clutch CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1847 of 2585

VALVE BODY

DESCRIPTION

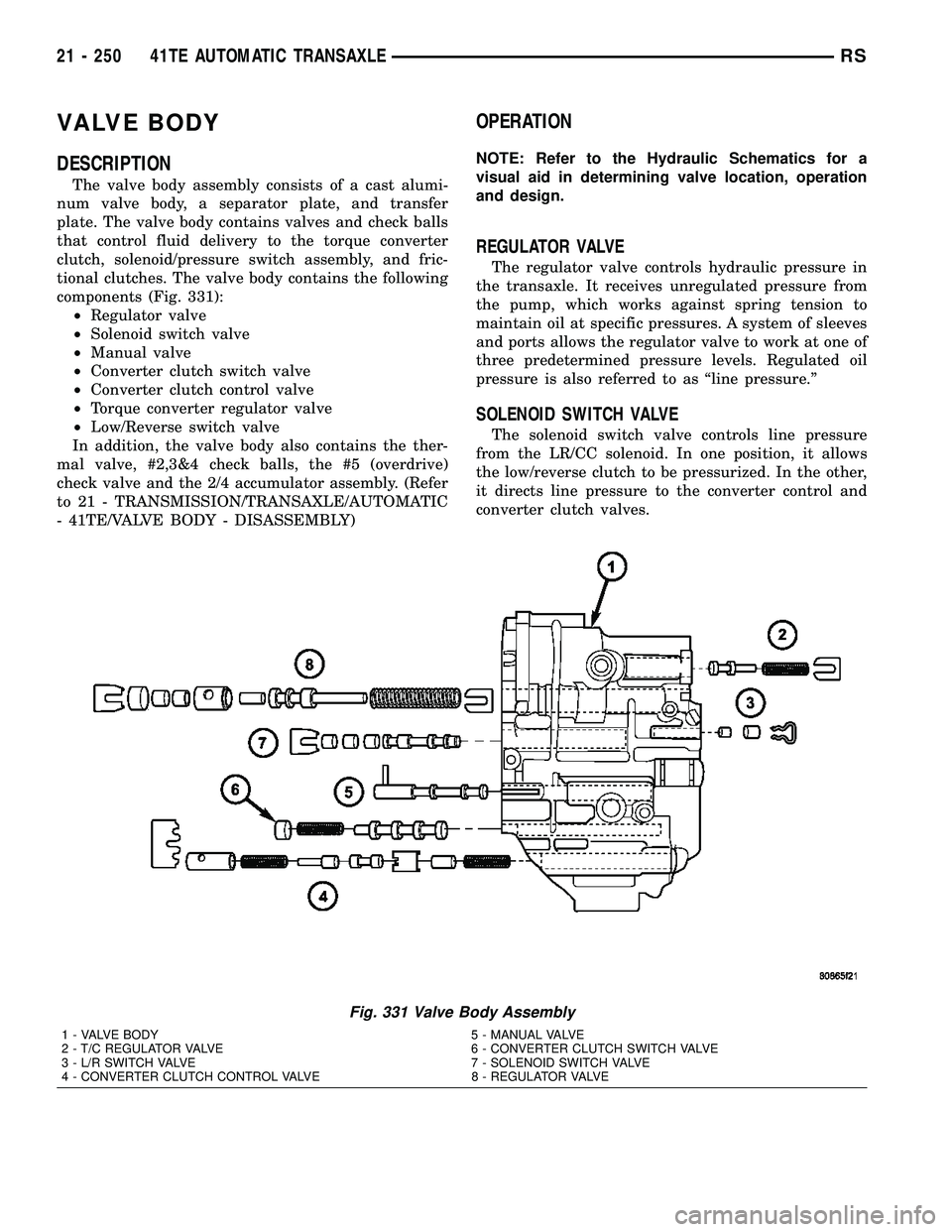

The valve body assembly consists of a cast alumi-

num valve body, a separator plate, and transfer

plate. The valve body contains valves and check balls

that control fluid delivery to the torque converter

clutch, solenoid/pressure switch assembly, and fric-

tional clutches. The valve body contains the following

components (Fig. 331):

²Regulator valve

²Solenoid switch valve

²Manual valve

²Converter clutch switch valve

²Converter clutch control valve

²Torque converter regulator valve

²Low/Reverse switch valve

In addition, the valve body also contains the ther-

mal valve, #2,3&4 check balls, the #5 (overdrive)

check valve and the 2/4 accumulator assembly. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/VALVE BODY - DISASSEMBLY)

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

REGULATOR VALVE

The regulator valve controls hydraulic pressure in

the transaxle. It receives unregulated pressure from

the pump, which works against spring tension to

maintain oil at specific pressures. A system of sleeves

and ports allows the regulator valve to work at one of

three predetermined pressure levels. Regulated oil

pressure is also referred to as ªline pressure.º

SOLENOID SWITCH VALVE

The solenoid switch valve controls line pressure

from the LR/CC solenoid. In one position, it allows

the low/reverse clutch to be pressurized. In the other,

it directs line pressure to the converter control and

converter clutch valves.

