air condition CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2521 of 2585

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times,

including when diagnostics are performed.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the a DRBIIItscan tool.

The following is a list of the system monitors:

²EGR Monitor (if equipped)²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor (if

equipped)

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperatures of 300É to 350ÉC (572É to 662ÉF),

the sensor generates a voltage that is inversely pro-

portional to the amount of oxygen in the exhaust.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. The PCM is

programmed to maintain the optimum air/fuel ratio.

At this mixture ratio, the catalyst works best to

remove hydrocarbons (HC), carbon monoxide (CO)

and nitrous oxide (NOx) from the exhaust.

The O2S is also the main sensing element for the

EGR (if equipped), Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate

²Reduced output voltage

²Dynamic shift

²Shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt (voltages are offset by 2.5 volts on NGC vehi-

cles). A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) DTC as well as

a O2S heater DTC, the O2S heater fault MUST be

repaired first. After the O2S fault is repaired, verify

that the heater circuit is operating correctly.

25 - 6 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2522 of 2585

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperatures of 300É to 350ÉC (572 É to 662ÉF),

the sensor generates a voltage that is inversely pro-

portional to the amount of oxygen in the exhaust.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 Air Fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrogen oxide

(NOx) from the exhaust.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The O2S circuit is monitored for a drop in voltage.

The sensor output is used to test the heater by iso-

lating the effect of the heater element on the O2S

output voltage from the other effects.

EGR MONITOR (if equipped)

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR monitor is used to test whether the EGR

system is operating within specifications. The diag-

nostic check activates only during selected engine/

driving conditions. When the conditions are met, the

EGR is turned off (solenoid energized) and the O2S

compensation control is monitored. Turning off the

EGR shifts the air fuel (A/F) ratio in the lean direc-

tion. The O2S data should indicate an increase in the

O2 concentration in the combustion chamber when

the exhaust gases are no longer recirculated. While

this test does not directly measure the operation of

the EGR system, it can be inferred from the shift in

the O2S data whether the EGR system is operating

correctly. Because the O2S is being used, the O2S

test must pass its test before the EGR test. Also

looks at EGR linear potentiometer for feedback.

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.FUEL SYSTEM MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the air fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio. This is done by making short term cor-

rections in the fuel injector pulse width based on the

O2S output. The programmed memory acts as a self

calibration tool that the engine controller uses to

compensate for variations in engine specifications,

sensor tolerances and engine fatigue over the life

span of the engine. By monitoring the actual air-fuel

ratio with the O2S (short term) and multiplying that

with the program long-term (adaptive) memory and

comparing that to the limit, it can be determined

whether it will pass an emissions test. If a malfunc-

tion occurs such that the PCM cannot maintain the

optimum A/F ratio, then the MIL will be illuminated.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

RSEMISSIONS CONTROL25-7

EMISSIONS CONTROL (Continued)

Page 2524 of 2585

OPERATION

OPERATION - SYSTEM

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRBIIITscan tool

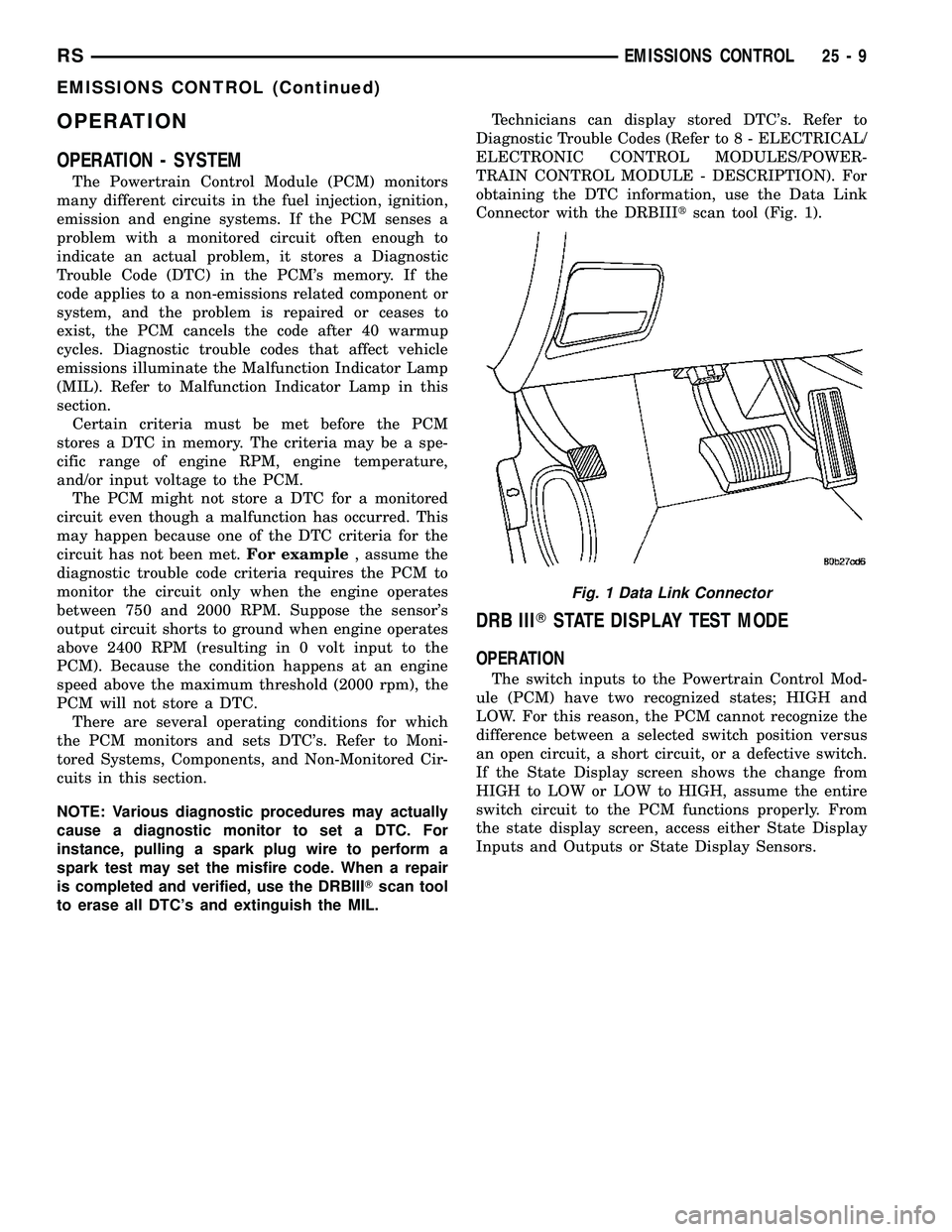

to erase all DTC's and extinguish the MIL.Technicians can display stored DTC's. Refer to

Diagnostic Trouble Codes (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/POWER-

TRAIN CONTROL MODULE - DESCRIPTION). For

obtaining the DTC information, use the Data Link

Connector with the DRBIIItscan tool (Fig. 1).

DRB IIITSTATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

Fig. 1 Data Link Connector

RSEMISSIONS CONTROL25-9

EMISSIONS CONTROL (Continued)

Page 2538 of 2585

De-energizing the solenoid, but not fully closing the

transducer bleed hole (because of low back-pressure),

varies the strength of vacuum applied to the EGR

valve. Varying the strength of the vacuum changes

the amount of EGR supplied to the engine. This pro-

vides the correct amount of exhaust gas recirculation

for different operating conditions.

This system does not allow EGR at idle.

A failed or malfunctioning EGR system can cause

engine spark knock, sags or hesitation, rough idle,

engine stalling and increased emissions.

REMOVAL - 2.4L

The EGR valve and Electrical EGR Transducer are

serviced as an assembly (Fig. 1).

(1) Disconnect vacuum tube from electric EGR

transducer. Inspect vacuum tube for damage.

(2) Remove electrical connector from solenoid.

(3) Remove EGR tube bolts from EGR valve.

(4) Remove EGR valve from cylinder head adaptor.

(5) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

Repair or replace as necessary.

INSTALLATION - 2.4L

The EGR valve and Electrical EGR Transducer are

serviced as an assembly (Fig. 1).

(1) Assemble EGR valve with new gasket onto the

cylinder head adaptor.

(2) Loose assemble the bolts from EGR valve to

EGR tube.

(3) Loose assemble the bolts from EGR valve to

cylinder head.

(4) Tighten bolts from EGR valve to cylinder head

to 22.8 N´m (200 25 in. lbs.) torque.

(5) Tighten bolts from EGR valve to EGR tube to

11.9 N´m (105 20 in. lbs.) torque.

(6) Reconnect vacuum hose and electrical connec-

tor to electrical EGR transducer.

