ignition CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2520 of 2585

period the switch ratio reaches a predetermined

value, a counter is incremented by one. The monitor

is enabled to run another test during that trip. When

the test fails 6 times, the counter increments to 3, a

malfunction is entered, and a Freeze Frame is stored,

the code is matured and the MIL is illuminated. If

the first test passes, no further testing is conducted

during that trip.

The MIL is extinguished after three consecutive

good trips. The good trip criteria for the catalyst

monitor is more stringent than the failure criteria. In

order to pass the test and increment one good trip,

the downstream sensor switch rate must be less than

45% of the upstream rate. The failure percentages

are 59% respectively.

Enabling ConditionsÐThe following conditions

must typically be met before the PCM runs the cat-

alyst monitor. Specific times for each parameter may

be different from engine to engine.

²Accumulated drive time

²Enable time

²Ambient air temperature

²Barometric pressure

²Catalyst warm-up counter

²Engine coolant temperature

²Vehicle speed

²MAP

²RPM

²Engine in closed loop

²Fuel level

Pending ConditionsÐ

²Misfire DTC

²Front Oxygen Sensor Response

²Front Oxygen Sensor Heater Monitor

²Front Oxygen Sensor Electrical

²Rear Oxygen Sensor Rationality (middle check)

²Rear Oxygen Sensor Heater Monitor

²Rear Oxygen Sensor Electrical

²Fuel System Monitor

²All TPS faults

²All MAP faults

²All ECT sensor faults

²Purge flow solenoid functionality

²Purge flow solenoid electrical

²All PCM self test faults

²All CMP and CKP sensor faults

²All injector and ignition electrical faults

²Idle Air Control (IAC) motor functionality

²Vehicle Speed Sensor

²Brake switch (auto trans only)

²Intake air temperature

ConflictÐThe catalyst monitor does not run if any

of the following are conditions are present:

²EGR Monitor in progress (if equipped)

²Fuel system rich intrusive test in progress

²EVAP Monitor in progress²Time since start is less than 60 seconds

²Low fuel level-less than 15 %

²Low ambient air temperature

²Ethanol content learn is taking place and the

ethanol used once flag is set

SuspendÐThe Task Manager does not mature a

catalyst fault if any of the following are present:

²Oxygen Sensor Monitor, Priority 1

²Oxygen Sensor Heater, Priority 1

²EGR Monitor, Priority 1 (if equipped)

²EVAP Monitor, Priority 1

²Fuel System Monitor, Priority 2

²Misfire Monitor, Priority 2

OPERATION - NON-MONITORED CIRCUITS

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor, fuel system, or mis-

fire diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables. The misfire will however,

increase the oxygen content in the exhaust, deceiving

the PCM in to thinking the fuel system is too lean.

Also see misfire detection.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression. Low compression lowers O2

content in the exhaust. Leading to fuel system, oxy-

gen sensor, or misfire detection fault.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR (if

equipped) or Fuel system or O2S fault.

RSEMISSIONS CONTROL25-5

EMISSIONS CONTROL (Continued)

Page 2521 of 2585

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times,

including when diagnostics are performed.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the a DRBIIItscan tool.

The following is a list of the system monitors:

²EGR Monitor (if equipped)²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor (if

equipped)

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperatures of 300É to 350ÉC (572É to 662ÉF),

the sensor generates a voltage that is inversely pro-

portional to the amount of oxygen in the exhaust.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. The PCM is

programmed to maintain the optimum air/fuel ratio.

At this mixture ratio, the catalyst works best to

remove hydrocarbons (HC), carbon monoxide (CO)

and nitrous oxide (NOx) from the exhaust.

The O2S is also the main sensing element for the

EGR (if equipped), Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate

²Reduced output voltage

²Dynamic shift

²Shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt (voltages are offset by 2.5 volts on NGC vehi-

cles). A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) DTC as well as

a O2S heater DTC, the O2S heater fault MUST be

repaired first. After the O2S fault is repaired, verify

that the heater circuit is operating correctly.

25 - 6 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2524 of 2585

OPERATION

OPERATION - SYSTEM

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRBIIITscan tool

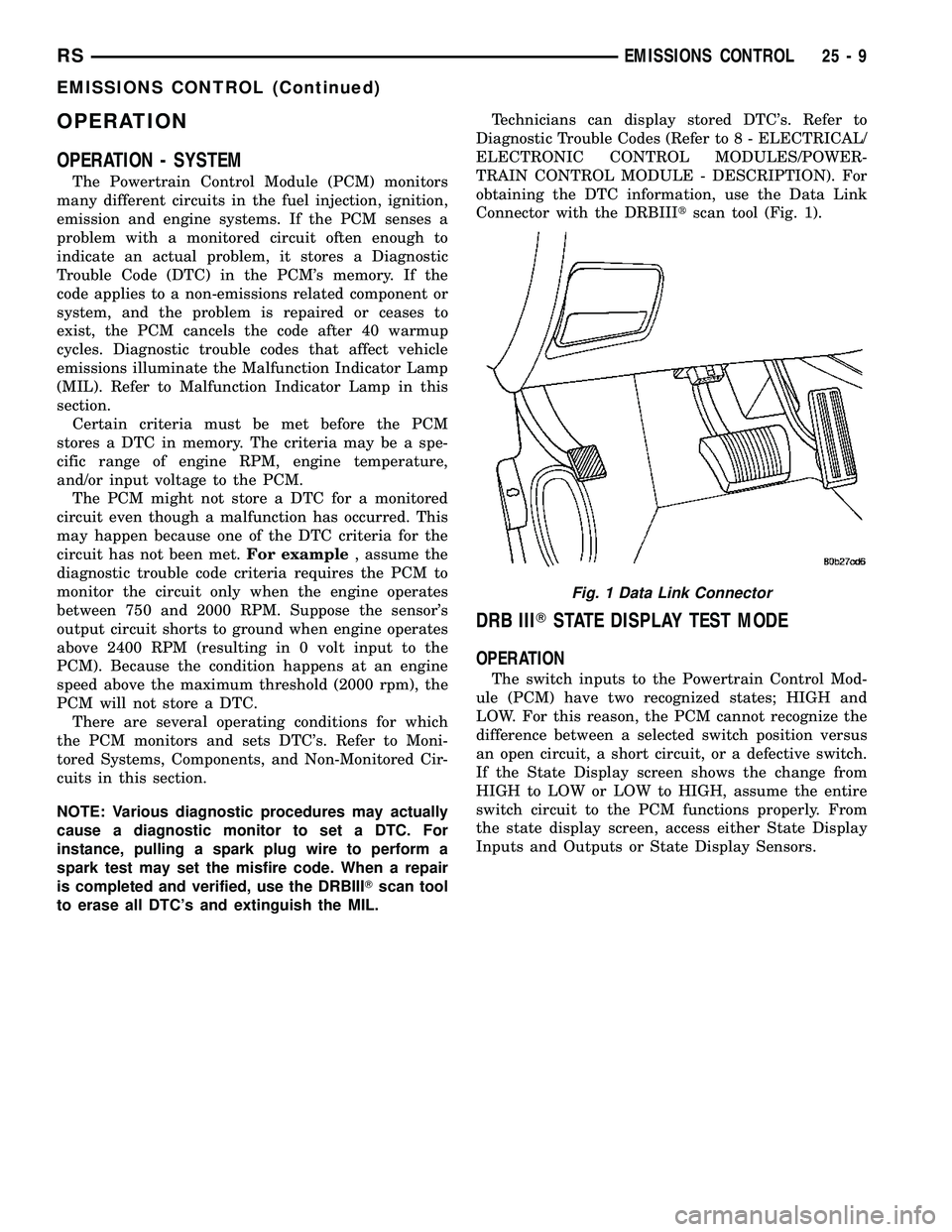

to erase all DTC's and extinguish the MIL.Technicians can display stored DTC's. Refer to

Diagnostic Trouble Codes (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/POWER-

TRAIN CONTROL MODULE - DESCRIPTION). For

obtaining the DTC information, use the Data Link

Connector with the DRBIIItscan tool (Fig. 1).

