 12.5

volts

REMOVAL

NOTE: The compressor clutch can be serviced in

the vehicle. The refrigerant system can remain fully-

charged during compressor clutch, pulley, or coil

replacement.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

2.4L - REMOVAL) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3/3.8L -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the engine wire harness connector

for the compressor clutch coil from the clutch coil pig-

tail wire connector on the top of the compressor.

(5) On models with the 3.3L and 3.8L engines, dis-

engage the retainer on the engine wire harness com-

pressor clutch coil take out from the bracket on the

top of the compressor.(6) On models with the 2.4L and 2.5L engines,

remove all of the compressor mounting bolts except

the upper left (rear of the compressor), which should

only be loosened. Allow the front (pulley end) of the

compressor to tilt downward far enough to access the

clutch for removal, then tighten the loosened upper

left compressor mounting bolt.

(7) On models with the 3.3L and 3.8L engines,

remove the two bolts and two nuts that secure the

compressor to the engine. Disengage the mounting

ear at the front of the compressor from the stud on

the engine, allow the front (pulley end) of the com-

pressor to tilt downward far enough to access the

clutch for removal, then reinstall and tighten the

upper left compressor mounting bolt.

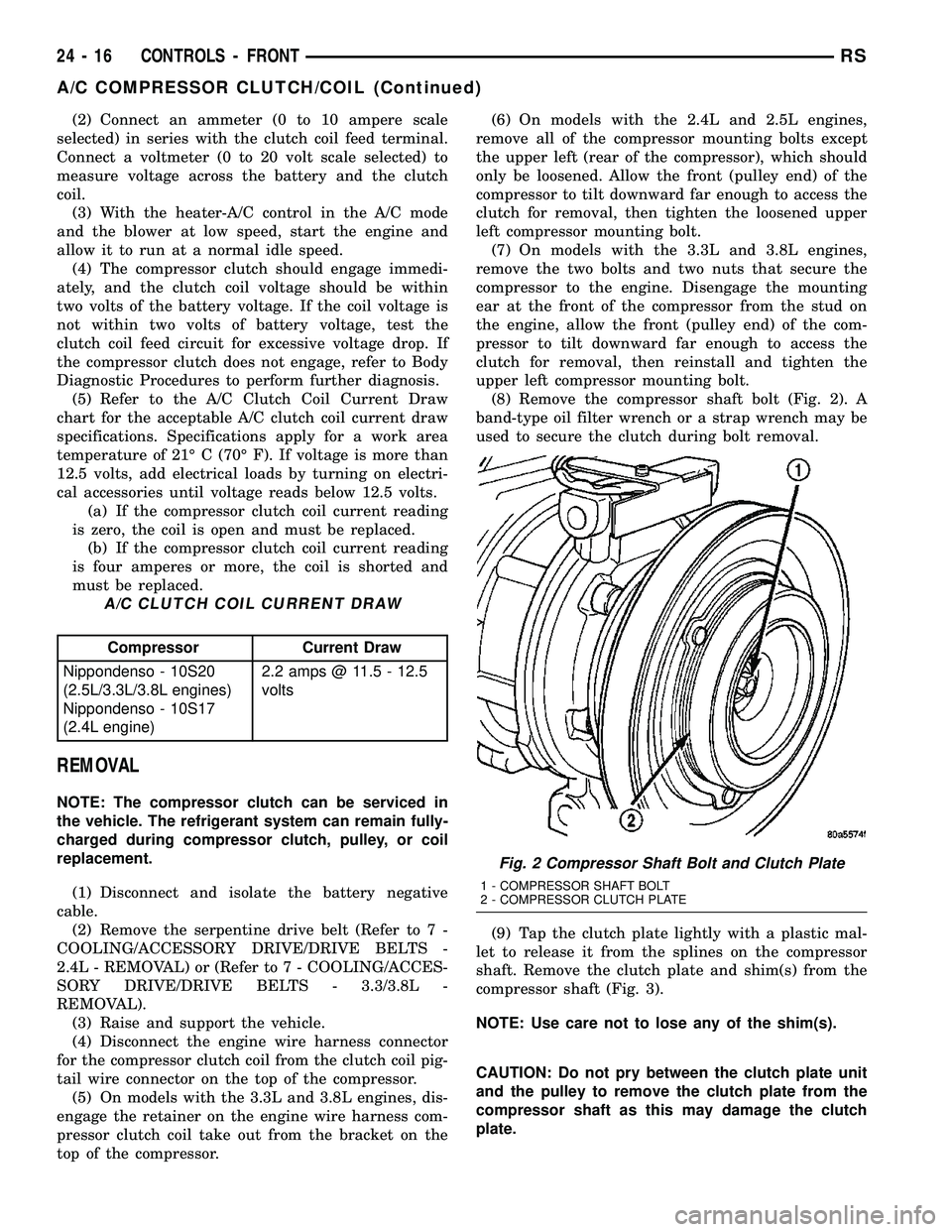

(8) Remove the compressor shaft bolt (Fig. 2). A

band-type oil filter wrench or a strap wrench may be

used to secure the clutch during bolt removal.

(9) Tap the clutch plate lightly with a plastic mal-

let to release it from the splines on the compressor

shaft. Remove the clutch plate and shim(s) from the

compressor shaft (Fig. 3).

NOTE: Use care not to lose any of the shim(s).

CAUTION: Do not pry between the clutch plate unit

and the pulley to remove the clutch plate from the

compressor shaft as this may damage the clutch

plate.

Fig. 2 Compressor Shaft Bolt and Clutch Plate

1 - COMPRESSOR SHAFT BOLT

2 - COMPRESSOR CLUTCH PLATE

24 - 16 CONTROLS - FRONTRS

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2414 of 2585

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

3.3L/3.8L - INSTALLATION).

(15) Lower the vehicle.

(16) Reconnect the battery negative cable.

