coil CHRYSLER VOYAGER 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2005Pages: 2339, PDF Size: 59.69 MB

Page 366 of 2339

FIRING ORDERAUTO SHUT DOWN RELAY

DESCRIPTION

The relay is located in the Power Distribution Cen-

ter (PDC). For the location of the relay within the

PDC, refer to the PDC cover for location. Check elec-

trical terminals for corrosion and repair as necessary

OPERATION

The engine switched battery (NGC vehicles)

informs the PCM when the ASD relay energizes. A 12

volt signal at this input indicates to the PCM that

the ASD has been activated. This input is also used

to power certain drivers on NGC vehicles.

When energized, the ASD relay on NGC vehicles

provides power to operate the injectors, ignition coil,

generator field, O2 sensor heaters (both upstream

and downstream), evaporative purge solenoid, EGR

solenoid (if equipped) wastegate solenoid (if

equipped), and NVLD solenoid (if equipped).

The ASD relay also provides a sense circuit to the

PCM for diagnostic purposes. If the PCM does not

receive 12 volts from this input after grounding the

control side of the ASD relay, it sets a Diagnostic

Trouble Code (DTC). The PCM energizes the ASD

any time there is an engine speed that exceeds a pre-

determined value (typically about 50 rpm). The ASD

relay can also be energized after the engine has been

turned off to perform an O2 sensor heater test, if

vehicle is equipped with OBD II diagnostics.

As mentioned earlier, the PCM energizes the ASD

relay during an O2 sensor heater test. On NGC vehi-

cles it checks the O2 heater upon vehicle start. The

PCM still operates internally to perform several

checks, including monitoring the O2 sensor heaters.

FIRING ORDER 2.4L

Firing Order 1-2-3-4-5-6 3.3/3.8L

1 - Electrical Connector

RSIGNITION CONTROL8I-3

IGNITION CONTROL (Continued)

Page 369 of 2339

(6) Pull sensor up out of the chain case cover.Do

not pull on the sensor wiring.There is an O-ring

on the body of the sensor. The O-ring may make

removal difficult. A light tap to top of sensor prior to

removal may reduce force needed for removal.

INSTALLATION

INSTALLATION - 2.4L

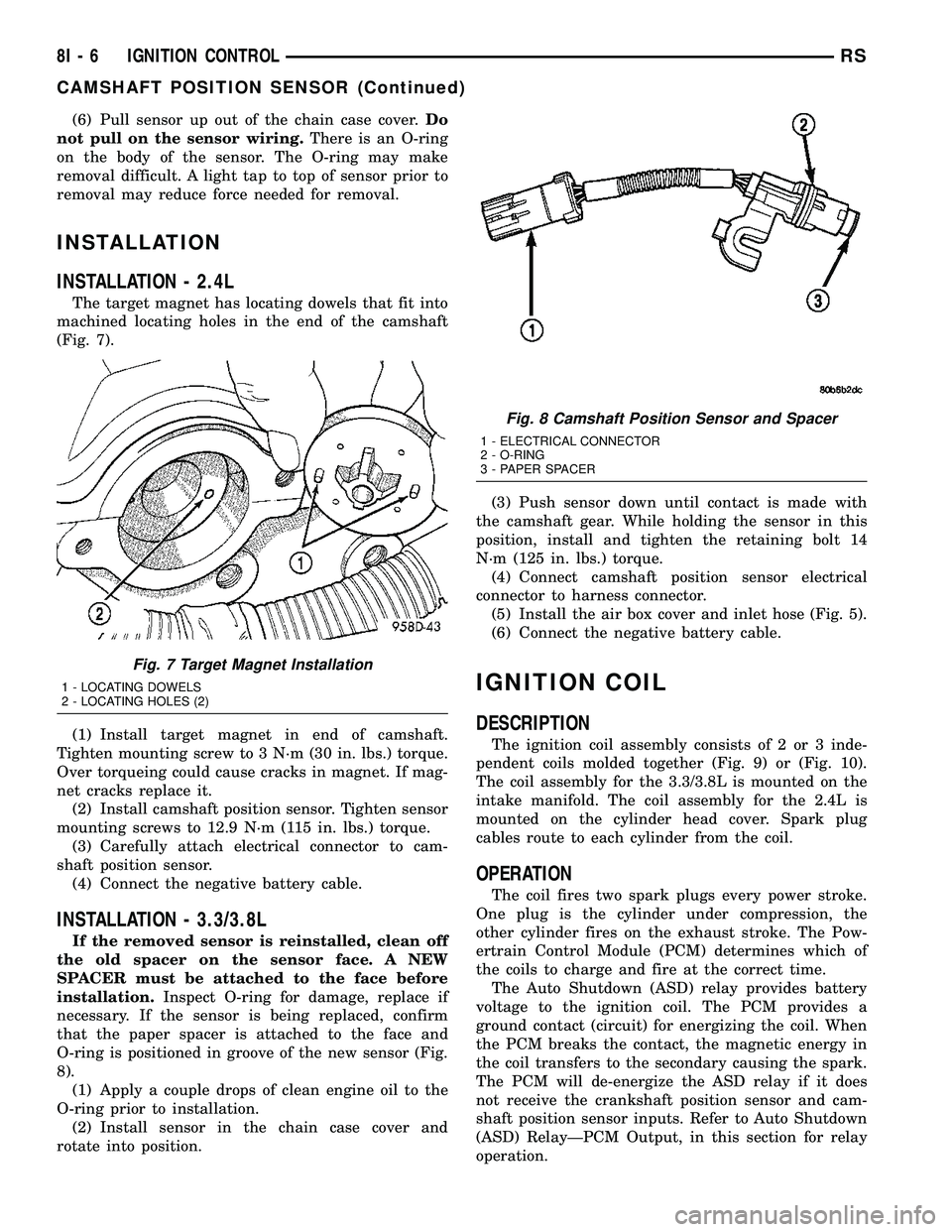

The target magnet has locating dowels that fit into

machined locating holes in the end of the camshaft

(Fig. 7).

(1) Install target magnet in end of camshaft.

Tighten mounting screw to 3 N´m (30 in. lbs.) torque.

Over torqueing could cause cracks in magnet. If mag-

net cracks replace it.

(2) Install camshaft position sensor. Tighten sensor

mounting screws to 12.9 N´m (115 in. lbs.) torque.

(3) Carefully attach electrical connector to cam-

shaft position sensor.

(4) Connect the negative battery cable.

