ignition CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2416 of 2585

heater control has detected a failure and a Diagnostic

Trouble Code (DTC) has been set. Refer to Body

Diagnostic Procedures to perform further diagnosis.

The LEDs or graphics will continue to flash even

after the ignition switch is cycled Off and On, until a

successful calibration is completed or until the vehi-

cle has been driven about 13 kilometers (8 miles).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(3) Place the instrument panel center bezel unit

face down on a suitable work surface. Take the

proper precautions to protect the center bezel from

cosmetic damage.

(4) If the vehicle is equipped with the optional

Automatic Temperature Control (ATC) system, dis-

connect the infrared sensor jumper harness connector

from the receptacle on the back of the A/C-heater

control (Fig. 9).

(5) Remove the six screws that secure the A/C-

heater control to the back of the instrument panel

center bezel.

(6) Remove the A/C-heater control from the instru-

ment panel center bezel.

INSTALLATION

(1) Position the A/C-heater control onto the back of

instrument panel center bezel.

(2) Install the six screws that secure the A/C-

heater control to the back of the instrument panel

center bezel. Tighten the screws to 2 N´m (17 in.

lbs.).

(3) If the vehicle is equipped with the optional

ATC system, reconnect the infrared sensor jumper

harness connector to A/C-heater control.(4) Install the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(5) Reconnect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION

The A/C pressure transducer is a switch that is

installed on a fitting located on the refrigerant liquid

line between the receiver/drier and the expansion

valve in the right rear corner of the engine compart-

ment. An internally threaded hex fitting on the

transducer connects it to the externally threaded

Schrader-type fitting on the liquid line. A rubber

O-ring seals the connection between the transducer

and the liquid line fitting. Three terminals within a

molded plastic connector receptacle on the top of the

transducer connect it to the vehicle electrical system

through a wire lead and connector of the headlamp

and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the liquid line.

The transducer will change its internal resistance in

response to the pressures it monitors. The power-

train control module (PCM) provides a five volt ref-

Fig. 9 A/C-Heater Control

1 - INFRARED SENSOR CONNECTOR (ATC ONLY)

2 - INFRARED SENSOR HARNESS (ATC ONLY)

3 - A/C-HEATER CONTROL AREA

4 - SCREW (6)

5- INSTRUMENT PANEL CENTER BEZEL

RSCONTROLS - FRONT24-21

A/C HEATER CONTROL (Continued)