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C-heater control to the A/C

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

A/C COMPRESSOR CLUTCH

RELAY

DESCRIPTION

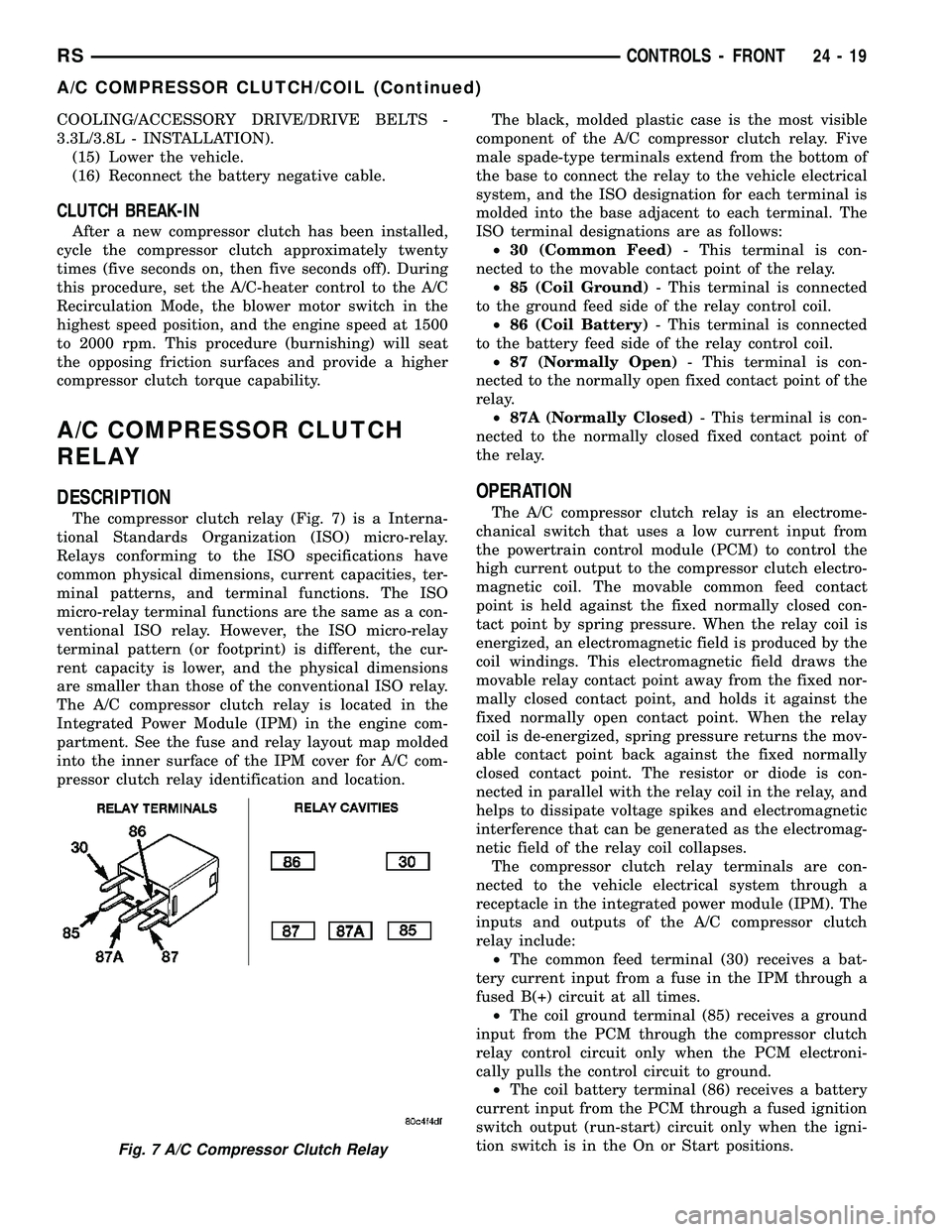

The compressor clutch relay (Fig. 7) is a Interna-

tional Standards Organization (ISO) micro-relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The ISO

micro-relay terminal functions are the same as a con-

ventional ISO relay. However, the ISO micro-relay

terminal pattern (or footprint) is different, the cur-

rent capacity is lower, and the physical dimensions

are smaller than those of the conventional ISO relay.

The A/C compressor clutch relay is located in the

Integrated Power Module (IPM) in the engine com-

partment. See the fuse and relay layout map molded

into the inner surface of the IPM cover for A/C com-

pressor clutch relay identification and location.The black, molded plastic case is the most visible

component of the A/C compressor clutch relay. Five

male spade-type terminals extend from the bottom of

the base to connect the relay to the vehicle electrical

system, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

OPERATION

The A/C compressor clutch relay is an electrome-

chanical switch that uses a low current input from

the powertrain control module (PCM) to control the

high current output to the compressor clutch electro-

magnetic coil. The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. The resistor or diode is con-

nected in parallel with the relay coil in the relay, and

helps to dissipate voltage spikes and electromagnetic

interference that can be generated as the electromag-

netic field of the relay coil collapses.

The compressor clutch relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the integrated power module (IPM). The

inputs and outputs of the A/C compressor clutch

relay include:

²The common feed terminal (30) receives a bat-

tery current input from a fuse in the IPM through a

fused B(+) circuit at all times.

²The coil ground terminal (85) receives a ground

input from the PCM through the compressor clutch

relay control circuit only when the PCM electroni-

cally pulls the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the PCM through a fused ignition

switch output (run-start) circuit only when the igni-

tion switch is in the On or Start positions.

Fig. 7 A/C Compressor Clutch Relay

RSCONTROLS - FRONT24-19

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2415 of 2585

²The normally open terminal (87) provides a bat-

tery current output to the compressor clutch coil

through the compressor clutch relay output circuit

only when the compressor clutch relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the compressor

clutch relay coil is de-energized.

The A/C compressor clutch relay cannot be

repaired and, if faulty or damaged, it must be

replaced. Refer to the appropriate wiring information

for diagnosis and testing of the micro-relay and for

complete HVAC wiring diagrams.

