airbag CHRYSLER VOYAGER 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 288 of 2339

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Sentry Key Remote Entry Module (SKREEM).

²Side Impact Airbag Control Module (SIACM)²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

interior lamps after 15 minutes after the ignition is

turned off, if they are not turned off by the driver.

²Chime Control

²Compass/Mini-Trip support.

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Headlamp Time Delay (with/without Automatic

Headlamps)

²Illuminated Entry

²Fade to Off Interior Lamps - This feature dims

the interior lighting (courtesy lamps) gradually if the

BCM does not receive any new inputs that would

cause the interior lamps to remain on.

²Pulse Width Modulated Instrument Panel Dim-

ming

²Door Lock Inhibit - This feature disables the

door lock functions if the key is in the ignition and

either front door is ajar. Pressing the Remote Keyless

Entry (RKE) lock/unlock button under these condi-

tions result in normal lock/unlock activation.

The BCM has the ability to LEARN additional fea-

tures in the vehicle, provided the appropriate switch

input and PCI data bus messages are received. Refer

to the LEARNED FEATURES table.

LEARNED FEATURES

FEATURE LEARNING KEY

REAR WIPER CONTROL ON HVAC CONTROL ON

INSTRUMENT PANELPCI BUS MESSAGE RECEIVED FROM HVAC

CONTROL

AUTOMATIC HEADLAMPS PCI MESSAGE FROM OVERHEAD OR HEADLAMP

SWITCH POSITION (AUTO)

REMOTE KEYLESS ENTRY SKREEM MESSAGE RECEIVED FROM MODULE

FRONT FOG LAMPS HEADLAMP SWITCH POSITION (PARK W/FRONT

FOG LAMPS)

POWER SLIDING DOOR PCI IFR RECEIVED FROM MODULE

THE BCM HAS FOUR SWITCH INPUTS FOR THE POWER SLIDING DOOR FEATURE; LOCATED IN THE

OVERHEAD CONSOLE ARE THE LEFT AND RIGHT SIDE SLIDING DOOR SWITCHES TO ACTIVATE EITHER

OR BOTH SLIDING DOORS UNDER THE PROPER CONDITIONS. ALSO ARE B-PILLAR SWITCHES LOCATED

ON THE LEFT AND RIGHT B-PILLAR POSTS.

POWER LIFTGATE PCI IFR RECEIVED FROM MODULE

RSELECTRONIC CONTROL MODULES8E-3

BODY CONTROL MODULE (Continued)

Page 336 of 2339

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................31

OPERATION...........................31

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................31

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................33

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................35

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................36SPECIFICATIONS

Torques.............................36

STARTER ...........................37

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................37

REMOVAL - 3.3/3.8L...................38

REMOVAL - 2.5L......................38

INSTALLATION

INSTALLATION - 2.4L..................39

INSTALLATION - 3.3/3.8L................39

INSTALLATION - 2.5L..................39

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

RSSTARTING8F-31

Page 360 of 2339

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

HORN SYSTEM........................1

HORN

DIAGNOSIS AND TESTING

HORN...............................3REMOVAL.............................4

INSTALLATION..........................4

HORN SWITCH

DESCRIPTION..........................4

HORN SYSTEM

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, REFER TO ELECTRICAL, RESTRAINTS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and Integrated Power Mod-

ule (IPM). The horn switch is a membrane switch

located in the airbag trim cover. The horns are

located forward of the left front wheel behind the

bumper fascia.

OPERATION

The horn relay plugs into the Integrated Power

Module (IPM) which is located in the engine com-

partment. For circuit information and component

locations, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING

HORN SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the Integrated

Power Module (IPM). If the fuse is blown, replace

with the correct fuse. If the horns fail to sound and

the new fuse blows when depressing the horn switch,

a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble, or a defective horn switch allowed the horn to

burn out is responsible.

If the fuse is OK, test horn relay.

If the relay is OK, test horn.

CAUTION: Continuous sounding of horn may

cause horn failure.

Should the horn sound continuously, unplug the

horn relay from IPM.

Refer to the appropriate wiring information.

RSHORN8H-1

Page 361 of 2339

HORN SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

HORN SOUNDS CONTINUOUSLY.

