clutch CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 1763 of 2585

(67) Install oil pan-to-case bolts and torque to 19

N´m (165 in. lbs.).

(68) Install solenoid/pressure switch assembly and

gasket to case (Fig. 161).

(69) Install and tighten solenoid/pressure switch

assembly-to-transaxle case bolts to 12 N´m (110 in.

lbs.) (Fig. 162).(70) Install and torque input and output speed

sensors to case to 27 N´m (20 ft. lbs.).

INSTALLATION

NOTE: If transaxle assembly has been replaced or

overhauled (clutch and/or seal replacement), it is

necessary to perfrom the TCM Quick Learn proce-

dure. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/TRANSMISSION CONTROL

MODULE - STANDARD PROCEDURE)

(1) Using a transmission jack and a helper, posi-

tion transaxle assembly to engine. Install and torque

bellhousing bolts to 95 N´m (70 ft. lbs.).

(2) Install upper mount assembly to transaxle and

torque bolts to 54 N´m (40 ft. lbs.) (Fig. 163).

(3) Raise engine/transaxle assembly into position.

Install and torque upper mount-to-bracket thru-bolt

to 75 N´m (55 ft. lbs.) (Fig. 163).

(4) Remove transmission jack and screw jack.

(5) Secure left wheelhouse splash shield.

(6) Install torque converter-to-drive plate bolts and

torque to 88 N´m (65 ft. lbs.)

(7) Install inspection cover.

(8) Install lateral bending brace.

(9) Install starter motor.

(10) Install front mount/bracket assembly.

Fig. 161 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 162 Attaching Bolts

