suspension CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2292 of 2585

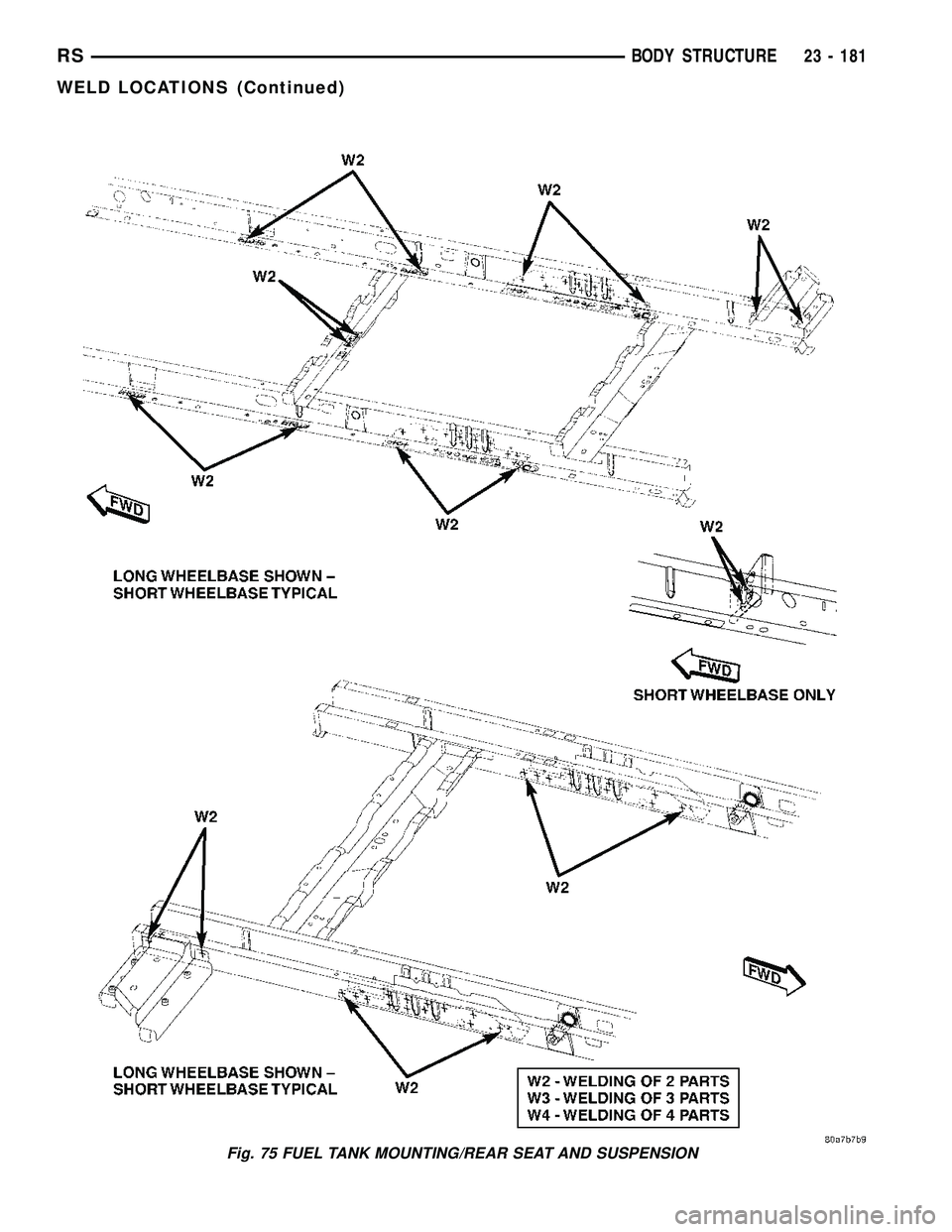

Fig. 75 FUEL TANK MOUNTING/REAR SEAT AND SUSPENSION

RSBODY STRUCTURE23 - 181

WELD LOCATIONS (Continued)

