Power system CHRYSLER VOYAGER 2004 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2004Pages: 2585, PDF Size: 62.54 MB

Page 2427 of 2585

WARNING: THE HEAT SINK FOR THE BLOWER

MOTOR POWER MODULE MAY GET VERY HOT

DURING NORMAL OPERATION. IF THE BLOWER

MOTOR WAS TURNED ON PRIOR TO SERVICING

THE BLOWER MOTOR POWER MODULE, WAIT

FIVE MINUTES TO ALLOW THE HEAT SINK TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the glove box from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - REMOVAL).

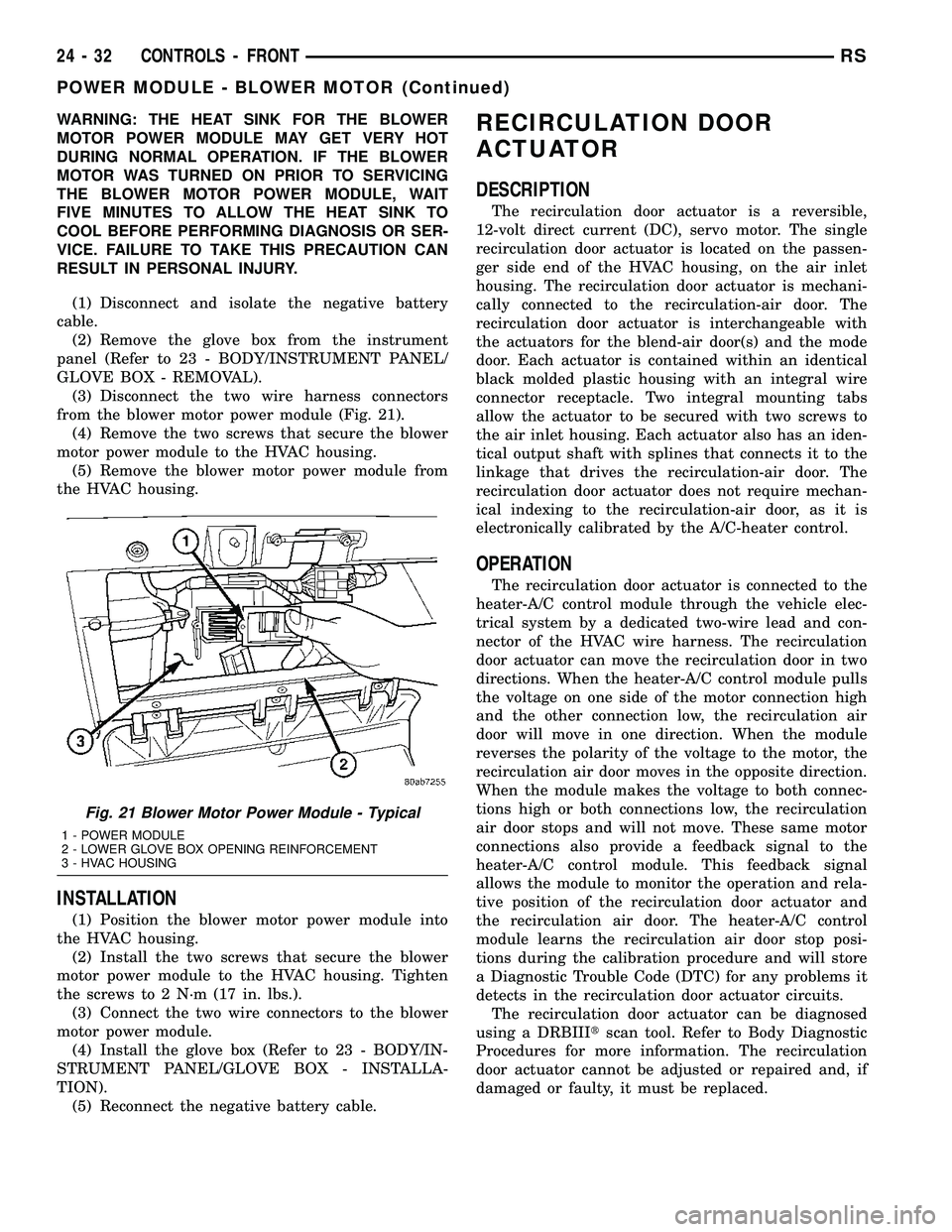

(3) Disconnect the two wire harness connectors

from the blower motor power module (Fig. 21).

(4) Remove the two screws that secure the blower

motor power module to the HVAC housing.

(5) Remove the blower motor power module from

the HVAC housing.

INSTALLATION

(1) Position the blower motor power module into

the HVAC housing.

(2) Install the two screws that secure the blower

motor power module to the HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(3) Connect the two wire connectors to the blower

motor power module.

(4) Install the glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION).

(5) Reconnect the negative battery cable.