1 - BOLTS

2 - SOLENOID AND PRESSURE SWITCH ASSEMBLY

Fig. 163 Left Mount to Bracket and Transaxle

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

21 - 166 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1778 of 2585

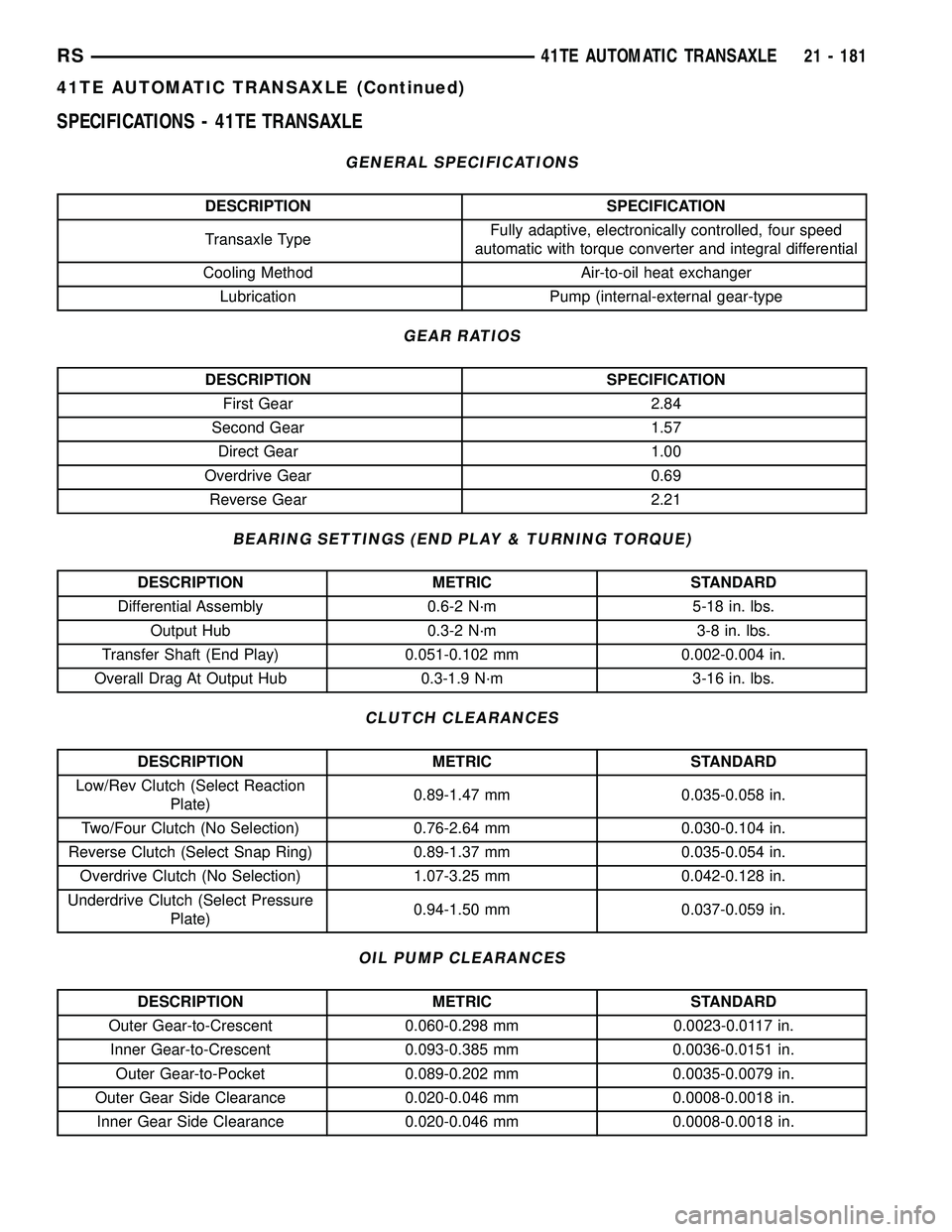

SPECIFICATIONS - 41TE TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeFully adaptive, electronically controlled, four speed

automatic with torque converter and integral differential

Cooling Method Air-to-oil heat exchanger

Lubrication Pump (internal-external gear-type

GEAR RATIOS

DESCRIPTION SPECIFICATION

First Gear 2.84

Second Gear 1.57

Direct Gear 1.00

Overdrive Gear 0.69

Reverse Gear 2.21

BEARING SETTINGS (END PLAY & TURNING TORQUE)

DESCRIPTION METRIC STANDARD

Differential Assembly 0.6-2 N´m 5-18 in. lbs.

Output Hub 0.3-2 N´m 3-8 in. lbs.

Transfer Shaft (End Play) 0.051-0.102 mm 0.002-0.004 in.

Overall Drag At Output Hub 0.3-1.9 N´m 3-16 in. lbs.

CLUTCH CLEARANCES

DESCRIPTION METRIC STANDARD

Low/Rev Clutch (Select Reaction

Plate)0.89-1.47 mm 0.035-0.058 in.

Two/Four Clutch (No Selection) 0.76-2.64 mm 0.030-0.104 in.

Reverse Clutch (Select Snap Ring) 0.89-1.37 mm 0.035-0.054 in.

Overdrive Clutch (No Selection) 1.07-3.25 mm 0.042-0.128 in.

Underdrive Clutch (Select Pressure

Plate)0.94-1.50 mm 0.037-0.059 in.

OIL PUMP CLEARANCES

DESCRIPTION METRIC STANDARD

Outer Gear-to-Crescent 0.060-0.298 mm 0.0023-0.0117 in.

Inner Gear-to-Crescent 0.093-0.385 mm 0.0036-0.0151 in.

Outer Gear-to-Pocket 0.089-0.202 mm 0.0035-0.0079 in.

Outer Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

Inner Gear Side Clearance 0.020-0.046 mm 0.0008-0.0018 in.

RS41TE AUTOMATIC TRANSAXLE21 - 181

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1779 of 2585

INPUT SHAFT

DESCRIPTION METRIC SPECIFICATION

End Play 0.127-0.635mm 0.005-0.025 in.

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, Differential Cover-to-Case 19 Ð 165

Bolt, Differential Ring Gear-to-Case 95 70 Ð

Bolt, Differential Bearing Retainer-to-

Case28 21 Ð

Bolt, Driveplate-to-Crankshaft 95 70 Ð

Bolt, Extension Housing/Plate-to-Case 28 21 Ð

Bolt, Oil Pan-to-Case 19 Ð 165

Bolt, Output Gear 271 200 Ð

Bolt, Output Gear Stirrup/Strap 23 17 Ð

Bolt, Oil Pump-to-Case 27 20 Ð

Bolt, Reaction Support-to-Case 27 20 Ð

Bolt, Solenoid/Pressure Switch

Assy.-to-Case12 Ð 110

Bolt, Torque Converter-to-Driveplate 75 55 Ð

Bolt, Transfer Gear Cover 20 Ð 175

Bolt, Valve Body-to-Case 12 Ð 105

Fitting, Oil Cooler Line 12 Ð 105

Nut, Tranfer Gear 271 200 Ð

Tap, Transaxle Pressure 5 Ð 45

Screw, L/R Clutch Retainer 5 Ð 45

Screw, Solenoid/Pressure Switch Assy.

