glove box CHRYSLER VOYAGER 2004 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 651 of 2585

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's

manual in the vehicle glove box for more information

on the power seat switch functions and the seat

adjusting procedures.

DIAGNOSIS AND TESTING - PASSENGER SEAT

SWITCH

(1) Remove the power seat switch, refer to the

Switch Removal and Installation procedures in this

section. (2) Using an ohmmeter, check pin #1 of the power

seat switch connector for continuity to ground. It

should be present, If OK go to Ste p3,IfNOTOK

repair the open ground circuit as required. (3) Using a voltmeter, check pin #5 of the power

seat switch connector for battery voltage. If OK, go to

Step 4. If not OK, repair the open voltage supply cir-

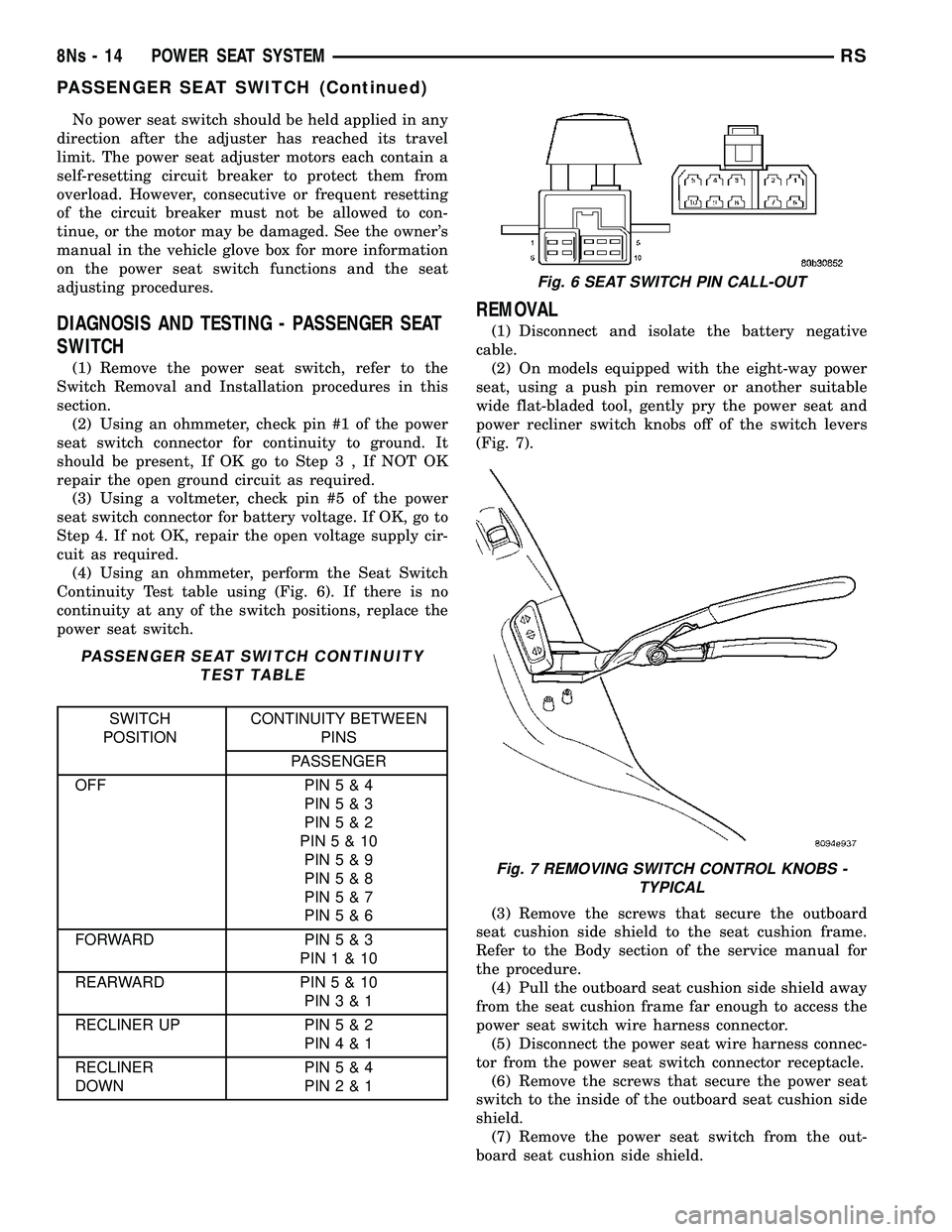

cuit as required. (4) Using an ohmmeter, perform the Seat Switch

Continuity Test table using (Fig. 6). If there is no

continuity at any of the switch positions, replace the

power seat switch.