NOTE: IMMEDIATELY UNPLUG HORN

RELAY IN THE IPM.(1) HORN RELAY

INOPERATIVE.(1) REPLACE RELAY.

(2) HORN CONTROL

CIRCUIT TO RELAY

SHORTED TO GROUND.(2) CHECK TERMINAL 85 IN IPM FOR

CONTINUITY TO GROUND. IF

CONTINUITY TO GROUND INDICATES:

(A) STEERING WHEEL HORN SWITCH/

LEAD SHORTED TO GROUND.

(B) WIRING HARNESS SHORTED TO

GROUND. FIND THE SHORT AND

REPAIR AS NECESSARY.

(3) PINCHED HORN SWITCH

WIRE UNDER DRIVER

AIRBAG MODULE.(3) REPLACE DRIVER AIRBAG TRIM

COVER.

(4) HORN SWITCH

INOPERATIVE.(4) REPLACE DRIVER AIRBAG TRIM

COVER.

(5) CLOCKSPRING

INOPERATIVE.(5) REPLACE CLOCKSPRING.

(6) FRONT CONTROL

MODULE INOPERATIVE.(6) REFER TO ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE.

HORN SOUND INTERMITTENTLY AS

THE STEERING WHEEL IS TURNED.(1) HORN RELAY CONTROL

CIRCUIT X3 IS SHORTED TO

GROUND INSIDE STEERING

COLUMN OR WHEEL.(1) REMOVE DRIVER AIRBAG AND/OR

WHEEL. CHECK FOR RUBBING OR

LOOSE WIRE/CONNECTOR, REPAIR AS

NECESSARY.

(2) PINCHED HORN SWITCH

WIRE UNDER DRIVER

AIRBAG MODULE.(2) REPLACE DRIVER AIRBAG TRIM

COVER.

(3) HORN SWITCH

INOPERATIVE.(3) REPLACE DRIVER AIRBAG TRIM

COVER.

(4) CLOCKSPRING

INOPERATIVE.(4) REPLACE CLOCKSPRING.

HORN DOES NOT SOUND (1) CHECK FUSE 8 IN

INTELLIGENT POWER

MODULE.(1) REPLACE FUSE IF BLOWN REPAIR

AS NECESSARY.

(2) NO VOLTAGE AT HORN

RELAY TERMINALS 30 & 86,

AND FUSE IS OK.(2) NO VOLTAGE, REPAIR THE CIRCUIT

AS NECESSARY.

(3) OPEN CIRCUIT FROM

TERMINAL 85 OF THE HORN

RELAY TO HORN SWITCH,

X3 CIRCUIT.(3) REPAIR CIRCUIT AS NECESSARY.

(4) HORN INOPERATIVE OR

DAMAGED.(4) CHECK VOLTAGE AT HORN WHEN

HORN SWITCH IS PRESSED. IF NO

VOLTAGE, REPLACE HORN.

(5) HORN SWITCH

INOPERATIVE.(5) REPLACE DRIVER AIRBAG TRIM

COVER.

8H - 2 HORNRS

HORN SYSTEM (Continued)

Page 362 of 2339

CONDITION POSSIBLE CAUSE CORRECTION

(6) CLOCKSPRING

INOPERATIVE.(6) REPLACE CLOCKSPRING.

(7) FRONT CONTROL

MODULE INOPERATIVE.(7) REFER TO ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE.

FUSE BLOWS WHEN HORN SOUNDS (1) SHORT CIRCUIT IN

HORN OR HORN WIRING.(1) REMOVE HORN RELAY, CHECK

FOR SHORTED HORN OR HORN

WIRING. DISCONNECT HORN WIRE

HARNESS TO ISOLATE SHORT AND

REPAIR AS NECESSARY.

(2) CLOCKSPRING

INOPERATIVE.(2) REPLACE CLOCKSPRING.

FUSE BLOWS WITHOUT BLOWING

HORN(1) SHORT CIRCUIT. (1) REMOVE RELAY, INSTALL NEW

FUSE, IF FUSE DOES NOT BLOW

REPLACE HORN RELAY. IF FUSE

BLOWS WITH RELAY REMOVED,

CHECK FOR SHORT TO GROUND

WITH OHMMETER ON CIRCUIT

BETWEEN TERMINALS 30 & 86 AND

THE FUSE TERMINAL. REPAIR AS

NECESSARY.

