CHRYSLER VOYAGER 2004 Service Manual

Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2041 of 2585

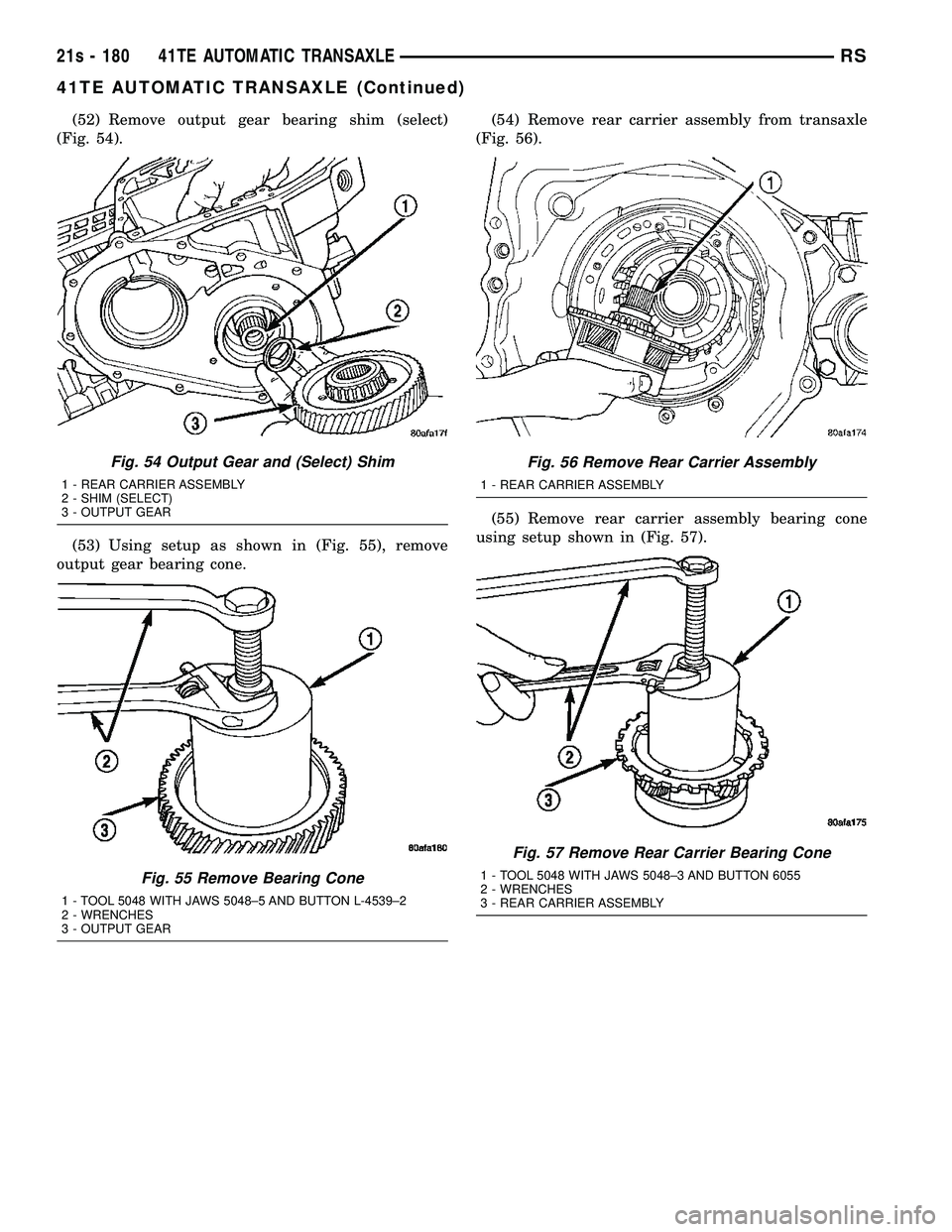

(52) Remove output gear bearing shim (select)

(Fig. 54).

(53) Using setup as shown in (Fig. 55), remove

output gear bearing cone. (54) Remove rear carrier assembly from transaxle

(Fig. 56).

(55) Remove rear carrier assembly bearing cone

using setup shown in (Fig. 57).

Fig. 54 Output Gear and (Select) Shim

1 - REAR CARRIER ASSEMBLY

2 - SHIM (SELECT)