RSEXHAUST GAS RECIRCULATION25-23

VALVE (Continued)

Page 2539 of 2585

ON-BOARD DIAGNOSTICS

TABLE OF CONTENTS

page page

TASK MANAGER

DESCRIPTION.........................24OPERATION...........................24

TASK MANAGER

DESCRIPTION

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is call the ªTask Managerº.

OPERATION

The Task Manager determines when tests happen

and when functions occur. Many of the diagnostic

steps required by OBD II must be performed under

specific operating conditions. The Task Manager soft-

ware organizes and prioritizes the diagnostic proce-

dures. The job of the Task Manager is to determine if

conditions are appropriate for tests to be run, moni-

tor the parameters for a trip for each test, and record

the results of the test. Following are the responsibil-

ities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator

²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are known as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will notrun a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the catalyst

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precise diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the catalyst monitor, the

Task Manager may still run the catalyst Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the catalyst system is

actually failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

25 - 24 ON-BOARD DIAGNOSTICSRS

Page 2544 of 2585

INDEX

ABS FASTENER TORQUE,

SPECIFICATIONS......................5-79

ABSORBER - DESCRIPTION, SHOCK.......2-37

ABSORBER - INSTALLATION, SHOCK......2-38

ABSORBER - OPERATION, SHOCK........2-37

ABSORBER - REMOVAL, SHOCK..........2-37

ABSORBER (UPPER BUSHING) -

ASSEMBLY, SHOCK....................2-38

ABSORBER (UPPER BUSHING) -

DISASSEMBLY, SHOCK.................2-37

A/C COMPRESSOR - DESCRIPTION......24-73

A/C COMPRESSOR - OPERATION........24-73

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-15

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-19

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-20

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-19

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-20

A/C COMPRESSOR CLUTCH/COIL -

DESCRIPTION.......................24-15

A/C COMPRESSOR CLUTCH/COIL -

INSPECTION........................24-17

A/C COMPRESSOR CLUTCH/COIL -

INSTALLATION.......................24-17

A/C COMPRESSOR CLUTCH/COIL -

OPERATION.........................24-15

A/C COMPRESSOR CLUTCH/COIL -

REMOVAL..........................24-16

A/C COMPRESSOR MOUNTING BRACKET

- 2.4L ENGINE - INSTALLATION.........24-76

A/C COMPRESSOR MOUNTING BRACKET

- 2.4L ENGINE - REMOVAL.............24-75

A/C CONDENSER - DESCRIPTION........24-76

A/C CONDENSER - INSTALLATION.......24-78

A/C CONDENSER - OPERATION..........24-76

A/C CONDENSER - REMOVAL...........24-77

A/C COOL DOWN TEST - DIAGNOSIS

AND TESTING........................24-6

A/C DISCHARGE LINE - INSTALLATION . . . 24-80

A/C DISCHARGE LINE - REMOVAL.......24-79

A/C EVAPORATOR - DESCRIPTION . . 24-80,24-97

A/C EVAPORATOR - INSTALLATION......24-80

A/C EVAPORATOR - INSTALLATION,

REAR..............................24-99

A/C EVAPORATOR - OPERATION....24-80,24-97

A/C EVAPORATOR - REMOVAL..........24-80

A/C EVAPORATOR - REMOVAL, REAR.....24-97

A/C EVAPORATOR LINE EXTENSION -

INSTALLATION, REAR.................24-99

A/C EVAPORATOR LINE EXTENSION -

REMOVAL..........................24-98

A/C EXPANSION VALVE - DESCRIPTION . . . 24-99

A/C EXPANSION VALVE - DIAGNOSIS

AND TESTING.......................24-81

A/C EXPANSION VALVE - INSTALLATION . 24-100

A/C EXPANSION VALVE - OPERATION.....24-99

A/C EXPANSION VALVE - REMOVAL.....24-100

A/C HEATER CONTROL - DESCRIPTION . . . 24-20

A/C HEATER CONTROL - INSTALLATION . . . 24-21

A/C HEATER CONTROL - REMOVAL......24-21

A/C PERFORMANCE TEST - DIAGNOSIS

AND TESTING........................24-7

A/C PRESSURE TRANSDUCER -

DESCRIPTION.......................24-21

A/C PRESSURE TRANSDUCER -

DIAGNOSIS AND TESTING.............24-22

A/C PRESSURE TRANSDUCER -

INSTALLATION.......................24-22

A/C PRESSURE TRANSDUCER -

OPERATION.........................24-21

A/C PRESSURE TRANSDUCER -

REMOVAL..........................24-22

A/C SYSTEM, CAUTION................24-66

A/C SYSTEM, SPECIFICATIONS..........24-11

A/C SYSTEM, WARNING...............24-65

ACCELERATOR PEDAL - INSTALLATION . . . 14-24

ACCELERATOR PEDAL - REMOVAL

.......14-24

ACCESSORY DRIVE BELT - DIAGNOSIS

AND TESTING

.........................7-7

ACCESSORY DRIVE BELT TENSION,

SPECIFICATIONS

.......................7-5

ACCUMULATOR - DESCRIPTION

.......21-188,

21s-206,21s-94

ACCUMULATOR - OPERATION

....21-189,21s-94A/C-HEATER CONTROL - DESCRIPTION . . . 24-34

A/C-HEATER CONTROL - INSTALLATION . . . 24-35

A/C-HEATER CONTROL - OPERATION.....24-34

A/C-HEATER CONTROL - REMOVAL......24-34

A/C-HEATER CONTROL CALIBRATION -

STANDARD PROCEDURE...............24-20

ACTUATOR - DESCRIPTION, BLEND

DOOR........................24-23,24-35

ACTUATOR - DESCRIPTION, ENGAGE.....8N-10

ACTUATOR - DESCRIPTION, LATCH......8N-14

ACTUATOR - DESCRIPTION, MODE

DOOR.............................24-30

ACTUATOR - DESCRIPTION,

RECIRCULATION DOOR................24-32

ACTUATOR - INSTALLATION, BLEND

DOOR........................24-23,24-36

ACTUATOR - INSTALLATION, ENGAGE....8N-11

ACTUATOR - INSTALLATION, INSIDE

HANDLE............................23-27

ACTUATOR - INSTALLATION, LATCH.....8N-14

ACTUATOR - INSTALLATION, MODE

DOOR.............................24-31

ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-33

ACTUATOR - OPERATION, BLEND DOOR . . 24-23,

24-35

ACTUATOR - OPERATION, ENGAGE......8N-11

ACTUATOR - OPERATION, LATCH........8N-14

ACTUATOR - OPERATION, MODE DOOR . . . 24-30

ACTUATOR - OPERATION,

RECIRCULATION DOOR................24-32

ACTUATOR - REAR - DESCRIPTION,

MODE DOOR........................24-39

ACTUATOR - REAR - INSTALLATION,

MODE DOOR........................24-40

ACTUATOR - REAR - OPERATION, MODE

DOOR.............................24-40

ACTUATOR - REAR - REMOVAL, MODE

DOOR.............................24-40

ACTUATOR - REMOVAL, BLEND DOOR . . . 24-23,

24-36

ACTUATOR - REMOVAL, ENGAGE........8N-11

ACTUATOR - REMOVAL, INSIDE HANDLE . . 23-27

ACTUATOR - REMOVAL, LATCH.........8N-14

ACTUATOR - REMOVAL, MODE DOOR....24-30

ACTUATOR - REMOVAL, RECIRCULATION

DOOR.............................24-33

ADAPTER - INSTALLATION, FRONT DISC

BRAKE CALIPER.................5-31,5s-30

ADAPTER - INSTALLATION, OIL FILTER . . . 9-139

ADAPTER - REMOVAL, FRONT DISC

BRAKE CALIPER.................5-31,5s-30

ADAPTER - REMOVAL, OIL FILTER.......9-139

ADAPTIVE MEMORIES, OPERATION -

FUEL CORRECTION OR................14-20

ADDING ADDITIONAL COOLANT -

STANDARD PROCEDURE.................7-5

ADDITIONAL COOLANT - STANDARD

PROCEDURE, ADDING...................7-5

ADHESIVE ATTACHED - INSTALLATION,

EXTERIOR NAME PLATES..............23-51

ADHESIVE ATTACHED - REMOVAL,

EXTERIOR NAME PLATES..............23-51

ADHESIVE LOCATIONS -

SPECIFICATIONS, STRUCTURAL

........23-156

ADJUSTABLE - INSTALLATION, PEDALS

. . . 5s-40

ADJUSTABLE - REMOVAL, PEDALS