(2) CLOCKSPRING

INOPERATIVE.(2) REPLACE CLOCKSPRING.

HORN

DIAGNOSIS AND TESTING

HORN

HORN

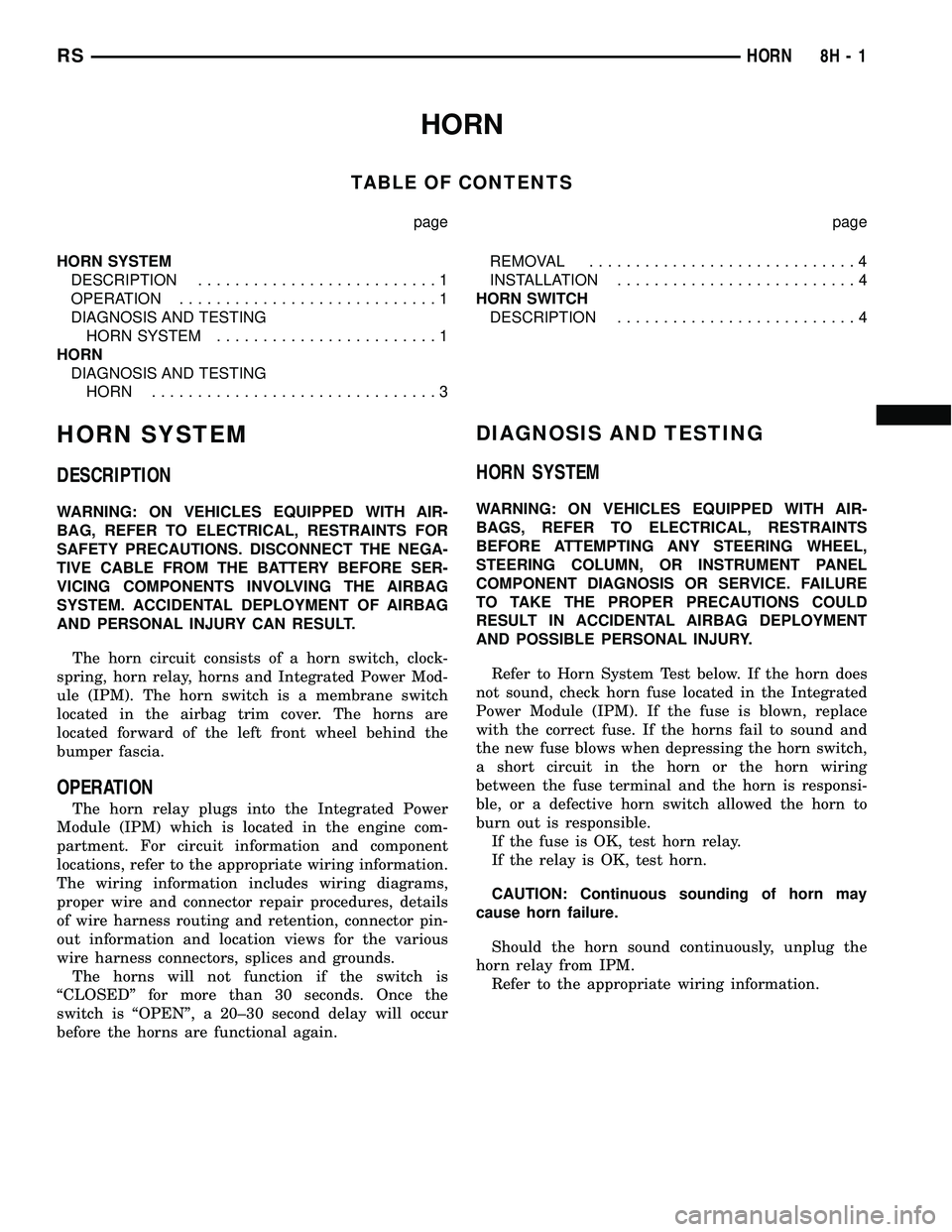

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 1).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer toHORNS WILL NOT

SOUND. If voltage is OK, go to step Step 5.

(5) Using ohmmeter, test ground wire for continu-

ity to ground.

(6) If no ground repair as necessary.