DRB IIITSTATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

Fig. 1 Data Link Connector

RSEMISSIONS CONTROL25-9

EMISSIONS CONTROL (Continued)

Page 2550 of 2585

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-153

CHANGE - STANDARD PROCEDURE,

DIFFERENTIAL ASSEMBLY FLUID.........3-40

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER...........9-137,9-53

CHANGE - STANDARD PROCEDURE,

OVERRUNNING CLUTCH HOUSING

FLUID..............................3-41

CHANGE - STANDARD PROCEDURE, PTU

FLUID..............................21-5

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-8

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-8

CHANNEL - INSTALLATION, WATER.....23-121

CHANNEL - REMOVAL, WATER.........23-121

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-72

CHARGE LEVEL TEST - 2.5L DIESEL -

DIAGNOSIS AND TESTING, SYSTEM......24-68

CHARGE LEVEL TEST - GASOLINE

ENGINES - DIAGNOSIS AND TESTING,

SYSTEM............................24-67

CHARGING - STANDARD PROCEDURE,

CONVENTIONAL BATTERY..............8F-11

CHARGING - STANDARD PROCEDURE,

SPIRAL PLATE BATTERY...............8F-10

CHARGING SYSTEM - DESCRIPTION.....8F-20

CHARGING SYSTEM - OPERATION.......8F-20

CHARTS - DIAGNOSIS AND TESTING,

STEERING SYSTEM DIAGNOSIS...........19-3

CHARTS - SPECIFICATIONS, COLOR

CODE..............................23-84

CHATTER COMPLAINTS - DIAGNOSIS

AND TESTING, CLUTCH.................6-6

CHECK - DIAGNOSIS AND TESTING,

COOLING SYSTEM FLOW................7-3

CHECK - DIAGNOSIS AND TESTING,

EXHAUST SYSTEM RESTRICTION.........11-2

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL.......................7-5

CHECK - STANDARD PROCEDURE,

ENGINE OIL LEVEL...................9-137

CHECK - STANDARD PROCEDURE, FLUID

LEVEL.............................21-71

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-53

CHECK, STANDARD PROCEDURE - FLUID

LEVEL AND CONDITION........21-201,21s-102

CHECK STRAP - INSTALLATION.........23-15

CHECK STRAP - REMOVAL.............23-15

CHECKING - STANDARD PROCEDURE,

BRAKE FLUID LEVEL..............5-32,5s-31

CHECKING - STANDARD PROCEDURE,

POWER STEERING FLUID LEVEL........19-44

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-14

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING..............9-52

CHECKING POWER STEERING BELT

TENSION - STANDARD PROCEDURE.......7-8

CHILD RESTRAINT ANCHOR -

DESCRIPTION........................8O-4

CHILD RESTRAINT ANCHOR -

OPERATION..........................8O-4

CHILD SEAT - INSTALLATION, QUAD.....23-89

CHILD SEAT - REMOVAL, QUAD.........23-89

CHILD SEAT MODULE, BENCH SEAT -

REMOVAL..........................23-87

CHIME SYSTEM - DIAGNOSIS AND

TESTING

............................8B-1

CHIME/BUZZER - DESCRIPTION

..........8B-1

CHIME/BUZZER - OPERATION

............8B-1

CHIME/BUZZER - WARNING

.............8B-1

CHIME/THERMISTOR - DESCRIPTION

....8N-10

CHIME/THERMISTOR - INSTALLATION

....8N-10

CHIME/THERMISTOR - OPERATION

......8N-10

CHIME/THERMISTOR - REMOVAL

.......8N-10

CHIRP PREFERENCE - STANDARD

PROCEDURE, HORN

..............8N-42,8N-5

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR

......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION

. . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION

. 8W-01-5

CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING, FEED

. . . 8F-32,8F-34CIRCUIT TEST - DIAGNOSIS AND

TESTING, CONTROL..............8F-30,8F-32

CIRCUIT TEST - DIAGNOSIS AND

TESTING, FEED.................8F-33,8F-35

CIRCUITS - OPERATION, NON-

MONITORED.........................25-5

CIRCUITS AND VALVES - OPERATION,

HYDRAULIC..........................5-83

CLAMP - STANDARD PROCEDURE,

HOSES..............................14-7

CLAMPS - DESCRIPTION, FUEL

LINES/HOSES........................14-6

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEAN, CLEANING...................21-114

CLEARANCE - STANDARD PROCEDURE,

MEASURING CONNECTING ROD

BEARING...........................9-120

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING........................9-12,9-84

CLOCK SPRING - DESCRIPTION..........8O-4

CLOCK SPRING - INSTALLATION.........8O-5

CLOCK SPRING - OPERATION...........8O-4

CLOCK SPRING - REMOVAL.............8O-5

CLOCK SPRING CENTERING -

STANDARD PROCEDURE...............8O-5

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT.....8J-1

CLUSTER BEZEL - INSTALLATION........23-63

CLUSTER BEZEL - REMOVAL.............23-63

CLUSTER DIAGNOSIS - DIAGNOSIS AND

TESTING............................8J-2

CLUSTER ILLUMINATION LAMPS -

INSTALLATION.......................8L-21

CLUSTER ILLUMINATION LAMPS -

REMOVAL..........................8L-21

CLUSTER LENS - INSTALLATION........8J-10

CLUSTER LENS - REMOVAL............8J-10

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, BI-

DIRECTIONAL OVERRUNNING...........3-34

CLUTCH - OPERATION, BI-DIRECTIONAL

OVERRUNNING.......................3-36

CLUTCH AIR PRESSURE TESTS -

DIAGNOSIS AND TESTING.......21-122,21s-30

CLUTCH ASSEMBLY - ASSEMBLY,

INPUT.....................21-216,21s-116

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT.....................21-208,21s-107

CLUTCH ASSY - 2.4L GAS -

INSTALLATION, MODULAR..............6-11

CLUTCH ASSY - 2.4L GAS - REMOVAL,

MODULAR...........................6-11

CLUTCH CHATTER COMPLAINTS -

DIAGNOSIS AND TESTING...............6-6

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-15

CLUTCH COVER AND DISC RUNOUT -

DIAGNOSIS AND TESTING...............6-6

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - INSTALLATION

...............6-12

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - REMOVAL

...................6-11

CLUTCH HOUSING FLUID CHANGE -

STANDARD PROCEDURE,

OVERRUNNING

.......................3-41

CLUTCH PEDAL INTERLOCK SWITCH -

INSTALLATION

........................6-14

CLUTCH PEDAL INTERLOCK SWITCH -

REMOVAL

...........................6-13

CLUTCH PEDAL UPSTOP SWITCH -

INSTALLATION

........................6-16

CLUTCH PEDAL UPSTOP SWITCH -

REMOVAL

...........................6-15

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR

.......................24-20

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR

.......................24-20

CLUTCH RELEASE LEVER AND BEARING

- INSTALLATION

.......................6-7

CLUTCH RELEASE LEVER AND BEARING

- REMOVAL

...........................6-6CLUTCH SYSTEM - DIAGNOSIS AND

TESTING.............................6-3

CLUTCH/COIL - DESCRIPTION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - INSPECTION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - INSTALLATION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - OPERATION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - REMOVAL, A/C

COMPRESSOR.......................24-16

CLUTCHES - DESCRIPTION, DRIVING . . . 21-190,

21s-95

CLUTCHES - DESCRIPTION, HOLDING . . . 21-207,

21s-106

CLUTCHES - OPERATION, DRIVING.....21-190,

21s-95

CLUTCHES - OPERATION, HOLDING....21-207,

21s-106

COAT/CLEARCOAT FINISH -

DESCRIPTION, BASE..................23-85

CODE - DESCRIPTION, PAINT...........23-85

CODE CHARTS - SPECIFICATIONS,

COLOR.............................23-84

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER..............8M-11

CODES - STANDARD PROCEDURE,

OBTAINING DIAGNOSTIC TROUBLE......8E-15

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER..............8M-11

COIL - DESCRIPTION, IGNITION............8I-6

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-15

COIL - OPERATION, IGNITION............8I-7

COLLAR - INSTALLATION, STRUCTURAL . . . 9-48

COLLAR - REMOVAL, STRUCTURAL.......9-47

COLOR CODE CHARTS -

SPECIFICATIONS.....................23-84

COLUMN - DESCRIPTION, STEERING.....19-10

COLUMN - DIAGNOSIS AND TESTING,

STEERING..........................19-12

COLUMN COVER - INSTALLATION,

LOWER STEERING...................23-70

COLUMN COVER - INSTALLATION, OVER

STEERING..........................23-70

COLUMN COVER - REMOVAL, LOWER

STEERING..........................23-70

COLUMN COVER - REMOVAL, OVER

STEERING..........................23-70

COLUMN COVER BACKING PLATE -

INSTALLATION, STEERING.............23-70

COLUMN COVER BACKING PLATE -

REMOVAL, STEERING.................23-70

COLUMN TORQUE, SPECIFICATIONS.....19-14

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER........................9-83,9-9

COMMON PROBLEM CAUSES -

DIAGNOSIS AND TESTING.............21-30

COMMUNICATION RECEIVE - PCM INPUT

- OPERATION, DATA BUS..............8E-15

COMMUNICATIONS INTERFACE (PCI)

BUS, OPERATION - PROGRAMMABLE....14-21

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING.............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-5

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-9

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-10

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-10

COMPLAINTS - DIAGNOSIS AND

TESTING, CLUTCH CHATTER

..............6-6

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER

. . 9-83,9-9

COMPRESSOR - DESCRIPTION, A/C

......24-73

COMPRESSOR - OPERATION, A/C

........24-73

COMPRESSOR - REMOVAL

.............24-74

RSINDEX7

Description Group-Page Description Group-Page Description Group-Page

Page 2554 of 2585

DISC BRAKE CALIPER GUIDE PINS (TRW

BRAKES) - INSTALLATION..............5s-30

DISC BRAKE CALIPER GUIDE PINS (TRW

BRAKES) - REMOVAL.................5s-30

DISC BRAKE CALIPER (TRW BRAKES) -

INSTALLATION, FRONT................5s-26

DISC BRAKE CALIPER (TRW BRAKES) -

REMOVAL, FRONT....................5s-23

DISC BRAKE SHOES - CLEANING....5-16,5-18,

5s-15,5s-17

DISC BRAKE SHOES - INSPECTION . . . 5-16,5-18,

5s-15,5s-17

DISC BRAKE SHOES - INSTALLATION,

REAR..........................5-19,5s-18

DISC BRAKE SHOES - REMOVAL, REAR . . . 5-17,

5s-16

DISC BRAKE SHOES (CONTINENTAL

TEVES BRAKES) - INSTALLATION,

FRONT.............................5s-15

DISC BRAKE SHOES (CONTINENTAL

TEVES BRAKES) - REMOVAL, FRONT.....5s-14

DISC BRAKE SHOES (DISC/DISC

BRAKES) - INSTALLATION, FRONT........5-16

DISC BRAKE SHOES (DISC/DISC

BRAKES) - REMOVAL, FRONT............5-14

DISC BRAKE SHOES (DISC/DRUM

BRAKES) - INSTALLATION, FRONT........5-17

DISC BRAKE SHOES (DISC/DRUM

BRAKES) - REMOVAL, FRONT............5-15

DISC BRAKE SHOES (TRW BRAKES) -

INSTALLATION, FRONT................5s-16

DISC BRAKE SHOES (TRW BRAKES) -

REMOVAL, FRONT....................5s-14

DISC BRAKES (EXPORT) - DESCRIPTION....5-13,

5s-12

DISC BRAKES (FRONT) - DESCRIPTION . . . 5-11,

5s-10

DISC BRAKES (FRONT) - OPERATION . 5-13,5s-12

DISC BRAKES (REAR) - DESCRIPTION....5-12,

5s-12

DISC BRAKES (REAR) - OPERATION . . 5-13,5s-13

DISC RUNOUT - DIAGNOSIS AND

TESTING, CLUTCH COVER...............6-6

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - INSTALLATION, A/C . . . 24-80