3 - OUTPUT GEAR

Fig. 55 Remove Bearing Cone

1 - TOOL 5048 WITH JAWS 5048±5 AND BUTTON L-4539±2

2 - WRENCHES

3 - OUTPUT GEAR

Fig. 56 Remove Rear Carrier Assembly

1 - REAR CARRIER ASSEMBLY

Fig. 57 Remove Rear Carrier Bearing Cone

1 - TOOL 5048 WITH JAWS 5048±3 AND BUTTON 6055

2 - WRENCHES

3 - REAR CARRIER ASSEMBLY

21s - 180 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2042 of 2585

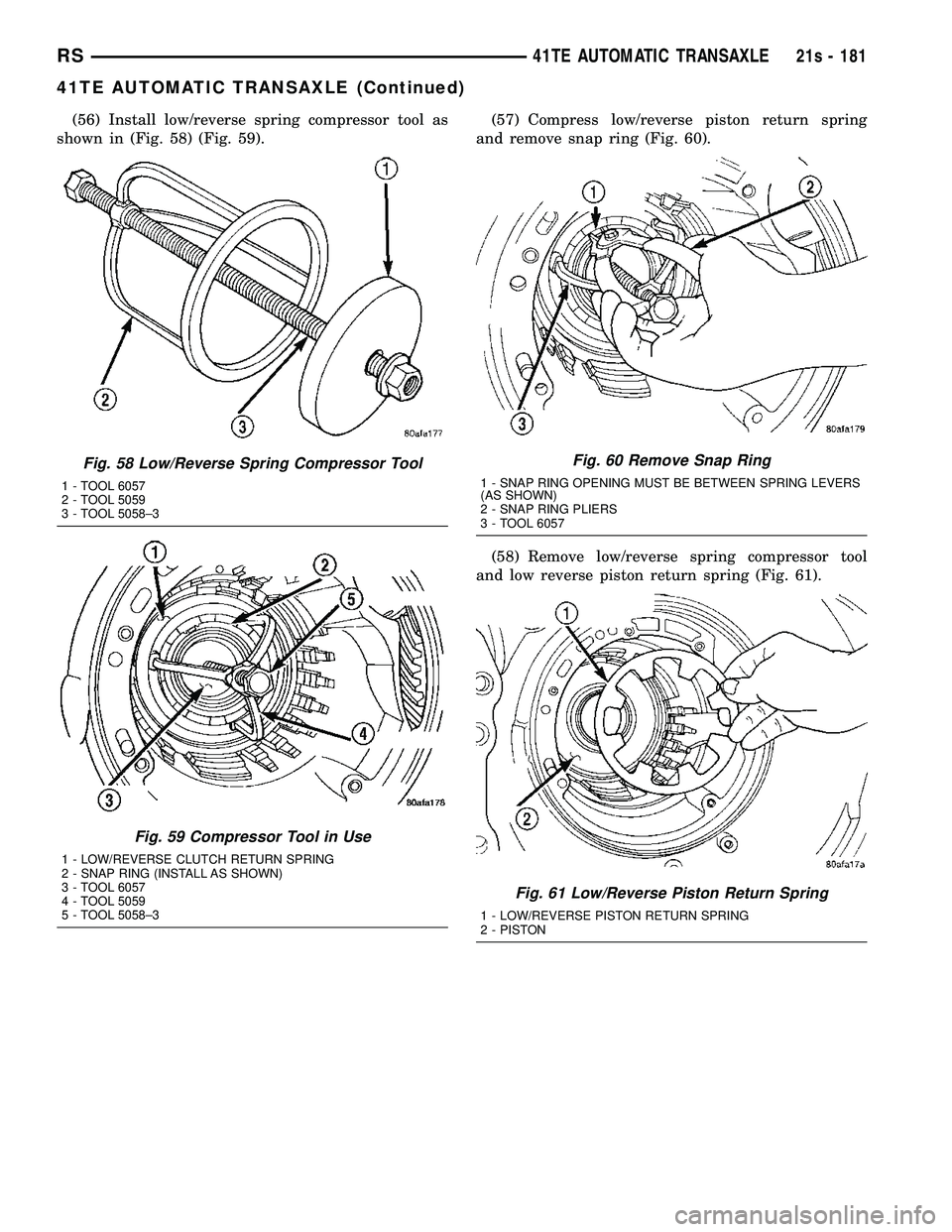

(56) Install low/reverse spring compressor tool as

shown in (Fig. 58) (Fig. 59). (57) Compress low/reverse piston return spring

and remove snap ring (Fig. 60).

(58) Remove low/reverse spring compressor tool

and low reverse piston return spring (Fig. 61).

Fig. 58 Low/Reverse Spring Compressor Tool

1 - TOOL 6057

2 - TOOL 5059

3 - TOOL 5058±3

Fig. 59 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

Fig. 60 Remove Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING LEVERS

(AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 61 Low/Reverse Piston Return Spring

1 - LOW/REVERSE PISTON RETURN SPRING

2 - PISTON

RS 41TE AUTOMATIC TRANSAXLE21s - 181

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2043 of 2585

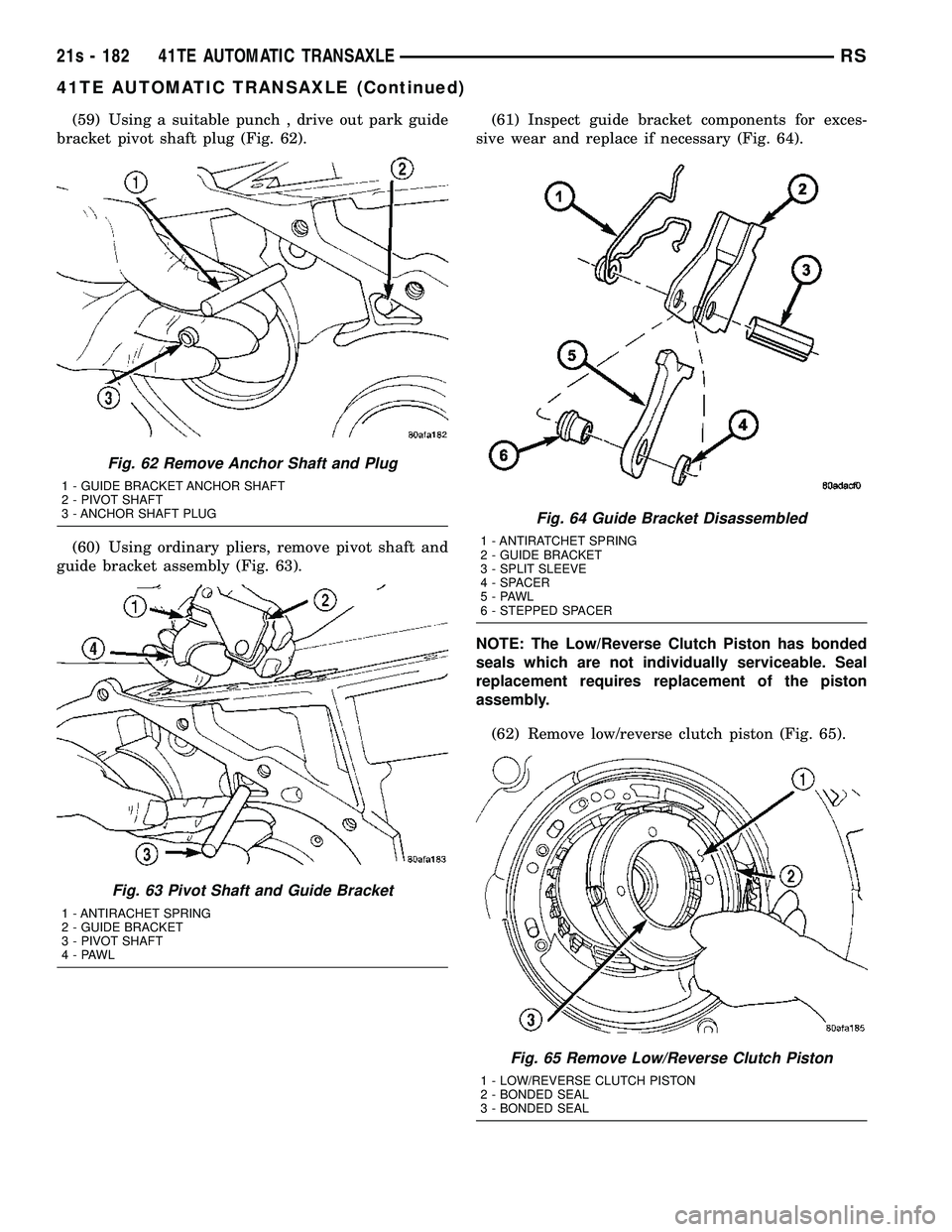

(59) Using a suitable punch , drive out park guide

bracket pivot shaft plug (Fig. 62).