PASSENGER SEAT SWITCH CONTINUITY TEST TABLE

SWITCH

POSITION CONTINUITY BETWEEN

PINS

PASSENGER

OFF PIN5&4 PIN5&3

PIN5&2

PIN5&10 PIN5&9

PIN5&8

PIN5&7

PIN5&6

FORWARD PIN5&3 PIN1&10

REARWARD PI N5&10

PIN3&1

RECLINER UP PI N5&2

PIN4&1

RECLINER

DOWN PIN5&4

PIN2&1

REMOVAL

(1) Disconnect and isolate the battery negative

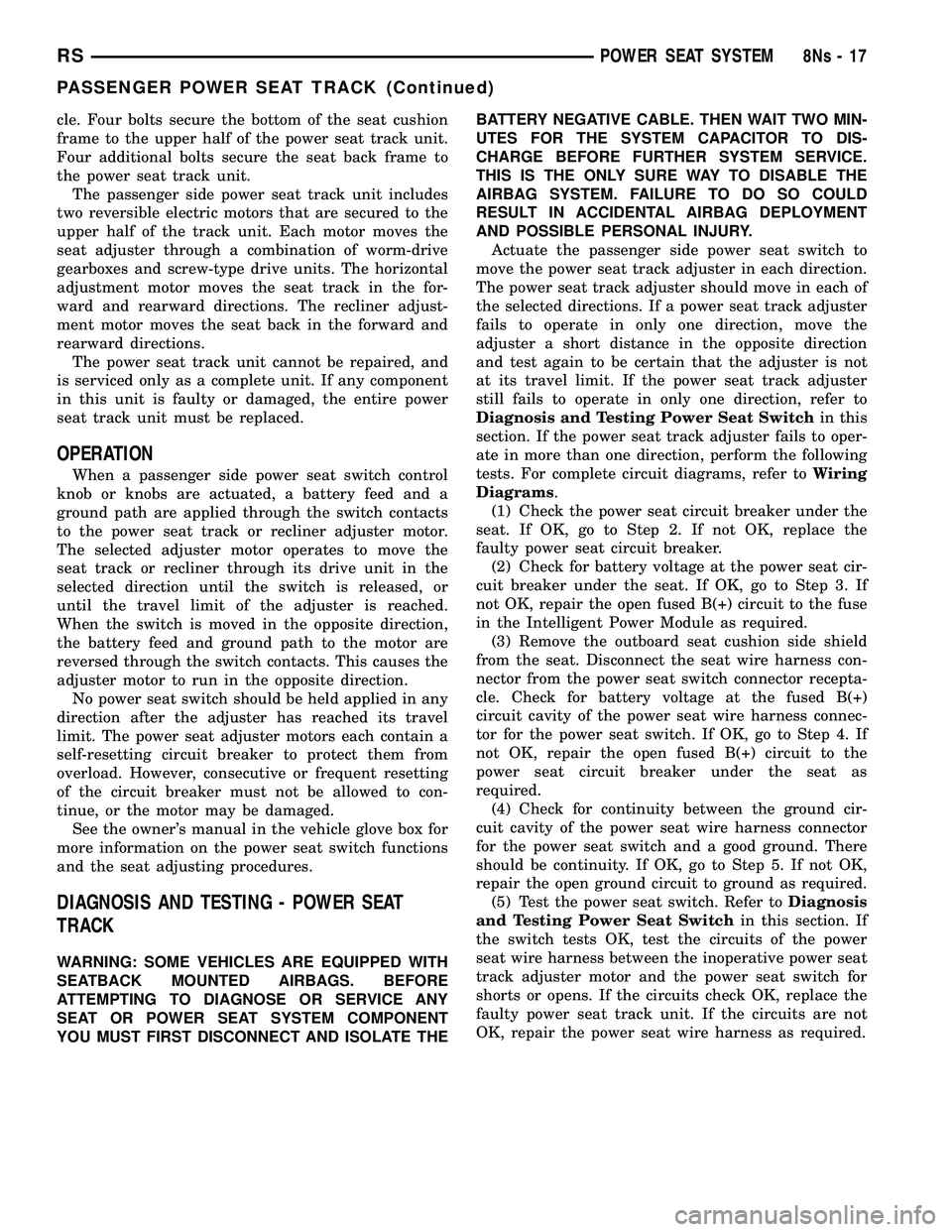

cable. (2) On models equipped with the eight-way power

seat, using a push pin remover or another suitable

wide flat-bladed tool, gently pry the power seat and

power recliner switch knobs off of the switch levers

(Fig. 7).

(3) Remove the screws that secure the outboard

seat cushion side shield to the seat cushion frame.

Refer to the Body section of the service manual for

the procedure. (4) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness connector. (5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle. (6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield. (7) Remove the power seat switch from the out-

board seat cushion side shield.

Fig. 6 SEAT SWITCH PIN CALL-OUT

Fig. 7 REMOVING SWITCH CONTROL KNOBS - TYPICAL

8Ns - 14 POWER SEAT SYSTEMRS

PASSENGER SEAT SWITCH (Continued)

Page 652 of 2585

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield. (2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.). (3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle. (4) Position the outboard seat cushion side shield

onto the seat cushion frame (5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.). (6) Install the switch knobs on the switch control

levers, if equipped. (7) Reconnect the battery negative cable.

DRIVER POWER SEAT TRACK

DESCRIPTION

The eight-way driver side power seat option

includes a electrically operated power seat track

located under the driver side front seat. The front

power seat track on the driver side of the vehicle also

provides the mounting location for the Memory Seat/

Mirror Module (MSMM). The power seat circuit

breakers are mounted on the rear of the driver side

power seat track, just behind the seat rear trim

panel. The lower half of the power seat track is

secured to the floor panel via four studs and nuts

that must be accessed from the underside of the vehi-

cle. Four bolts secure the bottom of the seat cushion

pan to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit. The power seat track unit includes four reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the four power seat

track motors used on models equipped with the

optional memory system incorporates a position

potentiometer integral to the motor assembly, which

electronically monitors the motor position. This

enables the memory system to function by referenc-

ing the motor positions programmed into the memory

seat/mirror module. The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. A third motor is the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

The forth motor is the recliner adjustment motor,

which moves the seat back in the forward and rear-

ward directions.

The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any component

in this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When the driver side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction. No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - DRIVER POWER

SEAT TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the driver side power seat switch to move

all three power seat track adjusters in each direction.

The power seat track adjusters should move in each

of the selected directions. If a power seat track

adjuster fails to operate in only one direction, move

the adjuster a short distance in the opposite direction

RS POWER SEAT SYSTEM8Ns-15

PASSENGER SEAT SWITCH (Continued)

Page 654 of 2585

cle. Four bolts secure the bottom of the seat cushion

frame to the upper half of the power seat track unit.