Fig. 331 Valve Body Assembly

1 - VALVE BODY 5 - MANUAL VALVE

2 - T/C REGULATOR VALVE 6 - CONVERTER CLUTCH SWITCH VALVE

3 - L/R SWITCH VALVE 7 - SOLENOID SWITCH VALVE

4 - CONVERTER CLUTCH CONTROL VALVE 8 - REGULATOR VALVE

21 - 250 41TE AUTOMATIC TRANSAXLERS

Page 1848 of 2585

MANUAL VALVE

The manual valve is operated by the mechanical

shift linkage. Its primary responsibility is to send

line pressure to the appropriate hydraulic circuits

and solenoids. The valve has three operating ranges

or positions.

CONVERTER CLUTCH SWITCH VALVE

The main responsibility of the converter clutch

switch valve is to control hydraulic pressure applied

to the front (off) side of the converter clutch piston.

Line pressure from the regulator valve is fed to the

torque converter regulator valve, where it passes

through the valve, and is slightly regulated. The

pressure is then directed to the converter clutch

switch valve and to the front side of the converter

clutch piston. This pressure pushes the piston back

and disengages the converter clutch.

CONVERTER CLUTCH CONTROL VALVE

The converter clutch control valve controls the

back (on) side of the torque converter clutch. When

the PCM/TCM energizes or modulates the LR/CC

solenoid to apply the converter clutch piston, both

the converter clutch control valve and the converter

control valve move, allowing pressure to be applied to

the back side of the clutch.

T/C REGULATOR VALVE

The torque converter regulator valve slightly regu-

lates the flow of fluid to the torque converter.

LOW/REVERSE SWITCH VALVE

The low/reverse clutch is applied from different

sources, depending on whether low (1st) gear or

reverse is selected. The low/reverse switch valve

alternates positions depending on from which direc-

tion fluid pressure is applied. By design, when the

valve is shifted by fluid pressure from one channel,

the opposing channel is blocked. The switch valve

alienates the possibility of a sticking ball check, thus

providing consistent application of the low/reverse

clutch under all operating conditions.

REMOVAL

NOTE: If valve body is replaced or reconditioned,

the TCM Quick Learn Procedure must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