(7) If wires test OK and horn does not sound,

replace horn.

HORNS SOUND CONTINUOUSLY

CAUTION: Continuous sounding of horns may

cause relay to fail.

The horn switch (membrane) sometimes can be the

cause without the switch being depressed.(1) Remove the horn relay from the intelligent

power module.

(2)

Using a continuity tester, test continuity from the

X3 cavity of the horn relay to ground. Refer to the

appropriate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(a)If continuity is detected, proceed to step Step 3.

(b) If NO continuity, replace the horn relay.

(3) Remove the airbag trim cover from the steering

wheel and disengage horn connector.

(4) Install horn relay into Integrated Power Mod-

ule (IPM).

(a)

If horn does not sound, replace airbag trim

cover.

(b) If horn sounds, repair grounded X3 circuit

from IPM to clockspring in the steering column.

HORNS WILL NOT SOUND

Check horn fuse#8intheIPM. If fuse is blown,

check for a shorted switch in the airbag module. and

refer to FUSE BLOWN section. If fuse is OK, refer to

FUSE OK section.

FUSE BLOWN

(1) Verify condition of battery terminals and volt-

age, (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

RSHORN8H-3

HORN SYSTEM (Continued)

Page 363 of 2339

- DIAGNOSIS AND TESTING). If battery connec-

tions and battery charge is OK proceed to Step 2.

(2) Using a voltmeter, test for battery voltage at

both sides of horn fuse 7. If voltage is OK, on both

sides of fuse, proceed to Fuse OK. If voltage is OK,

on one side of fuse, the fuse is blown, proceed to Step

3.

(3) Using a suitable ammeter in place of the fuse,

test amperage draw of the horn circuit. If amperage

draw is greater than 20 amps without the horn

switch depressed, a grounded circuit exists between

the fuse and the horn relay. Proceed to Step 4. If

amperage draw is greater than 20 amps with the

horn switch depressed, a grounded circuit exists

between the horn relay and the horn. Proceed to step

Step 5.

(4) Remove the horn relay from the IPM. If the

amperage draw drops to 0 amps, the horn switch or

circuit is shorted. If the amperage draw does not

drop to 0 amps, repair short at the IPM.

(5) Disengage a wire connector from one of the

horns. If amperage drops and the connected horn

sounds, replace the faulty horn. If amperage does not

drop with both horns disconnected and the horn

switch depressed, proceed to Step 6.

(6) Using a continuity tester, with the horns dis-

connected test continuity of the X2 cavity of the horn

relay to ground. If continuity is detected, the circuit

is grounded between the Junction Block and the

horns. Locate and repair pinched harness.

FUSE OK

(1) Remove the horn relay from the intelligent

power module.

(2) Using a continuity tester, Depress horn switch

and test continuity from the X3 cavity of the horn

relay to ground.

(a) If continuity is detected, proceed to Step 3.

(b) If NO continuity, proceed to Step 4.

(3) Using a suitable jumper wire, jump across the

fuse F62 cavity and the X2 cavity of the horn relay in

the Junction Block.

(a) If the horn sounds, replace the horn relay.

(b) If the horn does not sound, proceed to Step 4.

(4) Remove airbag trim cover from steering wheel.

Refer to ELECTRICAL, RESTRAINTS.

(5) Test continuity across horn switch connectors

with horn switch depressed.

(a) If continuity is detected, repair open circuit

between the relay and the horn switch.

(b) If NO continuity, replace airbag trim cover.

(6) Install horn relay into intelligent power mod-

ule.

(7) Disengage wire connectors from horns.(8) Using a voltmeter, with the horn switch

depressed test voltage across horn connector termi-

nals of the wire harness (Fig. 1).

(a) If voltage is detected, replace horns.

(b) If NO voltage, proceed to step Step 9.

(9) With the horn switch depressed, test for volt-

age between the X2 circuit and ground.

(a) If voltage OK, repair system ground at right

cowl area.

(b) If NO voltage, repair open X2 circuit between

the relay and the horns.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist and support the front of the vehicle on

safety stands.

(3) From behind the front fascia and forward of

the left front wheel, disconnect the wire connectors

from horn.

(4) Remove the mounting bracket attaching nut

from the bottom of radiator closure panel. Do not

remove the horn from mounting bracket.