Page 2293 of 2585

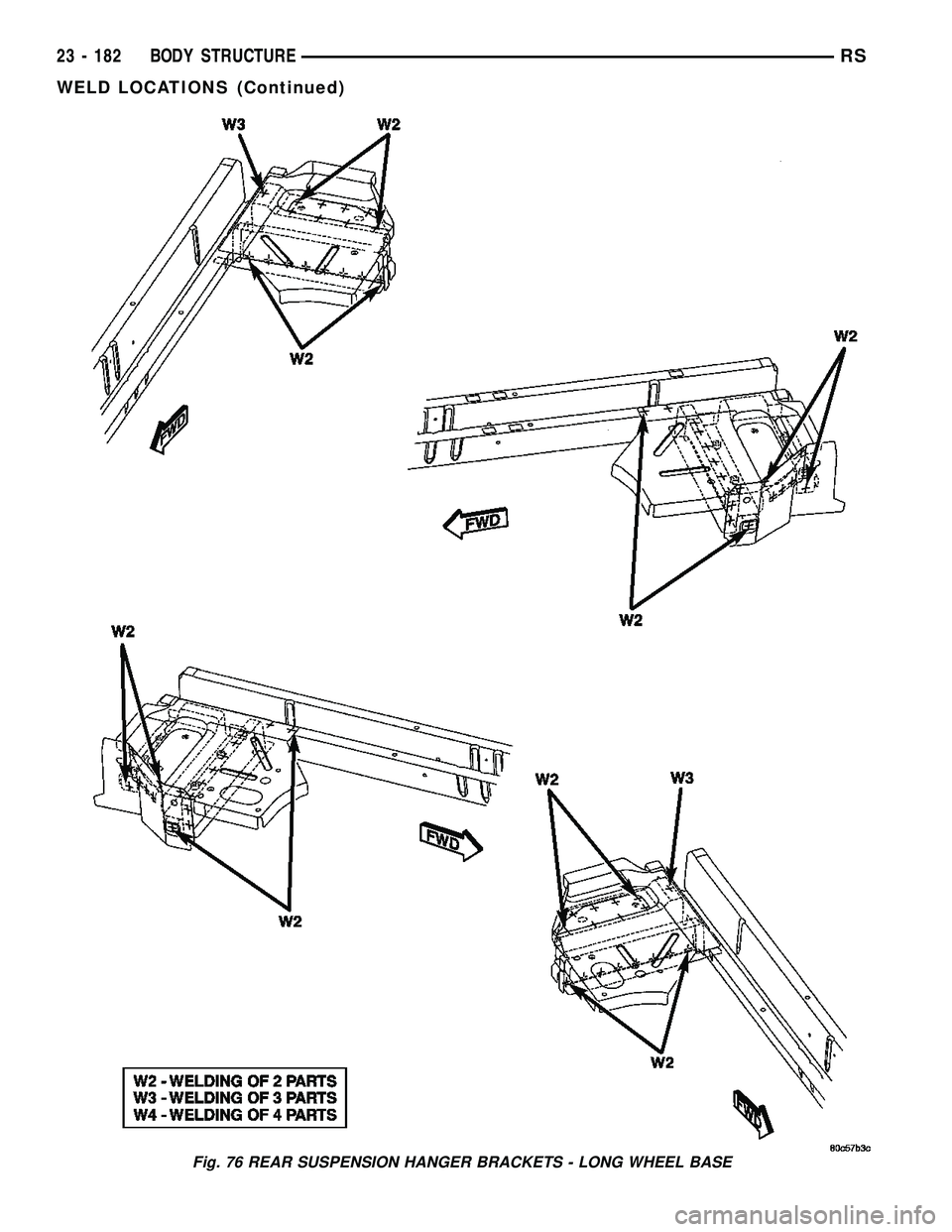

Fig. 76 REAR SUSPENSION HANGER BRACKETS - LONG WHEEL BASE

23 - 182 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2301 of 2585

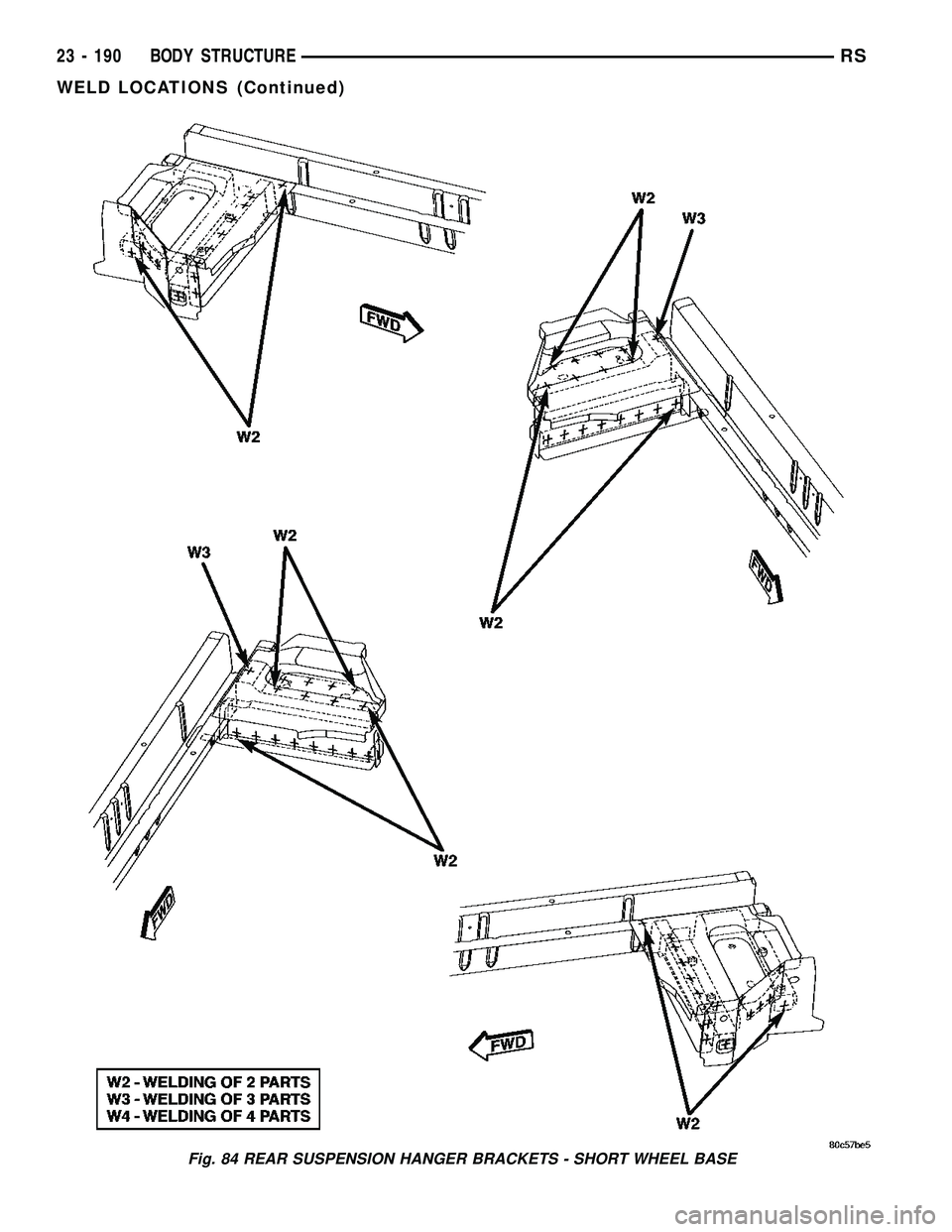

Fig. 84 REAR SUSPENSION HANGER BRACKETS - SHORT WHEEL BASE

23 - 190 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2311 of 2585

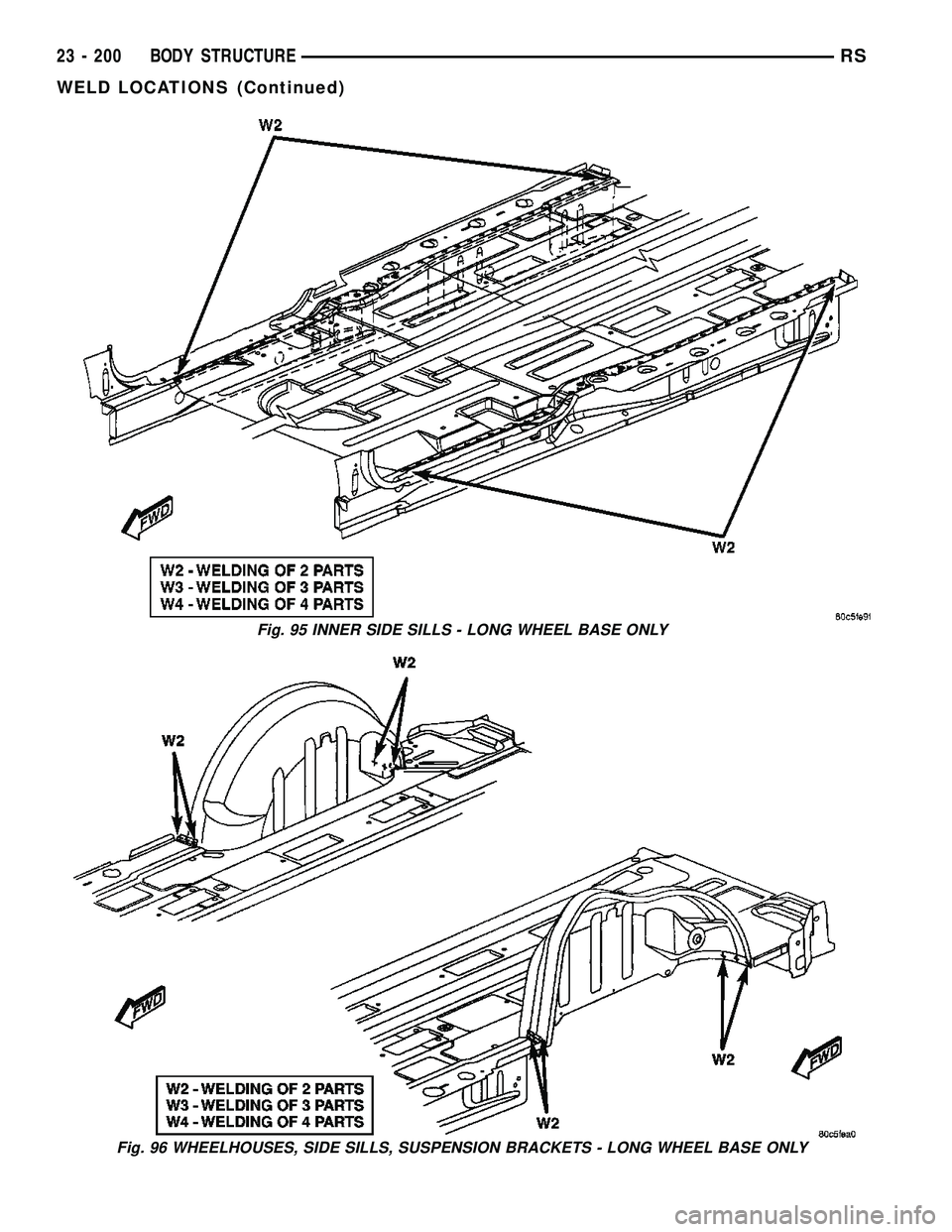