Connector4Ð35

Screw, Valve Body-to-Transfer Plate 5 Ð 45

Sensor, Input Speed 27 20 Ð

Sensor, Output Speed 27 20 Ð

Sensor, Transmission Range Sensor 5 Ð 45

21 - 182 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1785 of 2585

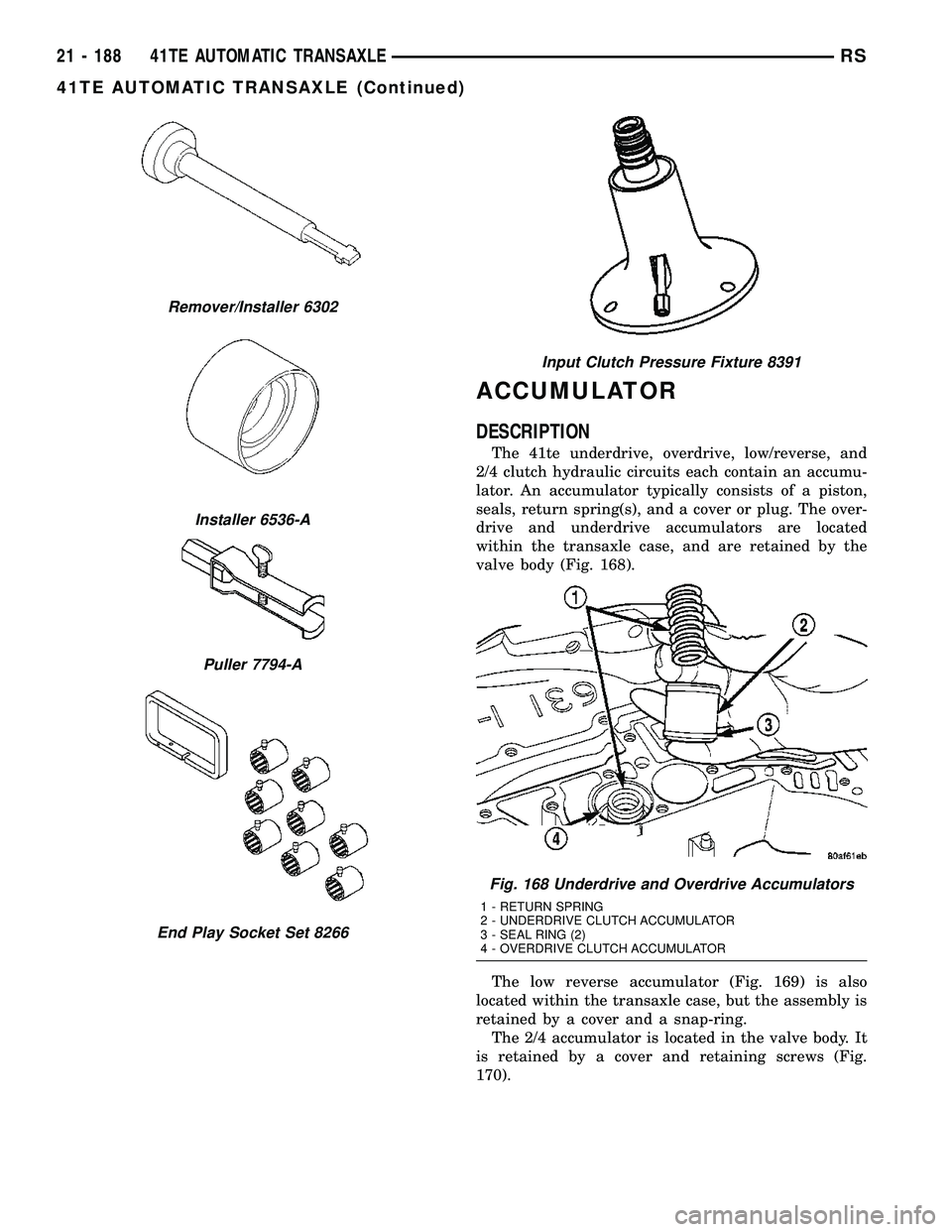

ACCUMULATOR

DESCRIPTION

The 41te underdrive, overdrive, low/reverse, and

2/4 clutch hydraulic circuits each contain an accumu-

lator. An accumulator typically consists of a piston,

seals, return spring(s), and a cover or plug. The over-

drive and underdrive accumulators are located

within the transaxle case, and are retained by the

valve body (Fig. 168).