DISCHARGE LINE - REMOVAL, A/C.......24-79

DISPLAY TEST MODE, OPERATION - DRB

IIITSTATE ...........................25-9

DISSASEMBLY, REMOVAL..............24-51

DISTRIBUTION DUCT - INSTALLATION....24-57

DISTRIBUTION DUCT - REMOVAL........24-57

DISTRIBUTION DUCTS - INSTALLATION,

FLOOR.............................24-50

DISTRIBUTION DUCTS - REMOVAL,

FLOOR.............................24-50

DISTRIBUTION SYSTEM - DESCRIPTION,

POWER..........................8W-97-1

DISTRIBUTION SYSTEM - OPERATION,

POWER..........................8W-97-1

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER...................8W-97-1

DOES NOT FILL - DIAGNOSIS AND

TESTING, VEHICLE...................25-16

DOME/CARGO LAMP - INSTALLATION....8L-22

DOME/CARGO LAMP - REMOVAL........8L-22

DOOR - INSTALLATION................23-16

DOOR - INSTALLATION, FUEL FILL.......23-52

DOOR - INSTALLATION, SLIDING........23-30

DOOR - REMOVAL....................23-15

DOOR - REMOVAL, FUEL FILL..........23-52

DOOR - REMOVAL, SLIDING............23-29

DOOR ACTUATOR - DESCRIPTION,

BLEND........................24-23,24-35

DOOR ACTUATOR - DESCRIPTION,

MODE.............................24-30

DOOR ACTUATOR - DESCRIPTION,

RECIRCULATION.....................24-32

DOOR ACTUATOR - INSTALLATION,

BLEND

........................24-23,24-36

DOOR ACTUATOR - INSTALLATION,

MODE

.............................24-31

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION

.....................24-33

DOOR ACTUATOR - OPERATION, BLEND

. . 24-23,

24-35

DOOR ACTUATOR - OPERATION, MODE

. . . 24-30DOOR ACTUATOR - OPERATION,

RECIRCULATION.....................24-32

DOOR ACTUATOR - REAR -

DESCRIPTION, MODE.................24-39

DOOR ACTUATOR - REAR -

INSTALLATION, MODE.................24-40

DOOR ACTUATOR - REAR - OPERATION,

MODE.............................24-40

DOOR ACTUATOR - REAR - REMOVAL,

MODE.............................24-40

DOOR ACTUATOR - REMOVAL, BLEND . . . 24-23,

24-36

DOOR ACTUATOR - REMOVAL, MODE....24-30

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-33

DOOR ADJUSTMENT - STANDARD

PROCEDURE, SLIDING................8N-28

DOOR ADJUSTMENTS, ADJUSTMENTS -

SLIDING............................23-30

DOOR BLOCKER LATCH - INSTALLATION,

FUEL FILL..........................23-53

DOOR BLOCKER LATCH - REMOVAL,

FUEL FILL..........................23-53

DOOR BLOCKER LATCH STRIKER -

INSTALLATION, FUEL FILL.............23-53

DOOR BLOCKER LATCH STRIKER -

REMOVAL, FUEL FILL.................23-53

DOOR BLOCKER LOCKOUT LINK -

INSTALLATION, FUEL FILL.............23-54

DOOR BLOCKER LOCKOUT LINK -

REMOVAL, FUEL FILL.................23-53

DOOR CONTROL MODULE -

DESCRIPTION, SLIDING...............8E-19

DOOR CONTROL MODULE -

INSTALLATION, SLIDING...............8E-20

DOOR CONTROL MODULE - OPERATION,

SLIDING............................8E-19

DOOR CONTROL MODULE - REMOVAL,

SLIDING............................8E-19

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION.......................8N-40

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS AND TESTING.............8N-40

DOOR CYLINDER LOCK SWITCH -

EXPORT - DESCRIPTION................8N-3

DOOR CYLINDER LOCK SWITCH -

EXPORT - DIAGNOSIS AND TESTING......8N-3

DOOR CYLINDER LOCK SWITCH -

EXPORT - INSTALLATION...............8N-4

DOOR CYLINDER LOCK SWITCH -

EXPORT - OPERATION.................8N-3

DOOR CYLINDER LOCK SWITCH -

EXPORT - REMOVAL...................8N-3

DOOR CYLINDER LOCK SWITCH -

INSTALLATION......................8N-41

DOOR CYLINDER LOCK SWITCH -

OPERATION.........................8N-40

DOOR CYLINDER LOCK SWITCH -

REMOVAL..........................8N-41

DOOR GLASS - INSTALLATION..........23-17

DOOR GLASS - INSTALLATION, REAR . . . 23-111

DOOR GLASS - INSTALLATION, SLIDING . 23-110

DOOR GLASS - REMOVAL.............23-17

DOOR GLASS - REMOVAL, REAR.......23-111

DOOR GLASS - REMOVAL, SLIDING.....23-110

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT...............23-113

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT...................23-113

DOOR INNER BELT MOLDING -

INSTALLATION, FRONT...............23-115

DOOR INNER BELT MOLDING -

REMOVAL, FRONT...................23-115

DOOR LEARN CYCLE - STANDARD

PROCEDURE, POWER.................8N-28

DOOR LOCK MOTOR - DIAGNOSIS AND

TESTING.......................8N-4,8N-41

DOOR LOCK MOTOR - INSTALLATION,

SLIDING.......................8N-44,8N-6

DOOR LOCK MOTOR - REMOVAL,

SLIDING.......................8N-44,8N-6

DOOR LOCK SWITCH - DIAGNOSIS AND

TESTING

.......................8N-4,8N-41

DOOR LOCK SWITCH - INSTALLATION

....8N-4,

8N-42

DOOR LOCK SWITCH - REMOVAL

. . . 8N-4,8N-42

DOOR MOTOR - DESCRIPTION, SLIDING

. . 8N-30

DOOR MOTOR - INSTALLATION, SLIDING

. 8N-31DOOR MOTOR - OPERATION, SLIDING . . . 8N-30

DOOR MOTOR - REMOVAL, SLIDING.....8N-30

DOOR OUTER BELT MOLDING -

INSTALLATION, FRONT...............23-113

DOOR OUTER BELT MOLDING -

REMOVAL, FRONT...................23-113

DOOR SILL PLATE - INSTALLATION,

SLIDING............................23-82

DOOR SILL PLATE - REMOVAL, SLIDING . . 23-82

DOOR SILL TRIM PLATE -

INSTALLATION.......................23-77

DOOR SILL TRIM PLATE - REMOVAL.....23-77

DOOR STOP BUMPER BEZEL -

INSTALLATION, SLIDING...............23-25

DOOR STOP BUMPER BEZEL -

REMOVAL, SLIDING..................23-25

DOOR SYSTEM - DESCRIPTION, POWER

SLIDING...........................8N-19

DOOR SYSTEM - DIAGNOSIS AND

TESTING, POWER SLIDING.............8N-22

DOOR SYSTEM - OPERATION, POWER

SLIDING...........................8N-21

DOOR WEATHERSTRIP - INSTALLATION,

FRONT............................23-114

DOOR WEATHERSTRIP - INSTALLATION,

SLIDING...........................23-115

DOOR WEATHERSTRIP - REMOVAL,

FRONT............................23-114

DOOR WEATHERSTRIP - REMOVAL,

SLIDING...........................23-115

DOSING PUMP - DESCRIPTION, FUEL . . . 24-115

DOSING PUMP - INSTALLATION, FUEL....24-116

DOSING PUMP - OPERATION, FUEL.....24-115

DOSING PUMP - REMOVAL, FUEL......24-115

DOWNSTREAM 1/2 - 2.4/3.3/3.8L -

REMOVAL..........................14-34

DOWNSTREAM 2/1, 2.4/3.3/3.8L -

INSTALLATION.......................14-34

D-PILLAR TRIM PANEL - INSTALLATION,

LEFT..............................23-78

D-PILLAR TRIM PANEL - INSTALLATION,

RIGHT.............................23-82

D-PILLAR TRIM PANEL - REMOVAL,

LEFT..............................23-78

D-PILLAR TRIM PANEL - REMOVAL,

RIGHT.............................23-81

DRAIN AND FILL - STANDARD

PROCEDURE, FLUID..................21-71

DRAIN TUBE - INSTALLATION..........23-120

DRAIN TUBE - REMOVAL.............23-119

DRAINCOCK - INSTALLATION, RADIATOR . . . 7-26

DRAINCOCK - REMOVAL, RADIATOR......7-26

DRAINING - STANDARD PROCEDURE,

COOLING SYSTEM.....................7-4

DRAINING FUEL TANK - STANDARD

PROCEDURE.........................14-2

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-13

DRB IIITSTATE DISPLAY TEST MODE,

OPERATION..........................25-9

DRIER - DESCRIPTION, RECEIVER.......24-91

DRIER - INSTALLATION, RECEIVER......24-92

DRIER - OPERATION, RECEIVER.........24-91

DRIER - REMOVAL, RECEIVER..........24-91

DRIVE - ASSEMBLY, FINAL......21-195,21s-99

DRIVE - DESCRIPTION, FINAL..........21s-95

DRIVE - DESCRIPTION, FLEX...........8N-36

DRIVE - DISASSEMBLY, FINAL . . . 21-190,21s-96

DRIVE - INSTALLATION, FLEX..........8N-37

DRIVE - OPERATION, FINAL...........21s-96

DRIVE - OPERATION, FLEX.............8N-36

DRIVE - REMOVAL, FLEX..............8N-37

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY..........................7-7