Fig. 95 INNER SIDE SILLS - LONG WHEEL BASE ONLY

Fig. 96 WHEELHOUSES, SIDE SILLS, SUSPENSION BRACKETS - LONG WHEEL BASE ONLY

23 - 200 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2371 of 2585

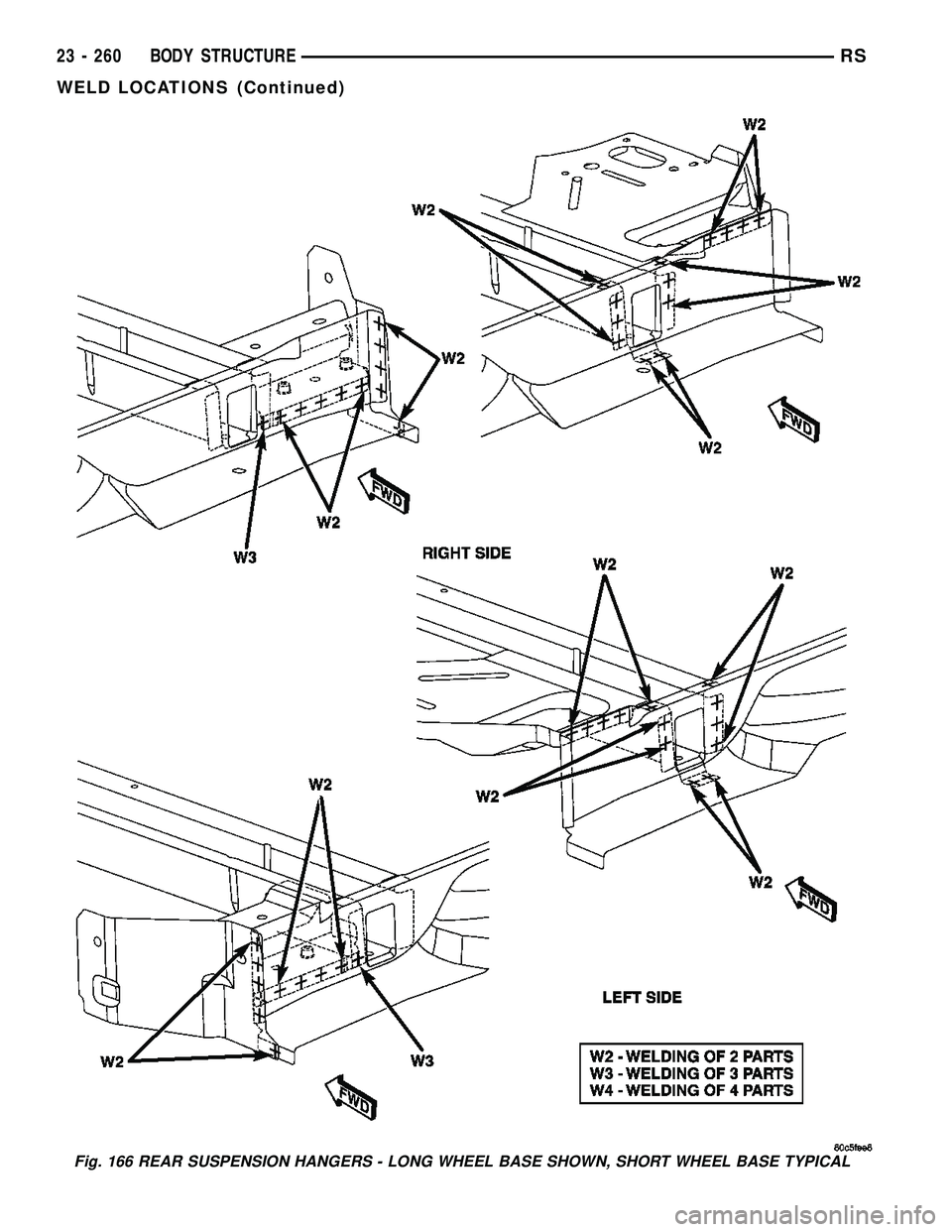

Fig. 166 REAR SUSPENSION HANGERS - LONG WHEEL BASE SHOWN, SHORT WHEEL BASE TYPICAL

23 - 260 BODY STRUCTURERS

WELD LOCATIONS (Continued)