Page 2441 of 2585

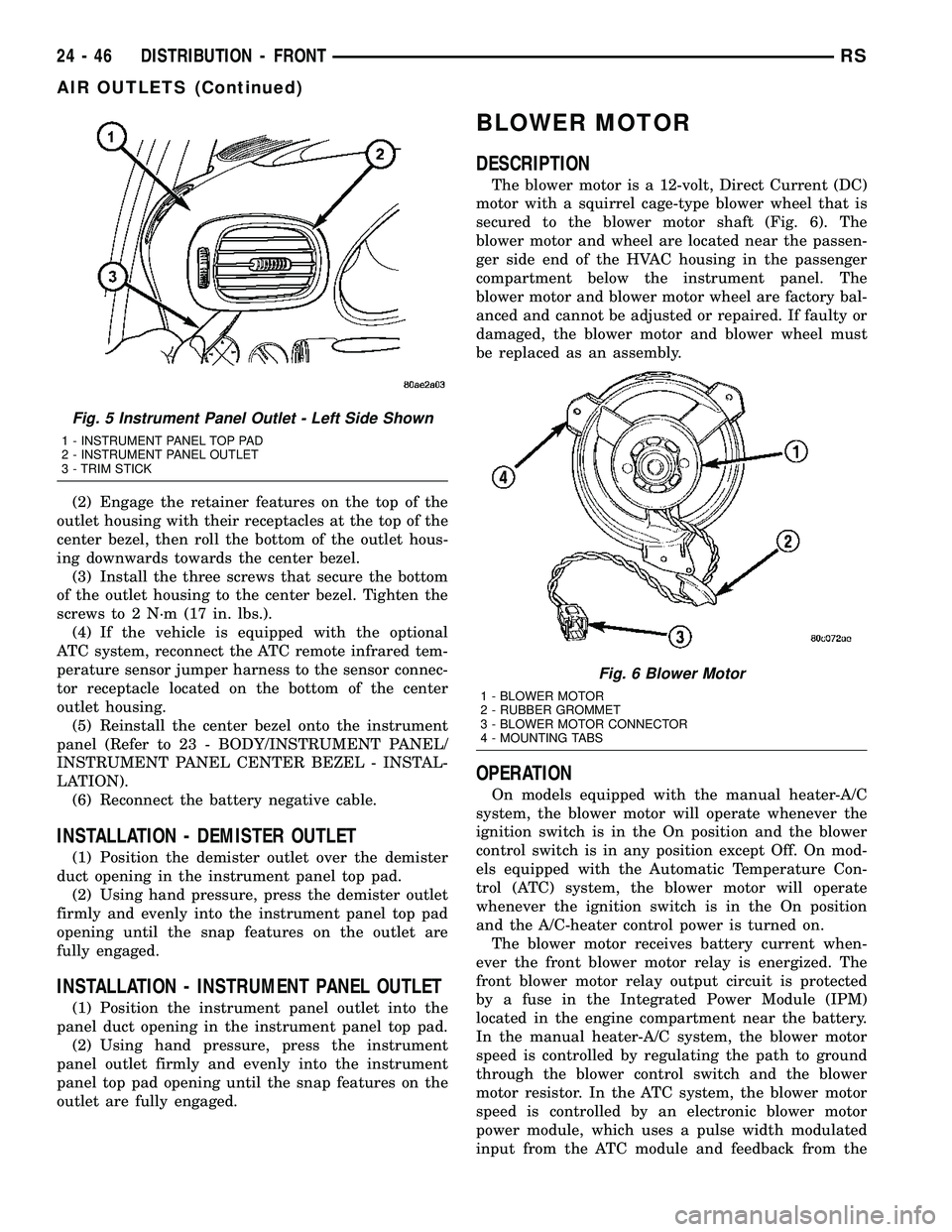

(2) Engage the retainer features on the top of the

outlet housing with their receptacles at the top of the

center bezel, then roll the bottom of the outlet hous-

ing downwards towards the center bezel.

(3) Install the three screws that secure the bottom

of the outlet housing to the center bezel. Tighten the

screws to 2 N´m (17 in. lbs.).

(4) If the vehicle is equipped with the optional

ATC system, reconnect the ATC remote infrared tem-

perature sensor jumper harness to the sensor connec-

tor receptacle located on the bottom of the center

outlet housing.

(5) Reinstall the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(6) Reconnect the battery negative cable.

INSTALLATION - DEMISTER OUTLET

(1) Position the demister outlet over the demister

duct opening in the instrument panel top pad.

(2) Using hand pressure, press the demister outlet

firmly and evenly into the instrument panel top pad

opening until the snap features on the outlet are

fully engaged.

INSTALLATION - INSTRUMENT PANEL OUTLET

(1) Position the instrument panel outlet into the

panel duct opening in the instrument panel top pad.

(2) Using hand pressure, press the instrument

panel outlet firmly and evenly into the instrument

panel top pad opening until the snap features on the

outlet are fully engaged.