DRIVE BELT TENSION, SPECIFICATIONS -

ACCESSORY..........................7-5

DRIVE BELTS - 2.4L - ADJUSTMENTS.....7-10

DRIVE BELTS - 2.4L - CLEANING..........7-9

DRIVE BELTS - 2.4L - INSPECTION........7-9

DRIVE BELTS - 2.4L - INSTALLATION......7-10

DRIVE BELTS - 2.4L - REMOVAL..........7-8

DRIVE BELTS - 3.3/3.8L - CLEANING......7-11

DRIVE BELTS - 3.3/3.8L - INSPECTION

....7-11

DRIVE BELTS - 3.3/3.8L - INSTALLATION

. . . 7-12

DRIVE BELTS - 3.3/3.8L - REMOVAL

......7-11

DRIVE PLATE MISALIGNMENT -

DIAGNOSIS AND TESTING

...............6-6

DRIVE UNIT - DESCRIPTION, LOWER

....8N-32

RSINDEX11

Description Group-Page Description Group-Page Description Group-Page

Page 2560 of 2585

HEATED SEAT SWITCH - INSTALLATION,

DRIVER............................8G-10

HEATED SEAT SWITCH - INSTALLATION,

PASSENGER........................8G-14

HEATED SEAT SWITCH - OPERATION,

DRIVER.............................8G-8

HEATED SEAT SWITCH - OPERATION,

PASSENGER........................8G-12

HEATED SEAT SWITCH - REMOVAL,

DRIVER............................8G-10

HEATED SEAT SWITCH - REMOVAL,

PASSENGER........................8G-14

HEATED SEAT SYSTEM - DESCRIPTION....8G-7

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SYSTEM - OPERATION.....8G-8

HEATER - DESCRIPTION, CABIN........24-112

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-20

HEATER - DIAGNOSIS AND TESTING,

DIESEL SUPPLEMENTAL CABIN........24-113

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-20

HEATER - OPERATION, ENGINE BLOCK....7-20

HEATER - REMOVAL, ENGINE BLOCK......7-20

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-4

HEATER CONTROL - DESCRIPTION, A/C . . . 24-20

HEATER CONTROL - INSTALLATION, A/C . . 24-21

HEATER CONTROL - REMOVAL, A/C.......24-21

HEATER CORE - DESCRIPTION....24-101,24-83

HEATER CORE - INSTALLATION . . . 24-103,24-85

HEATER CORE - OPERATION......24-101,24-83

HEATER CORE - REMOVAL.......24-102,24-84

HEATER CORE FILLING - STANDARD

PROCEDURE, REAR..................24-101

HEATER CORE TUBES - INSTALLATION . . . 24-85

HEATER CORE TUBES - REMOVAL.......24-83

HEATER HOSES - INSTALLATION.......24-104

HEATER HOSES - REMOVAL...........24-103

HEATER INLET HOSE - INSTALLATION....24-86

HEATER INLET HOSE - REMOVAL........24-85

HEATER LINES - INSTALLATION, REAR . . 24-111

HEATER PERFORMANCE TEST -

DIAGNOSIS AND TESTING.............24-10

HEATER RETURN HOSE - INSTALLATION . . 24-87

HEATER RETURN HOSE - REMOVAL......24-86

HEATER TESTING - DIAGNOSIS AND

TESTING, ENGINE BLOCK...............7-20

HEATER TUBES - REMOVAL,

UNDERBODY.......................24-109

HEATER UNIT - INSTALLATION.........24-119

HEATER UNIT - REMOVAL.............24-118

HEATER WIRING - INSTALLATION,

SUPPLEMENTAL DIESEL..............24-119

HEATER WIRING - REMOVAL,

SUPPLEMENTAL DIESEL..............24-119

HEAVY DUTY, CARGO - INSTALLATION,

AWD ...............................2-36

HEAVY DUTY, CARGO - REMOVAL, AWD . . . 2-36

HEIGHT ADJUSTER-BORC-PILLAR -

INSTALLATION, SEAT BELT.............8O-13

HEIGHT ADJUSTER-BORC-PILLAR -

REMOVAL, SEAT BELT................8O-13

HEIGHT ADJUSTER KNOB -

INSTALLATION, SEAT BELT.............8O-14

HEIGHT ADJUSTER KNOB - REMOVAL,

SEAT BELT .........................8O-14

HEIGHT MEASUREMENT - STANDARD

PROCEDURE, CURB...................2-55

HIGH AND LOW LIMITS - DESCRIPTION . . . 25-8

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER....................8L-6

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION

.......................24-73

HIGH PRESSURE RELIEF VALVE -

OPERATION

.........................24-73

HIGH SPEED OPERATION - STANDARD

PROCEDURE, TIRE PRESSURE

.....22-17,22s-9

HINGE - INSTALLATION

......23-18,23-40,23-60

HINGE - INSTALLATION, CENTER

........23-24HINGE - INSTALLATION, LOWER........23-28

HINGE - INSTALLATION, UPPER.........23-36

HINGE - REMOVAL.........23-17,23-40,23-60

HINGE - REMOVAL, BENCH SEAT BACK . . 23-102

HINGE - REMOVAL, CENTER............23-24

HINGE - REMOVAL, LOWER............23-28

HINGE - REMOVAL, UPPER.............23-36

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT, BENCH - INSTALLATION, SEAT

BACK.............................23-101

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT, BENCH - REMOVAL, SEAT BACK . . 23-101

HOISTING - STANDARD PROCEDURE......0-27

HOLD OPEN LATCH - INSTALLATION.....23-25

HOLD OPEN LATCH - REMOVAL.........23-25

HOLD OPEN LATCH CABLE -

INSTALLATION.......................23-38

HOLD OPEN LATCH CABLE - REMOVAL . . . 23-38

HOLD OPEN LATCH STRIKER -

INSTALLATION.......................23-26

HOLD OPEN LATCH STRIKER -

REMOVAL..........................23-26

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-15

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-16

HOLDDOWN - OPERATION, BATTERY.....8F-15

HOLDDOWN - REMOVAL, BATTERY . 8F-15,8F-16

HOLDER - INSTALLATION, CUP.........23-64

HOLDER - REMOVAL, CUP.............23-64

HOLDING CLUTCHES - DESCRIPTION . . . 21-207,

21s-106

HOLDING CLUTCHES - OPERATION.....21-207,

21s-106

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-5

HONING - STANDARD PROCEDURE,

CYLINDER BORE.................9-112,9-35

HOOD - INSTALLATION................23-61

HOOD - REMOVAL....................23-60

HOOD AJAR SWITCH - EXPORT -

INSTALLATION.......................8Q-3

HOOD AJAR SWITCH - EXPORT -

REMOVAL...........................8Q-3

HORN - DIAGNOSIS AND TESTING.......8H-3

HORN - INSTALLATION.................8H-5

HORN - REMOVAL....................8H-4

HORN CHIRP PREFERENCE - STANDARD

PROCEDURE....................8N-42,8N-5

HORN SWITCH - DESCRIPTION..........8H-5

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - INSTALLATION, HEATER INLET....24-86

HOSE - INSTALLATION, HEATER RETURN . 24-87

HOSE - REMOVAL, HEATER INLET.......24-85

HOSE - REMOVAL, HEATER RETURN.....24-86

HOSE CLAMPS - DESCRIPTION...........7-1

HOSE CLAMPS - OPERATION.............7-2

HOSES - DESCRIPTION, BRAKE TUBES....5-14,

5s-13

HOSES - INSPECTION, BRAKE TUBES.....5-14,

5s-13

HOSES - INSTALLATION, HEATER.......24-104

HOSES - INSTALLATION, WASHER.......8R-13

HOSES - OPERATION, BRAKE TUBES . 5-14,5s-13

HOSES - REMOVAL, HEATER..........24-103

HOSES - REMOVAL, WASHER..........8R-13

HOSES AND CLAMP - STANDARD

PROCEDURE.........................14-7

HOUSING - INSTALLATION, AIR

CLEANER........................9-24,9-99

HOUSING - INSTALLATION, HVAC........24-61

HOUSING - INSTALLATION, LOCK

CYLINDER..........................19-19

HOUSING - REMOVAL, AIR CLEANER . . 9-24,9-99

HOUSING - REMOVAL, HVAC...........24-60

HOUSING - REMOVAL, LOCK CYLINDER . . 19-17

HOUSING FLUID CHANGE - STANDARD

PROCEDURE, OVERRUNNING CLUTCH.....3-41

HOUSING FLUID LEAKAGE - DIAGNOSIS

AND TESTING, TORQUE CONVERTER . . . 21-123,

21s-31

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION

.....................8W-01-1

HUB / BEARING - DESCRIPTION

.......2-30,2-4

HUB / BEARING - INSTALLATION

......2-33,2-6

HUB / BEARING - OPERATION

........2-30,2-4

HUB / BEARING - REMOVAL

..........2-31,2-5HUB AND BEARING - DIAGNOSIS AND

TESTING.........................2-31,2-5

HVAC - LWB - INSTALLATION, SEAT

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR.........8O-16

HVAC - LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR...............8O-16