REMOVAL

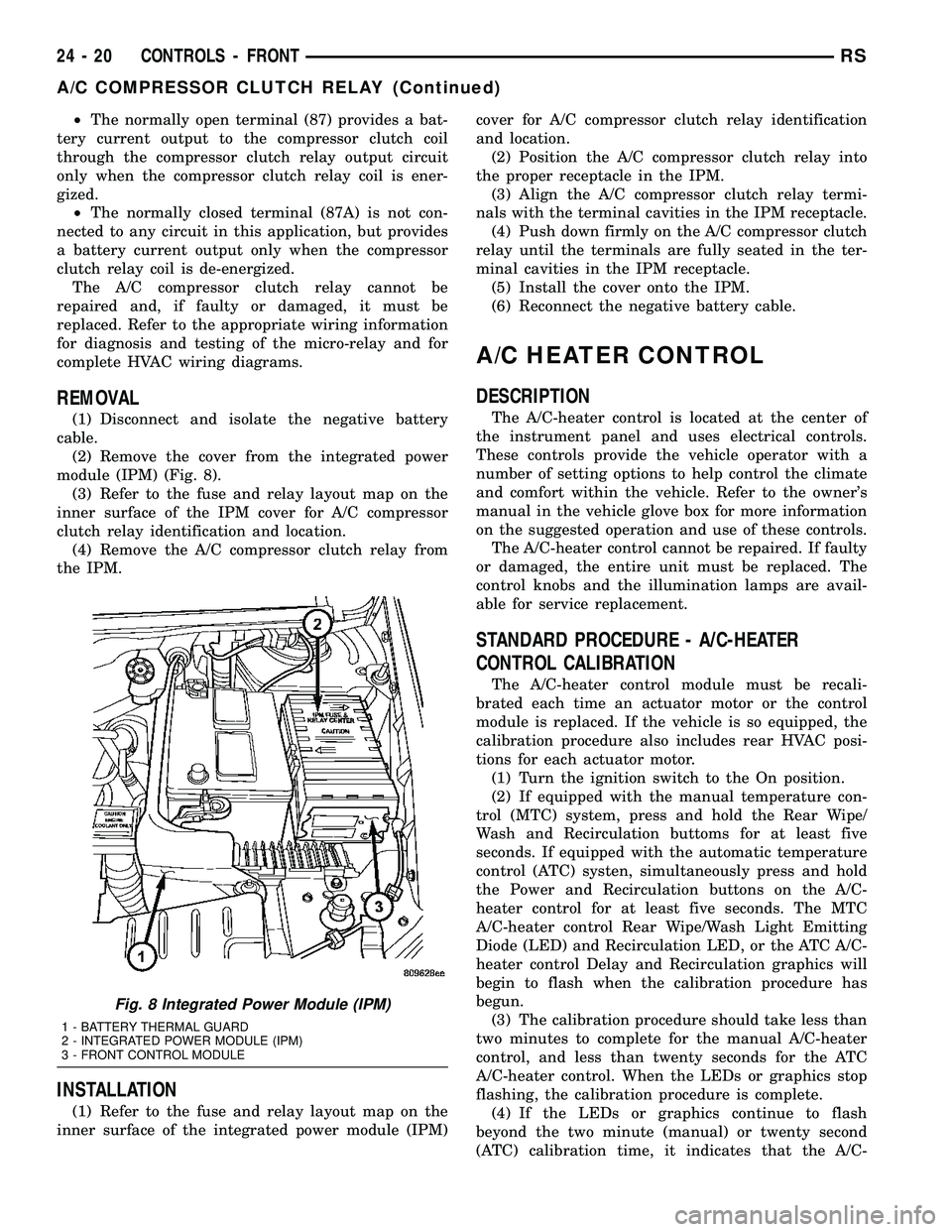

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 8).

(3) Refer to the fuse and relay layout map on the

inner surface of the IPM cover for A/C compressor

clutch relay identification and location.

(4) Remove the A/C compressor clutch relay from

the IPM.

INSTALLATION

(1) Refer to the fuse and relay layout map on the

inner surface of the integrated power module (IPM)cover for A/C compressor clutch relay identification

and location.

(2) Position the A/C compressor clutch relay into

the proper receptacle in the IPM.

(3) Align the A/C compressor clutch relay termi-

nals with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the A/C compressor clutch

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the negative battery cable.

A/C HEATER CONTROL

DESCRIPTION

The A/C-heater control is located at the center of

the instrument panel and uses electrical controls.

These controls provide the vehicle operator with a

number of setting options to help control the climate

and comfort within the vehicle. Refer to the owner's

manual in the vehicle glove box for more information

on the suggested operation and use of these controls.

The A/C-heater control cannot be repaired. If faulty

or damaged, the entire unit must be replaced. The

control knobs and the illumination lamps are avail-

able for service replacement.

STANDARD PROCEDURE - A/C-HEATER

CONTROL CALIBRATION

The A/C-heater control module must be recali-

brated each time an actuator motor or the control

module is replaced. If the vehicle is so equipped, the

calibration procedure also includes rear HVAC posi-

tions for each actuator motor.

(1) Turn the ignition switch to the On position.