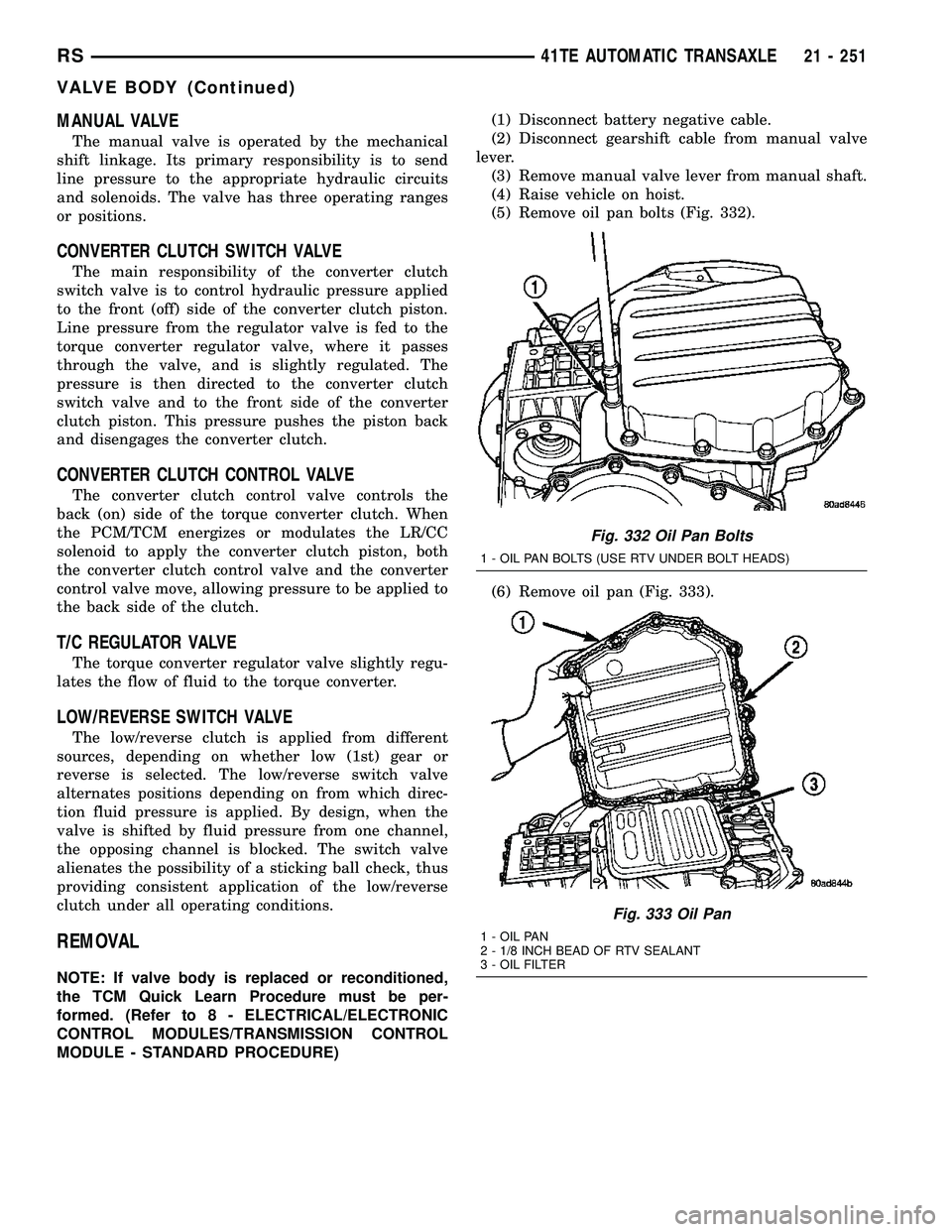

MODULE - STANDARD PROCEDURE)(1) Disconnect battery negative cable.

(2) Disconnect gearshift cable from manual valve

lever.

(3) Remove manual valve lever from manual shaft.

(4) Raise vehicle on hoist.

(5) Remove oil pan bolts (Fig. 332).

(6) Remove oil pan (Fig. 333).

Fig. 332 Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 333 Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

RS41TE AUTOMATIC TRANSAXLE21 - 251

VALVE BODY (Continued)

Page 1852 of 2585

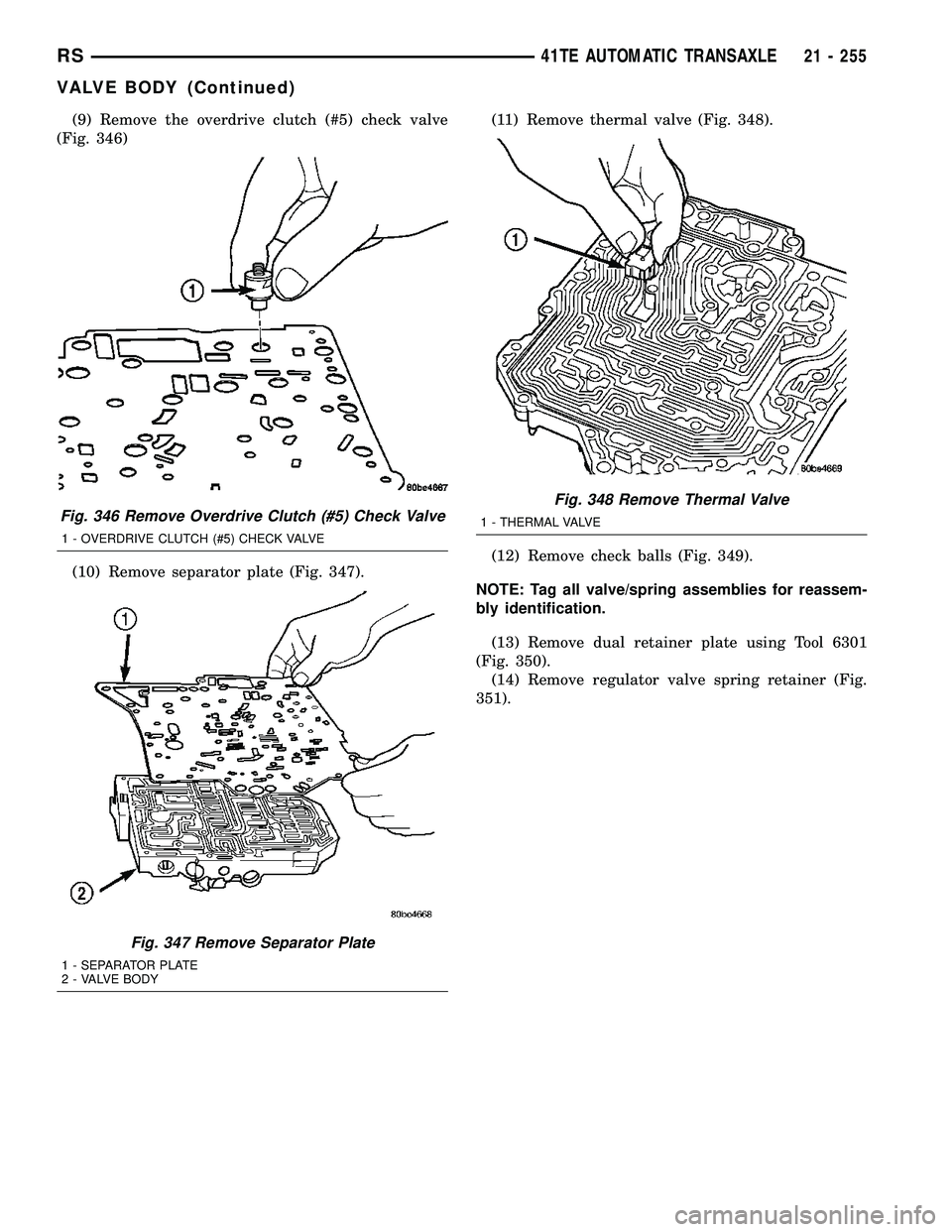

(9) Remove the overdrive clutch (#5) check valve

(Fig. 346)

(10) Remove separator plate (Fig. 347).(11) Remove thermal valve (Fig. 348).

(12) Remove check balls (Fig. 349).