HVAC HOUSING - INSTALLATION........24-61

HVAC HOUSING - REMOVAL............24-60

HVAC LOUVER - INSTALLATION, REAR . . . 23-81

HVAC LOUVER - REMOVAL, REAR.......23-81

HYDRAULIC CIRCUITS AND VALVES -

OPERATION..........................5-83

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS - DIAGNOSIS AND

TESTING............................9-34

HYDRAULIC LASH ADJUSTERS -

INSTALLATION........................9-34

HYDRAULIC LASH ADJUSTERS -

REMOVAL...........................9-34

HYDRAULIC LIFTERS - DIAGNOSIS AND

TESTING...........................9-113

HYDRAULIC LIFTERS (CAM IN BLOCK) -

DESCRIPTION.......................9-113

HYDRAULIC LIFTERS (CAM IN BLOCK) -

INSTALLATION.......................9-114

HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL..........................9-114

HYDRAULIC PRESSURE TESTS -

DIAGNOSIS AND TESTING.......21-120,21s-28

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS - 41TE TRANSAXLE....21-169

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS - 4XTE TRANSAXLE....21s-75

HYDROSTATIC LOCKED ENGINE -

STANDARD PROCEDURE............9-10,9-85

ICU - ASSEMBLY......................5-94

ICU - DISASSEMBLY...................5-93

ICU (INTEGRATED CONTROL UNIT) -

DESCRIPTION........................5-89

ICU (INTEGRATED CONTROL UNIT) -

OPERATION..........................5-90

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-2

IDENTIFICATION - DESCRIPTION,

VEHICLE............................23-1

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION, DIAGNOSIS AND

TESTING - SEAL......................21-3

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-9

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-28

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-29

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-28

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-29

IGNITION COIL - DESCRIPTION...........8I-6

IGNITION COIL - OPERATION.............8I-7

IGNITION INTERLOCK - DESCRIPTION....19-17

IGNITION SENSE - PCM INPUT -

OPERATION.........................8E-15

IGNITION SWITCH - INSTALLATION......19-16

IGNITION SWITCH - REMOVAL..........19-14

IGNITION SYSTEM - DESCRIPTION........8I-1

IGNITION SYSTEM - OPERATION..........8I-1

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-13

IIITSTATE DISPLAY TEST MODE,

OPERATION - DRB....................25-9

ILLUMINATION LAMPS - INSTALLATION,

CLUSTER...........................8L-21

ILLUMINATION LAMPS - REMOVAL,

CLUSTER...........................8L-21

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY

........................8E-18

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY

........................8E-19

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY

........................8E-18

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY

........................8E-18

INBOARD - 50/50 BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW

.......................8O-13

RSINDEX17

Description Group-Page Description Group-Page Description Group-Page

Page 2561 of 2585

INBOARD - 50/50 BENCH - REMOVAL,

SEAT BELT BUCKLE - SECOND ROW.....8O-13

INBOARD - INSTALLATION, SEAT BELT

BUCKLE - FRONT....................8O-12

INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE -

FIRST ROW.........................8O-12

INBOARD - QUAD BUCKET - REMOVAL,

SEAT BELT BUCKLE - FIRST ROW.......8O-12

INBOARD - REMOVAL, SEAT BELT

BUCKLE - FRONT....................8O-12

INDICATOR LAMP - DESCRIPTION,

VTSS/SKIS..........................8Q-7

INDICATOR LAMP - OPERATION,

VTSS/SKIS..........................8Q-8

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR..........22-16,22s-8

INFLATION PRESSURES - STANDARD

PROCEDURE, TIRE..............22-16,22s-8

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-6

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INFRARED TEMPERATURE SENSOR -

DESCRIPTION.......................24-29

INFRARED TEMPERATURE SENSOR -

OPERATION.........................24-29

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-37

INJECTION SYSTEM - OPERATION.......14-18

INJECTOR - DESCRIPTION, FUEL........14-26

INJECTOR - OPERATION, FUEL..........14-26

INLET AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-30

INLET FILTER - INSTALLATION..........14-13

INLET FILTER - REMOVAL..............14-13

INLET HOSE - INSTALLATION, HEATER....24-86

INLET HOSE - REMOVAL, HEATER.......24-85

INLET TUBE - 2.4L - DESCRIPTION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - INSTALLATION,

WATER PUMP........................7-35

INLET TUBE - 2.4L - REMOVAL, WATER

PUMP..............................7-35

INLET TUBE - 3.3/3.8L - INSTALLATION,

WATER PUMP........................7-36

INLET TUBE - 3.3/3.8L - REMOVAL,

WATER PUMP........................7-36

INNER - INSTALLATION, CV BOOT.........3-6

INNER - REMOVAL, CV BOOT.............3-6

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR......................23-115

INNER BELT MOLDING - REMOVAL,

FRONT DOOR......................23-115

INNER SEAL - INSTALLATION, HALF

SHAFT.............................21-12

INNER SEAL - REMOVAL, HALF SHAFT . . . 21-12

INNER/OUTER - INSTALLATION, CV

BOOT...............................3-17

INNER/OUTER - REMOVAL, CV BOOT......3-15

INPUT - DESCRIPTION, SPEED SENSOR . 21-239,

21s-140

INPUT - INSTALLATION, SPEED

SENSOR....................21-240,21s-141

INPUT - OPERATION, DATA BUS

COMMUNICATION RECEIVE - PCM.......8E-15

INPUT - OPERATION, IGNITION SENSE -

PCM...............................8E-15

INPUT - OPERATION, SENSOR RETURN -

PCM...............................8E-15

INPUT - OPERATION, SPEED SENSOR . . . 21-240,

21s-140

INPUT - REMOVAL, SPEED SENSOR....21-240,

21s-141

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-216,

21s-116

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY...............21-208,21s-107

INPUT FLANGE SEAL - INSTALLATION

.....3-45

INPUT FLANGE SEAL - REMOVAL

.........3-44

INPUT SHAFT - ASSEMBLY

........21-96,21s-5

INPUT SHAFT - DESCRIPTION

.....21-93,21s-1

INPUT SHAFT - DISASSEMBLY

.....21-93,21s-1INPUT SHAFT COVER SEAL -

INSTALLATION.......................21-14

INPUT SHAFT COVER SEAL - REMOVAL . . . 21-13

INPUT SHAFT END SEAL -

INSTALLATION.......................21-16

INPUT SHAFT END SEAL - REMOVAL.....21-15

INPUT SHAFT SEAL - INSTALLATION.....21-18

INPUT SHAFT SEAL - REMOVAL.........21-17

INSIDE HANDLE ACTUATOR -

INSTALLATION.......................23-27

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-27

INSIDE HANDLE CABLE - INSTALLATION . . 23-38

INSIDE HANDLE CABLE - REMOVAL......23-37

INSIDE LATCH HANDLE - INSTALLATION . . 23-34

INSIDE LATCH HANDLE - REMOVAL......23-34

INSPECT, INSPECTION...............21-114

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-1

INSTRUMENT CLUSTER - OPERATION.....8J-1

INSTRUMENT PANEL - INSTALLATION,

LOWER............................23-69

INSTRUMENT PANEL - REMOVAL,

LOWER............................23-69

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-9

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-8

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION.......................23-66

INSTRUMENT PANEL ASSEMBLY -

REMOVAL............................23-65

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION.......................23-68

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL..........................23-68

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-55

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-55

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-55

INSTRUMENT PANEL DUCTS - REMOVAL . 24-55

INSTRUMENT PANEL END CAP -

INSTALLATION.......................23-68

INSTRUMENT PANEL END CAP -

REMOVAL..........................23-68

INSTRUMENT PANEL OUTLET -

INSTALLATION.......................24-46

INSTRUMENT PANEL OUTLET -

REMOVAL..........................24-45

INSTRUMENT PANEL TOP COVER -

INSTALLATION.......................23-69

INSTRUMENT PANEL TOP COVER -

REMOVAL..........................23-68

INSTRUMENT PANEL TOP PAD

ASSEMBLY - INSTALLATION............23-72

INSTRUMENT PANEL TOP PAD

ASSEMBLY - REMOVAL................23-71

INTAKE MANIFOLD - DESCRIPTION . . 9-144,9-58

INTAKE MANIFOLD - INSTALLATION,

LOWER............................9-149

INTAKE MANIFOLD - INSTALLATION,

UPPER.............................9-147

INTAKE MANIFOLD - LOWER -

CLEANING..........................9-148

INTAKE MANIFOLD - LOWER -

INSPECTION....................9-148,9-60

INTAKE MANIFOLD - LOWER -

INSTALLATION........................9-60

INTAKE MANIFOLD - LOWER - REMOVAL . . 9-60

INTAKE MANIFOLD - REMOVAL, LOWER . . 9-148

INTAKE MANIFOLD - REMOVAL, UPPER . . . 9-145

INTAKE MANIFOLD - UPPER -

INSPECTION.........................9-59

INTAKE MANIFOLD - UPPER -

INSTALLATION........................9-59

INTAKE MANIFOLD - UPPER - REMOVAL . . . 9-58

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING...................9-145,9-58