(2) If equipped with the manual temperature con-

trol (MTC) system, press and hold the Rear Wipe/

Wash and Recirculation buttoms for at least five

seconds. If equipped with the automatic temperature

control (ATC) systen, simultaneously press and hold

the Power and Recirculation buttons on the A/C-

heater control for at least five seconds. The MTC

A/C-heater control Rear Wipe/Wash Light Emitting

Diode (LED) and Recirculation LED, or the ATC A/C-

heater control Delay and Recirculation graphics will

begin to flash when the calibration procedure has

begun.

(3) The calibration procedure should take less than

two minutes to complete for the manual A/C-heater

control, and less than twenty seconds for the ATC

A/C-heater control. When the LEDs or graphics stop

flashing, the calibration procedure is complete.

(4) If the LEDs or graphics continue to flash

beyond the two minute (manual) or twenty second

(ATC) calibration time, it indicates that the A/C-

Fig. 8 Integrated Power Module (IPM)

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE (IPM)

3 - FRONT CONTROL MODULE

24 - 20 CONTROLS - FRONTRS

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2416 of 2585

heater control has detected a failure and a Diagnostic

Trouble Code (DTC) has been set. Refer to Body

Diagnostic Procedures to perform further diagnosis.

The LEDs or graphics will continue to flash even

after the ignition switch is cycled Off and On, until a

successful calibration is completed or until the vehi-

cle has been driven about 13 kilometers (8 miles).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(3) Place the instrument panel center bezel unit

face down on a suitable work surface. Take the

proper precautions to protect the center bezel from

cosmetic damage.

(4) If the vehicle is equipped with the optional

Automatic Temperature Control (ATC) system, dis-

connect the infrared sensor jumper harness connector

from the receptacle on the back of the A/C-heater

control (Fig. 9).

(5) Remove the six screws that secure the A/C-

heater control to the back of the instrument panel

center bezel.

(6) Remove the A/C-heater control from the instru-

ment panel center bezel.

INSTALLATION

(1) Position the A/C-heater control onto the back of

instrument panel center bezel.

(2) Install the six screws that secure the A/C-

heater control to the back of the instrument panel

center bezel. Tighten the screws to 2 N´m (17 in.

lbs.).

(3) If the vehicle is equipped with the optional

ATC system, reconnect the infrared sensor jumper

harness connector to A/C-heater control.(4) Install the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(5) Reconnect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION

The A/C pressure transducer is a switch that is

installed on a fitting located on the refrigerant liquid

line between the receiver/drier and the expansion

valve in the right rear corner of the engine compart-

ment. An internally threaded hex fitting on the

transducer connects it to the externally threaded

Schrader-type fitting on the liquid line. A rubber

O-ring seals the connection between the transducer

and the liquid line fitting. Three terminals within a

molded plastic connector receptacle on the top of the

transducer connect it to the vehicle electrical system

through a wire lead and connector of the headlamp

and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the liquid line.

The transducer will change its internal resistance in

response to the pressures it monitors. The power-

train control module (PCM) provides a five volt ref-

Fig. 9 A/C-Heater Control

1 - INFRARED SENSOR CONNECTOR (ATC ONLY)

2 - INFRARED SENSOR HARNESS (ATC ONLY)

3 - A/C-HEATER CONTROL AREA

4 - SCREW (6)

5- INSTRUMENT PANEL CENTER BEZEL

RSCONTROLS - FRONT24-21

A/C HEATER CONTROL (Continued)

Page 2418 of 2585

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a single

blend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver's side end of the

HVAC housing, close to the middle of the distribution

housing. In the dual zone system, the same blend

door actuator used for the single zone system

becomes the passenger blend door actuator, and is

mechanically connected to only the passenger side

blend air door. In the dual zone system, a second sep-

arate blend door actuator is also located on the

driver side end of the HVAC housing, close to the

middle of the distribution housing, and is mechani-

cally connected to only the driver's side blend air

door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the distri-

bution housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module.

OPERATION

Each blend door actuator is connected to the A/C-

heater control through the vehicle electrical system

by a dedicated two-wire lead and connector from the

HVAC wire harness. The blend door actuator can

move the blend-air door in two directions. When the

A/C-heater control pulls the voltage on one side of

the motor connection high and the other connection

low, the blend-air door will move in one direction.