NOTE: Tag all valve/spring assemblies for reassem-

bly identification.

(13) Remove dual retainer plate using Tool 6301

(Fig. 350).

(14) Remove regulator valve spring retainer (Fig.

351).

Fig. 346 Remove Overdrive Clutch (#5) Check Valve

1 - OVERDRIVE CLUTCH (#5) CHECK VALVE

Fig. 347 Remove Separator Plate

1 - SEPARATOR PLATE

2 - VALVE BODY

Fig. 348 Remove Thermal Valve

1 - THERMAL VALVE

RS41TE AUTOMATIC TRANSAXLE21 - 255

VALVE BODY (Continued)

Page 1854 of 2585

(15) Remove remaining retainers as shown in (Fig.

352).(16) Remove valves and springs as shown in (Fig.

353).

NOTE: Refer to Valve Body Cleaning and Inspection

for cleaning procedures.

ASSEMBLY

NOTE: If valve body assembly is reconditioned, the

PCM/TCM Quick Learn Procedure must be per-

formed. (Refer to 8 - ELECTRICAL/ELECTRONIC

CONTROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Install valves and springs as shown in (Fig.

353).

Fig. 353 Springs and Valves Location

1 - VALVE BODY 5 - MANUAL VALVE

2 - T/C REGULATOR VALVE 6 - CONVERTER CLUTCH SWITCH VALVE

3 - L/R SWITCH VALVE 7 - SOLENOID SWITCH VALVE

4 - CONVERTER CLUTCH CONTROL VALVE 8 - REGULATOR VALVE

Fig. 352 Valve Retainer Location

1 - RETAINER

2 - RETAINER

RS41TE AUTOMATIC TRANSAXLE21 - 257

VALVE BODY (Continued)

Page 1857 of 2585

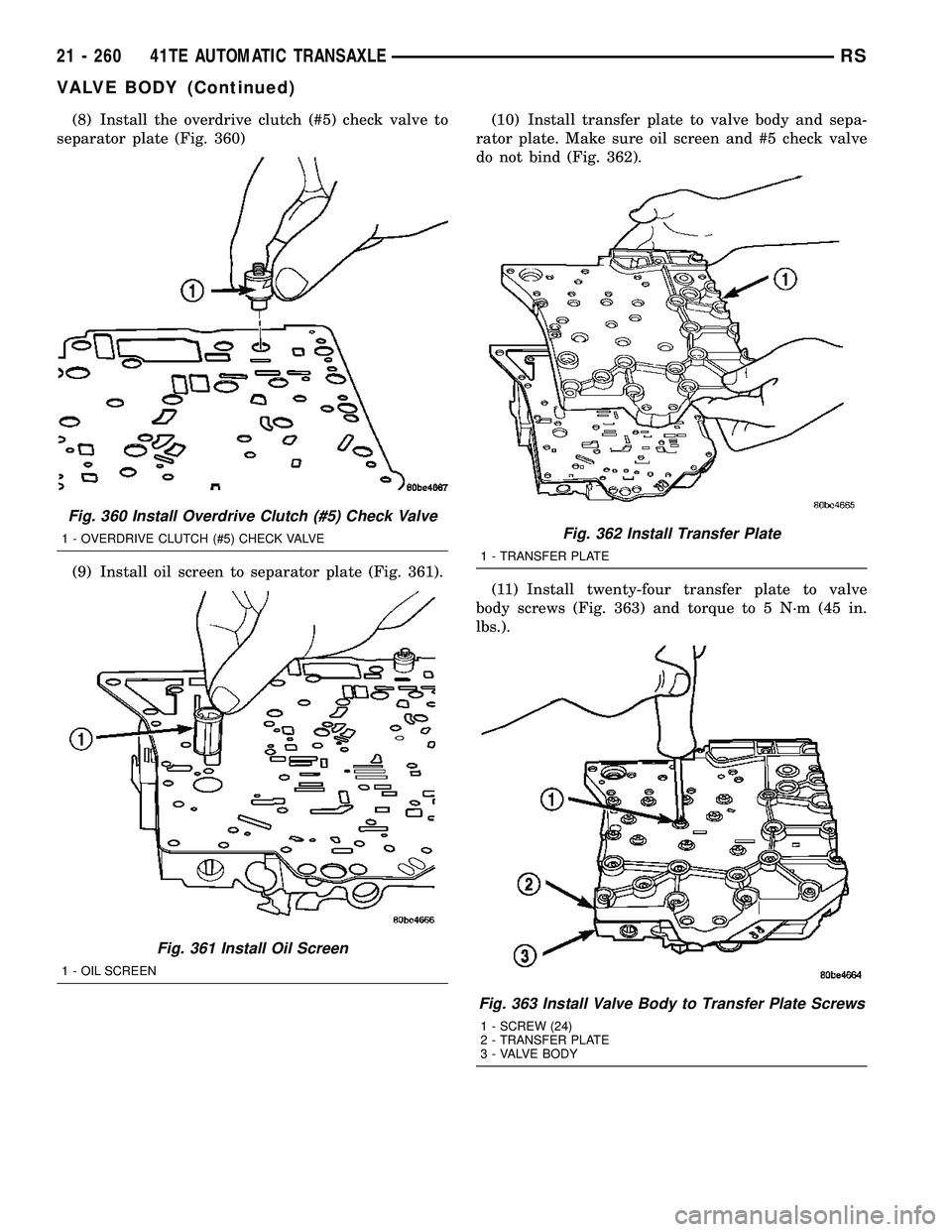

(8) Install the overdrive clutch (#5) check valve to

separator plate (Fig. 360)

(9) Install oil screen to separator plate (Fig. 361).(10) Install transfer plate to valve body and sepa-

rator plate. Make sure oil screen and #5 check valve

do not bind (Fig. 362).