(60) Using ordinary pliers, remove pivot shaft and

guide bracket assembly (Fig. 63). (61) Inspect guide bracket components for exces-

sive wear and replace if necessary (Fig. 64).

NOTE: The Low/Reverse Clutch Piston has bonded

seals which are not individually serviceable. Seal

replacement requires replacement of the piston

assembly.

(62) Remove low/reverse clutch piston (Fig. 65).

Fig. 62 Remove Anchor Shaft and Plug

1 - GUIDE BRACKET ANCHOR SHAFT

2 - PIVOT SHAFT

3 - ANCHOR SHAFT PLUG

Fig. 63 Pivot Shaft and Guide Bracket

1 - ANTIRACHET SPRING

2 - GUIDE BRACKET

3 - PIVOT SHAFT

4-PAWL

Fig. 64 Guide Bracket Disassembled

1 - ANTIRATCHET SPRING

2 - GUIDE BRACKET

3 - SPLIT SLEEVE

4 - SPACER

5-PAWL

6 - STEPPED SPACER

Fig. 65 Remove Low/Reverse Clutch Piston

1 - LOW/REVERSE CLUTCH PISTON

2 - BONDED SEAL

3 - BONDED SEAL

21s - 182 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2044 of 2585

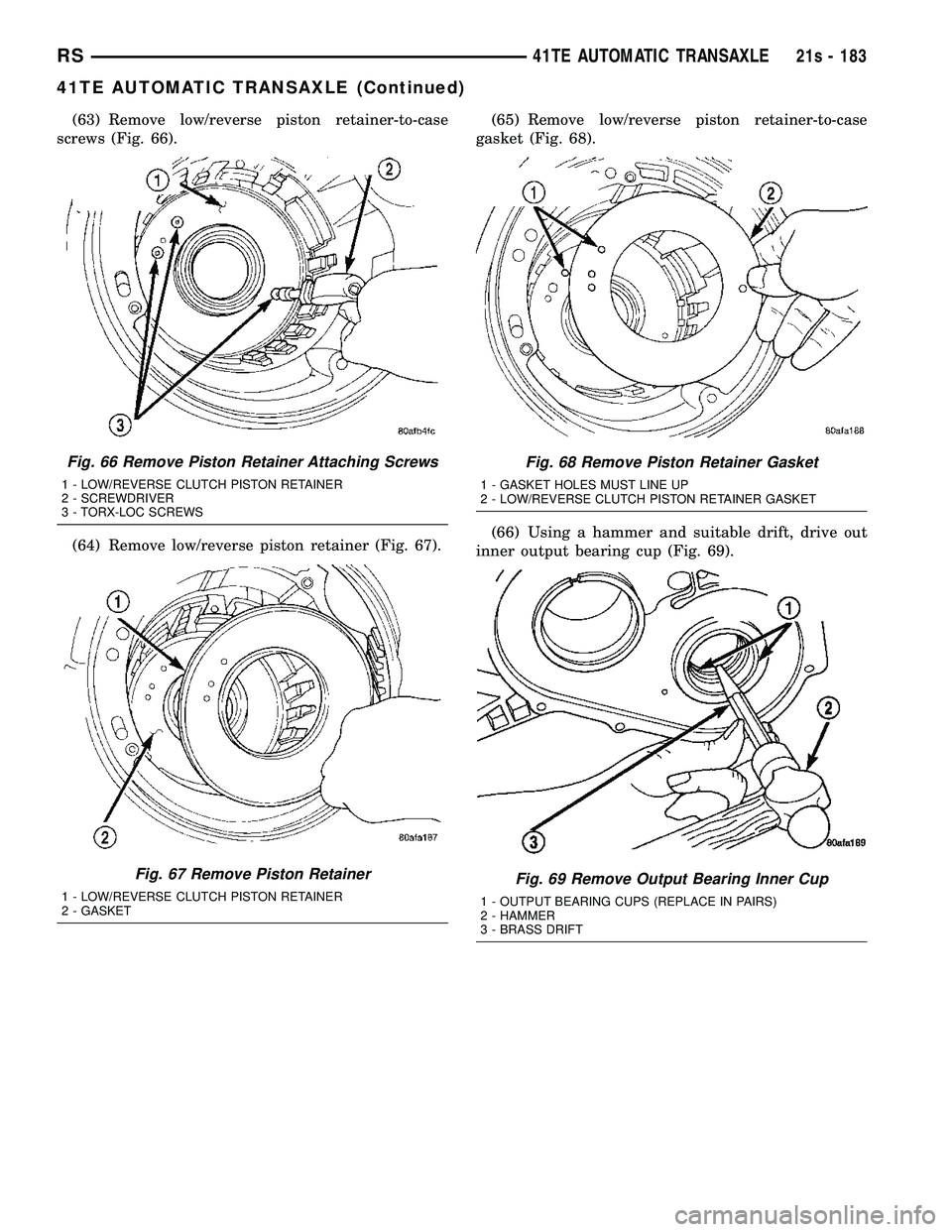

(63) Remove low/reverse piston retainer-to-case

screws (Fig. 66).

(64) Remove low/reverse piston retainer (Fig. 67). (65) Remove low/reverse piston retainer-to-case

gasket (Fig. 68).

(66) Using a hammer and suitable drift, drive out

inner output bearing cup (Fig. 69).