.......5s-38

ADJUSTABLE PEDALS SWITCH -

INSTALLATION

.......................5s-10

ADJUSTABLE PEDALS SWITCH -

REMOVAL

..........................5s-10

ADJUSTER-BORC-PILLAR -

INSTALLATION, SEAT BELT HEIGHT

......8O-13

ADJUSTER-BORC-PILLAR -

REMOVAL, SEAT BELT HEIGHT

..........8O-13

ADJUSTER - DIAGNOSIS AND TESTING,

DRUM BRAKE AUTOMATIC

.........5-13,5s-13

ADJUSTER - INSTALLATION, FRONT

SEAT TRACK MANUAL

................23-95

ADJUSTER - INSTALLATION, FRONT

SEAT TRACK POWER

.................23-95

ADJUSTER - REMOVAL, FRONT SEAT

TRACK MANUAL

.....................23-95

ADJUSTER - REMOVAL, FRONT SEAT

TRACK POWER

......................23-95

ADJUSTER KNOB - INSTALLATION, SEAT

BELT HEIGHT

.......................8O-14ADJUSTER KNOB - REMOVAL, SEAT

BELT HEIGHT.......................8O-14

ADJUSTER NOISE DIAGNOSIS -

DIAGNOSIS AND TESTING, HYDRAULIC

LASH...............................9-34

ADJUSTER TENSION RELEASE -

STANDARD PROCEDURE, PARKING

BRAKE AUTOMATIC...............5-58,5s-61

ADJUSTER TENSION RESET -

STANDARD PROCEDURE, PARKING

BRAKE AUTOMATIC...............5-59,5s-61

ADJUSTERS - INSTALLATION,

HYDRAULIC LASH.....................9-34

ADJUSTERS - REMOVAL, HYDRAULIC

LASH...............................9-34

AERATION - DIAGNOSIS AND TESTING,

COOLING SYSTEM.....................7-3

AFTER AN AIRBAG DEPLOYMENT -

STANDARD PROCEDURE, SERVICE.......8O-3

AIR CLEANER ELEMENT - INSTALLATION . . 9-24,

9-98

AIR CLEANER ELEMENT - REMOVAL . . 9-24,9-98

AIR CLEANER HOUSING - INSTALLATION . . 9-24,

9-99

AIR CLEANER HOUSING - REMOVAL . . 9-24,9-99

AIR CONDITIONER - DESCRIPTION,

HEATER .............................24-1

AIR CONDITIONER - OPERATION,

HEATER .............................24-4

AIR CONTROL MOTOR - DESCRIPTION,

IDLE...............................14-28

AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-29

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-28

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-29

AIR EXHAUSTER - DESCRIPTION, REAR

QUARTER PANEL/FENDER..............23-57

AIR EXHAUSTER - INSTALLATION, REAR

QUARTER PANEL/FENDER..............23-58

AIR EXHAUSTER - REMOVAL, REAR

QUARTER PANEL/FENDER..............23-57

AIR FILTER - DESCRIPTION............24-43

AIR FILTER - INSTALLATION............24-44

AIR FILTER - REMOVAL...............24-43

AIR GAP, SPECIFICATIONS - WHEEL

SPEED SENSOR.......................5-79

AIR INTAKE PIPE - INSTALLATION......24-114

AIR INTAKE PIPE - REMOVAL..........24-113

AIR OUTLETS - DESCRIPTION.....24-44,24-56

AIR OUTLETS - INSTALLATION..........24-56

AIR OUTLETS - REMOVAL.............24-56

AIR PRESSURE TESTS - DIAGNOSIS

AND TESTING, CLUTCH.........21-122,21s-30

AIR TEMPERATURE SENSOR -

DESCRIPTION, INLET.................14-30

AIRBAG - DESCRIPTION, DRIVER........8O-6

AIRBAG - DESCRIPTION, PASSENGER.....8O-8

AIRBAG - DESCRIPTION, SEAT..........8O-11

AIRBAG - INSTALLATION, DRIVER........8O-7

AIRBAG - INSTALLATION, PASSENGER . . . 8O-10

AIRBAG - OPERATION, DRIVER..........8O-6

AIRBAG - OPERATION, PASSENGER.......8O-9

AIRBAG - OPERATION, SEAT...........8O-11

AIRBAG - REMOVAL, DRIVER

............8O-6

AIRBAG - REMOVAL, PASSENGER

........8O-9

AIRBAG DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER AN

........8O-3

AIRBAG SYSTEM - DIAGNOSIS AND

TESTING

............................8O-2

AIRBAG TRIM COVER - INSTALLATION,

DRIVER

.............................8O-7

AIRBAG TRIM COVER - REMOVAL,

DRIVER

.............................8O-7

AIRBAGS - STANDARD PROCEDURE,

HANDLING

..........................8O-3

AJAR SWITCH - EXPORT -

INSTALLATION, HOOD

.................8Q-3

AJAR SWITCH - EXPORT - REMOVAL,

HOOD

..............................8Q-3

ALIGNMENT - DESCRIPTION, WHEEL

......2-47

ALIGNMENT - EXPORT - STANDARD

PROCEDURE, FRONT FOG LAMP UNIT

.....8L-9

ALIGNMENT - EXPORT - STANDARD

PROCEDURE, HEADLAMP UNIT

.........8L-14

ALIGNMENT - STANDARD PROCEDURE,

FRONT FOG LAMP UNIT

................8L-9

RSINDEX1

Description Group-Page Description Group-Page Description Group-Page

Page 2550 of 2585

CHAIN WEAR - STANDARD PROCEDURE,

MEASURING TIMING..................9-153

CHANGE - STANDARD PROCEDURE,

DIFFERENTIAL ASSEMBLY FLUID.........3-40

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER...........9-137,9-53

CHANGE - STANDARD PROCEDURE,

OVERRUNNING CLUTCH HOUSING

FLUID..............................3-41

CHANGE - STANDARD PROCEDURE, PTU

FLUID..............................21-5

CHANGER - DESCRIPTION, CD...........8A-7

CHANGER - INSTALLATION, CD..........8A-8

CHANGER - OPERATION, CD.............8A-7

CHANGER - REMOVAL, CD..............8A-8

CHANNEL - INSTALLATION, WATER.....23-121

CHANNEL - REMOVAL, WATER.........23-121

CHARGE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-72

CHARGE LEVEL TEST - 2.5L DIESEL -

DIAGNOSIS AND TESTING, SYSTEM......24-68

CHARGE LEVEL TEST - GASOLINE

ENGINES - DIAGNOSIS AND TESTING,

SYSTEM............................24-67

CHARGING - STANDARD PROCEDURE,

CONVENTIONAL BATTERY..............8F-11

CHARGING - STANDARD PROCEDURE,

SPIRAL PLATE BATTERY...............8F-10

CHARGING SYSTEM - DESCRIPTION.....8F-20

CHARGING SYSTEM - OPERATION.......8F-20

CHARTS - DIAGNOSIS AND TESTING,

STEERING SYSTEM DIAGNOSIS...........19-3

CHARTS - SPECIFICATIONS, COLOR

CODE..............................23-84

CHATTER COMPLAINTS - DIAGNOSIS

AND TESTING, CLUTCH.................6-6

CHECK - DIAGNOSIS AND TESTING,

COOLING SYSTEM FLOW................7-3

CHECK - DIAGNOSIS AND TESTING,

EXHAUST SYSTEM RESTRICTION.........11-2

CHECK - STANDARD PROCEDURE,

COOLANT LEVEL.......................7-5

CHECK - STANDARD PROCEDURE,

ENGINE OIL LEVEL...................9-137

CHECK - STANDARD PROCEDURE, FLUID

LEVEL.............................21-71

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-53

CHECK, STANDARD PROCEDURE - FLUID

LEVEL AND CONDITION........21-201,21s-102

CHECK STRAP - INSTALLATION.........23-15

CHECK STRAP - REMOVAL.............23-15

CHECKING - STANDARD PROCEDURE,

BRAKE FLUID LEVEL..............5-32,5s-31

CHECKING - STANDARD PROCEDURE,

POWER STEERING FLUID LEVEL........19-44

CHECKING BATTERY ELECTROLYTE

LEVEL - STANDARD PROCEDURE........8F-14

CHECKING ENGINE OIL PRESSURE -

DIAGNOSIS AND TESTING..............9-52

CHECKING POWER STEERING BELT

TENSION - STANDARD PROCEDURE.......7-8

CHILD RESTRAINT ANCHOR -

DESCRIPTION........................8O-4

CHILD RESTRAINT ANCHOR -

OPERATION..........................8O-4

CHILD SEAT - INSTALLATION, QUAD.....23-89

CHILD SEAT - REMOVAL, QUAD.........23-89

CHILD SEAT MODULE, BENCH SEAT -

REMOVAL..........................23-87

CHIME SYSTEM - DIAGNOSIS AND

TESTING

............................8B-1

CHIME/BUZZER - DESCRIPTION

..........8B-1

CHIME/BUZZER - OPERATION

............8B-1

CHIME/BUZZER - WARNING

.............8B-1

CHIME/THERMISTOR - DESCRIPTION

....8N-10

CHIME/THERMISTOR - INSTALLATION

....8N-10

CHIME/THERMISTOR - OPERATION

......8N-10

CHIME/THERMISTOR - REMOVAL

.......8N-10

CHIRP PREFERENCE - STANDARD

PROCEDURE, HORN

..............8N-42,8N-5

CIRCUIT - DIAGNOSIS AND TESTING,

AMBIENT TEMPERATURE SENSOR

......8M-12