RECIRCULATION DOOR

ACTUATOR

DESCRIPTION

The recirculation door actuator is a reversible,

12-volt direct current (DC), servo motor. The single

recirculation door actuator is located on the passen-

ger side end of the HVAC housing, on the air inlet

housing. The recirculation door actuator is mechani-

cally connected to the recirculation-air door. The

recirculation door actuator is interchangeable with

the actuators for the blend-air door(s) and the mode

door. Each actuator is contained within an identical

black molded plastic housing with an integral wire

connector receptacle. Two integral mounting tabs

allow the actuator to be secured with two screws to

the air inlet housing. Each actuator also has an iden-

tical output shaft with splines that connects it to the

linkage that drives the recirculation-air door. The

recirculation door actuator does not require mechan-

ical indexing to the recirculation-air door, as it is

electronically calibrated by the A/C-heater control.

OPERATION

The recirculation door actuator is connected to the

heater-A/C control module through the vehicle elec-

trical system by a dedicated two-wire lead and con-

nector of the HVAC wire harness. The recirculation

door actuator can move the recirculation door in two

directions. When the heater-A/C control module pulls

the voltage on one side of the motor connection high

and the other connection low, the recirculation air

door will move in one direction. When the module

reverses the polarity of the voltage to the motor, the

recirculation air door moves in the opposite direction.

When the module makes the voltage to both connec-

tions high or both connections low, the recirculation

air door stops and will not move. These same motor

connections also provide a feedback signal to the

heater-A/C control module. This feedback signal

allows the module to monitor the operation and rela-

tive position of the recirculation door actuator and

the recirculation air door. The heater-A/C control

module learns the recirculation air door stop posi-

tions during the calibration procedure and will store

a Diagnostic Trouble Code (DTC) for any problems it

detects in the recirculation door actuator circuits.

The recirculation door actuator can be diagnosed

using a DRBIIItscan tool. Refer to Body Diagnostic

Procedures for more information. The recirculation

door actuator cannot be adjusted or repaired and, if

damaged or faulty, it must be replaced.

Fig. 21 Blower Motor Power Module - Typical

1 - POWER MODULE

2 - LOWER GLOVE BOX OPENING REINFORCEMENT

3 - HVAC HOUSING

24 - 32 CONTROLS - FRONTRS

POWER MODULE - BLOWER MOTOR (Continued)

Page 2429 of 2585

CONTROLS - REAR

TABLE OF CONTENTS

page page

A/C-HEATER CONTROL

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................35

BLEND DOOR ACTUATOR

DESCRIPTION.........................35

OPERATION...........................35

REMOVAL.............................36

INSTALLATION.........................36

BLOWER MOTOR RELAY

DESCRIPTION.........................37

OPERATION...........................37

REMOVAL.............................38

INSTALLATION.........................38

BLOWER MOTOR RESISTOR

DESCRIPTION.........................38OPERATION...........................38

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR RESISTOR BLOCK..............38

REMOVAL.............................39

INSTALLATION.........................39

MODE DOOR ACTUATOR - REAR

DESCRIPTION.........................39

OPERATION...........................40

REMOVAL.............................40

INSTALLATION.........................40

POWER MODULE - REAR BLOWER MOTOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................42

A/C-HEATER CONTROL

DESCRIPTION

The rear heater-A/C system is controlled by rotary-

type blower motor and temperature controls, cen-

trally mounted in the headliner. The rear A/C-heater

control allows selection of three blower motor speeds

and an Off position when the center knob on the

front A/C-heater control is set to the Rear position,

otherwise the front unit controls both front and rear

heater-A/C operation.

OPERATION

With the rear A/C-heater control active, tempera-

ture selection dictates the air distribution mode (floor

or overhead air) of the rear unit. A cool temperature

setting directs flow to the overhead outlets and a

warm temperature setting to the floor. Refer to Body

Diagnostic Procedures for further diagnostic informa-

tion.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide flat

bladed tool, gently pry the top edge of the rear A/C-

heater control bezel away from the headliner far

enough to release the two snap clip retainers (Fig. 1).(3) Pull the rear A/C-heater control rearward far

enough to access the headliner wire harness connec-

tor on the back of the control.

(4) Disconnect the wire harness connector from the

rear A/C-heater control.

(5) Remove the rear A/C-heater control from the

headliner.