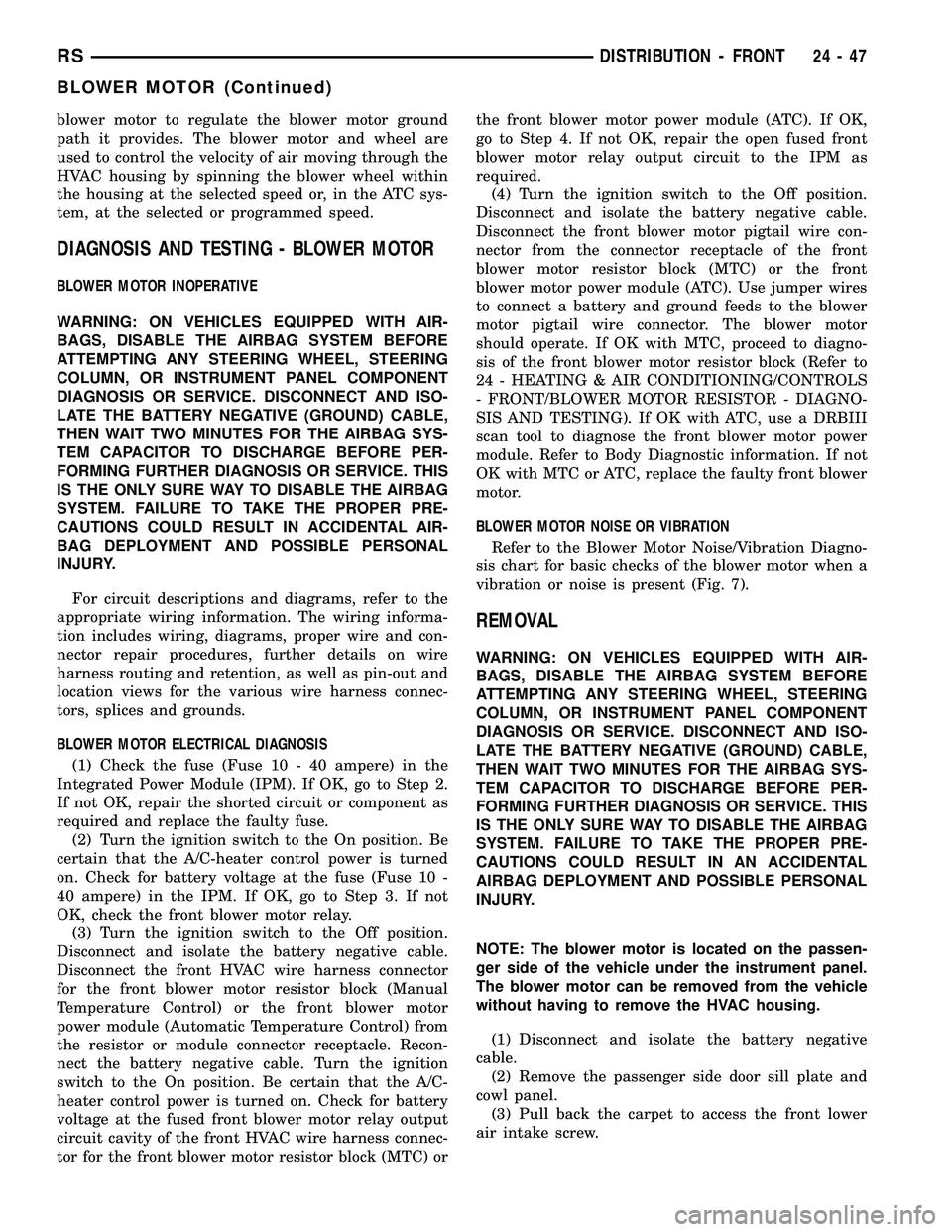

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 6). The

blower motor and wheel are located near the passen-

ger side end of the HVAC housing in the passenger

compartment below the instrument panel. The

blower motor and blower motor wheel are factory bal-

anced and cannot be adjusted or repaired. If faulty or

damaged, the blower motor and blower wheel must

be replaced as an assembly.

OPERATION

On models equipped with the manual heater-A/C

system, the blower motor will operate whenever the

ignition switch is in the On position and the blower

control switch is in any position except Off. On mod-

els equipped with the Automatic Temperature Con-

trol (ATC) system, the blower motor will operate

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

Fig. 5 Instrument Panel Outlet - Left Side Shown

1 - INSTRUMENT PANEL TOP PAD

2 - INSTRUMENT PANEL OUTLET

3 - TRIM STICK

Fig. 6 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

24 - 46 DISTRIBUTION - FRONTRS

AIR OUTLETS (Continued)

Page 2442 of 2585

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) orthe front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehicle

without having to remove the HVAC housing.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the passenger side door sill plate and

cowl panel.

(3) Pull back the carpet to access the front lower

air intake screw.

RSDISTRIBUTION - FRONT24-47

BLOWER MOTOR (Continued)