INTAKE MANIFOLD VACUUM PORT

REPAIR - STANDARD PROCEDURE.......9-145

INTAKE PIPE - INSTALLATION, AIR

......24-114

INTAKE PIPE - REMOVAL, AIR

.........24-113

INTAKE/EXHAUST VALVES & SEATS -

CLEANING

.................9-105,9-32,9s-22

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION

..............9-104,9-32,9s-21

INTAKE/EXHAUST VALVES & SEATS -

INSPECTION

...................9-105,9s-22INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION..................9-106,9s-23

INTAKE/EXHAUST VALVES & SEATS -

OPERATION....................9-104,9s-21

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL.....................9-105,9s-22

INTEGRAL ANTENNA - EXPORT -

DESCRIPTION, QUARTER GLASS.........8A-9

INTEGRAL ANTENNA - EXPORT -

DIAGNOSIS AND TESTING, QUARTER

GLASS..............................8A-9

INTEGRAL ANTENNA - EXPORT -

OPERATION, QUARTER GLASS...........8A-9

INTEGRATED POWER MODULE -

DESCRIPTION.....................8W-97-2

INTEGRATED POWER MODULE -

INSTALLATION....................8W-97-3

INTEGRATED POWER MODULE -

OPERATION.......................8W-97-2

INTEGRATED POWER MODULE -

REMOVAL........................8W-97-2

INTERACTIVE SPEED CONTROL (4

SPEED EATX ONLY) - OPERATION........8P-2

INTERFACE (PCI) BUS, OPERATION -

PROGRAMMABLE COMMUNICATIONS....14-21

INTERIOR LAMPS, SPECIFICATIONS......8L-20

INTERLOCK - DESCRIPTION, IGNITION....19-17

INTERLOCK SOLENOID - DESCRIPTION,

SHIFT......................21-233,21s-133

INTERLOCK SOLENOID - DIAGNOSIS

AND TESTING, BRAKE/TRANSMISSION

SHIFT......................21-235,21s-135

INTERLOCK SOLENOID - INSTALLATION,

SHIFT.......................21-236,21s-136

INTERLOCK SOLENOID - OPERATION,

SHIFT......................21-233,21s-134

INTERLOCK SOLENOID - REMOVAL,

SHIFT......................21-235,21s-135

INTERLOCK SWITCH - INSTALLATION,

CLUTCH PEDAL.......................6-14

INTERLOCK SWITCH - REMOVAL,

CLUTCH PEDAL.......................6-13

INTERMEDIATE SHAFT - ASSEMBLY....21-107,

21s-17

INTERMEDIATE SHAFT - DESCRIPTION . . 21-100,

21s-9

INTERMEDIATE SHAFT - DISASSEMBLY . 21-100,

21s-10

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INTERNATIONAL SYMBOLS -

DESCRIPTION.........................0-1

INTRODUCTION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS........9-3,9-76

IOD FUSE - DESCRIPTION...........8W-97-3

IOD FUSE - OPERATION.............8W-97-3

JOINT - DESCRIPTION, LOWER BALL......2-10

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL........................2-10

JOINT - OPERATION, LOWER BALL.......2-10

JOINT MOLDING - INSTALLATION, ROOF . . 23-58

JOINT MOLDING - REMOVAL, ROOF......23-58

JOUNCE BUMPER - DESCRIPTION........2-36

JOUNCE BUMPER - OPERATION..........2-36

JUMP STARTING - STANDARD

PROCEDURE.........................0-27

JUNCTION BLOCK - DESCRIPTION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - INSTALLATION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - OPERATION,