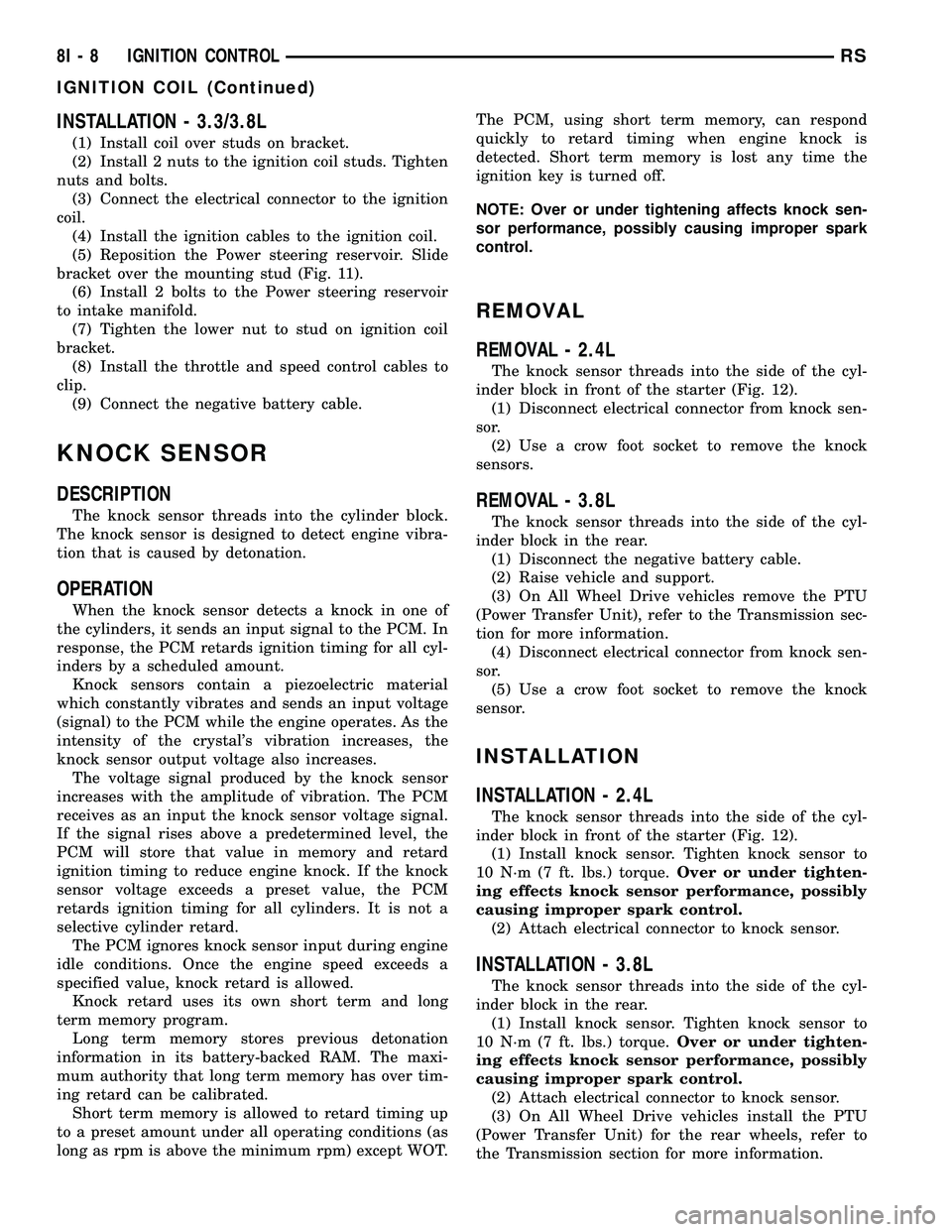

INSTALLATION - 3.3/3.8L

If the removed sensor is reinstalled, clean off

the old spacer on the sensor face. A NEW

SPACER must be attached to the face before

installation.Inspect O-ring for damage, replace if

necessary. If the sensor is being replaced, confirm

that the paper spacer is attached to the face and

O-ring is positioned in groove of the new sensor (Fig.

8).

(1) Apply a couple drops of clean engine oil to the

O-ring prior to installation.

(2) Install sensor in the chain case cover and

rotate into position.(3) Push sensor down until contact is made with

the camshaft gear. While holding the sensor in this

position, install and tighten the retaining bolt 14

N´m (125 in. lbs.) torque.

(4) Connect camshaft position sensor electrical

connector to harness connector.

(5) Install the air box cover and inlet hose (Fig. 5).

(6) Connect the negative battery cable.

IGNITION COIL

DESCRIPTION

The ignition coil assembly consists of 2 or 3 inde-

pendent coils molded together (Fig. 9) or (Fig. 10).

The coil assembly for the 3.3/3.8L is mounted on the

intake manifold. The coil assembly for the 2.4L is

mounted on the cylinder head cover. Spark plug

cables route to each cylinder from the coil.

OPERATION

The coil fires two spark plugs every power stroke.

One plug is the cylinder under compression, the

other cylinder fires on the exhaust stroke. The Pow-

ertrain Control Module (PCM) determines which of

the coils to charge and fire at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the magnetic energy in

the coil transfers to the secondary causing the spark.

The PCM will de-energize the ASD relay if it does

not receive the crankshaft position sensor and cam-

shaft position sensor inputs. Refer to Auto Shutdown

(ASD) RelayÐPCM Output, in this section for relay

operation.

Fig. 7 Target Magnet Installation

1 - LOCATING DOWELS

2 - LOCATING HOLES (2)

Fig. 8 Camshaft Position Sensor and Spacer

1 - ELECTRICAL CONNECTOR

2 - O-RING

3 - PAPER SPACER

8I - 6 IGNITION CONTROLRS

CAMSHAFT POSITION SENSOR (Continued)

Page 370 of 2339

REMOVAL

REMOVAL - 2.4L

The electronic ignition coil pack attaches directly

to the valve cover.

(1) Diconnect the negative battery cable.

(2) Disconnect electrical connector from coil pack.

(3) Remove coil pack mounting bolts.(4) Remove coil pack and heat shield (Fig. 9).

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove the throttle and speed control cables

from clip.

(3) Remove 2 bolts from the Power steering reser-

voir to intake manifold.

(4) Loosen the lower nut for the power steering

reservoir from stud on ignition coil bracket.

(5) Reposition the Power steering reservoir (Fig.

11).

(6) Remove the ignition cables from the ignition

coil.

(7) Disconnect the electrical connector from the

ignition coil.

(8) Remove 2 nuts from the ignition coil studs.

INSTALLATION

INSTALLATION - 2.4L

(1) Install ignition coil and heat shield to valve

cover and tighten bolts.

(2) Connect the electrical connector to the ignition

coil.

(3) Transfer spark plug cables to new coil pack.

The coil pack towers are numbered with the cylinder

identification. Be sure the ignition cables are fully

seated onto the towers.

(4) Connect the negative battery cable.

Fig. 9 IGNITION COIL - 2.4L

Fig. 10 IGNITION COIL - 3.3/3.8L

1 -Ignition Coil

Fig. 11 IGNITION COIL BRACKET 3.3/3.8L

RSIGNITION CONTROL8I-7

IGNITION COIL (Continued)

Page 371 of 2339

INSTALLATION - 3.3/3.8L

(1) Install coil over studs on bracket.

(2) Install 2 nuts to the ignition coil studs. Tighten

nuts and bolts.

(3) Connect the electrical connector to the ignition

coil.

(4) Install the ignition cables to the ignition coil.

(5) Reposition the Power steering reservoir. Slide

bracket over the mounting stud (Fig. 11).

(6) Install 2 bolts to the Power steering reservoir

to intake manifold.