Fig. 66 Remove Piston Retainer Attaching Screws

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - SCREWDRIVER

3 - TORX-LOC SCREWS

Fig. 67 Remove Piston Retainer

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - GASKET

Fig. 68 Remove Piston Retainer Gasket

1 - GASKET HOLES MUST LINE UP

2 - LOW/REVERSE CLUTCH PISTON RETAINER GASKET

Fig. 69 Remove Output Bearing Inner Cup

1 - OUTPUT BEARING CUPS (REPLACE IN PAIRS)

2 - HAMMER

3 - BRASS DRIFT

RS 41TE AUTOMATIC TRANSAXLE21s - 183

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2045 of 2585

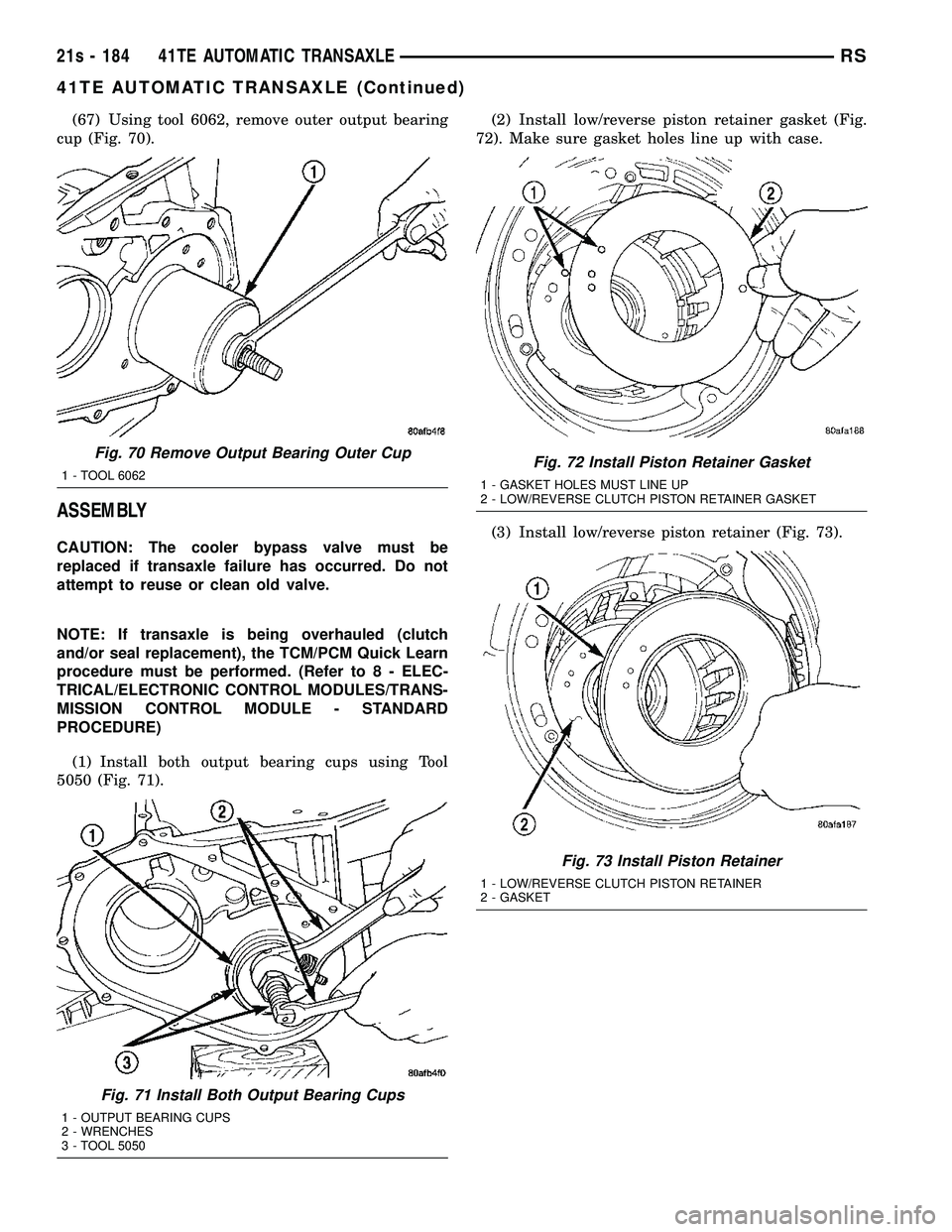

(67) Using tool 6062, remove outer output bearing

cup (Fig. 70).

ASSEMBLY

CAUTION: The cooler bypass valve must be

replaced if transaxle failure has occurred. Do not

attempt to reuse or clean old valve.

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement), the TCM/PCM Quick Learn

procedure must be performed. (Refer t o 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/TRANS-

MISSION CONTROL MODULE - STANDARD

PROCEDURE)

(1) Install both output bearing cups using Tool

5050 (Fig. 71). (2) Install low/reverse piston retainer gasket (Fig.

72). Make sure gasket holes line up with case.

(3) Install low/reverse piston retainer (Fig. 73).