Page 2374 of 2585

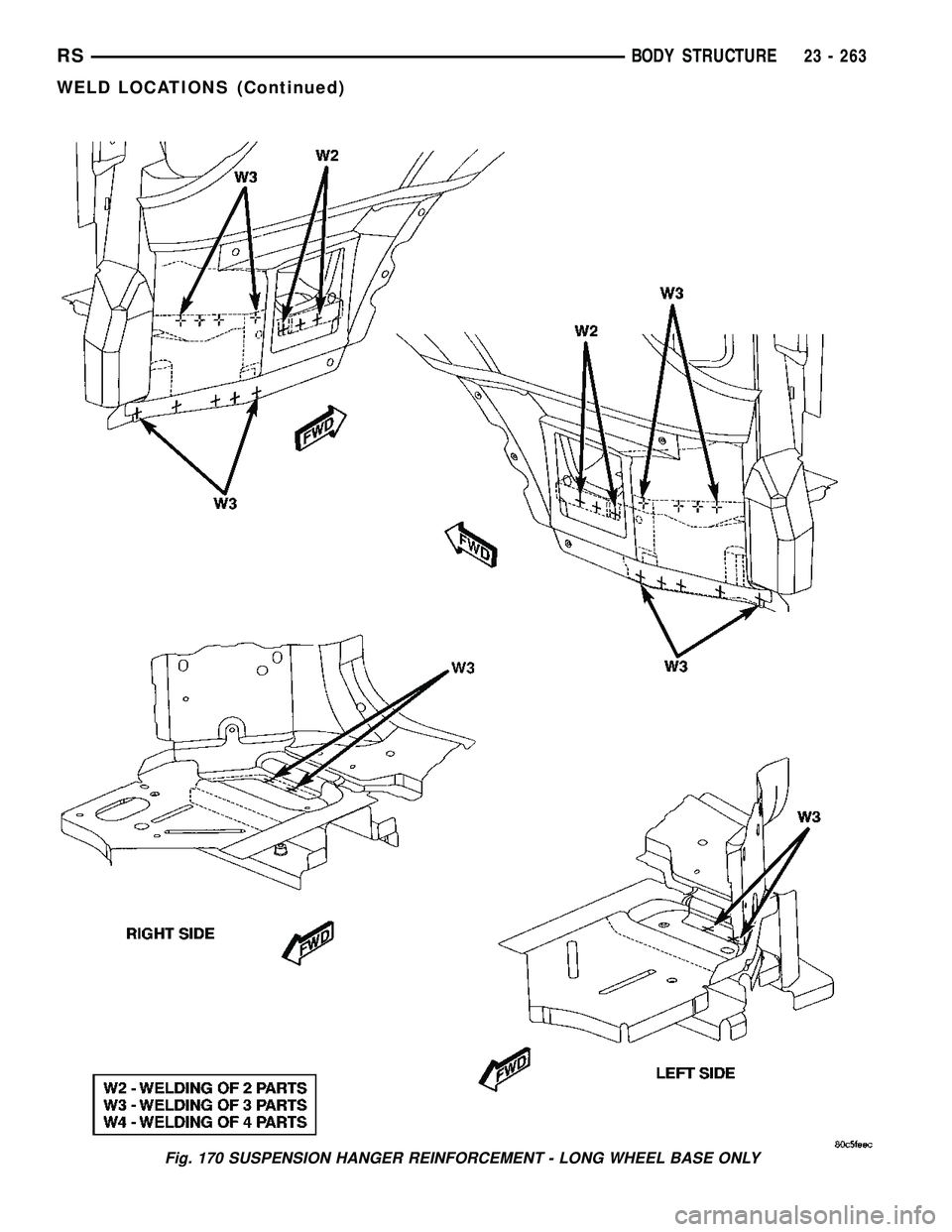

Fig. 170 SUSPENSION HANGER REINFORCEMENT - LONG WHEEL BASE ONLY

RSBODY STRUCTURE23 - 263

WELD LOCATIONS (Continued)

Page 2380 of 2585

Fig. 176 SUSPENSION HANGER REINFORCEMENT - SHORT WHEEL BASE ONLY

RSBODY STRUCTURE23 - 269

WELD LOCATIONS (Continued)

Page 2519 of 2585

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF.

The PCM sends a 5 volt bias to the oxygen sensor

every 1.6 seconds. The PCM keeps it biased for 35

ms each time. As the sensor cools down, the resis-

tance increases and the PCM reads the increase in

voltage. Once voltage has increased to a predeter-

mined amount, higher than when the test started,

the oxygen sensor is cool enough to test heater oper-

ation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 3 minutes

²Engine run time at a predetermined speed

and throttle opening.

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

Pending ConditionsÐThere are not conditions or

situations that prompt conflict or suspension of test-

ing. The oxygen sensor heater test is not run pending

resolution of MIL illumination due to oxygen sensor

failure.

SuspendÐThere are no conditions which exist for

suspending the Heater Monitor.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S strategy is based on the fact that as a cat-alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL (check

engine lamp) will be illuminated.

Monitor OperationÐTo monitor catalyst effi-

ciency, the PCM expands the rich and lean switch

points of the heated oxygen sensor. With extended

switch points, the air/fuel mixture runs richer and

leaner to overburden the catalytic converter. Once

the test is started, the air/fuel mixture runs rich and

lean and the O2 switches are counted. A switch is

counted when an oxygen sensor signal goes from

below the lean threshold to above the rich threshold.

The number of Rear O2 sensor switches is divided by

the number of Front O2 sensor switches to determine

the switching ratio.