(5) Separate the horn(s) from vehicle.

INSTALLATION

(1) Install the horns to the vehicle.

(2) Install the mounting bracket fastener.

(3) Reconnect the wire connectors to the horns.

(4) Lower the vehicle.

(5) Reconnect the battery negative cable.

HORN SWITCH

DESCRIPTION

The horn switch is molded into the airbag trim

cover. The horn switch can not be serviced separately.

For service procedures (Refer to 8 - ELECTRICAL/

RESTRAINTS/AIRBAG COVER - REMOVAL).

Fig. 1 Horn Connector

8H - 4 HORNRS

HORN (Continued)

Page 374 of 2339

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................3REMOVAL.............................11

INSTALLATION.........................11

CLUSTER LENS

REMOVAL.............................11

INSTALLATION.........................11

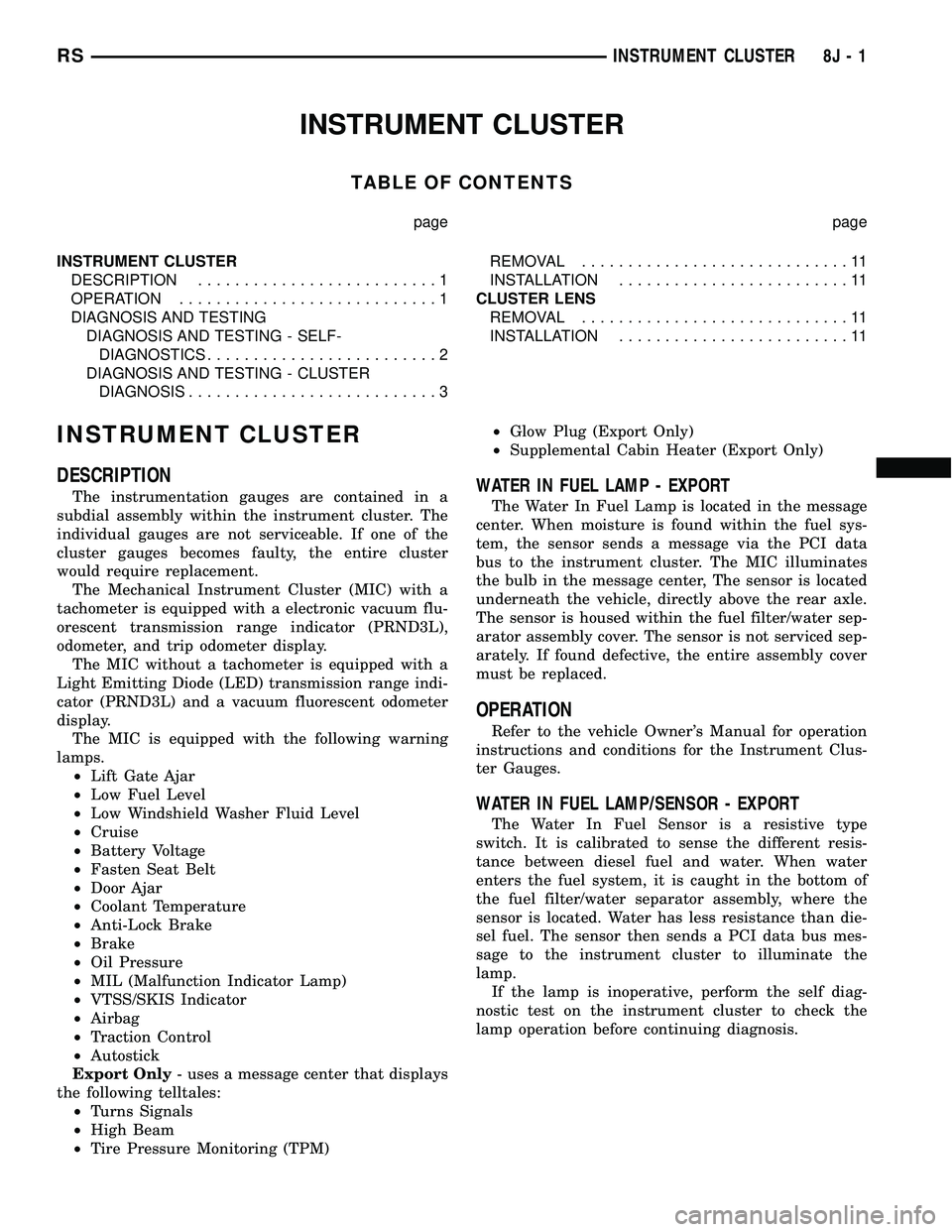

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The Mechanical Instrument Cluster (MIC) with a

tachometer is equipped with a electronic vacuum flu-

orescent transmission range indicator (PRND3L),

odometer, and trip odometer display.