Fig. 70 Remove Output Bearing Outer Cup

1 - TOOL 6062

Fig. 71 Install Both Output Bearing Cups

1 - OUTPUT BEARING CUPS

2 - WRENCHES

3 - TOOL 5050

Fig. 72 Install Piston Retainer Gasket

1 - GASKET HOLES MUST LINE UP

2 - LOW/REVERSE CLUTCH PISTON RETAINER GASKET

Fig. 73 Install Piston Retainer

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - GASKET

21s - 184 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2046 of 2585

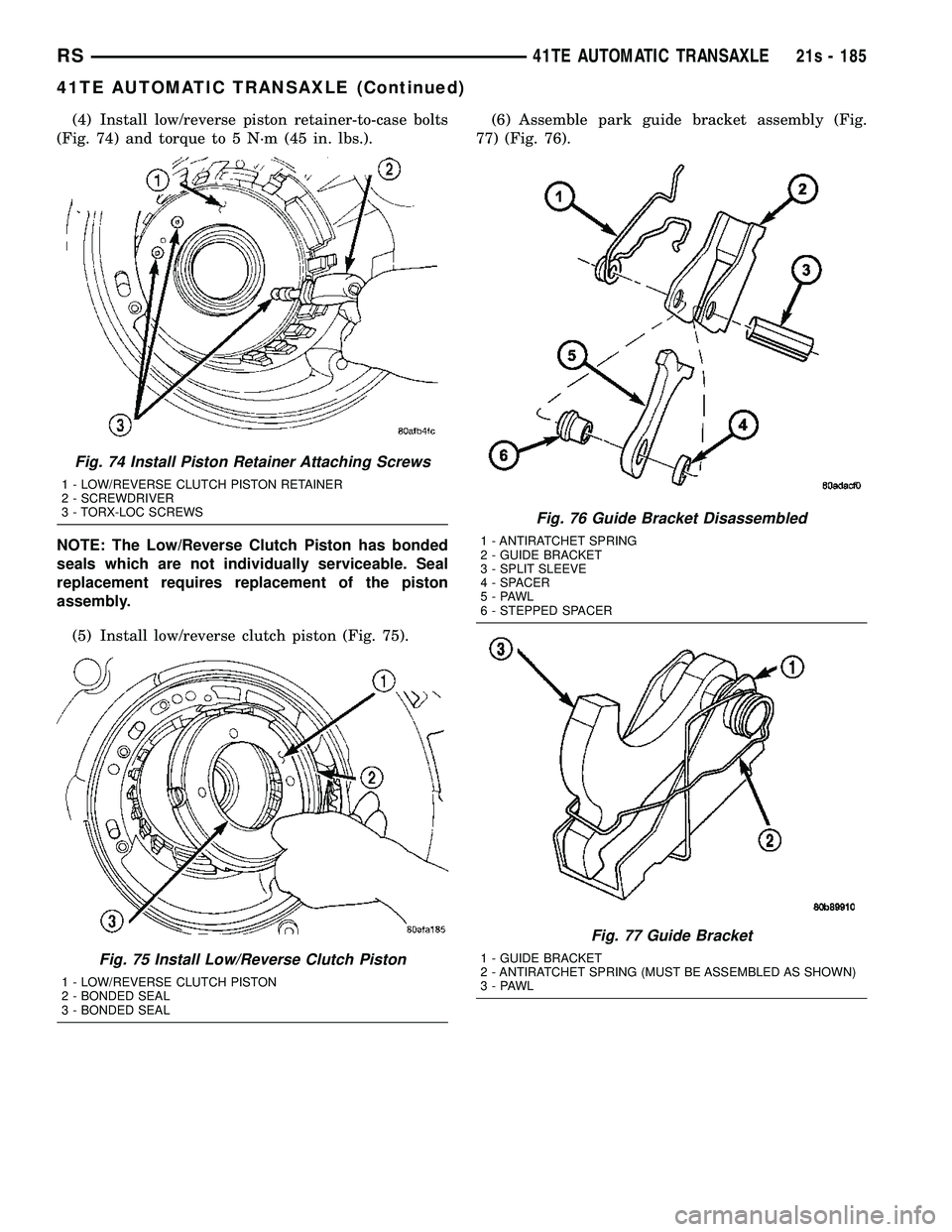

(4) Install low/reverse piston retainer-to-case bolts

(Fig. 74) and torque to 5 N´m (45 in. lbs.).

NOTE: The Low/Reverse Clutch Piston has bonded

seals which are not individually serviceable. Seal

replacement requires replacement of the piston

assembly.

(5) Install low/reverse clutch piston (Fig. 75). (6) Assemble park guide bracket assembly (Fig.

77) (Fig. 76).

Fig. 74 Install Piston Retainer Attaching Screws

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - SCREWDRIVER

3 - TORX-LOC SCREWS

Fig. 75 Install Low/Reverse Clutch Piston

1 - LOW/REVERSE CLUTCH PISTON

2 - BONDED SEAL

3 - BONDED SEAL

Fig. 76 Guide Bracket Disassembled

1 - ANTIRATCHET SPRING

2 - GUIDE BRACKET

3 - SPLIT SLEEVE

4 - SPACER

5-PAWL

6 - STEPPED SPACER

Fig. 77 Guide Bracket

1 - GUIDE BRACKET

2 - ANTIRATCHET SPRING (MUST BE ASSEMBLED AS SHOWN)