The test runs for 20 seconds. As catalyst efficiency

deteriorated over the life of the vehicle, the switch

rate at the downstream sensor approaches that of the

upstream sensor. If at any point during the test

25 - 4 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2556 of 2585

ENGINE OIL LEVEL CHECK, STANDARD

PROCEDURE.........................9-53

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING.......................9-136

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING, CHECKING...............9-52

ENGINE, SPECIAL TOOLS - 2.4L..........9-21

ENGINE, SPECIAL TOOLS - 3.3/3.8L.......9-95

ENGINE, SPECIFICATIONS - 3.3/3.8L . . 9-91,9s-11

ENGINE SPEED SENSOR - DESCRIPTION . . 14-26

ENGINE SPEED SENSOR - OPERATION....14-26

ENGINES - DESCRIPTION, ENGINE OIL -

DIESEL..............................0-6

ENGINES - DIAGNOSIS AND TESTING,

SYSTEM CHARGE LEVEL TEST -

GASOLINE..........................24-67

ENGINES - EXPORT - DESCRIPTION,

DIESEL.............................0-24

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS...................8N-43

ENTRY MODULE - DESCRIPTION,

SENTRY KEY REMOTE.................8Q-3

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS...........8N-43

ENTRY MODULE - DIAGNOSIS AND

TESTING, SENTRY KEY REMOTE.........8Q-5

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS...................8N-44

ENTRY MODULE - INSTALLATION,

SENTRY KEY REMOTE.................8Q-6

ENTRY MODULE - OPERATION, REMOTE

KEYLESS...........................8N-43

ENTRY MODULE - OPERATION, SENTRY

KEY REMOTE........................8Q-4

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS...........................8N-44

ENTRY MODULE - REMOVAL, SENTRY

KEY REMOTE........................8Q-5

ENTRY SYSTEM - DIAGNOSIS AND

TESTING, SENTRY KEY REMOTE.........8Q-3

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, KEYLESS..............8N-42,8N-5