Fig. 1 Rear A/C-Heater Control

1 - TRIM STICK

2 - BEZEL

3 - REAR A/C-HEATER CONTROL

4 - HEADLINER

24 - 34 CONTROLS - REARRS

Page 2432 of 2585

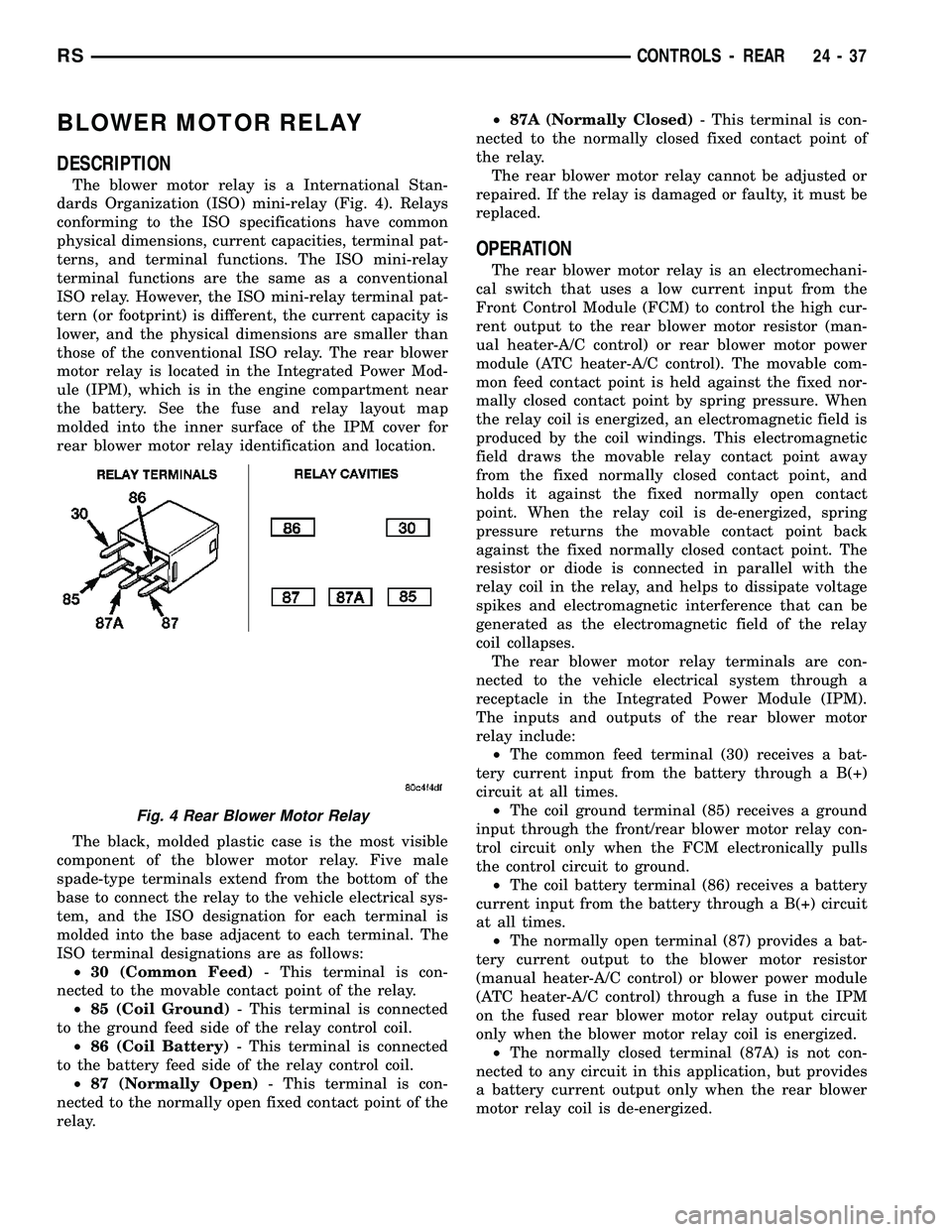

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO) mini-relay (Fig. 4). Relays

conforming to the ISO specifications have common

physical dimensions, current capacities, terminal pat-

terns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The rear blower

motor relay is located in the Integrated Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

rear blower motor relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The rear blower motor relay cannot be adjusted or

repaired. If the relay is damaged or faulty, it must be

replaced.

OPERATION

The rear blower motor relay is an electromechani-

cal switch that uses a low current input from the

Front Control Module (FCM) to control the high cur-

rent output to the rear blower motor resistor (man-

ual heater-A/C control) or rear blower motor power

module (ATC heater-A/C control). The movable com-

mon feed contact point is held against the fixed nor-

mally closed contact point by spring pressure. When

the relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. The

resistor or diode is connected in parallel with the

relay coil in the relay, and helps to dissipate voltage

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.

The rear blower motor relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the Integrated Power Module (IPM).

The inputs and outputs of the rear blower motor

relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(ATC heater-A/C control) through a fuse in the IPM

on the fused rear blower motor relay output circuit

only when the blower motor relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear blower

motor relay coil is de-energized.

Fig. 4 Rear Blower Motor Relay

RSCONTROLS - REAR24-37

Page 2433 of 2585

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Inte-

grated Power Module (IPM) (Fig. 5).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for rear blower

motor relay identification and location.

(4) Remove the rear blower motor relay from the

IPM.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Integrated Power Module

(IPM) cover for rear blower motor relay identification

and location.

(2) Position the rear blower motor relay to the

proper receptacle in the IPM.

(3) Align the rear blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.

(6) Reconnect the battery negative cable.

BLOWER MOTOR RESISTOR

DESCRIPTION

A rear blower motor resistor is used on this model

when it is equipped with the manual heater-A/C sys-

tem. Models equipped with the optional Automatic

Temperature Control (ATC) system use a rear blower

motor power module, instead of the blower motor

resistor block (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/POWER MODULE -

DESCRIPTION). The rear blower motor resistor

block is mounted to the rear HVAC housing, directly

above the expansion valve. The resistor block con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate is an electrical circuit board with two

resistors and a thermal fuse. The rear blower motor

resistor block is accessed for service by removing the

right quarter and D-pillar trim panels.