Four additional bolts secure the seat back frame to

the power seat track unit.The passenger side power seat track unit includes

two reversible electric motors that are secured to the

upper half of the track unit. Each motor moves the

seat adjuster through a combination of worm-drive

gearboxes and screw-type drive units. The horizontal

adjustment motor moves the seat track in the for-

ward and rearward directions. The recliner adjust-

ment motor moves the seat back in the forward and

rearward directions. The power seat track unit cannot be repaired, and

is serviced only as a complete unit. If any component

in this unit is faulty or damaged, the entire power

seat track unit must be replaced.

OPERATION

When a passenger side power seat switch control

knob or knobs are actuated, a battery feed and a

ground path are applied through the switch contacts

to the power seat track or recliner adjuster motor.

The selected adjuster motor operates to move the

seat track or recliner through its drive unit in the

selected direction until the switch is released, or

until the travel limit of the adjuster is reached.

When the switch is moved in the opposite direction,

the battery feed and ground path to the motor are

reversed through the switch contacts. This causes the

adjuster motor to run in the opposite direction. No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged. See the owner's manual in the vehicle glove box for

more information on the power seat switch functions

and the seat adjusting procedures.

DIAGNOSIS AND TESTING - POWER SEAT

TRACK

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Actuate the passenger side power seat switch to

move the power seat track adjuster in each direction.

The power seat track adjuster should move in each of

the selected directions. If a power seat track adjuster

fails to operate in only one direction, move the

adjuster a short distance in the opposite direction

and test again to be certain that the adjuster is not

at its travel limit. If the power seat track adjuster

still fails to operate in only one direction, refer to

Diagnosis and Testing Power Seat Switch in this

section. If the power seat track adjuster fails to oper-

ate in more than one direction, perform the following

tests. For complete circuit diagrams, refer to Wiring

Diagrams .

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker. (2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required. (3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required. (4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required. (5) Test the power seat switch. Refer to Diagnosis

and Testing Power Seat Switch in this section. If

the switch tests OK, test the circuits of the power

seat wire harness between the inoperative power seat

track adjuster motor and the power seat switch for

shorts or opens. If the circuits check OK, replace the

faulty power seat track unit. If the circuits are not

OK, repair the power seat wire harness as required.

RS POWER SEAT SYSTEM8Ns-17

PASSENGER POWER SEAT TRACK (Continued)

Page 659 of 2585

vacuum cleaning may be necessary to decontaminate

the interior of the vehicle.