The low reverse accumulator (Fig. 169) is also

located within the transaxle case, but the assembly is

retained by a cover and a snap-ring.

The 2/4 accumulator is located in the valve body. It

is retained by a cover and retaining screws (Fig.

170).

Remover/Installer 6302

Installer 6536-A

Puller 7794-A

End Play Socket Set 8266

Input Clutch Pressure Fixture 8391

Fig. 168 Underdrive and Overdrive Accumulators

1 - RETURN SPRING

2 - UNDERDRIVE CLUTCH ACCUMULATOR

3 - SEAL RING (2)

4 - OVERDRIVE CLUTCH ACCUMULATOR

21 - 188 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 1786 of 2585

OPERATION

The function of an accumulator is to cushion the

application of a frictional clutch element. When pres-

surized fluid is applied to a clutch circuit, the appli-

cation force is dampened by fluid collecting in the

respective accumulator chamber against the piston

and spring(s). The intended result is a smooth, firm

clutch application.

AUTOSTICK SWITCH

DESCRIPTION

Autostick is a driver-interactive transaxle feature

that offers manual gear shifting capability. The control

switch is part of the transaxle gear shift lever as

shown in (Fig. 171). It can only be serviced by replac-

ing the gearshift lever assembly. (Refer to 19 - STEER-

ING/COLUMN/GEAR SHIFT LEVER - REMOVAL)

OPERATION

When the shift lever is moved into the Autostick

position (as indicated by the Shift Lever Position

Indicator in the cluster), the transaxle remains in

whatever gear it was using before Autostick was acti-

vated. The TCM sends a 5 volt signal through the

switch and then monitors the signal for voltage drop.

Each switch state (driver command) results in a spe-

cific voltage reading sensed by the TCM. The TCM

then determines transaxle operation (upshift/down-

shift/OD Lockout) based on their corresponding volt-

age. Refer to the following chart for corresponding

switch states and voltage readings:

Switch State Voltage Reading

Autostick DOWN

depressed0.3V-1.6V

Autostick UP depressed 1.6V-2.8V

Overdrive OFF9Lockout9

depressed2.8V-3.8V

All switches open 3.8V-4.8V

-Voltage values <.3V and >4.8V are considered

INVALID and will result in a DTC

Fig. 169 Low/Reverse Accumulator Assembly

1 - ACCUMULATOR PISTON

2 - SEAL RINGS

3 - RETURN SPRINGS

4 - (NOTE NOTCH)

Fig. 170 2/4 Accumulator Assembly

1 - VALVE BODY

2 - RETAINER PLATE

3 - DETENT SPRING

4 - SPRINGS

5 - SEALS

6 - PISTON

Fig. 171 Autostick Switch Location (if equipped)

RS41TE AUTOMATIC TRANSAXLE21 - 189

ACCUMULATOR (Continued)

Page 1787 of 2585

Moving the switch up causes an upshift and moving

the switch down causes a downshift. The instrument

cluster will illuminate the selected gear. The vehicle

can be launched in 1st, 2nd, or 3rd gear while in the

Autostick mode. The speed control is operable in 3rd

and 4th gear Autostick mode. Speed control will be

deactivated if the transaxle is shifted to 2nd gear.

Shifting into OD position cancels the Autostick mode,

and the transaxle resumes the OD shift schedule.

DRIVING CLUTCHES

DESCRIPTION

Three hydraulically applied input clutches are used

to drive planetary components. The underdrive, over-

drive, and reverse clutches are considered input

clutches and are contained within the input clutch

assembly (Fig. 172). The input clutch assembly also

contains:

²Input shaft

²Input hub

²Clutch retainer

²Underdrive piston

²Overdrive/reverse piston

²Overdrive hub

²Underdrive hub

OPERATION

The three input clutches are responsible for driving

different components of the planetary geartrain.