The MIC without a tachometer is equipped with a

Light Emitting Diode (LED) transmission range indi-

cator (PRND3L) and a vacuum fluorescent odometer

display.

The MIC is equipped with the following warning

lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Oil Pressure

²MIL (Malfunction Indicator Lamp)

²VTSS/SKIS Indicator

²Airbag

²Traction Control

²Autostick

Export Only- uses a message center that displays

the following telltales:

²Turns Signals

²High Beam

²Tire Pressure Monitoring (TPM)²Glow Plug (Export Only)

²Supplemental Cabin Heater (Export Only)WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the message

center. When moisture is found within the fuel sys-

tem, the sensor sends a message via the PCI data

bus to the instrument cluster. The MIC illuminates

the bulb in the message center, The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP/SENSOR - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

Page 375 of 2339

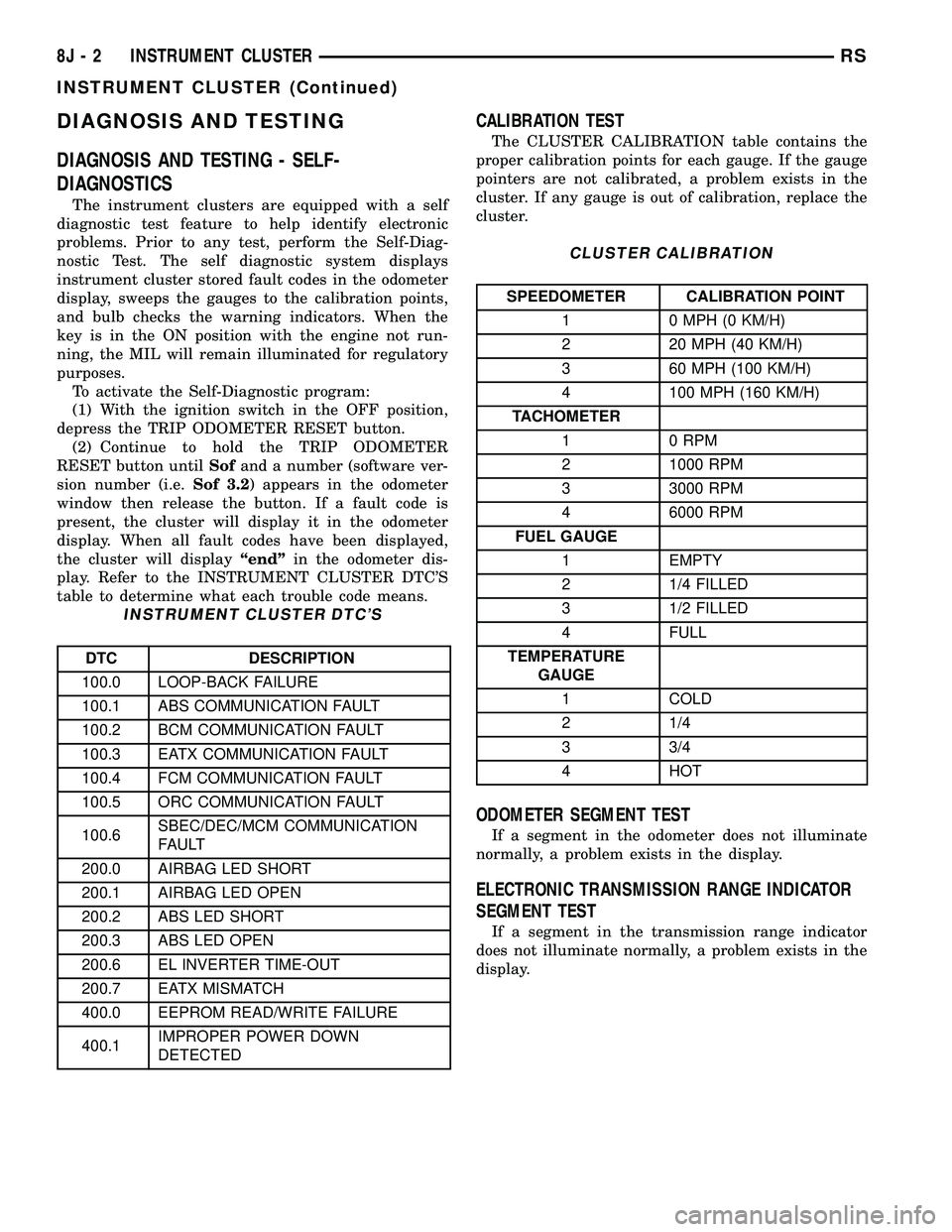

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 405 of 2339

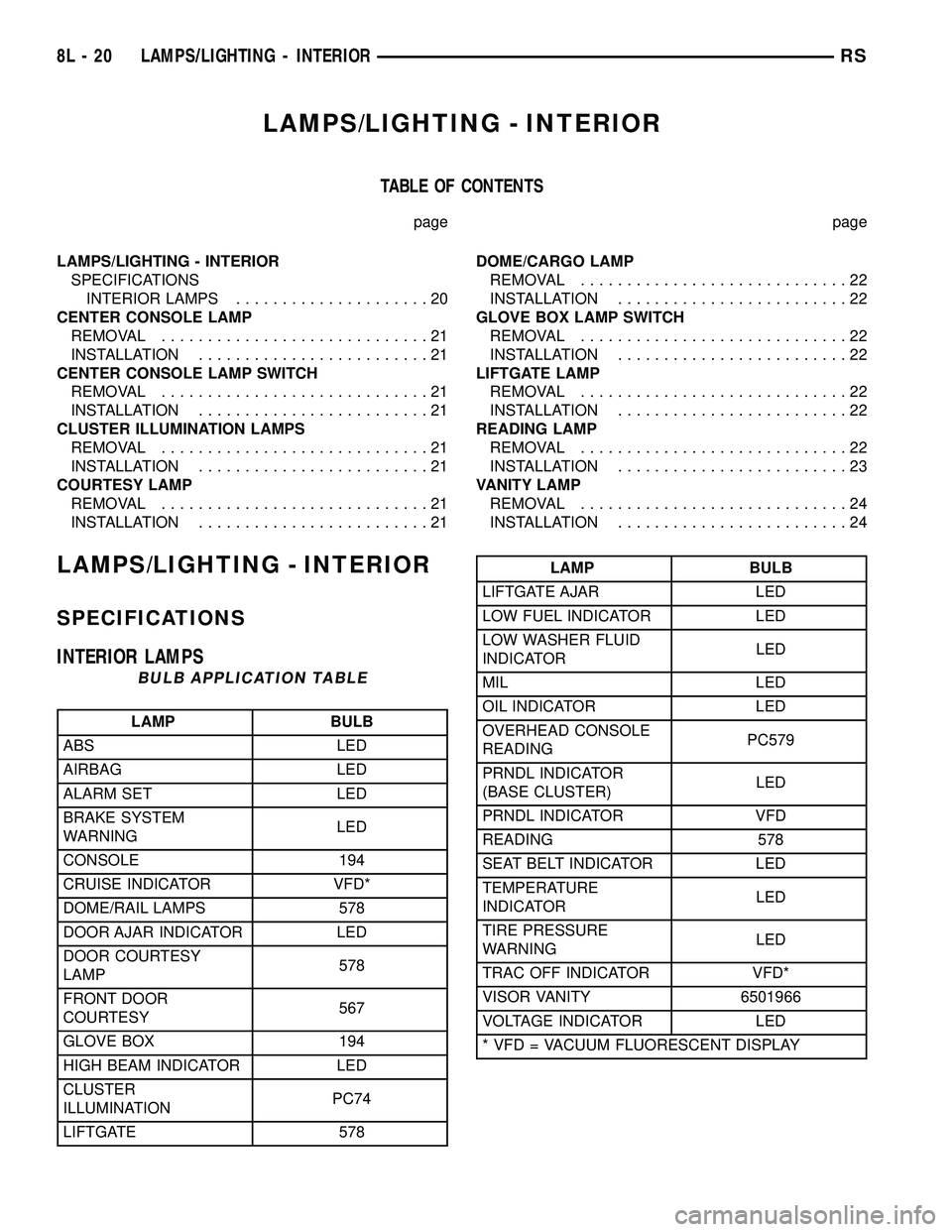

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................20

CENTER CONSOLE LAMP

REMOVAL.............................21

INSTALLATION.........................21

CENTER CONSOLE LAMP SWITCH

REMOVAL.............................21

INSTALLATION.........................21

CLUSTER ILLUMINATION LAMPS

REMOVAL.............................21

INSTALLATION.........................21

COURTESY LAMP

REMOVAL.............................21

INSTALLATION.........................21DOME/CARGO LAMP

REMOVAL.............................22