Page 2452 of 2585

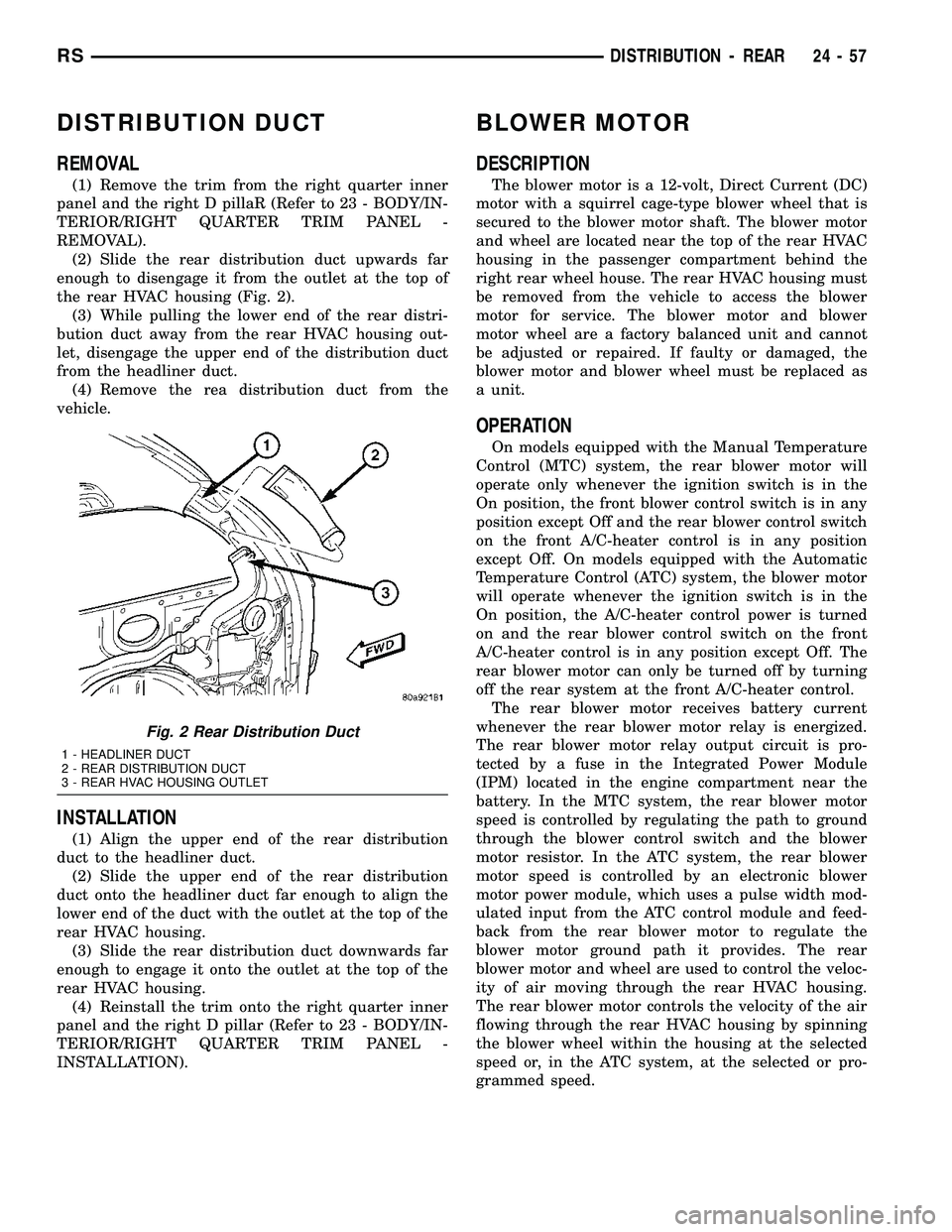

DISTRIBUTION DUCT

REMOVAL

(1) Remove the trim from the right quarter inner

panel and the right D pillaR (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

REMOVAL).

(2) Slide the rear distribution duct upwards far

enough to disengage it from the outlet at the top of

the rear HVAC housing (Fig. 2).

(3) While pulling the lower end of the rear distri-

bution duct away from the rear HVAC housing out-

let, disengage the upper end of the distribution duct

from the headliner duct.

(4) Remove the rea distribution duct from the

vehicle.

INSTALLATION

(1) Align the upper end of the rear distribution

duct to the headliner duct.

(2) Slide the upper end of the rear distribution

duct onto the headliner duct far enough to align the

lower end of the duct with the outlet at the top of the

rear HVAC housing.

(3) Slide the rear distribution duct downwards far

enough to engage it onto the outlet at the top of the

rear HVAC housing.

(4) Reinstall the trim onto the right quarter inner

panel and the right D pillar (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

INSTALLATION).