OPERATION

The rear blower motor resistor block is connected

to the vehicle electrical system through a dedicated

take out and connector of the rear HVAC wire har-

ness. The blower motor resistor has an electrical cir-

cuit board with two resistors, each of which will

reduce the current flow through the blower motor to

change the blower motor speed. The blower motor

switch in the manual heater-A/C system directs the

ground path for the rear blower motor through the

correct resistor to obtain the selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through both resistors. Each higher speed selected

with the blower motor switch applies the blower

motor ground path through fewer of the resistors,

increasing the blower motor speed. When the blower

motor switch is in the highest speed position, the

blower motor resistors are bypassed and the blower

motor receives a direct path to ground through the

blower motor switch.

The rear blower motor resistor block cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

Fig. 5 Integrated Power Module - Typical

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

24 - 38 CONTROLS - REARRS

BLOWER MOTOR RELAY (Continued)

Page 2436 of 2585

(6) Install the screw that secures the front of the

rear HVAC housing to the right quarter inner panel.

Tighten the screw to 11 N´m (97 in. lbs.).

(7) Install the screw that secures the back of the

rear HVAC housing to the right D-pillar. Tighten the

screw to 11 N´m (97 in. lbs.).

(8) Install the two screws that secure the top of

the quarter trim panel attaching bracket to the quar-

ter inner panel. Tighten the screws to 2 N´m (17 in.

lbs.).

(9) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(10) Reconnect the battery negative cable.