ENTRY TRANSMITTER PROGRAMMING -

STANDARD PROCEDURE, REMOTE

KEYLESS............................8N-5

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-70

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE..............8M-11

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-72

EVAP CANISTER - INSTALLATION, REAR . . 25-20

EVAP CANISTER - REMOVAL, REAR......25-19

EVAPORATION CONTROL SYSTEM -

OPERATION.........................25-10

EVAPORATOR - DESCRIPTION, A/C . 24-80,24-97

EVAPORATOR - INSTALLATION, A/C......24-80

EVAPORATOR - INSTALLATION, REAR

A/C................................24-99

EVAPORATOR - OPERATION, A/C . . . 24-80,24-97

EVAPORATOR - REMOVAL, A/C..........24-80

EVAPORATOR - REMOVAL, REAR A/C.....24-97

EVAPORATOR LINE EXTENSION -

INSTALLATION, REAR A/C..............24-99

EVAPORATOR LINE EXTENSION -

REMOVAL, A/C......................24-98

EVAPORATOR TEMPERATURE SENSOR -

DESCRIPTION.......................24-27

EVAPORATOR TEMPERATURE SENSOR -

OPERATION.........................24-28

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-12

EVAP/PURGE SOLENOID - INSTALLATION . 25-12

EVAP/PURGE SOLENOID - OPERATION....25-12

EVAP/PURGE SOLENOID - REMOVAL.....25-12

EXCESSIVE EXHAUST SYSTEM NOISE -

DIAGNOSIS AND TESTING..............11-2

EXHAUST MANIFOLD - CLEANING........9-61

EXHAUST MANIFOLD - INSPECTION.......9-61

EXHAUST MANIFOLD - INSTALLATION.....9-61

EXHAUST MANIFOLD - LEFT - CLEANING . . 9-152

EXHAUST MANIFOLD - LEFT -

INSPECTION

........................9-152

EXHAUST MANIFOLD - LEFT -

INSTALLATION

.......................9-152

EXHAUST MANIFOLD - LEFT - REMOVAL

. . 9-152

EXHAUST MANIFOLD - REMOVAL

.........9-61

EXHAUST MANIFOLD - RIGHT -

CLEANING

..........................9-151EXHAUST MANIFOLD - RIGHT -

INSPECTION........................9-151

EXHAUST MANIFOLD - RIGHT -

INSTALLATION.......................9-151

EXHAUST MANIFOLD - RIGHT -

REMOVAL..........................9-150

EXHAUST SYSTEM - DESCRIPTION.......11-1

EXHAUST SYSTEM NOISE - DIAGNOSIS

AND TESTING, EXCESSIVE..............11-2

EXHAUST SYSTEM RESTRICTION CHECK

- DIAGNOSIS AND TESTING.............11-2

EXHAUST SYSTEM, SPECIAL TOOLS......11-4

EXHAUST TUBE - INSTALLATION.......24-115

EXHAUST TUBE - REMOVAL...........24-114

EXHAUSTER - DESCRIPTION, REAR

QUARTER PANEL/FENDER AIR..........23-57

EXHAUSTER - INSTALLATION, REAR

QUARTER PANEL/FENDER AIR..........23-58

EXHAUSTER - REMOVAL, REAR

QUARTER PANEL/FENDER AIR..........23-57

EXPANSION VALVE - DESCRIPTION......24-81

EXPANSION VALVE - DESCRIPTION, A/C . . 24-99

EXPANSION VALVE - DIAGNOSIS AND

TESTING..........................24-100

EXPANSION VALVE - DIAGNOSIS AND

TESTING, A/C.......................24-81

EXPANSION VALVE - INSTALLATION......24-82

EXPANSION VALVE - INSTALLATION, A/C . 24-100

EXPANSION VALVE - OPERATION........24-81

EXPANSION VALVE - OPERATION, A/C....24-99

EXPANSION VALVE - REMOVAL.........24-82

EXPANSION VALVE - REMOVAL, A/C.....24-100

EXPORT - BRAKE ROTOR..........5-55,5s-58

EXPORT - DESCRIPTION...........5-58,5s-60

EXPORT - DESCRIPTION................0-15

EXPORT - DESCRIPTION................2-10

EXPORT - DESCRIPTION, ANTENNA

MODULE............................8A-6

EXPORT - DESCRIPTION, DIESEL

ENGINES............................0-24

EXPORT - DESCRIPTION, DOOR

CYLINDER LOCK SWITCH...............8N-3

EXPORT - DESCRIPTION, POWER

FOLDAWAY MIRROR SWITCH..........8N-48

EXPORT - DESCRIPTION, QUARTER

GLASS INTEGRAL ANTENNA.............8A-9

EXPORT - DIAGNOSIS AND TESTING,

ANTENNA MODULE....................8A-7

EXPORT - DIAGNOSIS AND TESTING,

DOOR CYLINDER LOCK SWITCH.........8N-3

EXPORT - DIAGNOSIS AND TESTING,

QUARTER GLASS INTEGRAL ANTENNA....8A-9

EXPORT - INSTALLATION...............2-11

EXPORT - INSTALLATION, ANTENNA

MODULE............................8A-7

EXPORT - INSTALLATION, DOOR

CYLINDER LOCK SWITCH...............8N-4

EXPORT - INSTALLATION, HEADLAMP

UNIT..............................8L-17

EXPORT - INSTALLATION, HOOD AJAR

SWITCH............................8Q-3

EXPORT - INSTALLATION, POWER

FOLDAWAY MIRROR SWITCH..........8N-49

EXPORT - OPERATION, ANTENNA

MODULE............................8A-6

EXPORT - OPERATION, DOOR CYLINDER

LOCK SWITCH........................8N-3

EXPORT - OPERATION, POWER

FOLDAWAY MIRROR SWITCH..........8N-48

EXPORT - OPERATION, QUARTER GLASS

INTEGRAL ANTENNA...................8A-9

EXPORT - REMOVAL...................2-11

EXPORT - REMOVAL, ANTENNA MODULE . . 8A-7

EXPORT - REMOVAL, DOOR CYLINDER

LOCK SWITCH........................8N-3

EXPORT - REMOVAL, HEADLAMP UNIT . . . 8L-17

EXPORT - REMOVAL, HOOD AJAR

SWITCH............................8Q-3

EXPORT - REMOVAL, POWER

FOLDAWAY MIRROR SWITCH

..........8N-48

EXPORT - STANDARD PROCEDURE,

FRONT FOG LAMP UNIT ALIGNMENT

......8L-9

EXPORT - STANDARD PROCEDURE,

HEADLAMP UNIT ALIGNMENT

..........8L-14

EXTENSION - INSTALLATION, REAR A/C

EVAPORATOR LINE

...................24-99

EXTENSION - REMOVAL, A/C

EVAPORATOR LINE

...................24-98EXTENSION TRIM - INSTALLATION,

A-PILLAR LOWER....................23-74

EXTENSION TRIM - REMOVAL, A-PILLAR

LOWER............................23-74

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - WARNING, LAMPS/

LIGHTING...........................8L-3

EXTERIOR HANDLE - INSTALLATION.....23-22,

23-40

EXTERIOR HANDLE - REMOVAL....23-21,23-40

EXTERIOR HANDLE SWITCH -

DESCRIPTION.......................8N-11

EXTERIOR HANDLE SWITCH -

INSTALLATION......................8N-12

EXTERIOR HANDLE SWITCH -

OPERATION.........................8N-11

EXTERIOR HANDLE SWITCH - REMOVAL . . 8N-11

EXTERIOR LAMPS, SPECIFICATIONS......8L-3

EXTERIOR NAME PLATES - ADHESIVE

ATTACHED - INSTALLATION............23-51

EXTERIOR NAME PLATES - ADHESIVE

ATTACHED - REMOVAL................23-51

EXTERIOR NAME PLATES - TAPE

ATTACHED - INSTALLATION............23-51

EXTERIOR NAME PLATES - TAPE

ATTACHED - REMOVAL................23-51

FACTOR SETTING - STANDARD

PROCEDURE, PINION............8E-15,8E-23

FAILED PARK SWITCH - DIAGNOSIS AND

TESTING..............................8R-2

FAN - DESCRIPTION, RADIATOR..........7-28

FAN - INSTALLATION, RADIATOR.........7-30

FAN - OPERATION, RADIATOR...........7-29

FAN - REMOVAL, RADIATOR.............7-30

FAN MOTOR - DIAGNOSIS AND

TESTING, RADIATOR...................7-29

FAN RELAY - DESCRIPTION, RADIATOR....7-30

FAN RELAY - INSTALLATION, RADIATOR . . . 7-30

FAN RELAY - OPERATION, RADIATOR......7-30

FAN RELAY - REMOVAL, RADIATOR.......7-30

FASCIA - INSTALLATION, FRONT.........13-1

FASCIA - INSTALLATION, REAR..........13-2

FASCIA - REMOVAL, FRONT.............13-1

FASCIA - REMOVAL, REAR..............13-2

FASCIA - SCUFF PAD - INSTALLATION,

REAR...............................13-4

FASCIA - SCUFF PAD - REMOVAL, REAR . . . 13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-2

FASTENER TORQUE, SPECIFICATIONS -

ABS ................................5-79

FASTENER TORQUE, SPECIFICATIONS -

BRAKE...........................5-9,5s-8

FASTENER TORQUE, SPECIFICATIONS -

FRONT SUSPENSION...................2-3

FASTENER TORQUE, SPECIFICATIONS -

POWER STEERING....................19-9

FASTENER TORQUE, SPECIFICATIONS -

REAR SUSPENSION...................2-28

FASTENER USAGE - DESCRIPTION......Intro.-5

FEED CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING.........8F-32,8F-34