NOTE: Refer to the ªElements In Useº chart in Diag-

nosis and Testing for a collective view of which

clutch elements are applied at each position of the

selector lever.

UNDERDRIVE CLUTCH

The underdrive clutch is hydraulically applied in

first, second, and third (direct) gears by pressurized

fluid against the underdrive piston. When the under-

drive clutch is applied, the underdrive hub drives the

rear sun gear.

OVERDRIVE CLUTCH

The overdrive clutch is hydraulically applied in

third (direct) and overdrive gears by pressurized fluid

against the overdrive/reverse piston. When the over-

drive clutch is applied, the overdrive hub drives the

front planet carrier.

REVERSE CLUTCH

The reverse clutch is hydraulically applied in

reverse gear only by pressurized fluid against the

overdrive/reverse piston. When the reverse clutch is

applied, the front sun gear assembly is driven.

FINAL DRIVE

DISASSEMBLY

NOTE: The differential is serviced as an assembly.

Differential service is limited to bearing cups and

cones. Any other differential component failure

must be remedied by differential assembly and

transfer shaft replacement.

Fig. 172 Input Clutch Assembly

1 - INPUT SHAFT

2 - UNDERDRIVE CLUTCH

3 - OVERDRIVE CLUTCH

4 - REVERSE CLUTCH

5 - OVERDRIVE SHAFT

6 - UNDERDRIVE SHAFT

21 - 190 41TE AUTOMATIC TRANSAXLERS

AUTOSTICK SWITCH (Continued)

Page 1799 of 2585

(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 210).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

Fig. 210 Transmission Fluid Temperature Chart

1 - MAX. LEVEL

2 - MIN. LEVEL

21 - 202 41TE AUTOMATIC TRANSAXLERS

FLUID (Continued)