(11) Perform the heater-A/C control calibration

procedure (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

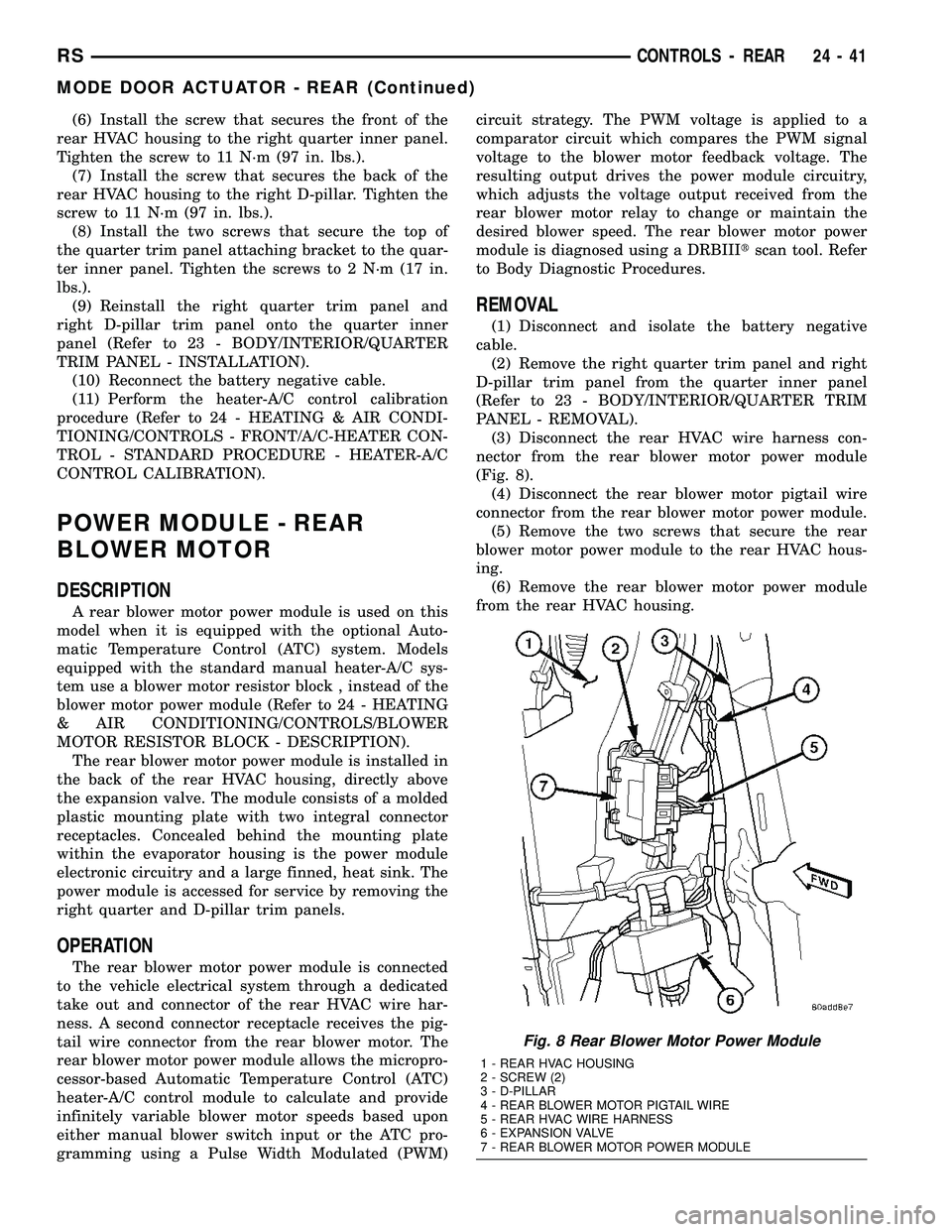

POWER MODULE - REAR

BLOWER MOTOR

DESCRIPTION

A rear blower motor power module is used on this

model when it is equipped with the optional Auto-

matic Temperature Control (ATC) system. Models

equipped with the standard manual heater-A/C sys-

tem use a blower motor resistor block , instead of the

blower motor power module (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - DESCRIPTION).

The rear blower motor power module is installed in

the back of the rear HVAC housing, directly above

the expansion valve. The module consists of a molded

plastic mounting plate with two integral connector

receptacles. Concealed behind the mounting plate

within the evaporator housing is the power module

electronic circuitry and a large finned, heat sink. The

power module is accessed for service by removing the

right quarter and D-pillar trim panels.

OPERATION

The rear blower motor power module is connected

to the vehicle electrical system through a dedicated

take out and connector of the rear HVAC wire har-

ness. A second connector receptacle receives the pig-

tail wire connector from the rear blower motor. The

rear blower motor power module allows the micropro-

cessor-based Automatic Temperature Control (ATC)

heater-A/C control module to calculate and provide

infinitely variable blower motor speeds based upon

either manual blower switch input or the ATC pro-

gramming using a Pulse Width Modulated (PWM)circuit strategy. The PWM voltage is applied to a

comparator circuit which compares the PWM signal

voltage to the blower motor feedback voltage. The

resulting output drives the power module circuitry,

which adjusts the voltage output received from the

rear blower motor relay to change or maintain the

desired blower speed. The rear blower motor power

module is diagnosed using a DRBIIItscan tool. Refer

to Body Diagnostic Procedures.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Disconnect the rear HVAC wire harness con-

nector from the rear blower motor power module

(Fig. 8).

(4) Disconnect the rear blower motor pigtail wire

connector from the rear blower motor power module.

(5) Remove the two screws that secure the rear

blower motor power module to the rear HVAC hous-

ing.

(6) Remove the rear blower motor power module

from the rear HVAC housing.

Fig. 8 Rear Blower Motor Power Module

1 - REAR HVAC HOUSING

2 - SCREW (2)

3 - D-PILLAR

4 - REAR BLOWER MOTOR PIGTAIL WIRE

5 - REAR HVAC WIRE HARNESS

6 - EXPANSION VALVE

7 - REAR BLOWER MOTOR POWER MODULE

RSCONTROLS - REAR24-41

MODE DOOR ACTUATOR - REAR (Continued)

Page 2441 of 2585

(2) Engage the retainer features on the top of the

outlet housing with their receptacles at the top of the

center bezel, then roll the bottom of the outlet hous-

ing downwards towards the center bezel.

(3) Install the three screws that secure the bottom

of the outlet housing to the center bezel. Tighten the

screws to 2 N´m (17 in. lbs.).

(4) If the vehicle is equipped with the optional

ATC system, reconnect the ATC remote infrared tem-

perature sensor jumper harness to the sensor connec-

tor receptacle located on the bottom of the center

outlet housing.

(5) Reinstall the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(6) Reconnect the battery negative cable.

INSTALLATION - DEMISTER OUTLET

(1) Position the demister outlet over the demister

duct opening in the instrument panel top pad.

(2) Using hand pressure, press the demister outlet

firmly and evenly into the instrument panel top pad

opening until the snap features on the outlet are

fully engaged.

INSTALLATION - INSTRUMENT PANEL OUTLET

(1) Position the instrument panel outlet into the

panel duct opening in the instrument panel top pad.

(2) Using hand pressure, press the instrument

panel outlet firmly and evenly into the instrument

panel top pad opening until the snap features on the

outlet are fully engaged.