(7) Tighten the lower nut to stud on ignition coil

bracket.

(8) Install the throttle and speed control cables to

clip.

(9) Connect the negative battery cable.

KNOCK SENSOR

DESCRIPTION

The knock sensor threads into the cylinder block.

The knock sensor is designed to detect engine vibra-

tion that is caused by detonation.

OPERATION

When the knock sensor detects a knock in one of

the cylinders, it sends an input signal to the PCM. In

response, the PCM retards ignition timing for all cyl-

inders by a scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives as an input the knock sensor voltage signal.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except WOT.The PCM, using short term memory, can respond

quickly to retard timing when engine knock is

detected. Short term memory is lost any time the

ignition key is turned off.

NOTE: Over or under tightening affects knock sen-

sor performance, possibly causing improper spark

control.

REMOVAL

REMOVAL - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Disconnect electrical connector from knock sen-

sor.

(2) Use a crow foot socket to remove the knock

sensors.

REMOVAL - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) On All Wheel Drive vehicles remove the PTU

(Power Transfer Unit), refer to the Transmission sec-

tion for more information.

(4) Disconnect electrical connector from knock sen-

sor.

(5) Use a crow foot socket to remove the knock

sensor.

INSTALLATION

INSTALLATION - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

INSTALLATION - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

(3) On All Wheel Drive vehicles install the PTU

(Power Transfer Unit) for the rear wheels, refer to

the Transmission section for more information.

8I - 8 IGNITION CONTROLRS

IGNITION COIL (Continued)

Page 373 of 2339

REMOVAL

When replacing the spark plugs and spark plug

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise, cross ignition of the spark plugs orshort cir-

cuit the cables to ground.

Always remove cables by grasping at the boot,

rotating the boot 1/2 turn, and pulling straight back

in a steady motion.

(1) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug.

(2) Remove the spark plug using a quality socket

with a foam insert.

(3) Inspect the spark plug condition.

INSTALLATION

When replacing the spark plugs and spark plug

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise, cross ignition of the spark plugs orshort cir-

cuit the cables to ground.

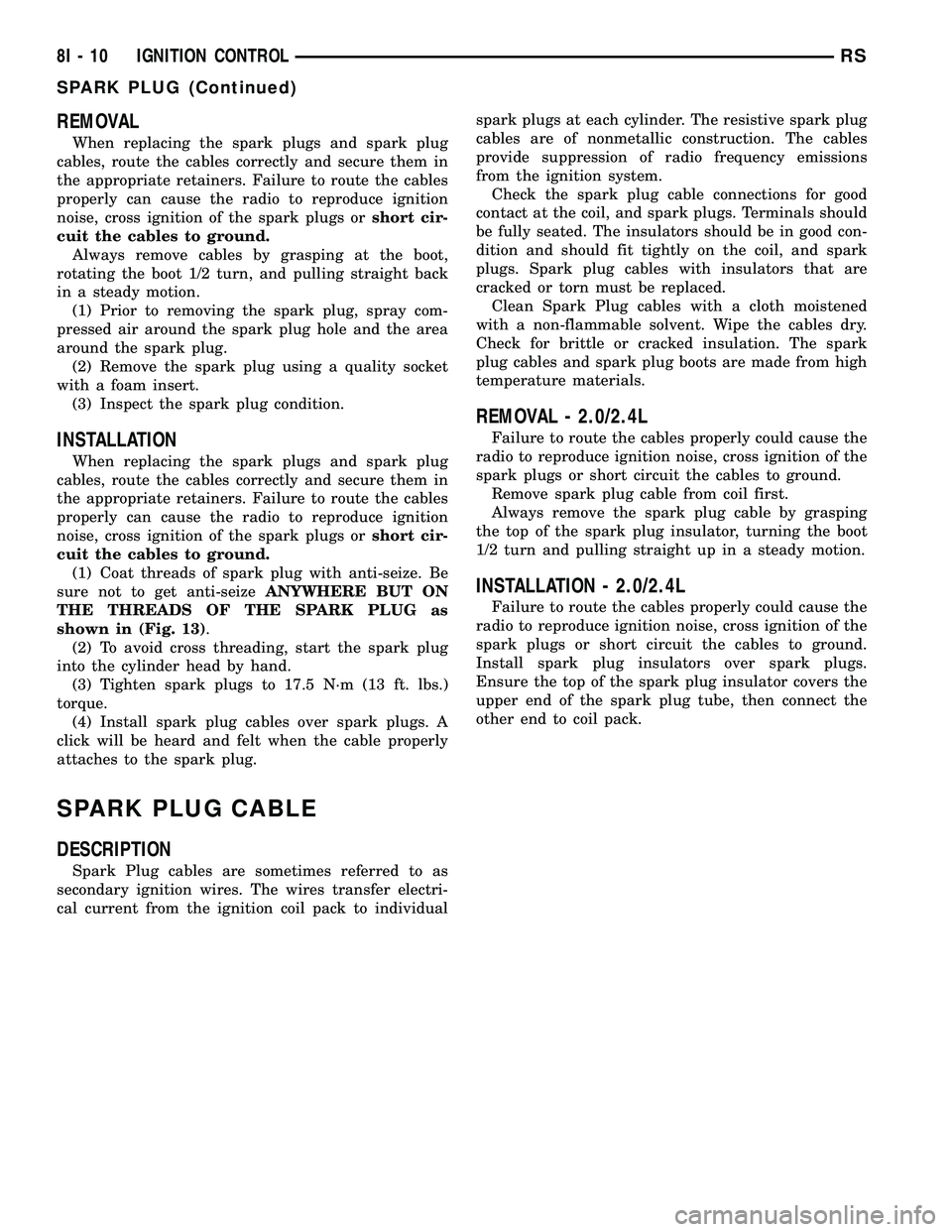

(1) Coat threads of spark plug with anti-seize. Be

sure not to get anti-seizeANYWHERE BUT ON

THE THREADS OF THE SPARK PLUG as

shown in (Fig. 13).

(2) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(3) Tighten spark plugs to 17.5 N´m (13 ft. lbs.)

torque.

(4) Install spark plug cables over spark plugs. A

click will be heard and felt when the cable properly

attaches to the spark plug.

SPARK PLUG CABLE

DESCRIPTION

Spark Plug cables are sometimes referred to as

secondary ignition wires. The wires transfer electri-

cal current from the ignition coil pack to individualspark plugs at each cylinder. The resistive spark plug

cables are of nonmetallic construction. The cables

provide suppression of radio frequency emissions

from the ignition system.

Check the spark plug cable connections for good

contact at the coil, and spark plugs. Terminals should

be fully seated. The insulators should be in good con-

dition and should fit tightly on the coil, and spark

plugs. Spark plug cables with insulators that are

cracked or torn must be replaced.

Clean Spark Plug cables with a cloth moistened

with a non-flammable solvent. Wipe the cables dry.

Check for brittle or cracked insulation. The spark

plug cables and spark plug boots are made from high

temperature materials.

REMOVAL - 2.0/2.4L

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

Remove spark plug cable from coil first.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

INSTALLATION - 2.0/2.4L

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube, then connect the

other end to coil pack.