NON-ABS.......................5-33,5s-32

JUNCTION BLOCK - REMOVAL, NON-ABS . . 5-33,

5s-32

KEY - DESCRIPTION, TRANSPONDER.....8Q-6

KEY - OPERATION, TRANSPONDER.......8Q-6

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-18

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY

...............8E-19

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY

.................8E-18

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY

............................8E-18

KEY REMOTE ENTRY MODULE -

DESCRIPTION, SENTRY

................8Q-3

KEY REMOTE ENTRY MODULE -

DIAGNOSIS AND TESTING, SENTRY

.......8Q-5

18 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2567 of 2585

OUTPUT - OPERATION, SPEED SENSOR . 21-241,

21s-142

OUTPUT - REMOVAL, SPEED SENSOR . . 21-241,

21s-143

OUTPUT - SBEC CONTROLLER -

OPERATION, 8-VOLT SUPPLY - PCM.....8E-15

OUTPUT FLANGE SEAL - INSTALLATION . . . 3-46

OUTPUT FLANGE SEAL - REMOVAL.......3-45

OUTPUT FLANGE SHIM SELECTION,

ADJUSTMENTS.......................21-7

OUTSIDE HANDLE - INSTALLATION......23-35

OUTSIDE HANDLE - REMOVAL..........23-35

OUTSIDE HANDLE CABLE -

INSTALLATION.......................23-37

OUTSIDE HANDLE CABLE - REMOVAL....23-37

OVER STEERING COLUMN COVER -

INSTALLATION.......................23-70

OVER STEERING COLUMN COVER -

REMOVAL..........................23-70

OVERHEAD CONSOLE - DESCRIPTION....8M-1

OVERHEAD CONSOLE - DIAGNOSIS AND

TESTING............................8M-2

OVERHEAD CONSOLE - OPERATION......8M-2

OVERHEAD CONSOLE - REMOVAL........8M-6

OVERHEAD CONSOLE, SPECIAL TOOLS . . . 8M-6

OVERRUNNING CLUTCH - DESCRIPTION,

BI-DIRECTIONAL......................3-34

OVERRUNNING CLUTCH - OPERATION,

BI-DIRECTIONAL......................3-36

OVERRUNNING CLUTCH HOUSING FLUID

CHANGE - STANDARD PROCEDURE........3-41

PAD - INSTALLATION, REAR FASCIA -

SCUFF..............................13-4

PAD - REMOVAL, REAR FASCIA - SCUFF . . . 13-3

PAD ASSEMBLY - INSTALLATION,

INSTRUMENT PANEL TOP..............23-72

PAD ASSEMBLY - REMOVAL,

INSTRUMENT PANEL TOP..............23-71

PAINT CODE - DESCRIPTION...........23-85

PAINTED TOUCH-UP - DESCRIPTION.....23-85

PAN - CLEANING, OIL.................9-140

PAN - INSPECTION, OIL...............9-140

PAN - INSTALLATION, OIL.........9-140,9-54

PAN - REMOVAL, OIL.............9-140,9-54

PANEL - INSTALLATION, BENCH

SEATBACK..........................23-99

PANEL - INSTALLATION, FRONT

SEATBACK..........................23-93

PANEL - INSTALLATION, GLASS........23-120

PANEL - INSTALLATION, LEFT D-PILLAR

TRIM..............................23-78

PANEL - INSTALLATION, LEFT QUARTER

TRIM..............................23-80

PANEL - INSTALLATION, LOWER

INSTRUMENT.......................23-69

PANEL - INSTALLATION, RIGHT

D-PILLAR TRIM......................23-82

PANEL - INSTALLATION, RIGHT

QUARTER TRIM......................23-79

PANEL - INSTALLATION, TRIM.....23-20,23-34,

23-44

PANEL - REMOVAL, BENCH SEATBACK . . . 23-99

PANEL - REMOVAL, FRONT SEATBACK....23-92

PANEL - REMOVAL, GLASS

............23-120

PANEL - REMOVAL, LEFT D-PILLAR

TRIM

..............................23-78

PANEL - REMOVAL, LEFT QUARTER

TRIM

..............................23-80

PANEL - REMOVAL, LOWER

INSTRUMENT

.......................23-69

PANEL - REMOVAL, RIGHT D-PILLAR

TRIM

..............................23-81

PANEL - REMOVAL, RIGHT QUARTER

TRIM

..............................23-79

PANEL - REMOVAL, TRIM

....23-20,23-33,23-43

PANEL ADJUSTMENT, ADJUSTMENTS -

SUNROOF GLASS

...................23-120

PANEL ANTENNA CABLE -

INSTALLATION, INSTRUMENT

............8A-9

PANEL ANTENNA CABLE - REMOVAL,

INSTRUMENT

........................8A-8

PANEL ASSEMBLY - INSTALLATION,

INSTRUMENT

.......................23-66

PANEL ASSEMBLY - REMOVAL,

INSTRUMENT

.......................23-65

PANEL CENTER BEZEL - INSTALLATION,

INSTRUMENT

.......................23-68PANEL CENTER BEZEL - REMOVAL,

INSTRUMENT.......................23-68

PANEL DEMISTER DUCTS -

INSTALLATION, INSTRUMENT...........24-55

PANEL DEMISTER DUCTS - REMOVAL,

INSTRUMENT.......................24-55

PANEL DUCTS - INSTALLATION,

INSTRUMENT.......................24-55

PANEL DUCTS - REMOVAL,

INSTRUMENT.......................24-55

PANEL END CAP - INSTALLATION,

INSTRUMENT.......................23-68

PANEL END CAP - REMOVAL,

INSTRUMENT.......................23-68

PANEL OUTLET - INSTALLATION,

INSTRUMENT.......................24-46

PANEL OUTLET - REMOVAL,

INSTRUMENT.......................24-45

PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC BODY............23-3

PANEL TOP COVER - INSTALLATION,

INSTRUMENT.......................23-69

PANEL TOP COVER - REMOVAL,

INSTRUMENT.......................23-68

PANEL TOP PAD ASSEMBLY -

INSTALLATION, INSTRUMENT...........23-72

PANEL TOP PAD ASSEMBLY - REMOVAL,

INSTRUMENT.......................23-71

PANEL/FENDER AIR EXHAUSTER -

DESCRIPTION, REAR QUARTER.........23-57

PANEL/FENDER AIR EXHAUSTER -

INSTALLATION, REAR QUARTER.........23-58

PANEL/FENDER AIR EXHAUSTER -

REMOVAL, REAR QUARTER..............23-57

PARK SWITCH - DIAGNOSIS AND

TESTING, FAILED.....................8R-2

PARKING BRAKE - INSTALLATION,

LEVER.........................5-65,5s-67

PARKING BRAKE - INSTALLATION,

SHOES.........................5-72,5s-75

PARKING BRAKE - REMOVAL, LEVER . 5-64,5s-67

PARKING BRAKE - REMOVAL, SHOES.....5-67,

5s-69

PARKING BRAKE AUTOMATIC ADJUSTER

TENSION RELEASE - STANDARD

PROCEDURE....................5-58,5s-61

PARKING BRAKE AUTOMATIC ADJUSTER

TENSION RESET - STANDARD

PROCEDURE....................5-59,5s-61

PARKING BRAKE CABLE (FRONT) -

INSTALLATION...................5-63,5s-65

PARKING BRAKE CABLE (FRONT) -

REMOVAL......................5-59,5s-62

PARKING BRAKE CABLE

(INTERMEDIATE) - INSTALLATION . . . 5-63,5s-66

PARKING BRAKE CABLE

(INTERMEDIATE) - REMOVAL.......5-60,5s-62

PARKING BRAKE CABLE (LEFT REAR) -

INSTALLATION...................5-64,5s-66

PARKING BRAKE CABLE (LEFT REAR) -

REMOVAL......................5-62,5s-64

PARKING BRAKE CABLE (RIGHT REAR) -

INSTALLATION...................5-63,5s-66

PARKING BRAKE CABLE (RIGHT REAR) -

REMOVAL......................5-60,5s-63

PARKING BRAKE CABLES -

ADJUSTMENT

...................5-64,5s-66

PARKING BRAKE LEVER AND FRONT

CABLE - INSTALLATION

............5-66,5s-69

PARKING BRAKE LEVER AND FRONT

CABLE - REMOVAL

...............5-65,5s-68

PARKING BRAKE SHOES - ADJUSTMENT

. . 5-73,

5s-76

PARK/TURN SIGNAL LAMP -

INSTALLATION

.......................8L-18

PARK/TURN SIGNAL LAMP - REMOVAL

. . . 8L-18

PASSENGER AIRBAG - DESCRIPTION

.....8O-8

PASSENGER AIRBAG - INSTALLATION

....8O-10

PASSENGER AIRBAG - OPERATION

.......8O-9

PASSENGER AIRBAG - REMOVAL

........8O-9

PASSENGER BENCH - INSTALLATION,

SEAT BELT BUCKLE - SECOND ROW -

THREE

.............................8O-15

PASSENGER BENCH - REMOVAL, SEAT

BELT BUCKLE - SECOND ROW - THREE

. . . 8O-15

PASSENGER HEATED SEAT SWITCH -

DESCRIPTION

.......................8G-12PASSENGER HEATED SEAT SWITCH -

DIAGNOSIS AND TESTING.............8G-13

PASSENGER HEATED SEAT SWITCH -

INSTALLATION......................8G-14

PASSENGER HEATED SEAT SWITCH -

OPERATION.........................8G-12

PASSENGER HEATED SEAT SWITCH -

REMOVAL..........................8G-14

PASSENGER POWER SEAT TRACK -

DESCRIPTION..................8N-16,8N-59

PASSENGER POWER SEAT TRACK -

INSTALLATION.................8N-18,8N-61

PASSENGER POWER SEAT TRACK -

OPERATION...................8N-17,8N-60

PASSENGER POWER SEAT TRACK -

REMOVAL.....................8N-18,8N-61

PASSENGER SEAT SWITCH -

DESCRIPTION..................8N-13,8N-56

PASSENGER SEAT SWITCH - DIAGNOSIS

AND TESTING..................8N-14,8N-57

PASSENGER SEAT SWITCH -

INSTALLATION.................8N-15,8N-57

PASSENGER SEAT SWITCH - OPERATION . 8N-13,

8N-56

PASSENGER SEAT SWITCH - REMOVAL . . 8N-14,

8N-57

PATTERNS - DIAGNOSIS AND TESTING,

TIRE WEAR....................22-16,22s-8

PCM GROUND - OPERATION...........8E-15

PCM INPUT - OPERATION, DATA BUS

COMMUNICATION RECEIVE.............8E-15

PCM INPUT - OPERATION, IGNITION

SENSE.............................8E-15

PCM INPUT - OPERATION, SENSOR

RETURN............................8E-15

PCM OUTPUT - OPERATION, 5 VOLT

SUPPLY............................8E-15

PCM OUTPUT - SBEC CONTROLLER -

OPERATION, 8-VOLT SUPPLY...........8E-15

PCM/SKIM PROGRAMMING - STANDARD

PROCEDURE.........................8E-2

PCV SYSTEM - DIAGNOSIS AND

TESTING...........................25-17

PCV VALVE - DESCRIPTION............25-16

PCV VALVE - OPERATION..............25-16

PEDAL - INSTALLATION, ACCELERATOR . . . 14-24

PEDAL - REMOVAL, ACCELERATOR......14-24

PEDAL INTERLOCK SWITCH -

INSTALLATION, CLUTCH................6-14

PEDAL INTERLOCK SWITCH - REMOVAL,

CLUTCH

.............................6-13

PEDAL TORQUE SHAFT - RHD -

INSTALLATION

...................5-39,5s-43

PEDAL TORQUE SHAFT - RHD -

REMOVAL

......................5-39,5s-42

PEDAL UPSTOP SWITCH -

INSTALLATION, CLUTCH

................6-16

PEDAL UPSTOP SWITCH - REMOVAL,

CLUTCH

.............................6-15

PEDALS - ADJUSTABLE - INSTALLATION

. . 5s-40

PEDALS - ADJUSTABLE - REMOVAL

......5s-38

PEDALS SWITCH - INSTALLATION,

ADJUSTABLE

........................5s-10

PEDALS SWITCH - REMOVAL,

ADJUSTABLE

........................5s-10

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS

........9-4,9-78

PERFORMANCE TEST - DIAGNOSIS AND

TESTING, A/C

........................24-7

PERFORMANCE TEST - DIAGNOSIS AND

TESTING, HEATER

....................24-10

PIN BUSHINGS (CONTINENTAL TEVES

BRAKES) - ASSEMBLY, CALIPER GUIDE

. . . 5s-24

PIN BUSHINGS (CONTINENTAL TEVES

BRAKES) - DISASSEMBLY, CALIPER

GUIDE

.............................5s-23

PIN BUSHINGS (DISC/DISC BRAKES) -

ASSEMBLY, CALIPER GUIDE

.............5-25

PIN BUSHINGS (DISC/DISC BRAKES) -

DISASSEMBLY, CALIPER GUIDE

..........5-24

PINCH SENSOR - DESCRIPTION

.........8N-17

PINCH SENSOR - INSTALLATION

........8N-17

PINCH SENSOR - OPERATION

..........8N-17

PINCH SENSOR - REMOVAL

............8N-17

PINION FACTOR SETTING - STANDARD

PROCEDURE

...................8E-15,8E-23

24 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2574 of 2585

SEAT TRACK MANUAL ADJUSTER -

INSTALLATION, FRONT................23-95

SEAT TRACK MANUAL ADJUSTER -

REMOVAL, FRONT....................23-95

SEAT TRACK POWER ADJUSTER -

INSTALLATION, FRONT................23-95

SEAT TRACK POWER ADJUSTER -

REMOVAL, FRONT....................23-95

SEATBACK ASSIST STRAP -

INSTALLATION, FRONT................23-92

SEATBACK ASSIST STRAP - REMOVAL,

FRONT.............................23-92

SEATBACK COVER - INSTALLATION,

FRONT.............................23-93

SEATBACK COVER - REMOVAL, FRONT . . . 23-93

SEATBACK PANEL - INSTALLATION,

BENCH.............................23-99

SEATBACK PANEL - INSTALLATION,

FRONT.............................23-93

SEATBACK PANEL - REMOVAL, BENCH . . . 23-99

SEATBACK PANEL - REMOVAL, FRONT....23-92

SEAT/MIRROR MODULE - DESCRIPTION,

MEMORY...........................8E-10

SEAT/MIRROR MODULE - DIAGNOSIS

AND TESTING, MEMORY...............8E-10

SEAT/MIRROR MODULE -

INSTALLATION, MEMORY..............8E-10

SEAT/MIRROR MODULE - OPERATION,

MEMORY...........................8E-10

SEAT/MIRROR MODULE - REMOVAL,

MEMORY...........................8E-10

SEATS - CLEANING, INTAKE/EXHAUST

VALVES.....................9-105,9-32,9s-22

SEATS - DESCRIPTION, INTAKE/

EXHAUST VALVES...........9-104,9-32,9s-21

SEATS - INSPECTION, INTAKE/EXHAUST

VALVES .......................9-105,9s-22

SEATS - INSTALLATION, INTAKE/

EXHAUST VALVES...............9-106,9s-23

SEATS - OPERATION, INTAKE/EXHAUST

VALVES .......................9-104,9s-21

SEATS - REMOVAL, INTAKE/EXHAUST

VALVES .......................9-105,9s-22

SEATS - STANDARD PROCEDURE,

REFACING VALVES AND VALVE.....9-104,9s-21

SECOND ROW - INSTALLATION, BENCH

SEAT RISER........................23-101

SECOND ROW - LEFT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR........................8O-17