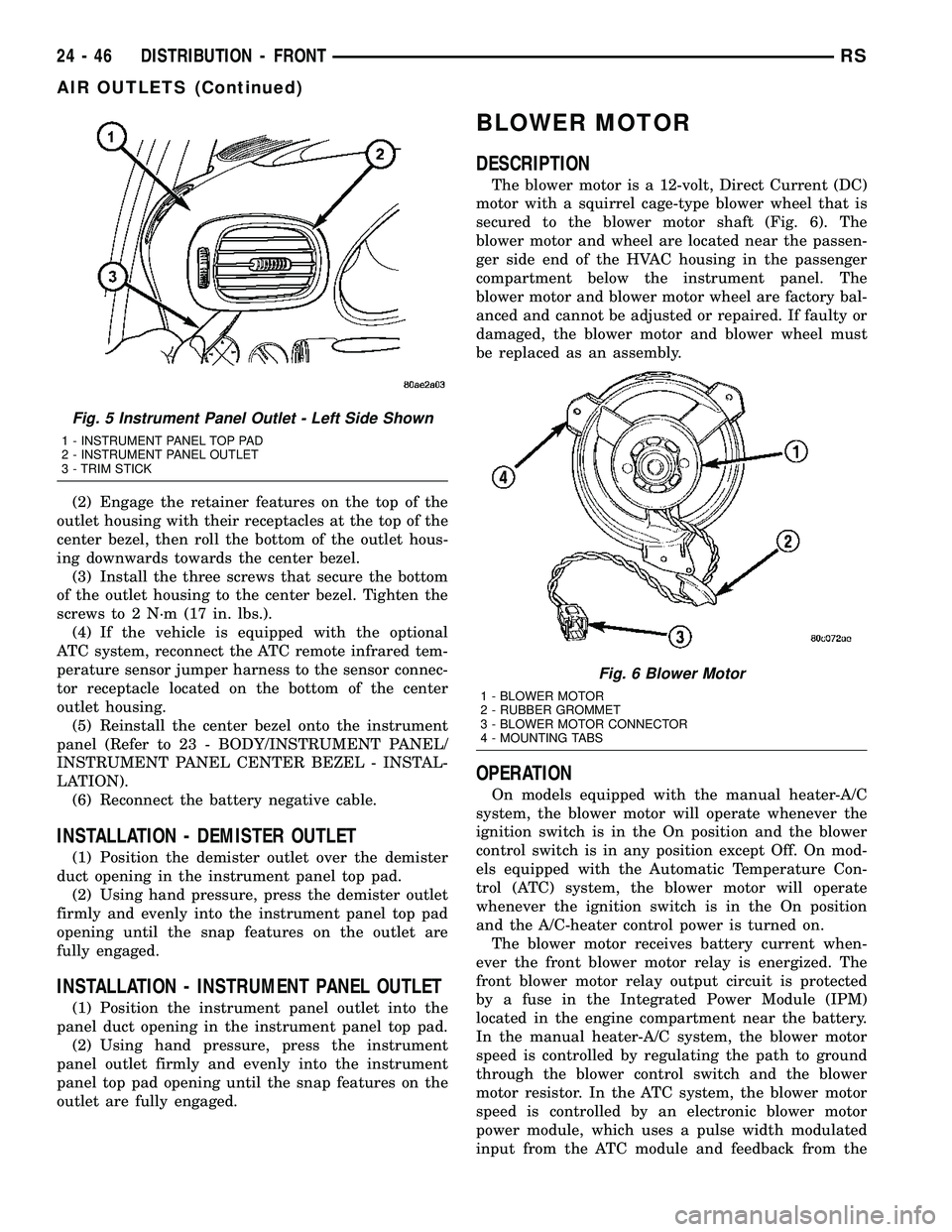

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 6). The

blower motor and wheel are located near the passen-

ger side end of the HVAC housing in the passenger

compartment below the instrument panel. The

blower motor and blower motor wheel are factory bal-

anced and cannot be adjusted or repaired. If faulty or

damaged, the blower motor and blower wheel must

be replaced as an assembly.

OPERATION

On models equipped with the manual heater-A/C

system, the blower motor will operate whenever the

ignition switch is in the On position and the blower

control switch is in any position except Off. On mod-

els equipped with the Automatic Temperature Con-

trol (ATC) system, the blower motor will operate

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

Fig. 5 Instrument Panel Outlet - Left Side Shown

1 - INSTRUMENT PANEL TOP PAD

2 - INSTRUMENT PANEL OUTLET

3 - TRIM STICK

Fig. 6 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

24 - 46 DISTRIBUTION - FRONTRS

AIR OUTLETS (Continued)

Page 2442 of 2585

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) orthe front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehicle

without having to remove the HVAC housing.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the passenger side door sill plate and

cowl panel.

(3) Pull back the carpet to access the front lower

air intake screw.

RSDISTRIBUTION - FRONT24-47

BLOWER MOTOR (Continued)

Page 2445 of 2585

(6) Install the four screws (from the bottom) that

secure the lower air inlet housing to the lower HVAC

housing. Tighten the screws to 2 N´m (17 in. lbs.).

(7) Install the one screw (from the top) that

secures the lower air inlet housing to the upper air

intake housing. Tighten the screws to 2 N´m (17 in.

lbs.).

(8) Connect the blower motor pigtail harness con-

nector to the blower motor resistor block or power

module, depending how vehicle is equipped.

(9) Install the recirculation door actuator (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS/

RECIRCULATION DOOR ACTUATOR - INSTALLA-

TION).

(10) Install the recirculation door actuator wire

harness lead into the routing clip on the lower air

inlet housing.

(11) Reinstall the carpet.

(12) Install the passenger side door sill plate and

cowl panel.

(13) Reconnect the battery negative cable.

(14) Perform the heater-A/C control calibration

procedure (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

DEFROSTER DUCT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - REMOVAL).