8I - 10 IGNITION CONTROLRS

SPARK PLUG (Continued)

Page 498 of 2339

Service replacement clocksprings are shipped pre-

centered and with a molded plastic shield that snaps

onto the rotor over the release button. The release

button secures the centered clockspring rotor to the

clockspring case and the shield prevents the release

button from being inadvertently depressed during

shipment and handling, but the shield must be

removed from the clockspring after it is installed on

the steering column (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - STANDARD PROCE-

DURE).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. The rotating

electrical components include the driver airbag, the

horn switch, the speed control switches, and the

remote radio switches, if the vehicle is so equipped.

The clockspring case is positioned and secured to the

upper steering column housing near the top of the

steering column. The connector receptacles on the

tail of the clockspring case connect the clockspring to

the vehicle electrical system through two connectors

from the instrument panel wire harness.

The clockspring rotor is movable and is keyed by

the tower formation that is molded onto the upper

surface of the rotor hub to an opening that is cast

into the steering wheel armature. Rubber bumper

blocks on either side of the clockspring tower forma-

tion eliminate contact noise between the clockspring

tower and the steering wheel. The lobe of the turn

signal cancel cam on the lower surface of the clock-

spring rotor hub contacts a turn signal cancel actua-

tor of the multi-function switch to provide automatic

turn signal cancellation. The yellow or black-sleeved

pigtail wires on the upper surface of the clockspring

rotor connect the clockspring to the driver airbag,

while a steering wheel wire harness connects the

connector receptacle on the upper surface of the

clockspring rotor to the horn switch and, if the vehi-

cle is so equipped, to the optional speed control

switches and remote radio switches on the steering

wheel.

The clockspring tape has travel limits and can be

damaged by being wound too tightly during full stop-

to-stop steering wheel rotation. To prevent this from

occurring, the clockspring is centered when it is

installed on the steering column. Centering the clock-

spring indexes the clockspring tape to the movable

steering components so that the tape can operatewithin its designed travel limits. However, if the

clockspring is removed from the steering column or if

the steering shaft is disconnected from the steering

gear, the clockspring spool can change position rela-

tive to the movable steering components and must be

re-centered following completion of the service or the

tape may be damaged (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - STANDARD PRO-

CEDURE).

Service replacement clocksprings are shipped pre-

centered and with a plastic shield installed over the

clockspring release button. This shield should not be

removed and the release button should not be

depressed until the clockspring has been installed on

the steering column. If the release button is

depressed before the clockspring is installed on a

steering column, the clockspring centering procedure

must be performed (Refer to 8 - ELECTRICAL/RE-

STRAINTS/CLOCKSPRING - STANDARD PROCE-

DURE).

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

If the rotating tape (wire coil) in the clockspring is

not positioned properly with the steering wheel and

the front wheels, the clockspring may fail. The fol-

lowing procedure MUST BE USED to center the

clockspring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4) Wait two minutes for the system reserve capac-

itor to discharge before beginning any airbag compo-

nent service.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness (if equipped).

(8) Disconnect the 4±way harness connector from

the speed control (if equipped)/horn harness to the

clockspring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Rotate the clockspring rotor clockwise until

the rotor stops. Do not apply excessive force.

(11) From the end of travel, rotate the rotor two

turns counterclockwise until the wires end up at the

top.

RSRESTRAINTS8O-11

CLOCKSPRING (Continued)

Page 583 of 2339

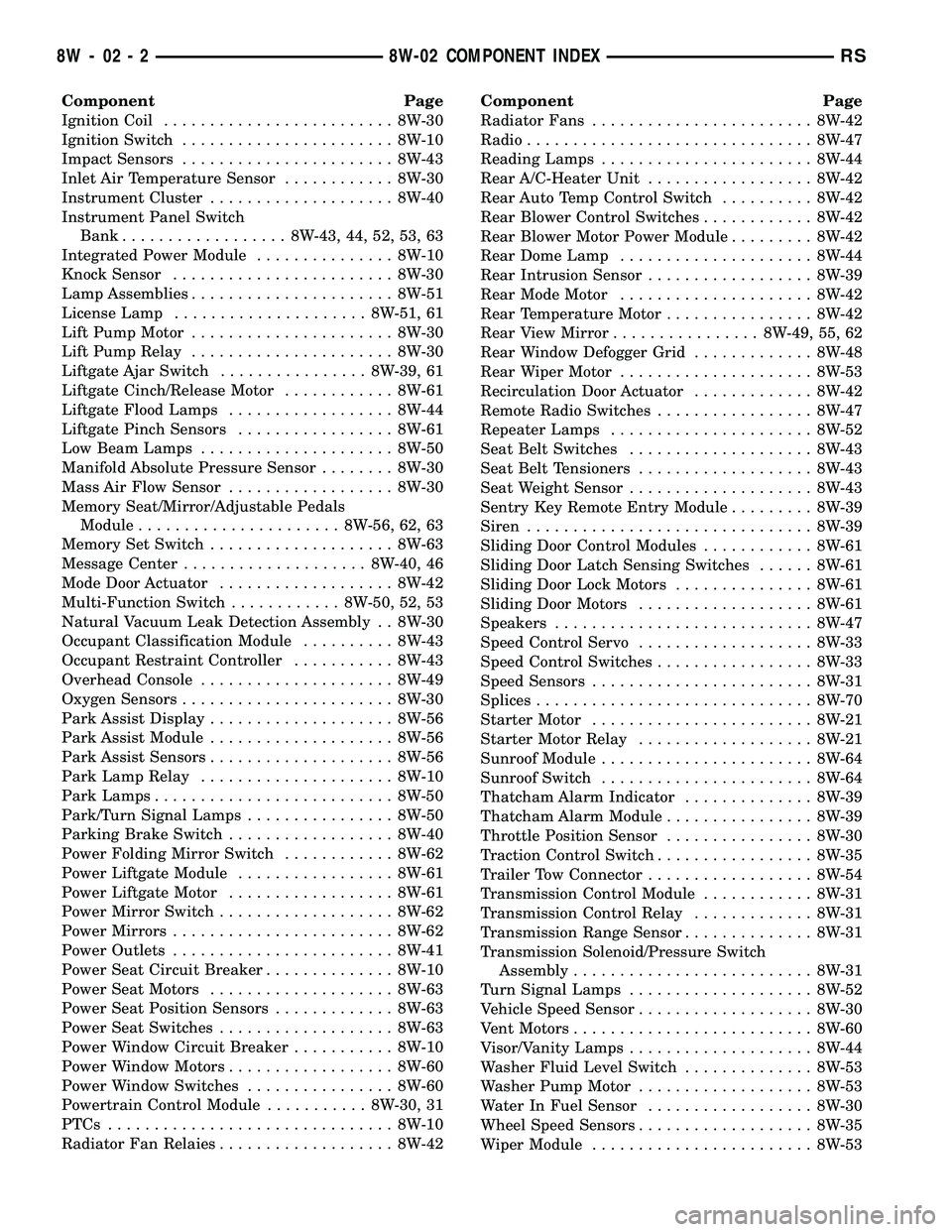

Component Page

Ignition Coil......................... 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Inlet Air Temperature Sensor............ 8W-30