Page 1804 of 2585

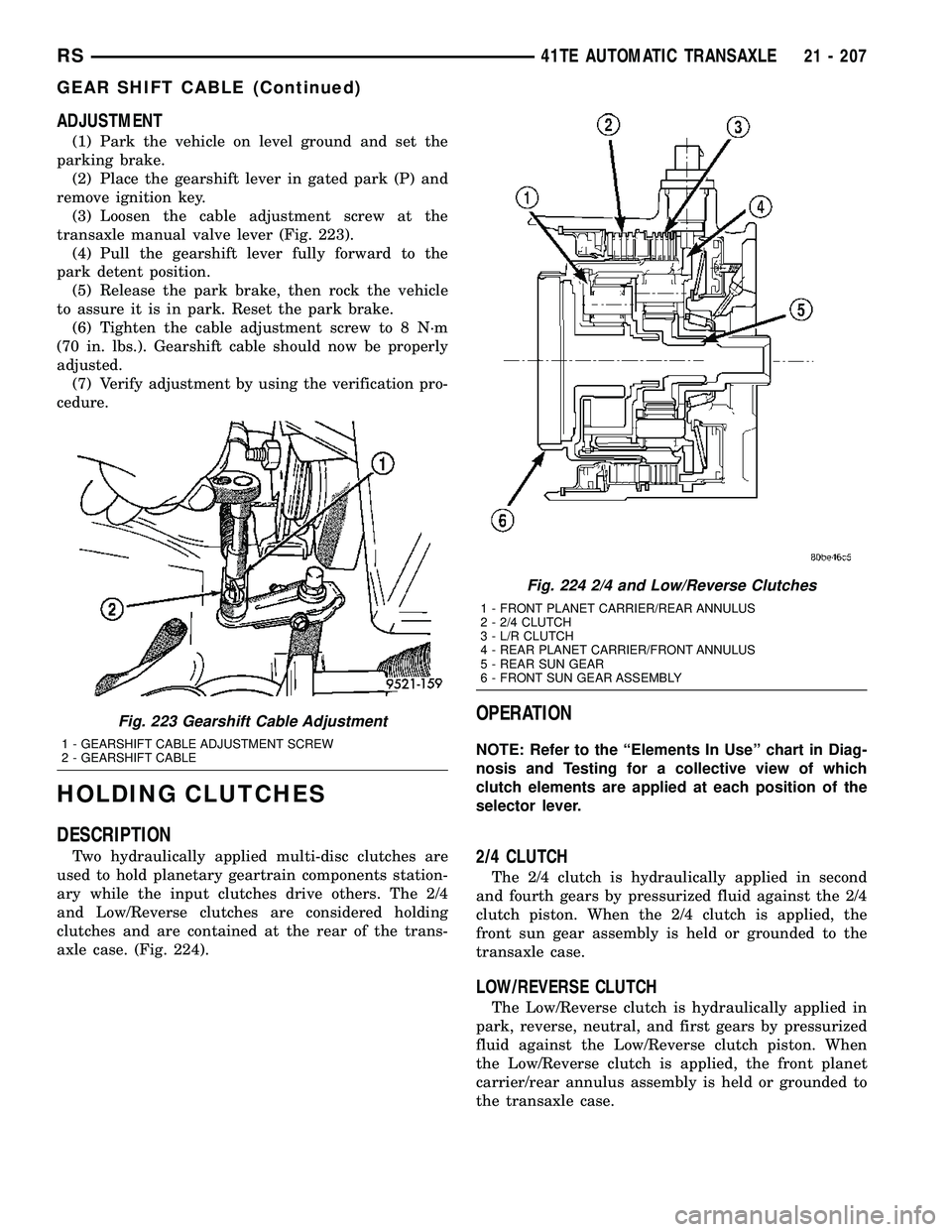

ADJUSTMENT

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in gated park (P) and

remove ignition key.

(3) Loosen the cable adjustment screw at the

transaxle manual valve lever (Fig. 223).

(4) Pull the gearshift lever fully forward to the

park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify adjustment by using the verification pro-

cedure.

HOLDING CLUTCHES

DESCRIPTION

Two hydraulically applied multi-disc clutches are

used to hold planetary geartrain components station-

ary while the input clutches drive others. The 2/4

and Low/Reverse clutches are considered holding

clutches and are contained at the rear of the trans-

axle case. (Fig. 224).

OPERATION

NOTE: Refer to the ªElements In Useº chart in Diag-

nosis and Testing for a collective view of which

clutch elements are applied at each position of the

selector lever.

2/4 CLUTCH

The 2/4 clutch is hydraulically applied in second

and fourth gears by pressurized fluid against the 2/4

clutch piston. When the 2/4 clutch is applied, the

front sun gear assembly is held or grounded to the

transaxle case.

LOW/REVERSE CLUTCH

The Low/Reverse clutch is hydraulically applied in

park, reverse, neutral, and first gears by pressurized

fluid against the Low/Reverse clutch piston. When

the Low/Reverse clutch is applied, the front planet

carrier/rear annulus assembly is held or grounded to

the transaxle case.

Fig. 223 Gearshift Cable Adjustment

1 - GEARSHIFT CABLE ADJUSTMENT SCREW

2 - GEARSHIFT CABLE

Fig. 224 2/4 and Low/Reverse Clutches

1 - FRONT PLANET CARRIER/REAR ANNULUS

2 - 2/4 CLUTCH

3 - L/R CLUTCH

4 - REAR PLANET CARRIER/FRONT ANNULUS

5 - REAR SUN GEAR

6 - FRONT SUN GEAR ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 207

GEAR SHIFT CABLE (Continued)