CHILD RESTRAINT ANCHOR

DESCRIPTION

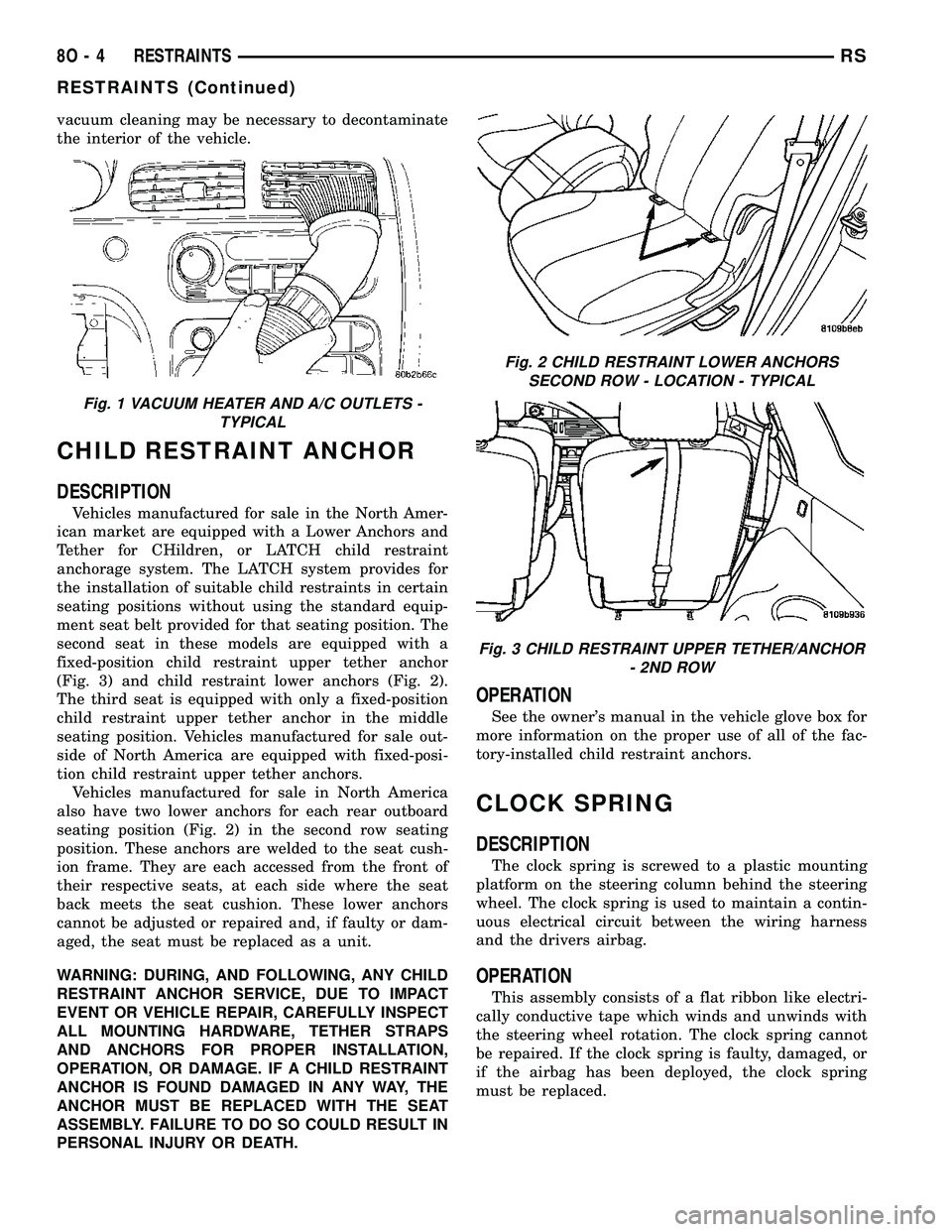

Vehicles manufactured for sale in the North Amer-

ican market are equipped with a Lower Anchors and

Tether for CHildren, or LATCH child restraint

anchorage system. The LATCH system provides for

the installation of suitable child restraints in certain

seating positions without using the standard equip-

ment seat belt provided for that seating position. The

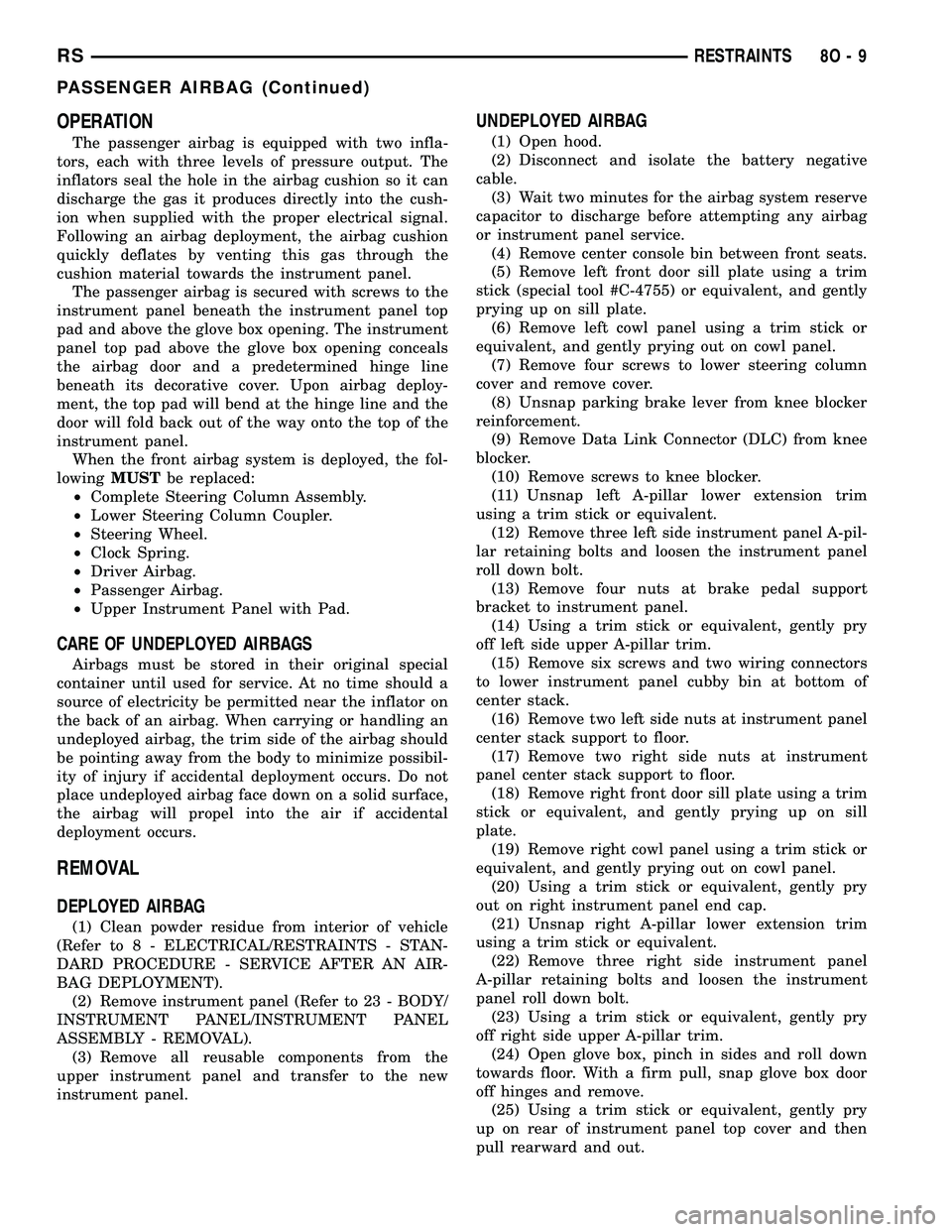

second seat in these models are equipped with a

fixed-position child restraint upper tether anchor

(Fig. 3) and child restraint lower anchors (Fig. 2).

The third seat is equipped with only a fixed-position

child restraint upper tether anchor in the middle

seating position. Vehicles manufactured for sale out-

side of North America are equipped with fixed-posi-

tion child restraint upper tether anchors.

Vehicles manufactured for sale in North America

also have two lower anchors for each rear outboard

seating position (Fig. 2) in the second row seating

position. These anchors are welded to the seat cush-

ion frame. They are each accessed from the front of

their respective seats, at each side where the seat

back meets the seat cushion. These lower anchors

cannot be adjusted or repaired and, if faulty or dam-

aged, the seat must be replaced as a unit.

WARNING: DURING, AND FOLLOWING, ANY CHILD

RESTRAINT ANCHOR SERVICE, DUE TO IMPACT

EVENT OR VEHICLE REPAIR, CAREFULLY INSPECT

ALL MOUNTING HARDWARE, TETHER STRAPS

AND ANCHORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. IF A CHILD RESTRAINT

ANCHOR IS FOUND DAMAGED IN ANY WAY, THE

ANCHOR MUST BE REPLACED WITH THE SEAT

ASSEMBLY. FAILURE TO DO SO COULD RESULT IN

PERSONAL INJURY OR DEATH.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the proper use of all of the fac-

tory-installed child restraint anchors.