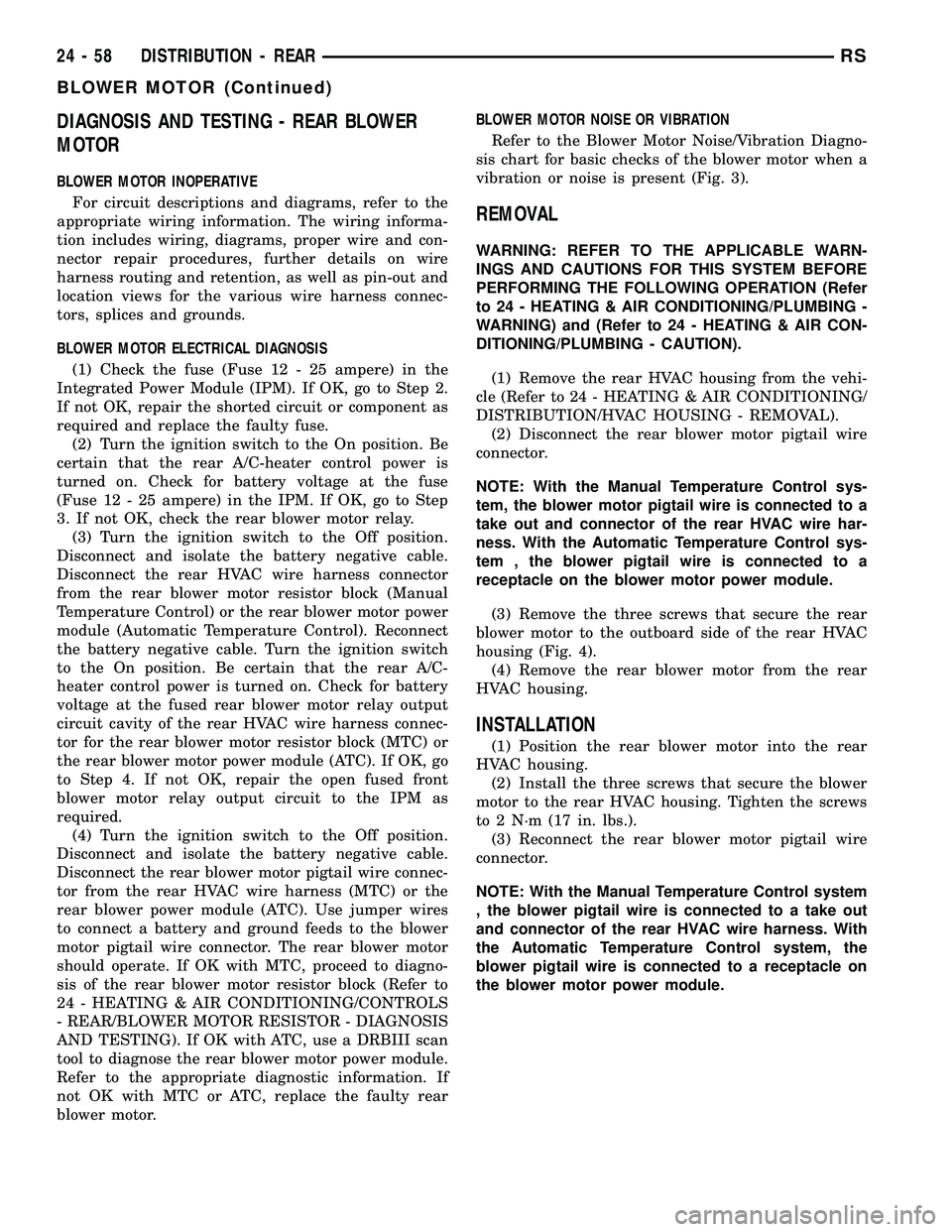

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft. The blower motor

and wheel are located near the top of the rear HVAC

housing in the passenger compartment behind the

right rear wheel house. The rear HVAC housing must

be removed from the vehicle to access the blower

motor for service. The blower motor and blower

motor wheel are a factory balanced unit and cannot

be adjusted or repaired. If faulty or damaged, the

blower motor and blower wheel must be replaced as

a unit.

OPERATION

On models equipped with the Manual Temperature

Control (MTC) system, the rear blower motor will

operate only whenever the ignition switch is in the

On position, the front blower control switch is in any

position except Off and the rear blower control switch

on the front A/C-heater control is in any position

except Off. On models equipped with the Automatic

Temperature Control (ATC) system, the blower motor

will operate whenever the ignition switch is in the

On position, the A/C-heater control power is turned

on and the rear blower control switch on the front

A/C-heater control is in any position except Off. The

rear blower motor can only be turned off by turning

off the rear system at the front A/C-heater control.

The rear blower motor receives battery current

whenever the rear blower motor relay is energized.

The rear blower motor relay output circuit is pro-

tected by a fuse in the Integrated Power Module

(IPM) located in the engine compartment near the

battery. In the MTC system, the rear blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the rear blower

motor speed is controlled by an electronic blower

motor power module, which uses a pulse width mod-

ulated input from the ATC control module and feed-

back from the rear blower motor to regulate the

blower motor ground path it provides. The rear

blower motor and wheel are used to control the veloc-

ity of air moving through the rear HVAC housing.

The rear blower motor controls the velocity of the air

flowing through the rear HVAC housing by spinning

the blower wheel within the housing at the selected

speed or, in the ATC system, at the selected or pro-

grammed speed.

Fig. 2 Rear Distribution Duct

1 - HEADLINER DUCT

2 - REAR DISTRIBUTION DUCT

3 - REAR HVAC HOUSING OUTLET

RSDISTRIBUTION - REAR24-57

Page 2453 of 2585

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR

BLOWER MOTOR INOPERATIVE

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear A/C-heater control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, check the rear blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector

from the rear blower motor resistor block (Manual

Temperature Control) or the rear blower motor power

module (Automatic Temperature Control). Reconnect

the battery negative cable. Turn the ignition switch

to the On position. Be certain that the rear A/C-

heater control power is turned on. Check for battery

voltage at the fused rear blower motor relay output

circuit cavity of the rear HVAC wire harness connec-

tor for the rear blower motor resistor block (MTC) or

the rear blower motor power module (ATC). If OK, go

to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear blower motor pigtail wire connec-

tor from the rear HVAC wire harness (MTC) or the

rear blower power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The rear blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the rear blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- REAR/BLOWER MOTOR RESISTOR - DIAGNOSIS

AND TESTING). If OK with ATC, use a DRBIII scan

tool to diagnose the rear blower motor power module.

Refer to the appropriate diagnostic information. If

not OK with MTC or ATC, replace the faulty rear

blower motor.BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 3).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control sys-

tem, the blower motor pigtail wire is connected to a

take out and connector of the rear HVAC wire har-

ness. With the Automatic Temperature Control sys-

tem , the blower pigtail wire is connected to a

receptacle on the blower motor power module.

(3) Remove the three screws that secure the rear

blower motor to the outboard side of the rear HVAC

housing (Fig. 4).

(4) Remove the rear blower motor from the rear

HVAC housing.

INSTALLATION

(1) Position the rear blower motor into the rear

HVAC housing.

(2) Install the three screws that secure the blower

motor to the rear HVAC housing. Tighten the screws

to 2 N´m (17 in. lbs.).

(3) Reconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control system

, the blower pigtail wire is connected to a take out

and connector of the rear HVAC wire harness. With

the Automatic Temperature Control system, the

blower pigtail wire is connected to a receptacle on

the blower motor power module.