When the A/C-heater control reverses the polarity of

the voltage to the motor, the blend-air door moves in

the opposite direction. When the A/C-heater control

makes the voltage to both connections high or both

connections low, the blend-air door stops and will not

move. The motor connections also provide a feedback

signal to the A/C-heater control. This feedback signal

allows the A/C-heater control to monitor the opera-

tion and relative positions of the blend door actuator

and the blend-air door. The A/C-heater control learnsthe blend door stop positions during the calibration

procedure and will store a diagnostic trouble code

(DTC) for any problems it detects in the blend door

actuator circuits.

The blend door actuator can be diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures for more information. The blend door actuators

cannot be adjusted or repaired and, if damaged or

faulty, they must be replaced.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The single zone heating and air conditioning

system is equipped with a single blend door actua-

tor. The dual zone system has two blend door

actuators, one for the driver side blend air door and

one for the passenger side blend air door. The

same service procedures can be used for each of

these actuators.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the silencer from beneath the driver

side end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

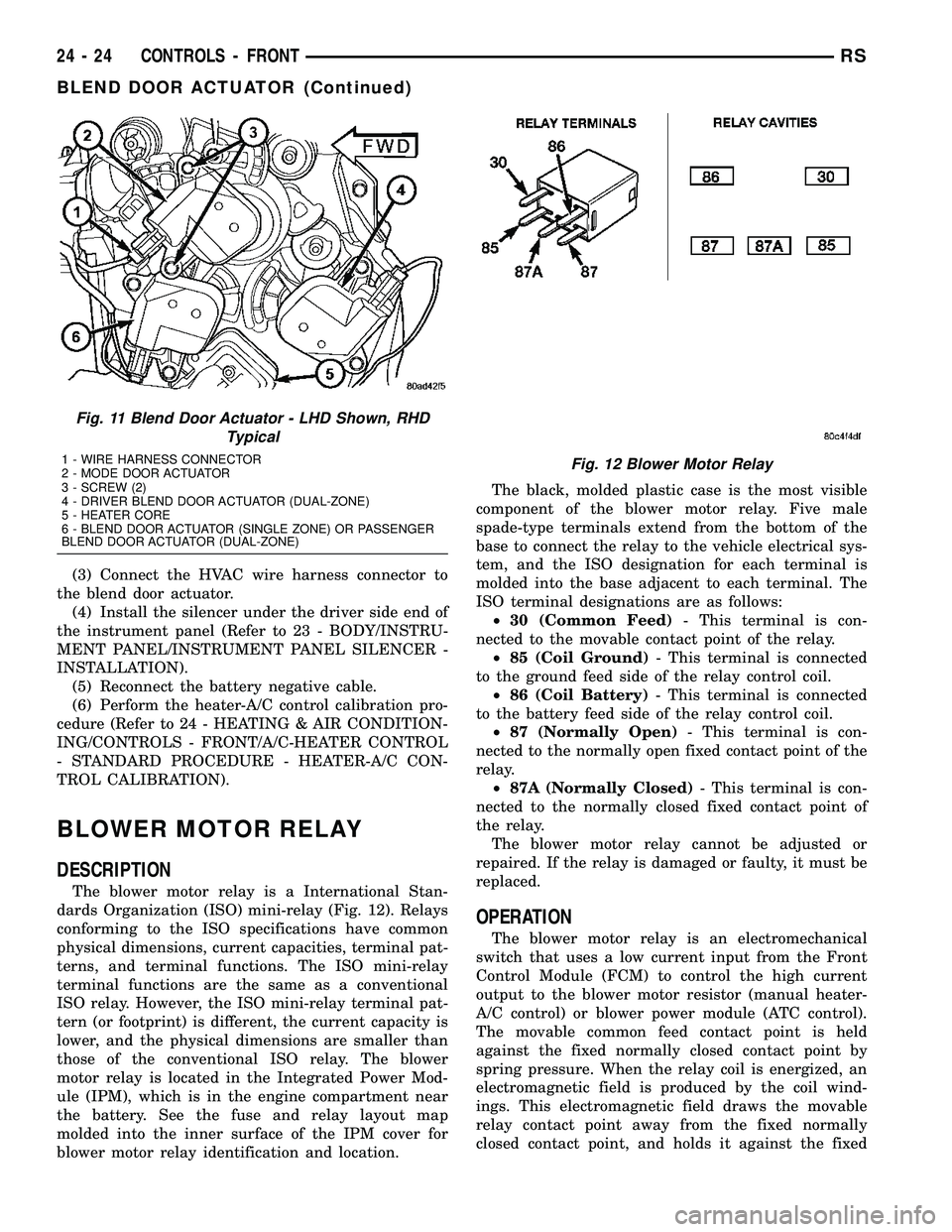

(3) Disconnect the wire harness connector from the

blend door actuator(s) (Fig. 11).