Page 1805 of 2585

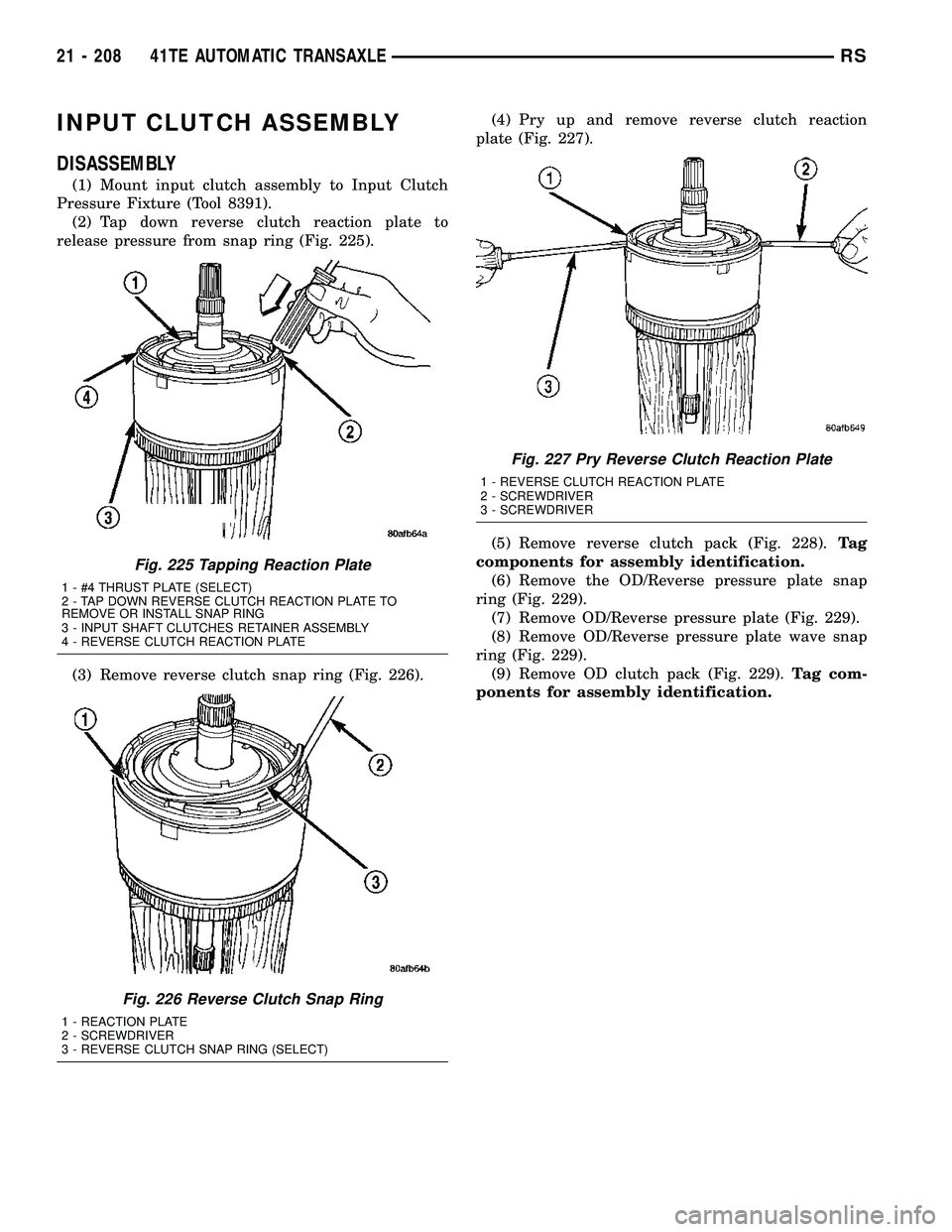

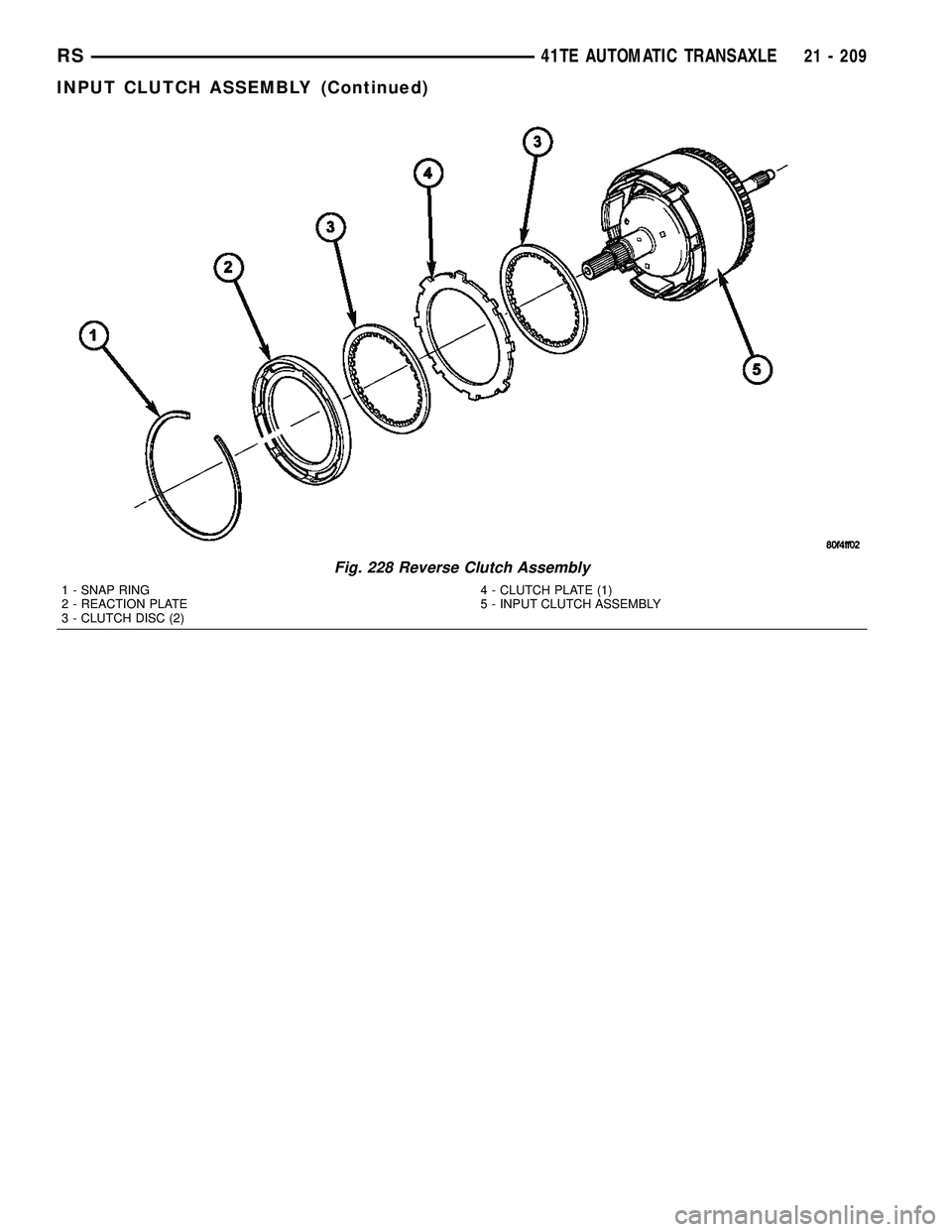

INPUT CLUTCH ASSEMBLY

DISASSEMBLY

(1) Mount input clutch assembly to Input Clutch

Pressure Fixture (Tool 8391).

(2) Tap down reverse clutch reaction plate to

release pressure from snap ring (Fig. 225).

(3) Remove reverse clutch snap ring (Fig. 226).(4) Pry up and remove reverse clutch reaction

plate (Fig. 227).

(5) Remove reverse clutch pack (Fig. 228).Ta g

components for assembly identification.

(6) Remove the OD/Reverse pressure plate snap

ring (Fig. 229).

(7) Remove OD/Reverse pressure plate (Fig. 229).

(8) Remove OD/Reverse pressure plate wave snap

ring (Fig. 229).

(9) Remove OD clutch pack (Fig. 229).Tag com-

ponents for assembly identification.

Fig. 225 Tapping Reaction Plate

1 - #4 THRUST PLATE (SELECT)

2 - TAP DOWN REVERSE CLUTCH REACTION PLATE TO

REMOVE OR INSTALL SNAP RING

3 - INPUT SHAFT CLUTCHES RETAINER ASSEMBLY

4 - REVERSE CLUTCH REACTION PLATE

Fig. 226 Reverse Clutch Snap Ring

1 - REACTION PLATE

2 - SCREWDRIVER

3 - REVERSE CLUTCH SNAP RING (SELECT)

Fig. 227 Pry Reverse Clutch Reaction Plate

1 - REVERSE CLUTCH REACTION PLATE

2 - SCREWDRIVER

3 - SCREWDRIVER

21 - 208 41TE AUTOMATIC TRANSAXLERS

Page 1806 of 2585

Fig. 228 Reverse Clutch Assembly

1 - SNAP RING

2 - REACTION PLATE

3 - CLUTCH DISC (2)4 - CLUTCH PLATE (1)

5 - INPUT CLUTCH ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 209

INPUT CLUTCH ASSEMBLY (Continued)