FEED CIRCUIT TEST - DIAGNOSIS AND

TESTING

......................8F-33,8F-35

FENDER - INSTALLATION, FRONT

........23-52

FENDER - REMOVAL, FRONT

...........23-52

FILL - DIAGNOSIS AND TESTING,

VEHICLE DOES NOT

..................25-16

FILL - STANDARD PROCEDURE, FLUID

DRAIN

.............................21-71

FILL DOOR - INSTALLATION, FUEL

.......23-52

FILL DOOR - REMOVAL, FUEL

..........23-52

FILL DOOR BLOCKER LATCH -

INSTALLATION, FUEL

.................23-53

FILL DOOR BLOCKER LATCH -

REMOVAL, FUEL

.....................23-53

FILL DOOR BLOCKER LATCH STRIKER -

INSTALLATION, FUEL

.................23-53

FILL DOOR BLOCKER LATCH STRIKER -

REMOVAL, FUEL

.....................23-53

FILL DOOR BLOCKER LOCKOUT LINK -

INSTALLATION, FUEL

.................23-54

FILL DOOR BLOCKER LOCKOUT LINK -

REMOVAL, FUEL

.....................23-53

RSINDEX13

Description Group-Page Description Group-Page Description Group-Page

Page 2558 of 2585

FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES) -

INSTALLATION.......................5s-15

FRONT DISC BRAKE SHOES

(CONTINENTAL TEVES BRAKES) -

REMOVAL..........................5s-14

FRONT DISC BRAKE SHOES (DISC/DISC

BRAKES) - INSTALLATION...............5-16

FRONT DISC BRAKE SHOES (DISC/DISC

BRAKES) - REMOVAL..................5-14

FRONT DISC BRAKE SHOES (DISC/

DRUM BRAKES) - INSTALLATION.........5-17

FRONT DISC BRAKE SHOES (DISC/

DRUM BRAKES) - REMOVAL............5-15

FRONT DISC BRAKE SHOES (TRW

BRAKES) - INSTALLATION..............5s-16

FRONT DISC BRAKE SHOES (TRW

BRAKES) - REMOVAL.................5s-14

FRONT DOOR GLASS RUN

WEATHERSTRIP - INSTALLATION.......23-113

FRONT DOOR GLASS RUN

WEATHERSTRIP - REMOVAL...........23-113

FRONT DOOR INNER BELT MOLDING -

INSTALLATION......................23-115

FRONT DOOR INNER BELT MOLDING -

REMOVAL.........................23-115

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION......................23-113

FRONT DOOR OUTER BELT MOLDING -

REMOVAL.........................23-113

FRONT DOOR WEATHERSTRIP -

INSTALLATION......................23-114

FRONT DOOR WEATHERSTRIP -

REMOVAL.........................23-114

FRONT FASCIA - INSTALLATION..........13-1

FRONT FASCIA - REMOVAL..............13-1

FRONT FENDER - INSTALLATION........23-52

FRONT FENDER - REMOVAL............23-52

FRONT FOG LAMP - DIAGNOSIS AND

TESTING............................8L-7

FRONT FOG LAMP - INSTALLATION.......8L-8

FRONT FOG LAMP - REMOVAL...........8L-8

FRONT FOG LAMP UNIT ALIGNMENT -

EXPORT - STANDARD PROCEDURE.......8L-9

FRONT FOG LAMP UNIT ALIGNMENT -

STANDARD PROCEDURE................8L-9

FRONT INBOARD - INSTALLATION, SEAT

BELT BUCKLE.......................8O-12

FRONT INBOARD - REMOVAL, SEAT

BELT BUCKLE.......................8O-12

FRONT MOUNT - INSTALLATION....9-131,9-49

FRONT MOUNT - REMOVAL........9-131,9-49

FRONT SEAT - INSTALLATION...........23-91

FRONT SEAT - REMOVAL..............23-91

FRONT SEAT BACK - INSTALLATION......23-92

FRONT SEAT BACK - REMOVAL.........23-92

FRONT SEAT CUSHION SIDE COVER -

INSTALLATION.......................23-94

FRONT SEAT CUSHION SIDE COVER -

REMOVAL..........................23-94

FRONT SEAT RISER - MANUAL TRACK -

INSTALLATION.......................23-95

FRONT SEAT RISER - MANUAL TRACK -

REMOVAL..........................23-94

FRONT SEAT TRACK - REAR COVER -

INSTALLATION.......................23-96

FRONT SEAT TRACK - REAR COVER -

REMOVAL..........................23-96

FRONT SEAT TRACK MANUAL

ADJUSTER - INSTALLATION............23-95

FRONT SEAT TRACK MANUAL

ADJUSTER - REMOVAL................23-95

FRONT SEAT TRACK POWER ADJUSTER

- INSTALLATION.....................23-95

FRONT SEAT TRACK POWER ADJUSTER

- REMOVAL.........................23-95

FRONT SEATBACK ASSIST STRAP -

INSTALLATION.......................23-92

FRONT SEATBACK ASSIST STRAP -

REMOVAL..........................23-92

FRONT SEATBACK COVER -

INSTALLATION.......................23-93

FRONT SEATBACK COVER - REMOVAL

....23-93

FRONT SEATBACK PANEL -

INSTALLATION

.......................23-93

FRONT SEATBACK PANEL - REMOVAL

....23-92

FRONT SUSPENSION - DESCRIPTION

......2-2

FRONT SUSPENSION - OPERATION

........2-2FRONT SUSPENSION FASTENER

TORQUE, SPECIFICATIONS...............2-3

FRONT SUSPENSION, SPECIAL TOOLS.....2-3

FRONT WASHER PUMP MOTOR -

INSTALLATION.......................8R-8

FRONT WASHER PUMP MOTOR -

REMOVAL...........................8R-8

FRONT WHEEL SPEED SENSOR -

INSTALLATION........................5-80

FRONT WHEEL SPEED SENSOR -

REMOVAL...........................5-79

FRONT WHEELHOUSE SPLASH SHIELD -

INSTALLATION.......................23-55

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL..........................23-55