CIRCUIT FUNCTIONS - DESCRIPTION

. . 8W-01-6

CIRCUIT INFORMATION - DESCRIPTION

. 8W-01-5

CIRCUIT RESISTANCE TEST -

DIAGNOSIS AND TESTING, FEED

. . . 8F-32,8F-34CIRCUIT TEST - DIAGNOSIS AND

TESTING, CONTROL..............8F-30,8F-32

CIRCUIT TEST - DIAGNOSIS AND

TESTING, FEED.................8F-33,8F-35

CIRCUITS - OPERATION, NON-

MONITORED.........................25-5

CIRCUITS AND VALVES - OPERATION,

HYDRAULIC..........................5-83

CLAMP - STANDARD PROCEDURE,

HOSES..............................14-7

CLAMPS - DESCRIPTION, FUEL

LINES/HOSES........................14-6

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEAN, CLEANING...................21-114

CLEARANCE - STANDARD PROCEDURE,

MEASURING CONNECTING ROD

BEARING...........................9-120

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING........................9-12,9-84

CLOCK SPRING - DESCRIPTION..........8O-4

CLOCK SPRING - INSTALLATION.........8O-5

CLOCK SPRING - OPERATION...........8O-4

CLOCK SPRING - REMOVAL.............8O-5

CLOCK SPRING CENTERING -

STANDARD PROCEDURE...............8O-5

CLUSTER - DESCRIPTION, INSTRUMENT . . . 8J-1

CLUSTER - OPERATION, INSTRUMENT.....8J-1

CLUSTER BEZEL - INSTALLATION........23-63

CLUSTER BEZEL - REMOVAL.............23-63

CLUSTER DIAGNOSIS - DIAGNOSIS AND

TESTING............................8J-2

CLUSTER ILLUMINATION LAMPS -

INSTALLATION.......................8L-21

CLUSTER ILLUMINATION LAMPS -

REMOVAL..........................8L-21

CLUSTER LENS - INSTALLATION........8J-10

CLUSTER LENS - REMOVAL............8J-10

CLUTCH - DESCRIPTION.................6-1

CLUTCH - DESCRIPTION, BI-

DIRECTIONAL OVERRUNNING...........3-34

CLUTCH - OPERATION, BI-DIRECTIONAL

OVERRUNNING.......................3-36

CLUTCH AIR PRESSURE TESTS -

DIAGNOSIS AND TESTING.......21-122,21s-30

CLUTCH ASSEMBLY - ASSEMBLY,

INPUT.....................21-216,21s-116

CLUTCH ASSEMBLY - DISASSEMBLY,

INPUT.....................21-208,21s-107

CLUTCH ASSY - 2.4L GAS -

INSTALLATION, MODULAR..............6-11

CLUTCH ASSY - 2.4L GAS - REMOVAL,

MODULAR...........................6-11

CLUTCH CHATTER COMPLAINTS -

DIAGNOSIS AND TESTING...............6-6

CLUTCH COIL - DIAGNOSIS AND

TESTING, A/C COMPRESSOR...........24-15

CLUTCH COVER AND DISC RUNOUT -

DIAGNOSIS AND TESTING...............6-6

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - INSTALLATION

...............6-12

CLUTCH DISC AND PRESSURE PLATE -

2.5L TD - REMOVAL

...................6-11

CLUTCH HOUSING FLUID CHANGE -

STANDARD PROCEDURE,

OVERRUNNING

.......................3-41

CLUTCH PEDAL INTERLOCK SWITCH -

INSTALLATION

........................6-14

CLUTCH PEDAL INTERLOCK SWITCH -

REMOVAL

...........................6-13

CLUTCH PEDAL UPSTOP SWITCH -

INSTALLATION

........................6-16

CLUTCH PEDAL UPSTOP SWITCH -

REMOVAL

...........................6-15

CLUTCH RELAY - DESCRIPTION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - INSTALLATION, A/C

COMPRESSOR

.......................24-20

CLUTCH RELAY - OPERATION, A/C

COMPRESSOR

.......................24-19

CLUTCH RELAY - REMOVAL, A/C

COMPRESSOR

.......................24-20

CLUTCH RELEASE LEVER AND BEARING

- INSTALLATION

.......................6-7

CLUTCH RELEASE LEVER AND BEARING

- REMOVAL

...........................6-6CLUTCH SYSTEM - DIAGNOSIS AND

TESTING.............................6-3

CLUTCH/COIL - DESCRIPTION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - INSPECTION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - INSTALLATION, A/C

COMPRESSOR.......................24-17

CLUTCH/COIL - OPERATION, A/C

COMPRESSOR.......................24-15

CLUTCH/COIL - REMOVAL, A/C

COMPRESSOR.......................24-16

CLUTCHES - DESCRIPTION, DRIVING . . . 21-190,

21s-95

CLUTCHES - DESCRIPTION, HOLDING . . . 21-207,

21s-106

CLUTCHES - OPERATION, DRIVING.....21-190,

21s-95

CLUTCHES - OPERATION, HOLDING....21-207,

21s-106

COAT/CLEARCOAT FINISH -

DESCRIPTION, BASE..................23-85

CODE - DESCRIPTION, PAINT...........23-85

CODE CHARTS - SPECIFICATIONS,

COLOR.............................23-84

CODE PLATE - DESCRIPTION, BODY....Intro.-1

CODES - STANDARD PROCEDURE,

ERASING TRANSMITTER..............8M-11

CODES - STANDARD PROCEDURE,

OBTAINING DIAGNOSTIC TROUBLE......8E-15

CODES - STANDARD PROCEDURE,

SETTING TRANSMITTER..............8M-11

COIL - DESCRIPTION, IGNITION............8I-6

COIL - DIAGNOSIS AND TESTING, A/C

COMPRESSOR CLUTCH...............24-15

COIL - OPERATION, IGNITION............8I-7

COLLAR - INSTALLATION, STRUCTURAL . . . 9-48

COLLAR - REMOVAL, STRUCTURAL.......9-47

COLOR CODE CHARTS -

SPECIFICATIONS.....................23-84

COLUMN - DESCRIPTION, STEERING.....19-10

COLUMN - DIAGNOSIS AND TESTING,

STEERING..........................19-12

COLUMN COVER - INSTALLATION,

LOWER STEERING...................23-70

COLUMN COVER - INSTALLATION, OVER

STEERING..........................23-70

COLUMN COVER - REMOVAL, LOWER

STEERING..........................23-70

COLUMN COVER - REMOVAL, OVER

STEERING..........................23-70

COLUMN COVER BACKING PLATE -

INSTALLATION, STEERING.............23-70

COLUMN COVER BACKING PLATE -

REMOVAL, STEERING.................23-70

COLUMN TORQUE, SPECIFICATIONS.....19-14

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER........................9-83,9-9

COMMON PROBLEM CAUSES -

DIAGNOSIS AND TESTING.............21-30

COMMUNICATION RECEIVE - PCM INPUT

- OPERATION, DATA BUS..............8E-15

COMMUNICATIONS INTERFACE (PCI)

BUS, OPERATION - PROGRAMMABLE....14-21

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-3

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-4

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING.............8M-10

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-5

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-9

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION......................8M-10

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-9

COMPASS/MINI-TRIP COMPUTER -

REMOVAL..........................8M-10

COMPLAINTS - DIAGNOSIS AND

TESTING, CLUTCH CHATTER

..............6-6

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER

. . 9-83,9-9

COMPRESSOR - DESCRIPTION, A/C

......24-73

COMPRESSOR - OPERATION, A/C

........24-73

COMPRESSOR - REMOVAL

.............24-74

RSINDEX7

Description Group-Page Description Group-Page Description Group-Page

Page 2551 of 2585

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-15

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-19

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-20

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-19

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-20

COMPRESSOR CLUTCH/COIL -

DESCRIPTION, A/C...................24-15

COMPRESSOR CLUTCH/COIL -

INSPECTION, A/C.....................24-17

COMPRESSOR CLUTCH/COIL -

INSTALLATION, A/C...................24-17

COMPRESSOR CLUTCH/COIL -

OPERATION, A/C.....................24-15

COMPRESSOR CLUTCH/COIL -

REMOVAL, A/C......................24-16

COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE - INSTALLATION, A/C.......24-76