(3) Place the instrument panel face down on a

suitable work surface. Be certain to take the proper

precautions to protect the face of the instrument

panel from cosmetic damage.(4) Remove the fasteners that secure the defroster

duct to the instrument panel armature.

(5) Remove the defroster duct from the instrument

panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the defroster duct to the instrument

panel.

(2) Install the fasteners that secure the defroster

duct to the instrument panel armature.

(3) Reinstall the instrument panel in the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - INSTALLA-

TION).

(4) Reconnect the battery negative cable.

FLOOR DISTRIBUTION DUCTS

REMOVAL

(1) Roll back the carpet on the front floor from

under the instrument panel toward the rear of the

vehicle (Refer to 23 - BODY/INTERIOR/CARPETS

AND FLOOR MATS - REMOVAL).

(2) Lift the center floor distribution duct upward

far enough to disengage its locator hole from the

weld stud on the front floor panel (Fig. 11).

(3) Pull the center floor distribution duct rearward

far enough to disengage it from the floor outlet of the

HVAC housing.

(4) Disassemble the right and/or left floor distribu-

tion ducts from the center floor distribution duct as

required.

INSTALLATION

(1) Assemble the right and/or left floor distribution

ducts onto the center floor distribution duct as

required.

(2) Slide the center floor distribution duct under

the instrument panel center stack far enough to

engage it to the floor outlet of the HVAC housing.

24 - 50 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

Page 2452 of 2585

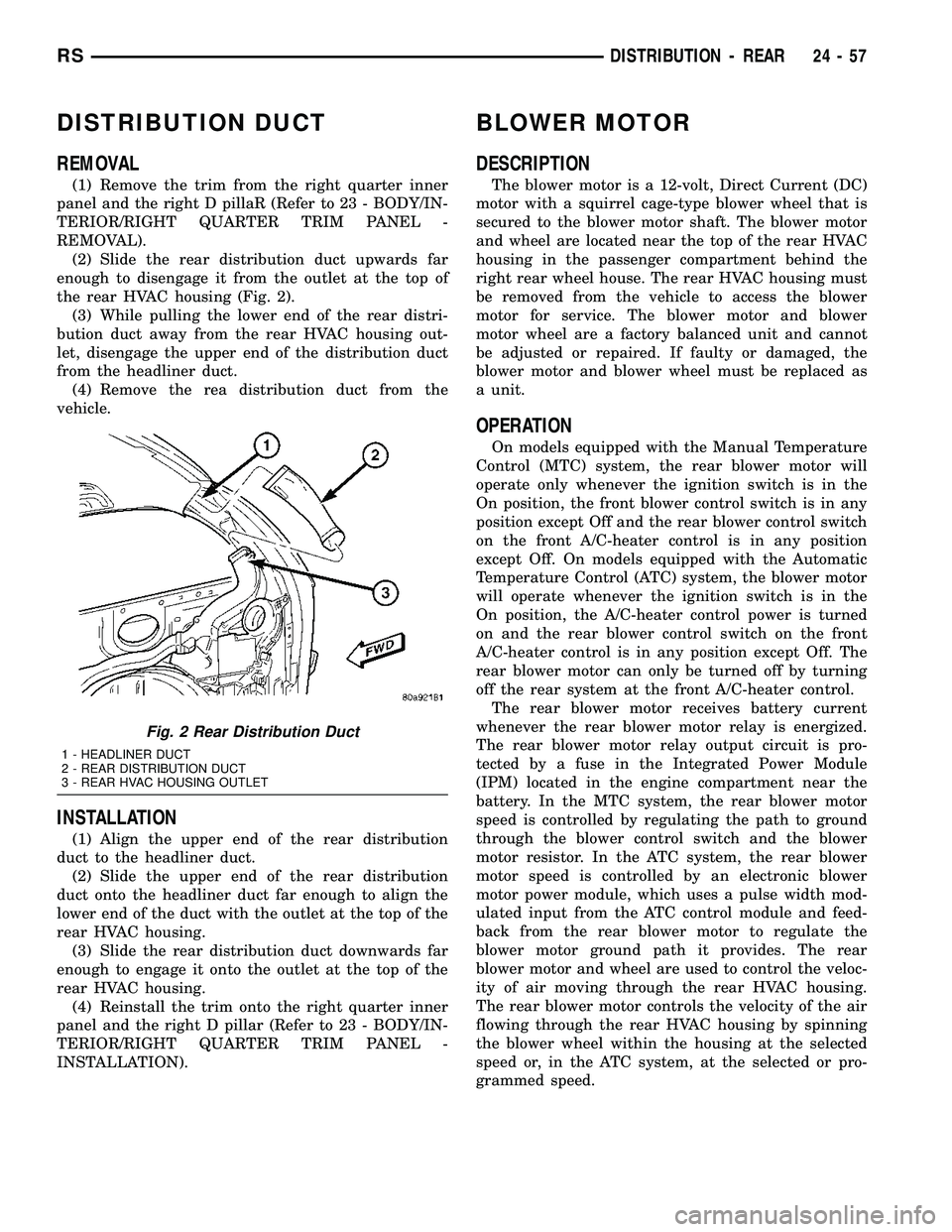

DISTRIBUTION DUCT

REMOVAL

(1) Remove the trim from the right quarter inner

panel and the right D pillaR (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

REMOVAL).