CLOCK SPRING

DESCRIPTION

The clock spring is screwed to a plastic mounting

platform on the steering column behind the steering

wheel. The clock spring is used to maintain a contin-

uous electrical circuit between the wiring harness

and the drivers airbag.

OPERATION

This assembly consists of a flat ribbon like electri-

cally conductive tape which winds and unwinds with

the steering wheel rotation. The clock spring cannot

be repaired. If the clock spring is faulty, damaged, or

if the airbag has been deployed, the clock spring

must be replaced.

Fig. 1 VACUUM HEATER AND A/C OUTLETS -

TYPICAL

Fig. 2 CHILD RESTRAINT LOWER ANCHORS

SECOND ROW - LOCATION - TYPICAL

Fig. 3 CHILD RESTRAINT UPPER TETHER/ANCHOR

- 2ND ROW

8O - 4 RESTRAINTSRS

RESTRAINTS (Continued)

Page 664 of 2585

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrument

panel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag.

²Passenger Airbag.

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Clean powder residue from interior of vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS - STAN-

DARD PROCEDURE - SERVICE AFTER AN AIR-

BAG DEPLOYMENT).

(2) Remove instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - REMOVAL).

(3) Remove all reusable components from the

upper instrument panel and transfer to the new

instrument panel.

UNDEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the airbag system reserve

capacitor to discharge before attempting any airbag

or instrument panel service.

(4) Remove center console bin between front seats.

(5) Remove left front door sill plate using a trim

stick (special tool #C-4755) or equivalent, and gently

prying up on sill plate.

(6) Remove left cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(7) Remove four screws to lower steering column

cover and remove cover.

(8) Unsnap parking brake lever from knee blocker

reinforcement.

(9) Remove Data Link Connector (DLC) from knee

blocker.

(10) Remove screws to knee blocker.

(11) Unsnap left A-pillar lower extension trim

using a trim stick or equivalent.

(12) Remove three left side instrument panel A-pil-

lar retaining bolts and loosen the instrument panel

roll down bolt.

(13) Remove four nuts at brake pedal support

bracket to instrument panel.

(14) Using a trim stick or equivalent, gently pry

off left side upper A-pillar trim.

(15) Remove six screws and two wiring connectors

to lower instrument panel cubby bin at bottom of

center stack.

(16) Remove two left side nuts at instrument panel

center stack support to floor.

(17) Remove two right side nuts at instrument

panel center stack support to floor.

(18) Remove right front door sill plate using a trim

stick or equivalent, and gently prying up on sill

plate.

(19) Remove right cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(20) Using a trim stick or equivalent, gently pry

out on right instrument panel end cap.

(21) Unsnap right A-pillar lower extension trim

using a trim stick or equivalent.

(22) Remove three right side instrument panel

A-pillar retaining bolts and loosen the instrument

panel roll down bolt.

(23) Using a trim stick or equivalent, gently pry

off right side upper A-pillar trim.

(24) Open glove box, pinch in sides and roll down

towards floor. With a firm pull, snap glove box door

off hinges and remove.

(25) Using a trim stick or equivalent, gently pry

up on rear of instrument panel top cover and then

pull rearward and out.

RSRESTRAINTS8O-9

PASSENGER AIRBAG (Continued)

Page 665 of 2585

(26) Using a trim stick or equivalent, gently pry

off the filler bezel just above the cup holder to expose

the lower screws to center bezel.

(27) Remove two screws and then using a trim

stick or equivalent, gently pry off instrument panel

center bezel.

(28) Remove center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats) and remove bezel.

(29) Slide cup holder assembly from instrument

panel.

(30) Remove nineteen screws to right lower instru-

ment panel trim (glove box surround), unplug glove

box lamp wire connector, and remove panel.

(31) Remove four screws and wiring connectors to

radio and remove radio.

(32) Remove one far left instrument panel speaker

retaining screw.

(33) Remove four screws along top front edge of

instrument panel cover/pad.

(34) Remove seven lower instrument panel cover/

pad retaining screws starting from right of vehicle

and only removing these seven, not all of them.

(35) Remove six upper fence line instrument panel

retaining bolts.

(36) Roll back instrument panel just enough to

increase access to the passenger airbag retaining

bolts at the reinforcement. Lift the instrument panel

up slightly so as not to damage the air distribution to

HVAC unit seal.

(37) Disconnect the passenger airbag electrical

connector. Using a trim stick or equivalent, gently

pry electrical connector off of instrument panel rein-

forcement.

(38) Remove the two passenger airbag to instru-

ment panel cover/pad retaining screws.

(39) Remove the three passenger airbag to instru-

ment panel reinforcement retaining bolts.

(40) Pull rearward slightly on the instrument

panel cover/pad to maneuver passenger airbag out

from reinforcement and instrument panel.

INSTALLATION

DEPLOYED AIRBAG

Transfer all reusable components to the new

instrument panel.

(1) Install new Passenger Airbag into instrument

panel.

(2) Install airbag attaching bolts to the instrument

panel.

(a) Torque the two bolts at instrument panel

retainer bosses to 2.7 .5 N´m (24 5 in. lbs.).

(b) Torque the three bolts that attach the pas-

senger airbag to cross-car beam to 10 2 N´m (90

15 in. lbs.).(3) Connect yellow wire connector to passenger air-

bag and affix connector to instrument panel rein-

forcement with push pins.

(4) Install Instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

UNDEPLOYED AIRBAG

(1) Pull rearward slightly on the instrument panel

cover/pad to maneuver passenger airbag up onto

reinforcement and instrument panel.

(2) Install the three passenger airbag to instru-

ment panel reinforcement retaining bolts but leave

loose. This will help align the passenger airbag for

the cover/pad fit.

(3) Install the two passenger airbag to instrument

panel cover/pad retaining screws. Torque screws to

2.7 .5 N´m (24 5 in. lbs.).