3-PAWL

RS 41TE AUTOMATIC TRANSAXLE21s - 185

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2047 of 2585

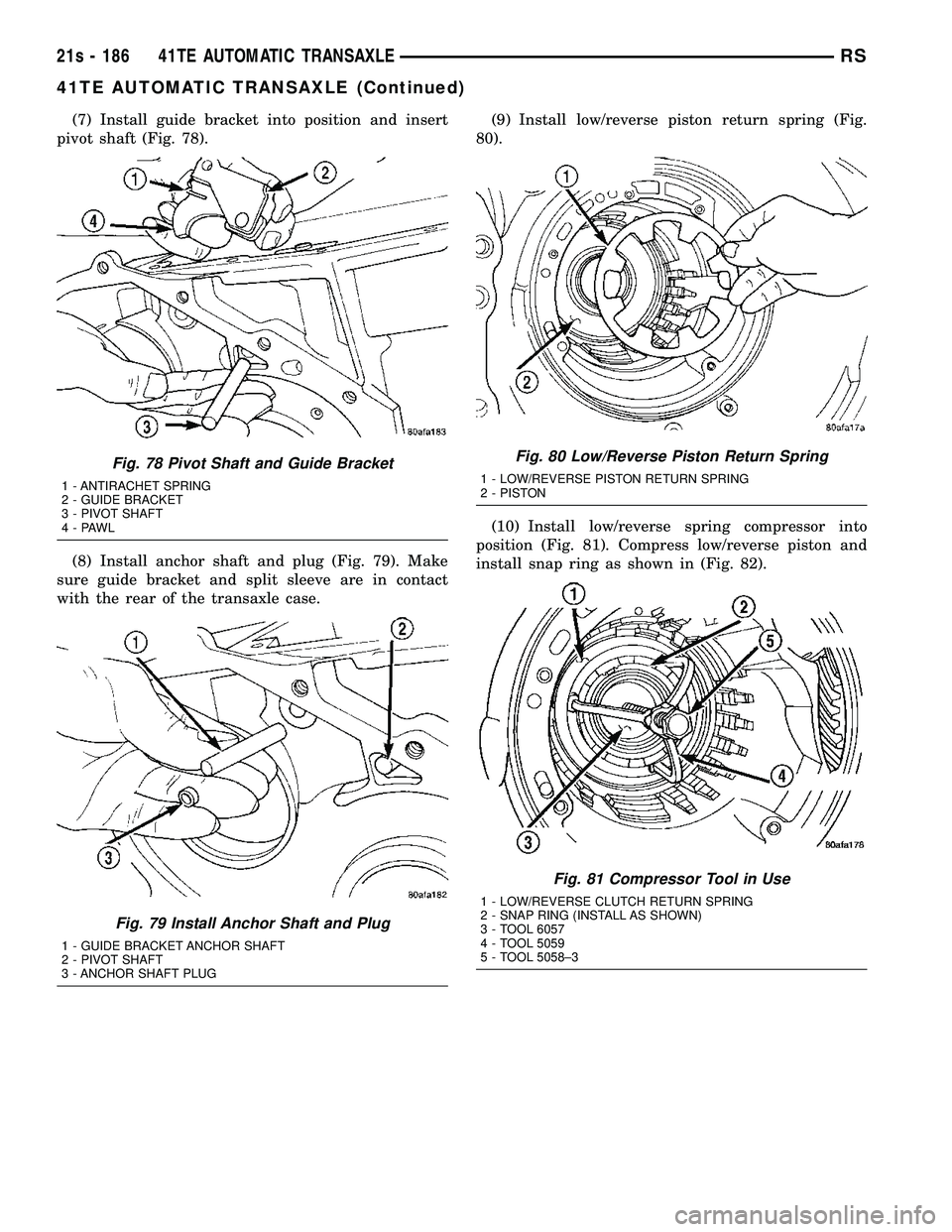

(7) Install guide bracket into position and insert

pivot shaft (Fig. 78).

(8) Install anchor shaft and plug (Fig. 79). Make

sure guide bracket and split sleeve are in contact

with the rear of the transaxle case. (9) Install low/reverse piston return spring (Fig.

80).

(10) Install low/reverse spring compressor into

position (Fig. 81). Compress low/reverse piston and

install snap ring as shown in (Fig. 82).

Fig. 78 Pivot Shaft and Guide Bracket

1 - ANTIRACHET SPRING

2 - GUIDE BRACKET

3 - PIVOT SHAFT

4-PAWL

Fig. 79 Install Anchor Shaft and Plug

1 - GUIDE BRACKET ANCHOR SHAFT

2 - PIVOT SHAFT

3 - ANCHOR SHAFT PLUG

Fig. 80 Low/Reverse Piston Return Spring

1 - LOW/REVERSE PISTON RETURN SPRING

2 - PISTON

Fig. 81 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

21s - 186 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2048 of 2585

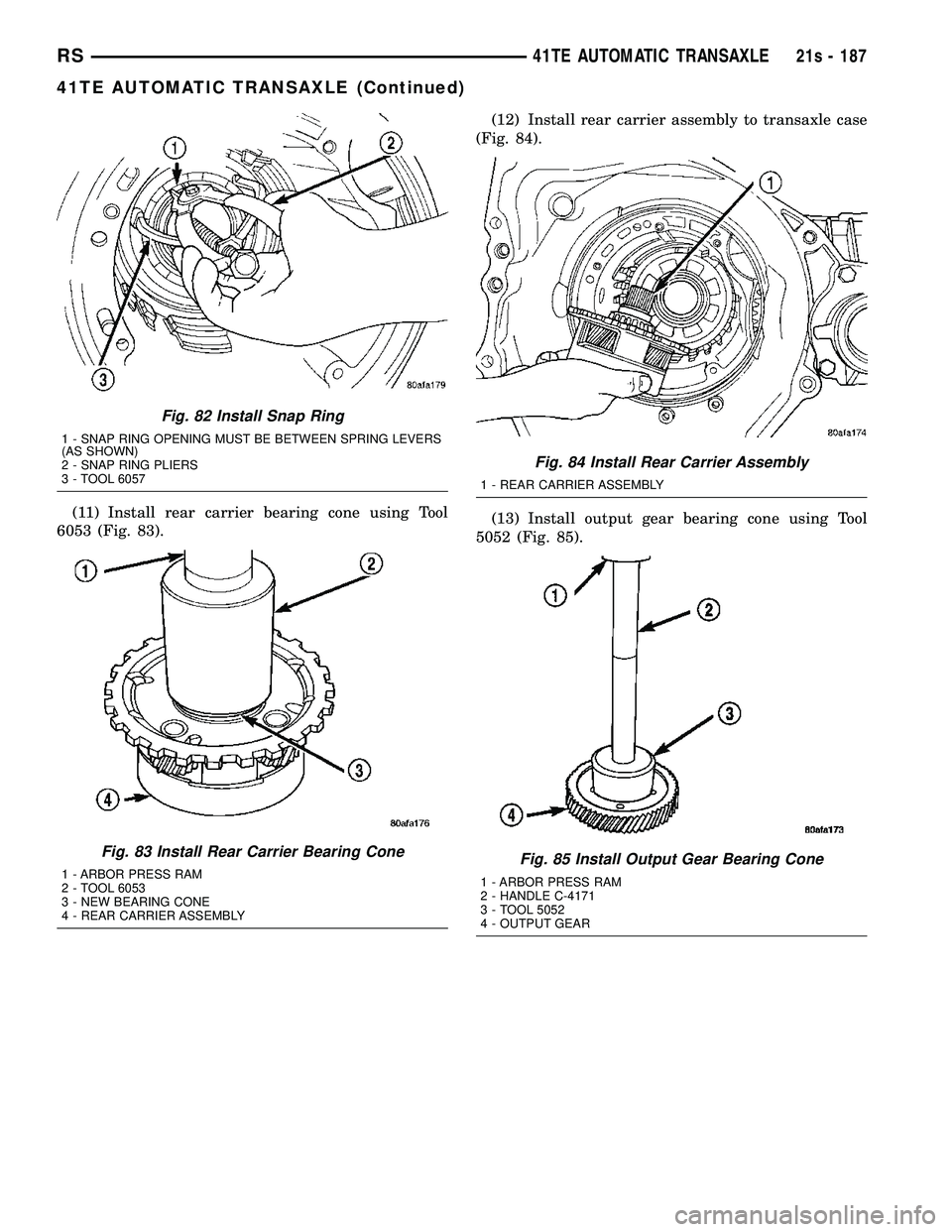

(11) Install rear carrier bearing cone using Tool

6053 (Fig. 83). (12) Install rear carrier assembly to transaxle case

(Fig. 84).

(13) Install output gear bearing cone using Tool

5052 (Fig. 85).