COMPRESSOR MOUNTING BRACKET -

2.4L ENGINE - REMOVAL, A/C..........24-75

COMPRESSOR NOISE DIAGNOSIS -

DIAGNOSIS AND TESTING.............24-74

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-9

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP.................8M-10

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP.........................8M-10

COMPUTER - OPERATION, COMPASS/

MINI-TRIP............................8M-9

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP.........................8M-10

CONCENTRATION TESTING - DIAGNOSIS

AND TESTING, COOLANT...............7-19

CONDENSER - DESCRIPTION, A/C.......24-76

CONDENSER - INSTALLATION, A/C.......24-78

CONDENSER - OPERATION, A/C.........24-76

CONDENSER - REMOVAL, A/C..........24-77

CONDITION CHECK, STANDARD

PROCEDURE - FLUID LEVEL....21-201,21s-102

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-4

CONNECTING ROD - DESCRIPTION,

PISTON........................9-116,9-42

CONNECTING ROD - INSTALLATION,

PISTON.............................9-44

CONNECTING ROD - REMOVAL, PISTON . . . 9-43

CONNECTING ROD BEARING

CLEARANCE - STANDARD

PROCEDURE, MEASURING.............9-120

CONNECTING ROD, FITTING.............9-45

CONNECTING RODS - STANDARD

PROCEDURE, FITTING.................9-116

CONNECTOR - DESCRIPTION, DATA LINK . . 8E-6

CONNECTOR - INSTALLATION.......8W-01-11

CONNECTOR - OPERATION, DATA LINK....8E-7

CONNECTOR - REMOVAL...........8W-01-11

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD....8M-1

CONSOLE - DIAGNOSIS AND TESTING,

OVERHEAD..........................8M-2

CONSOLE - INSTALLATION, LOWER......23-69

CONSOLE - OPERATION, OVERHEAD......8M-2

CONSOLE - REMOVAL, LOWER..........23-69

CONSOLE - REMOVAL, OVERHEAD.......8M-6

CONSOLE LAMP - INSTALLATION,

CENTER............................8L-21

CONSOLE LAMP - REMOVAL, CENTER....8L-21

CONSOLE LAMP SWITCH -

INSTALLATION, CENTER...............8L-21

CONSOLE LAMP SWITCH - REMOVAL,

CENTER............................8L-21

CONSOLE, SPECIAL TOOLS - OVERHEAD

. . 8M-6

CONSOLE TRAY - BRACKET ASSEMBLY -

INSTALLATION, FLOOR

................23-83

CONSOLE TRAY - BRACKET ASSEMBLY -

REMOVAL, FLOOR

....................23-83

CONSOLE TRAY - INSTALLATION, FLOOR

. . 23-83

CONSOLE TRAY - REMOVAL, FLOOR

.....23-83CONTAINER - DESCRIPTION, COOLANT

RECOVERY..........................7-19

CONTAINER - INSTALLATION, COOLANT

RECOVERY..........................7-20

CONTAINER - OPERATION, COOLANT

RECOVERY..........................7-19

CONTAINER - REMOVAL, COOLANT

RECOVERY..........................7-20

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID...........5-32,5s-31

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL (4 SPEED EATX ONLY) -

OPERATION, INTERACTIVE SPEED........8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-12

CONTROL ARM - INSPECTION, LOWER....2-14

CONTROL ARM - INSTALLATION, LOWER . . 2-16

CONTROL ARM - OPERATION, LOWER.....2-12

CONTROL ARM - REMOVAL, LOWER......2-12

CONTROL ARM (REAR BUSHING -

HYDRO) - ASSEMBLY, LOWER...........2-14

CONTROL ARM (REAR BUSHING -

HYDRO) - DISASSEMBLY, LOWER........2-14

CONTROL ARM (REAR BUSHING -

STANDARD) - ASSEMBLY, LOWER........2-14

CONTROL ARM (REAR BUSHING -

STANDARD) - DISASSEMBLY, LOWER.....2-13

CONTROL (ATC) - INSTALLATION,

AUTOMATIC TEMPERATURE............24-29

CONTROL (ATC) - REMOVAL,

AUTOMATIC TEMPERATURE............24-28

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-36

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-35

CONTROL CALIBRATION - STANDARD

PROCEDURE, A/C-HEATER.............24-20

CONTROL CIRCUIT TEST - DIAGNOSIS

AND TESTING..................8F-30,8F-32

CONTROL INFORMATION LABEL -

DESCRIPTION, VEHICLE EMISSION.......25-1

CONTROL MODULE - DESCRIPTION,

BODY...............................8s-1

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-3

CONTROL MODULE - DESCRIPTION,

FRONT..............................8E-7

CONTROL MODULE - DESCRIPTION,

POWER LIFTGATE....................8E-10

CONTROL MODULE - DESCRIPTION,

SLIDING DOOR......................8E-19

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-20

CONTROL MODULE - DIAGNOSIS AND

TESTING, FRONT......................8E-7

CONTROL MODULE - INSTALLATION,

BODY...............................8s-3

CONTROL MODULE - INSTALLATION,

BODY...............................8E-5

CONTROL MODULE - INSTALLATION,

FRONT..............................8E-8

CONTROL MODULE - INSTALLATION,

POWER LIFTGATE....................8E-11

CONTROL MODULE - INSTALLATION,

SLIDING DOOR......................8E-20

CONTROL MODULE - OPERATION, BODY . . . 8s-1

CONTROL MODULE - OPERATION, BODY . . . 8E-3

CONTROL MODULE - OPERATION,

FRONT..............................8E-7

CONTROL MODULE - OPERATION,

POWER LIFTGATE....................8E-11

CONTROL MODULE - OPERATION,

SLIDING DOOR......................8E-19

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-20

CONTROL MODULE - REMOVAL, BODY....8s-3

CONTROL MODULE - REMOVAL, BODY....8E-4

CONTROL MODULE - REMOVAL, FRONT . . . 8E-8

CONTROL MODULE - REMOVAL, POWER

LIFTGATE

...........................8E-11

CONTROL MODULE - REMOVAL,

SLIDING DOOR

......................8E-19

CONTROL MOTOR - DESCRIPTION, IDLE

AIR

...............................14-28

CONTROL MOTOR - INSTALLATION, IDLE

AIR

...............................14-29

CONTROL MOTOR - OPERATION, IDLE

AIR

...............................14-28CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-29