Instrument Cluster.................... 8W-40

Instrument Panel Switch

Bank.................. 8W-43, 44, 52, 53, 63

Integrated Power Module............... 8W-10

Knock Sensor........................ 8W-30

Lamp Assemblies...................... 8W-51

License Lamp..................... 8W-51, 61

Lift Pump Motor...................... 8W-30

Lift Pump Relay...................... 8W-30

Liftgate Ajar Switch................ 8W-39, 61

Liftgate Cinch/Release Motor............ 8W-61

Liftgate Flood Lamps.................. 8W-44

Liftgate Pinch Sensors................. 8W-61

Low Beam Lamps..................... 8W-50

Manifold Absolute Pressure Sensor........ 8W-30

Mass Air Flow Sensor.................. 8W-30

Memory Seat/Mirror/Adjustable Pedals

Module...................... 8W-56, 62, 63

Memory Set Switch.................... 8W-63

Message Center.................... 8W-40, 46

Mode Door Actuator................... 8W-42

Multi-Function Switch............ 8W-50, 52, 53

Natural Vacuum Leak Detection Assembly . . 8W-30

Occupant Classification Module.......... 8W-43

Occupant Restraint Controller........... 8W-43

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Park Assist Display.................... 8W-56

Park Assist Module.................... 8W-56

Park Assist Sensors.................... 8W-56

Park Lamp Relay..................... 8W-10

Park Lamps.......................... 8W-50

Park/Turn Signal Lamps................ 8W-50

Parking Brake Switch.................. 8W-40

Power Folding Mirror Switch............ 8W-62

Power Liftgate Module................. 8W-61

Power Liftgate Motor.................. 8W-61

Power Mirror Switch................... 8W-62

Power Mirrors........................ 8W-62

Power Outlets........................ 8W-41

Power Seat Circuit Breaker.............. 8W-10

Power Seat Motors.................... 8W-63

Power Seat Position Sensors............. 8W-63

Power Seat Switches................... 8W-63

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module........... 8W-30, 31

PTCs............................... 8W-10

Radiator Fan Relaies................... 8W-42Component Page

Radiator Fans........................ 8W-42

Radio............................... 8W-47

Reading Lamps....................... 8W-44

Rear A/C-Heater Unit.................. 8W-42

Rear Auto Temp Control Switch.......... 8W-42

Rear Blower Control Switches............ 8W-42

Rear Blower Motor Power Module......... 8W-42

Rear Dome Lamp..................... 8W-44

Rear Intrusion Sensor.................. 8W-39

Rear Mode Motor..................... 8W-42

Rear Temperature Motor................ 8W-42

Rear View Mirror................ 8W-49, 55, 62

Rear Window Defogger Grid............. 8W-48

Rear Wiper Motor..................... 8W-53

Recirculation Door Actuator............. 8W-42

Remote Radio Switches................. 8W-47

Repeater Lamps...................... 8W-52

Seat Belt Switches.................... 8W-43

Seat Belt Tensioners................... 8W-43

Seat Weight Sensor.................... 8W-43

Sentry Key Remote Entry Module......... 8W-39

Siren............................... 8W-39

Sliding Door Control Modules............ 8W-61

Sliding Door Latch Sensing Switches...... 8W-61

Sliding Door Lock Motors............... 8W-61

Sliding Door Motors................... 8W-61

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Speed Sensors........................ 8W-31

Splices.............................. 8W-70

Starter Motor........................ 8W-21

Starter Motor Relay................... 8W-21

Sunroof Module....................... 8W-64

Sunroof Switch....................... 8W-64

Thatcham Alarm Indicator.............. 8W-39

Thatcham Alarm Module................ 8W-39

Throttle Position Sensor................ 8W-30

Traction Control Switch................. 8W-35

Trailer Tow Connector.................. 8W-54

Transmission Control Module............ 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid/Pressure Switch

Assembly.......................... 8W-31

Turn Signal Lamps.................... 8W-52

Vehicle Speed Sensor................... 8W-30

Vent Motors.......................... 8W-60

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor................... 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper Module........................ 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXRS

Page 585 of 2339

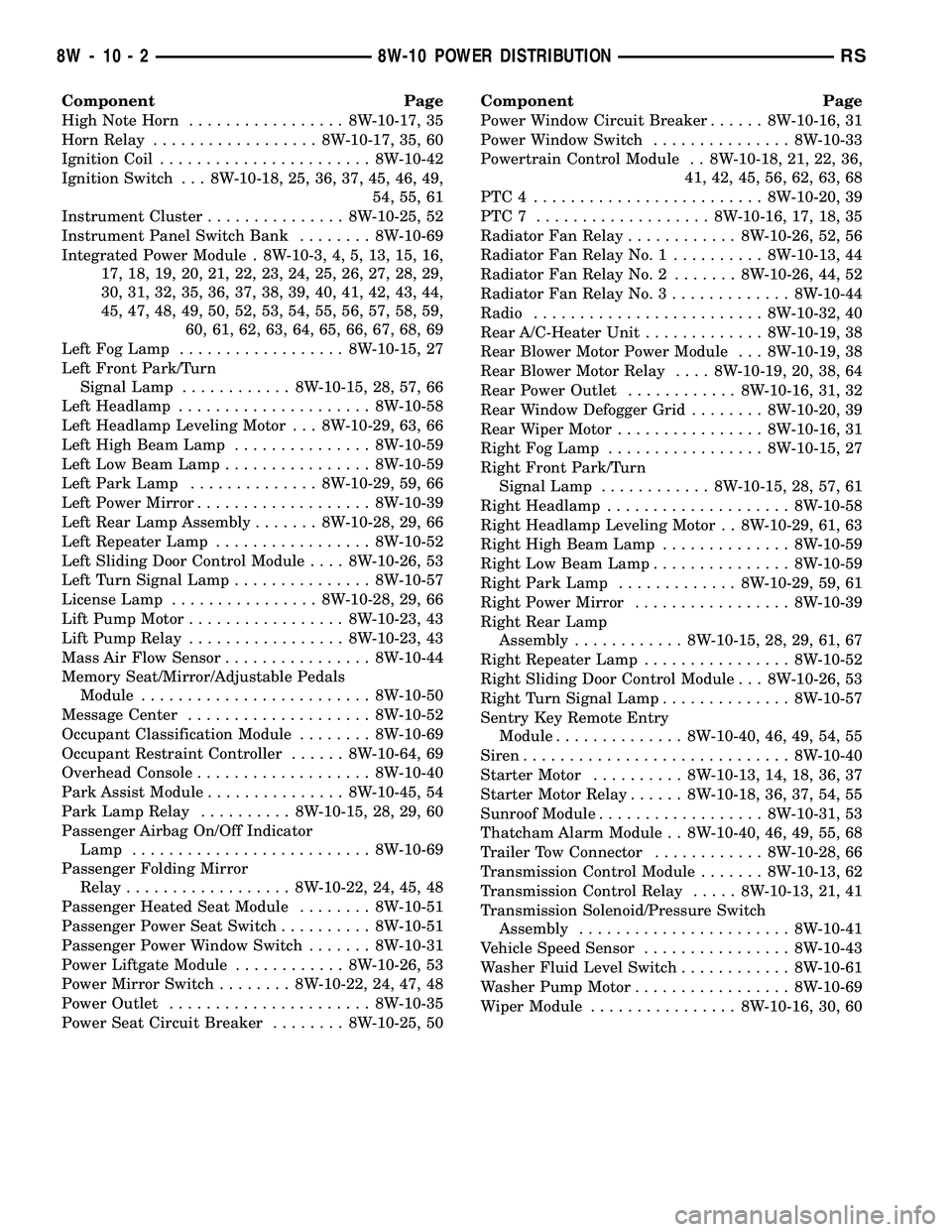

Component Page

High Note Horn................. 8W-10-17, 35

Horn Relay.................. 8W-10-17, 35, 60

Ignition Coil....................... 8W-10-42

Ignition Switch . . . 8W-10-18, 25, 36, 37, 45, 46, 49,

54, 55, 61

Instrument Cluster............... 8W-10-25, 52

Instrument Panel Switch Bank........ 8W-10-69

Integrated Power Module . 8W-10-3, 4, 5, 13, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29,