NOTE: Insure that the instrument panel cover/pad

locator pins are indexed properly at center stack

area prior to reassembly.

(4) Tighten the three passenger airbag to instru-

ment panel reinforcement retaining bolts. Torque

bolts to 10 2 N´m (90 15 in. lbs.).

(5) Connect the passenger airbag electrical connec-

tor. Install the connector onto the instrument panel

reinforcement with the push-pin fasteners.

(6) Roll the instrument panel forward lifting

slightly so as to seat the instrument panel air distri-

bution duct on top of the HVAC unit properly to

avoid any leaks or damage to the seal.

(7) Install six upper fence line instrument panel

retaining bolts.

(8) Install three right side instrument panel A-pil-

lar retaining bolts and tighten the right instrument

panel roll down bolt. Install the smaller 10 mm bolt

first to align the instrument panel properly.

(9) Install three left side instrument panel A-pillar

retaining bolts and tighten the left instrument panel

roll down bolt. Install the smaller 10 mm bolt first to

align the instrument panel properly.

(10) Install seven lower instrument panel cover/

pad retaining screws.

(11) Install four screws along top front edge of

instrument panel cover/pad.

(12) Install one far left instrument panel speaker

retaining screw.

8O - 10 RESTRAINTSRS

PASSENGER AIRBAG (Continued)

Page 666 of 2585

(13) Install wiring connectors to radio. Install

radio and four retaining screws.

(14) Connect glove box lamp wiring connector and

place right lower instrument panel trim (glove box

surround) into position.

(15) Install nineteen right lower instrument panel

trim (glove box surround) and install panel screws.

(16) Slide cup holder assembly into instrument

panel.

(17) Install center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats).

(18) Install instrument panel center bezel by align-

ing slots and firmly snapping into place.

(19) Install two screws to instrument panel center

bezel.

(20) Align filler bezel above cup holder over retain-

ing slots and firmly snap into place.

(21) Place instrument panel top cover into position

and firmly snap down rear edge of top cover.

(22) Install glove box. Align hinges, snap into

place, roll glove box upwards and push in sides to

fully install.

(23) Align right side upper A-pillar trim over

retaining slots and firmly snap into place.

(24) Align right A-pillar lower extension trim over

retaining slots and firmly snap into place.

(25) Align right instrument panel end cap over

retaining slots and firmly snap into place.

(26) Align right cowl panel over retaining slots and

firmly snap into place.

(27) Align right front door sill plate over retaining

slots and firmly snap into place.

(28) Install two right side nuts at instrument

panel center stack support to floor.

(29) Install two left side nuts at instrument panel

center stack support to floor.

(30) Connect the two wiring connectors to lower

instrument panel cubby bin at bottom of center stack

and install six screws.

(31) Align left side upper A-pillar trim over retain-

ing slots and firmly snap into place.

(32) Install four nuts at brake pedal support

bracket to instrument panel.

(33) Align left A-pillar lower extension trim over

retaining slots and firmly snap into place.

(34) Install knee blocker and retaining screws.

(35) Install Data Link Connector (DLC) into bot-

tom of knee blocker.

(36) Align parking brake lever and snap into place

on knee blocker reinforcement.

(37) Install lower steering column cover and four

retaining screws

(38) Align left cowl panel over retaining slots and

firmly snap into place.(39) Align left front door sill plate over retaining

slots and firmly snap into place.

(40) Install center console bin between front seats.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING).

PERSONAL INJURY OR DEATH MAY RESULT IF

THE SYSTEM TEST IS NOT PERFORMED PROP-

ERLY.

(41) Close hood.

(42) Verify system and vehicle operation.

SEAT AIRBAG

DESCRIPTION

The side impact airbag system Seat Airbags are

located in the outboard side of the front seat backs.

One in each front seat. The seat airbag inflator

assembly is within the airbag housing (Fig. 5). Each

airbag is mounted to the seat back frame. If deployed

or defective, the entire seat back assembly must be

replaced.

OPERATION

Only the Side Impact Airbag Control Module

(SIACM) can deploy the side airbags. When supplied

with the proper electrical signal, the seat airbag

inflator will produce a gas and discharge the bag

directly between the occupant and the side of the

vehicle, protecting the occupant. Upon deployment,

Fig. 5 SEAT AIRBAG - TYPICAL

RSRESTRAINTS8O-11

PASSENGER AIRBAG (Continued)