INSTALLATION.........................22

GLOVE BOX LAMP SWITCH

REMOVAL.............................22

INSTALLATION.........................22

LIFTGATE LAMP

REMOVAL.............................22

INSTALLATION.........................22

READING LAMP

REMOVAL.............................22

INSTALLATION.........................23

VANITY LAMP

REMOVAL.............................24

INSTALLATION.........................24

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET LED

BRAKE SYSTEM

WARNINGLED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY

LAMP578

FRONT DOOR

COURTESY567

GLOVE BOX 194

HIGH BEAM INDICATOR LED

CLUSTER

ILLUMINATIONPC74

LIFTGATE 578

LAMP BULB

LIFTGATE AJAR LED

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MIL LED

OIL INDICATOR LED

OVERHEAD CONSOLE

READINGPC579

PRNDL INDICATOR

(BASE CLUSTER)LED

PRNDL INDICATOR VFD

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE

INDICATORLED

TIRE PRESSURE

WARNINGLED

TRAC OFF INDICATOR VFD*

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VFD = VACUUM FLUORESCENT DISPLAY

8L - 20 LAMPS/LIGHTING - INTERIORRS

Page 454 of 2339

POWER SEAT SYSTEM

TABLE OF CONTENTS

page page

POWER SEAT SYSTEM

DESCRIPTION

POWER SEAT SYSTEM................31

MEMORY SYSTEM....................32

OPERATION

POWER SEAT SYSTEM................32

MEMORY SYSTEM....................33

DIAGNOSIS AND TESTING

POWER SEAT SYSTEM................33

MEMORY SYSTEM....................33

SEAT SWITCH

DESCRIPTION.........................34

OPERATION...........................34

DIAGNOSIS AND TESTING

DRIVER SEAT SWITCH.................34

REMOVAL.............................36INSTALLATION.........................36