CONTROL (MTC) - INSTALLATION,

MANUAL TEMPERATURE...............24-29

CONTROL (MTC) - REMOVAL, MANUAL

TEMPERATURE......................24-29

CONTROL RELAY - DESCRIPTION,

TRANSMISSION..............21-247,21s-150

CONTROL RELAY - OPERATION,

TRANSMISSION..............21-248,21s-150

CONTROL SWITCH - DIAGNOSIS AND

TESTING, TRACTION...................5-82

CONTROL SYSTEM - DESCRIPTION,

TRACTION...........................5-76

CONTROL SYSTEM - OPERATION,

AUTOMATIC TEMPERATURE...........24-112

CONTROL SYSTEM - OPERATION,

EVAPORATION.......................25-10

CONTROL SYSTEM - OPERATION,

MANUAL TEMPERATURE..............24-112

CONTROL SYSTEM - OPERATION,

TRACTION...........................5-77

CONTROLLER - DESCRIPTION,

OCCUPANT RESTRAINT................8O-8

CONTROLLER - INSTALLATION,

OCCUPANT RESTRAINT................8O-8

CONTROLLER - INSTALLATION, SBEC....8E-17

CONTROLLER - OPERATION, 8-VOLT

SUPPLY - PCM OUTPUT - SBEC.........8E-15

CONTROLLER - OPERATION, OCCUPANT

RESTRAINT..........................8O-8

CONTROLLER - REMOVAL, NGC.........8E-17

CONTROLLER - REMOVAL, OCCUPANT

RESTRAINT...........................8O-8

CONTROLLER - REMOVAL, SBEC........8E-16

CONTROLLER ANTILOCK BRAKE -

DESCRIPTION........................8E-5

CONTROLLER ANTILOCK BRAKE -

INSTALLATION........................8E-6

CONTROLLER ANTILOCK BRAKE -

OPERATION..........................8E-5

CONTROLLER ANTILOCK BRAKE -

REMOVAL...........................8E-6

CONVENTIONAL BATTERY CHARGING -

STANDARD PROCEDURE...............8F-11

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-4

CONVERTER - DESCRIPTION, TORQUE . . 21-242,

21s-144

CONVERTER - INSPECTION, CATALYTIC....11-5

CONVERTER - INSTALLATION, CATALYTIC . . 11-6

CONVERTER - INSTALLATION, TORQUE . . 21-247,

21s-149

CONVERTER - OPERATION, CATALYTIC....11-4

CONVERTER - OPERATION, TORQUE....21-245,

21s-148

CONVERTER - REMOVAL, CATALYTIC......11-5

CONVERTER - REMOVAL, TORQUE.....21-247,

21s-149

CONVERTER HOUSING FLUID LEAKAGE -

DIAGNOSIS AND TESTING, TORQUE....21-123,

21s-31

COOL DOWN TEST - DIAGNOSIS AND

TESTING, A/C........................24-6

COOLANT - DESCRIPTION, ENGINE.......7-19

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT - STANDARD PROCEDURE,

ADDING ADDITIONAL...................7-5

COOLANT CONCENTRATION TESTING -

DIAGNOSIS AND TESTING..............7-19

COOLANT LEVEL CHECK - STANDARD

PROCEDURE..........................7-5

COOLANT RECOVERY CONTAINER -

DESCRIPTION........................7-19

COOLANT RECOVERY CONTAINER -

INSTALLATION........................7-20

COOLANT RECOVERY CONTAINER -

OPERATION..........................7-19

COOLANT RECOVERY CONTAINER -

REMOVAL...........................7-20

COOLANT RECOVERY SYSTEM -

DIAGNOSIS AND TESTING

..............7-20

COOLANT SERVICE - STANDARD

PROCEDURE

.........................7-19

COOLANT TEMPERATURE SENSOR -

2.4L - DESCRIPTION, ENGINE

............7-21

COOLANT TEMPERATURE SENSOR -

2.4L - INSTALLATION, ENGINE

...........7-21

COOLANT TEMPERATURE SENSOR -

2.4L - REMOVAL, ENGINE

...............7-21

8 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2557 of 2585

FILL/CHECK LOCATIONS - DESCRIPTION,

FLUID...............................0-7

FILLER CAP - DESCRIPTION, FUEL.......25-12

FILLER CAP - OPERATION, FUEL........25-12

FILLER NECK SEAL - DIAGNOSIS AND

TESTING, RADIATOR CAP TO............7-27

FILLER TUBE - INSTALLATION, FUEL

TANK ..............................14-13

FILLER TUBE - REMOVAL, FUEL TANK....14-12

FILLING - STANDARD PROCEDURE,

COOLING SYSTEM.....................7-5

FILLING - STANDARD PROCEDURE,

REAR HEATER CORE.................24-101

FILTER - DESCRIPTION, AIR............24-43

FILTER - DESCRIPTION, OIL.............9-53

FILTER - INSTALLATION, AIR...........24-44

FILTER - INSTALLATION, INLET..........14-13

FILTER - INSTALLATION, OIL.......9-139,9-53

FILTER - REMOVAL, AIR...............24-43

FILTER - REMOVAL, INLET.............14-13

FILTER - REMOVAL, OIL...........9-139,9-53

FILTER ADAPTER - INSTALLATION, OIL . . . 9-139

FILTER ADAPTER - REMOVAL, OIL.......9-139

FILTER CHANGE - STANDARD

PROCEDURE, ENGINE OIL..........9-137,9-53

FILTER SERVICE - STANDARD

PROCEDURE, FLUID..........21-203,21s-104

FINAL DRIVE - ASSEMBLY......21-195,21s-99

FINAL DRIVE - DESCRIPTION............21s-95

FINAL DRIVE - DISASSEMBLY....21-190,21s-96

FINAL DRIVE - OPERATION............21s-96

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION............23-85

FINISH - DESCRIPTION, BASE

COAT/CLEARCOAT....................23-85

FIRING ORDER, SPECIFICATIONS.........8I-3

FIRST ROW - BENCH - INSTALLATION,

SEAT BELT BUCKLE..................8O-13

FIRST ROW - BENCH - REMOVAL, SEAT

BELT BUCKLE.......................8O-13

FIRST ROW - OUTBOARD -

INSTALLATION, SEAT BELT &

RETRACTOR........................8O-14

FIRST ROW - OUTBOARD - REMOVAL,

SEAT BELT & RETRACTOR.............8O-14

FIRST ROW INBOARD - QUAD BUCKET -

INSTALLATION, SEAT BELT BUCKLE......8O-12

FIRST ROW INBOARD - QUAD BUCKET -

REMOVAL, SEAT BELT BUCKLE.........8O-12

FITTING - CONNECTING ROD............9-45

FITTING - PISTON RING................9-45

FITTING - STANDARD PROCEDURE,

MAIN BEARING......................9-123

FITTING - STANDARD PROCEDURE,

PISTON RING.......................9-121

FITTING - STANDARD PROCEDURE,

PISTON TO CYLINDER BORE............9-42

FITTING CONNECTING RODS -

STANDARD PROCEDURE...............9-116

FITTING PISTONS - STANDARD

PROCEDURE........................9-117

FITTINGS - STANDARD PROCEDURE,

HANDLING TUBING...................24-70

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT.....................14-14

FLANGE SEAL - INSTALLATION, INPUT....3-45

FLANGE SEAL - INSTALLATION, OUTPUT . . . 3-46

FLANGE SEAL - REMOVAL, INPUT

........3-44

FLANGE SEAL - REMOVAL, OUTPUT

.......3-45

FLANGE SHIM SELECTION,

ADJUSTMENTS - OUTPUT

...............21-7

FLAP AND SPRING ASSEMBLY -

INSTALLATION, QUAD BUCKET SEAT

SIDE SHIELD/CUPHOLDER

............23-107

FLAP AND SPRING ASSEMBLY -

REMOVAL, QUAD BUCKET SEAT SIDE

SHIELD/CUPHOLDER

.................23-107

FLEX DRIVE - DESCRIPTION

...........8N-36

FLEX DRIVE - INSTALLATION

...........8N-37

FLEX DRIVE - OPERATION

.............8N-36

FLEX DRIVE - REMOVAL

...............8N-37

FLEX PLATE - INSTALLATION

...........9-131

FLEX PLATE - REMOVAL

...............9-131

FLEXIBLE FUEL ENGINE OIL -

DESCRIPTION

.........................0-3

FLOOR CONSOLE TRAY - BRACKET

ASSEMBLY - INSTALLATION

............23-83FLOOR CONSOLE TRAY - BRACKET

ASSEMBLY - REMOVAL................23-83

FLOOR CONSOLE TRAY - INSTALLATION . . 23-83

FLOOR CONSOLE TRAY - REMOVAL......23-83

FLOOR DISTRIBUTION DUCTS -

INSTALLATION.......................24-50

FLOOR DISTRIBUTION DUCTS -

REMOVAL..........................24-50

FLOOR HEAT DUCT - INSTALLATION,

REAR..............................24-63

FLOOR HEAT DUCT - REMOVAL, REAR . . . 24-62

FLOOR MATS - INSTALLATION, CARPETS . 23-76

FLOOR MATS - REMOVAL, CARPETS.....23-75

FLOW AND PRESSURE TEST -

DIAGNOSIS AND TESTING, POWER

STEERING SYSTEM....................19-1

FLOW CHECK - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-3

FLUID - DESCRIPTION, AUTOMATIC/

MANUAL TRANSAXLE...................0-4

FLUID - DESCRIPTION, AWD POWER

TRANSFER UNIT.......................0-6

FLUID AND FILTER SERVICE -

STANDARD PROCEDURE.......21-203,21s-104

FLUID CAPACITIES - SPECIFICATIONS......0-6

FLUID CHANGE - STANDARD

PROCEDURE, DIFFERENTIAL

ASSEMBLY..........................3-40

FLUID CHANGE - STANDARD

PROCEDURE, OVERRUNNING CLUTCH

HOUSING............................3-41

FLUID CHANGE - STANDARD

PROCEDURE, PTU......................21-5

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE.............5-32,5s-31

FLUID COOLER - DESCRIPTION.........19-44

FLUID COOLER - INSTALLATION.........19-45

FLUID COOLER - OPERATION...........19-44

FLUID COOLER - REMOVAL............19-44

FLUID DRAIN AND FILL - STANDARD

PROCEDURE........................21-71

FLUID FILL/CHECK LOCATIONS -

DESCRIPTION.........................0-7

FLUID LEAK DIAGNOSIS, DIAGNOSIS

AND TESTING........................21-3

FLUID LEAKAGE - DIAGNOSIS AND

TESTING, TORQUE CONVERTER

HOUSING....................21-123,21s-31

FLUID LEVEL AND CONDITION CHECK,

STANDARD PROCEDURE.......21-201,21s-102

FLUID LEVEL CHECK - STANDARD

PROCEDURE........................21-71

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, BRAKE..............5-32,5s-31