30, 31, 32, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44,

45, 47, 48, 49, 50, 52, 53, 54, 55, 56, 57, 58, 59,

60, 61, 62, 63, 64, 65, 66, 67, 68, 69

Left Fog Lamp.................. 8W-10-15, 27

Left Front Park/Turn

Signal Lamp............ 8W-10-15, 28, 57, 66

Left Headlamp..................... 8W-10-58

Left Headlamp Leveling Motor . . . 8W-10-29, 63, 66

Left High Beam Lamp............... 8W-10-59

Left Low Beam Lamp................ 8W-10-59

Left Park Lamp.............. 8W-10-29, 59, 66

Left Power Mirror................... 8W-10-39

Left Rear Lamp Assembly....... 8W-10-28, 29, 66

Left Repeater Lamp................. 8W-10-52

Left Sliding Door Control Module.... 8W-10-26, 53

Left Turn Signal Lamp............... 8W-10-57

License Lamp................ 8W-10-28, 29, 66

Lift Pump Motor................. 8W-10-23, 43

Lift Pump Relay................. 8W-10-23, 43

Mass Air Flow Sensor................ 8W-10-44

Memory Seat/Mirror/Adjustable Pedals

Module......................... 8W-10-50

Message Center.................... 8W-10-52

Occupant Classification Module........ 8W-10-69

Occupant Restraint Controller...... 8W-10-64, 69

Overhead Console................... 8W-10-40

Park Assist Module............... 8W-10-45, 54

Park Lamp Relay.......... 8W-10-15, 28, 29, 60

Passenger Airbag On/Off Indicator

Lamp.......................... 8W-10-69

Passenger Folding Mirror

Relay.................. 8W-10-22, 24, 45, 48

Passenger Heated Seat Module........ 8W-10-51

Passenger Power Seat Switch.......... 8W-10-51

Passenger Power Window Switch....... 8W-10-31

Power Liftgate Module............ 8W-10-26, 53

Power Mirror Switch........ 8W-10-22, 24, 47, 48

Power Outlet...................... 8W-10-35

Power Seat Circuit Breaker........ 8W-10-25, 50Component Page

Power Window Circuit Breaker...... 8W-10-16, 31

Power Window Switch............... 8W-10-33

Powertrain Control Module . . 8W-10-18, 21, 22, 36,

41, 42, 45, 56, 62, 63, 68

PTC4 ......................... 8W-10-20, 39

PTC7 ................... 8W-10-16, 17, 18, 35

Radiator Fan Relay............ 8W-10-26, 52, 56

Radiator Fan Relay No. 1.......... 8W-10-13, 44

Radiator Fan Relay No. 2....... 8W-10-26, 44, 52

Radiator Fan Relay No. 3............. 8W-10-44

Radio......................... 8W-10-32, 40

Rear A/C-Heater Unit............. 8W-10-19, 38

Rear Blower Motor Power Module . . . 8W-10-19, 38

Rear Blower Motor Relay.... 8W-10-19, 20, 38, 64

Rear Power Outlet............ 8W-10-16, 31, 32

Rear Window Defogger Grid........ 8W-10-20, 39

Rear Wiper Motor................ 8W-10-16, 31

Right Fog Lamp................. 8W-10-15, 27

Right Front Park/Turn

Signal Lamp............ 8W-10-15, 28, 57, 61

Right Headlamp.................... 8W-10-58

Right Headlamp Leveling Motor . . 8W-10-29, 61, 63

Right High Beam Lamp.............. 8W-10-59

Right Low Beam Lamp............... 8W-10-59

Right Park Lamp............. 8W-10-29, 59, 61

Right Power Mirror................. 8W-10-39

Right Rear Lamp

Assembly............ 8W-10-15, 28, 29, 61, 67

Right Repeater Lamp................ 8W-10-52

Right Sliding Door Control Module . . . 8W-10-26, 53

Right Turn Signal Lamp.............. 8W-10-57

Sentry Key Remote Entry

Module.............. 8W-10-40, 46, 49, 54, 55

Siren............................. 8W-10-40

Starter Motor.......... 8W-10-13, 14, 18, 36, 37

Starter Motor Relay...... 8W-10-18, 36, 37, 54, 55

Sunroof Module.................. 8W-10-31, 53

Thatcham Alarm Module . . 8W-10-40, 46, 49, 55, 68

Trailer Tow Connector............ 8W-10-28, 66

Transmission Control Module....... 8W-10-13, 62

Transmission Control Relay..... 8W-10-13, 21, 41

Transmission Solenoid/Pressure Switch

Assembly....................... 8W-10-41

Vehicle Speed Sensor................ 8W-10-43

Washer Fluid Level Switch............ 8W-10-61

Washer Pump Motor................. 8W-10-69

Wiper Module................ 8W-10-16, 30, 60

8W - 10 - 2 8W-10 POWER DISTRIBUTIONRS

Page 698 of 2339

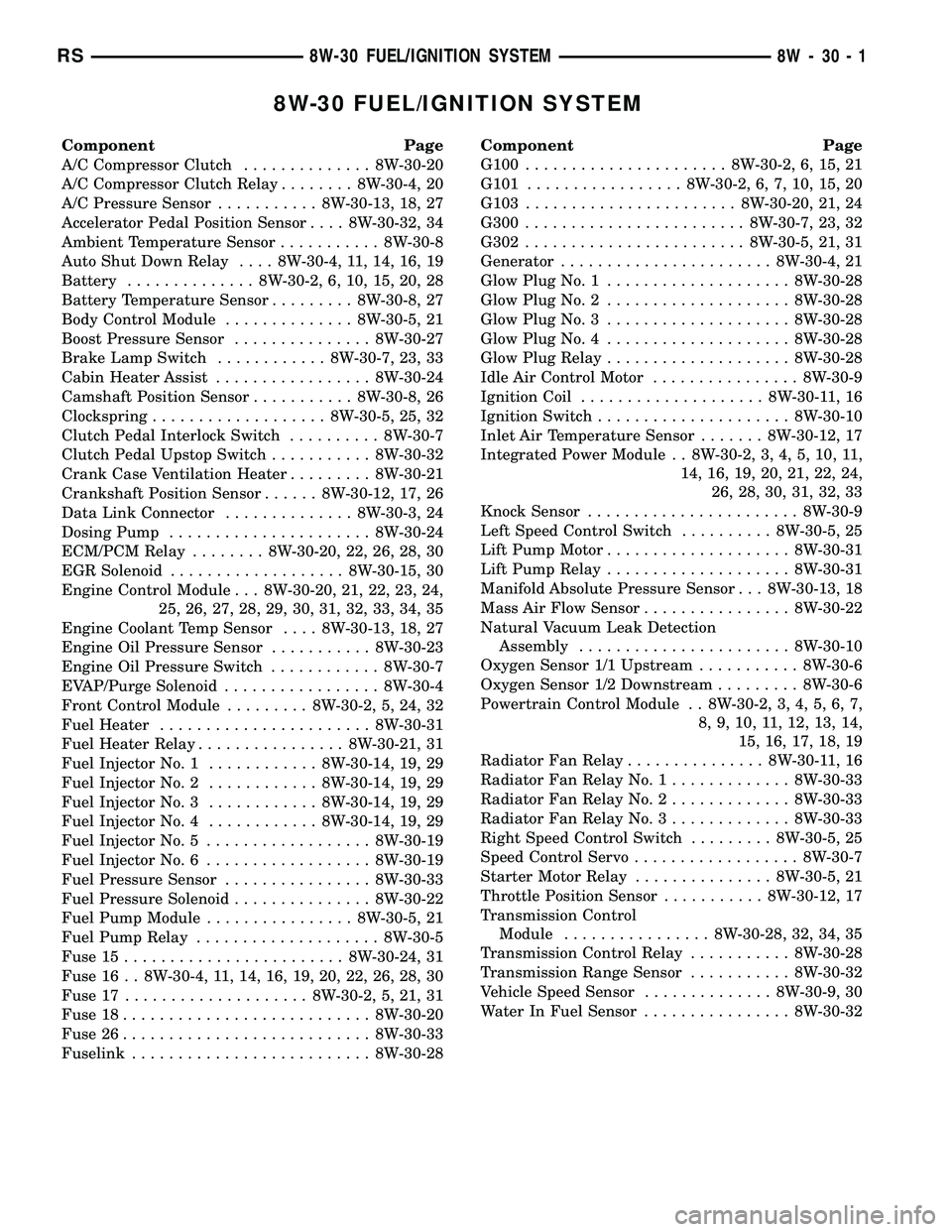

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch.............. 8W-30-20

A/C Compressor Clutch Relay........ 8W-30-4, 20

A/C Pressure Sensor........... 8W-30-13, 18, 27

Accelerator Pedal Position Sensor.... 8W-30-32, 34

Ambient Temperature Sensor........... 8W-30-8

Auto Shut Down Relay.... 8W-30-4, 11, 14, 16, 19

Battery.............. 8W-30-2, 6, 10, 15, 20, 28

Battery Temperature Sensor......... 8W-30-8, 27

Body Control Module.............. 8W-30-5, 21

Boost Pressure Sensor............... 8W-30-27

Brake Lamp Switch............ 8W-30-7, 23, 33

Cabin Heater Assist................. 8W-30-24

Camshaft Position Sensor........... 8W-30-8, 26

Clockspring................... 8W-30-5, 25, 32

Clutch Pedal Interlock Switch.......... 8W-30-7

Clutch Pedal Upstop Switch........... 8W-30-32

Crank Case Ventilation Heater......... 8W-30-21

Crankshaft Position Sensor...... 8W-30-12, 17, 26

Data Link Connector.............. 8W-30-3, 24

Dosing Pump...................... 8W-30-24

ECM/PCM Relay........ 8W-30-20, 22, 26, 28, 30

EGR Solenoid................... 8W-30-15, 30

Engine Control Module . . . 8W-30-20, 21, 22, 23, 24,

25, 26, 27, 28, 29, 30, 31, 32, 33, 34, 35

Engine Coolant Temp Sensor.... 8W-30-13, 18, 27

Engine Oil Pressure Sensor........... 8W-30-23

Engine Oil Pressure Switch............ 8W-30-7

EVAP/Purge Solenoid................. 8W-30-4

Front Control Module......... 8W-30-2, 5, 24, 32

Fuel Heater....................... 8W-30-31

Fuel Heater Relay................ 8W-30-21, 31

Fuel Injector No. 1............ 8W-30-14, 19, 29

Fuel Injector No. 2............ 8W-30-14, 19, 29

Fuel Injector No. 3............ 8W-30-14, 19, 29

Fuel Injector No. 4............ 8W-30-14, 19, 29

Fuel Injector No. 5.................. 8W-30-19

Fuel Injector No. 6.................. 8W-30-19

Fuel Pressure Sensor................ 8W-30-33

Fuel Pressure Solenoid............... 8W-30-22

Fuel Pump Module................ 8W-30-5, 21

Fuel Pump Relay.................... 8W-30-5

Fuse 15........................ 8W-30-24, 31

Fuse 16 . . 8W-30-4, 11, 14, 16, 19, 20, 22, 26, 28, 30

Fuse 17.................... 8W-30-2, 5, 21, 31

Fuse 18........................... 8W-30-20

Fuse 26........................... 8W-30-33

Fuselink.......................... 8W-30-28Component Page

G100...................... 8W-30-2, 6, 15, 21

G101................. 8W-30-2, 6, 7, 10, 15, 20

G103....................... 8W-30-20, 21, 24

G300........................ 8W-30-7, 23, 32

G302........................ 8W-30-5, 21, 31

Generator....................... 8W-30-4, 21

Glow Plug No. 1.................... 8W-30-28

Glow Plug No. 2.................... 8W-30-28