(2) Slide the rear distribution duct upwards far

enough to disengage it from the outlet at the top of

the rear HVAC housing (Fig. 2).

(3) While pulling the lower end of the rear distri-

bution duct away from the rear HVAC housing out-

let, disengage the upper end of the distribution duct

from the headliner duct.

(4) Remove the rea distribution duct from the

vehicle.

INSTALLATION

(1) Align the upper end of the rear distribution

duct to the headliner duct.

(2) Slide the upper end of the rear distribution

duct onto the headliner duct far enough to align the

lower end of the duct with the outlet at the top of the

rear HVAC housing.

(3) Slide the rear distribution duct downwards far

enough to engage it onto the outlet at the top of the

rear HVAC housing.

(4) Reinstall the trim onto the right quarter inner

panel and the right D pillar (Refer to 23 - BODY/IN-

TERIOR/RIGHT QUARTER TRIM PANEL -

INSTALLATION).

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft. The blower motor

and wheel are located near the top of the rear HVAC

housing in the passenger compartment behind the

right rear wheel house. The rear HVAC housing must

be removed from the vehicle to access the blower

motor for service. The blower motor and blower

motor wheel are a factory balanced unit and cannot

be adjusted or repaired. If faulty or damaged, the

blower motor and blower wheel must be replaced as

a unit.

OPERATION

On models equipped with the Manual Temperature

Control (MTC) system, the rear blower motor will

operate only whenever the ignition switch is in the

On position, the front blower control switch is in any

position except Off and the rear blower control switch

on the front A/C-heater control is in any position

except Off. On models equipped with the Automatic

Temperature Control (ATC) system, the blower motor

will operate whenever the ignition switch is in the

On position, the A/C-heater control power is turned

on and the rear blower control switch on the front

A/C-heater control is in any position except Off. The

rear blower motor can only be turned off by turning

off the rear system at the front A/C-heater control.

The rear blower motor receives battery current

whenever the rear blower motor relay is energized.

The rear blower motor relay output circuit is pro-

tected by a fuse in the Integrated Power Module

(IPM) located in the engine compartment near the

battery. In the MTC system, the rear blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the rear blower

motor speed is controlled by an electronic blower

motor power module, which uses a pulse width mod-

ulated input from the ATC control module and feed-

back from the rear blower motor to regulate the

blower motor ground path it provides. The rear

blower motor and wheel are used to control the veloc-

ity of air moving through the rear HVAC housing.

The rear blower motor controls the velocity of the air

flowing through the rear HVAC housing by spinning

the blower wheel within the housing at the selected

speed or, in the ATC system, at the selected or pro-

grammed speed.

Fig. 2 Rear Distribution Duct

1 - HEADLINER DUCT

2 - REAR DISTRIBUTION DUCT

3 - REAR HVAC HOUSING OUTLET

RSDISTRIBUTION - REAR24-57

Page 2453 of 2585

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR

BLOWER MOTOR INOPERATIVE

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear A/C-heater control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, check the rear blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector

from the rear blower motor resistor block (Manual

Temperature Control) or the rear blower motor power

module (Automatic Temperature Control). Reconnect

the battery negative cable. Turn the ignition switch

to the On position. Be certain that the rear A/C-

heater control power is turned on. Check for battery

voltage at the fused rear blower motor relay output

circuit cavity of the rear HVAC wire harness connec-

tor for the rear blower motor resistor block (MTC) or

the rear blower motor power module (ATC). If OK, go

to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear blower motor pigtail wire connec-

tor from the rear HVAC wire harness (MTC) or the

rear blower power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The rear blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the rear blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- REAR/BLOWER MOTOR RESISTOR - DIAGNOSIS

AND TESTING). If OK with ATC, use a DRBIII scan

tool to diagnose the rear blower motor power module.

Refer to the appropriate diagnostic information. If

not OK with MTC or ATC, replace the faulty rear

blower motor.BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 3).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control sys-

tem, the blower motor pigtail wire is connected to a

take out and connector of the rear HVAC wire har-

ness. With the Automatic Temperature Control sys-

tem , the blower pigtail wire is connected to a

receptacle on the blower motor power module.

(3) Remove the three screws that secure the rear

blower motor to the outboard side of the rear HVAC

housing (Fig. 4).

(4) Remove the rear blower motor from the rear

HVAC housing.

INSTALLATION

(1) Position the rear blower motor into the rear

HVAC housing.

(2) Install the three screws that secure the blower

motor to the rear HVAC housing. Tighten the screws

to 2 N´m (17 in. lbs.).

(3) Reconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control system

, the blower pigtail wire is connected to a take out

and connector of the rear HVAC wire harness. With

the Automatic Temperature Control system, the

blower pigtail wire is connected to a receptacle on

the blower motor power module.

24 - 58 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)