(11) Install twenty-four transfer plate to valve

body screws (Fig. 363) and torque to 5 N´m (45 in.

lbs.).

Fig. 360 Install Overdrive Clutch (#5) Check Valve

1 - OVERDRIVE CLUTCH (#5) CHECK VALVE

Fig. 361 Install Oil Screen

1 - OIL SCREEN

Fig. 362 Install Transfer Plate

1 - TRANSFER PLATE

Fig. 363 Install Valve Body to Transfer Plate Screws

1 - SCREW (24)

2 - TRANSFER PLATE

3 - VALVE BODY

21 - 260 41TE AUTOMATIC TRANSAXLERS

VALVE BODY (Continued)

Page 1862 of 2585

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

T850 MANUAL TRANSAXLE ................1

40TE AUTOMATIC TRANSAXLE .............2441TE AUTOMATIC TRANSAXLE

............166

T850 MANUAL TRANSAXLE

TABLE OF CONTENTS

page page

INPUT SHAFT DESCRIPTION ..........................1

DISASSEMBLY ..........................1

ASSEMBLY .............................5 INTERMEDIATE SHAFT

DESCRIPTION ..........................9

DISASSEMBLY .........................10

ASSEMBLY ............................17

INPUT SHAFT

DESCRIPTION

The input shaft assembly (Fig. 1) is part of the

transaxle geartrain, is driven by the clutch assembly,

and consists of the following components: ² Input Mainshaft

² 3rd Speed Gear

² 4th Speed Gear

² 3/4 Synchronizer

² 5th Input Gear

The input shaft meshes with the intermediate

shaft, and is supported by a needle bearing at the

front of the transaxle, and a sealed roller bearing at

the rear of the transaxle.

DISASSEMBLY

NOTE: When servicing the input shaft assembly, all

snap rings which are removed MUST be replaced

with new snap rings upon reassembly. The 5th gear

nut must be replaced also.

(1) Invert input shaft assembly and place in fix-

ture 8487. (2) Remove input bearing snap ring (Fig. 2).

(3) Remove input bearing. Place input shaft

assembly onto arbor press table, with the input bear-

ing supported by bearing splitter (Fig. 3). Using

adapter 8486-4, press bearing off of shaft, while

helper supports shaft to prevent dropping. (4) Place input shaft assembly back into fixture

8487. Secure fixture to bench with fasteners, or

secure to bench vise.