24 - 58 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)

Page 2507 of 2585

CABIN HEATER

TABLE OF CONTENTS

page page

CABIN HEATER

DESCRIPTION........................112

OPERATION

OPERATION - MANUAL TEMPERATURE

CONTROL SYSTEM...................112

OPERATION - AUTOMATIC TEMPERATURE

CONTROL SYSTEM...................112

DIAGNOSIS AND TESTING - DIESEL

SUPPLEMENTAL CABIN HEATER........113

AIR INTAKE PIPE

REMOVAL............................113

INSTALLATION........................114

EXHAUST TUBE

REMOVAL............................114

INSTALLATION........................115FUEL DOSING PUMP

DESCRIPTION........................115

OPERATION..........................115

REMOVAL............................115

INSTALLATION........................116

FUEL LINE

STANDARD PROCEDURE - CLEANING.....117

REMOVAL............................117

INSTALLATION........................118

HEATER UNIT

REMOVAL............................118

INSTALLATION........................119

SUPPLEMENTAL DIESEL HEATER WIRING

REMOVAL............................119

INSTALLATION........................119

CABIN HEATER

DESCRIPTION

Vehicles equipped with the diesel engine are also

equipped with a supplemental cabin heater. This

cabin heater is mounted under the vehicle and oper-

ates similar to an oil fired furnace. The heater burns

small amounts of fuel to provide additional heat to

the coolant. Coolant is routed from the engine, to the

supplemental cabin heater and then to the front

heater core. This provides additional heat to the pas-

senger compartment. The supplemental cabin heater

system is interfaced to the vehicles on-board com-

puter systems and DRBIIItdiagnostics.

The supplemental cabin heater has an electronic

control module that monitors the heat output of the

heater. The cabin heater operates at full load (5 kW),

half load or idle mode (no additional heat) depending

on engine coolant temperature.

OPERATION

OPERATION - MANUAL TEMPERATURE

CONTROL SYSTEM

The supplemental cabin heater is activated via the

temperature slide control or knob on the A/C-heater

control when equipped with the manual temperature

control (MTC) system. If the slide control or knob is

moved to or above the upper set point the cabin

heater is activated. The cabin heater can operate in a

full or partial load range as well as an idle mode alldependent on the engine coolant temperature. The

cabin heater will also turn off if the A/C-heater tem-

perature control is lowered to less than the lower set

point. The cabin heater can take up to three minutes

to completely shut down when either the heater tem-

perature is set below the lower set point or the vehi-

cle ignition is shut down.

NOTE: Do not apply a strong vacuum source such

as a garage ventilation system directly on the sup-

plemental cabin heater exhaust line. Too strong of a

vacuum can prevent the supplemental cabin heater

from starting. If required, place the vacuum source

at least 75 mm (3 in.) away from the exhaust line.

The supplemental cabin heater only operates when

the engine is running, the mileage exceeds 8 kilome-

ter (5 mph) and the fuel tank volume exceeds 1/8 of a

tank. The supplemental heater control module moni-

tors blower speed and combustion during its start-up.

The cabin heater should operate if the coolant tem-

perature is below 40É C (104É F).

OPERATION - AUTOMATIC TEMPERATURE

CONTROL SYSTEM

The automatic temperature control (ATC) system

will activate the supplemental cabin heater based on

engine coolant temperature and interior component

settings. The cabin heater can operate in a full or

partial load range as well as an idle mode all depen-

dent on the engine coolant temperature. The cabin

heater will also turn off if the A/C-heater tempera-

ture control is lowered to less than the lower set

24 - 112 CABIN HEATERRS

Page 2508 of 2585

point. The cabin heater can take up to three minutes

to completely shut down when either the heater tem-

perature is set below the lower set point or the vehi-

cle ignition is shut down.

NOTE: Do not apply a strong vacuum source such

as a garage ventilation system directly on the sup-

plemental cabin heater exhaust line. Too strong of a

vacuum can prevent the supplemental cabin heater

from starting. If required, place the vacuum source

at least 75 mm (3 in.) away from the exhaust line.

The supplemental cabin heater only operates when

the engine is running, the mileage exceeds 8 kilome-ter (5 mph) and the fuel tank volume exceeds 1/8 of a

tank. The supplemental heater control module moni-

tors blower speed and combustion during its start-up.

The cabin heater should operate if the coolant tem-

perature is below 40É C (104É F).

DIAGNOSIS AND TESTING - DIESEL

SUPPLEMENTAL CABIN HEATER

Refer to the Symptoms Diagnosis table for basic

checks of the diesel fueled supplemental cabin heater.

SYMPTOMS DIAGNOSIS

Symptom Possible Causes

Smell of diesel fuel. Check cabin heater system integration in vehicle's fuel system. Check

fuel lines for leakage, kinks or obstructions. If OK, Inspect the inlet

muffler, drain as necessary. Re-test the cabin heater and re-inspect.