Page 1292 of 2585

8W-97 POWER DISTRIBUTION SYSTEM

TABLE OF CONTENTS

page page

POWER DISTRIBUTION SYSTEM

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........1

INTEGRATED POWER MODULE

DESCRIPTION..........................2

OPERATION............................2

REMOVAL.............................2

INSTALLATION..........................3IOD FUSE

DESCRIPTION..........................3

OPERATION............................3

POWER OUTLET

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET . . 4

REMOVAL.............................5

INSTALLATION..........................5

POWER DISTRIBUTION

SYSTEM

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Outlets

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses

²Circuit splice blocks

²Flashers

²Fusible links

²Relays

Following are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

Terminal Pick Kit 6680

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-1

Page 2174 of 2585

INSTRUMENT PANEL

TABLE OF CONTENTS

page page

CLUSTER BEZEL

REMOVAL.............................63

INSTALLATION.........................63

CUP HOLDER

REMOVAL.............................64

INSTALLATION.........................64

GLOVE BOX

REMOVAL.............................64

INSTALLATION.........................64

GLOVE BOX LATCH

REMOVAL.............................64

INSTALLATION.........................64

GLOVE BOX LATCH STRIKER

REMOVAL.............................64

INSTALLATION.........................64

INSTRUMENT PANEL ASSEMBLY

REMOVAL.............................65

INSTALLATION.........................66

INSTRUMENT PANEL CENTER BEZEL

REMOVAL.............................68

INSTALLATION.........................68

INSTRUMENT PANEL END CAP

REMOVAL.............................68INSTALLATION.........................68

INSTRUMENT PANEL TOP COVER

REMOVAL.............................68

INSTALLATION.........................69

LOWER CONSOLE

REMOVAL.............................69

INSTALLATION.........................69

LOWER INSTRUMENT PANEL

REMOVAL.............................69

INSTALLATION.........................69

LOWER STEERING COLUMN COVER

REMOVAL.............................70

INSTALLATION.........................70

STEERING COLUMN COVER BACKING PLATE

REMOVAL.............................70

INSTALLATION.........................70

OVER STEERING COLUMN COVER

REMOVAL.............................70

INSTALLATION.........................70

INSTRUMENT PANEL TOP PAD ASSEMBLY

REMOVAL.............................71

INSTALLATION.........................72

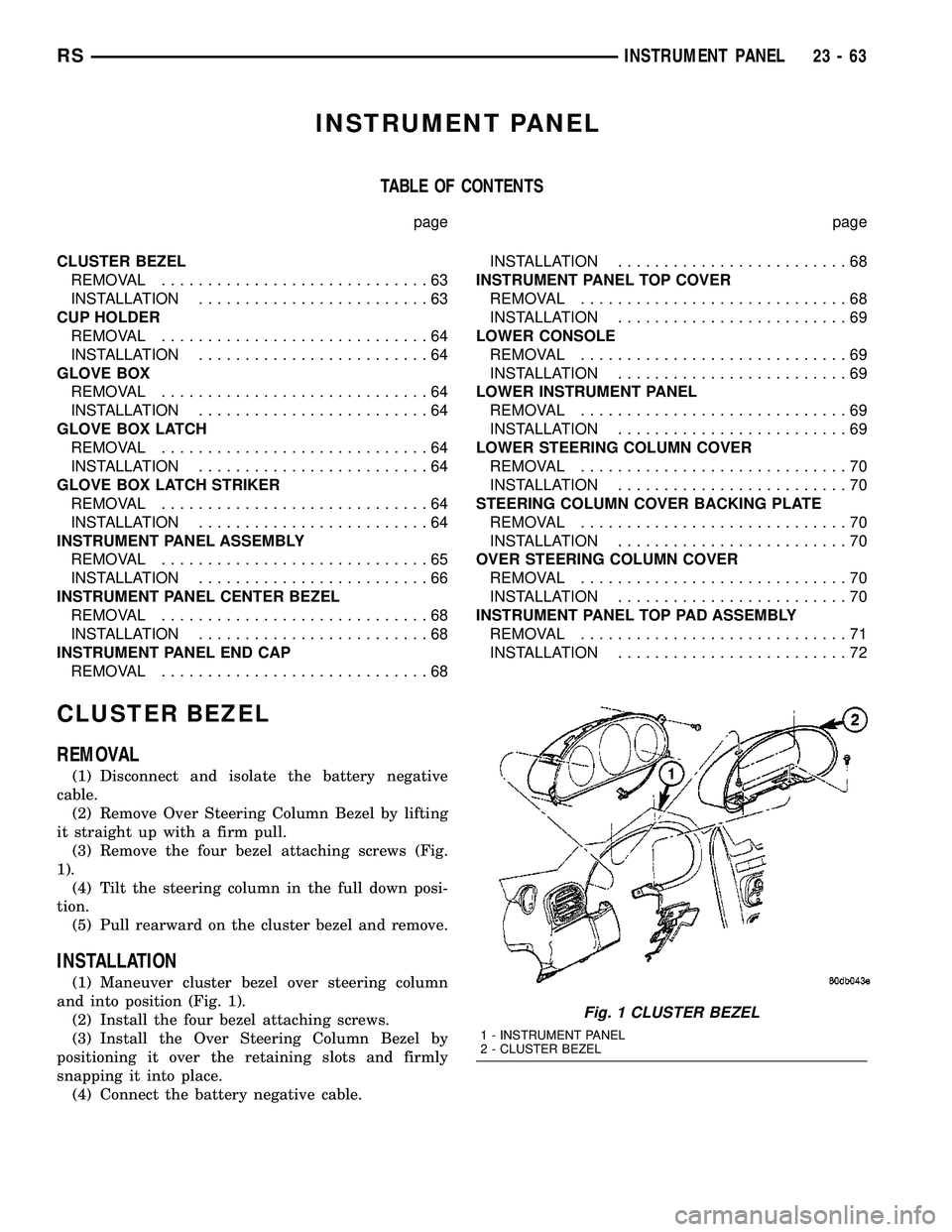

CLUSTER BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove Over Steering Column Bezel by lifting

it straight up with a firm pull.

(3) Remove the four bezel attaching screws (Fig.

1).

(4) Tilt the steering column in the full down posi-

tion.

(5) Pull rearward on the cluster bezel and remove.

INSTALLATION

(1) Maneuver cluster bezel over steering column

and into position (Fig. 1).

(2) Install the four bezel attaching screws.

(3) Install the Over Steering Column Bezel by

positioning it over the retaining slots and firmly

snapping it into place.

(4) Connect the battery negative cable.