(4) Remove the two screws that secure the blend

door actuator to the distribution housing.

(5) Remove the blend door actuator.

INSTALLATION

(1) Position the blend door actuator onto the distri-

bution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the blend air door linkage.

(2) Install the two screws that secure the blend

door actuator to the housing. Tighten the screws to 2

N´m (17 in. lbs.).

RSCONTROLS - FRONT24-23

Page 2419 of 2585

(3) Connect the HVAC wire harness connector to

the blend door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the battery negative cable.

(6) Perform the heater-A/C control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO) mini-relay (Fig. 12). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Integrated Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

blower motor relay identification and location.The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The blower motor relay cannot be adjusted or

repaired. If the relay is damaged or faulty, it must be

replaced.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (ATC control).

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

Fig. 11 Blend Door Actuator - LHD Shown, RHD

Typical

1 - WIRE HARNESS CONNECTOR

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - DRIVER BLEND DOOR ACTUATOR (DUAL-ZONE)

5 - HEATER CORE

6 - BLEND DOOR ACTUATOR (SINGLE ZONE) OR PASSENGER

BLEND DOOR ACTUATOR (DUAL-ZONE)Fig. 12 Blower Motor Relay

24 - 24 CONTROLS - FRONTRS

BLEND DOOR ACTUATOR (Continued)

Page 2420 of 2585

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Integrated Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Inte-

grated Power Module (IPM) (Fig. 13).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for front blower

motor relay identification and location.(4) Remove the front blower motor relay from the

IPM by pulling the relay straight up.

INSTALLATION

(1) Refer to the fuse and relay layout map on the

inner surface of the integrated power module (IPM)

cover for front blower motor relay identification and

location.

(2) Position the front blower motor relay to the

proper receptacle in the IPM.

(3) Align the front blower motor relay terminals

with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the front blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the negative battery cable.

Fig. 13 Integrated Power Module - Typical

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RSCONTROLS - FRONT24-25

BLOWER MOTOR RELAY (Continued)

Page 2421 of 2585

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

A blower motor resistor is used on this model when

it is equipped with the manual heater-A/C system.

Models equipped with the optional Automatic Tem-

perature Control (ATC) system use a blower power

module, instead of the blower motor resistor block

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS/POWER MODULE - DESCRIPTION).

The blower motor resistor block is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The resistor

block consists of a molded plastic mounting plate

with two integral connector receptacles. Concealed

behind the mounting plate are four coiled resistor

wires contained within a protective stamped steel

cage. The blower motor resistor block is accessed for

service by removing the glove box from the instru-

ment panel.

OPERATION

The blower motor resistor block is connected to the

vehicle electrical system through a dedicated take

out and connector of the instrument panel wire har-

ness. A second connector receptacle receives the pig-

tail wire connector from the blower motor. The

blower motor resistor has multiple resistor wires,

each of which will reduce the current flow through

the blower motor to change the blower motor speed.

The blower motor switch in the manual heater-A/C

system directs the ground path for the blower motor

through the correct resistor wire to obtain the

selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through all of the resistor wires. Each higher speed

selected with the blower motor switch applies the

blower motor ground path through fewer of the resis-

tor wires, increasing the blower motor speed.

The blower motor resistor cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR BLOCK

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

(3) Disconnect the two wire harness connectors

from the blower motor resistor block.

(4) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor, blower motor or blower motor

relay as required. If not OK, replace the faulty

blower motor resistor block.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE BLOWER MOTOR RESISTOR

BLOCK MAY GET VERY HOT DURING NORMAL

OPERATION. IF THE BLOWER MOTOR WAS

TURNED ON PRIOR TO SERVICING THE BLOWER

MOTOR RESISTOR BLOCK, WAIT FIVE MINUTES

TO ALLOW THE BLOWER MOTOR RESISTORS TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

24 - 26 CONTROLS - FRONTRS