Inspect the exhaust tube and cabin heater for the presence of external

fuel. If presence of external fuel is observed on the heater unit or in the

exhaust tube or after draining and testing. Remove the cabin heater

from vehicle and repair or replace components as required.

Heater does not achieve full load

operation.Check cabin heater operation with DRBIIITscan tool and replace

components as required.

Continuous white smoke from heater

exhaust during combustion operation.Check cabin heater operation with DRBIIITscan tool and replace

components as required. White smoke is typical in extreme weather

conditions.

Heater can not be switched off. Check cabin heater operation with DRBIIITscan tool and replace

components as required.

Heater does not operate. Diagnosis cabin heater control module using the DRBIIITscan tool and

the procedures listed in Vehicle Performance under Cabin Heater

Diagnosis in Group 18.

Loss of coolant (Leakage) or heater

develops smoke during combustion

operation and exhaust has an

extremely sweet smell.Inspect coolant hoses for leakage, kinks or loose hose connection.

Inspect the exhaust tube assembly for continuous flow, if OK there is an

internal heater leak and cabin heater should be inspected and

components should be replaced as required.

Loss of fuel (dripping). Check cabin heater system integration in vehicles fuel system. Check

fuel line connection for leakage. If OK there is an internal leak and

cabin heater should be inspected and replaced as required.

AIR INTAKE PIPE

REMOVAL

NOTE: The air intake tube for the supplemental

cabin heater is part of an assembly that includes

the heater cooling intake and return pipes. If the

cabin heater air intake tube requires removal or

replacement the entire cabin heater assembly will

require removal or replacement.(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(2) Remove clamps from the cabin heater tubes at

the lower heater port and the lower EGR connector

which are located under the hood.

(3) Remove the retaining clamp at the cabin

heater air intake muffler connection (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/INLET MUFFLER - REMOVAL).

(4) Remove the clamp at the flexible tube to steel

tube connection (Fig. 1).

RSCABIN HEATER24 - 113

CABIN HEATER (Continued)

Page 2513 of 2585

INSTALLATION

WARNING: DO NOT OPERATE THE DIESEL SUP-

PLEMENTAL CABIN HEATER IN AN ENCLOSED

AREA SUCH AS A GARAGE THAT DOES NOT HAVE

EXHAUST VENTILATION FACILITIES. ALWAYS VENT

THE CABIN HEATER EXHAUST WHEN OPERATING

THE CABIN HEATER. ALLOW THE DIESEL SUPPLE-

MENTAL CABIN HEATER TO COOL BEFORE PER-

FORMING ANY SERVICE PROCEDURES TO THE

CABIN HEATER. VERIFY THAT ALL DIESEL SUP-

PLEMENTAL CABIN HEATER FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING ANY SER-

VICE PROCEDURES TO THE CABIN HEATER. FAIL-

URE TO FOLLOW THESE INSTRUCTION MAY

RESULT IN PERSONAL INJURY OR DEATH.

NOTE: Verify that there is more than 1/8 of a tank of

fuel in the vehicle's fuel tank before performing this

procedure. Add fuel, if necessary.

(1) Install the cabin heater fuel supply line into

vehicle and fuel line retainers.

(2) Install the fuel line connection at the fuel tank

and tighten the connection securely.

(3) Install the fuel line at the dosing pump and

tighten the connection securely.

(4) Lower the vehicle.

NOTE: Failure to prime the dosing pump after drain-

ing the supplemental cabin fuel line will prevent

cabin heater activation during the first attempt to

start the cabin heater. This will also set a diagnostic

trouble code (DTC) in the cabin heater control's

memory. Do not perform the Dosing Pump Priming

procedure if an attempt was made to start the cabin

heater without priming the dosing pump first. This

will put excess fuel in the cabin heater and cause

smoke to emit from the cabin heater exhaust pipe

when cabin heater activation occurs.

(5) Connect the DRBIIItscan tool to the diagnos-

tic link connector.

(6) Turn the ignition to the ON position.

NOTE: Do not activate the dosing pump prime more

than one time. This will put excess fuel in the sup-

plemental cabin heater and cause smoke to emit

from the cabin heater exhaust pipe when cabin

heater activation occurs.

NOTE: A clicking noise heard coming from the dos-

ing pump indicates that the pump is operational.(7) With the DRBIIItscan tool in Cabin Heater,

select System Tests and Dosing Pump Prime. Allow

the dosing pump to run for the full 45 second cycle

time. When the 45 second cycle is complete, press

Page Back on the DRBIIItscan tool key pad to exit

the Dosing Pump Prime. The Dosing Pump Priming

procedure is now complete.