FLUID LEVEL CHECKING - STANDARD

PROCEDURE, POWER STEERING........19-44

FLUID LEVEL INSPECTION - STANDARD

PROCEDURE.........................21-4

FLUID LEVEL SWITCH - DESCRIPTION,

BRAKE..........................5-10,5s-9

FLUID LEVEL SWITCH - INSTALLATION,

BRAKE.........................5-11,5s-10

FLUID LEVEL SWITCH - INSTALLATION,

WASHER...........................8R-12

FLUID LEVEL SWITCH - OPERATION,

BRAKE..........................5-10,5s-9

FLUID LEVEL SWITCH - REMOVAL,

BRAKE

.........................5-11,5s-10

FLUID LEVEL SWITCH - REMOVAL,

WASHER

...........................8R-12

FLUID, SPECIFICATIONS - BRAKE

....5-33,5s-32

FLUIDS - DESCRIPTION, AWD REAR

DRIVELINE MODULE

....................0-6

FLUSH MEASUREMENTS -

SPECIFICATIONS, GAP

................23-124

FLYWHEEL - INSTALLATION

.............6-12

FLYWHEEL - REMOVAL

.................6-12

FOG LAMP - DIAGNOSIS AND TESTING,

FRONT

..............................8L-7

FOG LAMP - INSTALLATION, FRONT

.......8L-8

FOG LAMP - REMOVAL, FRONT

..........8L-8

FOG LAMP UNIT ALIGNMENT - EXPORT

- STANDARD PROCEDURE, FRONT

........8L-9

FOG LAMP UNIT ALIGNMENT -

STANDARD PROCEDURE, FRONT

.........8L-9

FOLDAWAY MIRROR SWITCH - EXPORT

- DESCRIPTION, POWER

..............8N-48FOLDAWAY MIRROR SWITCH - EXPORT

- INSTALLATION, POWER..............8N-49

FOLDAWAY MIRROR SWITCH - EXPORT

- OPERATION, POWER................8N-48

FOLDAWAY MIRROR SWITCH - EXPORT

- REMOVAL, POWER..................8N-48

FORK AND SHAFT - DESCRIPTION,

SHIFT.............................21-113

FORM-IN-PLACE GASKETS AND

SEALERS - STANDARD PROCEDURE . . 9-11,9-84

FRAME DIMENSIONS, SPECIFICATIONS....13-4

FRONT - DESCRIPTION, HALF SHAFT.......3-1

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL.......................9-127,9-40

FRONT - INSTALLATION, HALF SHAFT......3-4

FRONT - INSTALLATION, SEAT BELT &

RETRACTOR - OUTBOARD.............8O-14

FRONT - INSTALLATION, SPRING

MOUNTS............................2-44

FRONT - INSTALLATION, WHEEL

MOUNTING STUDS...................22-21

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL..........................9-127,9-40