Fig. 1 CLUSTER BEZEL

1 - INSTRUMENT PANEL

2 - CLUSTER BEZEL

RSINSTRUMENT PANEL23-63

Page 2175 of 2585

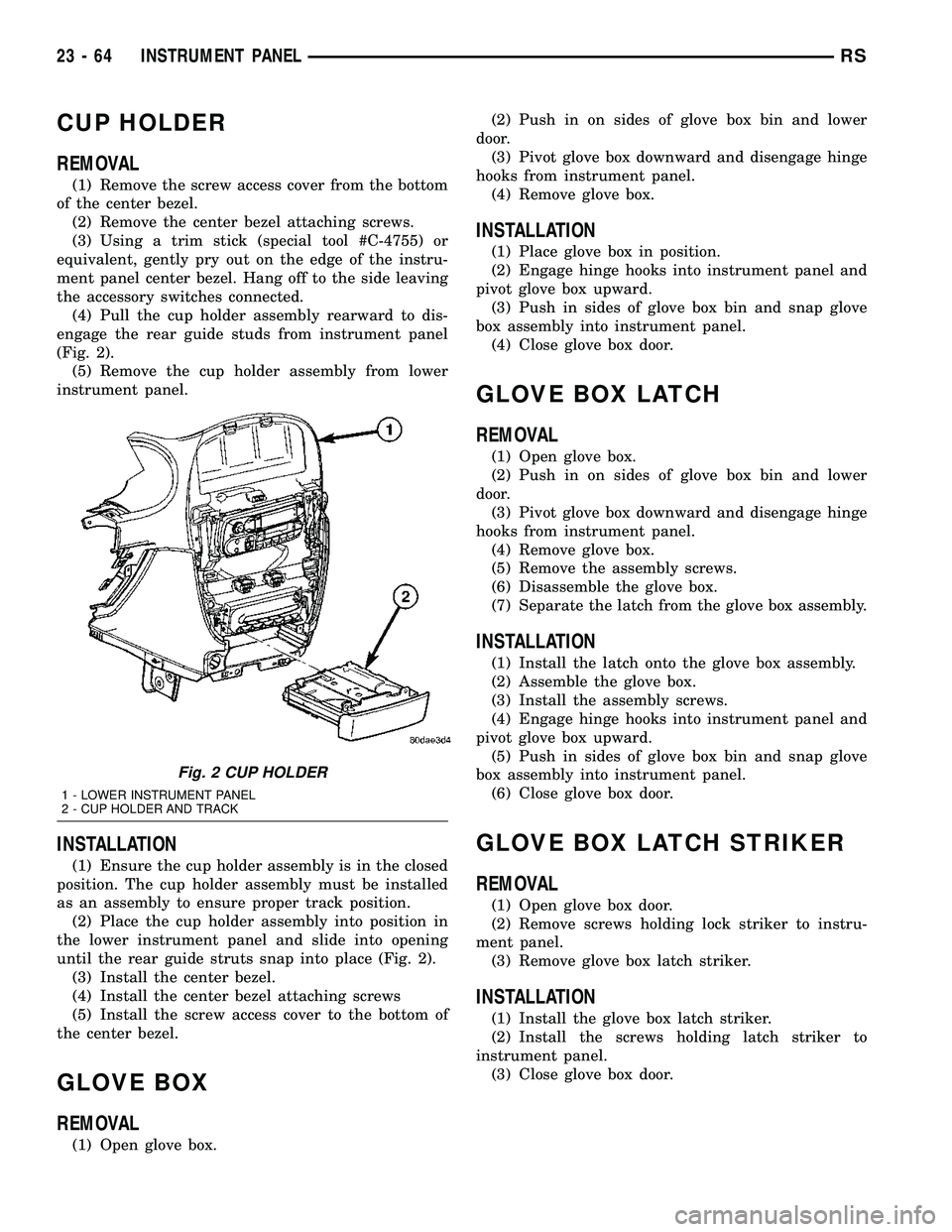

CUP HOLDER

REMOVAL

(1) Remove the screw access cover from the bottom

of the center bezel.

(2) Remove the center bezel attaching screws.

(3) Using a trim stick (special tool #C-4755) or

equivalent, gently pry out on the edge of the instru-

ment panel center bezel. Hang off to the side leaving

the accessory switches connected.

(4) Pull the cup holder assembly rearward to dis-

engage the rear guide studs from instrument panel

(Fig. 2).

(5) Remove the cup holder assembly from lower

instrument panel.

INSTALLATION

(1) Ensure the cup holder assembly is in the closed

position. The cup holder assembly must be installed

as an assembly to ensure proper track position.

(2) Place the cup holder assembly into position in

the lower instrument panel and slide into opening

until the rear guide struts snap into place (Fig. 2).

(3) Install the center bezel.

(4) Install the center bezel attaching screws

(5) Install the screw access cover to the bottom of

the center bezel.

GLOVE BOX

REMOVAL

(1) Open glove box.(2) Push in on sides of glove box bin and lower

door.

(3) Pivot glove box downward and disengage hinge

hooks from instrument panel.

(4) Remove glove box.

INSTALLATION

(1) Place glove box in position.

(2) Engage hinge hooks into instrument panel and

pivot glove box upward.

(3) Push in sides of glove box bin and snap glove

box assembly into instrument panel.

(4) Close glove box door.

GLOVE BOX LATCH

REMOVAL

(1) Open glove box.

(2) Push in on sides of glove box bin and lower

door.

(3) Pivot glove box downward and disengage hinge

hooks from instrument panel.

(4) Remove glove box.

(5) Remove the assembly screws.

(6) Disassemble the glove box.

(7) Separate the latch from the glove box assembly.

INSTALLATION

(1) Install the latch onto the glove box assembly.

(2) Assemble the glove box.

(3) Install the assembly screws.

(4) Engage hinge hooks into instrument panel and

pivot glove box upward.

(5) Push in sides of glove box bin and snap glove

box assembly into instrument panel.

(6) Close glove box door.

GLOVE BOX LATCH STRIKER

REMOVAL

(1) Open glove box door.

(2) Remove screws holding lock striker to instru-

ment panel.

(3) Remove glove box latch striker.

INSTALLATION

(1) Install the glove box latch striker.

(2) Install the screws holding latch striker to

instrument panel.

(3) Close glove box door.

Fig. 2 CUP HOLDER

1 - LOWER INSTRUMENT PANEL

2 - CUP HOLDER AND TRACK

23 - 64 INSTRUMENT PANELRS