HEATER UNIT

REMOVAL

WARNING: DO NOT OPERATE THE DIESEL SUP-

PLEMENTAL CABIN HEATER IN AN ENCLOSED

AREA SUCH AS A GARAGE THAT DOES NOT HAVE

EXHAUST VENTILATION FACILITIES. ALWAYS VENT

THE CABIN HEATER EXHAUST WHEN OPERATING

THE CABIN HEATER. ALLOW THE DIESEL SUPPLE-

MENTAL CABIN HEATER TO COOL BEFORE PER-

FORMING ANY SERVICE PROCEDURES TO THE

CABIN HEATER. VERIFY THAT ALL DIESEL SUP-

PLEMENTAL CABIN HEATER FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING ANY SER-

VICE PROCEDURES TO THE CABIN HEATER. FAIL-

URE TO FOLLOW THESE INSTRUCTION MAY

RESULT IN PERSONAL INJURY OR DEATH.

(1) Raise and support the vehicle. Take note of the

location of the flexible section of the cabin heater

exhaust tube.

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Carefully open one hose to the underbody tube

assembly and drain the remaining coolant. A salvage

hose is a good idea to control the residual coolant, as

flow will occur from both the cabin heater and the

hose and tube assemblies.

(4) Remove the second hose from the underbody

hose and tube assembly.

(5) Loosen the hose and tube assembly from the

toe-board crossmember at two locations.

(6) Disconnect the electrical connector from the

body harness near the toe-board crossmember and

rail.

(7) Remove the wiring harness from the toe-board

crossmember (Refer to 24 - HEATING & AIR CON-

DITIONING/CABIN HEATER/HEATER UNIT -

REMOVAL).

(8) Open the fuel filler cap. Disconnect the rubber

fuel hose between the body tube assembly and the

fuel pump nipple at the body tube joint. A minimal

amount of fuel may flow from the open port.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel.

24 - 118 CABIN HEATERRS

FUEL LINE (Continued)

Page 2517 of 2585

The following is a list of the monitored compo-

nents:

²Comprehensive Components

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

COMPREHENSIVE COMPONENTS

Along with the major monitors, OBD II requires

that the diagnostic system monitor any component

that could affect emissions levels. In many cases,

these components were being tested under OBD I.

The OBD I requirements focused mainly on testing

emissions-related components for electrical opens and

shorts.

However, OBD II also requires that inputs from

powertrain components to the PCM be tested for

rationality, and that outputs to powertrain compo-

nents from the PCM be tested forfunctionality.

Methods for monitoring the various Comprehensive

Component monitoring include:

(1) Circuit Continuity

²Open

²Shorted high

²Shorted to ground

(2) Rationality or Proper Functioning

²Inputs tested for rationality

²Outputs tested for functionality

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake/inlet Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Brake Switch

²Leak Detection Pump Switch or NVLD switch (if

equipped)

²P/N SwitchOutput FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Idle Air Control

²Purge Solenoid

²EGR Solenoid (if equipped)

²LDP Solenoid or NVLD solenoid (if equipped)

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen in

the exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV (volt-

ages are offset by 2.5 volts on NGC vehicles).

The information obtained by the sensor is used to

calculate the fuel injector pulse width. The PCM is

programmed to maintain the optimum air/fuel ratio.

At this mixture ratio, the catalyst works best to

remove hydrocarbons (HC), carbon monoxide (CO)

and nitrous oxide (NOx) from the exhaust.

The O2S is also the main sensing element for the

EGR (if equipped), Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse rate

is the time required for the sensor to switch from

lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

25 - 2 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2519 of 2585

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF.

The PCM sends a 5 volt bias to the oxygen sensor

every 1.6 seconds. The PCM keeps it biased for 35

ms each time. As the sensor cools down, the resis-

tance increases and the PCM reads the increase in

voltage. Once voltage has increased to a predeter-

mined amount, higher than when the test started,

the oxygen sensor is cool enough to test heater oper-

ation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 3 minutes

²Engine run time at a predetermined speed

and throttle opening.

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

Pending ConditionsÐThere are not conditions or

situations that prompt conflict or suspension of test-

ing. The oxygen sensor heater test is not run pending

resolution of MIL illumination due to oxygen sensor

failure.

SuspendÐThere are no conditions which exist for

suspending the Heater Monitor.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S strategy is based on the fact that as a cat-alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL (check

engine lamp) will be illuminated.

Monitor OperationÐTo monitor catalyst effi-

ciency, the PCM expands the rich and lean switch

points of the heated oxygen sensor. With extended

switch points, the air/fuel mixture runs richer and

leaner to overburden the catalytic converter. Once

the test is started, the air/fuel mixture runs rich and

lean and the O2 switches are counted. A switch is

counted when an oxygen sensor signal goes from

below the lean threshold to above the rich threshold.

The number of Rear O2 sensor switches is divided by

the number of Front O2 sensor switches to determine

the switching ratio.

The test runs for 20 seconds. As catalyst efficiency

deteriorated over the life of the vehicle, the switch

rate at the downstream sensor approaches that of the

upstream sensor. If at any point during the test

25 - 4 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)