FRONT - REMOVAL, HALF SHAFT..........3-2

FRONT - REMOVAL, SEAT BELT &

RETRACTOR - OUTBOARD.............8O-14

FRONT - REMOVAL, SPRING MOUNTS.....2-43

FRONT - REMOVAL, WHEEL MOUNTING

STUDS.............................22-20

FRONT - SPECIFICATIONS, HALF SHAFT . . . 3-15,

3-6

FRONT BRAKE ROTOR - INSTALLATION.....5-54,

5s-57

FRONT BRAKE ROTOR - REMOVAL . . . 5-54,5s-57

FRONT BUMPER REINFORCEMENT -

INSTALLATION........................13-2

FRONT BUMPER REINFORCEMENT -

REMOVAL...........................13-2

FRONT BUSHING - INSTALLATION, LEAF

SPRING.............................2-30

FRONT BUSHING - REMOVAL, LEAF

SPRING.............................2-29

FRONT CABLE - INSTALLATION.....5-64,5s-67

FRONT CABLE - INSTALLATION,

PARKING BRAKE LEVER...........5-66,5s-69

FRONT CABLE - REMOVAL.........5-64,5s-67

FRONT CABLE - REMOVAL, PARKING

BRAKE LEVER...................5-65,5s-68

FRONT CONTROL MODULE -

DESCRIPTION........................8E-7

FRONT CONTROL MODULE - DIAGNOSIS

AND TESTING........................8E-7

FRONT CONTROL MODULE -

INSTALLATION........................8E-8

FRONT CONTROL MODULE - OPERATION . . 8E-7

FRONT CONTROL MODULE - REMOVAL....8E-8

FRONT CRADLE CROSSMEMBER -

DESCRIPTION........................13-9

FRONT CRADLE CROSSMEMBER

THREAD REPAIR - DESCRIPTION

.........13-9

FRONT CROSSMEMBER MOUNT

BUSHINGS - INSTALLATION

............13-12

FRONT CROSSMEMBER MOUNT

BUSHINGS - REMOVAL

................13-12

FRONT DISC BRAKE CALIPER ADAPTER

- INSTALLATION

.................5-31,5s-30

FRONT DISC BRAKE CALIPER ADAPTER

- REMOVAL

.....................5-31,5s-30

FRONT DISC BRAKE CALIPER

(CONTINENTAL TEVES BRAKES) -

INSTALLATION

.......................5s-26

FRONT DISC BRAKE CALIPER

(CONTINENTAL TEVES BRAKES) -

REMOVAL

..........................5s-23

FRONT DISC BRAKE CALIPER

(DISC/DISC BRAKES) - INSTALLATION

.....5-27

FRONT DISC BRAKE CALIPER

(DISC/DISC BRAKES) - REMOVAL

.........5-24

FRONT DISC BRAKE CALIPER

(DISC/DRUM BRAKES) -

INSTALLATION

........................5-27

FRONT DISC BRAKE CALIPER

(DISC/DRUM BRAKES) - REMOVAL

.......5-24

FRONT DISC BRAKE CALIPER (TRW

BRAKES) - INSTALLATION

..............5s-26

FRONT DISC BRAKE CALIPER (TRW

BRAKES) - REMOVAL

.................5s-23

14 INDEXRS

Description Group-Page Description Group-Page Description Group-Page

Page 2560 of 2585

HEATED SEAT SWITCH - INSTALLATION,

DRIVER............................8G-10

HEATED SEAT SWITCH - INSTALLATION,

PASSENGER........................8G-14

HEATED SEAT SWITCH - OPERATION,

DRIVER.............................8G-8

HEATED SEAT SWITCH - OPERATION,

PASSENGER........................8G-12

HEATED SEAT SWITCH - REMOVAL,

DRIVER............................8G-10

HEATED SEAT SWITCH - REMOVAL,

PASSENGER........................8G-14

HEATED SEAT SYSTEM - DESCRIPTION....8G-7

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SYSTEM - OPERATION.....8G-8

HEATER - DESCRIPTION, CABIN........24-112

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-20

HEATER - DIAGNOSIS AND TESTING,

DIESEL SUPPLEMENTAL CABIN........24-113

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-20

HEATER - OPERATION, ENGINE BLOCK....7-20

HEATER - REMOVAL, ENGINE BLOCK......7-20

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-4

HEATER CONTROL - DESCRIPTION, A/C . . . 24-20

HEATER CONTROL - INSTALLATION, A/C . . 24-21

HEATER CONTROL - REMOVAL, A/C.......24-21

HEATER CORE - DESCRIPTION....24-101,24-83

HEATER CORE - INSTALLATION . . . 24-103,24-85

HEATER CORE - OPERATION......24-101,24-83

HEATER CORE - REMOVAL.......24-102,24-84

HEATER CORE FILLING - STANDARD

PROCEDURE, REAR..................24-101

HEATER CORE TUBES - INSTALLATION . . . 24-85

HEATER CORE TUBES - REMOVAL.......24-83

HEATER HOSES - INSTALLATION.......24-104

HEATER HOSES - REMOVAL...........24-103

HEATER INLET HOSE - INSTALLATION....24-86

HEATER INLET HOSE - REMOVAL........24-85

HEATER LINES - INSTALLATION, REAR . . 24-111

HEATER PERFORMANCE TEST -

DIAGNOSIS AND TESTING.............24-10

HEATER RETURN HOSE - INSTALLATION . . 24-87

HEATER RETURN HOSE - REMOVAL......24-86

HEATER TESTING - DIAGNOSIS AND

TESTING, ENGINE BLOCK...............7-20

HEATER TUBES - REMOVAL,

UNDERBODY.......................24-109

HEATER UNIT - INSTALLATION.........24-119

HEATER UNIT - REMOVAL.............24-118

HEATER WIRING - INSTALLATION,

SUPPLEMENTAL DIESEL..............24-119

HEATER WIRING - REMOVAL,

SUPPLEMENTAL DIESEL..............24-119

HEAVY DUTY, CARGO - INSTALLATION,

AWD ...............................2-36

HEAVY DUTY, CARGO - REMOVAL, AWD . . . 2-36

HEIGHT ADJUSTER-BORC-PILLAR -

INSTALLATION, SEAT BELT.............8O-13

HEIGHT ADJUSTER-BORC-PILLAR -

REMOVAL, SEAT BELT................8O-13

HEIGHT ADJUSTER KNOB -

INSTALLATION, SEAT BELT.............8O-14

HEIGHT ADJUSTER KNOB - REMOVAL,

SEAT BELT .........................8O-14

HEIGHT MEASUREMENT - STANDARD

PROCEDURE, CURB...................2-55

HIGH AND LOW LIMITS - DESCRIPTION . . . 25-8

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER....................8L-6

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION

.......................24-73

HIGH PRESSURE RELIEF VALVE -

OPERATION

.........................24-73

HIGH SPEED OPERATION - STANDARD

PROCEDURE, TIRE PRESSURE

.....22-17,22s-9

HINGE - INSTALLATION

......23-18,23-40,23-60

HINGE - INSTALLATION, CENTER

........23-24HINGE - INSTALLATION, LOWER........23-28

HINGE - INSTALLATION, UPPER.........23-36

HINGE - REMOVAL.........23-17,23-40,23-60

HINGE - REMOVAL, BENCH SEAT BACK . . 23-102

HINGE - REMOVAL, CENTER............23-24

HINGE - REMOVAL, LOWER............23-28

HINGE - REMOVAL, UPPER.............23-36

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT, BENCH - INSTALLATION, SEAT

BACK.............................23-101

HINGE COVERS - QUAD BUCKET, 50/50

SPLIT, BENCH - REMOVAL, SEAT BACK . . 23-101

HOISTING - STANDARD PROCEDURE......0-27

HOLD OPEN LATCH - INSTALLATION.....23-25

HOLD OPEN LATCH - REMOVAL.........23-25

HOLD OPEN LATCH CABLE -

INSTALLATION.......................23-38

HOLD OPEN LATCH CABLE - REMOVAL . . . 23-38

HOLD OPEN LATCH STRIKER -

INSTALLATION.......................23-26

HOLD OPEN LATCH STRIKER -

REMOVAL..........................23-26

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-15

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-16

HOLDDOWN - OPERATION, BATTERY.....8F-15

HOLDDOWN - REMOVAL, BATTERY . 8F-15,8F-16

HOLDER - INSTALLATION, CUP.........23-64

HOLDER - REMOVAL, CUP.............23-64

HOLDING CLUTCHES - DESCRIPTION . . . 21-207,

21s-106

HOLDING CLUTCHES - OPERATION.....21-207,

21s-106

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-5

HONING - STANDARD PROCEDURE,

CYLINDER BORE.................9-112,9-35

HOOD - INSTALLATION................23-61

HOOD - REMOVAL....................23-60

HOOD AJAR SWITCH - EXPORT -

INSTALLATION.......................8Q-3

HOOD AJAR SWITCH - EXPORT -

REMOVAL...........................8Q-3

HORN - DIAGNOSIS AND TESTING.......8H-3

HORN - INSTALLATION.................8H-5

HORN - REMOVAL....................8H-4

HORN CHIRP PREFERENCE - STANDARD

PROCEDURE....................8N-42,8N-5

HORN SWITCH - DESCRIPTION..........8H-5

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - INSTALLATION, HEATER INLET....24-86

HOSE - INSTALLATION, HEATER RETURN . 24-87

HOSE - REMOVAL, HEATER INLET.......24-85

HOSE - REMOVAL, HEATER RETURN.....24-86

HOSE CLAMPS - DESCRIPTION...........7-1

HOSE CLAMPS - OPERATION.............7-2

HOSES - DESCRIPTION, BRAKE TUBES....5-14,

5s-13

HOSES - INSPECTION, BRAKE TUBES.....5-14,

5s-13

HOSES - INSTALLATION, HEATER.......24-104

HOSES - INSTALLATION, WASHER.......8R-13

HOSES - OPERATION, BRAKE TUBES . 5-14,5s-13

HOSES - REMOVAL, HEATER..........24-103

HOSES - REMOVAL, WASHER..........8R-13

HOSES AND CLAMP - STANDARD

PROCEDURE.........................14-7

HOUSING - INSTALLATION, AIR

CLEANER........................9-24,9-99

HOUSING - INSTALLATION, HVAC........24-61

HOUSING - INSTALLATION, LOCK

CYLINDER..........................19-19

HOUSING - REMOVAL, AIR CLEANER . . 9-24,9-99

HOUSING - REMOVAL, HVAC...........24-60

HOUSING - REMOVAL, LOCK CYLINDER . . 19-17

HOUSING FLUID CHANGE - STANDARD

PROCEDURE, OVERRUNNING CLUTCH.....3-41

HOUSING FLUID LEAKAGE - DIAGNOSIS

AND TESTING, TORQUE CONVERTER . . . 21-123,

21s-31

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION

.....................8W-01-1

HUB / BEARING - DESCRIPTION

.......2-30,2-4

HUB / BEARING - INSTALLATION

......2-33,2-6

HUB / BEARING - OPERATION

........2-30,2-4

HUB / BEARING - REMOVAL

..........2-31,2-5HUB AND BEARING - DIAGNOSIS AND

TESTING.........................2-31,2-5

HVAC - LWB - INSTALLATION, SEAT

BELT & RETRACTOR - SECOND ROW -

RIGHT OUTBOARD WITH REAR.........8O-16

HVAC - LWB - REMOVAL, SEAT BELT &

RETRACTOR - SECOND ROW - RIGHT

OUTBOARD WITH REAR...............8O-16

HVAC HOUSING - INSTALLATION........24-61

HVAC HOUSING - REMOVAL............24-60

HVAC LOUVER - INSTALLATION, REAR . . . 23-81

HVAC LOUVER - REMOVAL, REAR.......23-81

HYDRAULIC CIRCUITS AND VALVES -

OPERATION..........................5-83

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS - DIAGNOSIS AND

TESTING............................9-34

HYDRAULIC LASH ADJUSTERS -

INSTALLATION........................9-34

HYDRAULIC LASH ADJUSTERS -

REMOVAL...........................9-34

HYDRAULIC LIFTERS - DIAGNOSIS AND

TESTING...........................9-113

HYDRAULIC LIFTERS (CAM IN BLOCK) -

DESCRIPTION.......................9-113

HYDRAULIC LIFTERS (CAM IN BLOCK) -

INSTALLATION.......................9-114

HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL..........................9-114

HYDRAULIC PRESSURE TESTS -

DIAGNOSIS AND TESTING.......21-120,21s-28

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS - 41TE TRANSAXLE....21-169

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS - 4XTE TRANSAXLE....21s-75

HYDROSTATIC LOCKED ENGINE -

STANDARD PROCEDURE............9-10,9-85

ICU - ASSEMBLY......................5-94

ICU - DISASSEMBLY...................5-93

ICU (INTEGRATED CONTROL UNIT) -

DESCRIPTION........................5-89

ICU (INTEGRATED CONTROL UNIT) -

OPERATION..........................5-90

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-2

IDENTIFICATION - DESCRIPTION,

VEHICLE............................23-1

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION, DIAGNOSIS AND

TESTING - SEAL......................21-3

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-9

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-28

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-29

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-28

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-29

IGNITION COIL - DESCRIPTION...........8I-6

IGNITION COIL - OPERATION.............8I-7

IGNITION INTERLOCK - DESCRIPTION....19-17

IGNITION SENSE - PCM INPUT -

OPERATION.........................8E-15

IGNITION SWITCH - INSTALLATION......19-16

IGNITION SWITCH - REMOVAL..........19-14

IGNITION SYSTEM - DESCRIPTION........8I-1

IGNITION SYSTEM - OPERATION..........8I-1

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-13

IIITSTATE DISPLAY TEST MODE,

OPERATION - DRB....................25-9

ILLUMINATION LAMPS - INSTALLATION,

CLUSTER...........................8L-21

ILLUMINATION LAMPS - REMOVAL,

CLUSTER...........................8L-21

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY

........................8E-18

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY

........................8E-19

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY

........................8E-18

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY

........................8E-18

INBOARD - 50/50 BENCH -

INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW

.......................8O-13

RSINDEX17

Description Group-Page Description Group-Page Description Group-Page