RS TRANSMISSION/TRANSAXLE21s-1

Page 1885 of 2585

40TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

40TE AUTOMATIC TRANSAXLE DESCRIPTION .........................25

OPERATION ...........................27

DIAGNOSIS AND TESTING DIAGNOSIS AND TESTING - 4XTETRANSAXLE GENERAL DIAGNOSIS .......27

DIAGNOSIS AND TESTING - ROAD TEST . . . 27

DIAGNOSIS AND TESTING - HYDRAULIC PRESSURE TESTS ....................28

DIAGNOSIS AND TESTING - CLUTCH AIR PRESSURE TESTS ....................30

DIAGNOSIS AND TESTING - TORQUE CONVERTER HOUSING FLUID LEAKAGE . . . 31

REMOVAL .............................31

DISASSEMBLY .........................34

ASSEMBLY ............................51

INSTALLATION .........................73

SCHEMATICS AND DIAGRAMS 4XTE TRANSAXLE HYDRAULICSCHEMATICS ........................75

SPECIFICATIONS - 41TE TRANSAXLE .......87

SPECIAL TOOLS .......................89

ACCUMULATOR DESCRIPTION .........................94

OPERATION ...........................94

DRIVING CLUTCHES DESCRIPTION .........................95

OPERATION ...........................95

FINAL DRIVE DESCRIPTION .........................95

OPERATION ...........................96

DISASSEMBLY .........................96

ASSEMBLY ............................99

ADJUSTMENTS DIFFERENTIAL BEARING PRELOADMEASUREMENT AND ADJUSTMENT ......100

FLUID STANDARD PROCEDURE FLUID LEVEL AND CONDITION CHECK . . . 102

STANDARD PROCEDURE - FLUID ANDFILTER SERVICE .....................104

GEAR SHIFT CABLE REMOVAL ............................105

HOLDING CLUTCHES DESCRIPTION ........................106

OPERATION ..........................106

INPUT CLUTCH ASSEMBLY DISASSEMBLY ........................107

ASSEMBLY ...........................116 OIL PUMP

DESCRIPTION ........................131

OPERATION ..........................131

DISASSEMBLY ........................131

ASSEMBLY ...........................132

PLANETARY GEARTRAIN DESCRIPTION ........................132

OPERATION ..........................132

SEAL - OIL PUMP REMOVAL ............................133

INSTALLATION ........................133

SHIFT INTERLOCK SOLENOID DESCRIPTION ........................133

OPERATION ..........................134

DIAGNOSIS AND TESTING - BRAKE/ TRANSMISSION SHIFT INTERLOCK

SOLENOID ..........................135

REMOVAL ............................135

INSTALLATION ........................136

SOLENOID/PRESSURE SWITCH ASSY DESCRIPTION ........................137

OPERATION ..........................137

REMOVAL ............................138

INSTALLATION ........................139

SPEED SENSOR - INPUT DESCRIPTION ........................140

OPERATION ..........................140

REMOVAL ............................141

INSTALLATION ........................141

SPEED SENSOR - OUTPUT DESCRIPTION ........................142

OPERATION ..........................142

REMOVAL ............................143

INSTALLATION ........................143

TORQUE CONVERTER DESCRIPTION ........................144

OPERATION ..........................148

REMOVAL ............................149

INSTALLATION ........................149

TRANSMISSION CONTROL RELAY DESCRIPTION ........................150

OPERATION ..........................150

TRANSMISSION RANGE SENSOR DESCRIPTION ........................150

OPERATION ..........................151

REMOVAL ............................151

INSTALLATION ........................152

VALVE BODY DESCRIPTION ........................152

21s - 24 40TE AUTOMATIC TRANSAXLERS

Page 1886 of 2585

OPERATION..........................152

REMOVAL ............................153

DISASSEMBLY ........................155 ASSEMBLY

...........................159

INSTALLATION ........................164

40TE AUTOMATIC

TRANSAXLE

DESCRIPTION

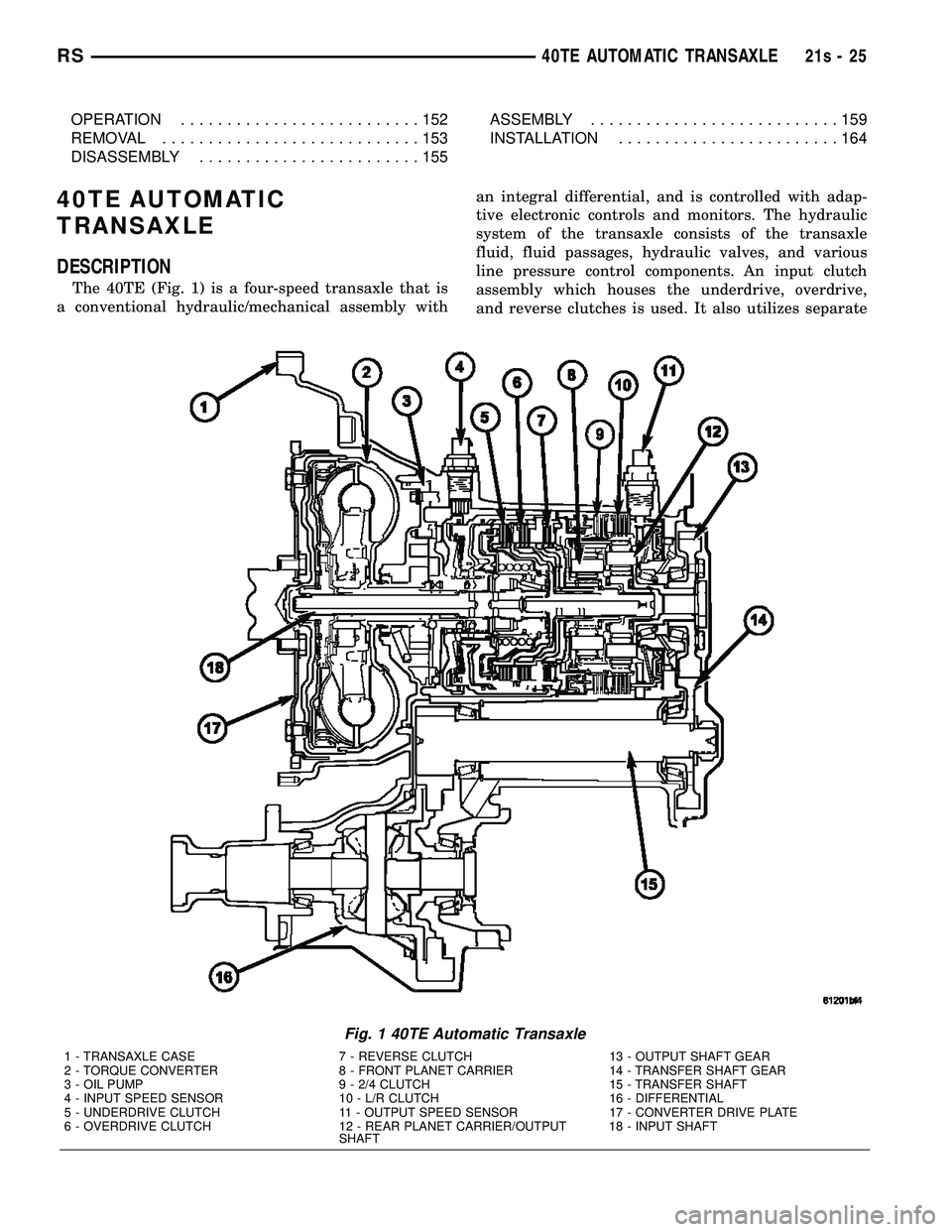

The 40TE (Fig. 1) is a four-speed transaxle that is

a conventional hydraulic/mechanical assembly with an integral differential, and is controlled with adap-