SECOND ROW - LEFT OUTBOARD -

REMOVAL, SEAT BELT & RETRACTOR....8O-17

SECOND ROW - REMOVAL, BENCH SEAT

RISER............................23-101

SECOND ROW - RIGHT OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR........................8O-15

SECOND ROW - RIGHT OUTBOARD -

REMOVAL, SEAT BELT & RETRACTOR

....8O-15

SECOND ROW - RIGHT OUTBOARD

WITH REAR HVAC - LWB -

INSTALLATION, SEAT BELT &

RETRACTOR

........................8O-16

SECOND ROW - RIGHT OUTBOARD

WITH REAR HVAC - LWB - REMOVAL,

SEAT BELT & RETRACTOR

.............8O-16

SECOND ROW - THREE PASSENGER

BENCH - INSTALLATION, SEAT BELT

BUCKLE

............................8O-15

SECOND ROW - THREE PASSENGER

BENCH - REMOVAL, SEAT BELT

BUCKLE

............................8O-15

SECOND ROW INBOARD - 50/50 BENCH

- INSTALLATION, SEAT BELT BUCKLE

....8O-13

SECOND ROW INBOARD - 50/50 BENCH

- REMOVAL, SEAT BELT BUCKLE

........8O-13

SECTION IDENTIFICATION AND

INFORMATION - DESCRIPTION

........8W-01-6

SECURITY - DESCRIPTION, VEHICLE

THEFT

..............................8Q-1

SECURITY - OPERATION, VEHICLE THEFT

. . 8Q-1

SECURITY SYSTEM - DIAGNOSIS AND

TESTING, VEHICLE THEFT

..............8Q-3

SELECTION, ADJUSTMENTS - OUTPUT

FLANGE SHIM

........................21-7

SELECTOR - INSTALLATION, GEARSHIFT

CABLE

.............................21-84SELECTOR - REMOVAL, GEARSHIFT

CABLE.............................21-81

SELF-DIAGNOSTICS - DIAGNOSIS AND

TESTING............................8J-2

SENDING UNIT / SENSOR -

DESCRIPTION, FUEL LEVEL.............14-5

SENDING UNIT / SENSOR -

INSTALLATION, FUEL LEVEL.............14-5

SENDING UNIT / SENSOR - OPERATION,

FUEL LEVEL..........................14-5

SENDING UNIT / SENSOR - REMOVAL,

FUEL LEVEL..........................14-5

SENSE - PCM INPUT - OPERATION,

IGNITION...........................8E-15

SENSITIVE DEVICES - STANDARD

PROCEDURE, ELECTROSTATIC

DISCHARGE (ESD).................8W-01-8

SENSOR - 2.4L - DESCRIPTION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - 2.4L - INSTALLATION, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - 2.4L - REMOVAL, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - 3.3/3.8L - DESCRIPTION,

ENGINE COOLANT TEMPERATURE........7-21

SENSOR - 3.3/3.8L - INSTALLATION,

ENGINE COOLANT TEMPERATURE........7-22

SENSOR - 3.3/3.8L - REMOVAL, ENGINE

COOLANT TEMPERATURE...............7-21

SENSOR - AWD - INSTALLATION, REAR

WHEEL SPEED........................5-80

SENSOR - AWD - REMOVAL, REAR

WHEEL SPEED........................5-80

SENSOR - DESCRIPTION, AMBIENT

TEMP.............................8M-11

SENSOR - DESCRIPTION, BATTERY

TEMPERATURE......................8F-23

SENSOR - DESCRIPTION, CAMSHAFT

POSITION............................8I-4

SENSOR - DESCRIPTION, CRANKSHAFT

POSITION..........................14-25

SENSOR - DESCRIPTION, ENGINE SPEED . 14-26

SENSOR - DESCRIPTION, EVAPORATOR

TEMPERATURE......................24-27

SENSOR - DESCRIPTION, FUEL LEVEL

SENDING UNIT.......................14-5

SENSOR - DESCRIPTION, HEATED SEAT . . 8G-12

SENSOR - DESCRIPTION, INFRARED

TEMPERATURE......................24-29

SENSOR - DESCRIPTION, INLET AIR

TEMPERATURE......................14-30

SENSOR - DESCRIPTION, KNOCK.........8I-8

SENSOR - DESCRIPTION, MAP..........14-30

SENSOR - DESCRIPTION, O2...........14-32

SENSOR - DESCRIPTION, PINCH........8N-17

SENSOR - DESCRIPTION, THROTTLE

POSITION..........................14-36

SENSOR - DESCRIPTION,

TRANSMISSION RANGE.......21-248,21s-150

SENSOR - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE..............8M-12

SENSOR - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-12

SENSOR - DIAGNOSIS AND TESTING,

TIRE PRESSURE

................22-10,22s-2

SENSOR - FWD - INSTALLATION, REAR

WHEEL SPEED

........................5-81

SENSOR - FWD - REMOVAL, REAR

WHEEL SPEED

........................5-81

SENSOR - INPUT - DESCRIPTION,

SPEED

.....................21-239,21s-140

SENSOR - INPUT - INSTALLATION,

SPEED

.....................21-240,21s-141

SENSOR - INPUT - OPERATION, SPEED

. 21-240,

21s-140

SENSOR - INPUT - REMOVAL, SPEED

. . . 21-240,

21s-141

SENSOR - INSTALLATION, FRONT

WHEEL SPEED

........................5-80

SENSOR - INSTALLATION, FUEL LEVEL

SENDING UNIT

.......................14-5

SENSOR - INSTALLATION, PINCH

........8N-17

SENSOR - INSTALLATION,

TRANSMISSION RANGE

.......21-249,21s-152

SENSOR - INSTALLATION, VEHICLE

SPEED

............................21-115

SENSOR - OPERATION, AMBIENT TEMP

. . 8M-11SENSOR - OPERATION, BATTERY

TEMPERATURE......................8F-23

SENSOR - OPERATION, CAMSHAFT

POSITION............................8I-4

SENSOR - OPERATION, CRANKSHAFT

POSITION..........................14-25

SENSOR - OPERATION, ENGINE SPEED . . . 14-26

SENSOR - OPERATION, EVAPORATOR

TEMPERATURE......................24-28

SENSOR - OPERATION, FUEL LEVEL

SENDING UNIT.......................14-5

SENSOR - OPERATION, HEATED SEAT....8G-12

SENSOR - OPERATION, INFRARED

TEMPERATURE......................24-29

SENSOR - OPERATION, KNOCK...........8I-8

SENSOR - OPERATION, MAP...........14-30

SENSOR - OPERATION, O2.............14-32

SENSOR - OPERATION, PINCH..........8N-17

SENSOR - OPERATION, THROTTLE

POSITION..........................14-36

SENSOR - OPERATION, TRANSMISSION

RANGE.....................21-248,21s-151

SENSOR - OUTPUT - DESCRIPTION,

SPEED.....................21-241,21s-142

SENSOR - OUTPUT - INSTALLATION,

SPEED.....................21-242,21s-143

SENSOR - OUTPUT - OPERATION,

SPEED.....................21-241,21s-142

SENSOR - OUTPUT - REMOVAL, SPEED . 21-241,

21s-143

SENSOR - REMOVAL, BATTERY

TEMPERATURE........................8F-23

SENSOR - REMOVAL, CRANKSHAFT

POSITION..........................14-25

SENSOR - REMOVAL, FRONT WHEEL

SPEED..............................5-79

SENSOR - REMOVAL, FUEL LEVEL

SENDING UNIT.......................14-5

SENSOR - REMOVAL, PINCH...........8N-17

SENSOR - REMOVAL, TRANSMISSION

RANGE.....................21-249,21s-151

SENSOR - REMOVAL, VEHICLE SPEED . . . 21-115

SENSOR - SPECIFICATIONS, BATTERY

TEMPERATURE......................8F-22

SENSOR - TPM - CAUTION........22-10,22s-2

SENSOR - TPM - DESCRIPTION....22-10,22s-1

SENSOR - TPM - INSTALLATION....22-12,22s-3

SENSOR - TPM - OPERATION......22-10,22s-2

SENSOR - TPM - REMOVAL.......22-11,22s-2

SENSOR AIR GAP, SPECIFICATIONS -

WHEEL SPEED........................5-79

SENSOR CIRCUIT - DIAGNOSIS AND