FRONT WIPER ARM ALIGNMENT -

STANDARD PROCEDURE...............8R-8

FRONT WIPER ARMS - INSTALLATION....8R-9

FRONT WIPER ARMS - REMOVAL........8R-9

FRONT WIPER MOTOR - INSTALLATION . . . 8R-9

FRONT WIPER MOTOR - REMOVAL.......8R-9

FRONT WIPER SYSTEM - DIAGNOSIS

AND TESTING........................8R-2

FRONT WIPER/WASHER SWITCH -

DIAGNOSIS AND TESTING..............8R-2

FRONT/QUAD SEAT CUSHION -

INSTALLATION.......................23-93

FRONT/QUAD SEAT CUSHION -

REMOVAL..........................23-93

FRONT-WHEEL-DRIVE - INSTALLATION....2-36

FRONT-WHEEL-DRIVE - REMOVAL........2-36

FUEL CORRECTION OR ADAPTIVE

MEMORIES, OPERATION...............14-20

FUEL DELIVERY - DESCRIPTION..........14-2

FUEL DELIVERY - OPERATION...........14-2

FUEL DELIVERY SYSTEM - DIAGNOSIS

AND TESTING........................14-2

FUEL DOSING PUMP - DESCRIPTION....24-115

FUEL DOSING PUMP - INSTALLATION . . . 24-116

FUEL DOSING PUMP - OPERATION.....24-115

FUEL DOSING PUMP - REMOVAL.......24-115

FUEL ENGINE OIL - DESCRIPTION,

FLEXIBLE.............................0-3

FUEL FILL DOOR - INSTALLATION.......23-52

FUEL FILL DOOR - REMOVAL...........23-52

FUEL FILL DOOR BLOCKER LATCH -

INSTALLATION.......................23-53

FUEL FILL DOOR BLOCKER LATCH -

REMOVAL..........................23-53

FUEL FILL DOOR BLOCKER LATCH

STRIKER - INSTALLATION..............23-53

FUEL FILL DOOR BLOCKER LATCH

STRIKER - REMOVAL.................23-53

FUEL FILL DOOR BLOCKER LOCKOUT

LINK - INSTALLATION.................23-54

FUEL FILL DOOR BLOCKER LOCKOUT

LINK - REMOVAL.....................23-53

FUEL FILLER CAP - DESCRIPTION.......25-12

FUEL FILLER CAP - OPERATION.........25-12

FUEL INJECTOR - DESCRIPTION.........14-26

FUEL INJECTOR - OPERATION..........14-26

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION..........................14-5

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-5

FUEL LINE - INSTALLATION...........24-118

FUEL LINE - REMOVAL...............24-117

FUEL LINES/HOSES AND CLAMPS -

DESCRIPTION........................14-6

FUEL PRESSURE REGULATOR -

INSTALLATION........................14-7

FUEL PRESSURE REGULATOR -

OPERATION..........................14-7

FUEL PRESSURE REGULATOR -

REMOVAL...........................14-7

FUEL PUMP - DESCRIPTION.............14-8

FUEL PUMP - OPERATION..............14-8

FUEL PUMP MODULE - DESCRIPTION.....14-8

FUEL PUMP MODULE - INSTALLATION....14-9

FUEL PUMP MODULE - OPERATION

.......14-8

FUEL PUMP MODULE - REMOVAL

........14-8

FUEL PUMP RELAY - DESCRIPTION

......14-28

FUEL PUMP RELAY - OPERATION

........14-28

FUEL REQUIREMENTS - DESCRIPTION

......0-4FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-6

FUEL, SPECIAL TOOLS............14-23,14-4

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE - STANDARD

PROCEDURE.........................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL TANK - DESCRIPTION............14-10

FUEL TANK - INSTALLATION............14-12

FUEL TANK - OPERATION..............14-11

FUEL TANK - REMOVAL...............14-11

FUEL TANK - STANDARD PROCEDURE,

DRAINING...........................14-2

FUEL TANK FILLER TUBE -

INSTALLATION.......................14-13

FUEL TANK FILLER TUBE - REMOVAL....14-12

FULL OPEN SWITCH - DESCRIPTION....8N-12,

8N-31

FULL OPEN SWITCH - INSTALLATION....8N-13

FULL OPEN SWITCH - OPERATION . 8N-12,8N-31

FULL OPEN SWITCH - REMOVAL........8N-13

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD...........8W-97-3

FUSE - OPERATION, IOD.............8W-97-3

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON......8W-01-10

FWD - INSTALLATION..................2-45

FWD - INSTALLATION, REAR WHEEL

SPEED SENSOR.......................5-81

FWD - INSTALLATION, SPRING...........2-42

FWD - REMOVAL......................2-45

FWD - REMOVAL, REAR WHEEL SPEED

SENSOR............................5-81

FWD - REMOVAL, SPRING..............2-41

GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE AND OIL . 9-10,9-86

GAP AND FLUSH MEASUREMENTS -

SPECIFICATIONS....................23-124

GAP, SPECIFICATIONS - WHEEL SPEED

SENSOR AIR.........................5-79

GAS - INSTALLATION, MODULAR

CLUTCH ASSY - 2.4L..................6-11

GAS - REMOVAL, MODULAR CLUTCH

ASSY - 2.4L..........................6-11

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD.............9-24,9-99,9s-16

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE....9-11,9-85

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE.......9-11,9-84

GASOLINE ENGINES - DIAGNOSIS AND

TESTING, SYSTEM CHARGE LEVEL

TEST..............................24-67

GEAR - DESCRIPTION.................19-26

GEAR - INSTALLATION, LHD............19-32

GEAR - INSTALLATION, RHD............19-33

GEAR & LINK ROD - DESCRIPTION, LIFT . 8N-16

GEAR & LINK ROD - INSTALLATION,

LIFT...............................8N-16

GEAR & LINK ROD - OPERATION, LIFT . . . 8N-16

GEAR & LINK ROD - REMOVAL, LIFT.....8N-16

GEAR - OPERATION...................19-27

GEAR - REMOVAL, LHD...............19-27

GEAR - REMOVAL, RHD...............19-31

GEAR END PLAY - ADJUSTMENT,

DIFFERENTIAL SIDE..................21-70

GEAR SHIFT CABLE - INSTALLATION....21-205

GEAR SHIFT CABLE - REMOVAL . 21-204,21s-105

GEAR SHIFT LEVER - INSTALLATION.....19-21

GEAR SHIFT LEVER - REMOVAL.........19-21

GEAR, SPECIAL TOOLS - POWER

STEERING..........................19-34

GEARSHIFT BOOT - INSTALLATION......21-73

GEARSHIFT BOOT - REMOVAL..........21-72

GEARSHIFT CABLE - CROSSOVER -

INSTALLATION.......................21-76

GEARSHIFT CABLE - CROSSOVER -

REMOVAL..........................21-73

GEARSHIFT CABLE - SELECTOR -

INSTALLATION

.......................21-84

GEARSHIFT CABLE - SELECTOR -

REMOVAL

..........................21-81

GEARSHIFT CABLE ADJUSTMENT,

ADJUSTMENTS

.....................21-206

GEARSHIFT KNOB - INSTALLATION

......21-87

GEARSHIFT KNOB - REMOVAL

..........21-87

RSINDEX15

Description Group-Page Description Group-Page Description Group-Page