tive electronic controls and monitors. The hydraulic

system of the transaxle consists of the transaxle

fluid, fluid passages, hydraulic valves, and various

line pressure control components. An input clutch

assembly which houses the underdrive, overdrive,

and reverse clutches is used. It also utilizes separate

Fig. 1 40TE Automatic Transaxle

1 - TRANSAXLE CASE 7 - REVERSE CLUTCH 13 - OUTPUT SHAFT GEAR

2 - TORQUE CONVERTER 8 - FRONT PLANET CARRIER 14 - TRANSFER SHAFT GEAR

3 - OIL PUMP 9 - 2/4 CLUTCH 15 - TRANSFER SHAFT

4 - INPUT SPEED SENSOR 10 - L/R CLUTCH 16 - DIFFERENTIAL

5 - UNDERDRIVE CLUTCH 11 - OUTPUT SPEED SENSOR 17 - CONVERTER DRIVE PLATE

6 - OVERDRIVE CLUTCH 12 - REAR PLANET CARRIER/OUTPUT

SHAFT18 - INPUT SHAFT

RS

40TE AUTOMATIC TRANSAXLE21s-25

Page 1887 of 2585

holding clutches: 2nd/4th gear and Low/Reverse. The

primary mechanical components of the transaxle con-

sist of the following:² Three multiple disc input clutches

² Two multiple disc holding clutches

² Four hydraulic accumulators

² Two planetary gear sets

² Hydraulic oil pump

² Valve body

² Solenoid/Pressure switch assembly

² Integral differential assembly

Control of the transaxle is accomplished by fully

adaptive electronics. Optimum shift scheduling is

accomplished through continuous real-time sensor

feedback information provided to the Powertrain

Control Module (PCM) or Transmission Control Mod-

ule (TCM). The PCM/TCM is the heart of the electronic control

system and relies on information from various direct

and indirect inputs (sensors, switches, etc.) to deter-

mine driver demand and vehicle operating condi-

tions. With this information, the PCM/TCM can

calculate and perform timely and quality shifts

through various output or control devices (solenoid

pack, transmission control relay, etc.). The PCM/TCM also performs certain self-diagnos-

tic functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

TRANSAXLE IDENTIFICATION

The 40TE transaxle is identified by a barcode label

that is fixed to the transaxle case as shown in (Fig.

2). The label contains a series of digits that can be

translated into useful information such as transaxle

part number, date of manufacture, manufacturing

origin, plant shift number, build sequence number,

etc. Refer to (Fig. 3) for identification label break-

down. If the tag is not legible or missing, the ªPKº num-

ber, which is stamped into the transaxle case behind

the transfer gear cover, can be referred to for identi-

fication. This number differs slightly in that it con-

tains the entire transaxle part number, rather than

the last three digits.

Fig. 2 Transaxle Identification Label

1 - IDENTIFICATION LABEL

Fig. 3 Identification Label Breakdown

1 - T=TRACEABILITY

2 - SUPPLIER CODE (PK=KOKOMO)

3 - COMPONENT CODE (TK=KOKOMO TRANSMISSION)

4 - BUILD DAY (344=DEC. 9)

5 - BUILD YEAR (9=1999)

6 - LINE/SHIFT CODE (3=3RD SHIFT)

7 - BUILD SEQUENCE NUMBER

8 - LAST THREE OF P/N

9 - ALPHA

10 - TRANSAXLE PART NUMBER

11 - P=PART NUMBER

21s - 26 40TE AUTOMATIC TRANSAXLERS

40TE AUTOMATIC TRANSAXLE (Continued)

Page 1888 of 2585

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

First ............................... 2.84 : 1

Second ............................. 1.57 : 1

Third .............................. 1.00 : 1

Overdrive ........................... 0.69 : 1

Reverse ............................ 2.21 : 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 4XTE TRANSAXLE

GENERAL DIAGNOSIS

NOTE: Before attempting any repair on a 4XTE four-

speed automatic transaxle, check for diagnostic trou-

ble codes (DTC's) using the DRB scan tool. Refer to

the Transmission Diagnostic Procedures Manual.

Transaxle malfunctions may be caused by these

general conditions: ² Poor engine performance

² Improper adjustments

² Hydraulic malfunctions

² Mechanical malfunctions

² Electronic malfunctions

Diagnosis of these problems should always begin by

checking the easily accessible variables: fluid level and

condition, gearshift cable adjustment. Then perform a

road test to determine if the problem has been corrected

or that more diagnosis is necessary. If the problem per-

sists after the preliminary tests and corrections are com-

pleted, hydraulic pressure checks should be performed.