MEMORY SWITCH

DESCRIPTION.........................36

OPERATION...........................36

DIAGNOSIS AND TESTING

MEMORY SWITCH....................37

REMOVAL.............................37

INSTALLATION.........................37

POWER SEAT TRACK

DESCRIPTION.........................37

OPERATION...........................38

DIAGNOSIS AND TESTING

POWER SEAT TRACK..................38

REMOVAL.............................38

INSTALLATION.........................39

POWER SEAT SYSTEM

DESCRIPTION

POWER SEAT SYSTEM

The power seat system option allows the driver

and front seat passenger to electrically adjust their

seating positions for optimum control and comfort.

The driver side power front seat can be adjusted in

eight different directions: up, down, front up, front

down, rear up, rear down, forward, rearward and

recliner forward and rearward. The passenger side

power front seat can be adjusted in four different

directions: forward, rearward and recliner forward

and rearward.

The power seat system receives battery current

through a 40 amp fuse in the Integrated Power Mod-

ule (IPM) and a 30 amp circuit breaker under the

seat so that the power seats remain operational,

regardless of the ignition switch position.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULDRESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The eight-way driver side power seat is also avail-

able with the heated seat and/or memory seat sys-

tem. The memory seat system automatically

positions the power seat for two different drivers.

Fig. 1 IDENTIFYING A SIDE AIRBAG EQUIPPED

SEAT

1 - AIRBAG LABEL

RSPOWER SEAT SYSTEM8N-31