Fig. 82 Install Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING LEVERS

(AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 83 Install Rear Carrier Bearing Cone

1 - ARBOR PRESS RAM

2 - TOOL 6053

3 - NEW BEARING CONE

4 - REAR CARRIER ASSEMBLY

Fig. 84 Install Rear Carrier Assembly

1 - REAR CARRIER ASSEMBLY

Fig. 85 Install Output Gear Bearing Cone

1 - ARBOR PRESS RAM

2 - HANDLE C-4171

3 - TOOL 5052

4 - OUTPUT GEAR

RS 41TE AUTOMATIC TRANSAXLE21s - 187

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2049 of 2585

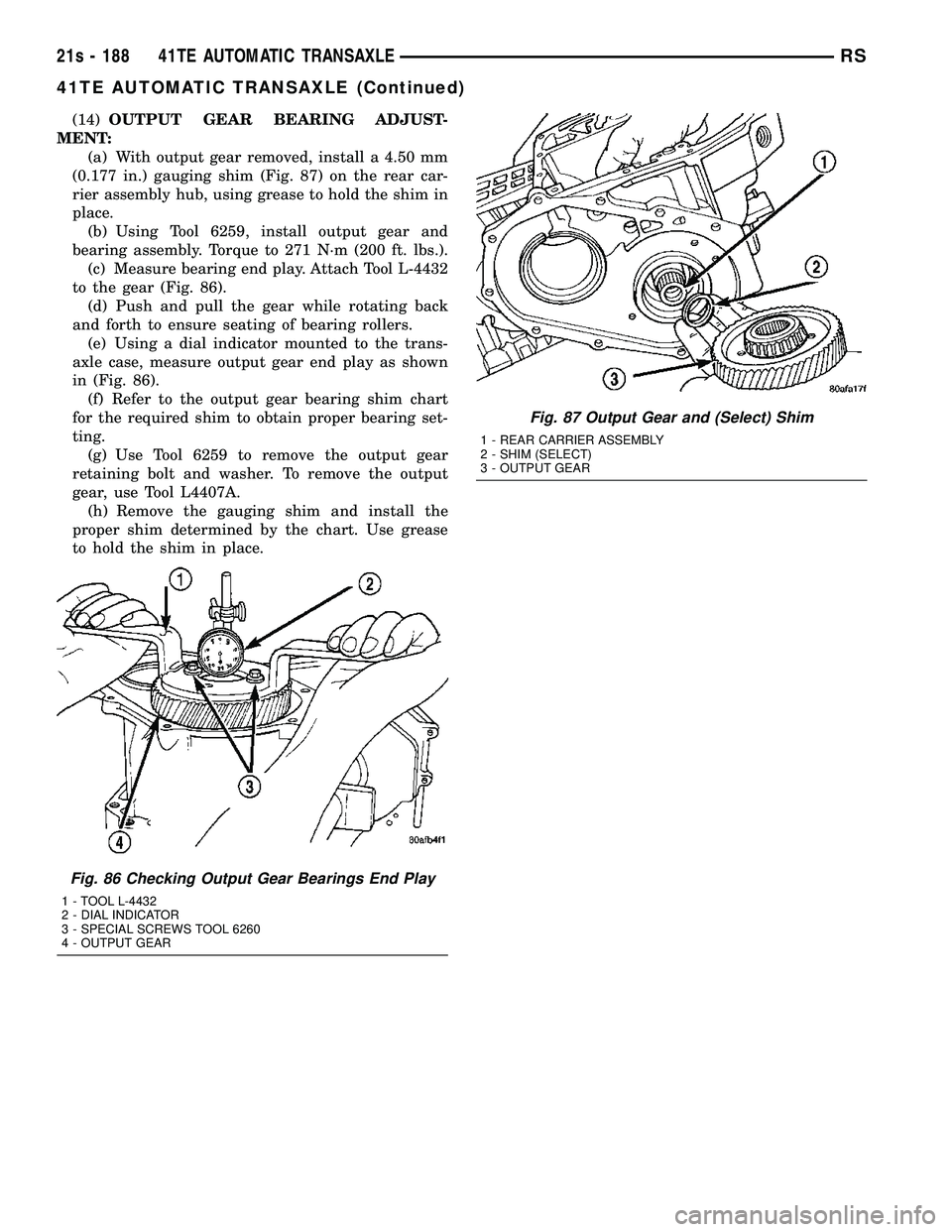

(14)OUTPUT GEAR BEARING ADJUST-

MENT: (a) With output gear removed, install a 4.50 mm

(0.177 in.) gauging shim (Fig. 87) on the rear car-

rier assembly hub, using grease to hold the shim in

place. (b) Using Tool 6259, install output gear and

bearing assembly. Torque to 271 N´m (200 ft. lbs.). (c) Measure bearing end play. Attach Tool L-4432

to the gear (Fig. 86). (d) Push and pull the gear while rotating back

and forth to ensure seating of bearing rollers. (e) Using a dial indicator mounted to the trans-