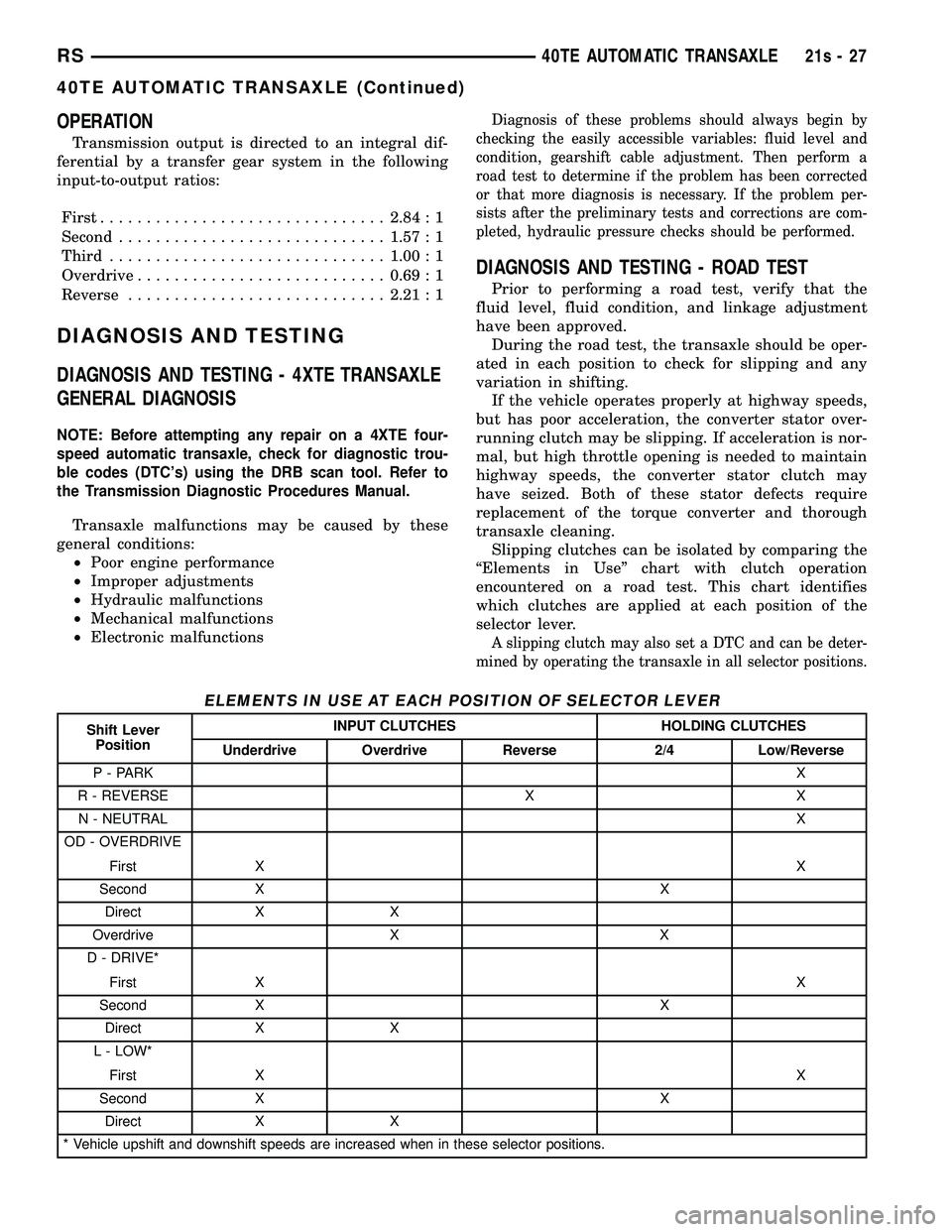

DIAGNOSIS AND TESTING - ROAD TEST

Prior to performing a road test, verify that the

fluid level, fluid condition, and linkage adjustment

have been approved. During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting. If the vehicle operates properly at highway speeds,

but has poor acceleration, the converter stator over-

running clutch may be slipping. If acceleration is nor-

mal, but high throttle opening is needed to maintain

highway speeds, the converter stator clutch may

have seized. Both of these stator defects require

replacement of the torque converter and thorough

transaxle cleaning. Slipping clutches can be isolated by comparing the

ªElements in Useº chart with clutch operation

encountered on a road test. This chart identifies

which clutches are applied at each position of the

selector lever.

A slipping clutch may also set a DTC and can be deter-

mined by operating the transaxle in all selector positions.

ELEMENTS IN USE AT EACH POSITION OF SELECTOR LEVER

Shift Lever Position INPUT CLUTCHES HOLDING CLUTCHES

Underdrive Overdrive Reverse 2/4 Low/Reverse

P - PARK X

R - REVERSE X X N - NEUTRAL X

OD - OVERDRIVE

First X X

Second X X Direct X X

Overdrive X X

D - DRIVE*

First X X

Second X X Direct X X

L - LOW*

First X X

Second X X

Direct X X

* Vehicle upshift and downshift speeds are increased when in these selector positions.

RS 40TE AUTOMATIC TRANSAXLE21s-27

40TE AUTOMATIC TRANSAXLE (Continued)