Glow Plug No. 3.................... 8W-30-28

Glow Plug No. 4.................... 8W-30-28

Glow Plug Relay.................... 8W-30-28

Idle Air Control Motor................ 8W-30-9

Ignition Coil.................... 8W-30-11, 16

Ignition Switch..................... 8W-30-10

Inlet Air Temperature Sensor....... 8W-30-12, 17

Integrated Power Module . . 8W-30-2, 3, 4, 5, 10, 11,

14, 16, 19, 20, 21, 22, 24,

26, 28, 30, 31, 32, 33

Knock Sensor....................... 8W-30-9

Left Speed Control Switch.......... 8W-30-5, 25

Lift Pump Motor.................... 8W-30-31

Lift Pump Relay.................... 8W-30-31

Manifold Absolute Pressure Sensor . . . 8W-30-13, 18

Mass Air Flow Sensor................ 8W-30-22

Natural Vacuum Leak Detection

Assembly....................... 8W-30-10

Oxygen Sensor 1/1 Upstream........... 8W-30-6

Oxygen Sensor 1/2 Downstream......... 8W-30-6

Powertrain Control Module . . 8W-30-2, 3, 4, 5, 6, 7,

8, 9, 10, 11, 12, 13, 14,

15, 16, 17, 18, 19

Radiator Fan Relay............... 8W-30-11, 16

Radiator Fan Relay No. 1............. 8W-30-33

Radiator Fan Relay No. 2............. 8W-30-33

Radiator Fan Relay No. 3............. 8W-30-33

Right Speed Control Switch......... 8W-30-5, 25

Speed Control Servo.................. 8W-30-7

Starter Motor Relay............... 8W-30-5, 21

Throttle Position Sensor........... 8W-30-12, 17

Transmission Control

Module................ 8W-30-28, 32, 34, 35

Transmission Control Relay........... 8W-30-28

Transmission Range Sensor........... 8W-30-32

Vehicle Speed Sensor.............. 8W-30-9, 30

Water In Fuel Sensor................ 8W-30-32

RS8W-30 FUEL/IGNITION SYSTEM8W-30-1

Page 972 of 2339

Component Page

Evaporator Temperature Sensor........ 8W-80-70

Floor Console Lamp................. 8W-80-70

Floor Console Power Outlet (Export).... 8W-80-70

Front Blower Module C1 (ATC)........ 8W-80-71

Front Blower Module C2 (ATC)........ 8W-80-71

Front Cigar Lighter................. 8W-80-71

Front Control Module................ 8W-80-72

Front Intrusion Sensor (United

Kingdom)....................... 8W-80-73

Front Reading Lamps/Switch.......... 8W-80-73

Fuel Heater (Diesel)................. 8W-80-73

Fuel Injector No. 1 (2.4L/3.3L/3.8L)..... 8W-80-73

Fuel Injector No. 1 (Diesel)............ 8W-80-73

Fuel Injector No. 2 (2.4L/3.3L/3.8L)..... 8W-80-74

Fuel Injector No. 2 (Diesel)............ 8W-80-74

Fuel Injector No. 3 (2.4L/3.3L/3.8L)..... 8W-80-74

Fuel Injector No. 3 (Diesel)............ 8W-80-74

Fuel Injector No. 4 (2.4L/3.3L/3.8L)..... 8W-80-75

Fuel Injector No. 4 (Diesel)............ 8W-80-75

Fuel Injector No. 5 (3.3L/3.8L)......... 8W-80-75

Fuel Injector No. 6 (3.3L/3.8L)......... 8W-80-75

Fuel Pressure Sensor (Diesel).......... 8W-80-76

Fuel Pressure Solenoid (Diesel)........ 8W-80-76

Fuel Pump Module.................. 8W-80-76

Generator......................... 8W-80-76

Glow Plug Relay (Diesel)............. 8W-80-77

Hands Free Module C1............... 8W-80-77

Hands Free Module C2............... 8W-80-77

Hands Free Module C3............... 8W-80-78

Headlamp Switch................... 8W-80-78

Headlamp Washer Pump Motor (Export) . 8W-80-78

High Note Horn.................... 8W-80-79

Hood Ajar Switch (Export)............ 8W-80-79

Idle Air Control Motor (Gas)........... 8W-80-79

Ignition Coil (2.4L).................. 8W-80-79

Ignition Coil (3.3L/3.8L).............. 8W-80-80

Ignition Switch..................... 8W-80-80

Inlet Air Temperature Sensor.......... 8W-80-80

Input Speed Sensor................. 8W-80-80

Instrument Cluster.................. 8W-80-81

Instrument Panel Switch Bank

(Except Heated Seats)............. 8W-80-81

Instrument Panel Switch Bank

(Heated Seats)................... 8W-80-81

Integrated Power Module C1.......... 8W-80-82

Integrated Power Module C2.......... 8W-80-82

Integrated Power Module C3.......... 8W-80-83

Integrated Power Module C4.......... 8W-80-83

Integrated Power Module C5.......... 8W-80-84

Integrated Power Module C6.......... 8W-80-84

Integrated Power Module C7.......... 8W-80-84

Integrated Power Module C8.......... 8W-80-85

Integrated Power Module C9.......... 8W-80-85

Knock Sensor (Except Export)......... 8W-80-85Component Page

Left B-Pillar Switch (Power Sliding

Door).......................... 8W-80-86

Left Cinch/Release Motor (Power Sliding

Door).......................... 8W-80-86

Left Curtain Airbag Squib............ 8W-80-86

Left Cylinder Lock Switch (Export)..... 8W-80-86

Left Door Speaker.................. 8W-80-87

Left Fog Lamp..................... 8W-80-87

Left Front Door Ajar Switch (Base)..... 8W-80-87

Left Front Door Lock Motor/Ajar Switch

(Except Base).................... 8W-80-87

Left Front Impact Sensor (Export)...... 8W-80-87

Left Front Impact Sensor (Except

Export)......................... 8W-80-88

Left Front Park/Turn Signal Lamp...... 8W-80-88

Left Front Wheel Speed Sensor........ 8W-80-88

Left Full Open Switch (Power Sliding

Door).......................... 8W-80-88

Left Headlamp (Caravan/Voyager Except

Export)......................... 8W-80-89

Left Headlamp (Town And Country)..... 8W-80-89

Left Headlamp Leveling Motor (Export) . . 8W-80-89

Left High Beam Lamp (Export)........ 8W-80-89

Left Instrument Panel Speaker........ 8W-80-90

Left Liftgate Flood Lamp (Export)...... 8W-80-90

Left Low Beam Lamp (Export)......... 8W-80-90

Left Mid Reading Lamp (Premium/

Luxury)........................ 8W-80-90

Left Park Lamp (Export)............. 8W-80-91

Left Power Mirror................... 8W-80-91

Left Rear Lamp Assembly............ 8W-80-91

Left Rear Pillar Speaker (Highline

Audio).......................... 8W-80-92

Left Rear Reading Lamp (Luxury)...... 8W-80-92

Left Rear Speaker.................. 8W-80-92

Left Rear Vent Motor................ 8W-80-92

Left Rear Wheel Speed Sensor......... 8W-80-93

Left Remote Radio Switch............ 8W-80-93

Left Repeater Lamp (Export).......... 8W-80-93

Left Side Impact Sensor 1 (Export)..... 8W-80-93

Left Side Impact Sensor 1 (Except

Export)......................... 8W-80-94

Left Side Impact Sensor 2............ 8W-80-94

Left Side Impact Sensor 3............ 8W-80-94

Left Sliding Door Control Module C1

(Power Sliding Door).............. 8W-80-94

Left Sliding Door Control Module C2

(Power Sliding Door).............. 8W-80-95

Left Sliding Door Latch Sensing Switch

(Power Sliding Door).............. 8W-80-95

Left Sliding Door Lock Motor (Power Sliding

Door).......................... 8W-80-95

Left Sliding Door Lock Motor/Ajar Switch

(Manual Sliding Door)............. 8W-80-96

RS8W-80 CONNECTOR PIN-OUTS8W-80-3