axle case, measure output gear end play as shown

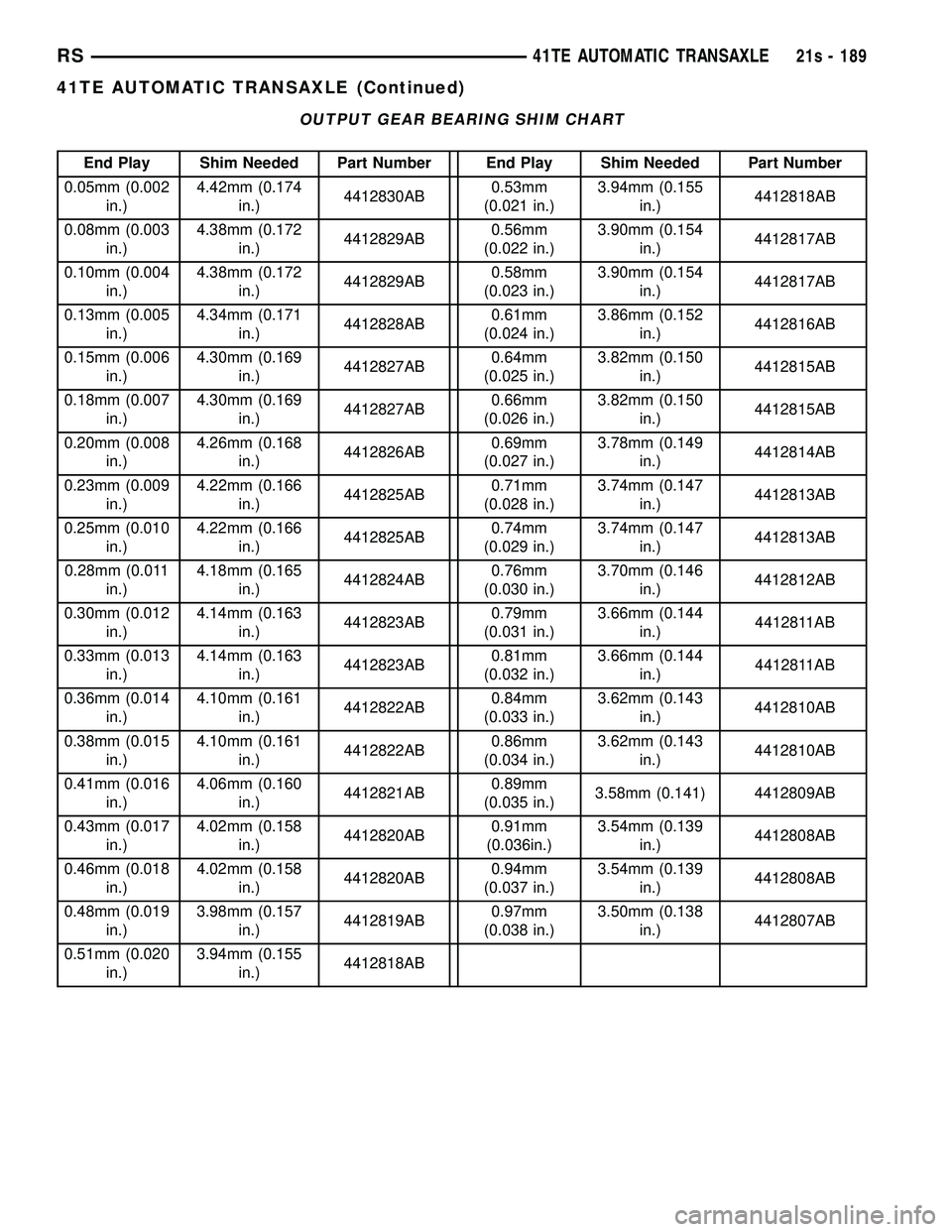

in (Fig. 86). (f) Refer to the output gear bearing shim chart

for the required shim to obtain proper bearing set-

ting. (g) Use Tool 6259 to remove the output gear

retaining bolt and washer. To remove the output

gear, use Tool L4407A. (h) Remove the gauging shim and install the

proper shim determined by the chart. Use grease

to hold the shim in place.

Fig. 86 Checking Output Gear Bearings End Play

1 - TOOL L-4432

2 - DIAL INDICATOR

3 - SPECIAL SCREWS TOOL 6260

4 - OUTPUT GEAR

Fig. 87 Output Gear and (Select) Shim

1 - REAR CARRIER ASSEMBLY

2 - SHIM (SELECT)

3 - OUTPUT GEAR

21s - 188 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

Page 2050 of 2585

OUTPUT GEAR BEARING SHIM CHART

End Play Shim Needed Part Number End Play Shim Needed Part Number

0.05mm (0.002 in.) 4.42mm (0.174

in.) 4412830AB 0.53mm

(0.021 in.) 3.94mm (0.155

in.) 4412818AB

0.08mm (0.003 in.) 4.38mm (0.172

in.) 4412829AB 0.56mm

(0.022 in.) 3.90mm (0.154

in.) 4412817AB

0.10mm (0.004 in.) 4.38mm (0.172

in.) 4412829AB 0.58mm

(0.023 in.) 3.90mm (0.154

in.) 4412817AB

0.13mm (0.005 in.) 4.34mm (0.171

in.) 4412828AB 0.61mm

(0.024 in.) 3.86mm (0.152

in.) 4412816AB

0.15mm (0.006 in.) 4.30mm (0.169

in.) 4412827AB 0.64mm

(0.025 in.) 3.82mm (0.150

in.) 4412815AB

0.18mm (0.007 in.) 4.30mm (0.169

in.) 4412827AB 0.66mm

(0.026 in.) 3.82mm (0.150

in.) 4412815AB

0.20mm (0.008 in.) 4.26mm (0.168

in.) 4412826AB 0.69mm

(0.027 in.) 3.78mm (0.149

in.) 4412814AB

0.23mm (0.009 in.) 4.22mm (0.166

in.) 4412825AB 0.71mm

(0.028 in.) 3.74mm (0.147

in.) 4412813AB

0.25mm (0.010 in.) 4.22mm (0.166

in.) 4412825AB 0.74mm

(0.029 in.) 3.74mm (0.147

in.) 4412813AB

0.28mm (0.011 in.) 4.18mm (0.165

in.) 4412824AB 0.76mm

(0.030 in.) 3.70mm (0.146

in.) 4412812AB

0.30mm (0.012 in.) 4.14mm (0.163

in.) 4412823AB 0.79mm

(0.031 in.) 3.66mm (0.144

in.) 4412811AB

0.33mm (0.013 in.) 4.14mm (0.163

in.) 4412823AB 0.81mm

(0.032 in.) 3.66mm (0.144

in.) 4412811AB

0.36mm (0.014 in.) 4.10mm (0.161

in.) 4412822AB 0.84mm

(0.033 in.) 3.62mm (0.143

in.) 4412810AB

0.38mm (0.015 in.) 4.10mm (0.161

in.) 4412822AB 0.86mm

(0.034 in.) 3.62mm (0.143

in.) 4412810AB

0.41mm (0.016 in.) 4.06mm (0.160

in.) 4412821AB 0.89mm

(0.035 in.) 3.58mm (0.141) 4412809AB

0.43mm (0.017 in.) 4.02mm (0.158

in.) 4412820AB 0.91mm

(0.036in.) 3.54mm (0.139

in.) 4412808AB

0.46mm (0.018 in.) 4.02mm (0.158

in.) 4412820AB 0.94mm

(0.037 in.) 3.54mm (0.139

in.) 4412808AB

0.48mm (0.019 in.) 3.98mm (0.157

in.) 4412819AB 0.97mm

(0.038 in.) 3.50mm (0.138

in.) 4412807AB

0.51mm (0.020 in.) 3.94mm (0.155

in.) 4412818AB

RS

41TE AUTOMATIC TRANSAXLE21s - 189

41TE AUTOMATIC TRANSAXLE (Continued)